Page 1

User’s Manual

3488 Mode Supplement

This manual describes the Agilent 3499A/B/C Switch/Control System

when used in the 3488 mode of ope rat ion. T hi s manual is a supplement

to the Agilent 3499A/B/C Switch/Control System User’s Manual (shipped

with the instr ument). Adobe Ac robat (PD F) vers ions of the user’s manual

are available at www.agilent.com.

©

Copyright Agilent Technologies, Inc. 1999-200 2

Agilent 349 9A/B/C

Switch/Control System

Page 2

Agilent 3499A/B/C at a Glance

The Agilent Technologies 3499A/B/C Switch/Control System provides a

convenient mechanical and programming environment for a v ariety of

plug-in modules. With appropriate plug-in modules, the Switch/Control

System pr ov id e s high density/high speed switching and digi tal I/O

capability.

Switch/Control System Features

•

Intuitive and easy-to-use user interface

•

GPIB (IEEE 488) or RS-232 interface control

•

External triggering capability

•

Built-in 4-bit digital I/O port

•

Store and recall up to 50 customized instrument setups

•

SCPI (Standard Commands for Programmable Instruments)

compatibilit y

•

Relay cycle count informa tion for preventive maintenance

•

Downloadable fir m war e upgrades

Agilent 3499A Features

•

Five plug -in slots

•

Full rack width

Agilent 3499B Features

•

Two plug -i n slots

•

Half rack width

Agilent 3499C Features

•

Nine plug-in slots

•

Full rack width

Note: Unless otherwise indicated, this manual applies to all Serial Numbers.

2

Page 3

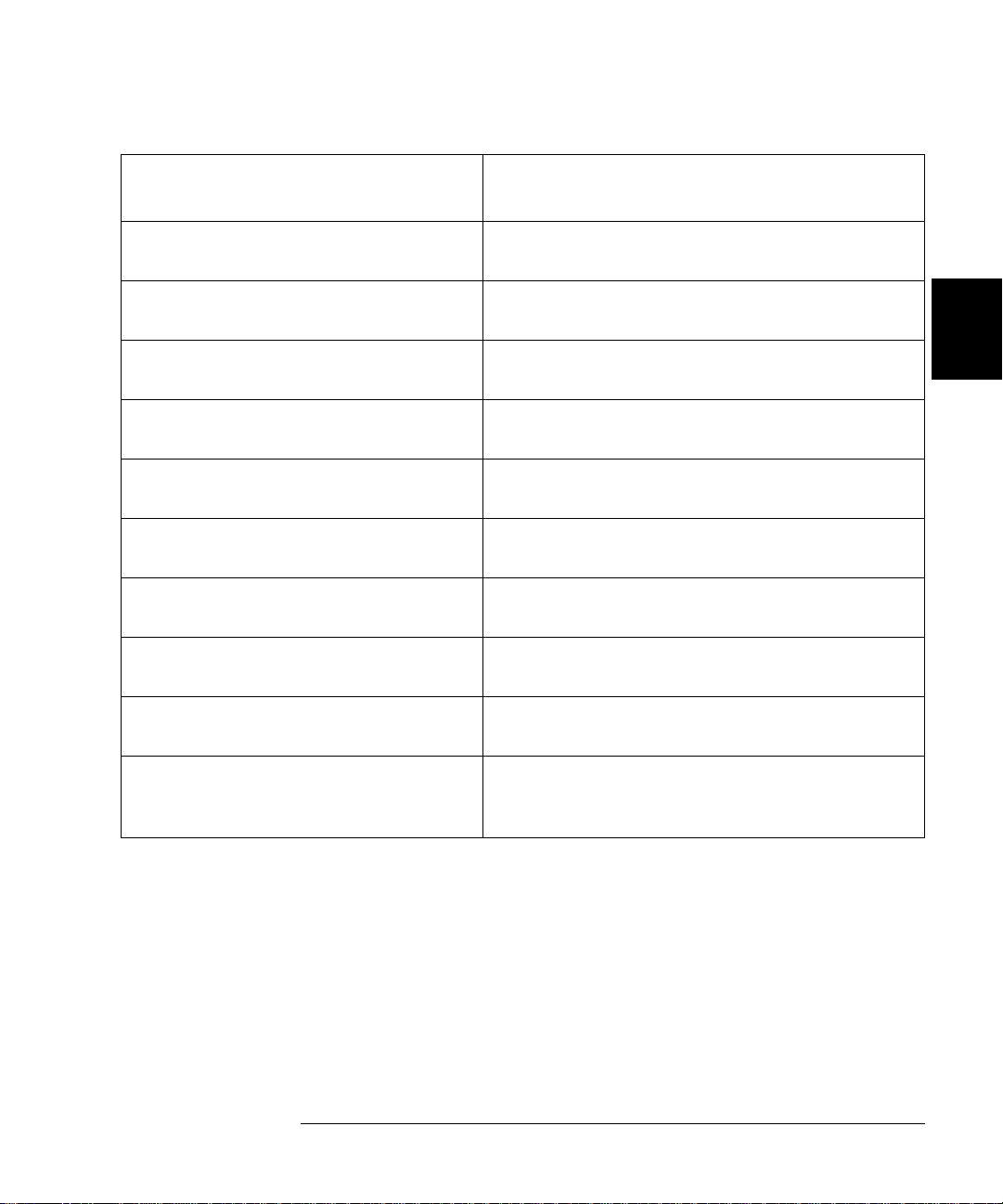

Plug-in Mo du les at a Glance

The Agilent 3499A/B/C mainframes support a variety of plug-in modules

to make test sys te m configuration easy.

Multip lexer Modules

N2260A 40-Channel MUX Module (armature relays)

N2266A 40-Channel MUX Module (reed relays)

N2270A 10-Channel High Voltage MUX Module

44470A 10-Channel MUX Module

44470D 20-Channel MUX Module

General Purpose Relay Modules

N2261A 40-Channel GP Relay Module

N2267A 8-Channel High Current GP Module

44471A 10-Channel GP Relay Module

44471D 20-Channel GP Relay Module

44477A 7-Channel Form-C Relay Module

Matrix Modules

N2262A 4 x 8 Matrix Module

44473A 4 x 4 Matrix Module

High Frequency Switching Modules

N2268A 50Ω 3.5GHz Dual 4-to-1 MUX Module

N2272A 1 GHz RF 1-to-9 MUX Module

N2276A/B Dual 1-to-6 (4) Microwave MUX/Attenuator Module

44472A Dual 4-Channel VHF Switch Module

44478A/B 50Ω/75Ω 1.3 GHz Multiplexer

44476A 3-Channel 18 GHz Switch Module

44476B 2-Channel Microwave Switch Module

1

1

Optic al Switch Modules

N2280A Optical Switch Quad 1-to-2 MUX Module

N2281A Optical Switch Dual 1-to-4 MUX Module

N2282A Optical Switch 1-to-8 MUX Module

1

Digita l I/ O M odules

N2263A 32 -Bit Digital I/O Module

44474A 16-Bit Digital I/O Module

Multifunc tion/Special Purpose Modules

N2264A 12-Channel GP & 3-Channel High-current GP & 16-Bit Digital I/O

N2265A 4 x 4 Matrix & 16-Bit Digital I/O Module

44475A Breadboard Module

1

These modules are NOT supported in the 3488 Mode of operation.

3

Page 4

The Front Pane l at a G lance

1. Power On/Standby 8. Scan Keys (see page 78)

2. Reset Module/Instrument 9. Main Menu

3. Shift/Local 10. Open/Close Relay Channels

4. Store/Recall Instrument State 11. Enter a Value/Confirm Selection

5. Monitor Channel/Port/Module 12. Read/Write Digital I/O Ports

6. View Menu 13. Knob

7. Mode Menu 14. Navigation Arrow Keys

Note

The front panel shown above is the Agilent 3499B. The 3499A and 3499C

front panels are similar and have identical functionality.

4

Page 5

Annunciators

The Display at a Glance

Channel/Slot Number

The display is divided into several areas. The channel and slot number is

always displayed on the right corner of the display. The main area,

which is in the center of the display, is primarily used to display channel

status (open or closed), information messages, menu items, prompt information, error messages, and so on. Around the display are annunciators

to indicate var ious sta te s of the inst ru m ent o pe rati o n. The a n nunciators

are summarized below.

Annunciator Indication

SCAN Scan is initiated.

MON Instrument is in monitor mode.

VIEW Scan list, errors or relay cycle counts are being viewed.

CONFIG Any configuration key has been pressed.

* Instrument is advancing a scan step.

ADRS Instrument is active on the remote interface.

RMT Instrument is in remote mode.

ERROR Error queue is not empty.

EXT Scan is waiting for external trigger source.

SHIFT Shift key has been pressed.

Other annunciators in the display are not used in the Agilent 3499A/B/C

system.

5

Page 6

The Rear Panel at a Glance

The figure be low sh o ws the A gilent 3499A rear panel.

Slot 1

Slot 2

Slot 3

Slot 0

Control Modul e

The figure be low sh o ws the A gilent 3499B rear panel.

Slot 4

Slot 5

GPIB Connector RS-232 Connector

Mini DIN Connector

Power Input

Slot 1

Slot 2

Slot 0

Control Module

GPIB Connector RS-232 Connector

Power Input

Mini DIN Connector

6

Page 7

The figure be low sh o ws the A gilent 3499C rear panel.

Option FP1 (1 -s lot) and FP2 (2-slot) filler panels can be ordered to cover

any un used slo ts.

Slot 0

Control Module

Mini DIN Connector

Slot 7

(2 slot width)

Slot 6

Slot 8

Slot 9

(3 slot width)

(3 slot width)

Slot 5

Slot 3

Slot 4

Slot 1

Slot 2

GPIB Connector

RS-232 Connector

Power Input

WARNING For prot ection from electri cal shock, the power cord grou nd must not be

defeated.

The Mini DIN Connector

The rear panel mini DIN connector is used to make connections to

external triggers and the built-in digital I/O port. An Agilent N2289A

cable (mini DIN to D9) can be ordered to assist connections to external

devices. The figure below shows the pins used in the mini DIN connector.

7

Page 8

In This Book

Quick Start Chapter 1 prepares the switch/control sy stem for use and

helps you get familiar with a few of its front-panel features.

Front - Panel Menu Operation Chapter 2 introduces you to the frontpanel menu and describes some of the switch/control system’s menu

features.

System Overview Chapt er 3 gives an overview of a switch/control

system, describes how parts of the system work together, and describes

the channel addressing scheme used.

Feature s and Function s Chapter 4 gives a detailed description of the

swit c h/control system’s capabilities and operation. This chapter is useful

for operating the sw it ch/c on t r ol s y st e m from th e front panel or the remote

interface.

Remote Interface Reference Chapter 5 contains the 3488 mode

language reference used to program the switch/control system over a

remote inter fa ce.

Error Mess ag es Chapter 6 lists the error messages that may appear as

you are working with the instrument.

Application Programs

application programs to help you develop programs for your switch/

contr ol sy st e m.

Note This manual does not describe the plug-in modules except in a general

way. Use the Agilent 3499A/B/C User’s Manual (shipped with the

instrument) for complete details. A PDF version is also available at

www.agilent.com.

If you have questions relating to the oper ation of the Agilent 3499A/B/C,

call 1-800-452-4844 in the United States, or contact your nearest Agilent

Technologies Sales Office.

If your 3499A/B/C fails within one year of purchase, Agilent will either

repair or replace it free of charge. Call 1-877-447-7278 in the United

States (and ask for “Agilent Express”) or contact your local Agilent

Technologies Sales Office.

Chapter 7 contains several remote in te rf a ce

8

Page 9

Contents

Chapter 1 Quick Start 11

To Prepare the Instrument for Use 13

To Install a Module in the 3499A/B/C 15

Basic Operation 17

To Rack Mount the 3499A/B/C 21

Filler Panels 24

Chapter 2 Front-Panel Operation 25

To Power On the Instru ment 27

To Select the System Mode 27

To Monitor a Channel or a Slot 28

To Use a Digital I/O Port 30

To View Instrument Errors 35

Scanning Operation 37

To Pair Two Modules Together 40

To Configure fo r External Trig ge r 41

To Configur e th e Po we r- o n Sta te 4 3

To Configure th e Rem o te Interface 45

To Perform a Self-test 47

To Query the Firmware Revision 48

To Query the Serial Number 49

Local/Remote Control 50

Contents

Chapter 3 System Overview 51

Agilent 3499A/B/C Switch/Control System 53

Mainframes Overview 54

Firmware and Control Module Description 55

3488 Mode Differences 57

Plug-in Modules Overview 58

Channel and Slot Addressing 67

Factory Default and Reset States 71

9

Page 10

Contents

Chapter 4 Features and Functions 73

Monitoring a Channel or a Slot 75

Switching a Relay Channel 77

Scanning 78

Digi tal I/O Ope r ation 84

State Storage 94

Error Conditions 96

Self-Test 96

Display Control 97

Relay Cycle Counts 98

Chapter 5 Remote Interface Reference 99

Command Syntax 101

3488 Mode Command Q uick Reference 1 02

3488 Mode Commands 104

Chapter 6 Error Messages 135

Contents

Error Messages 136

Self T est Errors 136

Chapter 7 Application Programs 137

Visual C++ Example Program 139

Visual BASIC Example Program 141

BASIC Example Program 143

Index 145

10

Page 11

1

1

Quick Start

Page 12

Quick Start

1

This chapter describes the procedure to install the plug-in modules into

an Agilent 3499A/B/C mainframe and mount t he m ainfram e onto a

system rack. The basic operations of the Agilent 3499A/B/C Switch/

Control System is also described. The chapter contents include:

•

To Prepare the Instrument for Use, on page 13

•

To Install a Modu le in the 3499A/B/C, on page 15

•

Basic Operation, on page 17

•

To Rack Mount the 3499A/B/C, on page 21

12

Page 13

Chapter 1 Quick Start

To Prepare the Instrument for Use

To Prepare the Instrument for Use

1 Check the list of suppl ied ite ms

Verify that you have received the following items with your

Agilent 3499A/B/C mainframe:

1

❏ One power cord;

❏ This User’s Manual;

❏ One Quick Reference Guide;

❏ One Tie Down Clip 03499-21002 (for Agilent 3499B only);

❏ Any plug-in modules that you ordered are delivered in separate

shipping containers.

2 Connect the power cord and turn on the instrument

1. Connect the 3499A/B/C to an AC po we r sou rc e with the supplied

power cor d .

2. Push the Power sw itc h located on the low e r left si de of the front

panel.

3. On power-up, every segment in the display will light up briefly,

including all annunciators. Following this “starburst” display, the

internal self- test will begin.

4. If the self-test passe s

address are displayed, together with a “beep” sound. Then the display

shows the instrument model number and the active slot (slot 0).

1

, the default system mode and the GPIB

4

SCPI GPIB 9

3499 0

1

If the self-test failed, the failure will be displayed on the front panel. For

details of all self-test errors, refer to “Error Messages” starting on page

135.

13

Page 14

Chapter 1 Quick Start

To Prepare the Instrument for Use

1

When shipped from the factory, the SCPI mode and the GPIB interface

address of “9” are used. Slot 0 refers to the built-in controller board of the

switch/control system.

If the Instrument Does Not Turn On

1. Verify that the power cord is firmly plugged into the power receptacle

on the rear panel of the 3499A/B/C.

2. Make sure that the power source the 3499A/B/C is plugged into is

energized.

3. Verify that the 3499A/B/C is turned on.

Note If the 3499A/B/C DOES NOT turn on after you perform the above

procedure, contact your nearest Agilent Service Center (see page 8).

14

Page 15

Chapter 1 Quick Start

To Install a Module in the 3499A/B/C

To Install a Module in the 3499A/B/C

The plug-in modules you ordered were not installed in the mainframe.

The figur e on pag e 16 sho ws how to install a pl ug -in m o dule into the

3499B mainframe. Other mainframes use similar procedures.

1

WARNING Disconnect th e p o wer cor d from the rear panel of the ma inframe prior to

installing or removing an y modules.

Caution Use anti-static procedure s when c onfiguring, installing or removing any

plug-in modules. To prevent contamination to the modules that could

degrade performance, handle the modules by the side edges or shields

only. Do not touch the board surfaces or components.

Each plug-in module may have terminal block(s) and/or the cables for

wiring to external cir cui ts . These terminations are also shipped

separately.

For more details about terminal blocks, cables, and connections, see the

Agilent 3499A/B/C User’s Manual (shipped with the instrument) or visit

www.agilent.com.

4

Module Removal

To remove a plug-in module from the Agilent 3499A/B/C mainframe,

reverse the procedures shown on page 16.

15

Page 16

1

STEP 1

STEP 2

1. Face the mainframe rear panel toward you.

2. Select a slot in which the module is to be

installed.

STEP 3

1. Wire the screw terminal block (module

dependent).

2. Attach the screw terminal block to the plug-in

module.

(for modules with terminal blocks)

1. Hold the sides of the module, component side

down

2. Insert the module into the slot guides and slide

3. Push firmly until the module “snaps” into place.

4. Push both pla stic levers inward to lock the

STEP 4

1. Push firmly until the terminal block “snaps” into

2. Secure the screw terminal block with the two

, by the metal shields.

the module toward the front of the instrument.

module.

(for modules with terminal blocks)

place.

screws (Torque < 8 in-lbs).

Module installation

16

Page 17

Chapter 1 Quick Start

Basic Operation

Basic Operation

An Agilent 3499A/B/C Switch/Control System can be easily operated

from the front-panel, or programmed with SCPI commands over the

remote inter fa ce.

The following sections are only intended to show the basic front-panel

operation. F or deta iled front-panel op erat i on, refer to the “Front-Panel

Operation” chapter on page 25. For more information about

programming the instrument, refer to the “Remote Interface Reference”

chapter on page 99.

Channel Addressing

A channel refers to an individual relay on a switching module, or an

individual bit/port on a digital I/O module. The channel address is in the

form of snn, where s repres ents sl ot number and nn represents a channel

number.

4

1

For all mainframes, slot 0 refers to the 3499 controller board. Valid slot

numbers are:

3499A slots 0 through 5

3499B slots 0 through 2

3499C slots 0 through 9

The chan ne l nu m b e r, nn, is plug-in module dependent. For additional

information about channel numbers of individual plug-in modules, refer

to the table beginning on page 67.

17

Page 18

1

Chapter 1 Quick Start

Basic Operation

To Sele ct a Slot and Channel

When the instrument is first turned on, the display shows the model

number and the slot n umber of the controller board.

3499

Use the knob to selec t a channel on the acti ve slot. For example, with the

display shown above, turning the knob to the right will select the first of

the individual built-in digital I/ O ports.

DIN

The “DIN ” indic a te s the p o rt is set for a digital input operation. As the

knob is turned, the additional ports are displayed followed by any

installed plug-in modules.

If you have installed one or more plug-in modules, you can select the

module by pressing the right arrow key. F o r example, if an N2260A (40channel MUX module) is installed in slot 1, pressing the right arrow key

will show the module name and slot number.

0

090

N2260A 1

Turning the knob will then step through the individual channels on that

module.

MUX

OPEN

100

18

Page 19

Chapter 1 Quick Start

Basic Operation

To Open or Clo s e a C h annel

When a channel is selected, y ou can open or close the channel using the

front panel keys. For example, with an N2260A 40-channel MUX

installed in slot 1, select channel 00 as de scribed on t he previous page.

1

MUX

OPEN

100

4

Press the CLOSE key to close the channel.

MUX

Press the

OPEN

MUX

In this manner, you can select and control as many channels as you need.

The N2260A has 40 channels numbered 0 through 39 (in slot 1, 100

through 139). You may also select additional plug-in modules and

channels by turning the knob.

CLOSED

key to open the channel

OPEN

100

100

19

Page 20

1

Chapter 1 Quick Start

Basic Operation

To Open All Channels on a Module

You can open individual channels on a module one at a time as described

above. There are times, however, when it would be more expedient to

open all channels on a module at once.

Use the arrow keys to select the module to work with. You cannot have

an individual channel selected for this operation. For example, select the

module in slot 1 (using t he N2 260A as an example) to show a display

similar to this:

N2260A

Press and hold the card reset key. When you first press the k e y, the

display shows:

1

HOLD TO RESET

When the card has been reset, the display briefly shows:

RESET CARD

and then returns to:

N2260A

1

To Reset All Modules

You can reset all channels on all modules in the mainframe at once.

Press the shift key and th e n press and hold th e res et key. The display

shows:

HOLD TO RESET

When the mainframe has been reset, the display will briefly show the

reset and then return to the slot or channel display.

RESET . . .

20

Page 21

Chapter 1 Quick Start

To Rack Mount the 3499A/B/C

To Rack Mount the 3499A/B/C

You can mount the Agilent 3499A/B/C on a standard 19-inch EIA rack

cabinet with the opti on al rack -mo unting kits. The ins tru ct io ns and

mounting hardware are included with each rack-mounting kit.

1

Agilent 34 99A

To rack mount a 3499A, the full-rack-width mainframe, order either:

•

Rack-mount kit with hand les, part number 5183-7170, or

•

Rack-mount kit without handles, part number 5183-7171.

3499A

SWITCH/CONTROL SYSTEM

To Rack Mount an Agilent 3499A

4

21

Page 22

1

Flange

Filler Panel

Chapter 1 Quick Start

To Rack Mount the 3499A/B/C

Agilent 34 99B

To rack mount a single 3499B, order either:

•

Adapter kit, part number 5183-7172

(includes t he f lange and filler panel).

3499B

SWITCH/CONTROL SYSTEM

To Rack Mou nt a Single Agilent 3499B with Adapter kit 5183-7172

OR

•

A Support Shelf, part number 5063-9255,

•

A slide kit, part number 1494-0015,

•

And a filler panel, part number 5002-3999.

To Rack Mount a Single Agilent 3499B on a support shelf

22

Page 23

Chapter 1 Quick Start

To Rack Mount the 3499A/B/C

To rack mount two Agilent 3499B’s side-by-side (or any Syst em II

instrument next to an Agilent 3499B), order:

•

A Support Shelf, part number 5063-9255,

•

And a slide kit, part number 1494-0015.

1

4

To Rack Mou nt Two Agilent 3499B’s Side-by-side

23

Page 24

1

Chapter 1 Quick Start

Filler Panels

Agilent 34 99C

To rack mount an Agilent 3499C, order either:

•

Adapter kit without handles, part number 5063-9216, or

•

Adapter kit with handles, part number 5063-9223.

Adapter kit

To Rack Mount an Agilent 3499C

Filler Panels

Order filler panels to cover any unused slots in an Agilent 3499A/B/C.

•

1-slot filler panel, part number 03499-00023 (option FP1)

•

2-slot filler panel, part number 03499-00024 (option FP2)

24

Page 25

2

2

Front- Panel Operation

Page 26

2

Front-Panel Operation

The Agilent 3499A/B/C mainframes all operate the same from the frontpanel. This chapter does not give a detailed description of every possible

front-panel operation. It does, however, give you a good overview of the

front-panel menus and front-panel keys. See the “Features and

Functions” chapter on page 73 for additional discussions of the

instrument’s capabilities and operation. This chapter contents include:

•

To Power On the Instrument, on page 27

•

To Select the System Mode, on page 27

•

To Monitor a Channel or a Slot, on page 28

•

To Use a Digital I/O Port, on pag e 30

•

To View Instrument Errors, on page 35

•

Scanning Operation, on page 37

•

To Pair Two Modules Together, on page 40

•

To Configure for External Trigger, on page 41

•

To Configure the Power-on State, on page 43

•

To Configure the Remote Interface, on page 45

•

To Perform a Self-test, on page 47

•

To Que r y the Firmware Revision, on pa ge 48

•

To Query the Serial Number, on page 49

•

Local/Remote Control, on page 50

The following con ventions are used for the front-panel operation.

•

All keys on the front-panel keyboard are expressed in bold font and

normally associated with a “press”. For example, press Mon.

•

All the front panel display annunciators are expressed in bold font

followed by an “annunciator”. For example, MON annunciator.

•

The information shown on the fron t panel dis play is enclosed w ithin a

pair of quotation mark s.

26

Page 27

To Power On the Instrument

Chapter 2 Front-Panel Operation

To Power On the Instrument

To power on the ins trument, press the power switch on the front panel.

If the instrument is powered up for the first time, the instrument will

use the fact ory default settings as shown on page 71. Other w i se, the

instrument will power on to the state specified. Refer to "To Configure

the Power-on State", on page 43 for more details.

4

To Select the System Mode

The instrument can be operated in either SCPI mode or 3488A mode

(except Firmware REV 3.0, see page page 55 for mor e details). When

shipped from the factory, the instrument is set to the SCPI mode.

Perform the fol lowing procedure to select the desired system mode for

the instrument before any operation.

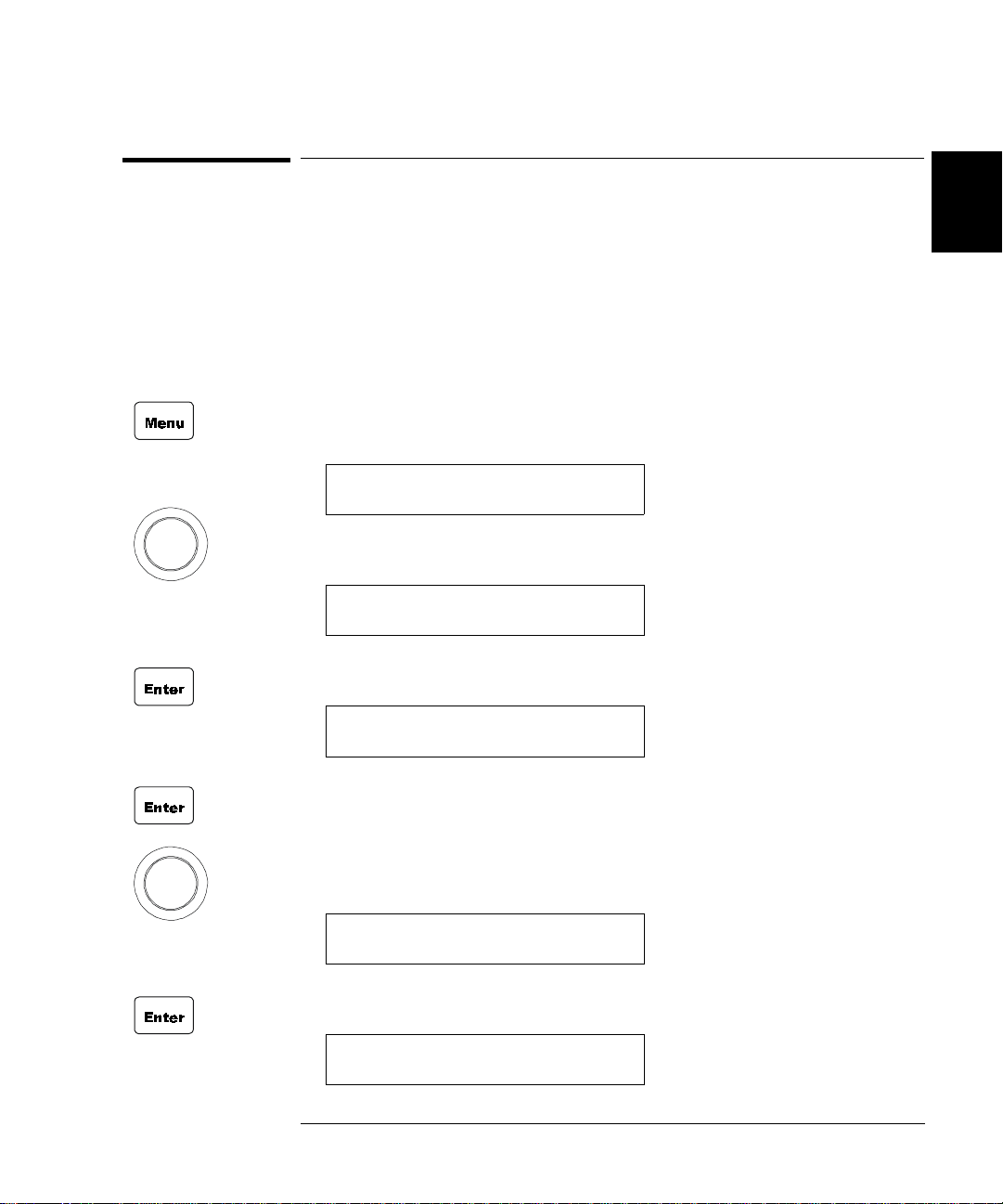

1. Press Menu, the CONFIG annunciator lights up. Turn the knob

until “SYSTEM MODE” is dis p layed, then press Enter.

SYSTEM MODE

2. Turn the knob until the desired system mode (i.e. 3488A MOD E ) is

displayed, then press Enter.

2

HP 3488A M OD E

3. The instrument will be reset if the system mode has been changed.

Otherwise, it retains the current mode and you can press Menu

again to exit this operation.

Note Switching between SCPI mode and 3488A mode will reset the

instrument to the factory default settings, except the GPIB address

which will retain its last setting.

This manual describes programming in the 3488 mode. For information

about the SCPI programming mode please refer to the User’s Manual

shipped with the Agilent 3499A/B/C, or visit www.agilent.com.

27

Page 28

Chapter 2 Front-Panel Operation

To Monitor a Chan nel or a Slot

2

To Monitor a Channel or a Slot

You can continuously monitor the current status of a particular

switching channel, a digital I/O port, or an entire plug-in module.

Monitoring from the front pane l is espec ially u seful when devel oping and

debugging remote interface commands.

1. Press the monitor key, the MON annunciator lights up to indicate the

instrument is in the monitoring state.

2. Select the slot or the channel/port to be monitored. The displayed

information depends on the selected module type. Typical displays

are shown in the table on page 76.

3. If only pa r t of the channel status on the module can be displayed at

one t i me, press Enter to display the next part.

For multiplexer modules and GP Relay modules, 10 channels can be

displayed at one time; for matrix modules, one Row or one Column

can be displayed at o ne time; for digital I/O modules, two 8-bit ports

can be displayed at one time. For multifunction modules, the first

function on the module is displayed, t hen the next.

4. Press the monitor key again to end monitoring (the MON

annunciator turns off).

Note The built-in digital I/O bits/port (on the controller module) can be

monitored either individually as bit channels (numbered 091 through

094) or as a 4-bit port (numbe red 090). However, the individual bit

channels on a digital I/O or multifunction module (with a DIO function)

cannot be monitored.

28

Page 29

Chapter 2 Front-Panel Operation

To Monitor a Channel or a Slot

.

Display Description

The display for a multiplexer or a GP relay module. This

1:0,,,,,,6,,,9, 2

display indic at es t hat the m o nitored module is in Slot 2 and

channels 10, 16, and 19 are closed.

The display for a matrix module. The top is the row

ROW 3:,1,,3,,,6,7 3

information, indicating that the relays on Row 3, Columns 1, 3,

6 and 7 of the module (in Slot 3) are closed. The lower display

is the column information, indicating that relays on column 3,

0;,,3,COL 3, 3

row 0 and 3 are closed.

The display for a digital I/O module. The first 2 digits on the left

00:H255 L254. 4

(“00” in this case) represents the “L” 8-bit port address. Adding

one to this value, the “H” 8-bit port address is obtained. Data

with a trailing decimal point indicates that the last operation on

that port was a WRITE, data without a trailing decimal point

indicates that the last operation on that port was a READ. This

display sh ows that th e data last read from Port 401 is 255 and

the data last written to Port 400 is 254.

The top display is for the built-in digital I/O Port 090 (control

DIO 12 090

module) and the data from the last operation.

The lower display indicates that data last written to the bit

channel 091 is 0.

DOUT 0 091

2

4

ROW 0:,1,,3, 5

00:H255 L254. 5

For a multifunction module, the first fu nction on the module is

displayed , then the next. This display is an example of a

multifunction module with matrix and DIO functions (in slot 5).

29

Page 30

Chapter 2 Front-Panel Operation

t

To Use a Digital I/O Port

To Use a Digital I/O Port

2

You can work with a digital I/O module as a port (all eight bits) or as

individual bits.

Readi ng a Digital I/O Po r t

You can read data from the built-in 4-bit digital I/O port, or any one of

the 8-bit ports on a digital I/O or multifunction module (with a DIO

function). You can read the entire p ort (all bit s) w h en you select the slot

(for example, the built-in port is channel 090). Alternately, you can read

an individual bit by selecting the channel (for example the first bit in the

built-in port is channel 091).

Perform the fol lowing procedure to read from a port:

1. Select a digital I/O por t. Use the kno b to se le ct the slot and channel

number. The channel number is in the form of snn, wher e s is the slot

number and nn is the channel number.

2. Read the data read from the selected port. For example, the display

below shows the data read from port 401.

DIN 401

DIN 401

255

11111111

Decimal forma

(default)

Binary format

The data display format of individual 8-bit ports can be specified

either in binar y or deci mal formats (as described on page 33). Once

specified, the format applies to all input and o utput operations on the

same port.

30

Page 31

Chapter 2 Front-Panel Operation

To Use a Digital I/O Port

Writing to a Digital I/O Port

You can write data to the built-in digital I/O port (num be red 090) or to

one of the built-in digital I/O port bits (numbered 091 through 094), or

any one of the 8-bit ports on a digital I/O or multifunc tion modul e (with a

DIO function). To write to a port:

1. Select a digital I/O por t. Use the kno b to se le ct the slot and channel

number. The channel number is in the form of snn, wher e s is the slot

number and nn is the channel number. In the display, “DIN”

indicates that the last operation on the port was a READ, and

“DOUT”, a WRITE.

4

2

DIN

2. Press the Write key. “DOUT” is displayed to indicate the port is now

an output port. The current port value is displaye d.

401

DOUT 401255

3. Edit the value. Use the arrow keys to select the to-be-edited bit (the

digit to be edited is set to half bright in the display).

Turn the knob to modify the value. Use the arr ow keys to select the

next digit and the knob to modify its value.

DOUT

4. When the value is the one desired, press Enter to output the data to

the selected port.

5. Press Write again to cancel the current write operation.

254

401

Note Data display format of individual 8-bit ports can be specified either in

binary or decimal values (refer to the procedure on page 33). Once

specified, the format applies to all input and output operations on the

same port.

31

Page 32

2

Chapter 2 Front-Panel Operation

To Use a Digital I/O Port

To Configure a D ig ital I/O Mod ul e

Digital I/O modules can be configured for handshake modes and control

line, flag line, and I/O line polarity. U se the Mode menu to configure

digital I/O parameters. See “Digital I/O Operation” on page 84 for

detailed descriptions of the operating modes. Only plug-in modules can

be configu red this way, the b uilt-in digital I/O port (control mod ule) can

only be configured at the port level (see page 33).

The following proc edure configures a plug-in digital I/O module to use a

two line digital h and shake mode (m o d e 5) f or data t rans f e rs.

1. Select the slot in which a digital I/O or multifunction module is

installed. Th e channel number is in the form of snn, where s is the

slot number and nn is the channel number.

N2263A

2. Press the Mode key. The CONFIG annunciator lights up in the

display and the first-level menu is shown .

CONFIG DIO

3. Press Enter to begin the configuration. The display shows the

second-level menu choice.

4

4

MODE 1 4

4. Turn the knob until the d es ired flow co ntr o l mo d e (i.e., M ODE 5) is

displayed. The displ a y ed mode is half-bright.

MODE 5

4

32

Page 33

Chapter 2 Front-Panel Operation

To Use a Digital I/O Port

5. Press Enter to select the new mode. The display changes to show the

next menu level.

CONT POL POS

6. You may change other configurati on paramete r s as desired using the

same p r oc e d ure. When all desire d co nf igurations have b e en ma de ,

press the Mode key to exit the configuration men u. The CONFIG

annunciator turns off.

4

4

To Configure a D I O Port

You can configure an individual digital I/O port to change the data

polarity and the display format. The following procedure changes the

built-in digital I/O port to display in binary number format.

1. Select a digital I /O port (i.e., port 090). The channel number is in the

form of snn, where s is the slot n umber and nn is the channel number.

DIN 090

2. Press the Mode key. The CONFIG annunciator lights up in the

display. The first level menu is shown:

DATA POLARITY

090

2

3. Turn the knob to select the second menu level

DISP FORMAT

4. Press Enter to select the format parameter.

DECIMAL

090

090

33

Page 34

Chapter 2 Front-Panel Operation

To Use a Digital I/O Port

5. Turn the knob until the desired data display format (i.e., BINARY) is

displayed.

2

6. Press Enter to make the change and return to the first level of the

BINARY

Mode me nu.

DISP FORMAT

7. Press Mode again to exit the current configuration, the CONFIG

annunciator turns off.

Note Once you have selected the data display format for a port, it applies to

both input and output operations on that port.

090

401

34

Page 35

To View Instrument Errors

Chapter 2 Front-Panel Operation

T o View Instrument Errors

You can view errors from the fron t panel. This feature is especially

useful when developing remote instrument control. If an error occurs,

the ERROR annunciator in the display will light. Errors are stored in

the error queue in the order they occur. You read the erro rs in the same

order. After all errors have been read, the queue is empty and the

ERROR annunciator turns off. To view instrument errors:

1. Press the View key. The VIEW annunciator lights up and the display

shows the first menu level.

ERROR

2. Press Enter to view the first error.

a. If no error is in the error queue (the ERROR annunciator is off),

the display shows “NO ERROR” and t hen automatic ally retur ns to

the first level of the View menu.

0

0

NO ERROR

4

2

ERROR

b. If there are errors (the ERRO R annunciator is on), the first error

in the error queue is displayed.

01:ERR -109

Press the right arrow key to scroll the display to show the entire

error m essage.

MISSING PARAMETER

0

35

Page 36

Chapter 2 Front-Panel Operation

To View Instrument Errors

3. Turn the knob to view other err o rs in the error queue (if any).

2

4. Press Enter to return to the first level of the View menu, the

ERROR annunciator turns off.

5. Press View again to exit the View menu operation, the VIEW

annunciator turns off.

Note All errors are cleared, and the ERROR annunciator turns off, once the

error queue is viewed. S ee the “Er ror Messages” chapter on page 135 for

a complete list of error messages.

36

Page 37

Scanning Operation

Chapter 2 Front-Panel Operation

Scanning Operation

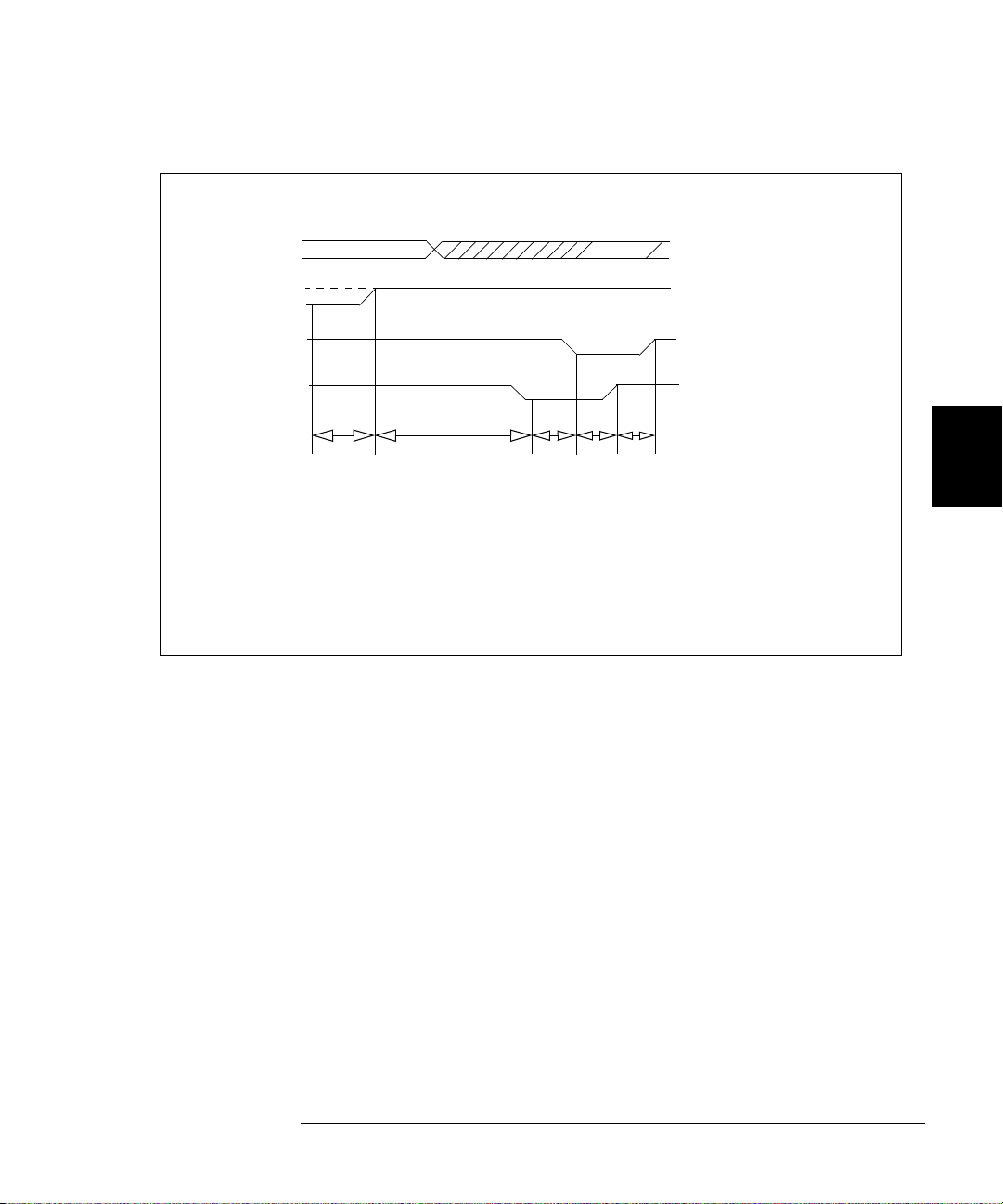

The instrument allows you to combine an external measurement device

such as a Digital Multimeter (DMM) with multiplexer channels to create

a scan. During a scan, the instrument closes the confi gured multiplexer

channels one at a time to allow a measurement to be m ade on that

channel.

Before initiating a scan, a scan list must be set up. You can also specify

an arm source, a trigger sourc e, and the number of sweeps (a sweep is

one pass through the scan list) to control the scan process. All these can

be done from the S.List menu. The procedure in this chapter des cribes a

simple sca n from the front panel. For more inform a tio n abo ut scanning

and using the par am e te rs to contro l a scan , see pag e 78.

4

To Create a Scan List

1. Press the S.List key to enter the scan list menu . The CONFIG

annunciator lights up and the first level of the menu is displayed.

ADD TO SCAN

2. Press Enter to begin the chann el selec tio n.

101

SELECT 101

2

3. Turn the knob to sel ect the firs t channel for the list (e.g., 103).

SELECT

4. Press Enter to add the chann el into the scan list. The star burst

character lights in the display to indicate the channel is now a part of

the scan li st.

SELECT *

103

103

37

Page 38

2

Chapter 2 Front-Panel Operation

Scanning Operation

5. Repeat step 3 and 4 to add additional channels to the list.

6. When the desired channels have been added, press the S.List key

again to return to the first level of the menu.

ADD TO SCAN

7. Press S.List again to exit the menu. The CONFIG a n nunc i ato r tur ns

off.

107

To Perform Scanning

After the scan configuration is complete, the actual scan can be

performed.

1. Press the Step key to close the first channel in the scan list.

2. Press the Step key again to o pen the f i rst c h annel a nd close the next

channel in the list.

This procedu re shows a simple way to scan, one channel at a time for

each press of a front pane l key. You can als o pres s the Scan key to scan

all channels in the list according to the various scan parameters set. In

the default parameter state, pressing the Scan key will cause all the

channels in the list to cycle through at the maximum possible speed.

While this occu rs, the SCAN annunciator is lighted. For details about

the scan parameters, see page 78.

To Clear a Scan List

You can clear a scan list once it has been configured.

1. Press the Shift key and then the S.List key. The display will briefly

show:

101

CLR SCAN LIST

and then return to norm al oper atio n.

38

Page 39

Chapter 2 Front-Panel Operation

Scanning Operation

To View a Scan List

You can view which channels are included in a scan list. This example

assumes that channels 103 through 107 are included in the scan list.

1. Press the View key. The VIEW annunciator lights up and the display

shows the first level menu.

ERROR

2. Turn the knob until “SCAN LIST” is displayed.

3. Press Enter. The first channel in the scan list is displayed on the

channel area.

101

101

SCAN LIST

4

2

103

001 OF 005

Turn the knob to view other channels in the scan list.

104

002 OF 005

4. Press Enter to return to the f i rst level of the V iew menu.

SCAN LIST

5. Press View again to exit the View menu. The VIEW annunciator

turns off.

107

39

Page 40

Chapter 2 Front-Panel Operation

To Pair Two Modules Together

To Pair Two Modules Together

2

You can pair two modules together so that they operate as a single unit.

The two m od ules to be paired must be identic a l (that is, they must have

the same model number) and be installed in the same mainframe. When

two modules are paired together, any operation on a channel of one

module will be d uplicated on the correspo nd ing channel of the other

module. The exam ple below pairs modules installed in slots 2 and 5.

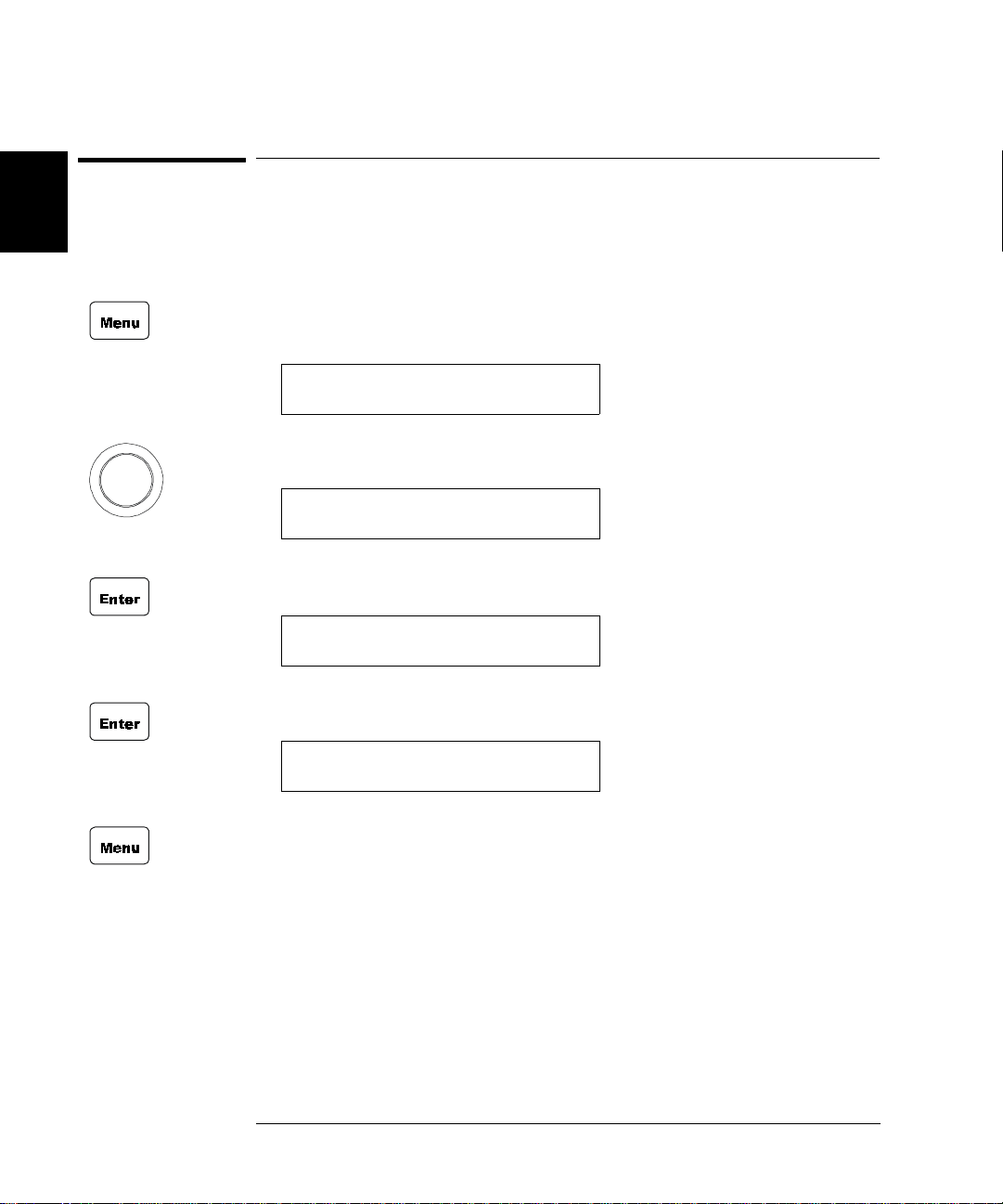

1. Press the Menu key. The CONFIG annunciator lights up and

“CARD PAIR” is displayed.

2. Press Enter.

When “FIRS T SLOT x” is displayed, turn the knob to selec t t he first

slot to be paired (i.e., Slot 2).

FIRST SLOT 2

3. Press Enter.

When “SECOND SLOT x” is displayed, turn the knob to select the

second slot to be paired (i.e., Slot 5) .

SECOND SLOT 5

4. Press Enter to return to the first level of the Me nu menu.

CARD PAIR

5. Press Menu again to exit the Menu menu. The CONFIG annunciator

turns off.

40

Page 41

Chapter 2 Front-Panel Operation

T o Configure for External Trigger

To Configure for External Trigger

You can use one of two modul e s for an external trigge r . The built-in rear

panel TRIG IN and TRIG OUT pair (on the control module) or the EI

(External Increment) and the CC (Channel Closed) pair on a 44474A

module. Only one pair can be used at a time. You can specify which pair

to use and whether a trigger out pulse is sent out when a relay is closed

during scanning operations. Refer to “Scanning” on page 78 for more

details.

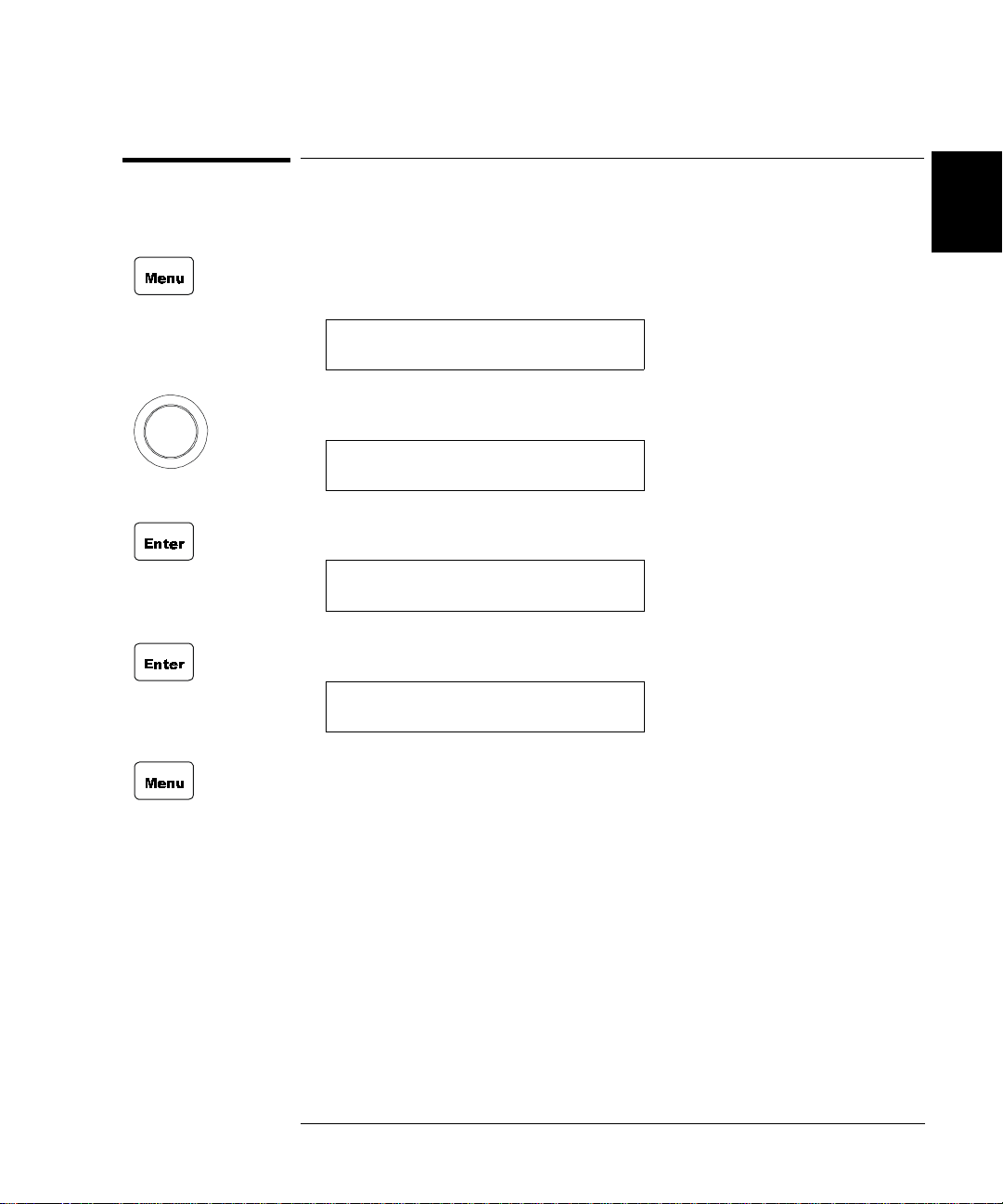

1. Press the Menu key. The CONFIG annunciator lights up and the

display shows the first level menu.

CARD PAIR

2. Turn the knob to s how th e sec on d m e nu item, “CONF EXT TRIG”.

CONF EXT TRIG

3. Press Enter. The display shows the next level menu.

TRIG SLOT 0

4

2

41

Page 42

2

Chapter 2 Front-Panel Operation

T o Configure for External Trigger

4. Turn the knob t o sele ct the s lot f or the ex ternal tr igger . Slot 0 (cont rol

module) is the bui lt- in external trigger (available at t he rear panel

mini D IN c o nn e c t or , se e pa g e 7 ). I f a 44474A i s no t i n s ta l l e d, o nl y slot

0 will be shown. Press Enter. The display shows the current setting

for the external tri gger.

DISABLE

5. Turn the knob to show th e alter nat e cho ice.

ENABLE

6. Press Enter to accept the choice and return to the fi rst level menu.

CONF EXT TRIG

7. Press the Menu key to exit the menu. The CONFI G annunciator

turns off.

42

Page 43

Chapter 2 Front-Panel Operation

To Configure the Power-on State

To Configure the Power-on State

Firmware Rev 4.0 ONLY. To read your firmware ve rsion, see the

procedure on page 48. For more information about firmware revisions,

see “Firmware and Control Module Description” on page 55.

An instrument with Firmware REV 4.0 or later c an be set to power on to

the reset state (see “Factory Default and Reset States” on page 71) or to a

state previously stor ed in a specified memory location. The instrument

will return to the specified state the next time it is turned on.

1. Press the Menu key. The CONFIG annunciator lights up and the

display shows the first menu level.

4

CARD PAIR

2. Turn the knob until “POWER ON SET” is displayed.

POWER ON SET

3. Press Enter to show th e sec on d le v e l me nu.

PWR ON RESET

2

4. To set the instrument power-on to the reset state, press Enter. The

instrument will return to the first level menu.

Alternately, to set the instrument power-on to a stored stat e : Turn

the knob until “USER SET UP” is displayed.

USER SET UP

5. Press Enter to select the stored state to use.

POWER ON 05

43

Page 44

Chapter 2 Front-Panel Operation

To Configure the Power-on State

6. Turn th e knob to select the desired memory location (i.e. , 08).

POWER ON 08

2

7. Press Enter to accept the stored state and return to the first level

menu. More information about storing states is given on page 94 of

this manual.

POWER ON SET

8. Press the Menu key again to exit the Menu menu. The CONFIG

annunciator turns off.

Note If the instrument is set to power on to a previo usl y stored setup that is

no longer valid, it will automatically power on to the reset state and

“RECALL FAILED” will be displayed.

44

Page 45

Chapter 2 Front-Panel Operation

To Configure the Remote Interface

To Configure the Remote Interface

In 3488 mode, the instrument can communicate with a computer over

the GPIB interface. When shipped from the factory, the GPIB interface is

selected and its address is set to “9”.

Note The RS-232 interface can be configured and used only in SCPI mode.

GPIB Int e r face

Each device on the GPIB interface must have a unique address.

•

When shipped from the factory, the GP IB interfa ce is selected and its

address is set to “9”. The GPIB address of the instrument can be set to

any value between 0 and 30.

•

The GPIB address is stored in non-volatile memory, and does not

change when the instrument is turned off or reset.

•

Switching between SCPI mode and 3488A m o de c auses the

3499A/B/C to select the GPIB interface and its address setting.

To set the GPIB interface:

1. Press the Menu key. The CONFIG annunciator lights up and the

first level menu is shown.

CARD PAIR

2

4

2. Turn the knob to select “INTERFACE” in the menu.

INTERFACE

3. Press Enter to show the second level menu The active interface is

shown. If necessary, turn the knob until “GPIB/488” is displayed.

GPIB/488

45

Page 46

Chapter 2 Front-Panel Operation

To Configure the Remote Interface

4. Press Enter to select the interface and show the first parameter.

2

ADDRESS 09

5. Turn the knob to set GPIB address (i.e., 07). Va l i d addres se s range

from 00 to 30.

ADDRESS 07

6. Press Enter to show the second parameter.

SRQ ON

7. Press Enter to enabl e the in str um e nt to assert the SRQ lin e w h en

powered up. If the computer is so configured, this can be used to

interrupt the system computer.

To disable this feature, turn the knob to select “SRQ OFF ” and press

Enter. The instrum e nt returns to the first level of the men u.

8. Press Menu again to exit the menu.The CONFIG annunciator turns

off.

46

Page 47

To Perform a Self-test

Chapter 2 Front-Panel Operation

To Perform a Self-test

The self-test feature of the instrument provides you with a method of

verifyin g proper instrument operation.

1. Press the Menu key. The CONFIG annunciator lights up and the

first level menu is shown.

CARD PAIR

2. Turn the knob to select “SELFTEST”.

SELFTEST

3. Press Enter. The self test will begin. The display will briefly show a

“starburst” pattern (all display segments lit). Following the pattern,

the disp lay indicates:

TEST. . .

while the internal tests are being performed. The self-test takes

several seconds to complete.

If the self-test is successful, “PASSED” will be displayed. Otherwise,

the reason of the failure will be displayed. For details on self-test

failures,

occur during a self-test (in 3488A m ode).” on page 136.

refer to “ T h e e r ro rs liste d b e low indicate fa ilu re s that ma y

2

4

PASSED

4. Press Enter to return to the first level of the m e nu.

SELFTEST

5. Press Menu again to exit the Menu menu, the CONFIG annunciator

turns off.

47

Page 48

Chapter 2 Front-Panel Operation

To Query the Firmware Revision

To Query the Firmware Revision

2

Perform the following procedur e to quer y the 3499A/B/ C fir m war e an d

revision. For a description of the firmware and hardware revisions, see

“Firmware and Control Module Description” on page 55.

1. Press the Menu key. The CONFIG annunciator lights up and the

first level menu is shown.

CARD PAIR

2. Turn the knob to select “REVISION INFO”.

REVISION INFO

3. Press Enter. The system firmware revisio n nu mber will be displayed.

REVISION 4.0 2.0

4. Press Enter to return to the first level of the Me nu menu.

REVISION INFO

5. Press Menu again to exit the Menu menu, the CONFIG annunciator

turns off.

48

Page 49

To Query the Serial Number

Chapter 2 Front-Panel Operation

To Query the Serial Number

Perform the following proced ur e to que r y the 3499A/B/ C serial number.

1. Press the Menu key. The CONFIG annunciator lights up and the

first level menu is shown.

CARD PAIR

1. Turn the knob to select “SERIAL NO”.

SERIAL NO

2. Press Enter. The Agilent 3499A/B/C serial number is displayed.

MY12345678

3. Press Enter again to return to the first level of the Menu menu.

SERIAL NO

2

4

4. Press Menu again to exit the Menu menu, the CONFIG annunciator

turns off.

49

Page 50

Chapter 2 Front-Panel Operation

Local/Remote Contro l

Local/Remote Control

2

Note If the front panel keys are locked thro ugh either the SYSTem:RWLock

The instrument operates in two data entry modes, local and remote. In

local mode, all keys on the front panel are fully functional. In remote

mode, some front panel keys are locked (exception are: Local, Mo n,

View, Enter, the arrow keys, and the knob).

The instrument will en ter the re mote state upo n receipt of any command

over the remote interface. The RMT annunciator lights.

You can regain control of the front panel keys when the instrument is in

remote by pressing the Shift (Local) key. The RMT annunciator turns

off and the instrument ret urn to local mode.

command on the RS-232 interface or a LOCAL LOCKOUT command on

the GPIB interface, the local key will not function. You can restore the

front panel operation by cycling power the instrument or by sending a

SYSTem:LOCal command on the RS-232 interface, or a LOCAL command

on the GPIB interface.

50

Page 51

3

3

System Overview

Page 52

3

System Overview

An Agilent 3499A/B/C Switch/Control System is composed of a

mainframe and a set of Plug-in modules. This chapter provides a typical

configuration of a test system using the 3499A/B/C for switching and

control, followe d by a descr iptio n of the three mainfram e s a nd all the

Plug-in modules. The following sections are included in this chapter:

•

Agilent 3499A/B/C Switch/Co ntrol System, on page 53

•

Mainframes Overview, on page 54

•

Firmware and Control Module Description, on page 55

•

3488 Mode Differences, on page 57

•

Plug-in Modules Overview, on page 58

•

Channel and Slot Addressing, on page 67

•

Factory Default and Reset States, on page 71

52

Page 53

Chapter 3 System Overview

Agilent 3499A/B/C Switch/Contro l System

Agilent 3499A/B/C Switch/Con t rol System

The Agilent 3499A/B/C Switch/Control System provides high density and

high speed switching for routing test signals to and from your DUTs

(devices under test) and test instruments such as external DMMs,

scopes, counters, power supplies, etc. Whether you are involved in a

large production test system or a small R&D bench top system, the

Agilent 3499A/B/C provides an ideal combination of price/performance

solution. W ith a wide variety of availab le plu g-in mo d ules, you can

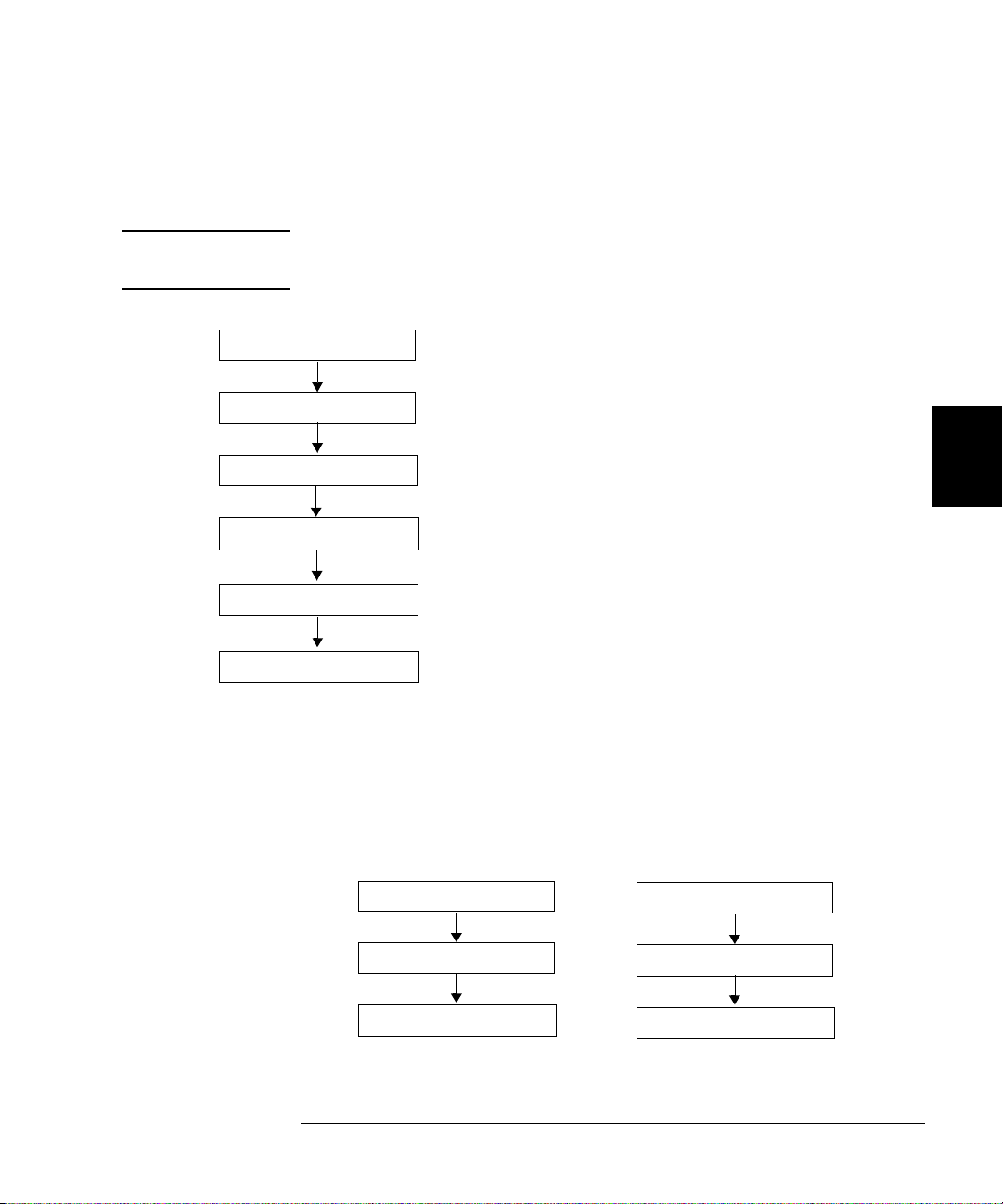

configure your test system much more e asi ly and flex ibly. The figure

below shows the typical configuration of a test system.

DUT

4

3

Agilent 3499A/B/C

IEEE488.2 (GPIB)

A Typical Test System

Source(s)

Plug-in

Modules

Instrument

Device(s)

Custom

Equipment

53

Page 54

Chapter 3 System Overview

Mainframes Overview

Mainframes Overview

Three mainframes are available:

Slots Available Rack Width

3499A

5 full width

3

3499B

3499C

1

The 3499C is d es ig ne d t o ac c om m od at e m u lti ple width plu g- i n mo du les and has 9 log ic al

slots but 14 mechanical slots. Slots 1 through 6 are 1-slot wide, slot 7 is 2-slots wide, and

slots 8 and 9 are each 3-slots wide. See the figure on page 7 for more information.

All mainframes can be either operated from the front-panel or

programed over a remote interface (GPIB or RS-232).

The mainframes can be operated in either of two system modes: SCPI

mode or 3488A mode. The SCPI mode allows the full realization of

performance potentials and advanced features, such as parallel

operation of mu ltiple relays on multiple modules. The 3488A mode is

included for backward compatibility with the legacy Agilent 3488A

system. This manual documents the 3488 mode of operation.

For information about the SCPI programming mode please refer to the

User’s Manual shipped with your Agilent 3499A/B/C, or visit

www.agilent.com.

2 half width

1

9

full width

54

Page 55

Chapter 3 System Overview

Firmware and Control Module Description

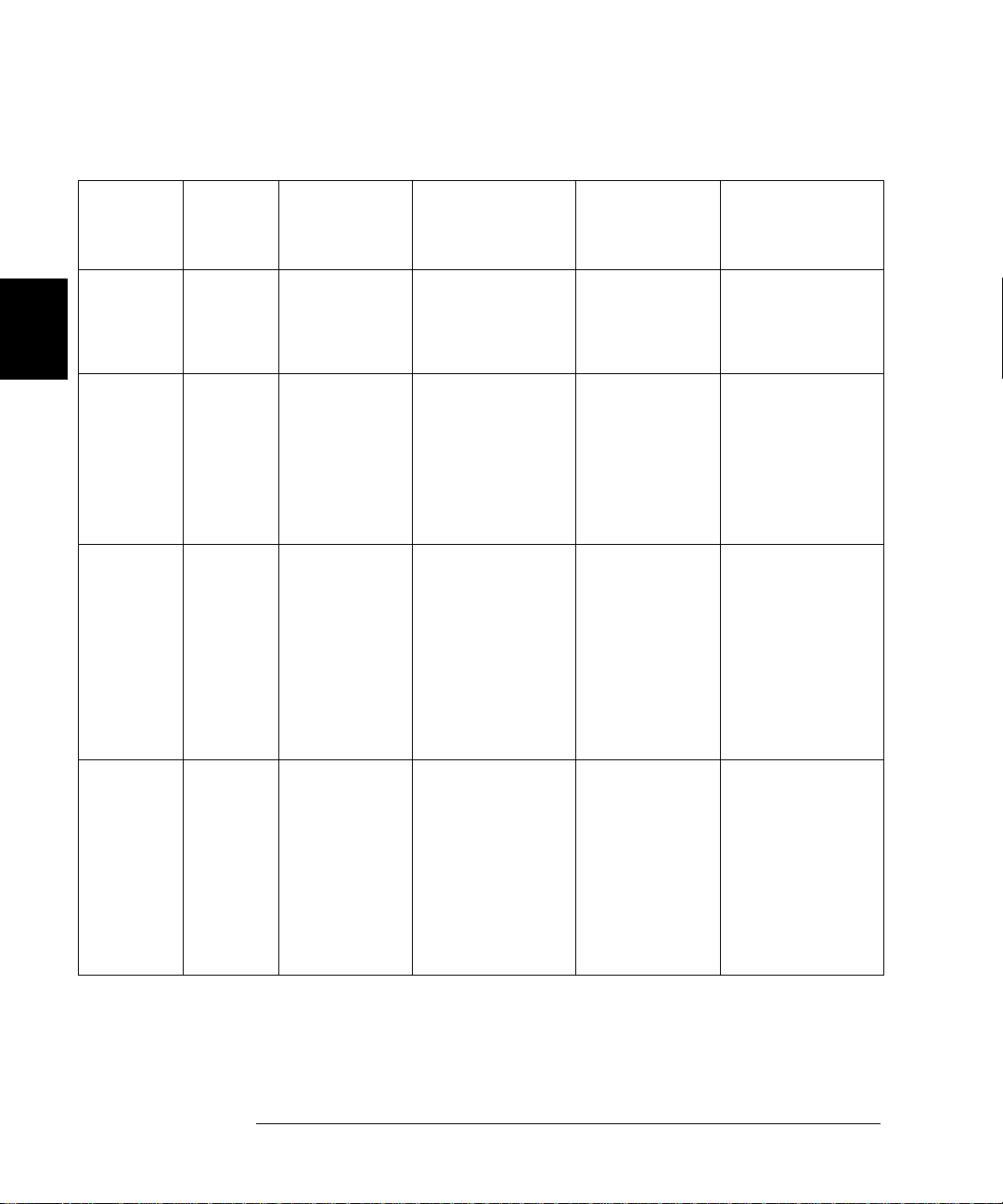

Firmware and Control Module Description

The Agilent 3499A/B/C and this manual support two versions of the

Agilent 3499A/B/C control module and four versions of fir mware.

Firmware revisions and control module versions can be queried from the

front-panel. See page 48 for a procedure to read the revision from the

front-panel.

From the front-panel:

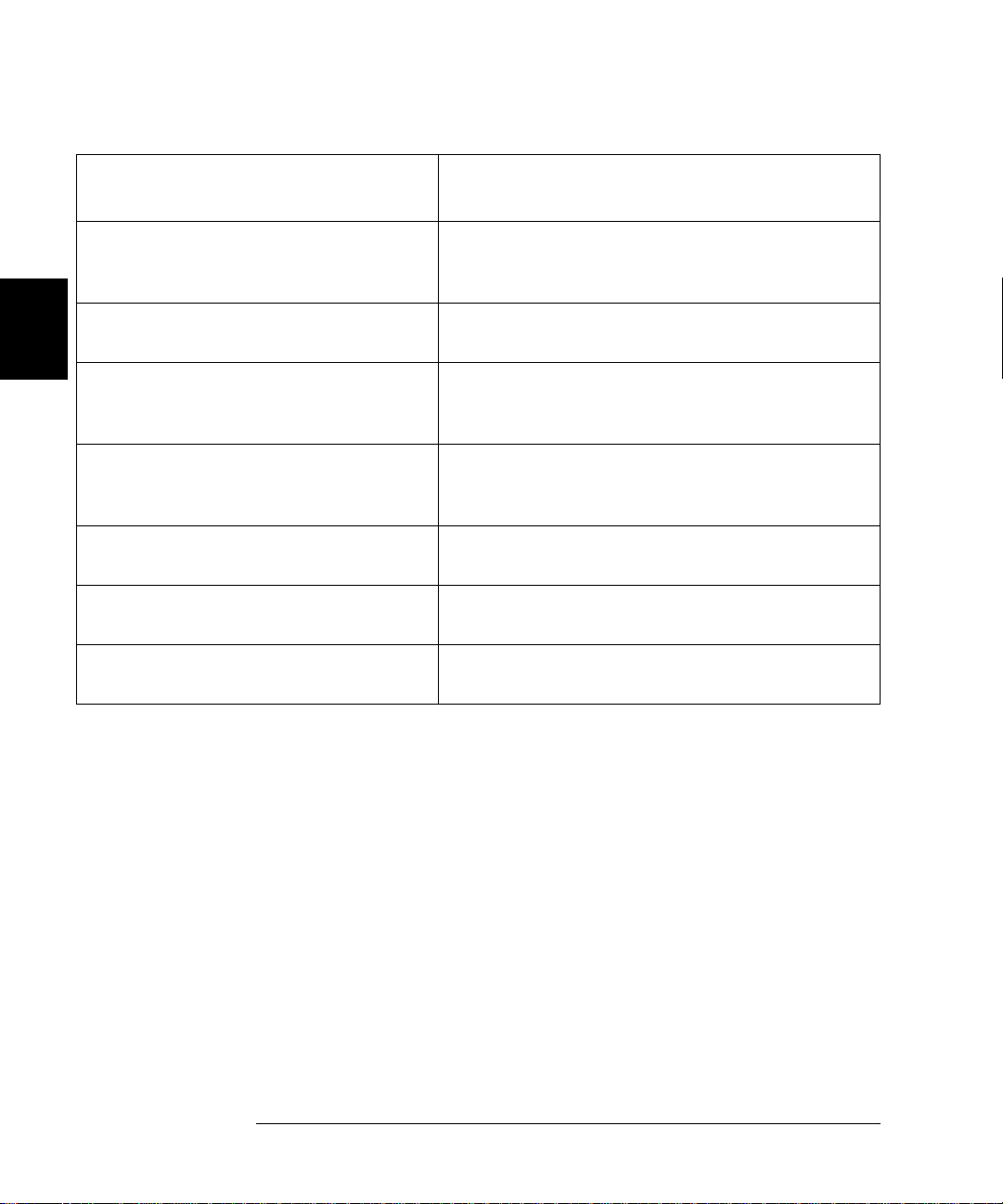

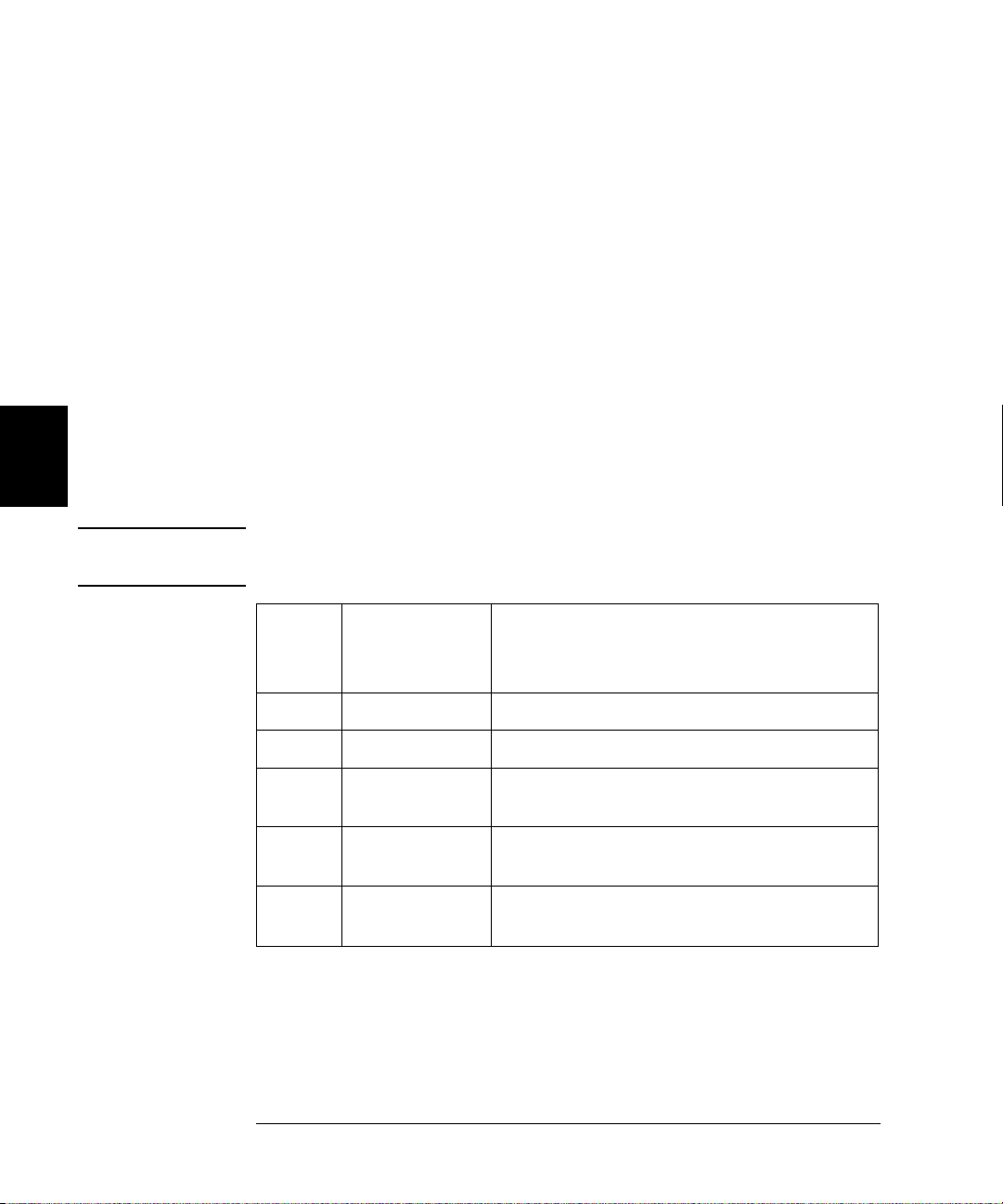

Control Module Revision Firmware Revision Typical Display

1.0 1.0 REVISION 1.0

1.0 2.0 REVISION 2.0

1.0 3.0 REVISION 3.0

2.0 4.0 REV 4.0 2.0

The table o n the next pag e lists the differe nces between firmware and

control module revisions.

4

3

55

Page 56

Chapter 3 System Overview

Firmwa re and Control Module Description

3

Firmware

Version

1.0 1.0 Stored setups

2.0 1.0 Stored setups

3.0 1.0 Stored setups

1

4.0

Control

Module

Version

2.0 Stored setups

State

Storage

are cleared if

power is

cycled.

are cleared if

power is

cycled.

are cleared if

power is

cycled.

are saved.

Instrument

can be

programmed

to power up in

a set state.

Plug-in module

Support

Must upgrade

hardware and

firmware.

Supports all

modules except:

N2272A

N2276A/B

N2282A

SCPI Mode

supports all

modules.

3488A Mode

supports all

modules except:

N2272A,

N2276A/B, o r

N2282A.

SCPI Mode:

supports all

modules.

3488A Mode

supports all

modules except:

N2272A,

N2276A/B, o r

N2282A.

Programming

Modes

Not App lic ab le YES

Firmwa re

Version 2.0

allows

programming in

both SCPI

Mode and

3488A Mode.

Firmwa re

Version 3.0

limits

programming to

either SCPI

Mode or 3488A

Mode (not both)

Firmwa re

Version 4.0

allows

programming in

both SCPI

Mode and

3488A Mode.

Firmware

Upgrade

Needed?

Upgrade to

Firmwa re

Revision 3.0

ONLY if using

N2272A,

N2276A/B, or

N2282A.

Upgrade to

firmware revision

4.0 ONLY if

control board

revision is

upgraded to 2.0.

NO

1

Upgrading to firmware revision 4.0 requires the control module be upgraded to revision 2.0.

Contro l module re vision 1. 0 does not support fi rmw are re visi on 4.0 .

56

Page 57

Chapter 3 System Overview

3488 Mode Differences

3488 Mode Differences

This manual describes using the Agilent 3499A/B/C in the 3488 mode of

operation. In general, the SCPI mode of operation is recommended. All

the features and functions of 3499A/B/C system and plug-in modules are

supported in SCPI mode. The 3488 mode is a subset and does not support

all available features.

Some of the major differences in 3488 mode of operation are summarized

below:

• The RS-232 interface is not supported in 3488 mode. You must use

the GPIB interface for remote programming.

• The 3488 mode d o es not provide as muc h control ove r the scann ing

process as SCPI mode. You cannot use the arm and trigger layers of

scan cont ro l.

• The 3488 mode only provides a ccess to the status byte register. You

cannot use the Standard Event or Operation Status registers.

4

3

• With firmware revision 4.0, you can store up to 40 setups (50 setups

in SCPI mode).

• Scan lists are not saved after cycling power.

• The relay cycle count feature is only available from the front-panel.

• The N2260A and N2266A can only be used in 40-channel 2-wire

mode.

• The 3488 Mode does not support the following plug-in modules:

N2272A, N2276A/B, or N2282A.

• Port numbering for Digital I/O modules is different.

57

Page 58

Chapter 3 System Overview

Plug-in Modules Overview

Plug-in Modules Overview

The Agilent 3499A/B/C mainfram e s sup p or t multiple Plug-in modules,

including all the existing 3488A modules (4447XX mo dules) , as well as

several new ones (N22XXX modules). Based on their functions, the

modules can be divided into five classes:

•

Multiplexer (MUX) modules

3

Note Refer to the Agilent 3499A/B/C User’s Manu al (s hippe d with the

•

General Purpose Relay (GP) modules

•

Matrix modules

•

Digital I/O (DIO) modules

•

Multifunction modules

•

Optical Modules

instrument) or visit www.agilent.com for the details of the individual

Plug-in modules.

58

Page 59

Chapter 3 System Overview

Plug-in Modules Overview

MUX Modules

A MUX (multiple xer) module switches one signal to mul tip le DUTs

(devices under test), or mu ltiple signals to one device, one at a time.

Example applications include capacitor leakage, connector/switch

contact, and insulation resistanc e te st sys tems. To exp and switchi ng

capacity or build special configurations, the multiplexer switching

modules can also be used with matrix or other switching modules. The

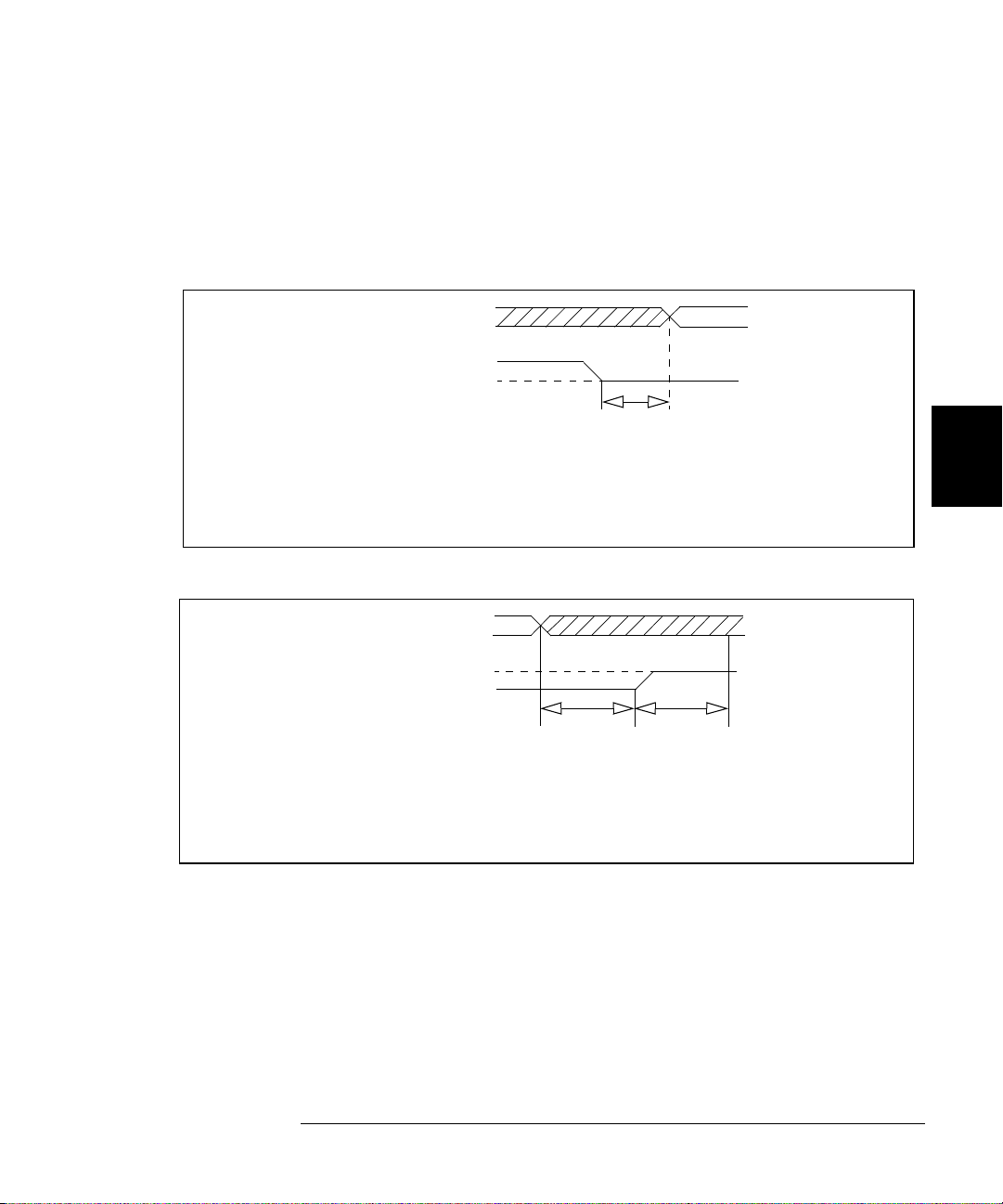

figure below shows a simple 1 x 4 Multiplexer.

Simple Multiplexer Switching

4

3

Multiplexers are available in seve ral types:

•

One-Wire (Single-Ended) Multiplexer for common LO measurements

•

Two-Wire Multiplexer for floating measurements

•

Four-Wire Multiplexer for resistance and RTD measurements

•

Very High Frequency (VHF) / Microwave Multiplexer for switching

frequenc ie s up to m icrowave (26.5 GHz).

The table o n the next page lists the available MUX m odul es .

59

Page 60

Chapter 3 System Overview

Plug-in Modules Overview

3

Model

Number

N2260A 40-Channel MUX

N2266A 40-Channel MUX

N2268A 50Ω 3.5 GHz Dual

N2270A 10-Channel High

44470A/D 10/20-Channel

Module Name

Module

Module

4-to-1 MUX

Module

Voltage MUX

Module

MUX Module

Mainframe

Slots

Required

1 Latching In 3488 mode, a 40-channel 2-

1 Reed non-

1 Latching Consists of two independent 1-

2Non-

1 Latching The 10/20 DPST (Double-pole

Relay

Type

latching

latching

Description

wire multiplexer, switches both

HI and LO inputs (200 V, 1 A)

with DPST relays.

In 3488 mode, a 40-channel 2wire multiplexer.

to-4 MUX switches which can

switch up to 30VDC or peak AC

at frequencies from DC to

3.5 GHz.

10-channel 2-wire High Voltage

MUX module with maximum

switching voltage 1000V peak

and maximu m s w itching power

10W.

Single-throw) relays switch both

HI and LO inputs up to 250V,

2A with low differential offsets

for accurate measurements.

44472A Dual 4-Channel

VHF Switch

Module

44478A/B 50Ω/75Ω 1.3 GHz

Multiplexer

60

1 Latching The two independent groups of

bidirectional 1x4 switches with

50Ω characteristic impedance

can be used for signals from

DC to 300 MHz.

1 Latching The two independent groups of

bidirectional 1x4 switches with

50Ω/75Ω characteristic

impedance can be used for

signals from DC to 1.3 GHz.

Page 61

Chapter 3 System Overview

Plug-in Modules Overview

GP Modules

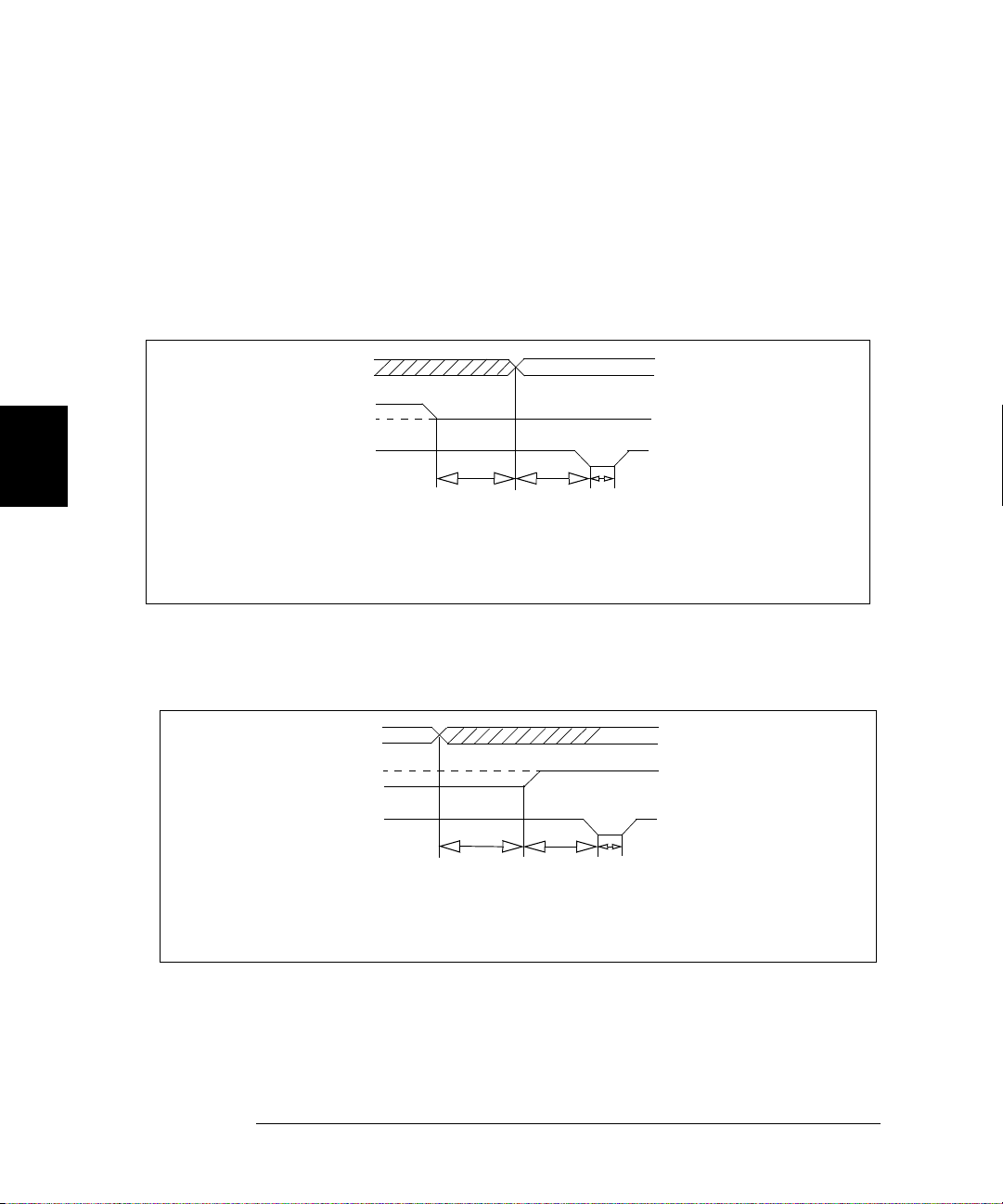

The GP (General Purpose) relay modules often consist of independent

latching or non-latching relays. They are useful for creating additional

isolation between circuits, providing safety interlocks, actuating other

relays or circuits, or building special topologies such as binary ladders

and tree structures. A sim ple 4- ch annel SPST (Single-pole Sin gle -thr o w)

GP switch is shown below.

4

L

CH01

CH02

CH03

CH04

H

L

H

L

H

L

H

CH01

CH02

CH03

CH04

3

The table b el ow lists th e available GP relay mo d ules.

Model

Number

N2261A 40-Channel GP

N2267A 8-Channel

44471A 10-Channel GP

Module Na me

Relay Module

High Current

GP Module

Relay Module

A Simple General Purpose Switch

Mainframe

Slots

Required

1 Latching The 40 independent SPST relays

1 Non-

1 Latching The 10 independent SPST (Single-

Relay

Type

latching

Description

provid e quality connections for low

level signals. Can a lso sw itch signals

up to 200V, 1A.

An 8-channel High Current GP module

which can switch up to 8A 250VAC or

5A 30VDC, with decreasi ng current to

1A at 125VDC.

pole Single-throw) relays provide

quality connections for low level

signals. Can also switch signals up to

250V, 2A.

61

Page 62

Chapter 3 System Overview

Plug-in Modules Overview

3

Model

Number

44471D 20-Channel GP

44475A Breadboard

44476A 3-Channel 18

44476B 2-Channel

Module Na me

Relay Module

Module

GHz Switch

Module

Microwave

Switch Module

Mainframe

Slots

Required

1 Latching The 20 independent SPST (Single-

1 NA Use the breadboard for custom circuits

1 Latching The 3 independent 50Ω SPDT (Single-

1 NA Similar t o the 44476A but does not

Relay

Type

Description

pole Single-throw) relays provide

quality connections for low level

signals. Can also switch signals up to

250V, 1A.

and special purpose functions in your

test system.

pole Double-throw) coaxial switches

with SMA connectors provide high

isolation, low insertion loss, and low

VSWR for switching signals up to

18 GHz.

have the coaxial switches installed.

A variety of coaxial switches can be

mounted onto the modul e to provide

3-, 4-, or 5-port switching up to

26.5 GHz.

44477A 7-Channel

Form-C Relay

Module

62

1 Latching 7 independent, break-before-make,

SPDT Form-C relays for general

purpose switching and control of

external devices up to 250V, 2A.

Page 63

Chapter 3 System Overview

Plug-in Modules Overview

Matrix Modules

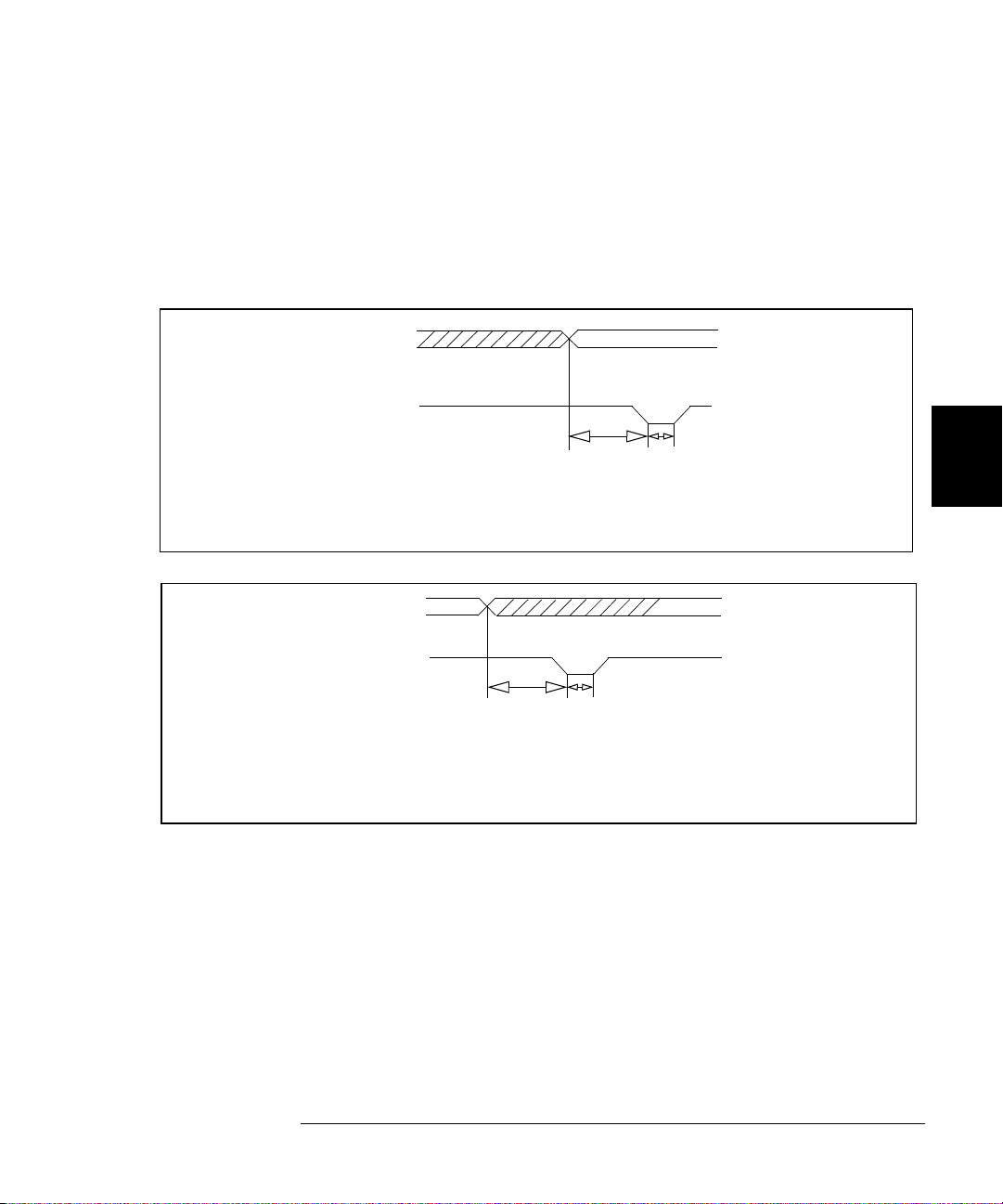

A matrix switch is the most versatile type of system switching. Any input

can be connected to any output, individually or in combination. This

helps minimize the need for compl ex wiring, and can sim pli fy t he D U T

interface. In addition, a matrix module can be used in conjunction with

other modules to provide a wide variety of switching combinations. A

matrix is arranged in rows and columns and a simple 4 x 4 matrix switch

is shown below.

4

3

The table b el ow lists th e ava ilable m atrix modules.

Model

Number

N2262A 4 x 8 Matrix

44473A 4 x 4 Matrix

Module

Name

Module

Module

Matr ix Switching

Mainframe

Slots

Required

1 Latching Each crosspoint or node of the 4 x 8

1 Latching Each crosspoint or node of the 4 x 4

Relay

Type

Description

matrix module uses a DPST (Doublepole Single-throw) relay to switch two

wires (Hi & Lo) for signals up to 200V,

1A.

matrix module uses a DPST (Doublepole Single-throw) relay to switch two

wires (Hi & Lo) for signals up to 250V,

2A.

63

Page 64

3

Chapter 3 System Overview

Plug-in Modules Overview

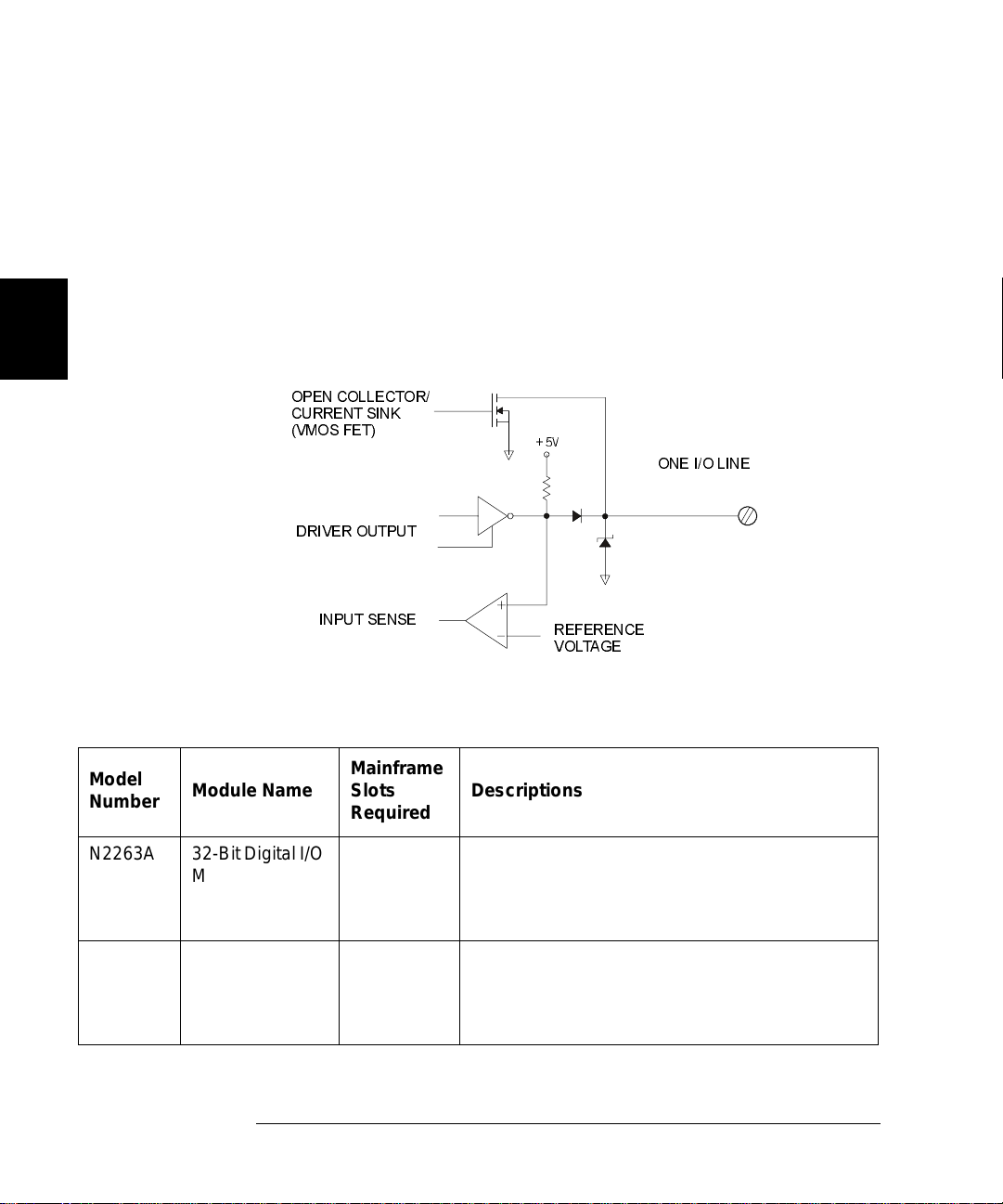

Digital I/O Mod ule s

The digital I/O modules provide high-density digital input/output

capabilities in an easy-to-control form. The independent TTL-compatible

inputs and outpu ts mak e it well-suited for monitorin g and controlling

devic e s compactly and cost-effecti vely. Typicall y, the dig i tal outpu ts are

used to provide drive for relatively high current devices such as

solenoids, relays and small motors. Th e d igital inputs are used to

monitor devices such as micro-sw itches. A simplified schematic of a

sing l e digit a l input and output l i ne is shown below.

OPEN COLLECTOR/

CURRENT SINK

(VMOS FET)

DRIVER OUTPUT

+5V

ONE I/O LINE

The table b el ow lists th e available d igita l I/ O modu les.

Model

Number

Module Name

N2263A 32-Bit Digital I/O

Module

44474A 16-Bit Digital I/O

Module

64

INPUT SENSE

A Simple Digital I/O Circuit

Mainframe

Slots

Descriptions

Required

1 The module offers 32-bidirectional I/O lines and

three handshake lines for sensing and control of

external devices up to 42 V, 600 mA. All lines

are TTL-compatible.

1 The module offers 16-bidirectional I/O lines and

four handshake lines for sensing and control of

external devices up to 30 V, 125 mA. All lines

are TTL-compatible.

REFERENCE

Page 65

Chapter 3 System Overview

Plug-in Modules Overview

Multifunction Modules

A multifunction modu le combines two or more functions such as MUX,

GP, Matrix, Digital I/O or DAC onto a single module, making it possible

to implement a complicated switching application with fewer modules.

Therefore, the cost is reduced by minimizing the number of mainframes

and modules requ ired.

Each separate function on a multifunction module can be operated

independently. Fo r example, an A gilent N2265A can be used as both a

4 x 4 matrix module and a 16-bit digital I/O module.

The table below lists the available multi fu nc tio n mod ules.

4

3

Model

Number

N2264A 12-Channel GP +

N2265A 4 x 4 Matrix +

Module Name

3-Channel Highcurrent GP +

16-Bit Digital I/O

Module

16-Bit Digital I/O

Module

Mainframe

Slots

Required

1 Non-

1 Latchi ng T he module provides 4 x 4 2-wire

Relay

Type

latching

Description

The module provides 12-channel

SPST (Single-pole Single-throw)

GP relays for signals up to 200 V, 1

A, 3-channel high-current GP

relays for signals up to 125 V, 5 A,

and 16-bit digital I/O for sensing

and control of external devices up

to 42 V, 600 mA.

matr ix for signals up to 200V, 1A,

and 16-bit digital I/O for sensing

and control of external devices up

to 42 V, 600 mA.

65

Page 66

Chapter 3 System Overview

Plug-in Modules Overview

Opti ca l M odules

The Agilent N228 0A an d N 2281A are optical switch modules. The table

below lists the information about these three optical modules.

3

Model

Number

N2280A Optical Switch Quad 1-to-

N2281A Optical Switch Dual 1-to-

Module Na me

2 MUX Module

4 MUX Module

Mainframe

Slots

Required

2Non-

2Non-

Relay

Type

latching

latching

Description

Four 1-to-2 Optical

Switches

Two 1-to-4 Optical

Switches

66

Page 67

Chapter 3 System Overview

Channel and Slot Addressing

Channel and Slot Addressing

A channel refers to an individual relay on a switching module, or an

individual bit/port on a digital I/O module. The channel address is in the

form of snn, where s repres ents sl ot number and nn represents a channel

number.

For all mainframes, slot 0 refers to the 3499A/B/C control board. Valid

slot numbers are:

3499A s lots 0 through 5

3499B s lots 0 through 2

3499C slots 0 through 9

The chan ne l nu m b e r, nn, is plug-in module dependent. Detailed

information about channel numbers of individual plug-in modules is

given below and on the following pages.

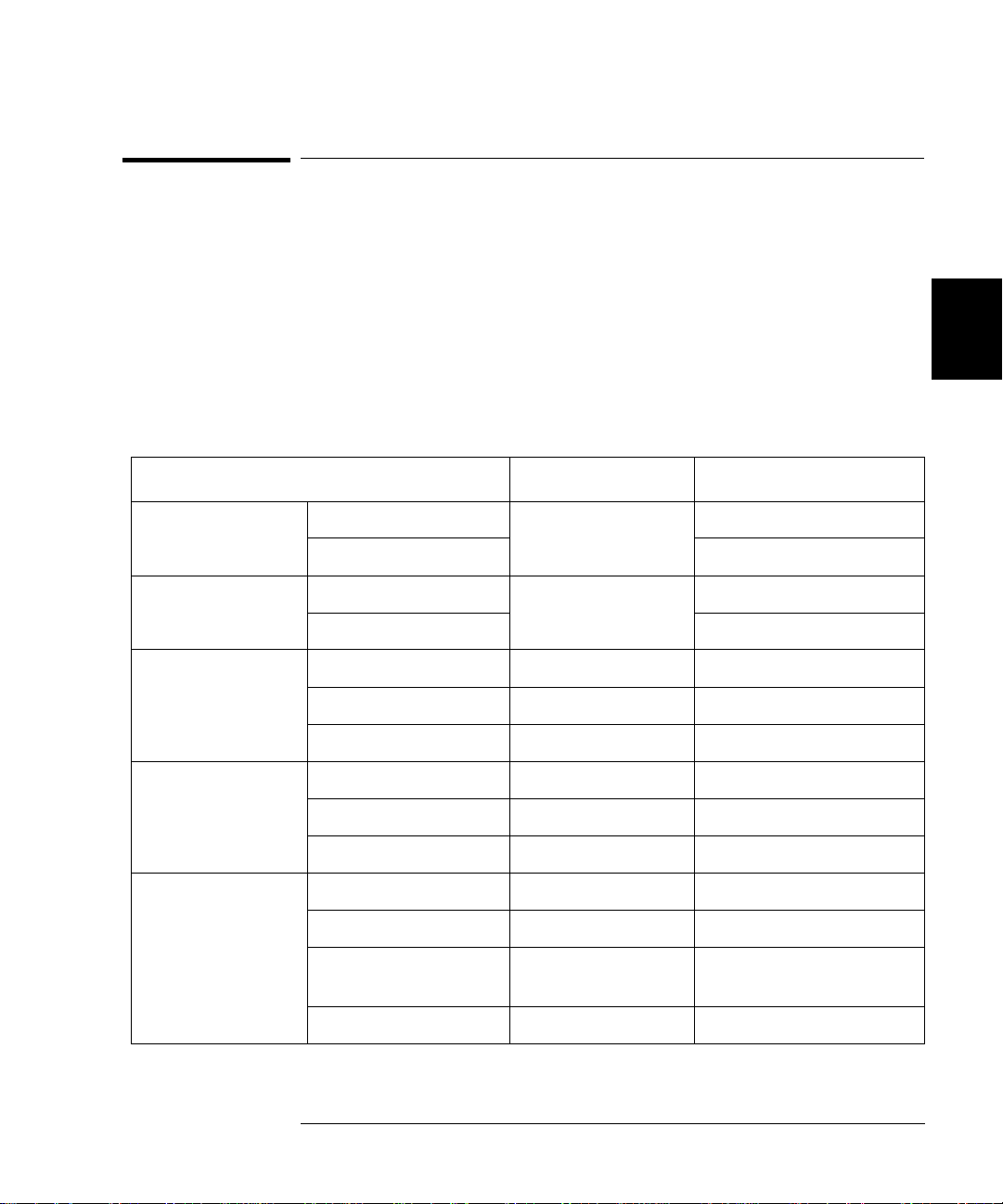

Plug-in Module

N2260A

40-Channel MUX Module

N2261A

40-Channel GP Relay Module

N2262A

4X8 Matrix Module

a. The N2260A and N2266A can be only be used as a 40-channel 2-wire MUX modulein 3488 mode.

b. A channel numb er on a mat rix modu le is for me d in Slot- Ro w- Col umn forma t , i.e. , chan nel ad dr e ss s23 mean s row 2,

colum n 3 in S l ot s.

a

Channel Addressing (snn)

s = Slot Number; nn = Channel Number

2-Wire Mode: s00, s01...s38, s39

s00, s01, s02, s03... s37, s38, s39

Row 0, 1, 2, 3; Column 0, 1, 2, 3... 6, 7

(s00, s01, s02... s07; s10, s11, s12... s17;

s20, s21, s22... s27; s30, s31, s32... s37)

b

4

3

67

Page 68

Chapter 3 System Overview

Channel and Slot Addressing

3

Plug-in Module

N2263A

32-Bit Digital I/O Module

N2264A

12-Channel GP Relay +

3-Channel High-current GP Relays +

16-Bit Digital I/O Module

N2265A

4x4 Matrix +

16-Bit Digital I/O Module

N2266A

40-Channel MUX Module

b

Channel Addressing (snn)

s = Slot Number; nn = Channel Number

Individual Bits: s00, s 01, s02... s30, s31

8-Bit Ports: s00, s01, s02, s03

16-Bit Ports: s04, s05

32-Bit Port: s06

12 GP Relays: s00, s01 , s02... s10, s11

3 High-current GP Relays: s20, s21, s2 2

16-Bit Digital I/O:

Individual Bits: s30, s 31, s 32 ... s44, s45

8-Bit Ports: s30, s31

16-Bit Port: s32

4x4 Matrix:

Row 0, 1, 2, 3; Column 0, 1, 2, 3

(s00, s01, s02, s03; s10, s11, s 12, s1 3;

s20, s21, s22, s23; s30, s31, s32, s33)

a

16-Bit Digital I/O:

Individual Bits: s40, s 41, s42... s54, s55

8-Bit Ports: s40, s41

16-Bit Port: s42

2-Wire Mode: s00, s01...s38, s39

N2267A

s00, s01, s02... s07

8-Channel High Current GP Module

N2268A

s00, s01, s02, s03; s10, s11, s 12 , s13

50Ω 3.5 GHz D ual 4-to-1 MUX Module

a. A chann el number on a m a trix module is formed in Slot -Row-Column format, i.e., channel address s23 means row 2,

colum n 3 in S l ot s.

b. The N2260A and N2 266A can only be us ed as a 40-channel 2-wire MUX module in 3488 mode .

68

Page 69

Chapter 3 System Overview

Channel and Slot Addressing

Plug-in Module

N2270A

10-Channel HIgh Voltage MUX Module

N2280A

Optical Switch Quad 1-to-2 M UX Module

N2281A

Optical Switch Dual 1-to-4 MUX Module

4-Bit Built-in Digital I/O

(slot 0 control module)

44470A

10-Channel MUX Module

44470D

20-Channel MUX Module

44471A

10-Channel GP Relay Module

44471D

20-Channel GP Relay Module

44472A

Dual 4-Channel VHF Module

Channel Addressing (snn)

s = Slot Number; nn = Channel Number

s00, s01, s02... s07

s00, s01; s10, s11; s20, s21; s 30 , s31

s00, s01, s02, s03;s10, s11, s12, s13

Individual Bits: 091, 092, 093, 094

4-Bit Port: 090

s00, s01, s02, s03... s08, s09

s00, s01, s02, s03... s18, s19

s00, s01, s02, s03... s08, s09

s00, s01, s02, s03... s18, s19

Group 0: s 00, s 01, s 02, s03

Group 1: s 10, s 11, s12, s13

4

3

44473A

4x4 Matrix Module

a. A chan nel number on a mat rix module is form ed in Slot-Row- Column fo rmat, i.e., cha nnel address s23 means row 2,

colum n 3 in S l ot s.

Row: 0, 1, 2, 3; Column: 0, 1, 2, 3

(

s00, s01, s02, s03; s10, s11, s12, s13;

s20, s21, s22, s23; s30, s31, s32, s33)

a

69

Page 70

Chapter 3 System Overview

Channel and Slot Addressing

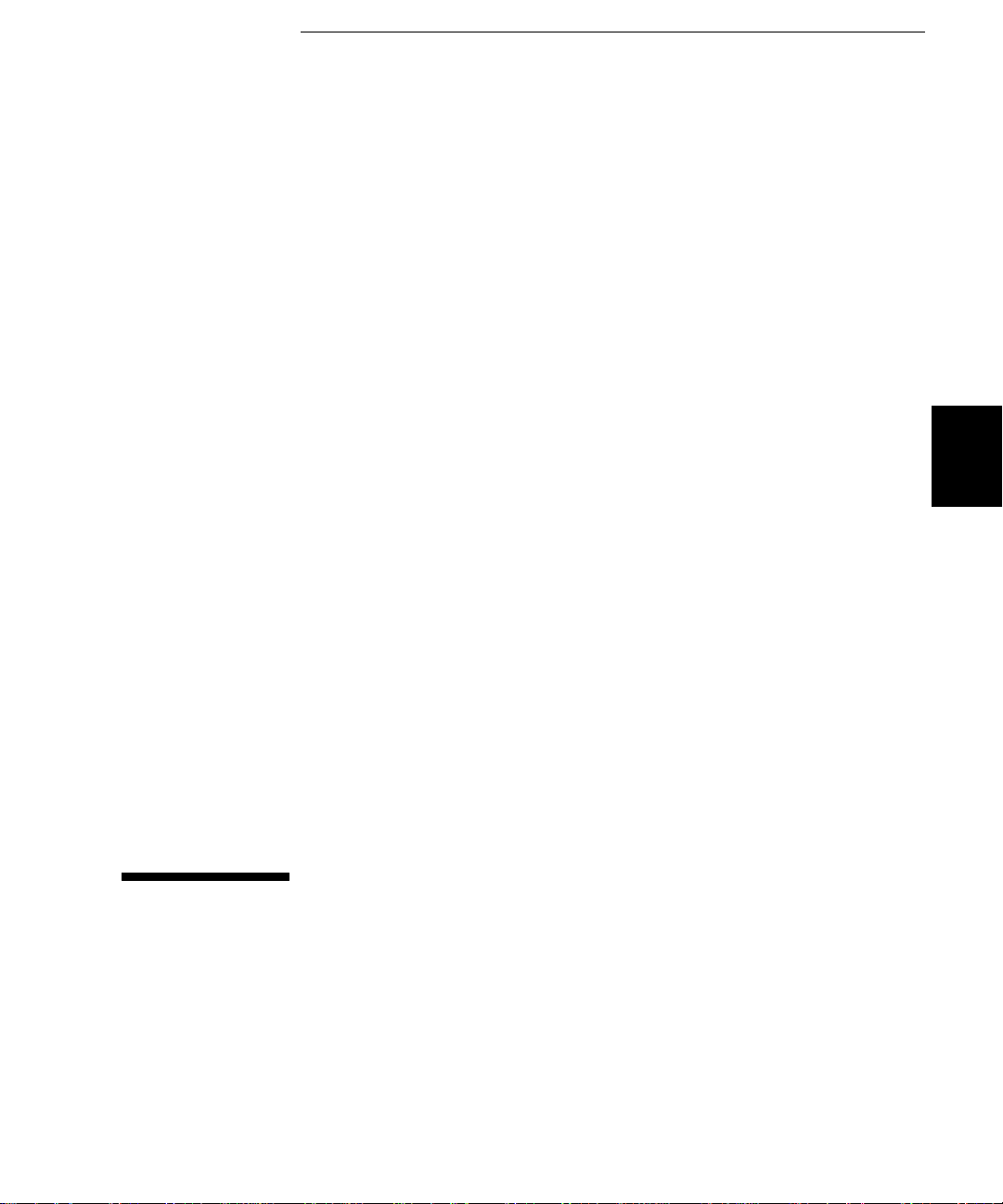

3

Plug-in Module

44474A

16-Bit Digital I/O Module

44475A

Breadboard Module

44476A

3-Channel 13 GHz Microwave

Switch Module

44476B

2-Channel 26 GHz Microwave

Switch Module

44477A

7-Channel Form-C Relay Module

44478A

50 Ω 1.3 GHz MUX Module

44478B

75 Ω 1.3 GHz MUX Module

Channel Addressing (snn)

s = Slot Number; nn = Channel Number

Individual Bits: s00, s 01, s02... s14, s15

8-Bit Ports: s00, s01

16-Bit Port: s02

N/A

s00, s01, s02

s00, s01

s00, s01, s02, s03, s04, s05, s06

Group 0: s00, s01, s02, s03

Group 1: s 10, s 11, s12, s13

Group 0: s 00, s 01, s 02, s03

Group 1: s 10, s 11, s12, s13

70

Page 71

Chapter 3 System Overview

Factory Default and Reset States

Factory Default and Reset States

The table on the next page shows the settings of the instrument after a

reset.

•You can reset the instrument either by pressing

Shift + Card Reset o n the front- pa nel, or with a RESET command

over the remote in terface.

•If a module is accidentally remo ve d o r installed while the

instrument power is on, the instrument will preform a reset.

3488 Mode Defaults

Item Factory Default Reset

4

3

Interface GPIB/488 GPIB (Address 9) Keep current setting

RS-232

System Mode SCPI Mode SCPI Mode Keep current setting

3488A Mode Keep current setting

System-Related Display State On On

Stored State Empty Keep current setting

Error Queue Empty Cleared

Module-Related Switching Channels Open Open

Digital I/O Ports Input Input

Card Pair None None

Scan-Related Scanning None Stop scan in progress

Scan List Empty Empty

Channel Delay

(seconds)

Trigger Out Pulse Disabled Disabled

b

00

Keep current setting

a

a. Curr ent setting inc l ud es th e selectio n of the G PI B int e rface and its a dd r es s se tting.

b. RS-232 interface CANNOT be used in 3488A mode.

71

Page 72

3

72

Page 73

4

4

Features and Functio ns

Page 74

4

Features and Functions

This chapter provides details about particular functions and features of

the Agilent 3499A/B/C Switch/Control System. The sections in this

chapter describe the features using both the fro nt-panel and the remo te

interface using SCPI commands. The examples in this chapter are

general. For specific procedures using the front panel refer to Chapter 2.

For SCPI command information refer to Chapter 5. The following

sections are included in this chapter:

•

Monitoring a Channel or a Slot, on page 75

•

Switching a Relay Channel, on page 77

•

Scanning, on page 78

•

Digital I/O Operation, on page 84

•

State Storage, on page 94

•

Error Conditions, on page 96

•

Self-Test, on page 96

•

Display Control, on page 97

•