Page 1

Agilent Technologies

Agilent Technologies

Agilent TechnologiesAgilent Technologies

3458A Multimeter

3458A Multimeter

3458A Multimeter3458A Multimeter

Assembly-Level Repair Manual

Assembly-Level Repair Manual

Assembly-Level Repair ManualAssembly-Level Repair Manual

Manual Part Number: 03458-90011

Printed in U.S.A

Page 2

AGILENT TECHNOLOGIES WARRANTY STATEMENT

AGILENT PRODUCT: 3458A Multimeter DURATION OF WARRANTY: 1 year

1. Agilent Technologies warrants Agilent hardware, accessories and supplies against defects in materials and workmanship for the period

specified above. If Agilent receives notice of such defects during the warranty period, Agilent will, at its option, either repair or replace

products which prove to be defective. Replacement products may be either new or like-new.

2. Agilent warrants that Agilent software will not fail to execute its programming instructions, for the period specified above, due to

defects in material and workmanship when properly installed and used. If Agilent receives notice of such defects during the warranty

period, Agilent will replace software media which does not execute its programming instructions due to such defects.

3. Agilent does not warrant that the operation of Agilent products will be interrupted or error free. If Agilent is unable, within a reasonable

time, to repair or replace any product to a condition as warranted, customer will be entitled to a refund of the purchase price upon prompt

return of the product.

4. Agilent products may contain remanufactured parts equivalent to new in performance or may have been subject to incidental use.

5. The warranty period begins on the date of delivery or on the date of installation if installed by Agilent. If customer schedules or delays

Agilent installation more than 30 days after delivery, warranty begins on the 31st day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or inadequate maintenance or calibration, (b) software, interfacing, parts

or supplies not supplied by Agilent, (c) unauthorized modification or misuse, (d) operation outside of the published environmental

specifications for the product, or (e) improper site preparation or maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE WARRANTIES ARE EXCLUSIVE AND NO OTHER

WARRANTY OR CONDITION, WHETHER WRITTEN OR ORAL, IS EXPRESSED OR IMPLIED AND AGILENT

SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY OR CONDITIONS OF MERCHANTABILITY, SATISFACTORY

QUALITY, AND FITNESS FOR A PARTICULAR PURPOSE.

8. Agilent will be liable for damage to tangible property per incident up to the greater of $300,000 or the actual amount paid for the product

that is the subject of the claim, and for damages for bodily injury or death, to the extent that all such damages are determined by a court

of competent jurisdiction to have been directly caused by a defective Agilent product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS WARRANTY STATEMENT ARE CUSTOMER’S

SOLE AND EXLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE, IN NO EVENT WILL AGILENT OR ITS SUPPLIERS BE

LIABLE FOR LOSS OF DATA OR FOR DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDING LOST PROFIT OR

DATA), OR OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW ZEALAND: THE WARRANTY TERMS CONTAINED IN THIS

STATEMENT, EXCEPT TO THE EXTENT LAWFULLY PERMITTED, DO NOT EXCLUDE, RESTRICT OR MODIFY AND ARE

IN ADDITION TO THE MANDATORY STATUTORY RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

U.S. Government Restricted Rights

The Software and Documentation have been developed entirely at private expense. They are delivered and licensed as "commercial

computer software" as defined in DFARS 252.227- 7013 (Oct 1988), DFARS 252.211-7015 (May 1991) or DFARS 252.227-7014 (Jun

1995), as a "commercial item" as defined in FAR 2.101(a), or as "Restricted computer software" as defined in FAR 52.227-19 (Jun

1987)(or any equivalent agency regulation or contract clause), whichever is applicable. You have only those rights provided for such

Software and Documentation by the applicable FAR or DFARS clause or the Agilent standard software agreement for the product

involved.

3458A Multimeter Assembly Level Repair Manual

Copyright © 1988, 2000 Agilent Technologies, Inc. All rights reserved.

Edition 2

2

Page 3

Documentation History

All Editions and Updates of this manual and their creation date are listed below. The first Edition of the manual is Edition 1. The Edition

number increments by 1 whenever the manual is revised. Updates, which are issued between Editions, contain replacement pages to

correct or add additional information to the current Edition of the manual. Whenever a new Edition is created, it will contain all of the

Update information for the previous Edition. Each new Edition or Update also includes a revised copy of this documentation history page.

Edition 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . May, 1988

Update 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . February, 1992

Edition 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . October, 1992

Edition 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . February, 1994

Edition 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . December, 2000

Safety Symbols

Instruction manual symbol affixed to

product. Indicates that the user must refer to

the manual for specific WARNING or

CAUTION information to avoid personal

injury or damage to the product.

Indicates the field wiring terminal that must

be connected to earth ground before

operating the equipment — protects against

electrical shock in case of fault.

or

Frame or chassis ground terminal—typ ically

connects to the equipment's metal frame.

WARNING

CAUTION

Alternating current (AC)

Direct current (DC).

WARNING, RISK OF ELECTRIC SHOCK.

Calls attention to a procedure, practice, or

condition that could cause bodily injury or

death.

Calls attention to a procedure, practice, or

condition that could possibly cause damage to

equipment or permanent loss of data.

WARNINGS

The following general safety precautions must be observed during all phases of operation, service, and repair of this product. Failure to

comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and

intended use of the product. Agilent Technologies assumes no liability for the customer's failure to comply with these requirements.

Ground the equipment: For Safety Class 1 equipment (equipment having a protective earth terminal), an uninterruptible safety earth

ground must be provided from the mains power source to the product input wiring terminals or supplied power cable.

DO NOT operate the product in an explosive atmosphere or in the presence of flammable gases or fumes.

For continued protection against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current rating and type. DO NOT

use repaired fuses or short-circuited fuse holders.

Keep away from live circuits: Operating personnel must not remove equipment covers or shields. Procedures involving the removal of

covers or shields are for use by service-trained personnel only. Under certain conditions, dangerous voltages may exist even with the

equipment switched off. To avoid dangerous electrical shock, DO NOT perform procedures involving cover or shield removal unless you

are qualified to do so.

DO NOT operate damaged equipment: Whenever it is possible that the safety protection features built into this product have been

impaired, either through physical damage, excessive moisture, or any other reason, REMOVE POWER and do not use the product until

safe operation can be verified by service-trained personnel. If necessary, return the product to Agilent for service and repair to ensure that

safety features are maintained.

DO NOT service or adjust alone: Do not attempt internal service or adjustment unless another person, capable of rendering first aid and

resuscitation, is present.

DO NOT substitute parts or modify equipment: Because of the danger of introducing additional hazards, do not install substitute parts

or perform any unauthorized modification to the product. Return the product to Agilent for service and repair to ensure that safety features

are maintained.

Measuring high voltages is always hazardous: ALL multimeter input terminals (both front and rear) must be considered hazardous

whenever inputs greater than 42V (dc or peak) are connected to ANY input terminal.

Permanent wiring of hazardous voltage or sources capable of delivering grater than 150 VA should be labeled, fused, or in some other

way protected against accidental bridging or equipment failure.

DO NOT leave measurement terminals energized when not in use.

DO NOT use the front/rear switch to multiplex hazardous signals between the front and rear terminals of the multimeter.

3

Page 4

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name: Agilent Technologies, Incorporated

Manufacturer’s Address:

815 14

Loveland, CO 80537

USA

Declares, that the product

Product Name: Multimeter

Model Number: 3458A

Product Options: This declaration covers all options of the above product(s).

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC

(including 93/68/EEC) and carries the CE Marking accordingly

Conforms with the following product standards:

th

ST. S.W.

EMC Standard

IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011:1991

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995

IEC 61000-4-3:1995 / EN 61000-4-3:1995

IEC 61000-4-4:1995 / EN 61000-4-4:1995

IEC 61000-4-5:1995 / EN 61000-4-5:1995

IEC 61000-4-6:1996 / EN 61000-4-6:1996

IEC 61000-4-11:1994 / EN 61000-4-11:1994

Canada: ICES-001:1998

Australia/New Zealand: AS/NZS 2064.1

The product was tested in a typical configuration with Agilent Technologies test systems.

Safety

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

UL 3111-1: 1994

8 March 2001

Date

Limit

Group 1 Class A

4kV CD, 8kV AD

3 V/m, 80-1000 MHz

0.5kV signal lines, 1kV power lines

0.5 kV line-line, 1 kV line-ground

3V, 0.15-80 MHz I cycle, 100%

Dips: 30% 10ms; 60% 100ms

Interrupt > 95%@5000ms

Ray Corson

Product Regulation Program Manager

Authorized EU-representative: Agilent Technologies Deutschland GmbH, Herrenberger Stra>e 130, D 71034 Böblingen, Germany

For further information, please contact your local Agilent Technologies sales office, agent or distributor.

Revision: B.01 Issue Date: March 2001

4

Page 5

Contents

Safety Symbols ........................................................3

WARNINGS ............................................................3

Chapter 1 General Information

Introduction .............................................................7

Manual Description .................................................7

Instrument Description ............................................7

Safety Considerations ..............................................8

Instrument Identification .........................................8

Tools And Equipment Required ..............................8

Tools Required ...................................................8

Test Equipment Required ................................... 9

Chapter 2 Operating Information

Introduction ...........................................................11

Before Applying Power .........................................11

Applying Power .....................................................12

Power-On Self-Test .......................................... 12

Power-On State .................................................12

The Display ......................................................13

Operating from the Front Panel .............................14

Making a Measurement .................................... 15

Changing the Measurement Function ...............15

Autorange and Manual Ranging .......................16

Self-Test ...........................................................17

Reading the Error Register ...............................18

Resetting the Multimeter ..................................19

Using the Configuration Keys .......................... 19

Using the MENU Keys .....................................23

Query Commands .............................................24

Display Control ................................................25

Digits Displayed ...............................................26

Recall ................................................................27

Operating from Remote .........................................27

Input/Output Statements ...................................27

Reading the GPIB Address ...............................27

Changing the GPIB Address ............................28

Sending a Remote Command ...........................28

Getting Data from the Multimeter ....................28

The Local Key ..................................................29

Chapter 3 Disassembly/Assembly

Procedures and Parts List

Introduction ...........................................................31

Static Handling ...................................................... 31

Clean Handling ......................................................32

Printed Circuit Assembly Identification ................ 32

Board Part Number .......................................... 32

Engineering Revision Code ............................. 32

Covers Removal/Installation Procedures .............. 33

Tools Required ................................................. 33

Covers Removal Procedure .............................. 33

Covers Installation Procedure .......................... 36

Assemblies Removal/Installation Procedures ....... 39

Tools Required ................................................. 39

DC Circuitry Assembly Removal/Installation

Procedures ........................................................ 40

DC Reference Assembly Removal/Installation

Procedures ........................................................ 44

AC Converter Assembly Removal/Installation

Procedures ........................................................ 45

A/D Converter Assembly Removal/Installation

Procedures ........................................................ 46

Inguard Power Supply Assembly Removal/

Installation Procedures ..................................... 49

Outguard Controller Assembly Removal/

Installation Procedures ..................................... 51

Outguard Power Supply Assembly Removal/

Installation Procedures ..................................... 52

Display Logic Assembly Removal/Installation

Procedures ........................................................ 56

Front/Rear Terminals Switch Removal/Installation

Procedures ........................................................ 61

Replaceable Parts .................................................. 63

Ordering Information ....................................... 63

Direct Mail Ordering ........................................ 63

Telephone Ordering ......................................... 63

Replaceable Parts List ...................................... 64

Chapter 4 Assembly Level

Troubleshooting

Introduction ........................................................... 67

Test Equipment Required ...................................... 67

3458A Adjustments/Calibration ............................ 67

Assemblies Removal/Installation Procedures ....... 68

3458A Technical Description ............................... 68

General Description ......................................... 68

Technical Description ...................................... 69

Outguard Section ............................................. 70

Inguard Section ................................................ 71

Assembly Level Troubleshooting ......................... 73

Contents 5

Page 6

3458A Failures .................................................73

Power Supplies Troubleshooting ........................... 82

Outguard Power Supplies Troubleshooting .....84

Inguard Power Supplies Troubleshooting ........ 84

6 Contents

Page 7

Chapter 1 General Information

Introduction

This manual has information to perform assembly level troubleshooting of

the 3458A Multimeter. Included are the removal/installation procedures of

the instrument's printed circuit board assemblies, and a parts list. This manual

is intended for use by service-trained personnel only. Operating and

programming personnel should refer to the 3458A Multimeter User’s Guide.

Detailed operating and programming information is excluded from this

manual. Only sufficient information for service purposes is included. For

more detailed operating and programming information, refer to the 3458A

Multimeter User’s Guide.

WARNING The information in this manual is for the use of Service Trained

Personnel only. To avoid electrical shock, do not perform any

procedures in this manual or do any servicing to the 3458A,

unless you are qualified to do so.

Manual Description

This manual is separated into the four following chapters.

Chapter 1 - General Information

Chapter 1 contains a brief description of the instrument and other general

information.

Chapter 2 - Operating Information

Chapter 2 summarizes instrument operation geared for service-trained

personnel. Only service related commands are summarized. For more

operating information, refer to the 3458A Multimeter User’s Guide.

Chapter 3 - Removal/Installation Procedures and Mechanical Parts List

Chapter 3 has the removal/installation procedures for the 3458A Printed

Circuit Board Assemblies. The section also has a mechanical parts list.

Chapter 4 - Assembly Level Troubleshooting

Chapter 4 contains a block diagram theory of operation and assembly level

troubleshooting information.

Instrument Description

The 3458A is a high precision digital multimeter that can measure AC and

DC volts, AC and DC current, AC+DC volts, AC+DC current, resistance,

period, and frequency. It can also perform complex math calculations.

Chapter 1 General Information 7

Page 8

The multimeter has a maximum reading rate of 100,000 readings/sec. The

maximum input voltage is 1000 V peak and the resolution is from 4 1/2 to

81/2 digits.

The 3458A has a digitizing function that converts continuous analog signals

into discrete samples.

All instrument functions are selectable from the front panel or remotely over

the General Purpose Interface Bus (GPIB).

Safety Considerations

The 3458A is a safety class 1 instrument provided with a protective earth

terminal. The instrument and manuals should be reviewed for safety

markings and instructions before operation. Refer to the Safety Summary

preceding this section for appropriate safety instructions and markings

covering the instrument.

Instrument Identification

Agilent instruments are identified by a two part, ten-digit serial number. The

serial number is located on the instrument's rear panel between the rear

terminals and fan filter. The number is in the form 0000A00000. The first

four digits, called the serial number prefix, is the same for all identical

instruments. It changes only when a change is made to the instrument. The

letter indicates the country of origin (A indicates the instrument was built in

the United States of America). The last five digits, called the serial number

suffix, are unique for each instrument.

Be sure to include the entire serial number, both prefix and suffix, in any

correspondence about your instrument.

Tools And Equipment Required

Tools Required You need the following tools for instrument covers removal and installation.

1. #1 Pozidriv screwdriver.

2. #TX15 Torx driver.

3. #TX10 Torx driver.

You need the following tools for the printed circuit board assemblies

removal/installation procedures.

1. #1 Pozidriv screwdriver.

2. TX10 Torx driver.

8 Chapter 1 General Information

Page 9

3. 6 millimeter nut driver (for A/D Converter assembly only).

4. 7 millimeter nut driver (for Outguard Controller assembly only)

5. Small flat bladed screwdriver (for Display Logic assembly only)

6. Large screwdriver (e.g., #2 Pozidriv; for Display Logic assembly

only)

Test Equipment

Required

You need the following to troubleshoot the 3458A.

1. 4 1/2 digit digital multimeter that can measure +5 V, +18 V, and

-18 V DC.

2. Computer with GPIB capability (for GPIB failures only).

3. Logic Probe or Oscilloscope than can measure a 1 µS 5 V pulse (for

Ext Out failures only).

Chapter 1 General Information 9

Page 10

10 Chapter 1 General Information

Page 11

Chapter 2 Operating Information

Introduction

This section summarizes the 3458A operating information. The

3458A User’s Guide has the complete operating information.

Before Applying Power

• Make sure the line voltage selection switches on the multimeter's rear

panel are set to match the local line voltage.

• Make sure the proper line fuse is installed.

If you have any questions concerning installation or power requirements,

refer to Chapter 1.

Table 1. Line Voltage Limits

Nominal Value (RMS) Allowable Limits (RMS) Fuse Fuse part #

100 VAC 90 VAC to 110 VAC 1.5A 250V NTD FE UL 2110-0043

120 VAC 108 VAC to 132 VAC 1.5A 250V NTD FE UL 2110-0043

220 VAC 198 VAC to 242 VAC 0.5A 250V TD FE UL 2110-0202

240 VAC 216 VAC to 250 VAC 0.5A 250V TD FE UL 2110-0202

Figure 1. AC line voltage switch positions

Chapter 2 Operating Information 11

Page 12

Applying Power

Power Cords

Australia Denmark Europe Great Brittain Switzerland U.S.A U.S.A.

Country Part Number Option Voltage

Australia 8120-1369 901 250V 6A

Denmark 1820-2956 912 259V 6A

Europe 1820-1689 902 250V 6A

Great Brittain 1820-1351 900 250V 6A

Switzerland 1820-2104 906 250V 6A

United States 1820-1378 903 120 10A

United States 1820-0698 904 240V 10A

Power cords supplied by Agilent have polarities matched to the power input socket

on the instrument.

NOTE:

*CSA certification includes only these power cords

Plugs are viewed from connector and. Shape of molded plug may vary

within country

Figure 2. Power Cords

To turn on the multimeter, depress the front panel Power switch. If the

multimeter does not appear to turn on, verify that the multimeter is connected

to line power. If line power is not the problem, remove the power cord and

check the line power fuse and the line voltage selection switch settings.

Power-On Self-Test When power is applied, the multimeter performs a limited power-on self-test.

This test verifies that the multimeter is operating but does not necessarily

verify that measurements will be accurate.

Power-On State When the power-on self-test is finished, the multimeter beeps once,

automatically triggers, automatically selects the range, and performs DC

voltage measurements. Also, the multimeter has set many of its commands

to predefined power-on values as shown in Table 2, This is called the

power-on state.

12 Chapter 2 Operating Information

Page 13

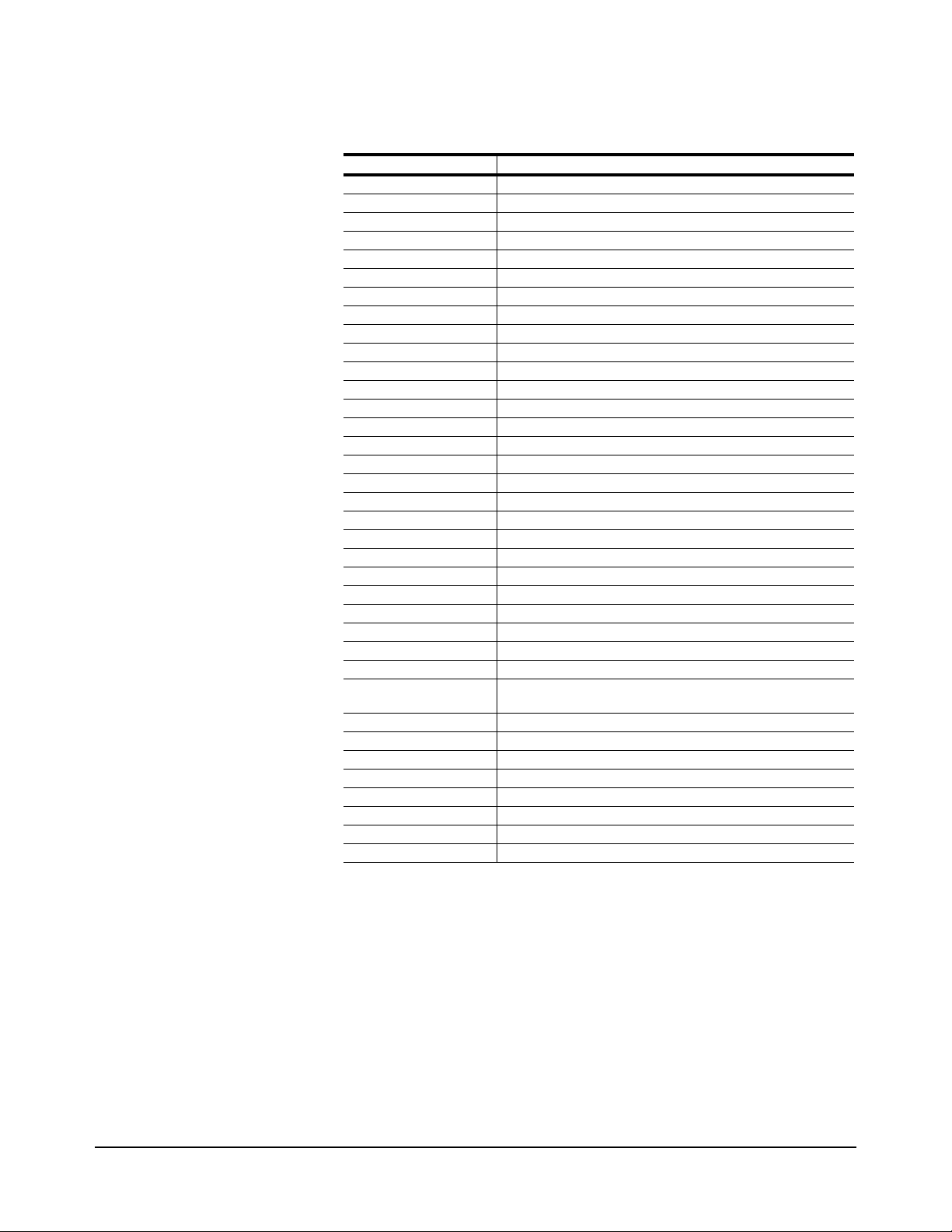

Table 2. Power-On State

Command Description

ACBAND 20, 2E6 AC bandwidth 20Hz - 2MHz

AZERO ON Autozero enabled

DCV AUTO DC voltage, autorange

DEFEAT OFF Defeat disabled

DELAY -1 Default delay

DISP ON Display Enabled

EMASK 32767 Enable all error conditions

END OFF Disable GPIB EOI function

EXTOUT ICOMP, NEG Input complete EXTOUT signal, negative pulse

FIXEDZ OFF Disable fixed input resistance

FSOURCE ACV Frequency and period source is AC voltage

INBUF OFF Disable input buffer

LEVEL 0, AC Level trigger at 0%, AC-coupled

LFILTER OFF Level filter disabled

LFREQ 50 or 60 Measured line frequency rounded to 50 or 60Hz

LOCK OFF Keyboard enabled

MATH OFF Disable real-time math

MEM OFF Disable reading memory (last memory operation = FIFO)

MFORMAT SREAL Single real reading memory format

MMATH OFF Disable post-process math

NDIG 7 Display 7.5 digits

NPLC 10 10 power line cycles of integration time

NRDGS 1, AUTO 1 reading per trigger, auto sample event

OCOMP OFF Disable offset compensated resistance

OFORMAT ASCII ASCII output format

QFORMAT NORM Normal query format

RATIO OFF Disable ratio measurements

RQS 0 (or 8) 0 disables status register conditions (if power-on

SETACV ANA Analog AC voltage mode

SLOPE POS Positive slope for level triggering

SSRC LEVEL, AUTO Level sync source event, auto synchronous AC voltage

SWEEP lOOE-9,1024 Sample interval 100 nanoseconds, 1024 samples

TARM AUTO Auto trigger arm event

TBUFF OFF Disable external trigger buffering

TIMER 1 1 second timer interval

TRIG AUTO Auto trigger event

DEGREE = 20 REF=l SCALE = 1 RES=50 PERC = 1

SRQ was on when power was removed, value = 8).

All math registers set to 0 except:

The Display In the power-on state, the display is continuously updated with each new DC

voltage reading. Along the bottom of the display are a series of annunciators.

These annunciators alert you to a variety of conditions. For example, the

SMPL annunciator flashes whenever the multimeter has completed a

reading. Table 3 describes the meaning of each display annunciator.

Chapter 2 Operating Information 13

Page 14

Table 3. Display Annunciators

Display Annunciator Description

SMPL Flashes whenever a reading is completed

REM The multimeter is in the GPIB remote mode

SRQ The multimeter has generated a GPIB service request

TALK The multimeter is addressed to talk on GPIB

LSTN The multimeter is addressed to listen on GPIB

AZERO OFF Autozero is disabled

MRNG Autorange is disabled (the multimeter is using a fixed range)

MATH One or two real-time or post-process math operations enabled

ERR An error has been detected

SHIFT The shift key has been pressed

MOREINFO More information concerning the present configuration is available

(use the right arrow key to view the information)

Note If the ERR annunciator is illuminated at this point, an error was detected

during or after the power-on self-test. You will learn how to determine the

error later in this chapter in “Reading the Error Register”.

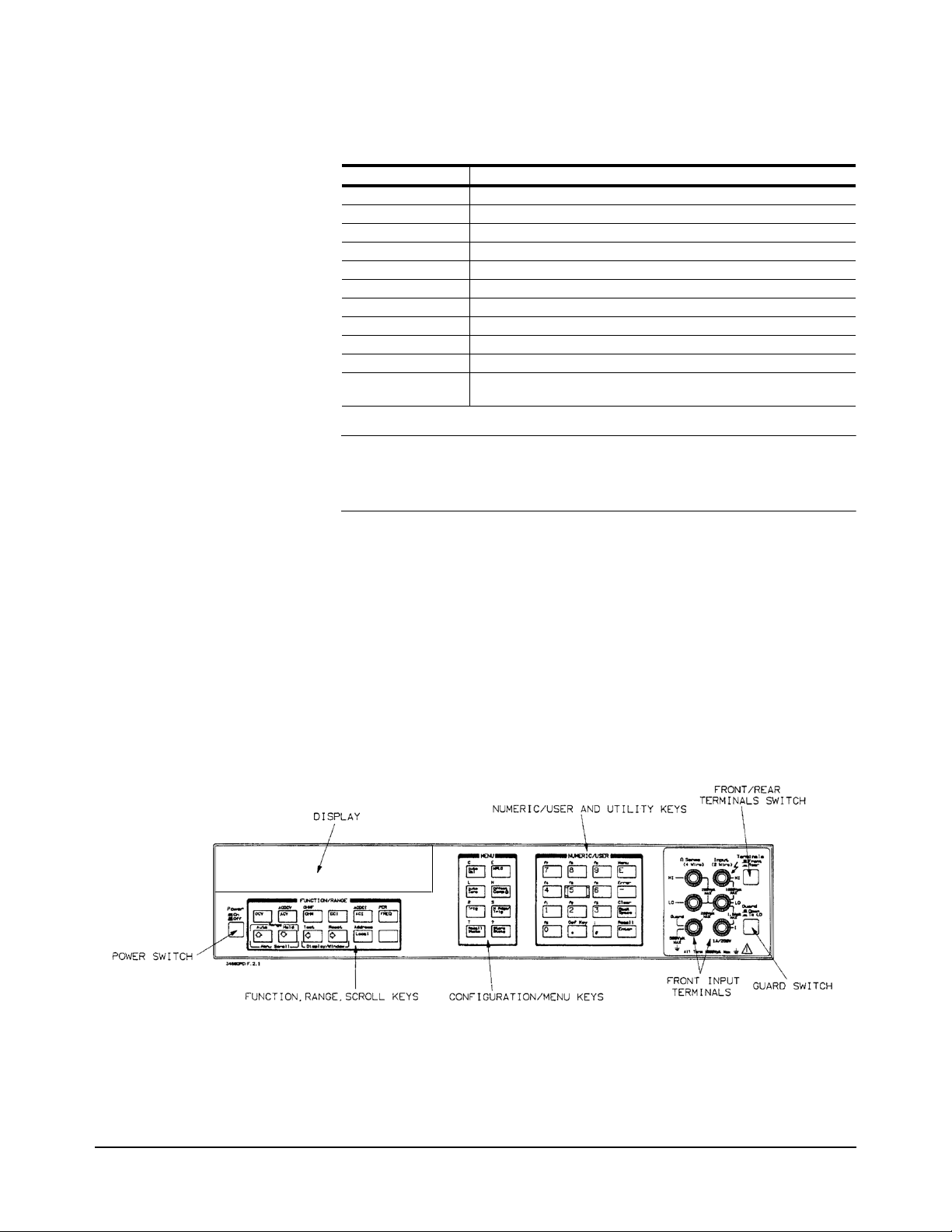

Operating from the Front Panel

This section shows you how to make a simple DC voltage measurement, how

to use the various front panel keys, and describes the multimeter functions

important to front panel operation. Figure 3 shows the multimeter's front

panel features.

Figure 3. Front Panel

14 Chapter 2 Operating Information

Page 15

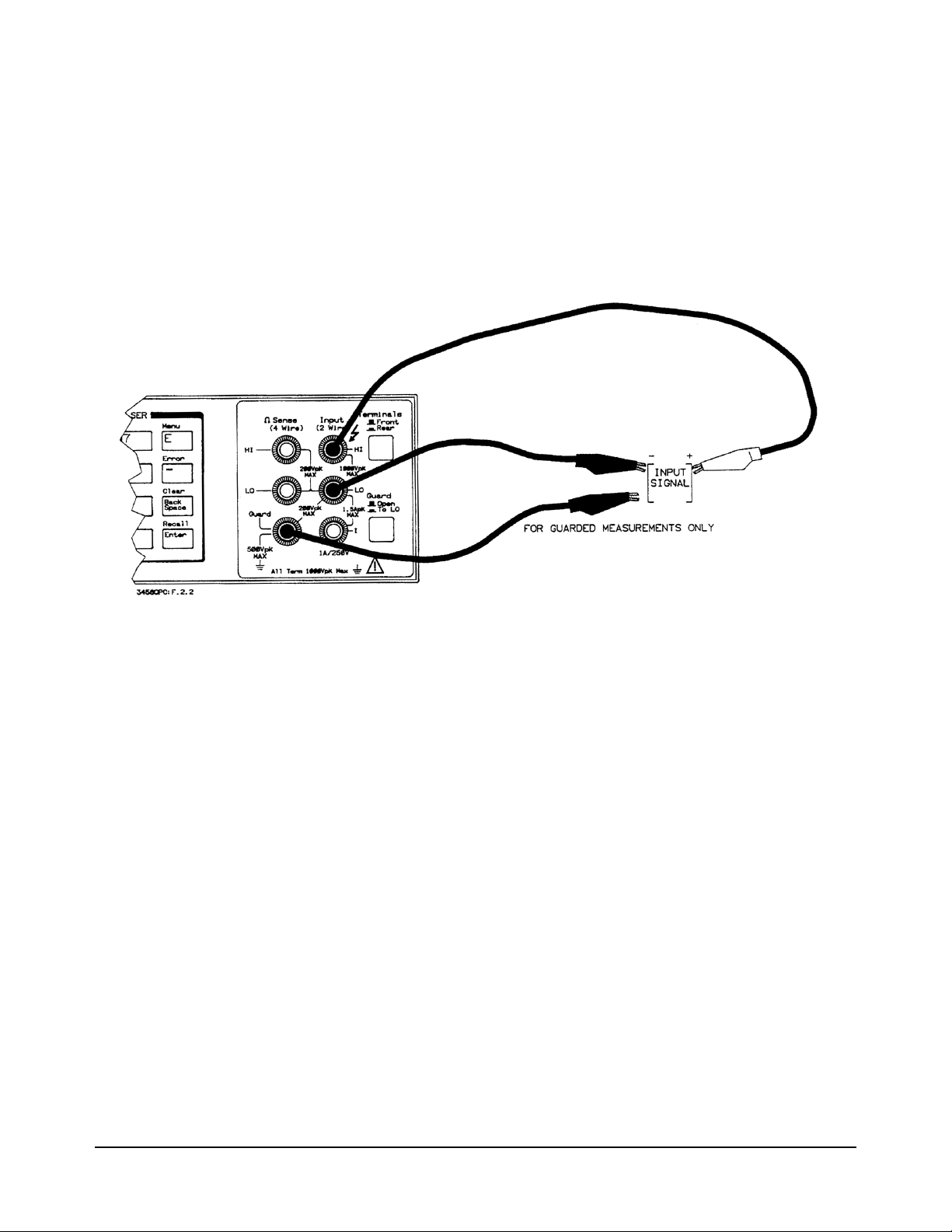

Making a

Measurement

In the power-on state, DC voltage measurements are selected and the

multimeter automatically triggers and selects the range. In the power-on

state, you can make DC voltage measurements simply by connecting a DC

voltage to the input terminals as shown in Figure 4. The connections shown

in Figure 4 also apply for AC voltage, 2-wire resistance, AC+DC voltage,

digitizing, and frequency or period measurements from a voltage input

source. Refer to Chapter 3 for a CAUTlON concerning the multimeter's

maximum input voltage and current.

Figure 4. Standard 2-wire (plus guard) measurements

Changing the

Measurement

Function

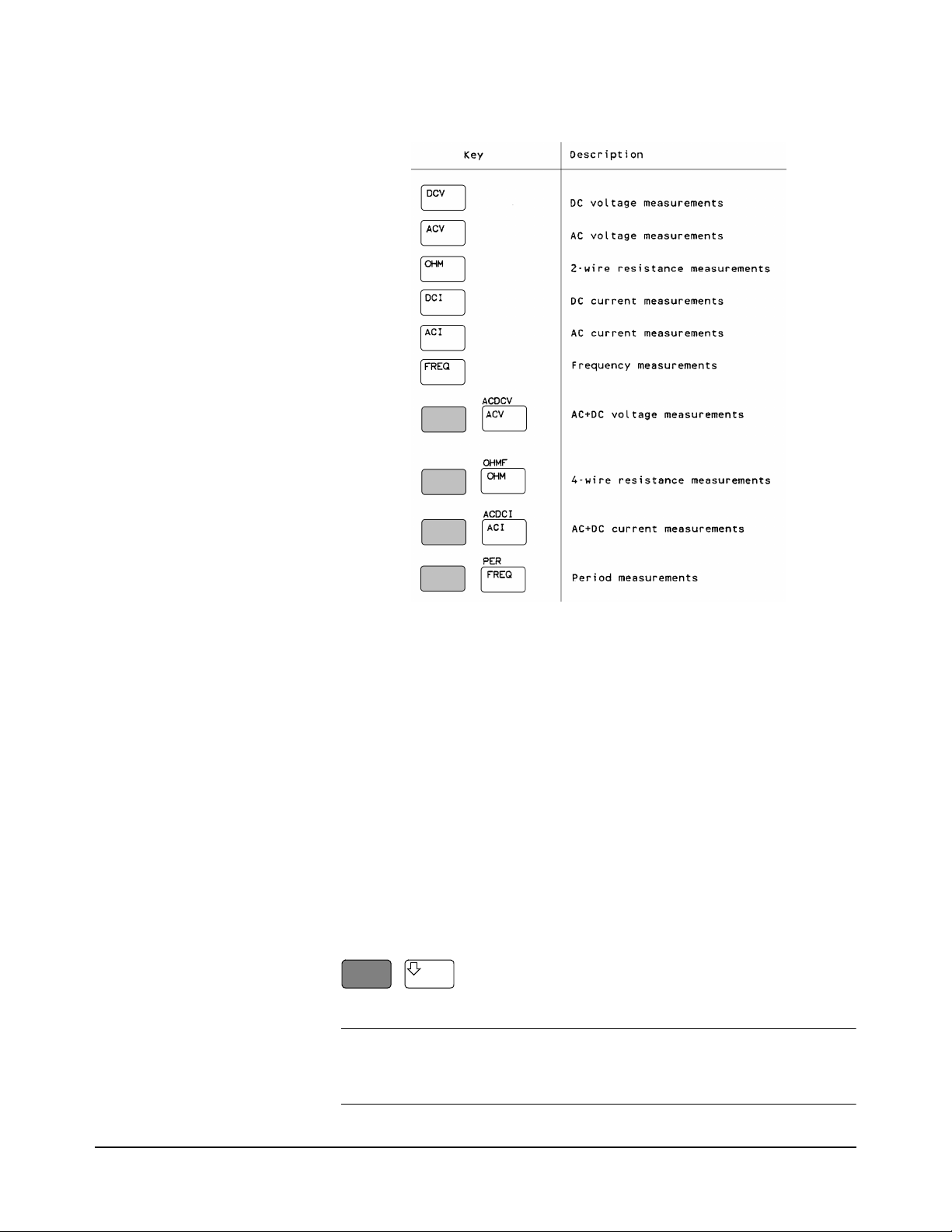

The row of keys located directly under the display (FUNCTION keys) select

the multimeter's standard measurement functions. Table 4 shows the

FUNCTION keys and the measurement function selected by each.

Chapter 2 Operating Information 15

Page 16

Table 4. Function Keys

Autorange and

Manual Ranging

Hold This choice allows you to shut off autoranging. To do this, let autorange

Note When you press the blue shift key, the display’s SHIFT annunicator

In addition to the functions selected by the FUNCTION keys, the multimeter

can perform direct-sampled or sub-sampled digitizing, ratio measurements,

and AC or AC+DC voltage measurements using the synchronous or random

measurement methods. These functions can be selected from the front panel

by accessing the appropriate command(s) using the alphabetic menu keys

(these keys are discussed later in this section under "Using the MENU

Keys").

In the power-on state, the multimeter automatically selects the appropriate

measurement range. This is called autorange. In many cases, you will

probably want to continue using autorange. However, you have two other

ranging choices: hold and manual ranging.

choose a range and then

Press:

Hold

illuminates. The shifted keyboard functions are printed in blue above the

keys.

16 Chapter 2 Operating Information

Page 17

Notice the display's MRNG (manual range) annunciator is on. This

annunciator is on whenever you are not using autorange.

Manual Ranging The second choice lets you manually select the range. When the multimeter

is in the measurement mode (that is, the multimeter is making and displaying

measurements or the display is showing OVLD) you can change the range

by pressing the up or down arrow keys. To go to a higher range.

Press:

By repeatedly pressing the up arrow key, you can increment up to the highest

range. When you reach the highest range, pressing the up arrow key no longer

changes the range. To go to a lower range.

Press:

By repeatedly pressing the down arrow key, you can decrement down to the

lowest range. When you reach the lowest range, pressing the down arrow key

no longer changes the range. To return to autoranging.

Press:

Auto

Self-Test When you applied power to the multimeter, it automatically performed a

limited power-on self-test. Before you start making measurements, however,

you may want to have more confidence that the multimeter is fully

operational. This is the job of the self-test. The self-test performs a series of

tests that check the multimeter's operability and accuracy.

Note Always disconnect any input signals before you run self-test. If you leave

an input signal connected to the multimeter, it cause a self-test failure.

The self-test takes over 50 seconds. To run self-test.

Press:

Test

If the self-test passed, the display shows:

When self-test passes, you have a high confidence that the multimeter is

operational and, assuming proper calibration and autocalibration, that

Chapter 2 Operating Information 17

Page 18

measurements will be accurate.

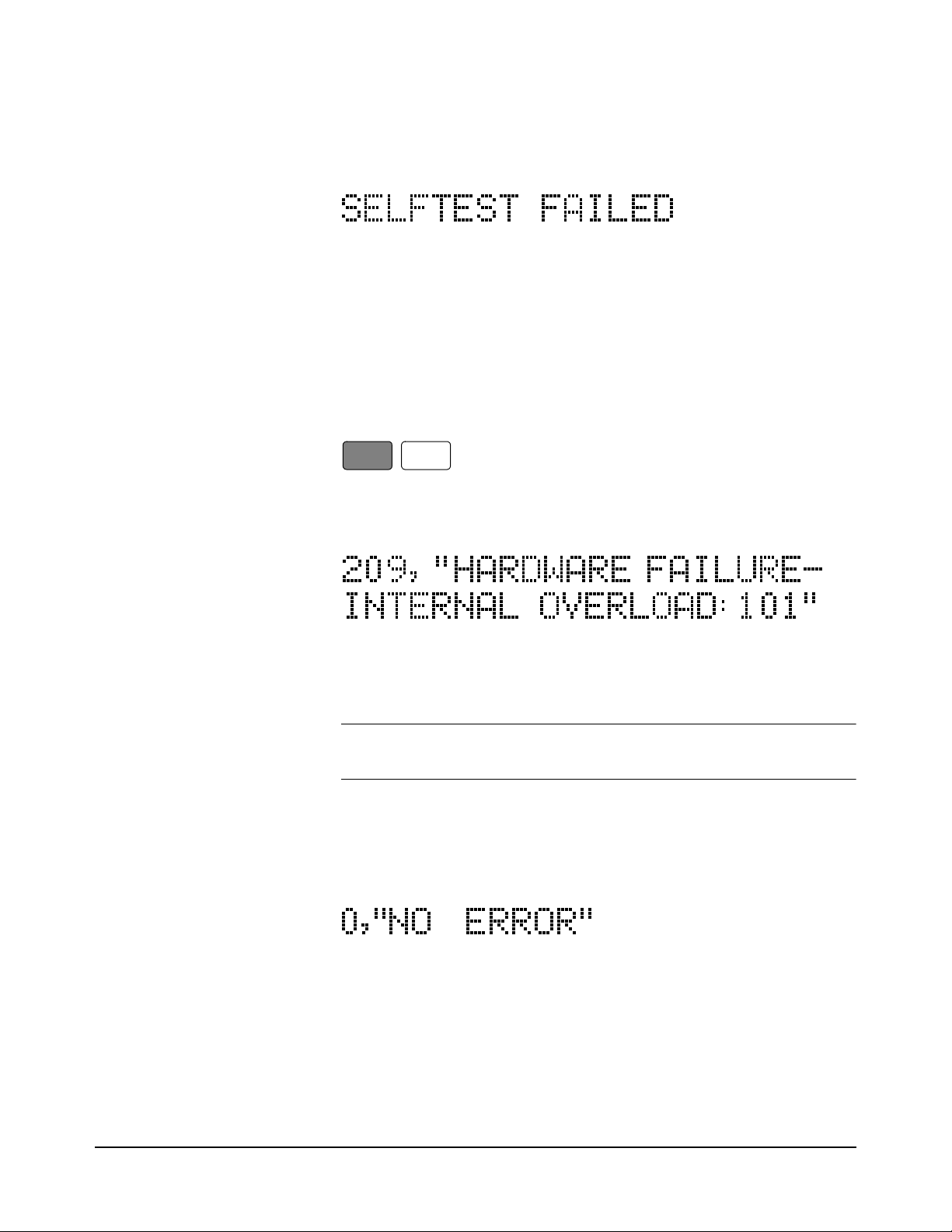

If any of the tests failed, the ERR annunciator illuminates and the display

shows:

If the self-test failed, one or more error conditions have been detected. Refer

to the next section "Reading the Error Register".

Reading the Error

Register

Note When you get a hardware error (200-series prefix), run the self-test again. If

Whenever the display's ERR annunciator is illuminated, one or more errors

have been detected. A record of hardware errors is stored in the auxiliary

error register. A record of programming and syntax errors is stored in the

error register. To read the error record(s).

Press:

Error

_

The lowest numbered error and a description of the error is displayed. For

example, a possible error message is:

Use the right arrow key to view the entire message. When the error message

has a 100-series numeric prefix (e.g., 105), it indicates a programming or

syntax error. A 200-series prefix (e.g., 209) indicates a hardware error.

you repeatedly get the error, the multimeter may need repair.

If the ERR annunciator is still illuminated, more errors have been recorded.

Repeat the above key sequence until all errors have been read and the ERR

annunciator is no longer illuminated. When you have read all the errors, the

error annunciator goes off. If you try to read another error, the display shows:

You do not have to run self-test to get an error. The multimeter detects errors

that occur while entering data, when changing functions or ranges, and so

on. The multimeter beeps whenever it detects an error.

Whenever you want to clear information (such as an error description) from

the display and return it to displaying measurements.

Press:

18 Chapter 2 Operating Information

Page 19

Clear

Back

Space

Note You can also clear the display by repeatedly pressing the Back Space key

(unshifted).

Resetting the

Multimeter

Many times during operation, you may wish to return to the power-on state.

The front panel Reset key returns you to the power-on state without having

to cycle the multimeter's power. To reset the multimeter.

Press:

Reset

The multimeter begins the reset process with a display test which illuminates

all display elements including the annunciators as shown in Figure 5. (By

holding down the Reset key, the multimeter continuously performs its

display test).

Figure 5. Display Test

Caution Pressing the shifted front panel Reset key performs the

Using the

Configuration Keys

power-on sequence which has the same effect as cycling the

multimeter’s power. This destroys any stored reading and

compressed subprograms, sets the power-on SRQ bit in the

status register (these functions are discussed later in this

manual), resets the A/D converter reference frequency and

performs the power-on self test. Executing the RESET

command from the alphabetic command menu (MENU keys)

returns the mulitmeter to the power-on state but does not

perform the power-on sequence. The MENU keys are discussed

later in this chapter.

The configuration keys (unshifted MENU keys) let you rapidly access the

most frequently used multimeter features. Table 5 shows each key, the

corresponding multimeter command, and the function of each. (These

Chapter 2 Operating Information 19

Page 20

functions are discussed in detail in Chapters 3 and 4.)

Table 5. Configuration Key Functions

We will use the Trig key to demonstrate how to use the configuration keys.

Press:

Trig

The display shows:

This is the command header for the trigger command. Notice the multimeter

automatically placed a space after the command header.

Selecting a Parameter For parameters that have a list of choices (non-numeric parameters), you can

use the up and down arrow keys to review the choices.

Press:

20 Chapter 2 Operating Information

Page 21

The display shows:

Press:

The display shows:

When using the up or down arrow keys, if you step past the last parameter

choice, a wraparound occurs to the other end of the menu. Suppose you want

to suspend triggering. Press the up or down arrow key until the display shows:

Press:

Enter

You have now changed the trigger event from auto (power-on state) to HOLD

which causes the multimeter to stop taking readings. (Triggering is discussed

in detail in Chapter 4.)

Default Values Most parameters have a default value. A default value is the value selected

when you execute a command but do not specify a value. For example, the

default value for the trigger parameter is SGL.

Press:

Trig

Press:

Enter

Notice that the multimeter takes one reading and then stops (after the single

trigger, the trigger event becomes HOLD regardless of the previously

specified trigger event). You can also enter-1 to select the default value.

Press:

Enter

_

1

Enter

Chapter 2 Operating Information 21

Page 22

The multimeter again takes a single reading and then stops.

Numeric Parameters Some commands use numeric parameters. A numeric parameter is the actual

value used by the multimeter. We will use the NPLC configuration key to

demonstrate numeric parameters.

Press:

NPLC

This display shows:

Notice that if you press the up or down arrow key, no parameter choice is

displayed. This means there is no menu and you must enter a number. For

example.

Press:

1

Enter

You have now selected 1 power line cycle of integration time for the A/D

converter. Integration time is the actual time that the A/D converter measures

the input signal. (Integration time is discussed in detail in Chapter 3.)

Exponential Parameters You can also enter numeric parameters using exponential notation. For

example.

Press:

NPLC

1

0

0

E

_

3

Enter

You have now selected 0.1 power line cycles of integration time. At this

point, you should reset the multimeter to return the number of power line

cycles to 10 by pressing:

Reset

Multiple Parameters Many commands have more than one parameter. (Multiple parameters are

separated by commas.) We will use the NRDGS command, which has two

parameters, as an example of a command with multiple parameters.

Press:

N Rdge/

Trig

The display shows:

22 Chapter 2 Operating Information

Page 23

The first parameter in the NRDGS command is a numeric parameter that

specifies the number of readings made per trigger event. For example, to

specify 5 readings per trigger event.

Press:

5

The display shows:

The second parameter of the NRDGS command specifies the event that

initiates each reading. Since this is not a numeric parameter, a menu is

available for this parameter. Use the up or down arrow keys to cycle through

the list of choices. When the display shows:

Execute the command by pressing:

Enter

You have now selected five readings per trigger event. If you execute the

TRIG SGL command, for example, the multimeter will take five readings

and then stop. (The NRDGS command is discussed in detail in Chapter 4.)

Using the MENU Keys In addition to the configuration keys, the multimeter has an alphabetic

command menu that can be accessed using the shifted MENU keys labeled

C, E, L, N, R, S, and T. Each of these letters corresponds to the area you

will enter into the command menu. For example, to enter the menu with

commands starting with T.

Press:

T

Recall

State

The display shows:

You can now use the Menu Scroll keys (up or down arrow keys} to step

through the menu in alphabetical order (down arrow key) or in reverse

alphabetical order (up arrow key). For example, starting with the TARM

display shown above, by pressing the down arrow key once, the display

shows the next command in alphabetical order (TBUFF). (You can also press

and hold the up or down arrow key to rapidly step through the menu.) Once

you have found the desired command, you can press the Enter key to execute

it immediately (using default parameter values if applicable). If you need to

specify command parameter(s), with the command displayed, press the right

Chapter 2 Operating Information 23

Page 24

arrow key or the comma key (or, if the first parameter is numeric, a numeric

key). This selects the command and allows you to specify or select

parameter(s) using the procedures described earlier in this section.

There are two alphabetic menus available: FULL and SHORT. You can

select between these menus using the shifted Menu key. The specified menu

choice is stored in continuous memory (not lost when power is removed).

The FULL menu contains all commands except query commands that can

be constructed by appending a question mark to a command (e.g., BEEP,

BEEP?). (Query commands are discussed next.) The SHORT menu

eliminates the GPIB bus-related commands, commands that are seldom used

from the front panel, and any commands that have dedicated front panel keys

(e.g., the NPLC key or the Trig key).

Query Commands There are a number of commands in the alphabetic command directory that

end with a question mark. These commands are called query commands since

each returns a response to a particular question. For example, access the

LINE? query command from the command menu and press the Enter key.

The multimeter responds to this query command by measuring and

displaying the power line frequency. (Use the right arrow key to view the

entire response.) As another example, access the TEMP? command from the

command menu and press Enter. This command returns the multimeter's

internal temperature in degrees Centigrade.

Standard Queries The FULL command menu contains the following standard query

commands:

AUXERR? MCOUNT?

CAL? MSIZE?

CALNUM? OPT?

ERR? REV?

ERRSTR? SSPARM?

ID? STB?

ISCALE? TEMP?

LINE?

Additional Queries In addition to the queries listed above, you can create others by appending a

question mark to any command that can be used to program the multimeter.

For example, the AZERO command (Auto Zero configuration key) enables

or disables the autozero function. You can determine the present autozero

mode by appending a question mark to the AZERO command. To do this,

Press:

?

Auto

Zero

The multimeter responds by displaying the present autozero mode (power-on

mode = ON). (Notice that this command is immediately executed; you do

not have to press the Enter key.)

Store

State

Note The QFORMAT command can be used to specify whether query responses

24 Chapter 2 Operating Information

Page 25

will be numeric, alpha, or a combination of alpha and numeric. Refer to the

QFORMAT command, in Chapter 6, for more information.

Display Control The shifted Clear key, the Back Space key, and the Display/Window keys

(left and right arrow keys) allow you to control the display.

Clearing the Display Whenever you want to clear information (such as a query response) from the

display.

Press:

Clear

Back

Space

Display Editing The Back Space key allows you to edit parts of a command string while

entering the string or when the string is recalled (discussed later), For alpha

parameters or command headers, pressing the Back Space key once erases

the entire parameter or header. For commas, spaces, and numeric parameters,

only one character is erased each time you press Back Space. For example,

Press:

N Rdge/

Trig

1

0

The display shows:

By pressing the Back Space key once, the entire second parameter (LINE)

is erased. The display shows:

Now by pressing Back Space once, the comma is erased. Pressing Back

Space two more times erases both numeric characters (10). At this point, you

can reenter the first parameter using the numeric keypad and the second

parameter using the Menu Scroll keys. Press the Enter key to execute the

edited command.

Viewing Long Displays When entering commands containing more than 16 characters, the previously

entered characters are scrolled off the left side of the display to make room

for those being entered. The Display/Window keys (left and right arrow

keys) allow you to view the entire line by scrolling it left or right. The

Display/Window keys can also be used to view long strings such as error

messages, the calibration string (CALSTR? command), and user-defined key

definitions (discussed later). For example.

Press:

N Rgds/

Trig

100000

Chapter 2 Operating Information 25

Page 26

The display shows:

By pressing the left arrow key, you can view the first part of the command

while scrolling the last part off the right side of the display. Now, by pressing

the right arrow key, you can view the last part of the command and scroll the

first part off the left side of the display.

Note Think of the display as a window you can move to the left or right using the

arrow keys.

MORE INFO Display In addition to scrolling the display left and right, the Display/Window keys

allow you to view additional display information when the display's MORE

INFO annunciator is illuminated. For example, access and execute the

SETACV RNDM command from the alphabetic command menu. Now press

the front panel ACV key. Notice that the multimeter's MORE INFO

annunciator is illuminated. This means there is more information available

than is being displayed.

Press:

The present AC voltage measurement method (SETACV RNDM) is

displayed. At this point, reset the multimeter to return it to the power-on state

by pressing:

Reset

Digits Displayed When the multimeter is displaying readings, you can vary the number of

digits it displays. In the power-on state, the display is showing 7.5 digits

although the multimeter is resolving 8.5 digits. To display all 8.5 digits.

Press:

N

Offset

Comp 9

8

Note The display’s leftmost digit (referred to as a 1/2 digit) is implied when you

are specifying display digits.

The NDlG command only masks digits from the display. It does not affect

readings sent to reading memory or transferred over the GPIB bus. Also, you

cannot view more digits than are being resolved by the multimeter.

Enter

26 Chapter 2 Operating Information

Page 27

Recall You can easily recall the last executed command without repeating the

command entry process.

Press:

The display will show the last command executed. (You cannot recall

commands that are executed immediately such as Reset or DCV, or any

command that contained the calibration security code.) By repeating the

above keystrokes, you can recall previously executed commands. After

recalling the desired command, you can modify it (see "Display Editing"

earlier in this section) and execute it by pressing Enter.

Operating from Remote

This section shows you the fundamentals of operating the multimeter from

remote. This includes reading and changing the GPIB address, sending a

command to the multimeter, and retrieving data from the multimeter.

Recall

Enter

Input/Output

Statements

Reading the GPIB

Address

The statements used to operate the multimeter from remote depend on the

computer and its language. In particular, you need to know the statements

the computer uses to input and output information. For example, the input

statements for the Hewlett-Packard Series 200/300 BASIC language are:

ENTER or TRANSFER

The output statement is:

OUTPUT

Read your computer manuals to find out which statements you need to use.

The examples in this manual use Hewlett-Packard Series 200/300 BASIC

language.

Before you can operate the multimeter from remote, you need to know its

GPIB address (factory setting = 22). To check the address.

Press:

Address

Local

A typical display is:

The displayed response is the device address. When sending a remote

command, you append this address to the GPIB interface's select code

(normally 7). For example, if the select code is 7 and the device address is

22, the combination is 722.

Chapter 2 Operating Information 27

Page 28

Changing the GPIB

Address

Every device on the GPIB bus must have a unique address. If you need to

change the multimeter's address, access the ADDRESS command from the

command menu (MENU keys), with the display showing:

You can enter the new address. For example.

Press:

Sending a Remote

Command

Getting Data from the

Multimeter

1

You have now changed the address to 15. If you want to change the address

back to 22, repeat the above procedure (or use the Recall key) and specify

22 instead of 15.

To send the multimeter a remote command, combine the computer's output

statement with the GPIB select code, the device address, and finally, the

multimeter command. For example, to make the multimeter beep, send:

OUTPUT 722; "BEEP"

Notice the display's REM and LSTN annunciators are illuminated. This

means the multimeter is in the remote mode and has been addressed to listen

(receive a command).

The multimeter is capable of outputting readings and responses to query

commands. As an example, have the multimeter generate a response to a

query command by sending:

OUTPUT 722;"ID?"

When you send a query from remote, the multimeter does not display the

response as it did when you executed the command from its front panel.

Instead, the multimeter sends the response to its output buffer. The output

buffer is a register that holds a query response or a single reading until it is

read by the computer or replaced by new information. Use the computer's

input statement to get the response from the output buffer. For example, the

following program reads the response (3458A) and prints it.

5

Enter

10 ENTER 722;A$

20 PRINT A$

30 END

The same technique allows you to get readings from the multimeter.

Whenever the multimeter is making measurements and you have not enabled

reading memory (reading memory is discussed in Chapter 4), you can get a

reading by running the following program.

10 ENTER 722;A

20 PRINT A

30 END

28 Chapter 2 Operating Information

Page 29

The Local Key When you press a key on the multimeter's keyboard while operating from

remote, the multimeter does not respond. This is because the multimeter is

in the remote mode (as indicated by the display's REM annunciator) and is

ignoring all but the Local key. To return the multimeter to local mode.

Press:

Local

Chapter 2 Operating Information 29

Page 30

30 Chapter 2 Operating Information

Page 31

Chapter 3 Disassembly/Assembly

Procedures and Parts List

Introduction

This section contains the 3458A Covers and Printed Circuit Assemblies

Disassembly/Assembly procedures. Also included is the 3458A Parts Lists

and listings of printed circuit board assemblies.

WARNING Only personnel with knowledge of electronic circuitry and an

awareness with the hazards involved should remove and install

any printed circuit board assemblies.

Caution To prevent equipment circuit damage, always remove the ac

line power cord before removing or replacing any assembly. To

prevent electrostatic discharge (ESD) damage to ICs, always

observe anti-static techniques when assemblies are handled or

serviced.

Static Handling

Static electricity is a familiar phenomenon which, except for an occasional

shock, doesn't seem very serious. However, it has been proven that in the

electronics industry electrostatic discharge (ESD) is a major cause of

component failure. In many cases, the component damaged may not

immediately fail, causing low instrument reliability and future repairs. ESD

damage can occur at static levels below human perception. It has also been

shown that ESD can affect both passive and active devices.

The following guidelines are the minimum requirements for a static safe

service environment.

• The workbench should be equipped with a conductive table mat. The

mat should be grounded to earth ground through a 1 M ohm resistor.

The mat should be equipped with at least one swivel connector for

connecting wrist straps.

• All service and handling personnel should wear a conductive wrist strap

in contact with bare skin. This strap should be connected to the swivel

connector on the conductive table mat through a 1 M ohm resistor.

• All metal equipment at a workstation must be grounded. This includes

soldering irons, solder removers, shelving, and equipment stands.

Chapter 3 Disassembly/Assembly Procedures and Parts List 31

Page 32

Clean Handling

• Only one common ground should be provided at the workstation.

• The workstation should be kept free of nonconductors. No common

plastics, polybags, cardboard, cigarette or candy wrappers should be

allowed. There should not be rugs or carpet on the floor, shelving, or

bench top.

• Only proper containers should be used for shipping, storing or

transporting assemblies. This is required on any assembly shipped to

Agilent Technologies for repair or replacement.

Due to the accuracy of the 3458A, use the following clean handling

techniques when removing/installing printed circuit board assemblies.

• Handle the assemblies only by their edges.

• Be sure to place them on a clean workbench away from dirty or dusty

conditions.

Printed Circuit Assembly Identification

The printed circuit assemblies within the 3458A Multimeter are identified

by the part number of the printed circuit board and the engineering revision

code (ERC). These two sequences of numbers are used to exactly identify

the electrical characteristics of the printed circuit board. In any

correspondence concerning a particular printed circuit board, it is important

to accurately identify the board configuration. This is done by using the

board part number, followed by the engineering revision code (ERC) on the

board. For example:

03458-66505-2825

would identify a particular printed circuit board in the 3458A. The board

part number is 03458-66505 and the ERC is 2825.

Board Part Number The Agilent Technologies part number of a printed circuit board is etched

on the board. This is a ten-digit number, separated by a hyphen into two

groups of five digits. The first five digits identify the model number or

accessory number of which the printed circuit board is a part. The last five

digits are a unique part number identifying the printed circuit board.

Engineering Revision

Code

On the Engineering Revision Code (ERC) label, the four-digit code is in the

form of YYWW, where YY represents the last two digits of the year minus

60 and WW is the week code. For example, an Engineering Revision Code

of 2825 would identify a change made in the 25th week of 1988.

The ERC number is updated whenever a change is made to the assembly.

This change may be a printed circuit board revision, a component change, or

32 Chapter 3 Disassembly/Assembly Procedures and Parts List

Page 33

NOTE

The label numbers

in Figures 5 to 10

show the order of

cover removal. Use

reverse order for

installation.

a revised test and assembly procedure. The ERC should be checked against

schematics, component locator diagrams, and parts lists to ensure

compatibility. ERCs with values lower than those noted on the schematics,

component locator diagrams, and parts lists are described in a backdating

section. ERCs with a value higher that those noted will be covered by a

manual change sheet, manual update, or manual revisions.

Figure 6. Right Side Handle Removal/Installation

Covers Removal/Installation Procedures

The following procedures show how to remove the top/bottom covers and

shields on the 3458A. Removal of the covers and shields are required to

replace the printed circuit board assemblies.

Tools Required You need:

1. #1 Pozidriv screwdriver

2. #TX15 Torx driver

3. #TX10 Torx driver

Covers Removal

Procedure

Do the following:

1. Remove all connections to the 3458A.

2. Remove ac power from the 3458A.

3. Refer to Figure 6. Turn the instrument so its right side (as seen from

the front) faces you.

4. Use the #1 Pozidriv to remove the right side handle strap screws.

Then remove the strap.

Chapter 3 Disassembly/Assembly Procedures and Parts List 33

Page 34

5. Refer to Figure 7. Turn the instrument so its left side faces you.

Figure 7. Remove/Install Left Side Handle

6. Use the #1 Pozidriv to remove the left side handle strap screws. Then

remove the strap.

7. Refer to Figure 8. Use the #TX10 Torx driver to remove both or either

the top and bottom cover ground screws, depending on which cover is

to be removed.

8. Refer to Figure 9. Turn the instrument so its rear faces you.

9. Use the #TX15 Torx driver to remove the four rear bezel screws.

Then remove the rear bezel.

10. If you do not wish to remove the top cover, continue with step 12.

11. To remove the top cover, pull the cover toward the rear until it clears

the front panel. Then slide it forward and away from the instrument.

12. If you do not wish to remove the bottom cover, continue with step 14.

13. Turn the 3458A over so its top sits on your workbench. To remove the

bottom cover, pull the cover toward the rear until it clears the front

panel. Then slide it forward and away from the instrument. Leave the

instrument in its present position.

14. If you do not wish to remove the bottom shield, continue with step 16.

15. Refer to Figure 10. Use the #TX10 Torx driver to remove the bottom

shield screw. Then remove the shield. Pull the shield toward the rear

of the instrument until the shield retainers line up with the slots in the

shield. Lift the shield off.

34 Chapter 3 Disassembly/Assembly Procedures and Parts List

Page 35

16. If you do not wish to remove the top shield, continue with step 19.

Figure 8. Remove/Install Cover Ground Screws

Figure 9. Remove/Install Rear Bezel

Chapter 3 Disassembly/Assembly Procedures and Parts List 35

Page 36

Figure 10. Remove/Install Bottom Shield Screw

17. Refer to Figure 11. Turn the instrument over so its bottom sits on your

workbench.

18. Use the #TX10 Torx driver to remove the top shield screw. Then

remove the shield. Pull the shield toward the rear of the instrument

until the shield retainers line up with the slots in the shield. Lift the

shield off.

19. Refer to the appropriate procedures in this section to remove the

printed circuit board assembly.

Covers Installation

Procedure

36 Chapter 3 Disassembly/Assembly Procedures and Parts List

Do the following:

1. Remove all connections to the 3458A.

2. If installing the top shield is not required, continue with step 6.

3. Refer to Figure 11. Turn the instrument over so its bottom sits on your

workbench.

4. Line up the slots on the top shield with the shield retainers. Then push

the shield toward the front of the instrument until the shield screw hole

Page 37

lines up with the hole in the chassis. Use the #TX10 Torx driver to

reinstall the shield screw.

5. If installing the bottom shield is not required, continue with step 9.

6. Refer to Figure 10. Turn the instrument over so its top sits on your

workbench.

Figure 11. Remove/Install Top Shield Screw

7. Remove ac power from the 3458A.

8. Line up the slots on the bottom shield with the shield retainers. Then

push the shield toward the front of the instrument until the shield

screw hole lines up with the screw hole in the chassis. Use the #TX10

Torx driver to reinstall the shield screw.

9. If installing the bottom cover is not required, continue with step 11.

10. Install the bottom cover by placing it over the chassis with the front of

the cover just clearing the front panel. Then push the cover toward the

front of the instrument into the front panel bezel.

11. If installing the top cover is not required, continue with step 14.

Chapter 3 Disassembly/Assembly Procedures and Parts List 37

Page 38

12. Turn the 3458A over so the bottom sits on your workbench.

13. Install the top cover by placing it over the chassis with the front of the

cover just clearing the front panel. Then push the cover toward the

front of the instrument into the front panel bezel.

14. Refer to Figure 9. Turn the instrument so its rear faces you.

15. Reinstall the rear bezel. Use the #TX15 Torx driver to reinstall the

four rear bezel screws.

16. Refer to Figure 8. Turn the instrument so its left side faces you. Use

the #TX10 Torx driver to reinstall the top and/or bottom cover ground

screws.

WARNING For safety purposes and proper operation, it is imperative that

the cover grounding screws be reinstalled.

17. Refer to Figure 7. Reinstall the left side handle strap. Use the

#1 Pozidriv to reinstall the side handle strap screws.

18. Refer to Figure 6. Turn the instrument so its right side faces you.

19. Reinstall the right side handle strap. Use the #1 Pozidriv to reinstall

side handle strap screws.

20. Your instrument is now ready for use. Agilent Technologies suggests

that after you apply power that you perform an automatic calibration

on the instrument. To do this, use the "ACAL ALL" command.

38 Chapter 3 Disassembly/Assembly Procedures and Parts List

Page 39

Assemblies Removal/Installation Procedures

Table 6 lists all 3458A printed circuit board assemblies and assembly

locations in the instrument. The assembly locations are also shown in

Figure 12 and Figure 13.

Table 6. 3458A Assemblies Locations

Ref Desig Part Number Assembly

A1 03458-66501 DC Circuitry Inguard/Top

A2 03458-66502 AC Circuitry Inguard/Bottom

A3 03458-66503 A/D Converter and

A4 03458-66504 Inguard Power

A5 03458-66505 Outguard Controller Outguard/Top

A5 03458-66515 Outguard Controller

A6 03458-66506 Outguard Power

A7 03458-66507 Display Logic Front Panel

A9 03458-66509 DC Reference Inguard/Top

A9 03458-66519 DC Reference

A10 03458-66510 Front/Rear Switch Inguard/Top

Tools Required You need:

1. #1 Pozidriv screwdriver

Description

Location in Instrument

Inguard/Bottom

Inguard Logic

Inguard/Bottom

Supply

Outguard/Top

(Opt 001)

Outguard/Bottom

Supply

Inguard/Top

(Opt 002)

2. #TX15 Torx driver

3. #TX10 Torx driver

4. 7 millimeter nut driver (for Outguard Controller assembly only)

5. Small flat bladed screwdriver (for Display Logic assembly only)

6. Large screwdriver (e.g., #2 Pozidriv; for Display Logic assembly

only)

Chapter 3 Disassembly/Assembly Procedures and Parts List 39

Page 40

DC Circuitry

Assembly

Removal/Installation

Procedures

The following procedures show how to remove and install the DC Circuitry

Printed Circuit Board Assembly.

Figure 12. Assembly Locations (Top of Instrument)

40 Chapter 3 Disassembly/Assembly Procedures and Parts List

Page 41

Figure 13. Assembly Locations (Bottom of Instrument)

Refer to Figure 14 for the following procedures.

Removal Procedure 1. Use the Covers Removal Procedure in this section of the manual to

remove the 3458A top cover and top shield. It is not necessary to

remove the bottom cover and bottom shield.

Chapter 3 Disassembly/Assembly Procedures and Parts List 41

Page 42

2. Set the 3458A on your workbench with the top facing you.

3. Unplug the following wires and cables. Unless otherwise noted, all

wires and cables are unplugged from the DC Circuitry assembly.

a. Blue wire from the metal inguard shield. This wire is not plugged

into the DC Circuitry assembly, but must be unplugged to remove

the assembly. Move the wire out of the way.

b. Grey wire from the metal inguard circuit ground. This wire is not

plugged into the DC Circuitry assembly, but must be unplugged to

remove the assembly. Move the wire out of the way.

c. Yellow wire from P202. Move the wire out of the way.

d. Orange wire from P7. Move the wire out of the way.

e. Grey wire from P6. Move the wire out of the way.

f. Black and white wires from P8 and P9, respectively. The black and

white wires form a white cable. Move the cable out of the way.

g. Grey 20 pin cable from P3. Move the cable out of the way.

4. Use the #TX 10 Torx driver to remove the two screws from the

DC Reference assembly.

5. Use the #TX10 Torx driver to remove the eight screws from the

DC Circuitry assembly.

6. Use the plastic board extractor on the DC Circuitry board to unplug

the board from the inguard chassis. Then completely remove the

board.

Installation Procedure 1. Line up the DC Circuitry board with the connector in the inguard

chassis. Plug the board into the connector.

2. Use the #TX10 Torx driver to install the eight screws on the

DC Circuitry assembly.

3. Use the #TX10 Torx driver to install the two screws on the

DC Reference assembly.

4. Plug in the following wires and cables:

a. Locate the blue wire connected to the power transformer. Plug the

wire into the metal inguard shield.

b. Locate the grey wire connected to the power transformer. Plug the

wire into the metal inguard circuit ground.

42 Chapter 3 Disassembly/Assembly Procedures and Parts List

Page 43

Figure 14. DC Circuitry Assembly Removal/Installation

c. Locate the yellow wire connected to the Front/Rear Switch

assembly. Plug it into P202 on the DC Circuitry assembly.

d. Locate the orange wire connected to the Front/Rear Switch

assembly. Plug it into P7 on the DC Circuitry assembly.

Chapter 3 Disassembly/Assembly Procedures and Parts List 43

Page 44

e. Locate the grey wire connected to the Front/Rear Switch assembly.

Plug it into P6 on the DC Circuitry assembly.

f. Locate the white cable with the white and black wires connected to

the Front/Rear Switch assembly. Plug the white and black wires

into P8 and P9, respectively. P8 and P9 are on the DC Circuitry

assembly.

g. Locate the grey 20-pin cable connected to the A/D Converter and

Inguard Logic assembly. Line up the cable plug with socket P3 on

the DC Circuitry assembly. Then plug the cable all the way in.

5. Use the Covers Installation Procedure in this section of the manual to

install the 3458A top cover and top shield.

DC Reference

Assembly

Removal/Installation

The following procedures show how to remove and install the DC Reference

Printed Circuit Board Assembly.

Refer to Figure 14 for the following procedures.

Procedures

Removal Procedure 1. Use the Covers Removal Procedure in this section of the manual to

remove the 3458A top cover and top shield. It is not necessary to

remove the bottom cover and bottom shield.

2. Set the 3458A on your workbench with the top facing you.

3. Use the #TX10 Torx driver to remove the two screws from the

DC Reference assembly.

4. Unplug and remove the board from the DC Circuitry assembly.

Installation Procedure 1. A top and bottom cover needs to be installed over the reference device

located on the DC Reference assembly. To install the covers, place

one cover over the top of the device and another on the bottom side of

the DC Reference assembly printed circuit board. Use your fingers to

hold the covers in place. Then line up the screw holes in the covers

with the screw holes on the printed circuit board. The covers should

now completely enclose the reference device.

2. Line up the DC Reference board with the connectors on the

DC Circuitry assembly. Hold the covers over the reference device in

place while installing the DC Reference assembly. Then plug the

board all the way into the connectors.

3. Use the #TX10 Torx driver to install the two screws on the

DC Reference assembly.

4. Use the Covers Installation Procedure in this section of the manual to

install the 3458A top cover and top shield.

44 Chapter 3 Disassembly/Assembly Procedures and Parts List

Page 45

Figure 15. AC Converter Assembly Removal/Installation

AC Converter

Assembly

Removal/Installation

The following procedures show how to remove and install the AC Converter

Printed Circuit Board Assembly.

Refer to Figure 15 for the following procedures.

Procedures

Removal Procedure 1. Use the Covers Removal Procedure in this section of the manual to

remove the 3458A bottom cover and bottom shield. It is not necessary

to remove the top cover and top shield.

2. Set the 3458A on your workbench with the bottom facing you.

3. Unplug the grey 20-pin cable from the AC Converter assembly.

4. Unplug the black striped white wire from the metal inguard chassis.

Chapter 3 Disassembly/Assembly Procedures and Parts List 45

Page 46

5. For easier removal of the AC Converter assembly, you may wish to

unplug and lay aside both the blue and grey fiber optic cables

connecting the A/D Converter and Inguard Logic assembly to the

outguard.

6. Remove the pushrod from the Guard switch. You may need to pry the

pushrod loose with a small flat blade screwdriver. Then completely

remove it from the rear of the front panel.

7. Use the #TX10 Torx driver to remove the four screws from the

AC Converter assembly.

8. Unplug and remove the AC Converter board from the inguard chassis.

Installation Procedure 1. Line up the AC Converter board with the connector in the inguard

chassis. Then plug the board all the way into the connector.

2. Use the #TX 10 Torx driver to install the four screws on the

AC Converter assembly.

3. Locate the grey 20-pin cable connected to the Inguard Power Supply

assembly. Line up the cable plug with the socket on the

AC Converter assembly. Then plug the cable all the way in.

4. Plug the black striped white wire from the AC Converter into the

metal inguard chassis.

5. Plug in both the blue and grey fiber optic cables into the A/D

Converter and Inguard Logic assembly, if previously unplugged.

6. Guide the Guard switch pushrod through the rear of the front panel's

access hole. Then align the pushrod with the Guard switch shaft and

push it all the way onto the shaft.

7. Use the Covers Installation Procedure in this section of the manual to

install the 3458A bottom cover and bottom shield.

A/D Converter

Assembly

Removal/Installation

The following procedures show how to remove and install the A/D Converter

and Inguard Logic Printed Circuit Board Assembly.

Refer to Figure 16 for the following procedures.

Procedures

Removal Procedure 1. Use the Covers Removal Procedure in this section of the manual to

remove the 3458A bottom cover and bottom shield. It is not necessary

to remove the top cover and top shield.

2. Set the 3458A on your workbench with the bottom facing you.

3. Locate the grey 20-pin cable that connects the A/D Converter and

46 Chapter 3 Disassembly/Assembly Procedures and Parts List

Page 47

Inguard Logic assembly to the Inguard Power Supply assembly.

Unplug this cable at the A/D Converter and Inguard Logic assembly.

4. Locate the grey 20-pin cable that connects the A/D Converter and

Inguard Logic assembly to the DC Circuitry assembly. Unplug this

cable at the A/D Converter and Inguard Logic assembly.

5. Unplug both sets (four cables) of the blue and grey fiber optic cables

that connect the A/D Converter and Inguard Logic assembly to the

Outguard Power Supply assembly.

Figure 16. A/D Converter and Inguard Logic Assembly

6. Use the #TX10 Torx driver to remove the three screws on the shield

and the two screws on the A/D Converter and Inguard Logic assembly.

Then remove the shield.

7. Unplug and remove the A/D Converter and Inguard Logic board from

the inguard chassis.

Installation Procedure 1. Line up the A/D Converter and Inguard Logic board with the

Chapter 3 Disassembly/Assembly Procedures and Parts List 47

Page 48

NOTE

The label numbers in

Figures 16 and 17

show the order

assembly removal.

Use reverse order

for installation.

connector in the inguard chassis. Then plug the board all the way into

the connector.

2. Place the A/D Converter and Inguard Logic shield on the board. Then

use the #TX10 Torx driver to install the three screws on the shield.

3. Locate the grey 20-pin cable connected to the Inguard Power Supply

assembly. Line up the cable plug with the corresponding socket on the

A/D Converter and Inguard Logic assembly. Then plug the cable all

the way in.

Figure 17. Remove/Install Transformer Cable on Inguard Power Supply

4. Locate the grey 20-pin cable connected to the DC Circuitry assembly.

Line up the cable plug with the corresponding socket on the A/D

Converter and Inguard Logic assembly. Then plug the cable all the

way in.

5. Plug in both sets of the blue and grey fiber optic cables into the

corresponding sockets on the A/D Converter and Inguard Logic

assembly.

6. Use the Covers Installation Procedure in this section of the manual to

install the 3458A bottom cover and bottom shield.

48 Chapter 3 Disassembly/Assembly Procedures and Parts List

Page 49

Inguard Power

Supply Assembly

The following procedures show how to remove and install the Inguard Power

Supply Printed Circuit Board Assembly.

Removal/Installation

Procedures

Removal Procedure 1. Use the Covers Removal Procedure in this section of the manual to

remove the 3458A top/bottom covers and top/bottom shields.

2. Set the 3458A on your workbench with the top facing you.

3. Refer to Figure 17. Unplug the 5-wire cable from the Inguard Power

Supply assembly. This cable is connected to the power transformer.

4. Refer to Figure 18 for the rest of this procedure.

5. Set the 3458A on your workbench with the bottom facing you.

Figure 18. Inguard Power Supply Assembly Removal/Installation

6. Locate the grey 20-pin cable that connects between the A/C Converter

assembly and Inguard Power Supply assembly. Unplug the cable at

the power supply assembly.

7. Locate the grey 20-pin cable that connects between the A/D Converter

assembly and Inguard Power Supply assembly. Unplug the cable at

the power supply assembly, and Inguard Logic assembly.

8. Use the #TX 10 Torx driver to remove the three screws on the Inguard

Power Supply assembly.

9. Push the Inguard Power Supply assembly toward the left, of the

instrument (as seen from the front) until it clears the slot in the chassis.

Then remove the board from the instrument.

Chapter 3 Disassembly/Assembly Procedures and Parts List 49

Page 50

Installation Procedure 1. Set the 3458A on your workbench with the bottom facing you.

2. Refer to Figure 18. Line up the Inguard Power Supply assembly with