Page 1

Agilent 34410A/11A

6 ½ Digit Multimeter

(includes the L4411A 1U DMM)

User’s Guide

Agilent Technologies

Page 2

Notices

© Agilent Technologies, Inc. 2005, 2006,

2007

No p art o f this manual may be rep roduc ed in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Agilent

Technologies, Inc. as governed by United

States and international copyright laws.

Manual Part Number

34410-90001

Edition

Fourth Edition. February 2007

Printed in Malaysia

Agilent Technologies, Inc.

3501 Stevens Creek Blvd.

Santa Clara, CA 95052 USA

Microsoft® and Windows® are U.S. registered trademarks of Microsoft Corporation.

Software Revision

This guide is valid for the firmware that was

installed in the instrument at the time of

manufacture. However, upgrading the firmware may add or change product features.

For the latest firmware and documentation,

go to the product page at:

www.agilent.com/find/34410A

or

www.agilent.com/find/34411A

or

www.agilent.com/find/L4411A

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

Restricted Rights Legend

U.S. Government Restricted Rights. Software and technical data rights granted to

the federal government include only those

rights customarily provided to end user customers. Agilent provides this customary

commercial license in Software and technical data pursuant to FAR 12.211 (Technical

Data) and 12.212 (Computer Software) and,

for the Department of Defense, DFARS

252.227-7015 (Technical Data - Commercial

Items) and DFARS 227.7202-3 (Rights in

Commercial Computer Software or Computer Software Documentation).

Safety Notices

CAUTION

A CAUTION notice denotes a haz-

ard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

WARNING

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and

met.

2 34410A/11A/L4411A User’s Guide

Page 3

Safety Information

Do not defeat power cord safety ground feature. Plug in to a grounded (earthed) outlet.

Do not use product in any manner not specified by the manufacturer.

Do not install substitute parts or perform

any unauthorized modification to the product. Return the product to an Agilent Technologi es Sales and S ervice Office for service

and repair to ensure that safety features are

maintained.

Safety Symbols

Earth Ground

Chassis Ground

Risk of electric shock

Refer to manual for additional safety information

CAT II (300V) IEC Measurement Category II.

Inputs may be connected to

mains (up to 300 VAC) under

Category II overv oltage conditions.

WARNING

Main Power and Test Input Disconnect: Unplug instrument from

wall outlet, remove power cord,

and remove all probes from all

terminals before servicing. Only

qualified, service-trained personnel should remove the cover from

the instrument.

WARNING

Line and Current Protection

Fuses: For continued protection

against fire, replace the line fuse

and the current-protection fuse

only with fuses of the specified

type and rating.

WARNING

Front/Rear Switch: Do not

change the position of the

Front/Rear switch on the front

panel while signals are present on

either the front or rear set of terminals. The switch is not intended

as an active multiplexer. Switching while high voltages or currents are present may cause

instrument damage and lead to

the risk of electric shock.

WARNING

IEC Measurement Category II. The

HI and LO input terminals may be

connected to mains in IEC Category II installations for line voltages up to 300 VAC. To avoid the

danger of electric shock, do not

connect the inputs to mains for

line voltages above 300 VAC. See

"IEC Measurement Category II

Overvoltage Protection" on the

following page for further information.

WARNING

Protection Limits: To avoid instrument damage and the risk of electric shock, do not exceed any of

the Protection Limits defined in

the following section.

34410A/11A/L4411A User’s Guide 3

Page 4

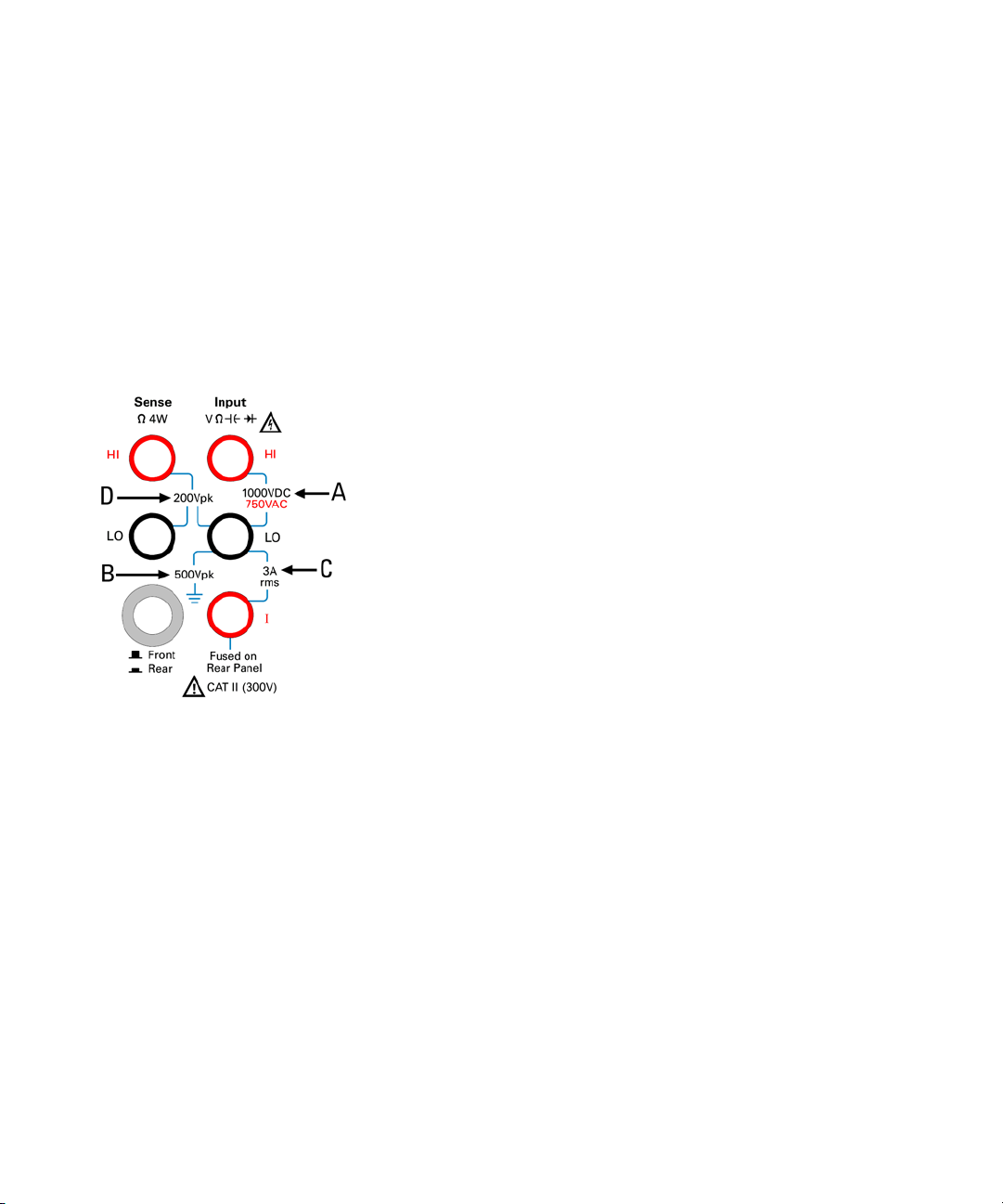

Protection Limits

The A gilent 3441 0A/11A and L4411A D igital

Multimeters provide protection circuitry to

prevent damage to the instrument and to

protect against the danger of electric shock,

provided the Protection Limits are not

exceeded. To ensure safe operation of the

instrument, do not exceed the Protection

Limits shown on the front and rear panel,

and defined below:

Note: The front-panel terminals are shown

above. The rear-panel terminals are identical. The Front/Rear switch selects the terminal set to be used. Do not operate this

switch while signals are present on the

front or rear terminals. The current-protec-

tion fuse is on the rear panel.

Input Terminal Protection

Limits

Protection Limits are defined for the input

terminals:

Main Input (HI and LO) Terminals. The HI

and LO input terminals are used for voltage,

resistance, capacitance, and diode test

measurements. Two Protection Limits are

defined for these terminals:

HI to LO Protection Limit. The Protection

Limit from HI to LO ("A" in the figure at

left) is 1000 VDC or 750 VAC, which is

also the maximum voltage measurement.

This limit can also be expressed as 1000

Vpk maximum.

LO to Ground Protection Limit. The LO

input terminal can safely "float" a maximum of 500 Vpk relative to ground. T his is

Protection Limit "B" in the figure.

As is implied by the above limits, the Protection Limit for the HI input terminal is a maximum of 1500 Vpk relative to ground.

Current Input Terminal. The current input

("I") terminal has a Protection Limit of 3A

(rms) maximum current flowing from the LO

input terminal. This is Protection Limit "C"

in the figure. Note that the current input terminal will be at approximately the same

voltage as the LO terminal.

Note: The current-protection circuitry

includes a fuse on the rear panel. To maintain protection, replace this fuse only with a

fuse of the specified type and rating.

Sense Terminal Protection

Limits

The HI and LO sense terminals are used

only for four-wire resistance and temperature measurements ("

tion Limit is 200 Vpk for all of the terminal

pairings ("D" in the figure):

LO sense to LO input.

HI sense to LO input.

HI sense to LO sense.

Ω 4W"). The Protec-

Note: The 200 Vpk limit on the sense terminals is the Protection Limit. Operational

voltages in resistance measurements are

much lower — less than 10 V in normal

operation.

IEC Measurement Category II

Overvoltage Protection

To protect against the danger of electric

shock, the A gi lent 34410A/11A and L4411A

Digital Multimeters provide overvoltage protection for line-voltage mains connections

meeting both of the following conditions:

The HI and LO input terminals are connected to the mains under Measurement

Category II conditions, defined below,

and

The mains are limited to a maximum line

voltage of 300 VAC.

IEC Measurement Category II includes electrical devices connected to mains at an outlet on a branch circuit. Such devices include

most small appliances, test equipment, and

other devices that plug into a branch outlet

or socket. The 34410A/11A and L4411A

may be used to make measurements with

the HI and LO inputs connected to mains in

such devices, or to the branch outlet itself

(up to 300 VAC). However, the 34410A/11A

and L4411A may not be used with its HI and

LO inputs connected to mains in permanently installed electrical devices such as

the main circuit-breaker panel, sub-panel

disconnect boxes, or permanently wired

motors. Such devices and circuits are subject to overvoltages that may exceed the

protection limits of the 34410A/11A and

L4411A.

Note: Voltages above 300 VAC may be measured only in circuits that are isolated from

mains. However, transient overvoltages are

also present on circuits that are isolated

from mains. The Agilent 34410A /11A and

L4411A are designed to safely withstand

occasional transient overvoltages up to

2500 Vpk. Do not use this equipment to

measure circuits wh ere transient overvoltages could exceed this level.

4 34410A/11A/L4411A User’s Guide

Page 5

Additional Notices

Waste Electrical and

Electronic Equipment (WEEE)

Directive 2002/96/EC

This product complies with the WEEE Directive (2002/96/EC) marking requirement.

The affixed product label (see below) indicates that you must not discard this electrical/electronic product in domestic

household waste.

Product Category: With reference to the

equipment types in the WEEE directive

Annex 1, this product is classified as a

"Monitoring and Control instrumentation"

product.

Do not dispose in domestic household

waste.

To return unwanted products, contact your

local Agilent office, or see

www.agilent.com/environment/product

for more information.

Agilent 34138A Test Lead Set

The Agilent 34410A/11A is provided with

an Agilent 34138A Test Lead Set, described

below.

Test L e a d Ra t i n g s

Test Leads - 1000V, 15A

Fine Tip Probe Attachments - 300V, 3A

Mini Grabber Attachment - 300V, 3A

SMT Grabber Attachments - 300V, 3A

Operation

The Fine Tip, Mini Grabber, and SMT Grabber attachments plug onto the probe end of

the Test Leads.

Maintenance

If any portion of the Test Lead Set is worn or

damaged, do not use. Replace with a new

Agilent 34138A Test Lead Set.

WARNING

If the Test Lead Set is used in a

manner not specified by Agilent

Technologies, the protection provided by the Test Lead Set may be

impaired. Also, do not use a damaged or worn Test Lead Set.

Instrument damage or personal

injury may result.

34410A/11A/L4411A User’s Guide 5

Page 6

DECLARATION OF CONFORMITY

According to EN ISO/IEC 17050-1:2004

Manufacturer’s Name:

Manufacturer’s Address:

Agilent Technologies, Incorporated

900 South Taft Ave

Loveland, CO 80537

USA

Declares under sole responsibility that the product as originally delivered

Product Name:

Model Number:

Product Options:

6 ½ Digit Multimeter

34410A, 34411A, L4411A

This declaration covers all options of the above product(s)

complies with the essential requirements of the following applicable European Directives, and

carries the CE marking accordingly:

Low Voltage Directive (73/23/EEC, amended by 93/68/EEC)

EMC Directive (89/336/EEC, amended by 93/68/EEC)

and conforms with the following product standards:

EMC

IEC 61326:2002 / EN 61326:1997+A1:1998 +A2:2000+A3:2003

CISPR 11:1990 / EN 55011:1990 Class A Group 1

IEC 61000-4-2:1995 / EN 61000-4-2:1995 4 kV/4 kV contact/air

IEC 61000-4-3:1995 / EN 61000-4-3/1995 3 V/m, 80-1000 MHz

IEC 61000-4-4:1995 / EN 61000-4-4:1995 0.5 kV signal lines, 1 kV power lines

IEC 61000-4-5:1995 / EN 61000-4-5:1995 0.5 kV line-line, 1 kV line-ground

IEC 61000-4-6:1996 / EN 61000-4-6:1996 3 V, 0.15-80 MHz

IEC 61000-4-11:1994 / EN 61000-4-11:1994 1 cycle, >95%

Canada: ICES-001:2004

Australia/New Zealand: AS/NZS CISPR 11:2002

Safety

Standard Limit

Reference Standards

The product was tested in a typical configuration with Agilent Technologies test systems.

IEC 61010-1:2001 / EN 61010-1:2001

168520

Canada: CAN/CSA-C22.2 No. 61010-1-04,

USA: ANSI/UL 61010-1:2005

Supplementary Information:

This DoC applies to above-listed products placed on the EU market after:

17 January 2007

Date

For further information, please contact your local Agilent Technologies sales office, agent or distributor,

or Agilent Technologies Deutschland GmbH, Herrenberger Straße 130, D 71034 Böblingen, Germany.

David L. Kepler

Quality Manager

6 34410A/11A/L4411A User’s Guide

Page 7

Agilent 34410A/11A/L4411A at a Glance

The Agilent 34410A, 34411A, and L4411A multimeters provide

6½-digit, high-performance dc and ac measurements.

• Voltage and Current Measurements. DC and AC

• Resistance Measurements. 2-wire and 4-wire.

•Continuity and Diode Testing.

• Frequency and Period Measurements.

• Capacitance Measurements.

• Temperature Measurements. Thermistor and RTD.

• Auto and Manual Ranging.

• Math Features. Null, dB, dBm, limits, and statistics.

• Data Logging. Into non-volatile instrument memory.

• Instrument State Storage. User-defined named states.

• GPIB (IEEE-488), USB, and LAN. Three standard remote

interfaces. LXI Class C Compliant.

• Web I n t e r fa ce. Direct web browser access to instrument.

• SCPI Compatibility. For easy instrument programming.

• Voltmeter Complete and External Trigger Signals.

Synchronize with other instruments in your test system.

(true-rms).

Note: This manual covers operation of the Agilent 34410A,

34411A, and L4411A 6½ Digit Multimeters. The features

described in this manual, except where otherwise noted, apply

to each of the multimeters.

Key Differences:

Model 34410A Model 34411A/L4411A

• Up to 10,000 readings per second. • Up to 50,000 readings per second.

• Reading memory (buffer) up

to 50,000 readings.

• Reading memory (buffer) up

to 1 million readings.

• Pretriggering, internal level triggering,

and digitizer specifications.

34410A/11A/L4411A User’s Guide 7

Page 8

The Front Panel at a Glance (34410A/11A)

1 On/Off Switch 8 Exit Key (Auto Range)

2 Measurement Function Keys 9 Shift Key (Local)

3 Configuration Key 10 Menu Navigation Keypad (Range)

4 Second Display Key (Reset) 11 Front/Rear Switch

5 Null Key (Math Functions) 12 HI and LO Sense Terminals (4-wire measurements)

6 Data Logger Key (Utility) 13 HI and LO Input Terminals (all functions except current)

7 Trigger Key (Auto Trig) 14 Current Input Terminal (ac and dc current)

WARNING

Front/Rear Switch: Do not change the position of the Front/Rear switch on the front panel while signals are

present on either the front or rear set of terminals. This switch is not intended as an active multiplexer.

Switching while high voltages or currents are present may cause instrument damage and lead to the risk of

electric shock.

8 34410A/11A/L4411A User’s Guide

Page 9

The Rear Panel at a Glance (34410A/11A)

1 Current Input Fuse (front and rear)

2 HI and LO Sense Terminals (4-wire resistance and temperature)

3 HI and LO Input Terminals (voltage, resistance, and other functions)

4 Current Input Terminal (ac current and dc current only)

5 External Trigger Input (BNC)

6 Voltmeter Complete Output (BNC)

7 LAN Interface Connector

8 USB Interface Connector

9 GPIB Interface Connector

10 Chassis Ground

11 Power-Line Voltage Setting

12 Power-Line Fuse-Holder Assembly

WARNING

For protection from electrical shock, the power cord ground must not be defeated. For continued protection

from fire, replace fuses only with fuses of the specified type and rating.

34410A/11A/L4411A User’s Guide 9

Page 10

The Display at a Glance (34410A/11A)

Alphanumeric Displays:

1 Primary display line

2 Secondary display line

Annunciators: Annunciators:

3

(measurement in progress) 12 Shift (shift key just pressed)

*

4 Hi-Z (high input impedance, Vdc only) 13 Math (dB or dBm function enabled)

5 OComp (offset compensation) 14 Stats (statistics functions enabled)

6 ManRng (manual ranging) 15 Limits (limit-test function enabled)

7 Trig (wait-for-trigger state) 16 Rear (rear-panel terminals active)

8 Hold (reading hold) 17 4W (four-wire ohms or temperature)

9 Remote (remote interface operation) 18 (continuity test function enabled)

10 Error (error in queue) 19 (diode-check function enabled)

11 Null (null function enabled)

The following key refers to the primary front-panel display.

For further information, see Chapter 2, “Features and

Functions”.

10 34410A/11A/L4411A User’s Guide

Page 11

In This Guide…

1Quick Start

In this chapter you prepare the multimeter for use and become

familiar with the most common front-panel operations.

2 Features and Functions

In this chapter you will find a detailed description of the

multimeter’s capabilities and operation. This chapter presents

both front-panel and remote interface operation of the

instrument.

Note. Refer to the Agilent 34410A/11A/L4411A Programmer’s

Reference help system for a detailed description of the SCPI

commands.

3Remote Interface

This chapter describes how to connect the multimeter using a

remote interface.

4 Measurement Tutorial

This chapter discusses measurement techniques and

considerations to help you reduce sources of error and obtain

the best accuracy from your instrument.

5 Specifications

This chapter lists the 34410A/11A/L4411A multimeter

specifications and describes how to interpret these

specifications.

34410A/11A/L4411A User’s Guide 11

Page 12

12 34410A/11A/L4411A User’s Guide

Page 13

Agilent 34410A/11A/L4411A 6½ Digit Multimeter

User’s Guide

1

Quick Start

This chapter gives you a quick overview of the 34410A/11A

multimeter’s front panel and basic features. The examples will

help you become familiar with your meter, its measuring

functions, and basic operation.

Basic Multimeter Operations 20

Preparing the Multimeter for Use 20

Using the Front Panel (34410A/11A) 21

Front-Panel Keys 21

Front-Panel Display Shortcuts 22

Making Basic Measurements (34410A/11A) 23

To M ea s ur e D C Vo l ta ge 24

To Measure AC Voltage 24

To Measure DC Current 25

To Measure AC Current 25

To Make a 2-Wire Resistance Measurement 26

To Make a 4-wire Resistance Measurement 26

To Measure Frequency 27

To M ea s ur e P er i od 27

To Measure Capacitance 28

To Make a 2-Wire Temperature Measurement 29

To Make a 4-Wire Temperature Measurement 29

To Te st C on ti nu i ty 30

To Check Diodes 30

Other Basics of Operation 31

If the Multimeter Does Not Turn On 31

To Replace the Power-Line Fuse (34410A/11A) 32

To Ad j us t t h e Ca r r ying H andl e 33

To Rack Mount the Multimeter (34410A/11A) 34

Agilent Technologies

19

Page 14

1Quick Start

Basic Multimeter Operations

This section introduces the basics of the 34410A/11A multimeter, and how to

use it.

NOTE

For basic information unique to the L4411A, refer to the L4411A Getting Started Guide

(p/n L4411-90001).

Preparing the Multimeter for Use

To verify that your 34410A or 34411A multimeter is ready for use:

1 Check the list of supplied items.

Verify that you have received the following items with your multimeter. If

anything is missing, contact your nearest Agilent Sales Office.

• Test Lead Set.

• Power Cord.

• USB 2.0 Cable.

• Agilent 34410A/11A/L4411A Product Reference CD–ROM.

• Agilent Automation Ready (IO Libraries) CD–ROM.

• Certificate of Calibration.

The product documentation, including the Agilent 34410A/11A/L4411A

Programmer’s Reference Help and the product manuals, are included on

the Product Reference CD–ROM. Printed (hardcopy) manuals are optional,

and included only if you ordered them.

2 Connect the power cord and turn on the multimeter.

The front–panel display will light up while the multimeter performs its

power–on self–test. The multimeter powers up in the dc voltage function

with autoranging enabled (unless a previous user has configured power–up

using a non–default stored state (see “Multimeter State Storage” on

page 48).

20 34410A/11A/L4411A User’s Guide

Page 15

Using the Front Panel (34410A/11A)

This section introduces the 34410A/11A multimeter front panel.

Front-Panel Keys

The front panel provides keys to select various functions and operations.

Pressing a measurement function key (e.g. ) selects that function. Press

to enter the configuration menu for the selected measurement function.

Most keys have a shifted function printed in blue above the key. To perform a

shifted function, press , and then press the key that has the desired label

above it.

To view and select menu items, use the menu navigation keypad (for example

the or keys). The current (or default) selection is displayed in FULL

BRIGHTNESS. All other choices are displayed in HALF BRIGHTNESS. The selections

on each menu level scroll, but do not wrap. Arrow annunciators on the second

display line indicate additional selections to the left or right. To accept a

selection, press .

To set numeric parameters, use or to select a digit, and or to

increase or decrease that digit.

Quick Start 1

34410A/11A/L4411A User’s Guide 21

Page 16

1Quick Start

Front-Panel Display Shortcuts

Direct front panel shortcuts are provided for three commonly used display

functions: ranging, digit masking, and integration time.

Ranging. The multimeter’s manual range can be set directly from the

navigation keypad.

To manually change the current multimeter range, press or . The

ManRng annunciator will light, and the selected range (e.g. 100mV RANGE) will

be briefly displayed on the second line.

Digit Masking. The navigation keypad provides a shortcut to mask (change

the number of digits displayed) the reading on the main display, easing

readability.

To enable digit masking during any measurement function, press or

. DIGIT MASK will be displayed, along with a list of choices (3.5, 4.5, 5.5,

6.5 and AUTO) on the second display line. Press

or to scroll through and select one of these settings, and then press

.

Integration Time (Bandwidth, Gate Time). Four measurement functions allow

you to select the multimeter’s integration time: dc voltage, dc current,

resistance, and temperature. The ac voltage and current measurements allow

you to select the ac signal filter (bandwidth). The frequency/period function

allows you to select gate time. The navigation keypad provides a shortcut for

quickly changing these settings.

• If the multimeter is configured to take the measurement using an

integration time in NPLCs, pressing or during front panel

measurement operations will increase or decrease the integration time

setting.

• If either the ac voltage or ac current measurement function is selected,

pressing or during front panel measurement operations will

increase or decrease the bandwidth setting.

• If the frequency/period measurement function is selected, pressing or

during front panel measurement operations will increase or decrease

the gate time setting.

22 34410A/11A/L4411A User’s Guide

Page 17

Making Basic Measurements (34410A/11A)

This section introduces the many types of measurements that you can make

with your 34410A/11A multimeter, and how to make connections for each

measurement. Most basic measurements can be taken using the factory

default settings. A more complete description of all multimeter functions,

measurement parameter configuration and remote interface operation is

provided in Chapter 2.

For each measurement, connect the test leads as shown. The test lead

connections are the same for the front or rear set of terminals.

Before making test lead connections, use the Front/Rear button on the front

panel to select either the front or rear set of terminals. The Rear annunciator

lights if the rear terminals are selected.

WARNING

Do not press the Front/Rear button while signals are present on either the front or rear

set of terminals. Switching while high voltages or currents are present can cause

instrument damage, and may increase the risk of electric shock.

Quick Start 1

NOTE

34410A/11A/L4411A User’s Guide 23

For basic measurement connection information unique to the L4411A, refer to the L4411A

Getting Started Guide (p/n L4411-90001).

Page 18

1Quick Start

To Measure DC Voltage

Press to select the dc voltage function.

• Ranges: 100 mV, 1 V, 10 V, 100 V, 1000 V

• Configurable parameters: INTEGRATION, RANGE, INPUT Z (input impedance),

AUTO ZERO, NULL, and NULL VALUE

Connect test leads as shown:

DC Voltage

To M ea su r e A C Vo lt ag e

Press to select the ac voltage function.

• Ranges: 100 mV, 1 V, 10 V, 100 V, 750 V

• AC Technique: true–RMS, ac–coupled

• Configurable parameters: AC FILTER, RANGE, NULL and NULL VALUE

Connect test leads as shown:

AC Voltage

24 34410A/11A/L4411A User’s Guide

Page 19

Quick Start 1

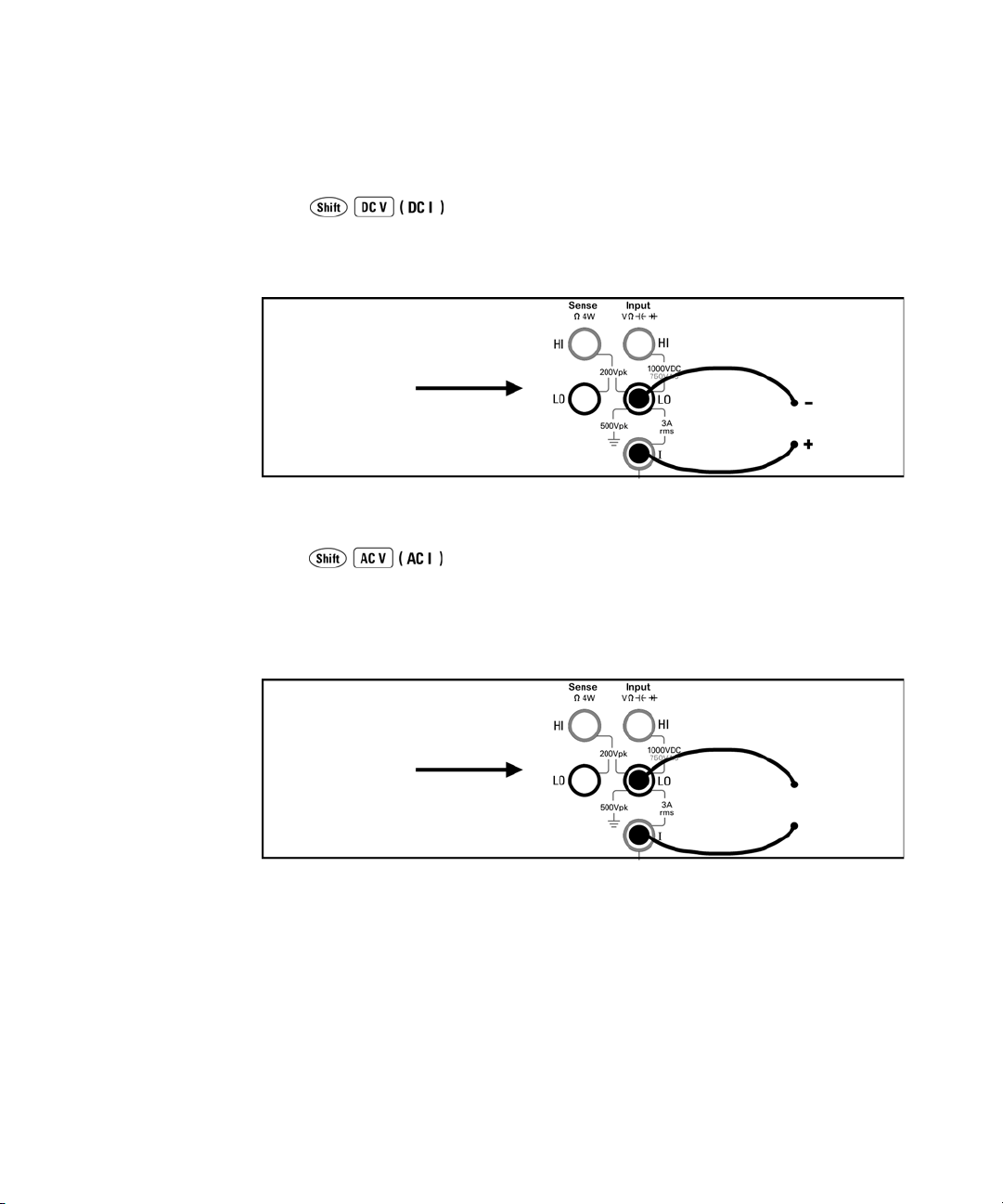

To Measure DC Current

Press to select the dc current function.

• Ranges: 100 mA, 1 mA, 10 mA, 100 mA, 1 A, 3 A

• Configurable parameters: INTEGRATION, RANGE, AUTO ZERO, NULL, and NULL VALUE

Connect test leads as shown:

DC Current

To Measure AC Current

Press to select the ac current function.

• Ranges: 100 mA, 1 mA, 10 mA, 100 mA, 1 A, 3 A

• AC Technique: true–RMS, ac–coupled

• Configurable parameters: AC FILTER, RANGE, NULL and NULL VALUE

Connect test leads as shown:

AC Current

34410A/11A/L4411A User’s Guide 25

Page 20

1Quick Start

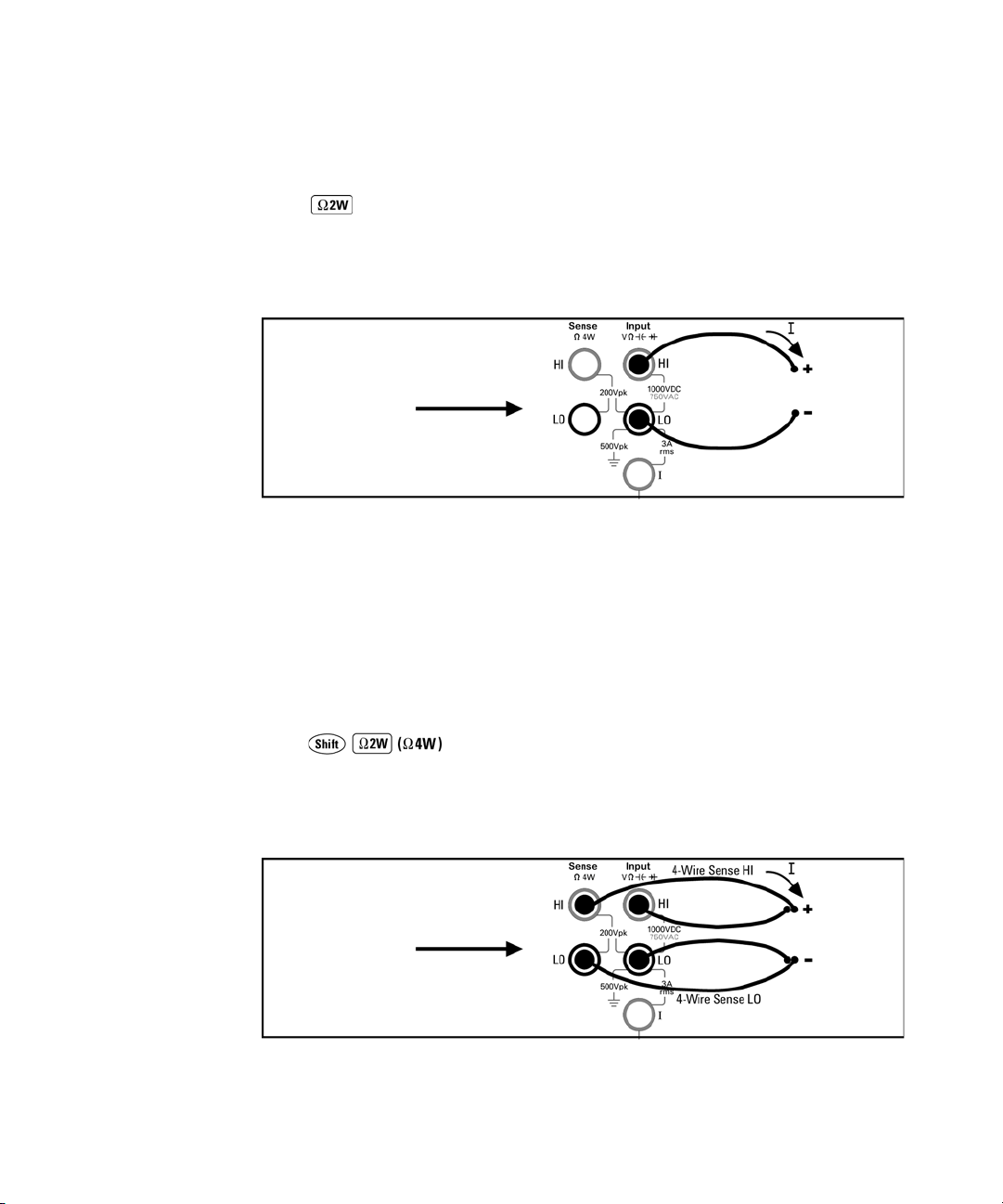

To Make a 2-Wire Resistance Measurement

Press to select the 2-wire resistance function.

• Ranges: 100 W, 1 kW, 10 kW, 100 kW, 1 MW, 10 MW, 100 MW, 1 GW

• Configurable parameters: INTEGRATION, RANGE, OFFSET COMP, AUTO ZERO, NULL,

and NULL VALUE

Connect test leads as shown:

Resistance

To null–out the test lead resistance:

1 Connect one end of the test leads at the meter, and short the probe ends

together.

2 Press null.

3 Connect the probe ends to the test circuit, and measure the corrected

resistance value.

To Make a 4-wire Resistance Measurement

Press to select the 4-wire resistance function.

• Ranges: 100 W, 1 kW, 10 kW, 100 kW, 1 MW, 10 MW, 100 MW, 1 GW

• Configurable parameters: INTEGRATION, RANGE, OFFSET COMP, NULL, and NULL

VALUE

Connect test leads as shown:

Resistance

All 4-wire resistance measurements are made with auto-zero on.

26 34410A/11A/L4411A User’s Guide

Page 21

Quick Start 1

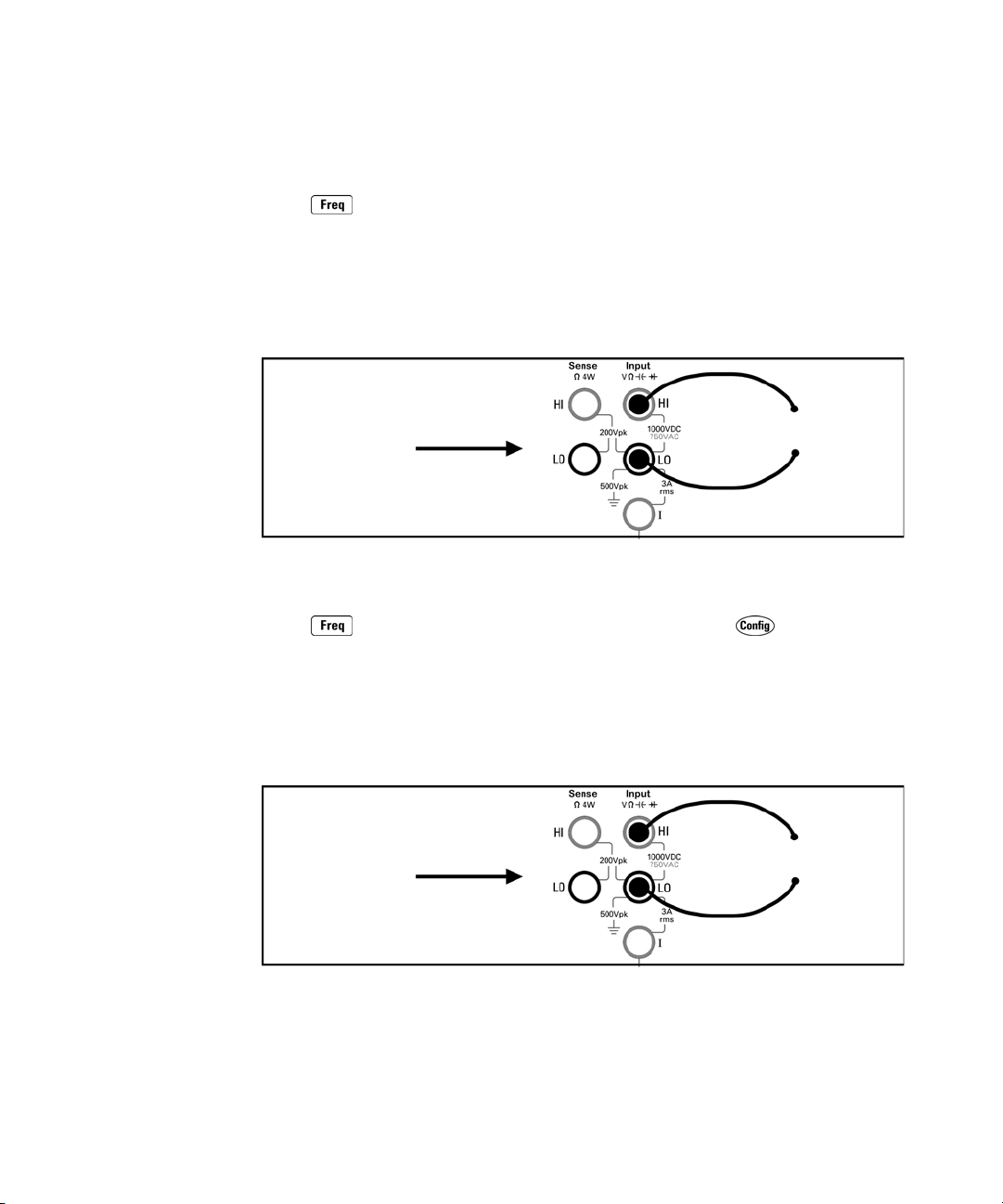

To Measure Frequency

Press to select the frequency function.

• Measurement band: 3 Hz to 300 kHz

• Input signal range: 100 mVAC to 750 VAC

• Technique: reciprocal counting

• Configurable parameters: GATE TIME, RANGE, AC FILTER, NULL and NULL VALUE

Connect test leads as shown:

AC Signal

To M ea su r e P e ri o d

Press to select the frequency function. Then press and select

PERIOD from the menu.

• Measurement band: 0.33 s to 3.3 ms

• Input signal range: 100 mVAC to 750 VAC

• Technique: reciprocal counting

• Configurable parameters: GATE TIME, RANGE, AC FILTER, NULL and NULL VALUE

Connect test leads as shown:

AC Signal

34410A/11A/L4411A User’s Guide 27

Page 22

1Quick Start

To M ea su r e C ap a ci ta nc e

Press to select the capacitance function.

• Ranges: 1 nF, 10 nF, 100 nF, 1 mF, 1 0 mF

• Configurable parameters: RANGE, NULL, and NULL VALUE

Connect test leads as shown:

Capacitance

To null–out the test lead capacitance:

1 Disconnect the + lead’s probe end from the test circuit, and leave open.

2 Press null.

3 Reconnect the + lead’s probe end to the test circuit, and measure the

corrected capacitance value.

28 34410A/11A/L4411A User’s Guide

Page 23

Quick Start 1

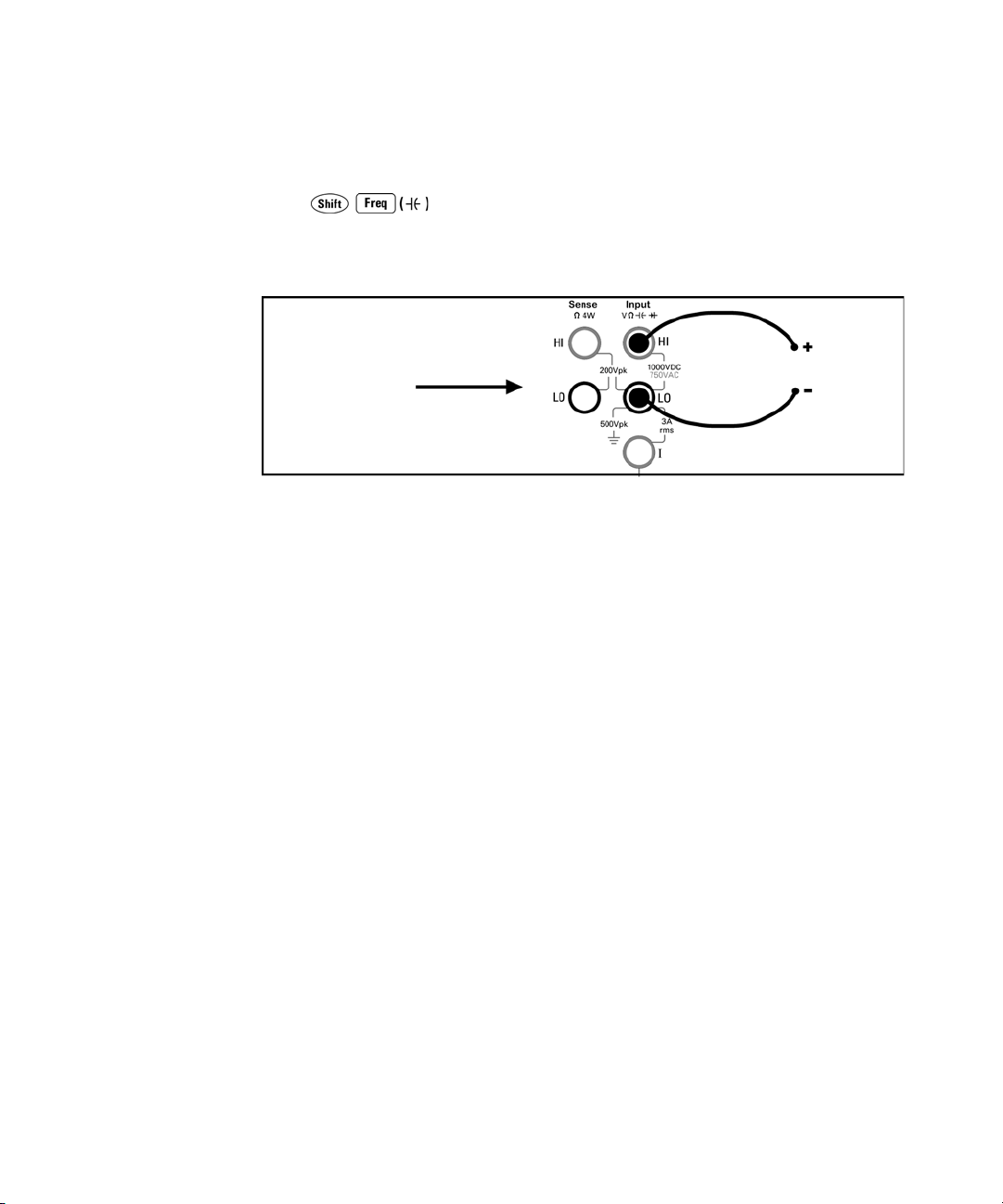

To Make a 2-Wire Temperature Measurement

Press to select the temperature function. Then press

and select RTD-2W or THERMISTOR-2W from the menu.

• Probe types: 2.2 kW, 5 kW, 10 kW thermistors; 0.00385%/ºC RTD

• Configurable parameters: PROBE TYPE, THERMISTOR or RTD value, AUTO ZERO, OFFSET

COMP (RTD probes only), INTEGRATION, UNITS, NULL, and NULL VALUE

Connect test leads as shown:

Thermistor or RTD

To Make a 4-Wire Temperature Measurement

Press to select the temperature function. Then press

and select RTD-4W or THERMISTOR-4W from the menu.

• Probe types: 2.2 kW, 5 kW, 10 kW thermistors; 0.00385%/ºC RTD

• Configurable parameters: PROBE TYPE, THERMISTOR or RTD value, OFFSET COMP

(RTD probes only), INTEGRATION, UNITS, NULL, and NULL VALUE

Connect test leads as shown:

Thermistor or RTD

All 4-wire temperature measurements are made with auto-zero on.

34410A/11A/L4411A User’s Guide 29

Page 24

1Quick Start

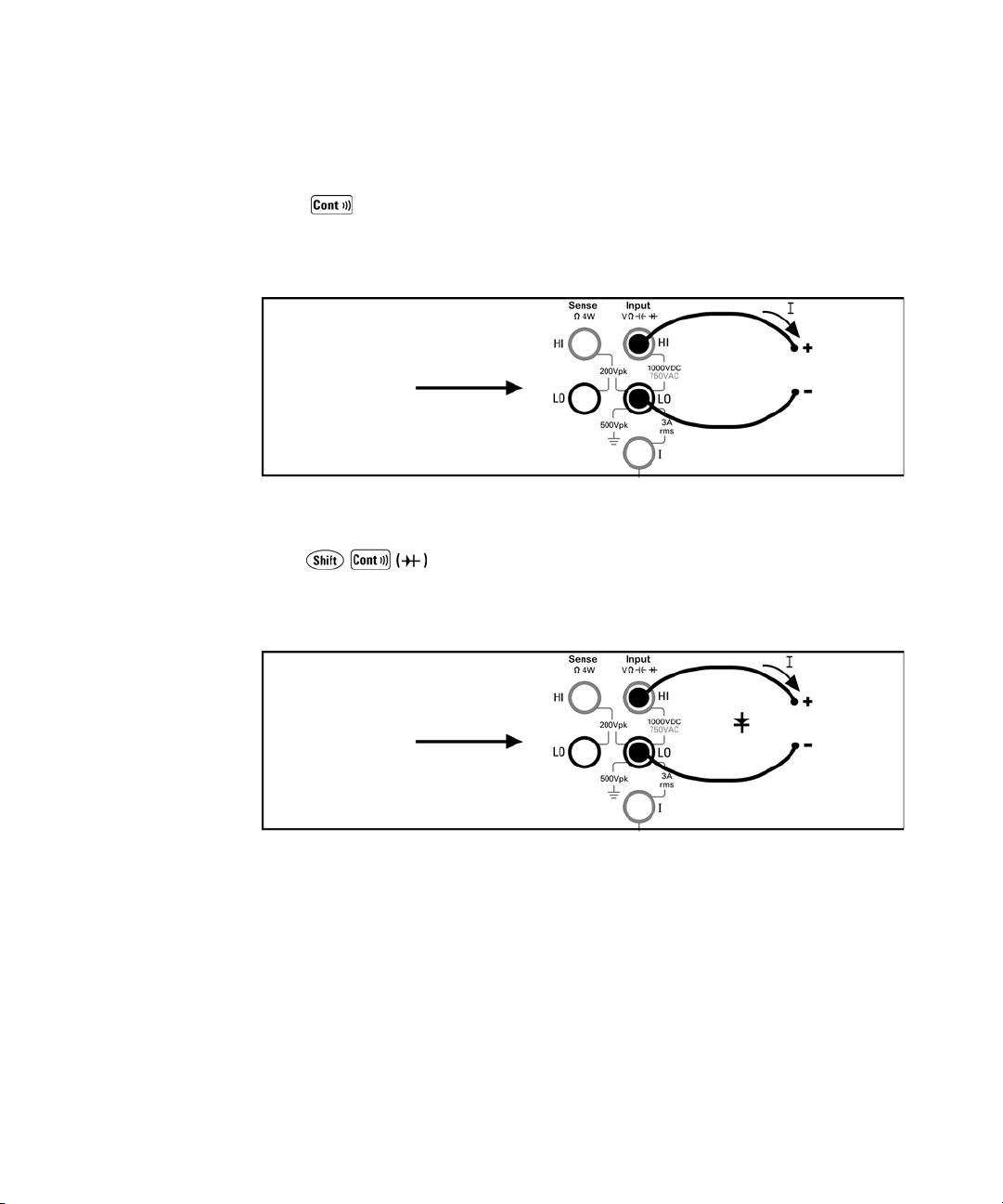

To Te st C o nt i n u i t y

Press to select the continuity function.

• Test current source: 1 mA

• Beeper Threshold: beeps below 10W

Connect test leads as shown:

Open or Closed Circuit

To C h e ck D i o d e s

Press to select the diode test function.

• Test current source: 1 mA

• Beeper Threshold: 0.3V

Connect test leads as shown:

~ voltage

measured

The diode check function is used to indicate correct diode operation;

closed–circuit on forward bias and open–circuit on reverse–bias.

~ 0.8V (not adjustable)

Forward Bias

30 34410A/11A/L4411A User’s Guide

Page 25

Other Basics of Operation

This section covers basic troubleshooting and general use.

If the Multimeter Does Not Turn On

Use the following steps to help solve problems you might encounter when

turning on the multimeter. If you need more help, see the Service Guide for

instructions on returning the multimeter to Agilent for service.

1 Verify that there is ac power to the multimeter.

First, verify that the multimeter’s Power switch is in the “On” position. Also,

make sure that the power cord is firmly plugged into the power module on the

rear panel. You should also make sure that the power source you plugged the

multimeter into is energized.

2 Verify the power–line voltage setting.

The line voltage is set to the proper value for your country when the

multimeter is shipped from the factory. Change the voltage setting if it is not

correct. The settings are: 100, 120, 220, or 240 Vac (for 230 Vac operation, use

the 220 Vac setting).

See “To Replace the Power-Line Fuse (34410A/11A)” on page 32 if you need to

change the line–voltage setting.

Quick Start 1

3 Verify that the power–line fuse is good.

The multimeter is shipped from the factory with a power–line fuse installed.

The supplied fuse is a 250 mAT, 250V, slow–blow, 5x20mm fuse, Agilent part

number 2110–0817. If you determine that the fuse is faulty, replace it with one

of the same size and rating.

See “To Replace the Power-Line Fuse (34410A/11A)” on page 32 if you need to

replace the power–line fuse.

The current input path is also fused. The supplied fuse is a 3 AT, 250V,

slow–blow, 5x20mm fuse, Agilent part number 2110–0780, and is housed in

a standard screw–in fuse holder on the left side of the rear panel. If you

determine that the fuse is faulty, replace it with one of the same size and

rating.

34410A/11A/L4411A User’s Guide 31

Page 26

1Quick Start

To Replace the Power-Line Fuse (34410A/11A)

Remove power cord first. Then follow these steps:

Depress tab (1) and pull fuse holder (2) from Remove line-voltage selector from fuse

rear panel.

Rotate line-voltage selector and reinstall so

correct voltage appears in fuse holder window.

holder assembly.

Agilent Part Number 2110-0817

(250 mAT, 250V, slow-blow, 5x20mm)

Replace fuse holder assembly in rear panel.

Verify that the correct line voltage is selected and the power-line fuse is good.

NOTE

For multimeter operations with a 230 VAC supply, set the line–voltage selector to 220V.

32 34410A/11A/L4411A User’s Guide

Page 27

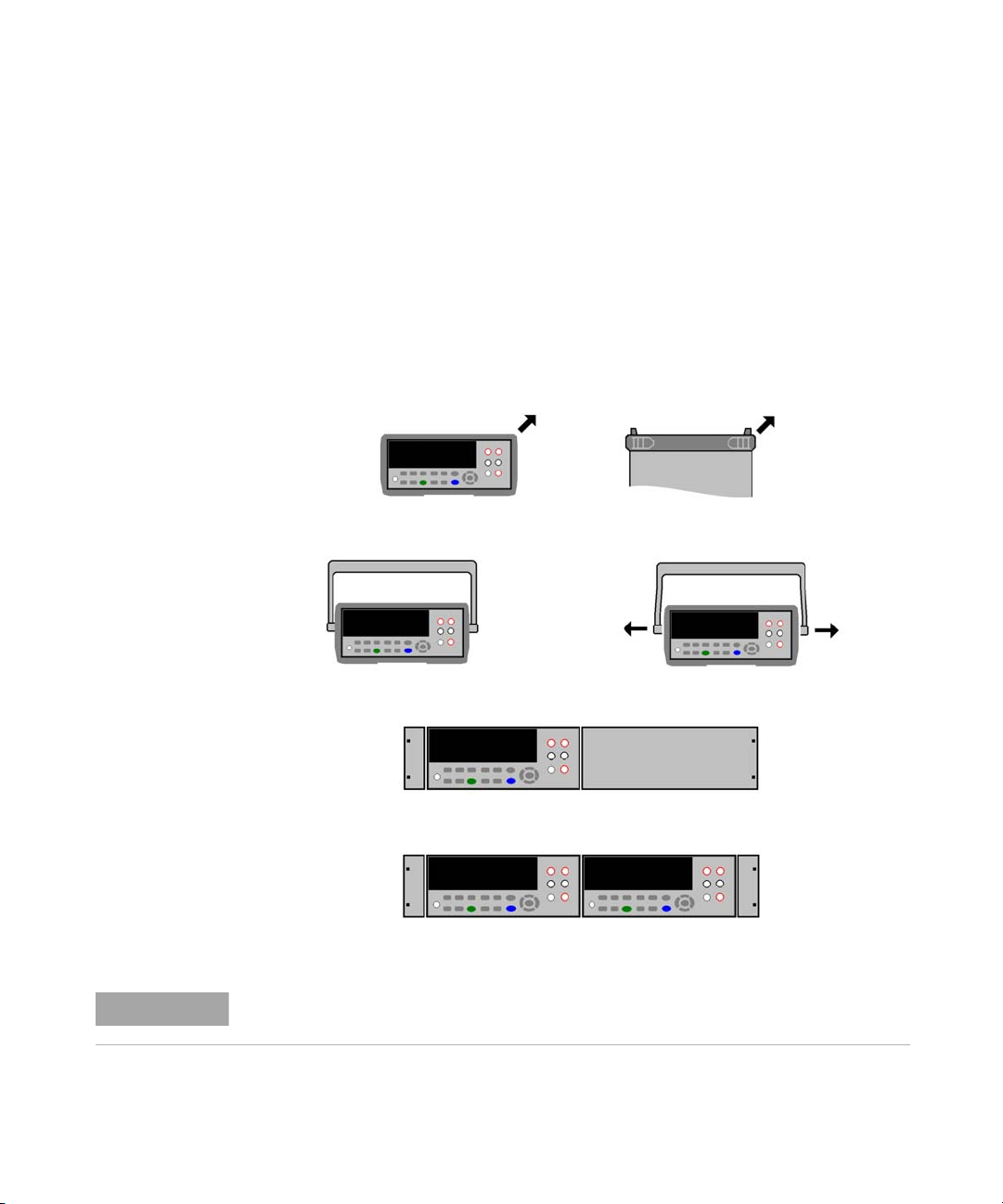

To Adjust the Carrying Handle

To adjust the position, grasp the handle by the sides and pull outward. Then,

rotate the handle to the desired position.

Bench-Top Viewing Positions

Quick Start 1

Carrying Position

34410A/11A/L4411A User’s Guide 33

Page 28

1Quick Start

To Rack Mount the Multimeter (34410A/11A)

You can mount the 34410A/11A in a standard 19–inch rack cabinet using the

available rack–mount kits. Instructions and mounting hardware are included

with each kit. Any Agilent

either the 272.3 mm or the 348.3 mm depth can be rack mounted side–by–side

with the 34410A/11A. For example, a 34410A/11A and a 34401A, or two

34410A/11As, can be mounted side–by–side, as shown below.

You must remove the carrying handle, and the front and rear rubber bumpers,

before rack mounting an instrument.

To remove each bumper, stretch a corner and slide it off.

System II (half-width, 2U height) instrument of

To remove the handle, rotate it to the vertical position and pull the ends outward.

To rack mount a single instrument, order adaptor kit 5063-9240

To rack mount two instruments side-by-side, order lock-link kit

5061-8769 and flange kit 5063-9212

NOTE

34 34410A/11A/L4411A User’s Guide

Refer to the L4411A Getting Started Guide for procedures and part numbers for rack

mounting the L4411A.

Page 29

Contents

1Quick Start19

Basic Multimeter Operations 20

Preparing the Multimeter for Use 20

Using the Front Panel 21

Front-Panel Keys 21

Front-Panel Display Shortcuts 22

Making Basic Measurements 23

To Measure DC Voltage 24

To Measure AC Voltage 24

To Measure DC Current 25

To Measure AC Current 25

To Make a 2-Wire Resistance Measurement 26

To Make a 4-wire Resistance Measurement 26

To Measure Frequency 27

To Measure Period 27

To Measure Capacitance 28

To Make a 2-Wire Temperature Measurement 29

To Make a 4-Wire Temperature Measurement 29

To Test Continuity 30

To Check Diodes 30

Other Basics of Operation 31

If the Multimeter Does Not Turn On 31

To Replace the Power-Line Fuse 32

To Adjust the Carrying Handle 33

To Rack Mount the Multimeter 34

34410A/11A User’s Guide 35

Page 30

Contents

2 Features and Functions 35

SCPI Commands 37

Front Panel Features (34410A/11A) 38

Front Panel Display 38

Displayed Messages 38

Self–Guiding Menus 38

Annunciators 40

Second Display Options 41

Turning the Display Off 41

Front–Panel Display Shortcuts 42

Front Panel Alphanumeric Character Entry 43

Front Panel Measurement Configuration Menus 44

Configuring DC Voltage and DC Current Measurements 44

Configuring AC Voltage and Current Measurements 45

Configuring Resistance Measurements 45

Configuring Frequency and Period Measurements 46

Configuring Temperature Measurements 46

Configuring Capacitance Measurements 47

Continuity and Diode Tests 47

Advanced Configuration Options 48

Multimeter State Storage 48

Accessing Reading Memory 49

Front/Rear Input Terminal Switching (34410A/11A) 49

Multimeter Reset 50

DC Measurements 51

Integration Time and Resolution 51

DC Input Impedance 53

AC Measurements 54

AC Filter 54

Gate Time 55

Auto Zero 56

Ranging 57

Null Measurements 59

36 34410A/11A/L4411A User’s Guide

Page 31

Miscellaneous Configuration Settings 60

Radix Character (34410A/11A) 60

Thousands Separator (34410A/11A) 60

Beeper (34410A/11A) 61

Math Functions 62

dB Measurements 63

dBm Measurements 64

Using Statistics 65

Limit Testing 66

Triggering the Multimeter 67

Selecting a Trigger Source 67

Auto Triggering (34410A/11A) 68

Single Triggering (34410A/11A) 68

Reading Hold (34410A/11A) 69

Immediate Triggering 69

Software (Bus) Triggering 70

Internal (Level) Triggering (34411A/L4411A) 70

Number of Samples per Trigger 71

Number of Pre-Trigger Samples (34411A/L4411A) 71

Trigger Delay 72

Automatic Trigger Delay 73

External Triggering 75

Trigger Slope 77

Contents

Data Logging 78

System-Related Operations 82

Self–Test 82

Error Conditions 83

Reading the Error Queue 84

Calibration 84

Power-On and Reset State 85

34410A/11A/L4411A User’s Guide 37

Page 32

Contents

3 Remote Interface Configuration 87

Configuring the GPIB Interface 89

Configuring the USB Interface 90

Configuring the LAN Interface 91

Configuring LAN Parameters 92

DHCP 92

Auto–IP 92

IP Address 93

Subnet Mask 93

Default Gateway 94

Host Name 94

DNS Server 95

Web Password 95

Instrument Unexpectedly Goes into Remote 95

Setting up a LAN connection from the Front Panel 96

Setting up a LAN connection from the Remote Interface 97

Agilent 34410A/11A Web Interface 98

4 Measurement Tutorial 99

DC Measurement Considerations 101

Thermal EMF Errors 101

Loading Errors (dc volts) 101

Noise Rejection 102

Rejecting Power–Line Noise Voltages 102

Common Mode Rejection (CMR) 102

Noise Caused by Magnetic Loops 103

Noise Caused by Ground Loops 103

Resistance Measurement Considerations 104

4–Wire Ohms Measurements 104

Removing Test Lead Resistance Errors 105

Minimizing Power Dissipation Effects 105

Errors in High Resistance Measurements 105

True RMS AC Measurements 106

38 34410A/11A/L4411A User’s Guide

Page 33

True RMS Accuracy and High–Frequency Signal Content 107

Estimating High–Frequency (Out–of–Band) Error 110

Other Primary Measurement Functions 112

Frequency and Period Measurement Errors 112

DC Current Measurements 112

Capacitance Measurements 113

Temperature Measurements 115

Probe Type Choice 115

2–Wire vs. 4–Wire Measurements 115

Auto Zero On/Off 116

Integration 116

Offset Compensation 116

NULL Reading: 116

High-Speed Measurements 117

Making High–Speed AC Measurements 117

Making High–Speed dc and Resistance Measurements 118

Contents

Other Sources of Measurement Error 119

Settling Time Effects 119

Loading Errors (ac volts) 119

Measurements Below Full Scale 120

High–Voltage Self–Heating Errors 120

AC Current Measurement Errors (Burden Voltage) 120

Low–Level Measurement Errors 120

Common Mode Errors 122

Leakage Current Errors 122

34410A/11A/L4411A User’s Guide 39

Page 34

Contents

5 Specifications 123

DC Characteristics 125

AC Characteristics 128

Frequency and Period Characteristics 130

Capacitance Characteristics 132

Temperature Characteristics 132

Additional 34411A Specifications 133

Measurement and System Speeds 134

System Speeds 135

Data From Memory 136

General Specifications 136

Dimensions 138

To C al c u l a t e To t a l Me a s ur em e nt E rr o r 139

Interpreting Accuracy Specifications 141

Transfer Accuracy 141

24–Hour Accuracy 141

90–Day and 1–Year Accuracy 141

Temperature Coefficients 141

Configuring for Highest Accuracy Measurements 142

DC Voltage, DC Current, and Resistance Measurements: 142

AC Voltage and AC Current Measurements: 142

Frequency and Period Measurements: 142

6 Appendix: Firmware and Driver Updates 143

Downloading the Update Utility and Firmware 144

Downloading and Installing the Firmware Update 144

Downloading IVI-COM Driver Updates 147

40 34410A/11A/L4411A User’s Guide

Page 35

Agilent 34410A/11A/L4411A 6½ Digit Multimeter

User’s Guide

2

Features and Functions

SCPI Commands 37

Front Panel Features (34410A/11A) 38

Front Panel Display 38

Displayed Messages 38

Self–Guiding Menus 38

Annunciators 40

Second Display Options 41

Turn i n g t h e D i s pl a y Off 41

Front–Panel Display Shortcuts 42

Front Panel Alphanumeric Character Entry 43

Front Panel Measurement Configuration Menus 44

Configuring DC Voltage and DC Current Measurements 44

Configuring AC Voltage and Current Measurements 45

Configuring Resistance Measurements 45

Configuring Frequency and Period Measurements 46

Configuring Temperature Measurements 46

Configuring Capacitance Measurements 47

Continuity and Diode Tests 47

Advanced Configuration Options 48

Multimeter State Storage 48

Accessing Reading Memory 49

Front/Rear Input Terminal Switching (34410A/11A) 49

Multimeter Reset 50

DC Measurements 51

Integration Time and Resolution 51

DC Input Impedance 53

AC Measurements 54

AC Filter 54

Agilent Technologies

35

Page 36

2Features and Functions

Gate Time 55

Auto Zero 56

Ranging 57

Null Measurements 59

Miscellaneous Configuration Settings 60

Radix Character (34410A/11A) 60

Thousands Separator (34410A/11A) 60

Beeper (34410A/11A) 61

Math Functions 62

dB Measurements 63

dBm Measurements 64

Using Statistics 65

Limit Testing 66

Triggering the Multimeter 67

Selecting a Trigger Source 67

Auto Triggering (34410A/11A) 68

Single Triggering (34410A/11A) 68

Reading Hold (34410A/11A) 69

Immediate Triggering 69

Software (Bus) Triggering 70

Internal (Level) Triggering (34411A/L4411A) 70

Number of Samples per Trigger 71

Number of Pre-Trigger Samples (34411A/L4411A) 71

Trigger Delay 72

Automatic Trigger Delay 73

External Triggering 75

Trigger Slope 77

Data Logging 78

System-Related Operations 82

Self–Test 82

Error Conditions 83

Reading the Error Queue 84

Calibration 84

Power-On and Reset State 85

36 34410A/11A/L4411A User’s Guide

Page 37

SCPI Commands

The Agilent 34410A/11A/L4411A complies with the syntax rules and

conventions of SCPI (Standard Commands for Programmable Instruments).

Features and Functions 2

NOTE

For complete SCPI command syntax information, refer to the Agilent 34410A/11A/L4411A

Programmer’s Reference Help. This is a standard Windows help system, provided on the

Agilent 34410A/11A/L4411A Product Reference CD-ROM that came with your instrument.

SCPI Language Conventions. Throughout this guide, the following

conventions are used for SCPI command syntax for remote interface

programming:

• Braces ( { } ) enclose the parameter choices for a given command string.

The braces are not sent with the command string.

• A vertical bar ( | ) separates multiple parameter choices for a given

command string.

• Triangle brackets ( < > ) indicate that you must specify a value for the

enclosed parameter. The brackets are not sent with the command string.

• Some parameters are enclosed in square brackets ( [ ] ). This indicates that

the parameter is optional and can be omitted. The brackets are not sent

with the command string. If you do not specify a value for an optional

parameter, the instrument chooses a default value.

SCPI Language Version. You can determine the SCPI version to which your

instrument adheres by sending a command from the remote interface.

• You can query the SCPI version from the remote interface only.

•

Remote Interface Operation: The SYSTem:VERSion? query returns the

SCPI version in the form “YYYY.V”, where “YYYY” represents the year of

the version, and “V” represents a version number for that year (for example,

1994.0).

34410A/11A/L4411A User’s Guide 37

Page 38

2Features and Functions

Front Panel Features (34410A/11A)

Front Panel Display

The Agilent 34410A/11A provides a two–line, alphanumeric display, with

annunciators to indicate certain non–default instrument states.

Displayed Messages

While taking measurements, the primary display line shows the current

reading, with units (for example: “-0.001,02 VDC”). For some functions the

second display line can be enabled to display a secondary measurement.

When a menu is open (for example, to configure a measurement), the primary

display line indicates the menu, or the parameter to be set or selected, while

the second line displays the selections, or a value to be set.

The second line also displays momentary messages to convey instrument state

changes.

Self–Guiding Menus

The Agilent 34410A/11A provides context–sensitive menus to configure

measurements and other functions. The following general guidelines apply to

menu operations.

• In this guide, “navigation keypad” refers to the , , , and keys,

and the key.

• Several keys (or shifted key sequences) open a menu. These include:

• to configure the currently selected measurement function.

• to select a secondary measurement for the second display line.

• to set up and use the data logger function.

• to turn on and select the math functions.

• to return the multimeter to auto trigger mode,

enable reading hold, or select various triggering options.

• to configure utility options or the remote interface.

• to reset the multimeter to its reset state (equivalent

to the *RST command in SCPI).

• When you press , the Shift annunciator is lit. It toggles on and off.

38 34410A/11A/L4411A User’s Guide

Page 39

Features and Functions 2

• If the multimeter is in the remote interface mode (Remote annunciator is

lit), pressing

operation.

• Once you have entered a menu, use the or keys to view and select a

menu item from those displayed on the second line.

The selected (or default) item is displayed in full brightness (for example,

dBM in the menu above). All other choices are displayed in half brightness

(OFF, dB, or STATS above).

The menu selections scroll, but do not wrap. Arrows indicate additional

selections, if any, to the left or right. In the example above, the arrow

indicates at least one more selection to the right of STATS.

• To confirm a selection, press the key, which also takes you to the next

menu level. If you are already at the last level in the menu, pressing

exits the menu.

(Local) once returns the multimeter to local (front panel)

• To review a menu configuration, press repeatedly to view, in order,

the current selections, and then exit the menu.

• To step through the remaining menu choices after making the desired

selections, hold down the key.

• The key that you used to enter the menu (for example, or ),

serves to confirm selections and advance in the menu exactly like the

key.

• To exit a menu before completing its sequence, press . If you have made

changes, you are prompted whether to save or discard them.

NOTE

34410A/11A/L4411A User’s Guide 39

In some menus, the second display is used to enter a number or text. See“Front Panel

Alphanumeric Character Entry” on page 43 for further information.

In a few cases, long strings are displayed in a menu (for example the USB ID string) that

require scrolling with the and keys in order to view the entire string.

Page 40

2Features and Functions

Annunciators

There are several annunciators, mostly in a line at the top of the display. Each

annunciator lights to indicate a particular non–default meter state:

•

* A measurement is in progress (the “sample annunciator”).

• Hi–Z For DC voltage measurements in the 100 mV, 1 V or 10 V ranges, an

input impedance of >10 GΩ is configured.

• OComp For resistance measurements in the 100 Ω, 1 kΩ and 10 kΩ ranges,

offset compensation is enabled.

• ManRng For the selected measurement function, a manual range is

selected (autoranging is off).

• Tr i g Triggering is enabled. The meter is in the “wait–for–trigger” state.

• Hold The reading hold function is enabled.

• Remote The multimeter is operating in the remote interface mode.

• Error A hardware error or remote interface error has been detected, and a

message is in the error queue.

• Null The null feature is enabled for the present measurement function.

• Shift The key has been pressed (toggles on and off).

• Math Either the dB or dBm math function is enabled.

• Stats The statistics math function is enabled.

• Limits The limit test math function is enabled.

• Rear The Front/Rear switch is set to Rear and the rear set of input terminals

is connected internally to make measurements.

• 4W A four–wire resistance or temperature function is selected.

• The continuity function is selected.

• The diode test function is selected.

40 34410A/11A/L4411A User’s Guide

Page 41

Features and Functions 2

Second Display Options

Many measurement functions allow a secondary measurement to be displayed

simultaneously on the second display line:

Primary Function Second Display Function

DC V, DC I, AC V, AC I Peak–to–Peak value

Freq AC Voltage

Temp Raw Resistance**

*

*ac voltage of the input waveform

**actual raw resistance measured across temperature probe and leads

• Front Panel Operation: Press

2ND DISPLAY > PK-TO-PK (Where primary function is voltage or current.)

Once the second display is enabled, you can scroll through all second

display items, including STATS or LIMITS if these functions are enabled.

• Remote Interface Operation: The following command selects the measurement

or math function to be displayed on the second display line. The <feed>

parameter is a quoted ASCII string designating the function to be displayed,

such as VOLTage:PTPeak.

DISPlay:WINDow2:TEXT:FEED <feed>

The following query returns the currently selected

quoted ASCII string:

DISPlay:WINDow2:TEXT:FEED?

Refer to the Agilent 34410A/11A/L4411A Programmer’s Reference Help for

a complete description and syntax for these commands.

<feed>

parameter, as a

Turning the Display Off

This feature is available from the remote interface only.

For security reasons, you may want to disable the front panel display. When

disabled, the entire front panel display (except for the Error and Remote

annunciators) goes dark.

• Remote Interface Operation: The following command turns off the display:

DISPlay OFF

The following command queries the display setting:

DISPlay?

The query returns a “0” (OFF) or “1” (ON).

Refer to the Agilent 34410A/11A/L4411A Programmer’s Reference Help for

a complete description and syntax for these commands.

34410A/11A/L4411A User’s Guide 41

Page 42

2Features and Functions

Front–Panel Display Shortcuts

Direct front–panel shortcuts are provided for three commonly used display

functions: ranging, digit masking, and integration time. These shortcuts are

available only when you are not in a menu.

Ranging. The meter range can be set directly from the navigation keypad.

• To manually change the range, press or . The

lights, and the selected range (for example, 100mV RANGE) is briefly displayed

on the second line.

• To toggle between the selected manual range and autoranging, press

Note: This is a dual–function key, not a shifted key. Pressing when in

a menu will exit the menu.

Digit Masking. The navigation keypad provides a shortcut to mask (change

the number of digits displayed) the reading on the main display.

• To enable digit masking for the selected measurement function, press

(3.5, 4.5, 5.5, 6.5 and AUTO). Select the desired setting (use the keys)

and press .

• Masking digits only affects what is displayed. It does not affect

measurement speed or accuracy.

ManRng annunciator

. The ManRng annunciator toggles on or off, as appropriate.

or . DIGIT MASK will be displayed, along with a list of choices

Integration Time (Bandwidth, Gate Time). Four measurement functions allow

you to select the integration time: dc voltage, dc current, resistance, and

temperature. The ac voltage and ac current measurements allow you to select

the ac signal filter (bandwidth). The frequency/period function allows you to

select gate time. The navigation keypad provides a shortcut for quickly

changing these settings.

• If the multimeter is configured to take the measurement using an

integration time in NPLCs, press or to increase or decrease the

integration time setting and display the new setting briefly. You can scroll

through the entire range of integration time settings:

Agilent 34410A, PLCs: 0.006, 0.02, 0.06, 0.2, 1, 2, 10 and 100

Agilent 34411A/L4411A, PLCs: 0.001, 0.002, 0.006, 0.02, 0.06, 0.2, 1, 2, 10, 100

42 34410A/11A/L4411A User’s Guide

Page 43

Features and Functions 2

• If the multimeter is configured to take the measurement using an aperture

integration time, press or to display APERTURE, with the current setting

on the second line (for example, 101.005mSEC). You can then use the

navigation keypad to change the aperture setting. The and keys

have their usual functions.

• If either the ac voltage or ac current function is selected, press or to

increase or decrease the bandwidth setting, and briefly display the new

setting on the second line. You can scroll through the three available

bandwidth settings: 3 HZ : SLOW, 20 HZ : MEDIUM, or 200 HZ : FAST.

• If the frequency/period measurement function is selected, pressing or

during front panel measurement operations will increase or decrease

the gate time setting, and briefly display the new setting on the second

display line (for example, if the setting was 0.1 GATE TIME, the display will

show 0.01 GATE TIME when you press ). Repeated use of or will

scroll through the selection of gate time settings in seconds (0.001 GATE TIME,

0.01 GATE TIME, 0.1 GATE TIME, and 1 GATE TIME).

Front Panel Alphanumeric Character Entry

When you are in certain menus, particularly the utility menus, you may need

to manually enter a number or alphanumeric string on the second display line.

• To enter a number or character, press or to select the displayed

character (digit or letter) you wish to edit. The selected character will flash

to indicate it can be edited. Use the and keys to modify a digit (from

0 to 9) or a letter (from A to Z).

• To quickly enter large numbers, you may press to scroll over to the most

significant digit allowed and/or add leading zeros. For non–zero

floating–point entries, you may also press to scroll to the magnitude

prefix (for example, u, m, k, M), then use the and keys to change the

numerical entry.

Arrow annunciators on the second display line will indicate if there are

editable characters left or right of the one selected.

34410A/11A/L4411A User’s Guide 43

Page 44

2Features and Functions

Front Panel Measurement Configuration Menus

Each measurement function is configured separately, except for Ω 2W and

Ω 4W (which are partially inter–dependent), and frequency and period,

(which share a configuration menu). The configuration settings (for example,

integration, and range) for each measurement function are retained when

switching between functions.

• To enter the configuration menu for any selected measurement function, press

. The menus are context–sensitive; only the options applicable to the

selected function will appear.

• When digit masking is enabled (see “Digit Masking.” on page 42) the DIGIT

MASK submenu will appear before other configuration choices.

• For further information, see “Advanced Configuration Options” on

page 48.

Configuring DC Voltage and DC Current Measurements

For dc voltage and dc current measurements, the menu selections are:

INTEGRATION, RANGE, AUTO ZERO, NULL and NULL VALUE. For dc voltage

measurements only, you can also configure INPUT Z.

• INTEGRATION: Allows you to set the integration time for the measurement in

two ways; in power–line cycles (select NPLC) or in seconds (select APERTURE).

• RANGE: Allows you to select a fixed range (select MANUAL), or let the

multimeter automatically select the range using the autoranging feature

(select AUTO).

• INPUT Z: Allows you to select an input impedance of 10 MΩ (select 10 M) or

>10 GΩ (select HI–Z) for the 100 mVdc, 1 Vdc and 10 Vdc ranges only.

• AUTO ZERO: Allows you to enable for all readings (select ON), enable for one

reading (select ONCE), or disable (select OFF) the auto zero feature, which

subtracts a zero reading from each measurement.

• NULL: Allows you to enable (ON) or disable (OFF) the null measurement

feature, which measures the difference between a stored null value and the

input signal.

• NULL VALUE: Allows you to view and edit the null value (if enabled).

44 34410A/11A/L4411A User’s Guide

Page 45

Features and Functions 2

Configuring AC Voltage and Current Measurements

For ac voltage and ac current measurements, your menu selections are:

AC FILTER, RANGE, NULL and NULL VALUE.

• AC FILTER: Allows you to select one of three choices (3 HZ : SLOW, 20 HZ :

MEDIUM, 200 HZ : FAST). The ac filter allows you to trade off low–frequency

bandwidth versus ac settling time.

• RANGE: Allows you to let the multimeter automatically select the range using

the autoranging feature (select AUTO), or you may select a fixed range

(select MANUAL).

• NULL: Allows you to enable (ON) or disable (OFF) the null measurement

feature, which measures the difference between a stored null value and the

input signal.

• NULL VALUE: Allows you to view and edit the null value (if enabled).

Configuring Resistance Measurements

For 2–wire and 4–wire resistance measurements, your menu selections are:

INTEGRATION, RANGE, OFFSET COMP, AUTO ZERO, NULL and NULL VALUE.

• INTEGRATION: Allows you to set the integration time for the measurement in

two ways; in power–line cycles (NPLC) or in seconds (APERTURE).

• RANGE: Allows you to let the multimeter automatically select the range using

the autoranging feature (select AUTO), or you may select a fixed range

(select MANUAL).

• OFFSET COMP: Allows you to enable (ON) or disable (OFF) the offset

compensation feature. With offset compensation enabled, the multimeter

makes a normal resistance measurement first, followed by a second

measurement to determine any offset voltage in the input circuitry. The

resultant displayed measurement corrects for this offset. Enabling offset

compensation increases measurement time.

• AUTO ZERO: Allows you to enable for all readings (ON), enable for one reading

(ONCE), or disable (OFF) the auto zero feature, which subtracts a subsequent

zero reading from each measurement.

• NULL: Allows you to enable (ON) or disable (OFF) the null measurement

feature, which measures the difference between a stored null value and the

input signal.

• NULL VALUE: Allows you to view and edit the null value (if enabled).

34410A/11A/L4411A User’s Guide 45

Page 46

2Features and Functions

Configuring Frequency and Period Measurements

For frequency and period measurements, your menu selections are: CONFIGURE,

GATE TIME, RANGE, AC FILTER, NULL and NULL VALUE.

• CONFIGURE: Allows you to select either FREQUENCY or PERIOD as the primary

measurement.

• GATE TIME: Allows you to select one of four choices (0.001, 0.01, 0.1, or 1) for

gate time, in seconds.

• RANGE: Allows you to let the multimeter automatically select the range using

the autoranging feature (select AUTO), or you may select a fixed range

(select MANUAL).

• AC FILTER: Allows you to select from three choices (3 HZ : SLOW,

20 HZ : MEDIUM, or 200 HZ : FAST). The ac filter allows you to trade off

low–frequency bandwidth versus ac settling time.

• NULL: Allows you to enable (ON) or disable (OFF) the null measurement

feature, which measures the difference between a stored null value and the

input signal.

• NULL VALUE: Allows you to view and edit the null value (if enabled).

Configuring Temperature Measurements

For temperature measurements, your menu selections are: PROBE TYPE, OFFSET

COMP, AUTO ZERO, INTEGRATION, NULL, NULL VALUE, and UNITS.

• PROBE TYPE: Allows you to select from four choices (RTD–4W, RTD–2W,

THERMISTOR–2W, or THERMISTOR–4W) of temperature probe type.

• OFFSET COMP (for RTD probes only): Allows you to enable (ON) or disable

(OFF) the offset compensation feature. With offset compensation enabled,

the multimeter makes a normal temperature measurement first, followed by

a second measurement to determine any offset voltage in the input

circuitry. The resultant displayed measurement corrects for this offset.

Enabling offset compensation increases measurement time.

• AUTO ZERO: Allows you to enable (ON) or disable (OFF) the auto zero feature

for 2–wire temperature measurements. This feature subtracts a subsequent

zero reading from each measurement.

Note that 4–wire temperature measurements are automatically made

with auto zero always on.

• INTEGRATION: Allows you to set the integration time for the measurement in

two ways; in power–line cycles (NPLC) or in seconds (APERTURE).

46 34410A/11A/L4411A User’s Guide

Page 47

Features and Functions 2

• NULL: Allows you to enable (ON) or disable (OFF) the null measurement

feature, which measures the difference between a stored null value and the

input signal.

• NULL VALUE: Allows you to view and edit the null value (if enabled).

• UNITS: Allows you to select the temperature scale: Celsius (select C),

Fahrenheit (select F), or Kelvin (select K).

Configuring Capacitance Measurements

For capacitance measurements, your configuration menu choices are: RANGE,

NULL and NULL VALUE.

• RANGE: Allows you to let the multimeter automatically select the range using

the autoranging feature (select AUTO), or you may select a fixed range

(select MANUAL).

• NULL: Allows you to enable (ON) or disable (OFF) the null measurement

feature, which measures the difference between a stored null value and the

input signal.

• NULL VALUE: Allows you to view and edit the null value (if enabled).

Continuity and Diode Tests

There are no parameters to configure, nor any menus for these functions.

• Continuity Test. The range and resolution are fixed for continuity tests.

• The range is 1 kΩ (a 2-wire resistance measurement).

• The meter beeps (even if beep is disabled) for each measurement that is

less than or equal to the continuity threshold (which is 10 Ω), and the

actual resistance reading is displayed on the front panel.

• From 10 Ω to 1.2 kΩ the meter displays the actual resistance reading

with no beep. If the reading exceeds 1.2 kΩ, the meter displays "OPEN" on

the front panel (no beep).

• Diode Test. The range and resolution are fixed for diode tests.

• The range is 1 Vdc (with a 1 mA current source output).

• The voltage is displayed on the front panel if it is in the 0 to 1.2 volt

range. The meter beeps when the signal transitions to the 0.3 to 0.8 volt

threshold (unless beep is disabled). If the signal is greater than 1.2 volts,

"OPEN" is displayed on the front panel.

34410A/11A/L4411A User’s Guide 47

Page 48

2Features and Functions

Advanced Configuration Options

NOTE

The Remote Interface Operation segments within the following topics describes how the

instrument feature is used/accessed from a (remote) programming environment. For the

L4411A, this represents the only method of accessing the instrument. See the L4411A

Getting Started Guide for details.

Multimeter State Storage

The present multimeter state, including all settings for measurement

configuration, math operations, triggering operations, system operations and

I/O configuration, can be saved in one of five non–volatile stored states and

later recalled. State 0 (POWER_DOWN) retains the multimeter configuration at

power down. States 1 – 4 (STATE_1, STATE_2, STATE_3, STATE_4) are available for

storing other configurations.

• Front Panel Operation: Press to open the utility menu.

• To store the present multimeter state (for example, to STATE_1):

UTILITY MENU > STORE/RECALL > STORE > STORE STATE > 1: STATE_1 > CHANGE NAME

Use the navigation keypad to enter a new name (up to 12 characters), or

just press to store with the default name.

• To recall any of five stored states (for example: STATE_1):

UTILITY MENU > STORE/RECALL > RECALL > RECALL STATE > 1: STATE_1

• To delete a state you have stored (for example: STATE_1):

UTILITY MENU > STORE/RECALL > DELETE > DELETE STATE > 1: STATE_1

• To rename a state you have stored (for example: STATE_1):

UTILITY MENU > STORE/RECALL > RENAME > RENAME STATE > 1: STATE_1 > CHANGE NAME

Use the navigation keypad to enter a new name (up to 12 characters), or

just press to store with the current name.

• To select any previously stored state (0 – 4) as the power–on default

state (for example: STATE_1):

UTILITY MENU > STORE/RECALL > PWR-ON > PWR-ON AUTO > ON > PWR-ON STATE > 1: STATE_1

48 34410A/11A/L4411A User’s Guide

Page 49

• Remote Interface Operation: Refer to the MEMory command subsystem in the

Agilent 34410A/11A/L4411A Programmer’s Reference Help for a complete

description and syntax of the commands that store, recall, and name

multimeter states from the remote interface.

Accessing Reading Memory

Reading memory is accessed directly from the remote interface only.

The multimeter’s reading memory is a first–in–first–out (FIFO) buffer holding

up to 50,000 readings (34410A) or 1 million readings (34411A/L4411A). The

oldest readings are preserved.

• Remote Interface Operation: The following command transfers readings stored

in non–volatile memory into the multimeter’s output buffer, from where

you can read them into your compu ter:

FETCh?

The following command will obtain whatever readings are present in

NVMEM, and erase them as they are read:

R?

Features and Functions 2

Refer to the Agilent 34410A/11A/L4411A Programmer’s Reference Help for

a complete description and syntax for these commands.

Front/Rear Input Terminal Switching (34410A/11A)

• Front Panel Operation: The Front/Rear switch manually selects the set of input

terminals (front or rear) that is connected internally for measurements.

Both sets are equivalent and include Sense (LO and HI), Input (LO and HI), and

Current (I) terminals. The Rear annunciator is lit when the rear inputs are

selected. See “The Front Panel at a Glance (34410A/11A)” on page 8, for the

location of the Front/Rear switch. The Front/Rear switch has no effect on the

Ext Trig or VM Comp connectors.

WARNING

34410A/11A/L4411A User’s Guide 49

Do not change the position of the Front/Rear switch while signals are present on either

the front or rear set of terminals. Switching while high voltages or currents are present

may cause instrument damage, and may increase the risk of electric shock.

Page 50

2Features and Functions

• Remote Interface Operation: The Front/Rear switch is manually switchable only,

and cannot be controlled from the remote interface. The following query

returns the current switch setting:

ROUTe:TERMinals?

The query returns either “FRON” or “REAR”

Multimeter Reset

The reset function resets most multimeter settings to their factory settings,

except if the power–on state has been manually set to a stored state (see

“Multimeter State Storage” on page 48). The reset function is faster than

cycling power because the power–on self tests are omitted.

• Certain settings such as I/O addresses are stored in non–volatile memory,

and are not affected by a reset.

• Refer to “Power-On and Reset State” on page 85 for a complete listing of the

settings affected by a (front panel or remote interface) reset command.

• Front Panel Operation: To reset the multimeter, press . RESET

DMM is displayed, along with the options NO (default) and YES. Select YES to

reset the multimeter.

• Remote Interface Operation: The following commands reset the multimeter to

the instrument reset state:

SYSTem:PRESet

*RST

Refer to the Agilent 34410A/11A/L4411A Programmer’s Reference Help for

a complete description and syntax for these commands.

50 34410A/11A/L4411A User’s Guide

Page 51

DC Measurements

Integration Time and Resolution

For dc voltage, dc current, resistance, and temperature measurements, the

multimeter provides two ways to set integration time, both of which affect the

measurement resolution. These are in the number of power–line cycles

(NPLCs) and aperture (settable in seconds).

NPLC mode. Using NPLCs sets the number of power–line cycles during

which the multimeter’s analog–to–digital (A/D) converter samples the input

signal for a measurement. The multimeter automatically detects the AC line

frequency, using it and the NPLC selection to set integration time. Use a larger

NPLC value for better resolution. Use a smaller value for faster measurements.

To obt a in normal mode (line–frequency noise) rejection, you must select NPLC

mode, with an integral number of power–line cycles (for example, 1, 10, or 100

NPLC). The following table shows the resulting resolution for each integration

time value (in power–line cycles) selected.

Integration Time Resolution

0.001 PLC* 30 ppm x Range

0.002 PLC

0.006 PLC 6.0 ppm x Range

0.02 PLC 3.0 ppm x Range

0.06 PLC 1.5 ppm x Range

0.2 PLC 0.7 ppm x Range

1 PLC (default) 0.3 ppm x Range

2 PLC 0.2 ppm x Range

10 PLC 0.1 ppm x Range

100 PLC 0.03 ppm x Range

* 15 ppm x Range

*Model 34411A/L4411A

Features and Functions 2

• Front Panel Operation: Select a dc measurement function (DC V, DC I, Ω 2W,

Ω 4W or Te m p ). Press as required:

...

> INTEGRATION > NPLC

Select the desired NPLC value: 0.006, 0.02, 0.06, 0.2, 1, 2, 10 or 100. (The

34411A also allows you to select 0.001 or 0.002.) Then step through or exit the

configuration menu.

34410A/11A/L4411A User’s Guide 51

Page 52

2Features and Functions

• Remote Interface Operation: The following commands set the integration time

in NPLC:

[SENSe:]VOLTage[:DC]:NPLC {<

[SENSe:]CURRent[:DC]:NPLC {<

[SENSe:]RESistance:NPLC {<

[SENSe:]FRESistance:NPLC {<

[SENSe:]TEMPerature:NPLC {<

Each of these commands also has a query form.

Refer to the Agilent 34410A/11A/L4411A Programmer’s Reference Help for

a complete description and syntax for these commands.

Aperture mode. Aperture is the period, measured in seconds, during which

the multimeter’s analog–to–digital (A/D) converter samples the input signal

for a measurement. A longer aperture yields better resolution; a shorter

aperture provides for faster measurements. This mode allows the user to set a

specific integration time, not based on power–line frequency. Values range

from 100 µs to 1 second for the 34410A, and from 20 µs to 1 second for the

34411A/L4411A.

• To allow for normal mode (line frequency noise) rejection, select the NPLC

option for INTEGRATION, with an integral number of NPLCs. Use the APERTURE

method only if you need precise control over the multimeter’s integration

time, in seconds.

PLCs

>>MIN>MAX>DEF}

PLCs

>>MIN>MAX>DEF}

PLCs

>>MIN>MAX>DEF}

PLCs

>>MIN>MAX>DEF}

PLCs

>>MIN>MAX>DEF}

• Front Panel Operation: Select a dc measurement function (DC V, DC I, Ω 2W,

Ω 4W or Te m p ). Press as required:

...

> INTEGRATION > APERTURE

Use the navigation keypad to set the desired aperture value, and press .

Then step through or exit the configuration menu.

• Remote Interface Operation: The following commands set the aperture value,

in seconds:

[SENSe:]VOLTage[:DC]:APERture {<

[SENSe:]CURRent[:DC]:APERture {<

[SENSe:]RESistance:APERture {<

[SENSe:]FRESistance:APERture {<

[SENSe:]TEMPerature:APERture {<

Each of these commands also has a query form.

52 34410A/11A/L4411A User’s Guide

seconds

seconds

seconds

seconds

seconds

>>MIN>MAX>DEF}

>>MIN>MAX>DEF}

>>MIN>MAX>DEF}

>>MIN>MAX>DEF}

>>MIN>MAX>DEF}

Page 53

Features and Functions 2

The following command (similar queries for current, resistance and

temperature) returns whether aperture mode is enabled:

[SENSe:]VOLTage[:DC]:APERture:ENABled?

This query returns a “0” (disabled) or “1” (enabled).

Refer to the Agilent 34410A/11A/L4411A Programmer’s Reference Help for

a complete description and syntax for these commands.

DC Input Impedance

Applies to dc voltage measurements only.

The default setting for the multimeter’s input impedance is fixed at 10 MΩ for

all dc voltage ranges, to minimize noise pickup. To reduce the effects of

measurement loading errors when making low–voltage measurements, this