Service Guide

Publication Number 33250-90011 (order as 33250-90100 manual set)

Edition 2, March 2003

© Copyright Agilent Technologies, Inc. 2000, 2003

For Safety information, Warranties, and Regulatory information,

see the pages following the Index.

Agilent 33250A

80 MHz Function /

Arbitrary Waveform Generator

Agilent 33250A at a Glance

The Agilent Technologies 33250A is a high-performance 80 MHz

synthesized function generator with built-in arbitrary waveform and

pulse capabilities. Its combination of bench-top and system features

makes this function generator a versatile solution for your testing

requirements now and in the future.

Convenient bench-top features

• 10 standard waveforms

• Built-in 12-bit 200 MSa/s arbitrary waveform capability

• Precise pulse waveform capabilities with adjustable edge time

• LCD color display provides numeric and graphical views

• Easy-to-use knob and numeric keypad

• Instrument state storage with user-defined names

• Portable, ruggedized case with non-skid feet

Flexible system features

• Four downloadable 64K-point arbitrary waveform memories

• GPIB (IEEE-488) interface and RS-232 interface are standard

• SCPI (Standard Commands for Programmable Instruments) compatibility

Note: Unless otherwise indicated, this manual applies to all Serial Numbers.

2

The Front Panel at a Glance

1 Graph Mode/Local Key

2 Menu Operation Softkeys

3 Waveform Selection Keys

4 Knob

5 Modulation/Sweep/Burst Menus

6 State Storage Menu

Note: To get context-sensitive help on any front-panel key or menu softkey,

press and hold down that key.

7 Utility Menu

8 Instrument Help Topic Menu

9 Output Enable/Disable Key

10 Manual Trigger Key (used for

Sweep and Burst only)

11

Cursor Keys

3

The Front-Panel Display at a Glance

Menu Mode

Numeric

Readout

Mode

Information

Trigger

Information

Softkey Labels

Units

Output

Status

Graph Mode

To enter the Graph Mode, press the key.

Parameter

Name

Parameter

Value

Display

Icon

Signal

Ground

The softkey colors correspond

to the waveform parameters.

4

Front-Panel Number Entry

You can enter numbers from the front-panel using one of two methods.

Use the knob and arrow keys to modify the displayed number.

+

Use the numeric keypad and menu softkeys to select the units.

5

The Rear Panel at a Glance

1

External 10 MHz Reference Input Terminal

2

Internal 10 MHz Reference Output Terminal

3 RS-232 Interface Connector

4 External Modulation Input Terminal

Use the menu to:

• Select the GPIB or RS-232 interface (see chapter 2 in User’s Guide).

• Select the GPIB address (see chapter 2 in User’s Guide).

• Set the RS-232 baud rate, parity, and handshake (see chapter 2 in User’s Guide).

5

Input: External Trig/FSK/ Burst Gate

Output: Trigger Output

6 GPIB Interface Connector

7 Chassis Ground

WARNING For protection from electrical shock, the power cord ground must not be

defeated. If only a two-contact electrical outlet is available, connect the

instrument’s chassis ground screw (see above) to a good earth ground.

6

In This Book

Specifications Chapter 1 lists the function generator’s specifications.

Quick Start Chapter 2 prepares the function generator for use and

helps you get familiar with a few of its front-panel features.

Front-Panel Menu Operation Chapter 3 introduces you to the frontpanel menu and describes some of the function generator’s menu features.

Calibration Procedures Chapter 4 provides calibration, verification,

and adjustment procedures for the function generator.

Theory of Operation Chapter 5 describes the block diagram and

circuit-level theory related to the operation of the function generator.

Service Chapter 6 provides guidelines for returning your function

generator to Agilent Technologies for servicing, or for servicing it

yourself.

Replaceable Parts Chapter 7 contains a detailed parts list of the

function generator.

Backdating Chapter 8 describes the differences between this manual

and older issues of this manual.

Schematics Chapter 9 contains the function generator’s schematics

and component locator drawings.

If you have questions relating to the operation of the Agilent 33250A,

call 1-800-452-4844 in the United States, or contact your nearest Agilent

Technologies Office.

If your 33250A fails within three years of purchase, Agilent will either

repair or replace it free of charge. Call 1-877-447-7278 in the United

States (and ask for “Agilent Express”) or contact your local Agilent

Technologies Office.

7

8

Contents

Chapter 1 Specifications 13

Chapter 2 Quick Start

To Prepare the Function Generator for Use 21

To Adjust the Carrying Handle 22

To Set the Output Frequency 23

To Set the Output Amplitude 24

To Set a DC Offset Voltage 26

To Set the Duty Cycle 27

To Configure a Pulse Waveform 28

To View a Waveform Graph 29

To Output a Stored Arbitrary Waveform 30

To Use the Built-In Help System 31

To Rack Mount the Function Generator 33

Chapter 3 Front-Panel Menu Operation

4

Front-Panel Menu Reference 37

To Reset the Function Generator 39

To Select the Output Termination 39

To Read the Calibration Information 40

To Unsecure and Secure for Calibration 41

To Store the Instrument State 44

To Configure the Remote Interface 45

Chapter 4 Calibration Procedures

Agilent Technologies Calibration Services 49

Calibration Interval 50

Adjustment is Recommended 50

Time Required for Calibration 51

Automating Calibration Procedures 52

Recommended Test Equipment 53

Test Considerations 54

Performance Verification Tests 55

Internal Timebase Verification 60

AC Amplitude (high-impedance) Verification 61

Low Frequency Flatness Verification 62

0 dB Range Flatness Verification 63

+10 dB Range Flatness Verification 65

+20 dB Range Flatness Verification 66

Contents

9

Contents

Chapter 4 Calibration Procedures (continued)

Calibration Security 68

Calibration Message 70

Calibration Count 70

General Calibration/Adjustment Procedure 71

Aborting a Calibration in Progress 72

Sequence of Adjustments 72

Self-Test 73

Frequency (Internal Timebase) Adjustment 74

Internal ADC Adjustment 75

Output Impedance Adjustment 76

AC Amplitude (high-impedance) Adjustment 78

Low Frequency Flatness Adjustment 80

0 dB Range Flatness Adjustments 81

+10 dB Range Flatness Adjustments 83

+20 dB Range Flatness Adjustment 85

Pulse Width (Trailing Edge Delay) Adjustment 87

Pulse Edge Time Adjustment 88

Duty Cycle Adjustment 89

Output Amplifier Adjustment (Optional) 90

Calibration Errors 91

Contents

Chapter 5 Theory of Operation

Block Diagram 95

Main Power Supply 97

On-Board Power Supplies 98

Waveform DAC and Filters 100

Digital Waveform, Pulse, and Sync 101

Digital Waveform Translator 104

Amplitude Multiplier 106

Main Output Circuitry 107

System ADC 110

System DAC 112

10

Contents

Chapter 5 Theory of Operation (continued)

Synthesis IC 113

Timebase 115

Phase Locked Loops 116

Clock Divider 118

Trigger and Delay 120

Waveform RAM 122

Synchronous Multiplexer 123

Main Processor 124

Main Gate Array 125

DSP and Gateway 126

Earth-Referenced Logic 126

Front Panel 127

Chapter 6 Service

Operating Checklist 130

Types of Service Available 131

Repackaging for Shipment 132

Cleaning 132

Electrostatic Discharge (ESD) Precautions 133

Surface Mount Repair 133

Troubleshooting Hints 134

Self-Test Procedures 136

Disassembly 140

4

Contents

Chapter 7 Replaceable Parts

33250-66511 Main PC Assembly (A1) 153

33205-66502 Front-Panel PC Assembly (A2) 176

33250A Chassis Assembly 177

33250A Front-Panel Assembly 178

Manufacturer’s List 179

Chapter 8 Backdating 181

11

Contents

Contents

Chapter 9 Schematics

A1 Earth Referenced Communications Schematic 185

A1 Main Processor Schematic 186

A1 Main Gate Array Schematic 187

A1 Display Controller Schematic 188

A1 DSP Schematic 189

A1 Modulation Schematic 190

A1 System DAC Schematic 191

A1 Timebase Schematic 192

A1 Phase-Locked Loops Schematic 193

A1 Trigger Schematic 194

A1 Clock Divider and Control Schematic 195

A1 Synthesis IC Schematic 196

A1 Waveform Memory Schematic 197

A1 Synchronous Multiplexer Schematic 198

A1 Digital Waveform and Sync Schematic 199

A1 Variable-Edge Level Translation Schematic 200

A1 Waveform DAC, Filters, and Comparator Schematic 201

A1 Multiplier Schematic 202

A1 Main Output Circuitry Schematic 203

A1 Power Supply Schematic 204

A2 Keyboard Schematic 205

A2 Display Schematic 206

A1 Component Locator (top) 207

A1 Component Locator (bottom) 208

A2 Component Locator (top) 209

A2 Component Locator (bottom) 210

12

1

1

Specifications

1

Chapter 1 Specifications

Agilent 33250A Function / Arbitrary Waveform Generator

WAVEFORMS

Standard Waveforms: Sine, Square, Ramp,

Arbitrary Waveforms

Waveform Length: 1 to 64K points

Amplitude Resolution: 12 bits (including sign)

Repetition Rate: 1 µHz to 25 MHz

Sample Rate: 200 MSa/s

Filter Bandwidth: 50 MHz

Non-Volatile Memory:

Pulse, Noise, Sin(x)/x,

Exponential Rise,

Exponential Fall,

Negative Ramp,

Cardiac, DC Volts

Four 64K waveforms

FREQUENCY CHARACTERISTICS

Sine: 1 µHz to 80 MHz

Square: 1 µHz to 80 MHz

Ramp: 1 µHz to 1 MHz

Pulse: 500 µHz to 50 MHz

Noise (Gaussian): 50 MHz bandwidth

Arb: 1 µHz to 25 MHz

Resolution: 1 µHz;

Accuracy (1 year):

except pulse, 5 digits

2 ppm, 18°C to 28°C

3 ppm, 0°C to 55°C

SINEWAVE SPECTRAL PURITY

Harmonic Distortion

< 3 Vpp

DC to 1 MHz:

1 MHz to 5 MHz:

5 MHz to 80 MHz:

-60 dBc

-57 dBc

-37 dBc

2

> 3 Vpp

-55 dBc

-45 dBc

-30 dBc

SIGNAL CHARACTERISTICS

Square Wave

Rise / Fall Time: < 8 ns

Overshoot: < 5%

Asymmetry: 1% of period + 1 ns

Jitter (rms)

< 2 MHz: 0.01% + 525 ps

> 2 MHz: 0.1% + 75 ps

Duty Cycle

< 25 MHz: 20.0% to 80.0%

25 MHz to 50 MHz: 40.0% to 60.0%

50 MHz to 80 MHz: 50.0% (fixed)

Pulse

1

Period: 20.00 ns to 2000.0 s

Pulse Width: 8.0 ns to 1999.9 s

Variable Edge Time: 5.00 ns to 1.00 ms

Overshoot: < 5%

Jitter (rms): 100 ppm + 50 ps

Ramp

Linearity: < 0.1% of peak output

Symmetry: 0.0% to 100.0%

Arb

Minimum Edge Time: < 10 ns

Linearity: < 0.1% of peak output

Settling Time: < 50 ns to 0.5% of

Jitter (rms): 30 ppm + 2.5 ns

4

final value

Total Harmonic Distortion

DC to 20 kHz: < 0.2% + 0.1 mVrms

Spurious (non-harmonic)

DC to 1 MHz: -60 dBc

1 MHz to 20 MHz: -50 dBc

20 MHz to 80 MHz: -50 dBc + 6 dBc/octave

Phase Noise (30 kHz band)

10 MHz < -65 dBc (typical)

80 MHz < -47 dBc (typical)

3

14

_______________

1

A total of four waveforms can be stored.

2

Harmonic distortion at low amplitudes is limited by

a -70 dBm floor.

3

Spurious noise at low amplitudes is limited by

a -75 dBm floor.

4

Edge time decreased at higher frequency.

Chapter 1 Specifications

Agilent 33250A Function /Arbitrary Waveform Generator

1

OUTPUT CHARACTERISTICS

Amplitude (into 50Ω): 10 mVpp to 10 Vpp

Accuracy (at 1 kHz, >10 mVpp, Autorange On):

± 1% of setting ±1 mVpp

Flatness (sinewave relative to 1 kHz, Autorange On)

< 10 MHz: ± 1% (0.1 dB)

10 MHz to 50 MHz: ± 2% (0.2 dB)

50 MHz to 80 MHz ± 5% (0.4 dB)

Units: Vpp, Vrms, dBm,

Resolution: 0.1 mV or 4 digits

Offset (into 50Ω): ± 5 Vpk ac + dc

Accuracy: 1% of setting + 2 mV

Waveform Output

Impedance: 50Ω typical (fixed)

Isolation: 42 Vpk max. to Earth

Protection:

High Level, Low Level

+ 0.5% of amplitude

>10 MΩ (output disabled)

Short-circuit protected

Overload relay automatically disables

main output

1

3

MODULATION CHARACTERISTICS

AM Modulation

Carrier Waveforms:

Modulating Waveforms:

Modulating Frequency: 2 mHz to 20 kHz

Depth: 0.0% to 120.0%

Source: Internal / External

Sine, Square, Ramp, Arb

Sine, Square, Ramp,

Noise, Arb

BURST

2

Waveforms:

Frequency: 1 µHz to 80 MHz

Burst Count: 1 to 1,000,000 cycles,

Start / Stop Phase: -360

Internal Period: 1 ms to 500 s

Gate Source: External Trigger

Trigger Source: Single, External, or

Trigger Delay

N-Cycle, Infinite: 0.0 ns to 85.000 s

Sine, Square, Ramp,

Pulse, Noise, Arb

or Infinite

.0° to

Internal Rate

SWEEP

Waveforms:

Type: Linear or Logarithmic

Direction: Up or Down

Start F / Stop F: 100 µHz to 80 MHz

4

;

Sweep Time: 1 ms to 500 s

Trigger: Single, External, or

Marker: Falling edge of Sync

Sine, Square, Ramp, Arb

Internal

signal (programmable)

+360.0

5

°

4

FM Modulation

Carrier Waveforms:

Modulating Waveforms:

Modulating Frequency: 2 mHz to 20 kHz

Peak Deviation: DC to 80 MHz

Source: Internal / External

FSK

Carrier Waveforms:

Modulating Waveforms: 50% duty cycle square

Internal Rate: 2 mHz to 100 kHz

Frequency Range: 1 µHz to 80 MHz

Source: Internal / External

External Modulation Input

Voltage Range: ± 5V full scale

Input Impedance: 10 kΩ

Frequency: DC to 20 kHz

Sine, Square, Ramp, Arb

Sine, Square, Ramp,

Noise, Arb

Sine, Square, Ramp, Arb

_______________

1

Add 1/10th of output amplitude and offset

specification per °C for operation outside of

18 °C to 28 °C range (1-year specification).

2

20 mVpp to 20 Vpp into open-circuit load.

3

dB rounded to 1 digit. Instrument adheres

to “% ” specification.

4

Short-circuit protected to ground at all times.

5

Sine and square waveforms above 25 MHz are

allowed only with an “Infinite” burst count.

15

1

Chapter 1 Specifications

Agilent 33250A Function / Arbitrary Waveform Generator

SYSTEM CHARACTERISTICS

Configuration TImes (typical)

Function Change

Standard:

Pulse: 660 ms

Built-In Arb:

Frequency Change: 24 ms

Amplitude Change: 50 ms

Offset Change: 50 ms

Select User Arb:

Modulation Change: < 200 ms

Arb Download Times GPIB / RS-232 (115 Kbps)

Arb Length Binary ASCII Integer ASCII Real

64K points 23 sec 92 sec 154 sec

16K points 6 sec 23 sec 39 sec

8K points 3 sec 12 sec 20 sec

4K points 1.5 sec 6 sec 10 sec

2K points 0.75 sec 3 sec 5 sec

2

2

1

102 ms

240 ms

< 400 ms for < 16K points

TRIGGER CHARACTERISTICS

Trigger Input

Input Level: TTL-compatible

Slope: Rising or falling

Pulse Width: > 100 ns

Input Impedance: 10 kΩ, DC coupled

Latency

Sweep: < 10 µs (typical)

Burst: < 100 ns (typical)

Jitter (rms)

Sweep: 2.5 µs

Burst: 1 ns;

Trigger Output

Level:

Pulse Width: > 450 ns

Maximum Rate: 1 MHz

Fanout: < 4 Agilent 33250As

(selectable)

except pulse, 300 ps

TTL-compatible into 50

CLOCK REFERENCE

Phase Offset

Range: -360

Resolution: 0.001

External Reference Input

Lock Range: 10 MHz ± 35 kHz

Level: 100 mVpp to 5 Vpp

Impedance:

Lock Time: < 2 s

Internal Reference Output

Frequency: 10 MHz

3

Level: 632 mVpp (0 dBm),

Impedance:

° to

°

1 kΩ nominal, ac coupled

nominal

50Ω nominal, ac coupled

SYNC OUTPUT

Level: TTL-compatible

Impedance: 50Ω nominal

_______________

1

Time to change parameter and output new signal.

Ω

2

Modulation or sweep off.

3

Times for 5-digit integer and 12-digit real numbers.

into > 1 kΩ

+360

°

16

Agilent 33250A Function /Arbitrary Waveform Generator

GENERAL SPECIFICATIONS

Power Supply: 100-240 V (±10%)

Power Consumption: 140 VA

Operating Environment:

Operating Altitude: 3000 meters

Pollution Degree: Indoor or Sheltered Use,

Storage Temperature:

Stored States: Four (4) named user

Power-On State: Default or Last

for 50-60 Hz operation,

100-127 V (±10%)

for 50-400 Hz operation.

IEC 60664 CAT II

0 °C to

55

70

°C

°C

80% R.H. to 40 °C

IEC 60664 Degree 2

-30 °C to

configurations

Chapter 1 Specifications

Safety Designed to:

1

EMC Tested to:

Acoustic Noise: 40 dBA

Warm-Up Time: 1 hour

Calibration Interval: 1 year

Warranty: 3 years standard

Accessories Included:

IEC-61326-1

EN61010-1, CSA1010.1

UL-3111-1

IEC-61000-4-3 criteria B

IEC-61000-4-6 criteria B

User’s Guide,

Service Guide,

Quick Reference

Test Data,

Connectivity Software,

RS-232 Cable,

Power Cord

1

,

4

Guide,

Interface: IEEE-488 and RS-232

standard

Language: SCPI-1997, IEEE-488.2

Dimensions (WxHxD)

Bench Top: 254 x 104 x 374 mm

Rack Mount: 213 x 89 x 348 mm

Weight: 4.6 kg

_______________

1

Radiated and conducted immunity testing:

When the product is tested at 3 V/m according

to IEC/EN 61000-4-3:1995 or tested at 3 Vrms

according to IEC/EN 61000-4-6:1996, the product

may not meet criteria A, but does meet criteria B.

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001

du Canada.

N10149

17

1

Chapter 1 Specifications

Agilent 33250A Function / Arbitrary Waveform Generator

PRODUCT DIMENSIONS

103.6 mm

254.4 mm

88.5 mm

216.6 mm 348.3 mm

374.0 mm

All dimensions are

shown in millimeters.

18

2

2

Quick Start

2

Quick Start

One of the first things you will want to do with your function generator

is to become acquainted with the front panel. We have written the

exercises in this chapter to prepare the instrument for use and help

you get familiar with some of its front-panel operations. This chapter

is divided into the following sections:

• To Prepare the Function Generator for Use, on page 21

• To Adjust the Carrying Handle, on page 22

• To Set the Output Frequency, on page 23

• To Set the Output Amplitude, on page 24

• To Set a DC Offset Voltage, on page 26

• To Set the Duty Cycle, on page 27

• To Configure a Pulse Waveform, on page 28

• To View a Waveform Graph, on page 29

• To Output a Stored Arbitrary Waveform, on page 30

• To Use the Built-In Help System, on page 31

• To Rack Mount the Function Generator, on page 33

20

Chapter 2 Quick Start

Power

Switch

To Prepare the Function Generator for Use

To Prepare the Function Generator for Use

1 Check the list of supplied items.

Verify that you have received the following items with your instrument.

If anything is missing, please contact your nearest Agilent Sales Office.

❑ One power cord.

❑ One User’s Guide.

❑ This Service Guide.

❑ One folded Quick Reference Guide.

❑ Certificate of Calibration.

❑ Connectivity software on CD-ROM.

❑ One RS-232 cable.

2 Connect the power cord and turn on the function generator.

Several power-on information messages are displayed after the function

generator performs its power-on self-test. The GPIB address is displayed.

The function generator powers up in the sine wave function at 1 kHz

with an amplitude of 100 mV peak-to-peak (into a 50Ω termination).

At power-on, the Output connector is disabled. To enable the Output

connector, press the key.

If the function generator does not turn on, verify that the power cord is

firmly connected to the power receptacle on the rear panel (the powerline voltage is automatically sensed at power-on). You should also make

sure that the function generator is connected to a power source that is

energized. Then, verify that the function generator is turned on.

2

4

If you need further assistance, refer to chapter 6 for instructions on

returning the function generator to Agilent for service.

21

Chapter 2 Quick Start

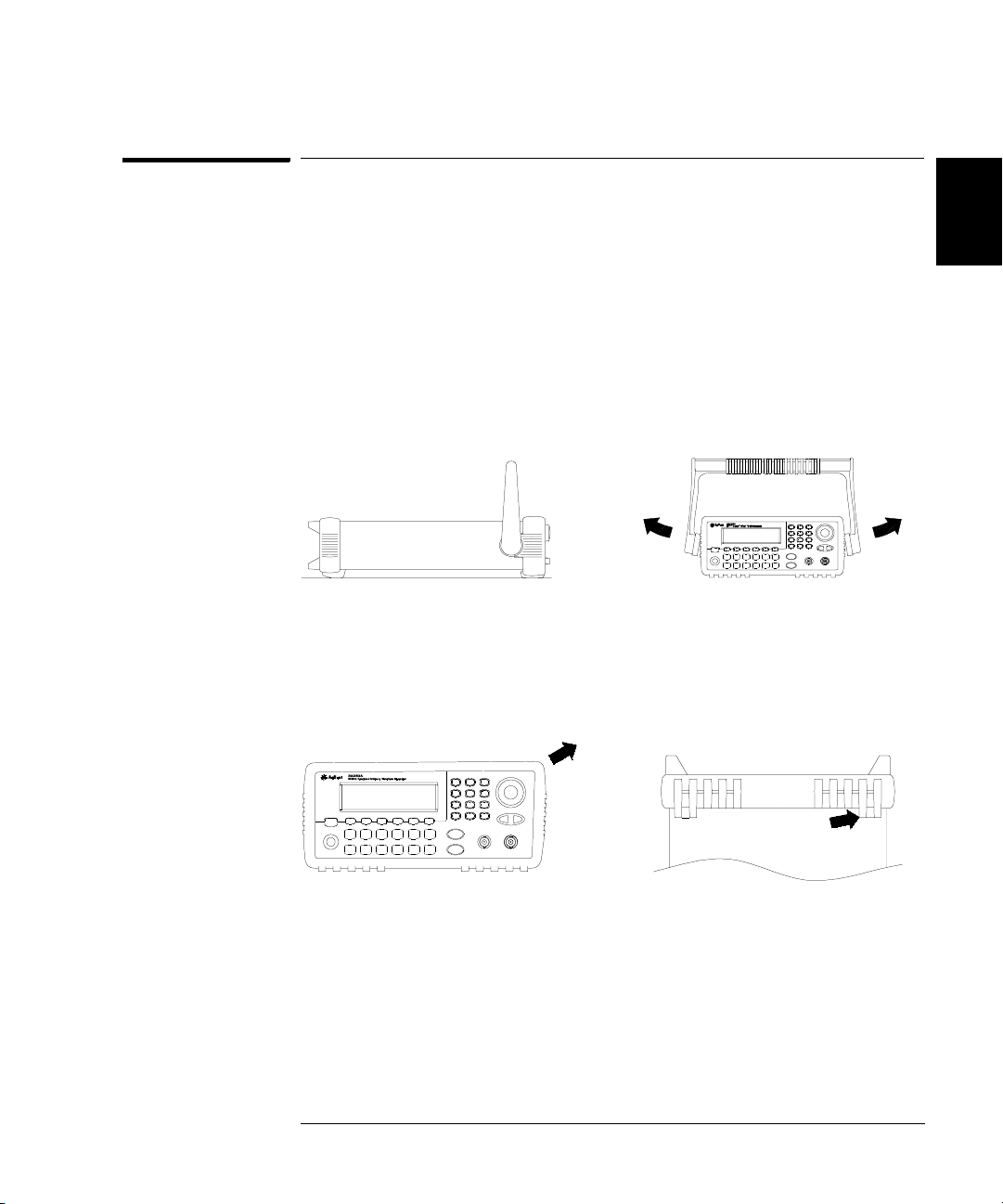

To Adjust the Carrying Handle

To Adjust the Carrying Handle

2

To adjust the position, grasp the handle by the sides and pull outward.

Then, rotate the handle to the desired position.

Bench-top viewing positions Carrying position

22

To Set the Output Frequency

Chapter 2 Quick Start

To Set the Output Frequency

At power-on, the function generator outputs a sine wave at 1 kHz with

an amplitude of 100 mV peak-to-peak (into a 50Ω termination).

The following steps show you how to change the frequency to 1.2 MHz.

1Press the “Freq” softkey.

The displayed frequency is either the power-on value or the frequency

previously selected. When you change functions, the same frequency is

used if the present value is valid for the new function. To set the

waveform period instead, press the Freq softkey again to toggle to the

Period softkey (the current selection is highlighted).

2 Enter the magnitude of the desired frequency.

Using the numeric keypad, enter the value “1.2”.

2

4

3 Select the desired units.

Press the softkey that corresponds to the desired units. When you select

the units, the function generator outputs a waveform with the displayed

frequency (if the output is enabled). For this example, press MHz

Note: You can also enter the desired value using the knob and arrow keys.

.

23

Chapter 2 Quick Start

To Set the Output Amplitude

To Set the Output Amplitude

2

At power-on, the function generator outputs a sine wave with an

amplitude of 100 mV peak-to-peak (into a 50Ω termination).

The following steps show you how to change the amplitude to 50 mVrms.

1Press the “Ampl” softkey.

The displayed amplitude is either the power-on value or the amplitude

previously selected. When you change functions, the same amplitude is

used if the present value is valid for the new function. To set the amplitude

using a high level and low level, press the Ampl softkey again to toggle to

the HiLevel and LoLevel softkeys (the current selection is highlighted).

2 Enter the magnitude of the desired amplitude.

Using the numeric keypad, enter the value “50”.

3 Select the desired units.

Press the softkey that corresponds to the desired units. When you select

the units, the function generator outputs the waveform with the displayed

amplitude (if the output is enabled). For this example, press mV

Note: You can also enter the desired value using the knob and arrow keys.

24

RMS

.

Chapter 2 Quick Start

To Set the Output Amplitude

You can easily convert the displayed amplitude from one unit to another.

For example, the following steps show you how to convert the amplitude

from Vrms to Vpp.

4 Enter the numeric entry mode.

Press the key to enter the numeric entry mode.

5 Select the new units.

Press the softkey that corresponds to the desired units. The displayed

value is converted to the new units. For this example, press the Vpp

softkey to convert 50 mVrms to its equivalent in volts peak-to-peak.

2

4

To change the displayed amplitude by decades, press the right-arrow

key to move the cursor to the units on the right side of the display.

Then, rotate the knob to increase or decrease the displayed amplitude

by decades.

25

Chapter 2 Quick Start

To Set a DC Offset Voltage

To Set a DC Offset Voltage

2

At power-on, the function generator outputs a sine wave with a dc offset

of 0 volts (into a 50Ω termination). The following steps show you how to

change the offset to –1.5 mVdc.

1Press the “Offset” softkey.

The displayed offset voltage is either the power-on value or the offset

previously selected. When you change functions, the same offset is used

if the present value is valid for the new function.

2 Enter the magnitude of the desired offset.

Using the numeric keypad, enter the value “–1.5”.

3 Select the desired units.

Press the softkey that corresponds to the desired units. When you select

the units, the function generator outputs the waveform with the displayed

offset (if the output is enabled). For this example, press mVdc.

Note: You can also enter the desired value using the knob and arrow keys.

Note: To select dc volts from the front panel, press and then select

the DC On softkey. Press the Offset softkey to enter the desired voltage level.

26

To Set the Duty Cycle

Chapter 2 Quick Start

To Set the Duty Cycle

Applies only to square waves. At power-on, the duty cycle for square

waves if 50%. You can adjust the duty cycle from 20% to 80% for output

frequencies up to 25 MHz. The following steps show you how to change

the duty cycle to 30%.

1 Select the square wave function.

Press the key and then set the desired output frequency to any

value less than 25 MHz.

2Press the “Duty Cycle” softkey.

The displayed duty cycle is either the power-on value or the percentage

previously selected. The duty cycle represents the amount of time per

cycle that the square wave is at a high level (note the icon on the right

side of the display).

3 Enter the desired duty cycle.

Using the numeric keypad or the knob, select a duty cycle value of “30”.

The function generator adjusts the duty cycle immediately and outputs a

square wave with the specified value (if the output is enabled).

2

4

27

Chapter 2 Quick Start

To Configure a Pulse Waveform

To Configure a Pulse Waveform

2

You can configure the function generator to output a pulse waveform

with variable pulse width and edge time. The following steps show you

how to configure a 500 ms pulse waveform with a pulse width of 10 ms

and edge times of 50 µs.

1 Select the pulse function.

Press the key to select the pulse function and output a pulse

waveform with the default parameters.

2 Set the pulse period.

Press the Period softkey and then set the pulse period to 500 ms.

3 Set the pulse width.

Press the Pulse Width softkey and then set the pulse width to 10 ms.

The pulse width represents the time from the 50% threshold of the rising

edge to the 50% threshold of the next falling edge (note the display icon).

4 Set the edge time for both edges.

Press the Edge Time softkey and then set the edge time for both the rising

and falling edges to 50 µs. The edge time represents the time from the

10% threshold to the 90% threshold of each edge (note the display icon).

28

To View a Waveform Graph

Chapter 2 Quick Start

To View a Waveform Graph

In the Graph Mode, you can view a graphical representation of the

current waveform parameters. Each softkey parameter is shown in a

different color corresponding to the lines above the softkeys at the

bottom of the display. Note that the softkeys are listed in the same order

as in the normal display mode.

1 Enable the Graph Mode.

Press the key to enable the Graph Mode. The name of the parameter

currently selected is shown in the upper-left corner of the display and the

numeric value is highlighted.

2 Select the desired parameter.

To select a specific parameter, note the colored bars above the softkeys at

the bottom of the display and select the corresponding color. For example,

to select amplitude, press the softkey below the magenta-colored bar.

• As in the normal display mode, you can edit numbers using the

numeric keypad or the knob and arrow keys.

2

4

• Parameters which normally toggle when you press a key a second time

(e.g., Freq / Period) also toggle in the Graph Mode.

• To exit the Graph Mode, press again.

The key also serves as a key to restore front-panel control

after remote interface operations.

29

Chapter 2 Quick Start

To Output a Stored Arbitrary Waveform

To Output a Stored Arbitrary Waveform

2

There are five built-in arbitrary waveforms stored in non-volatile memory.

The following steps show you how to output the built-in “exponential fall”

waveform from the front panel.

1 Select the arbitrary waveform function.

When you press the key to select the arbitrary waveform function,

a temporary message is displayed indicating which waveform is currently

selected (the default is “exponential rise”).

2 Select the active waveform.

Press the Select Wform softkey and then press the Built-In softkey to

select from the five built-in waveforms. Then press the Exp Fall softkey.

The waveform is output using the present settings for frequency,

amplitude, and offset unless you change them.

The selected waveform is now assigned to the key. Whenever you

press this key, the selected arbitrary waveform is output. To quickly

determine which arbitrary waveform is currently selected, press .

30

To Use the Built-In Help System

To Use the Built-In Help System

Chapter 2 Quick Start

The built-in help system is designed to provide context-sensitive

assistance on any front-panel key or menu softkey. A list of help topics

is also available to assist you with several front-panel operations.

1 View the help information for a function key.

Press and hold down the key. If the message contains more

information than will fit on the display, press the ↓ softkey or turn the

knob clockwise to view the remaining information.

Press DONE to exit the help menu.

2 View the help information for a menu softkey.

Press and hold down the Freq softkey. If the message contains more

information than will fit on the display, press the ↓ softkey or rotate the

knob clockwise to view the remaining information.

2

4

Press DONE to exit the help menu.

31

2

Chapter 2 Quick Start

To Use the Built-In Help System

3 View the list of help topics.

Press the key to view the list of available help topics. To scroll

through the list, press the ↑ or ↓ softkey or rotate the knob. Select the

third topic “Get HELP on any key” and then press SELECT.

Press DONE to exit the help menu.

4 View the help information for displayed messages.

Whenever a limit is exceeded or any other invalid configuration is found,

the function generator will display a message. For example, if you enter

a value that exceeds the frequency limit for the selected function,

a message will be displayed. The built-in help system provides additional

information on the most recent message to be displayed.

Press the key, select the first topic “View the last message displayed”,

and then press SELECT.

Local Language Help: The built-in help system in available in multiple

languages. All messages, context-sensitive help, and help topics appear

in the selected language. The menu softkey labels and status line

messages are not translated.

To select the local language, press the key, press the System

softkey, and then press the Help In softkey. Select the desired language.

32

Chapter 2 Quick Start

To Rack Mount the Function Generator

To Rack Mount the Function Generator

You can mount the Agilent 33250A in a standard 19-inch rack cabinet

using one of two optional kits available. Instructions and mounting

hardware are included with each rack-mounting kit. Any Agilent

System II instrument of the same size can be rack-mounted beside the

Agilent 33250A.

Note: Remove the carrying handle, and the front and rear rubber bumpers,

before rack-mounting the instrument.

To remove the handle, rotate it to vertical and pull the ends outward.

4

2

Front Rear (bottom view)

To remove the rubber bumper, stretch a corner and then slide it off.

33

2

Chapter 2 Quick Start

To Rack Mount the Function Generator

To rack mount a single instrument, order adapter kit 5063-9240.

To rack mount two instruments side-by-side, order lock-link kit 5061-9694

and flange kit 5063-9212. Be sure to use the support rails in the rack cabinet.

In order to prevent overheating, do not block the flow of air into or out of

the instrument. Be sure to allow enough clearance at the rear, sides, and

bottom of the instrument to permit adequate internal airflow.

34

3

3

Front-Panel Menu Operation

3

Front-Panel Menu Operation

This chapter introduces you to the front-panel keys and menu operation.

This chapter does not give a detailed description of every front-panel key

or menu operation. It does, however, give you an overview of the frontpanel menus and many front-panel operations. See the Agilent 33250A

User’s Guide for a complete discussion of the function generator’s

capabilities and operation.

• Front-Panel Menu Reference, on page 37

• To Reset the Function Generator, on page 39

• To Select the Output Termination, on page 39

• To Read the Calibration Information, on page 40

• To Unsecure and Secure for Calibration, on page 41

• To Store the Instrument State, on page 44

• To Configure the Remote Interface, on page 45

36

Chapter 3 Front-Panel Menu Operation

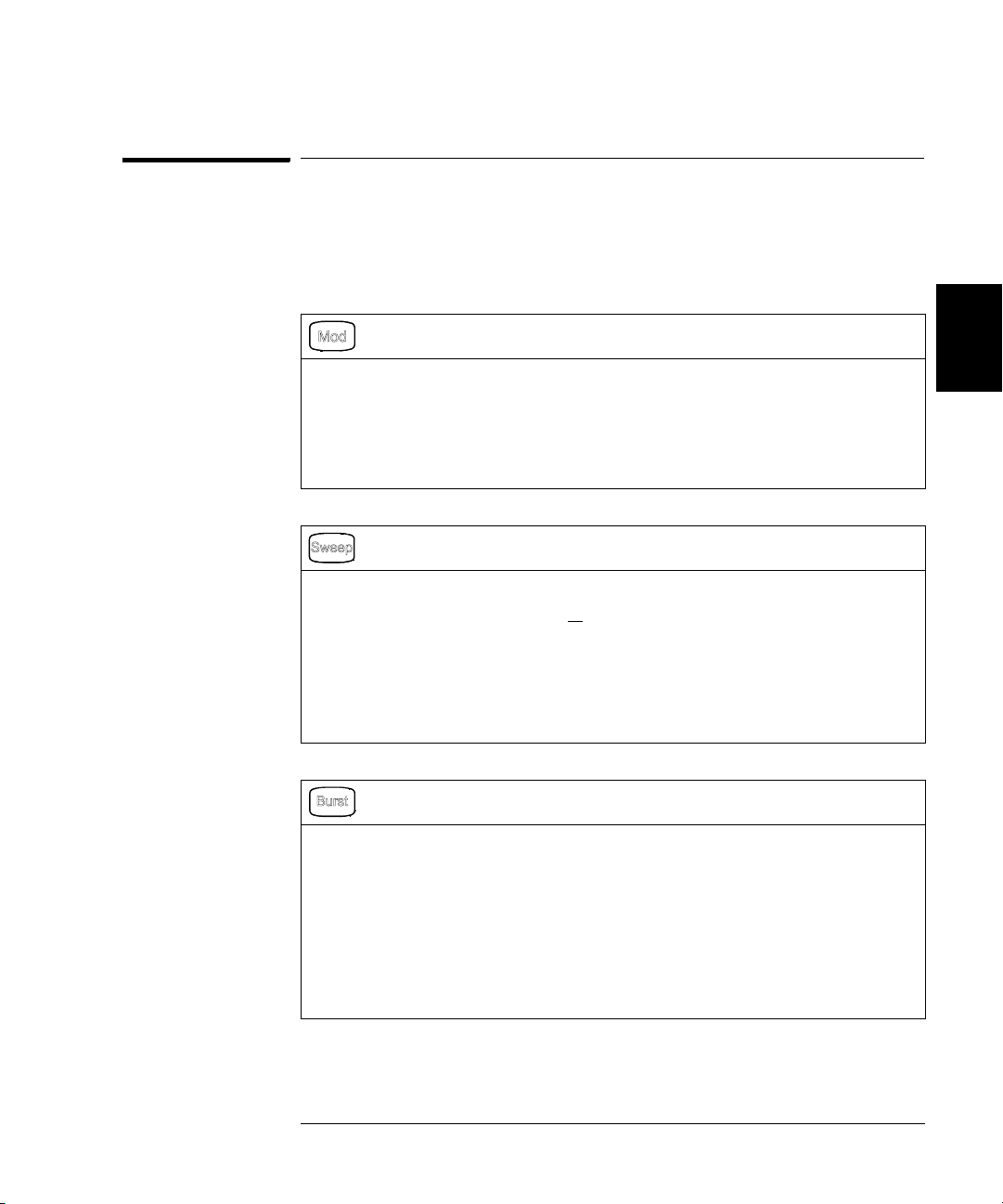

Front-Panel Menu Reference

Front-Panel Menu Reference

This section gives an overview of the front-panel menus. The remainder

of this chapter shows examples of using the front-panel menus.

Configure the modulation parameters for AM, FM, and FSK.

• Select the modulation type.

• Select an internal or external modulation source.

• Specify the AM modulation depth, modulating frequency, and modulation shape.

Specify the FM frequency deviation, modulating frequency, and modulation shape.

•

• Specify the FSK “hop” frequency and FSK rate.

Configure the parameters for frequency sweep.

• Select linear or logarithmic sweeping.

• Select the start/stop frequencies or

• Select the time in seconds required to complete a sweep.

• Specify a marker frequency.

• Specify an internal or external trigger source for the sweep.

• Specify the slope (rising or falling edge) for an external trigger source.

• Specify the slope (rising or falling edge) of the “Trig Out” signal.

Configure the parameters for burst.

• Select the triggered (N Cycle) or externally-gated burst mode.

• Select the number of cycles per burst (1 to 1,000,000, or Infinite).

• Select the starting phase angle of the burst (-360° to +360°).

• Specify the time from the start of one burst to the start of the next burst.

• Specify a delay between the trigger and the start of the burst.

• Specify an internal or external trigger source for the burst.

• Specify the slope (rising or falling edge) for an external trigger source.

• Specify the slope (rising or falling edge) of the “Trig Out” signal.

center/ span frequencies.

4

3

37

3

Chapter 3 Front-Panel Menu Operation

Front-Panel Menu Reference

Store and recall instrument states.

• Store up to four instrument states in non-volatile memory.

• Assign a custom name to each storage location.

• Recall stored instrument states.

• Restore all instrument settings to their factory default values.

• Select the instrument’s power-on configuration (last or factory default).

Configure system-related parameters.

• Generate a dc-only voltage level.

• Enable/disable the Sync signal which is output from the “Sync” connector.

• Select the output termination (1Ω to 10 kΩ, or Infinite).

• Enable/disable amplitude autoranging.

• Select the waveform polarity (normal or inverted).

• Select the GPIB address.

• Configure the RS-232 interface (baud rate, parity, and handshake mode).

Select how periods and commas are used in numbers displayed on the front panel.

•

• Select the local language for front-panel messages and help text.

• Enable/disable the tone heard when an error is generated.

• Enable/disable the display bulb-saver mode.

• Adjust the contrast setting of the front-panel display.

• Perform an instrument self-test.

• Secure/unsecure the instrument for calibration and perform manual calibrations.

• Query the instrument’s firmware revision codes.

View the list of Help topics.

• View the last message displayed.

• View the remote command error queue.

• Get HELP on any key.

• How to generate a dc-only voltage level.

• How to generate a modulated waveform.

• How to create an arbitrary waveform.

• How to reset the instrument to its default state.

• How to view a waveform in the Graph Mode.

• How to synchronize multiple instruments.

• How to obtain Agilent Technical Support.

38

Chapter 3 Front-Panel Menu Operation

To Reset the Function Generator

To Reset the Function Generator

To reset the instrument to its factory default state, press and then

select the Set to Defaults softkey. Select YES to confirm the operation.

A complete listing of the instrument’s power-on and reset conditions,

see the “Factory Default Settings” table inside the rear cover of this manual.

To Select the Output Termination

The Agilent 33250A has a fixed series output impedance of 50 ohms to

the front-panel Output connector. If the actual load impedance is

different than the value specified, the displayed amplitude and offset

levels will be incorrect. The load impedance setting is simply provided

as a convenience to ensure that the displayed voltage matches the

expected load.

1Press .

2 Navigate the menu to set the output termination.

Press the Output Setup softkey and then select the Load softkey.

4

3

3 Select the desired output termination.

Use the knob or numeric keypad to select the desired load impedance

or press the Load softkey again to choose “High Z”.

39

3

Chapter 3 Front-Panel Menu Operation

To Read the Calibration Information

To Read the Calibration Information

You can use the instrument’s calibration memory to read the calibration

count and calibration message.

Calibration Count You can query the instrument to determine how

many calibrations have been performed. Note that your instrument was

calibrated before it left the factory. When you receive your instrument,

read the count to determine its initial value. The count value increments

by one for each calibration point, and a complete calibration may

increase the value by many counts.

Calibration Message The instrument allows you to store one message

in calibration memory. For example, you can store such information as

the date when the last calibration was performed, the date when the

next calibration is due, the instrument’s serial number, or even the name

and phone number of the person to contact for a new calibration.

You can record a calibration message only from the remote interface

and only when the instrument is unsecured.

You can read the message from either the front-panel or over the remote

interface. You can read the calibration message whether the instrument

is secured or unsecured.

1 Select the Cal Info interface.

Press and then select the Cal Info softkey from the “Test/Cal” menu.

The first line in the display shows the calibration count.

The second line shows the calibration message.

The last line indicates the current version of the firmware.

The calibration information will time-out and disappear after a few seconds.

Select the Cal Info softkey to show the information again.

2 Exit the menu.

Press the DONE softkey.

40

Chapter 3 Front-Panel Menu Operation

To Unsecure and Secure for Calibration

To Unsecure and Secure for Calibration

This feature allows you to enter a security code to prevent accidental

or unauthorized adjustments of the instrument. When you first receive

your instrument, it is secured. Before you can adjust the instrument,

you must unsecure it by entering the correct security code.

• The security code is set to AT33250A when the instrument is shipped

from the factory. The security code is stored in non-volatile memory,

and does not change when power has been off, after a Factory Reset

(*RST command), or after an Instrument Preset (SYSTem:PRESet

command).

• The security code may contain up to 12 alphanumeric characters.

The first character must be a letter, but the remaining characters

can be letters, numbers, or an underscore ( _ ). You do not have to

use all 12 characters but the first character must always be a letter.

Note: If you forget your security code, you can disable the security feature

by applying a temporary short inside the instrument as described in

“To Unsecure the Instrument Without the Security Code”, on page 69.

4

3

41

3

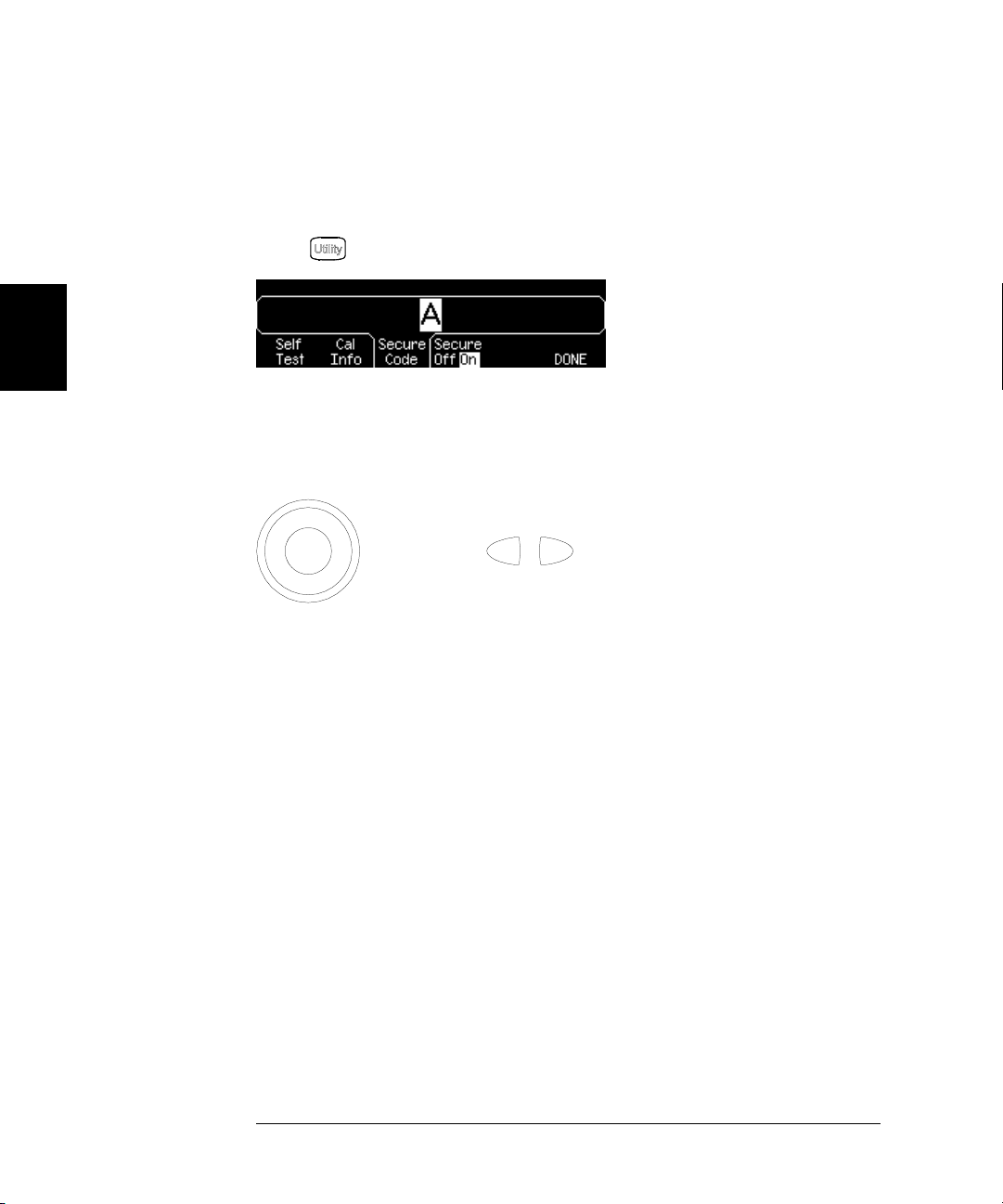

Chapter 3 Front-Panel Menu Operation

To Unsecure and Secure for Calibration

To Unsecure for Calibration

1 Select the Secure Code interface.

Press and then select the Test/C a l softkey.

2 Enter the Secure Code.

Use the knob to change the displayed character. Use the arrow keys to

move to the next character.

+

When the last character of the secure code is entered, the instrument

will be unsecured.

3 Exit the menu.

Press the DONE softkey.

42

Chapter 3 Front-Panel Menu Operation

To Unsecure and Secure for Calibration

To Secure After Calibration

1 Select the Secure Code interface.

Press and then select the Test/C a l softkey.

2Enter a Secure Code.

Enter up to 12 alphanumeric characters. The first character must be

a letter.

Use the knob to change the displayed character. Use the arrow keys to

move to the next character.

4

3

+

3 Secure the Instrument.

Select the Secure softkey.

4 Exit the menu.

Press the DONE softkey.

43

3

Chapter 3 Front-Panel Menu Operation

To Store the Instrument State

To Store the Instrument State

You can store the instrument state in one of four non-volatile storage

locations. A fifth storage location automatically holds the power-down

configuration of the instrument. When power is restored, the instrument

can automatically return to its state before power-down.

1 Select the desired storage location.

Press and then select the Store State softkey.

2 Select a custom name for the selected location.

If desired, you can assign a custom name to each of the four locations.

• The name can contain up to 12 characters. The first character must

be a letter but the remaining characters can be letters, numbers, or

the underscore character (“_”).

• To add additional characters, press the right-arrow key until the

cursor is to the right of the existing name and then turn the knob.

• To delete all characters to the right of the cursor position, press .

• To use numbers in the name, you can enter them directly from the

numeric keypad. Use the decimal point from the numeric keypad to

add the underscore character (“_” ) to the name.

3 Store the instrument state.

Press the STORE STATE softkey. The instrument stores the selected

function, frequency, amplitude, dc offset, duty cycle, symmetry, as well

as any modulation parameters in use. The instrument does not store

volatile waveforms created in the arbitrary waveform function.

44

Chapter 3 Front-Panel Menu Operation

To Configure the Remote Interface

To Configure the Remote Interface

The instrument is shipped with both a GPIB (IEEE-488) interface and an

RS-232 interface. Only one interface can be enabled at a time. The GPIB

interface is selected when the instrument is shipped from the factory.

4

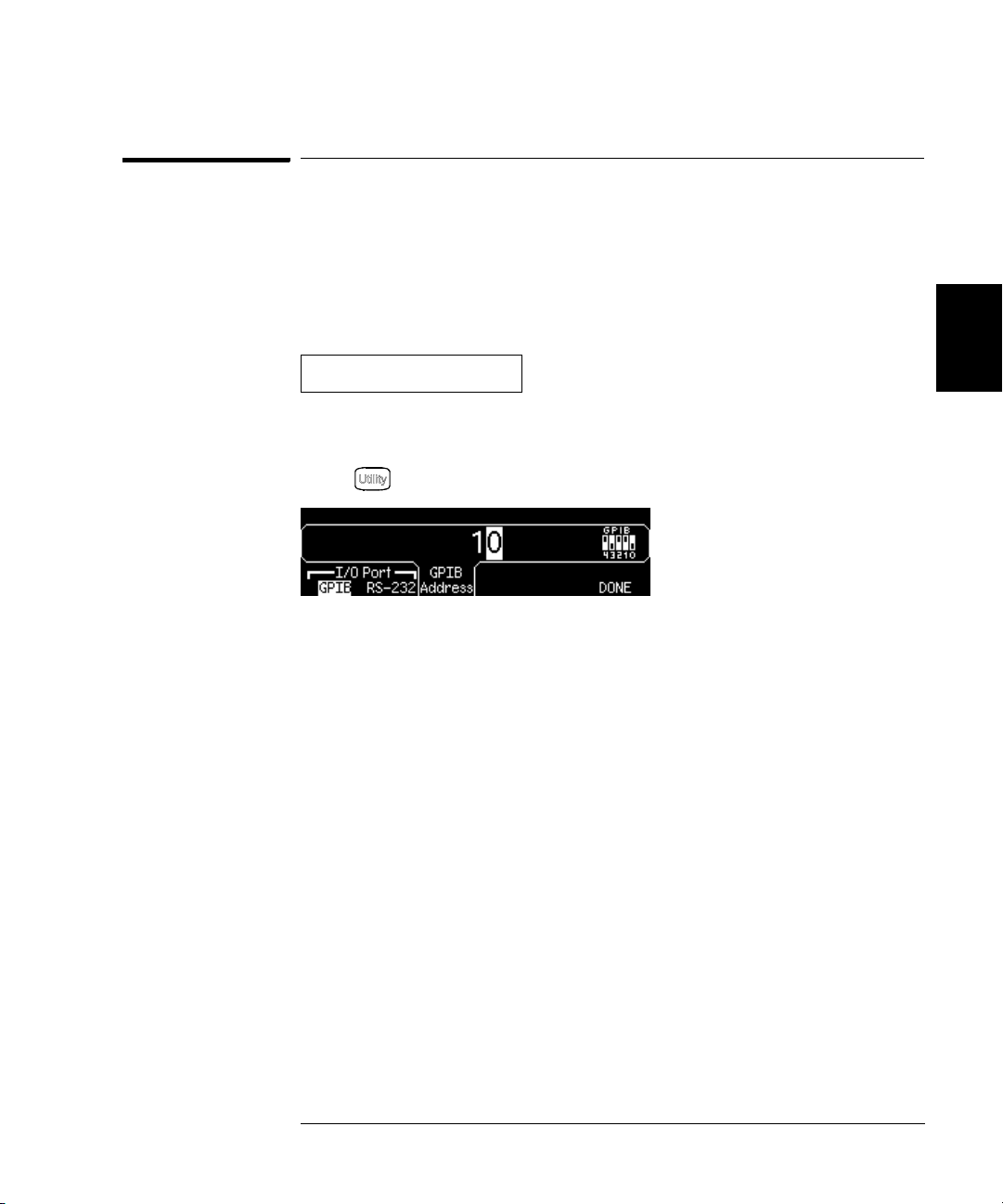

GPIB Configuration

1 Select the GPIB interface.

Press and then select the GPIB softkey from the “I/O” menu.

2 Select the GPIB address.

Press the GPIB Address softkey and enter the desired address using the

numeric keypad or knob. The factory setting is “10”.

The GPIB address is shown on the front-panel display at power-on.

3 Exit the menu.

Press the DONE softkey.

3

45

3

Chapter 3 Front-Panel Menu Operation

To Configure the Remote Interface

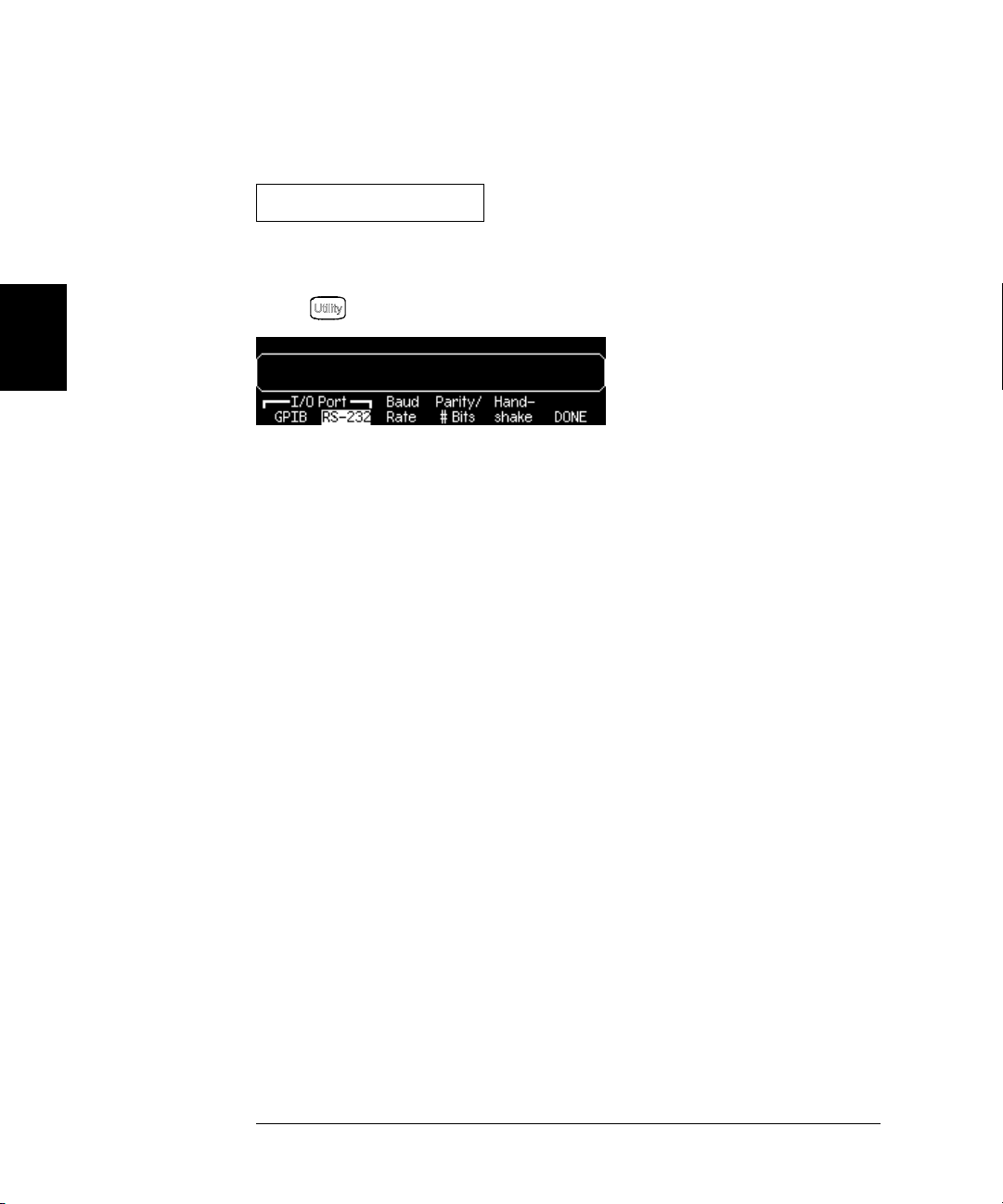

RS-232 Configuration

1 Select the RS-232 interface.

Press and then select the RS-232 softkey from the “I/O” menu.

2 Set the baud rate.

Press the Baud Rate softkey and select one of the following:

300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600 (factory setting),

or 115200 baud.

3 Select the parity and number of data bits.

Press the Parity / # Bits softkey and select one of the following:

None (8 data bits, factory setting), Even (7 data bits), or Odd (7 data bits).

When you set the parity, you are also setting the number of data bits.

4 Select the handshake mode.

Press the Handshake softkey and select one of the following:

None, DTR /DSR (factory setting), Modem, RTS / CTS, or XON / XOFF.

5 Exit the menu.

Press the DONE softkey.

46

4

4

Calibration Procedures

4

Calibration Procedures

This chapter contains procedures for verification of the instrument’s

performance and adjustment (calibration). The chapter is divided into

the following sections:

• Agilent Technologies Calibration Services, on page 49

• Calibration Interval, on page 50

• Adjustment is Recommended, on page 50

• Time Required for Calibration, on page 51

• Automating Calibration Procedures, on page 52

• Recommended Test Equipment, on page 53

• Test Considerations, on page 54

• Performance Verification Tests, on page 55

• Internal Timebase Verification, on page 60

• AC Amplitude (high-impedance) Verification, on page 61

• Low Frequency Flatness Verification, on page 62

• 0 dB Range Flatness Verification, on page 63

• +10 dB Range Flatness Verification, on page 65

• +20 dB Range Flatness Verification, on page 66

• Calibration Security, on page 68

• Calibration Message, on page 70

• Calibration Count, on page 70

• General Calibration/Adjustment Procedure, on page 71

• Sequence of Adjustments, on page 72

• Aborting a Calibration in Progress, on page 72

• Self-Test, on page 73

• Frequency (Internal Timebase) Adjustment, on page 74

• Internal ADC Adjustment, on page 75

• Output Impedance Adjustment, on page 76

• AC Amplitude (high-impedance) Adjustment, on page 78

• Low Frequency Flatness Adjustment, on page 80

• 0 dB Range Flatness Adjustments, on page 81

• +10 dB Range Flatness Adjustments, on page 83

• +20 dB Range Flatness Adjustment, on page 85

• Pulse Width (Trailing Edge Delay) Adjustment, on page 87

• Pulse Edge Time Adjustment, on page 88

• Duty Cycle Adjustment, on page 89

• Output Amplifier Adjustment (Optional), on page 90

• Calibration Errors, on page 91

48

Chapter 4 Calibration Procedures

Agilent Technologies Calibration Services

Closed-Case Electronic Calibration The instrument features closedcase electronic calibration. No internal mechanical adjustments are

required. The instrument calculates correction factors based upon the

input reference value you set. The new correction factors are stored in

non-volatile memory until the next calibration adjustment is performed.

Non-volatile EEPROM calibration memory does not change when power

has been off or after a remote interface reset.

4

Agilent Technologies Calibration Services

When your instrument is due for calibration, contact your local

Agilent Technologies Service Center for a low-cost recalibration.

The Agilent 33250A is supported on automated calibration systems

which allow Agilent to provide this service at competitive prices.

4

49

Chapter 4 Calibration Procedures

Calibration Interval

Calibration Interval

The instrument should be calibrated on a regular interval determined by

the measurement accuracy requirements of your application. A 1-year

interval is adequate for most applications. Accuracy specifications are

warranted only if adjustment is made at regular calibration intervals.

Accuracy specifications are not warranted beyond the 1-year calibration

interval. Agilent Technologies does not recommend extending calibration

intervals beyond 2 years for any application.

Adjustment is Recommended

4

Whatever calibration interval you select, Agilent Technologies

recommends that complete re-adjustment should always be performed

at the calibration interval. This will assure that the Agilent 33250A

will remain within specification for the next calibration interval.

This criteria for re-adjustment provides the best long-term stability.

Performance data measured using this method can be used to extend

future calibration intervals.

Use the Calibration Count (see page 70) to verify that all adjustments

have been performed.

50

Chapter 4 Calibration Procedures

Time Required for Calibration

Time Required for Calibration

The Agilent 33250A can be automatically calibrated under computer control.

With computer control you can perform the complete calibration

procedure and performance verification tests in approximately 30 minutes

once the instrument is warmed-up (see “Test Considerations” on page 54).

Manual adjustments and verifications, using the recommended test

equipment, will take approximately 2 hours.

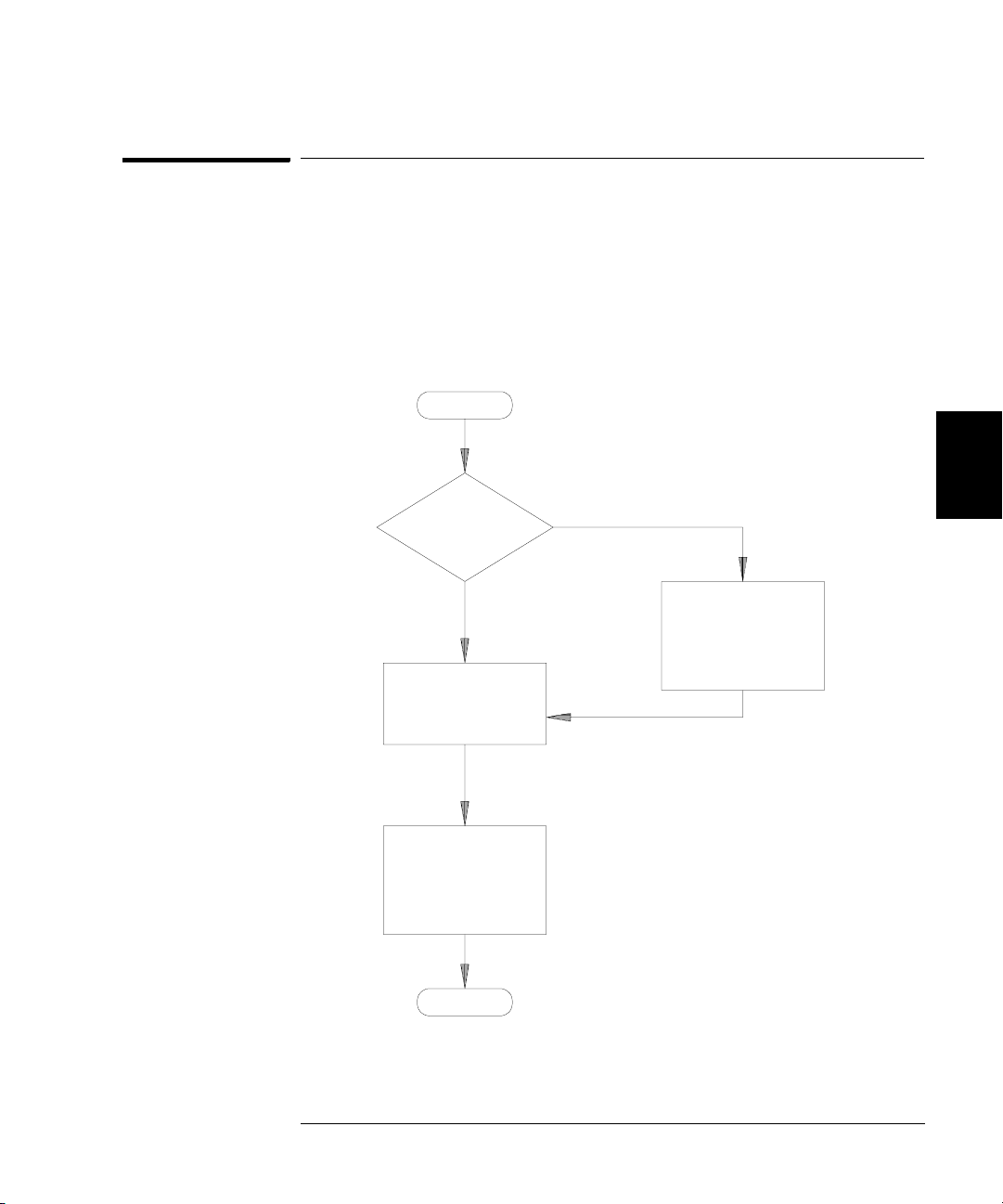

START

4

Incoming

Verification?

NO

Perform

Adjustments

(approx 1 Hour)

Do Performance

Verification Tests

(approx 1 Hour)

DONE

YES

4

Do Performance

Verification Tests

(approx 1 Hour)

51

4

Chapter 4 Calibration Procedures

Automating Calibration Procedures

Automating Calibration Procedures

You can automate the complete verification and adjustment procedures

outlined in this chapter if you have access to programmable test

equipment. You can program the instrument configurations specified

for each test over the remote interface. You can then enter readback

verification data into a test program and compare the results to the

appropriate test limit values.

You can also adjust the instrument from the remote interface. Remote

adjustment is similar to the local front-panel procedure. You can use a

computer to perform the adjustment by first selecting the required

function and range. The calibration value is sent to the instrument and

then the calibration is initiated over the remote interface. The instrument

must be unsecured prior to initiating the calibration procedure.

For further information on programming the instrument, see chapters

3 and 4 in the Agilent 33250A User’s Guide.

52

Chapter 4 Calibration Procedures

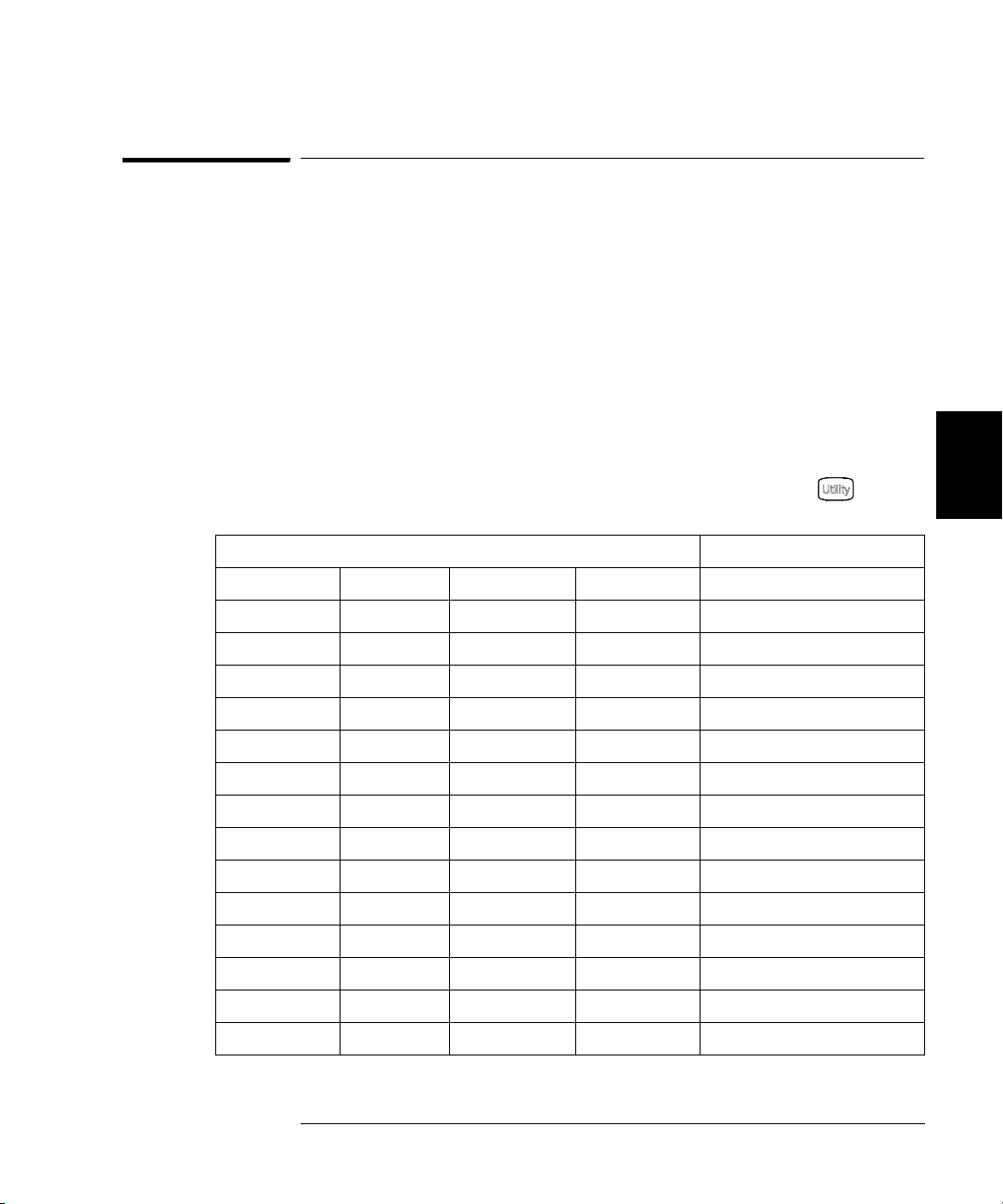

Recommended Test Equipment

Recommended Test Equipment

The test equipment recommended for the performance verification and

adjustment procedures is listed below. If the exact instrument is not

available, substitute calibration standards of equivalent accuracy.

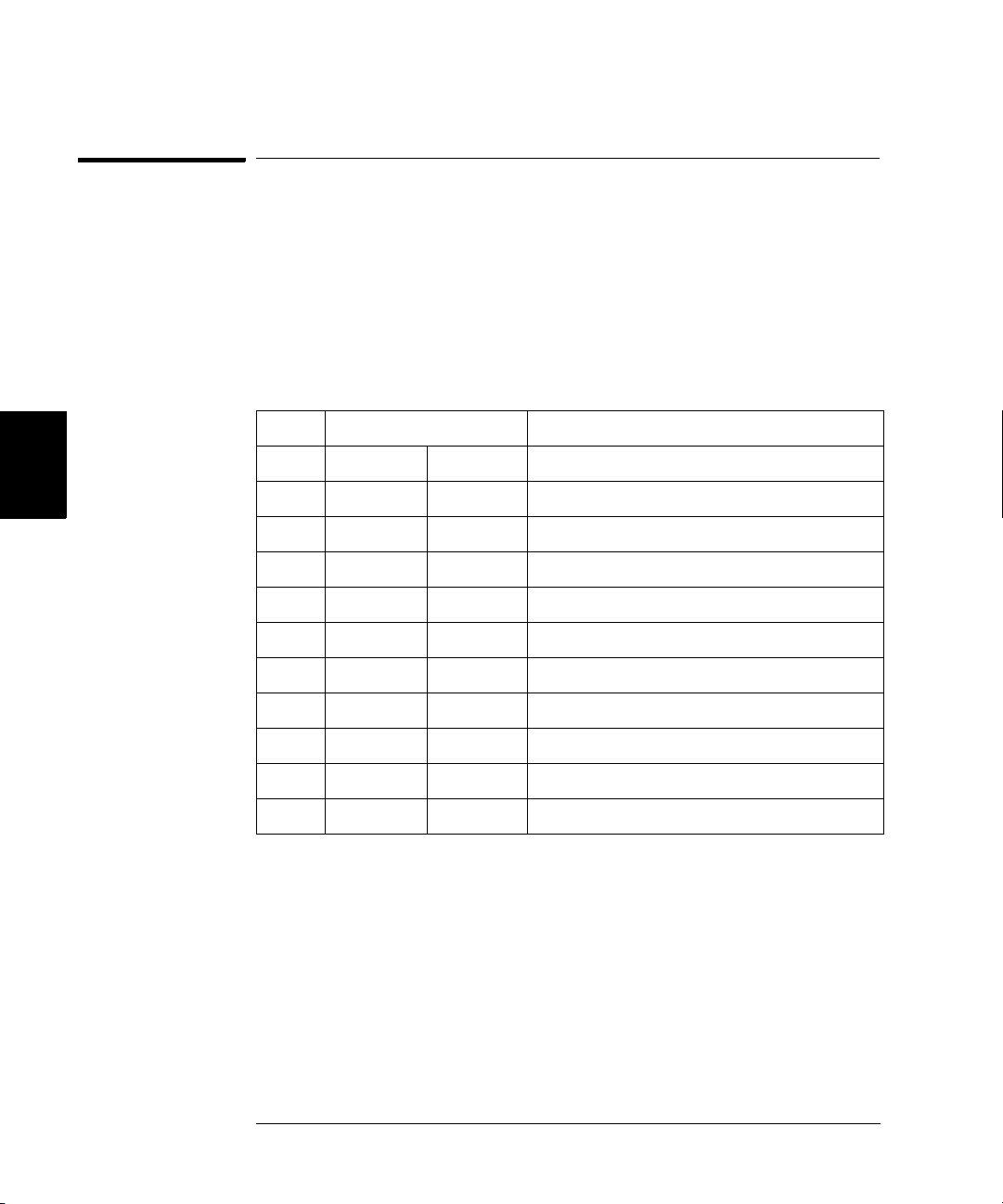

Instrument Requirements Recommended Model Use*

Digital Multimeter

(DMM)

Power Meter 100 kHz to 100 MHz

ac volts, true rms, ac coupled

accuracy: ±0.02% to 1 MHz

dc volts

accuracy: 50 ppm

resolution: 100 µV

Resistance

Offset-compensated

accuracy: ±0.1Ω

1 µW to 100 mW (–30 dBm to +20 dBm)

accuracy: 0.02 dB

resolution: 0.01 dB

Agilent 3458A Q, P, T

Agilent E4418B Q, P, T

4

4

Power Head 100 kHz to 100 MHz

1 µW to 100 mW (–30 dBm to +20 dBm)

Attenuator –20 dB Agilent 8491A Opt 020 Q, P, T

Frequency Meter accuracy: 0.1 ppm Agilent 53131A Opt 010

Oscilloscope 500 MHz

2 Gs/second

50Ω input termination

Adapter N type (m) to BNC (m) N type (m) to BNC (m) Q, P, T

Cable BNC (m) to dual-banana (f) Agilent 10110B Q, P, T

Cable (2 required) Dual banana (m) to dual banana (m) Agilent 11000-60001 Q, P, T

Cable RG58, BNC (m) to dual banana Agilent 11001-60001 Q, P, T

Cable RG58, BNC (m) to BNC (m) Agilent 8120-1840 Q, P, T

* Q = Quick Verification P = Performance Verification

T = Troubleshooting O = Optional Verification

Agilent 8482A Q, P, T

Q, P, T

(high stability)

Agilent 54831B Q, P, T

53

4

Chapter 4 Calibration Procedures

Test Considerations

Test Considerations

For optimum performance, all procedures should comply with the

following recommendations:

• Assure that the calibration ambient temperature is stable and

between 18 °C and 28 °C. Ideally, the calibration should be performed

at 23 °C

• Assure ambient relative humidity is less than 80%.

• Allow a 1-hour warm-up period before verification or adjustment.

• Keep the measurement cables as short as possible, consistent with

the impedance requirements.

• Use only RG-58 or equivalent 50

±1 °C.

Ω cable.

54

Chapter 4 Calibration Procedures

Performance Verification Tests

Performance Verification Tests

Use the Performance Verification Tests to verify the measurement

performance of the instrument. The performance verification tests use

the instrument’s specifications listed in the “Specifications” chapter

beginning on page 13.

You can perform four different levels of performance verification tests:

• Self-Test A series of internal verification tests that give high

confidence that the instrument is operational.

• Quick Verification A combination of the internal self-tests and

selected verification tests.

• Performance Verification Tests An extensive set of tests that are

recommended as an acceptance test when you first receive the

instrument or after performing adjustments.

• Optional Verification Tests Tests not performed with every

calibration. Perform these tests following repairs to the output amplifier.

4

4

55

Chapter 4 Calibration Procedures

Performance Verification Tests

Self-Test

A brief power-on self-test occurs automatically whenever you turn on the

instrument. This limited test assures that the instrument is operational.

To perform a complete self-test:

1 Press on the front panel.

2 Select the Self Test softkey from the “Test/Cal” menu.

A complete description of the self-tests can be found in chapter 6.

The instrument will automatically perform the complete self-test

procedure when you release the key. The self-test will complete in

approximately 30 seconds.

4

• If the self-test is successful, “Self Test Pass” is displayed on the

front panel.

• If the self-test fails, “Self Test Fail” and an error number are displayed.

If repair is required, see chapter 6, “Service,” for further details.

56

Chapter 4 Calibration Procedures

Performance Verification Tests

Quick Performance Check

The quick performance check is a combination of internal self-test and

an abbreviated performance test (specified by the letter

performance verification tests). This test provides a simple method to

achieve high confidence in the instrument’s ability to functionally

operate and meet specifications. These tests represent the absolute

minimum set of performance checks recommended following any service

activity. Auditing the instrument’s performance for the quick check

points (designated by a Q) verifies performance for normal accuracy drift

mechanisms. This test does not check for abnormal component failures.

To perform the quick performance check, do the following:

1 Perform a complete self-test. A procedure is given on page 56.

Q in the

4

2 Perform only the performance verification tests indicated with the

letter Q.

3 If the instrument fails the quick performance check, adjustment or

repair is required.

Performance Verification Tests

The performance verification tests are recommended as acceptance

tests when you first receive the instrument. The acceptance test results

should be compared against the specifications given in chapter 1.

After acceptance, you should repeat the performance verification tests at

every calibration interval.

If the instrument fails performance verification, adjustment or repair

is required.

Adjustment is recommended at every calibration interval. If adjustment

is not made, you must guard band, using no more than 80% of the

specifications listed in chapter 1, as the verification limits.

4

57

4

Chapter 4 Calibration Procedures

Performance Verification Tests

Amplitude and Flatness Verification Procedures

Special Note: Measurements made during the AC Amplitude (highimpedance) Verification procedure (see page 61) are used as reference

measurements in the flatness verification procedures (beginning on

page 62). Additional reference measurements and calculated references

are used in the flatness verification procedures. Photo-copy and use the

table on page 59 to record these reference measurements and perform

the calculations.

The flatness verification procedures use both a DMM and a Power Meter

to make the measurements. To correct the difference between the DMM

and Power Meter measurements, the Power Meter reference measurement

level is adjusted to set the 0.00 dB level to the DMM measurement made

at 1 kHz. The flatness error of the DMM at 100 kHz is used to set the

required 0.00 dB reference.

The instrument internally corrects the difference between the high-Z

input of the DMM and the 50Ω input of the Power Meter when setting

the output level.

The reference measurements must also be converted from Vrms (made

by the DMM) to dBm (made by the Power Meter).

The equation used for the conversion from Vrms (High-Z) to dBm

(at 50Ω) is as follows:

Power (dBm) = 10 log(5.0 * V

Flatness measurements for the –10 dB, –20dB, and –30 dB attenuator

ranges are verified as a part of the 0 dB verification procedure.

No separate verification procedure is given for these ranges.

rms

2

)

58

Chapter 4 Calibration Procedures

Performance Verification Tests

Amplitude and Flatness Verification Worksheet

1. Enter the following measurements (from procedure on page 61).

1kHz_0dB_reference = __________________________ Vrms

1kHz_10dB_reference = __________________________ Vrms

1kHz_20dB_reference = __________________________ Vrms

2. Calculate the dBm value of the rms voltages.

1kHz_0dB_reference_dBm ==10 * log(5.0 * 1kHz_0dB_reference2)

__________________________ dBm

1kHz_10dB_reference_dBm ==10 * log(5.0 * 1kHz_10dB_reference

__________________________ dBm

1kHz_20dB_reference_dBm ==10 * log(5.0 * 1kHz_20dB_reference

__________________________ dBm

2

)

2

)

3. Enter the following measurements (from the procedure on page 62).

100kHz_0dB_reference = __________________________ Vrms

100kHz_10dB_reference = __________________________ Vrms

100kHz_20dB_reference = __________________________ Vrms

4. Calculate the dBm value of the rms voltages.

100kHz_0dB_reference_dBm ==10 * log(5.0 * 100kHz_0dB_reference2)

__________________________ dBm

100kHz_10dB_reference_dBm ==10 * log(5.0 * 100kHz_10dB_reference

__________________________ dBm

100kHz_20dB_reference_dBm ==10 * log(5.0 * 100kHz_20dB_reference

__________________________ dBm

2

)

2

)

5. Calculate the offset values.

4

100kHz_0dB_offset ==100kHz_0dB_reference_dBm – 1kHz_0dB_reference_dBm

__________________________ dBm (use on page 63)

100kHz_10dB_offset ==100kHz_10dB_reference_dBm

__________________________ dBm (use on page 65)

100kHz_20dB_offset ==100kHz_20dB_reference_dBm – 1kHz_20dB_reference_dBm

__________________________ dBm (use on page 66)

– 1kHz_10dB_reference_dBm

59

4

Chapter 4 Calibration Procedures

Internal Timebase Verification

Internal Timebase Verification

This test verifies the output frequency accuracy of the instrument.

All output frequencies are derived from a single generated frequency.

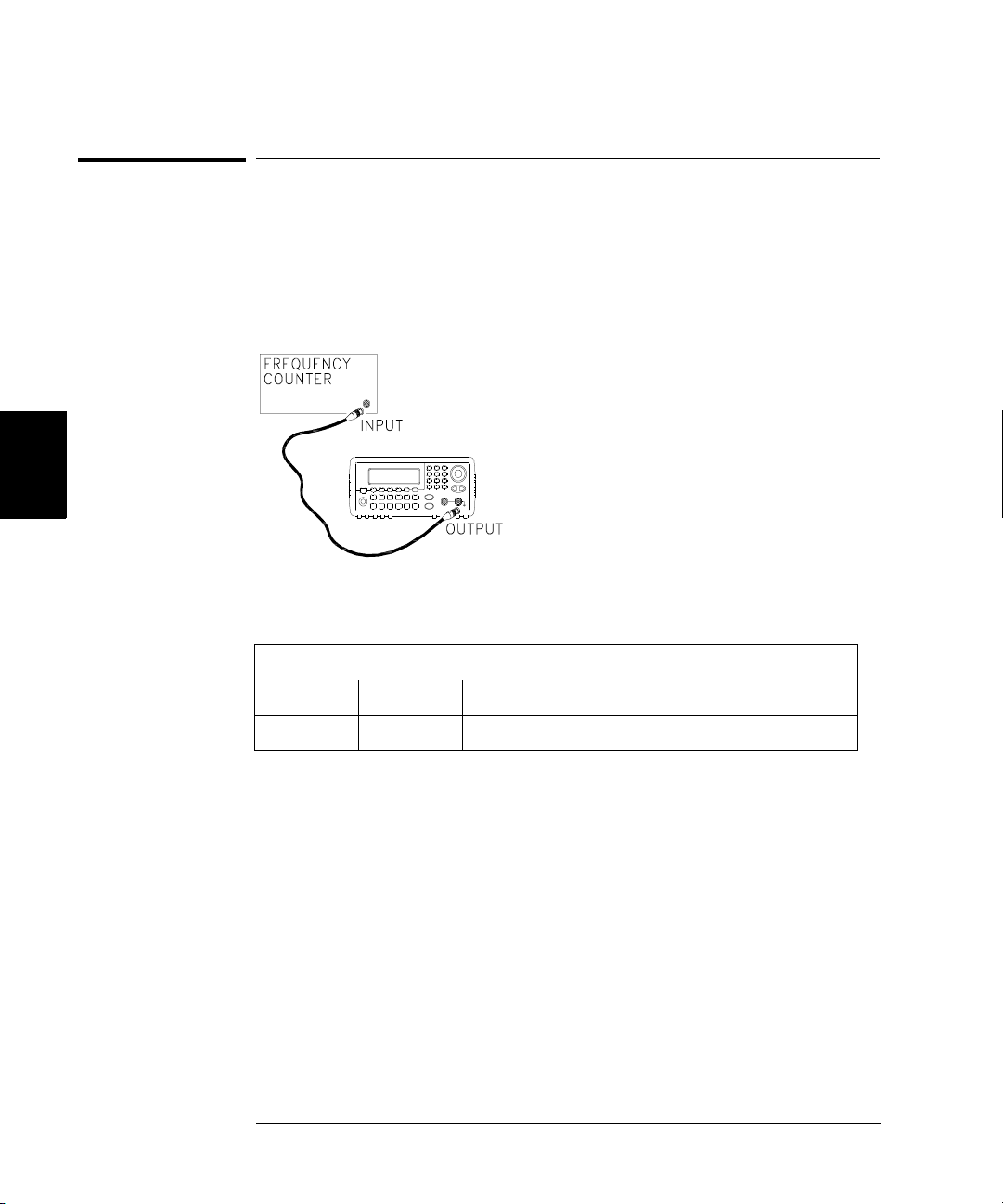

1 Connect a frequency counter as shown below (the frequency counter

input should be terminated at 50

Ω).

2 Set the instrument to the output described in the table below and

measure the output frequency. Be sure the instrument output is enabled.

Agilent 33250A Measurement

Function Amplitude Frequency Nominal Error

Q Sine Wave 1.00 Vpp 10.000,000,0 MHz 10.000 MHz ±20 Hz

3 Compare the measured frequency to the test limits shown in the table.

60

Chapter 4 Calibration Procedures

AC Amplitude (high-impedance) Verification

AC Amplitude (high-impedance) Verification

This procedure checks the ac amplitude output accuracy at a frequency

of 1 kHz, and establishes reference measurements for the higher

frequency flatness verification procedures.

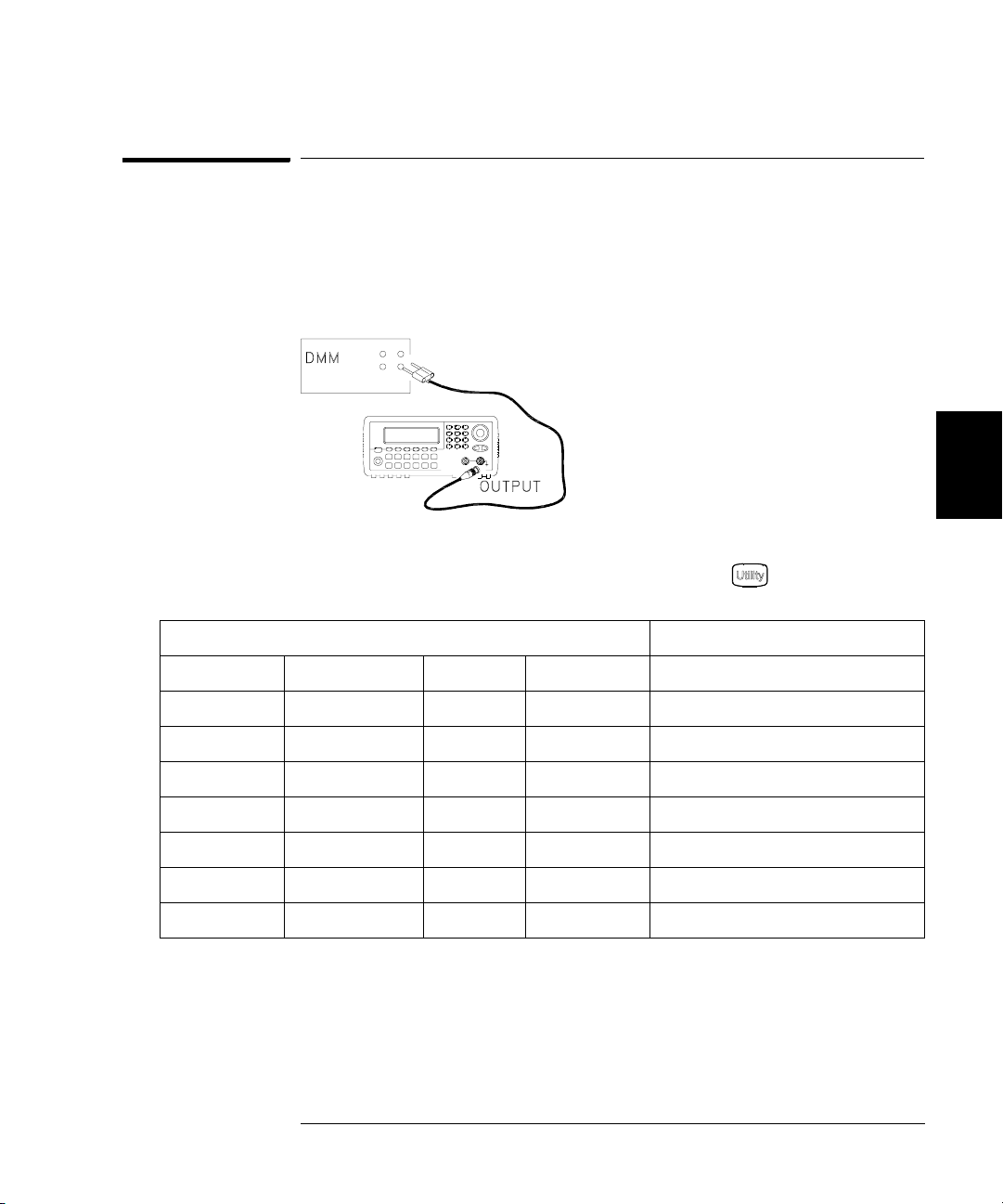

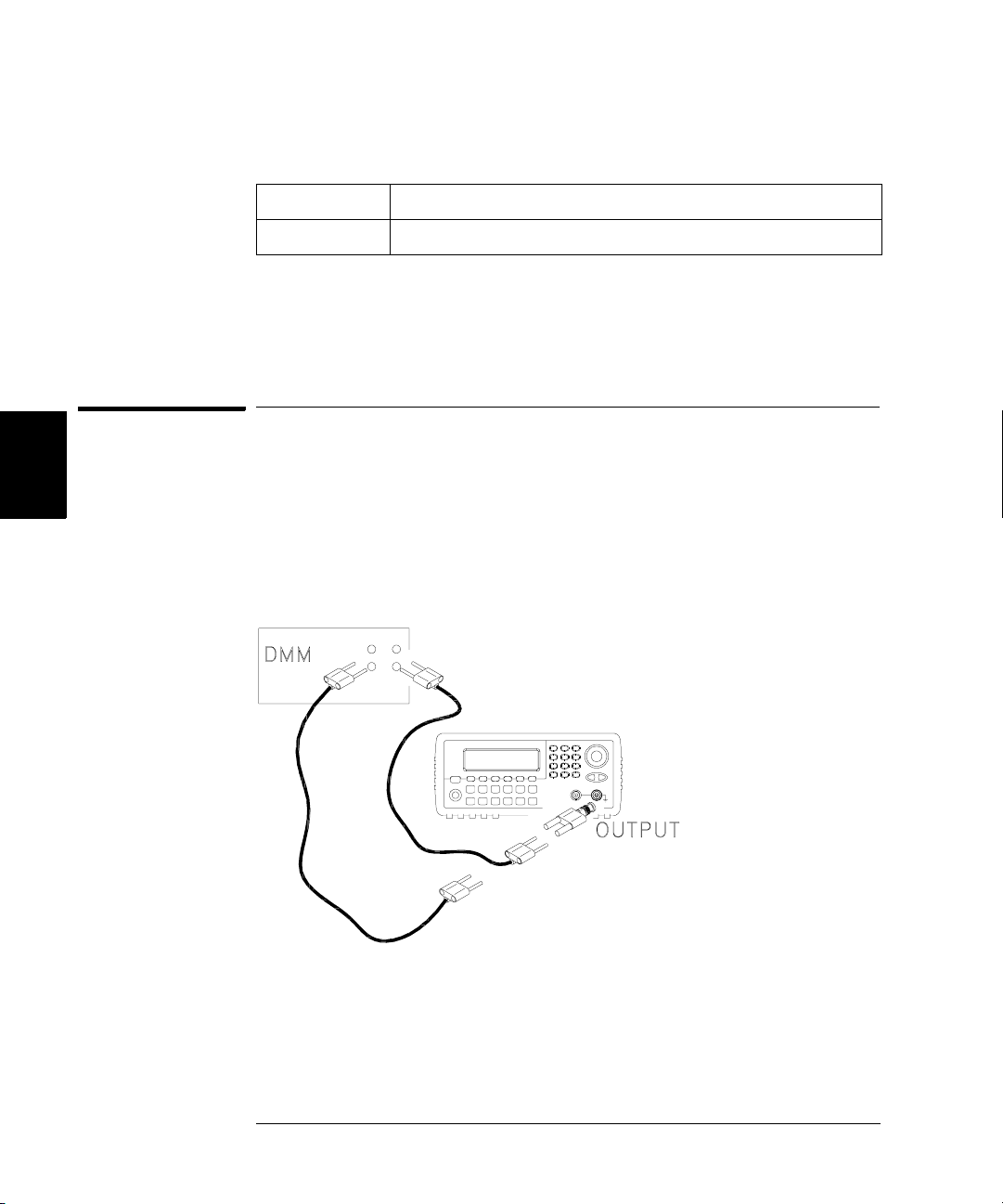

1 Set the DMM to measure Vrms Volts. Connect the DMM as shown below.

4

2 Set the instrument to each output described in the table below and

measure the output voltage with the DMM. Press to set the output

impedance to High-Z. Be sure the output is enabled.

4

Agilent 33250A Measurement

Output Setup Function Frequency Amplitude Nominal Error*

Q High Z Sine Wave 1.000 kHz 20.0 mVrms 0.020 Vrms ± 0.00091 Vrms

Q High Z Sine Wave 1.000 kHz 67.0 mVrms 0.067 Vrms ± 0.00138 Vrms

Q High Z Sine Wave 1.000 kHz 200.0 mVrms 0.200 Vrms ± 0.00271 Vrms

1

Q High Z Sine Wave 1.000 kHz 670.0 mVrms 0.670 Vrms

Q High Z Sine Wave 1.000 kHz 2.000 Vrms 2.0000 Vrms 2± 0.0207 Vrms

Q High Z Sine Wave 1.000 kHz 7.000 Vrms 7.000 Vrms

4

Q High Z Square Wave

* Based upon 1% of setting ±1 mVpp (50Ω); converted to Vrms for High-Z.

1

Enter the measured value on the worksheet (page 59) as 1kHz_0dB_reference.

2

Enter the measured value on the worksheet (page 59) as 1kHz_10dB_reference.

3

Enter the measured value on the worksheet (page 59) as 1kHz_20dB_reference.

4

Square wave amplitude accuracy is not specified. This measurement and error

may be used as a guideline for typical operation.

1.000 kHz 900.0 mVrms 0.900 Vrms ± 0.0100 Vrms

± 0.00741 Vrms

3

± 0.0707 Vrms

3 Compare the measured voltage to the test limits shown in the table.

61

4

Chapter 4 Calibration Procedures

Low Frequency Flatness Verification

Low Frequency Flatness Verification

This procedure checks the AC amplitude flatness at 100 kHz using the

reference measurements recorded in the Amplitude and Flatness

Verification Worksheet. These measurements also establish an error value

used to set the power meter reference. The transfer measurements are

made at a frequency of 100 kHz using both the DMM and the power meter.

1 Set the DMM to measure ac Volts. Connect the DMM as shown in the

figure on page 61.

2 Set the instrument to each output described in the table below and

measure the output voltage with the DMM. Press to set the output

impedance to High-Z. Be sure the output is enabled.

Agilent 33250A Measurement

Output Setup Function Frequency Amplitude Nominal Error

Q High Z Sine Wave 100.000 kHz 670.0 mVrms 0.670 Vrms

Q High Z Sine Wave 100.000 kHz 2.0 Vrms 2.000 Vrms

Q High Z Sine Wave 100.000 kHz 7.000 Vrms 7.000 Vrms

1

Enter the measured value on the worksheet (page 59)

as 100kHz_0dB_reference.

2

Enter the measured value on the worksheet (page 59)

as 100kHz_10dB_reference.

3

Enter the measured value on the worksheet (page 59)

as 100kHz_20dB_reference.

1

± 0.0067 Vrms

2

± 0.020 Vrms

3

± 0.070 Vrms

3 Compare the measured voltage to the test limits shown in the table.

4 You have now recorded all the required measurements on the worksheet

(page 59). Complete the worksheet by making all the indicated calculations.

62

Chapter 4 Calibration Procedures

0 dB Range Flatness Verification

0 dB Range Flatness Verification

This procedure checks the high frequency ac amplitude flatness above

100 kHz on the 0 dB attenuator range.

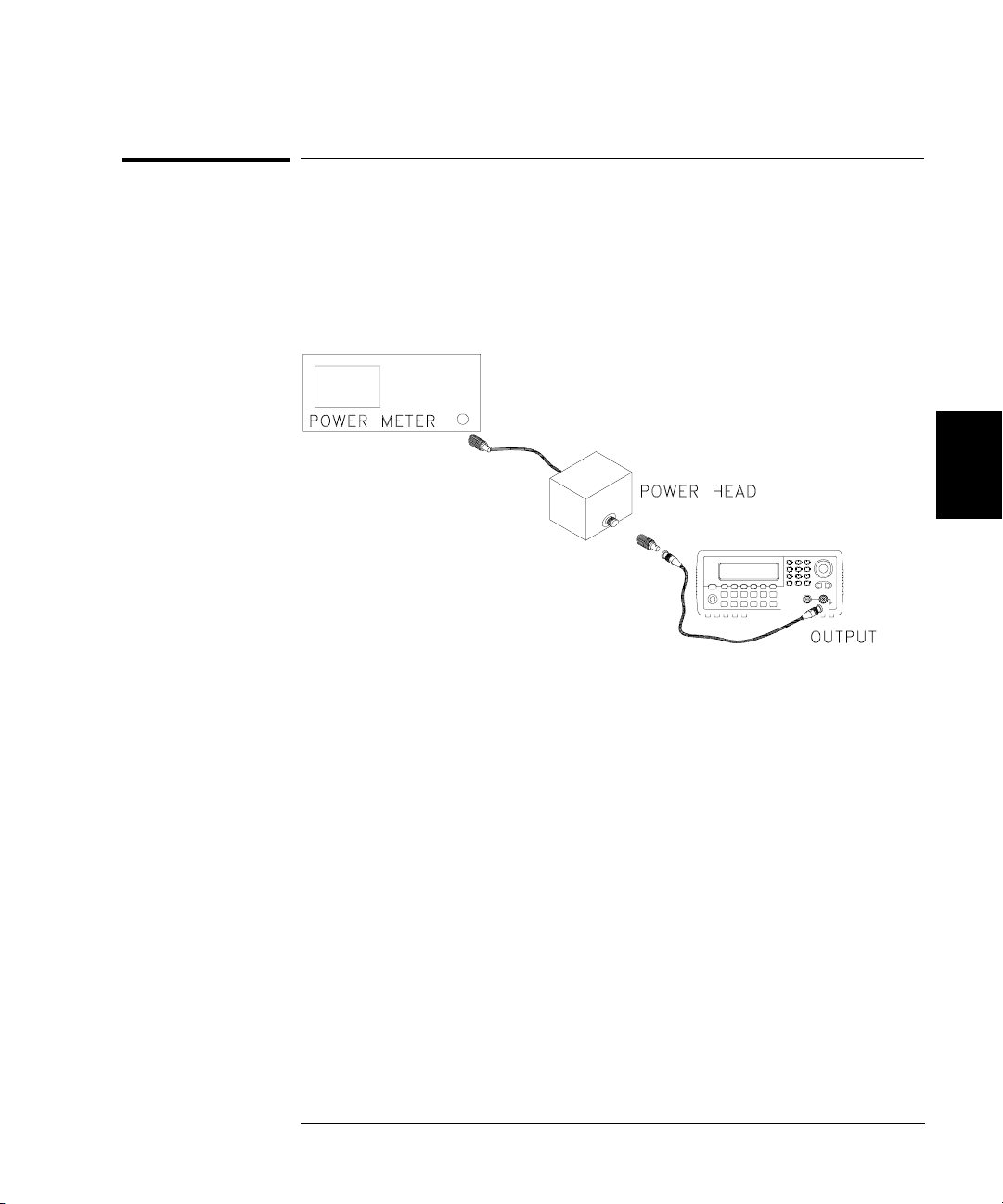

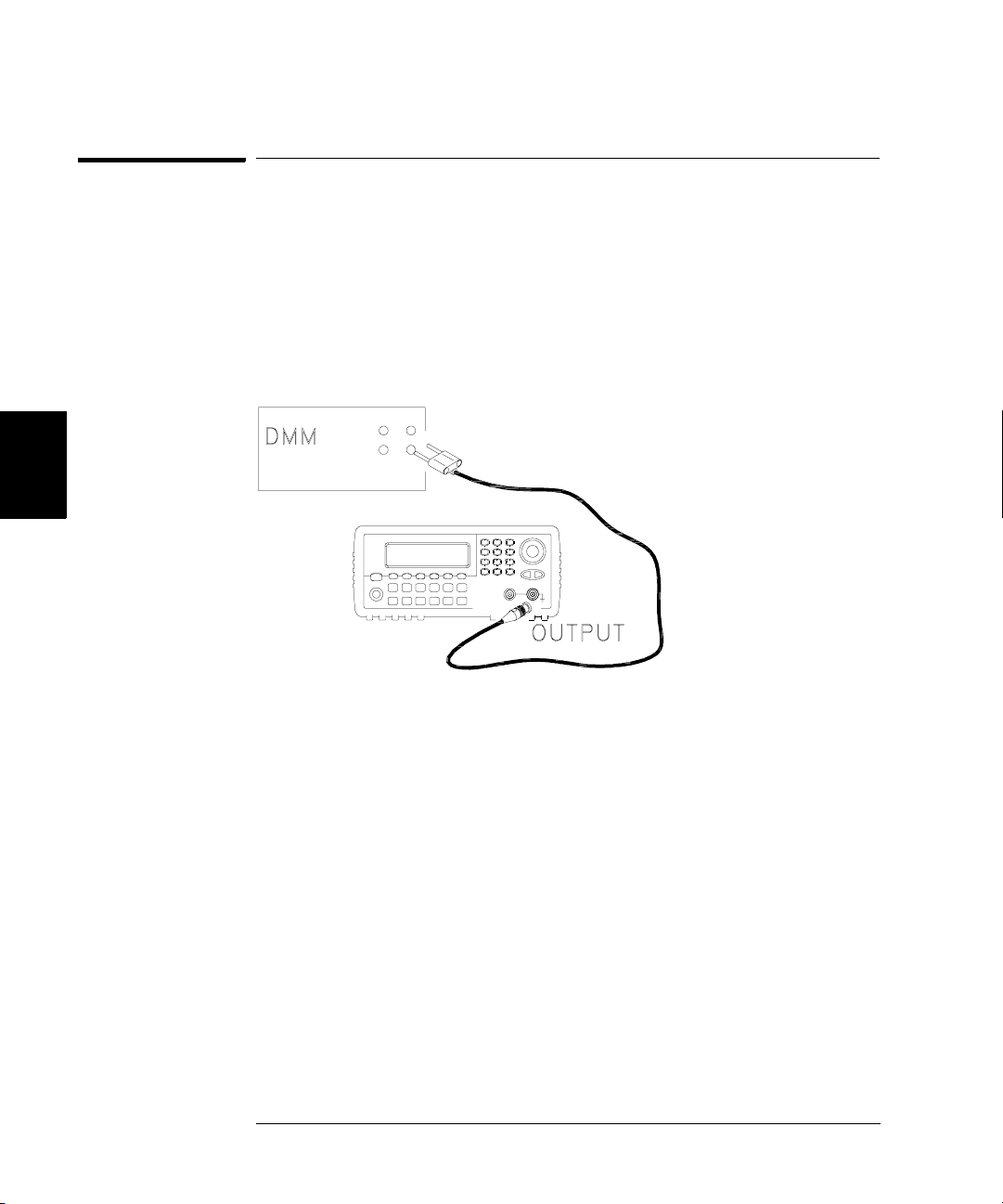

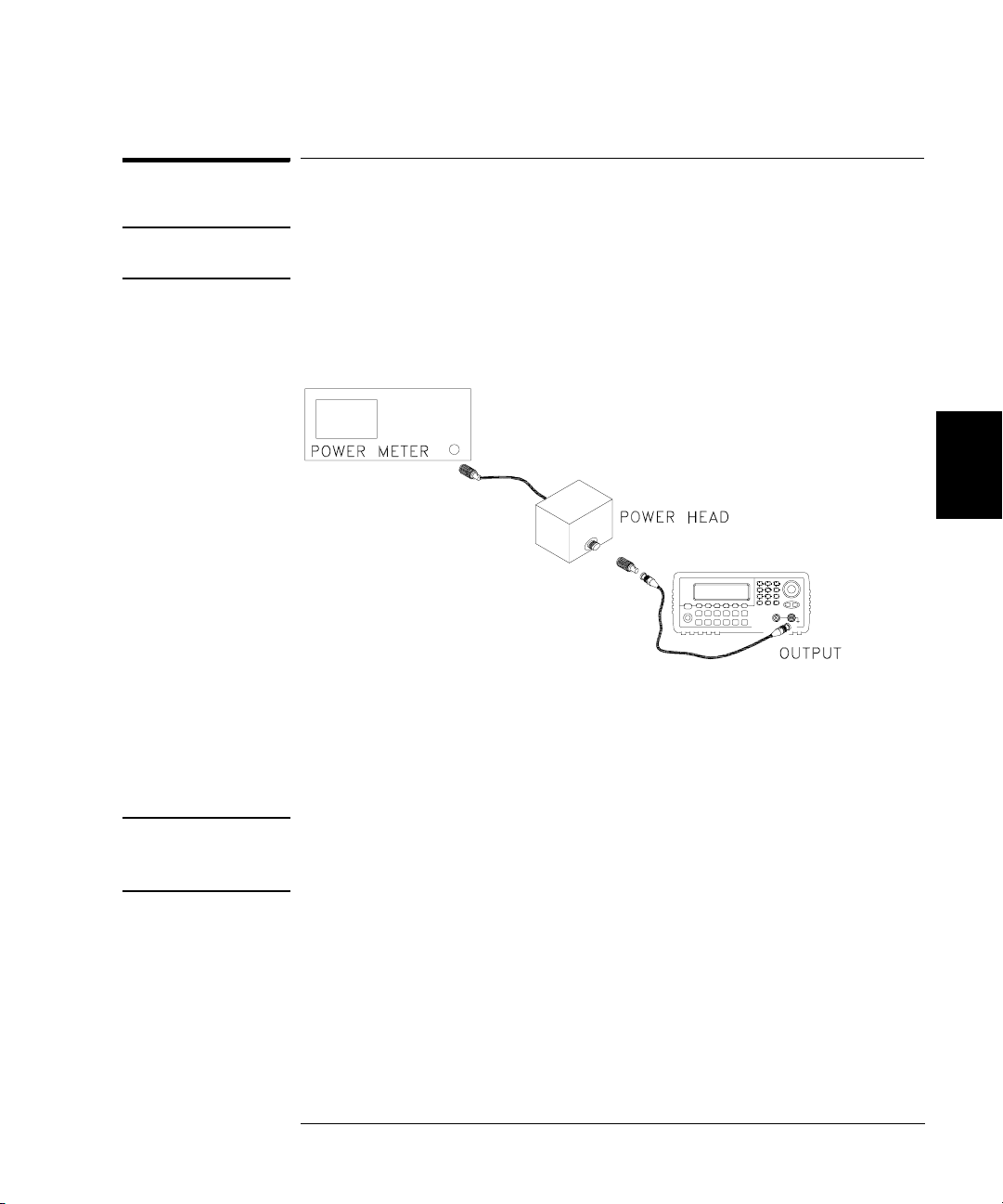

1 Connect the power meter to measure the output amplitude of the

instrument as shown below.

4

4

2 Set the power meter reference level to equal 100kHz_0dB_offset.

This sets the power meter to directly read the flatness error

specification. 100kHz_0dB_offset is calculated on the Amplitude and

Flatness Verification Worksheet.

63

Chapter 4 Calibration Procedures

0 dB Range Flatness Verification

3 Set the instrument to each output described in the table below and

measure the output amplitude with the power meter. Press to set

the output impedance to 50Ω. Be sure the output is enabled.

Agilent 33250A Measurement

Output Setup Function Amplitude Frequency Nominal Error

Q 50 Ω Sine Wave +3.51 dBm 100.000 kHz 0 dB ± 0.086 dB

50 Ω Sine Wave +3.51 dBm 200.000 kHz 0 dB ± 0.086 dB

50 Ω Sine Wave +3.51 dBm 500.000 kHz 0 dB ± 0.086 dB

50 Ω Sine Wave +3.51 dBm 1.500 MHz 0 dB ± 0.086 dB

50 Ω Sine Wave +3.51 dBm 5.000 MHz 0 dB ± 0.086 dB

4

Q 50 Ω Sine Wave +3.51 dBm 10.000 MHz 0 dB ± 0.086 dB

50 Ω Sine Wave +3.51 dBm 25.000 MHz 0 dB ± 0.177 dB

50 Ω Sine Wave +3.51 dBm 40.000 MHz 0 dB ± 0.177 dB

Q 50 Ω Sine Wave +3.51 dBm 50.000 MHz 0 dB ± 0.177 dB

50 Ω Sine Wave +3.51 dBm 60.000 MHz 0 dB ± 0.423 dB

50 Ω Sine Wave +3.51 dBm 65.000 MHz 0 dB ± 0.423 dB

50 Ω Sine Wave +3.51 dBm 70.000 MHz 0 dB ± 0.423 dB

50 Ω Sine Wave +3.51 dBm 75.000 MHz 0 dB ± 0.423 dB

Q 50 Ω Sine Wave +3.51 dBm 80.000 MHz 0 dB ± 0.423 dB

4 Compare the measured output to the test limits shown in the table.

64

Chapter 4 Calibration Procedures

+10 dB Range Flatness Verification

+10 dB Range Flatness Verification

This procedure checks the high frequency ac amplitude flatness above

100 kHz on the +10 dB attenuator range.

1 Connect the power meter to measure the output amplitude of the

instrument as shown on page 63.

2 Set the power meter reference level to equal to the calculated

100kHz_10dB_offset value. This sets the power meter to directly read

the flatness error specification. 100kHz_10dB_offset is calculated on

the Amplitude and Flatness Verification Worksheet.

3 Set the instrument to each output described in the table below and

measure the output amplitude with the power meter. Press to set

the output impedance to 50Ω. Be sure the output is enabled.

Agilent 33250A Measurement

4

4

Output Setup Function Amplitude Frequency Nominal Error

Q 50 Ω Sine Wave +13.00 dBm 100.000 kHz 0 dB ± 0.086 dB

50 Ω Sine Wave +13.00 dBm 200.000 kHz 0 dB ± 0.086 dB

50 Ω Sine Wave +13.00 dBm 500.000 kHz 0 dB ± 0.086 dB

50 Ω Sine Wave +13.00 dBm 1.500 MHz 0 dB ± 0.086 dB

50 Ω Sine Wave +13.00 dBm 5.000 MHz 0 dB ± 0.086 dB

Q 50 Ω Sine Wave +13.00 dBm 10.000 MHz 0 dB ± 0.086 dB

50 Ω Sine Wave +13.00 dBm 25.000 MHz 0 dB ± 0.177 dB

50 Ω Sine Wave +13.00 dBm 40.000 MHz 0 dB ± 0.177 dB

Q 50 Ω Sine Wave +13.00 dBm 50.000 MHz 0 dB ± 0.177 dB

50 Ω Sine Wave +13.00 dBm 60.000 MHz 0 dB ± 0.423 dB

50 Ω Sine Wave +13.00 dBm 65.000 MHz 0 dB ± 0.423 dB

50 Ω Sine Wave +13.00 dBm 70.000 MHz 0 dB ± 0.423 dB

50 Ω Sine Wave +13.00 dBm 75.000 MHz 0 dB ± 0.423 dB

Q 50 Ω Sine Wave +13.00 dBm 80.000 MHz 0 dB ± 0.423 dB

4 Compare the measured output to the test limits shown in the table.

65

4

Chapter 4 Calibration Procedures

+20 dB Range Flatness Verification

+20 dB Range Flatness Verification

This procedure checks the high frequency ac amplitude flatness above

100 kHz on the +20 dB attenuator range.

1 Connect the power meter to measure the output voltage of the

instrument as shown below.

2 Set the power meter reference level to equal to the calculated

100kHz_20dB_offset value. This sets the power meter to directly read the

flatness error specification. 100kHz_20dB_offset is calculated on the

Amplitude and Flatness Verification Worksheet.

Caution Most power meters will require an attenuator or special power head to

measure the +20 dB output.

66

Chapter 4 Calibration Procedures

+20 dB Range Flatness Verification

3 Set the instrument to each output described in the table below and

measure the output amplitude with the power meter. Press to set

the output impedance to 50Ω. Be sure the output is enabled

Agilent 33250A Measurement

Output Setup Function Amplitude Frequency Nominal Error

Q 50 Ω Sine Wave +23.90 dBm 100.000 kHz 0 dB ± 0.086 dB

50 Ω Sine Wave +23.90 dBm 200.000 kHz 0 dB ± 0.086 dB

50 Ω Sine Wave +23.90 dBm 500.000 kHz 0 dB ± 0.086 dB

50 Ω Sine Wave +23.90 dBm 1.500 MHz 0 dB ± 0.086 dB

50 Ω Sine Wave +23.90 dBm 5.000 MHz 0 dB ± 0.086 dB

4

Q 50 Ω Sine Wave +23.90 dBm 10.000 MHz 0 dB ± 0.086 dB

50 Ω Sine Wave +23.90 dBm 25.000 MHz 0 dB ± 0.177 dB

50 Ω Sine Wave +23.90 dBm 40.000 MHz 0 dB ± 0.177 dB

Q 50 Ω Sine Wave +23.90 dBm 50.000 MHz 0 dB ± 0.177 dB

50 Ω Sine Wave +23.90 dBm 60.000 MHz 0 dB ± 0.423 dB

50 Ω Sine Wave +23.90 dBm 65.000 MHz 0 dB ± 0.423 dB

50 Ω Sine Wave +23.90 dBm 70.000 MHz 0 dB ± 0.423 dB

50 Ω Sine Wave +23.90 dBm 75.000 MHz 0 dB ± 0.423 dB

Q 50 Ω Sine Wave +23.90 dBm 80.000 MHz 0 dB ± 0.423 dB

4 Compare the measured output to the test limits shown in the table.

4

67

Chapter 4 Calibration Procedures

Calibration Security

Calibration Security

This feature allows you to enter a security code to prevent accidental

or unauthorized adjustments of the instrument. When you first receive

your instrument, it is secured. Before you can adjust the instrument,

you must unsecure it by entering the correct security code.

See “To Unsecure and Secure for Calibration”, on page 41 for a procedure

to enter the security code.

4

• The security code is set to

from the factory. The security code is stored in non-volatile memory,

and does not change when power has been off, after a Factory Reset

(

*RST command), or after an Instrument Preset (SYSTem:PRESet

command).

• The security code may contain up to 12 alphanumeric characters.

The first character must be a letter, but the remaining characters

can be letters, numbers, or an underscore ( _ ). You do not have to

use all 12 characters but the first character must always be a letter.

Note: If you forget your security code, you can disable the security feature

by applying a temporary short inside the instrument as described on the

following page.

AT33250A when the instrument is shipped

68

Chapter 4 Calibration Procedures

Calibration Security

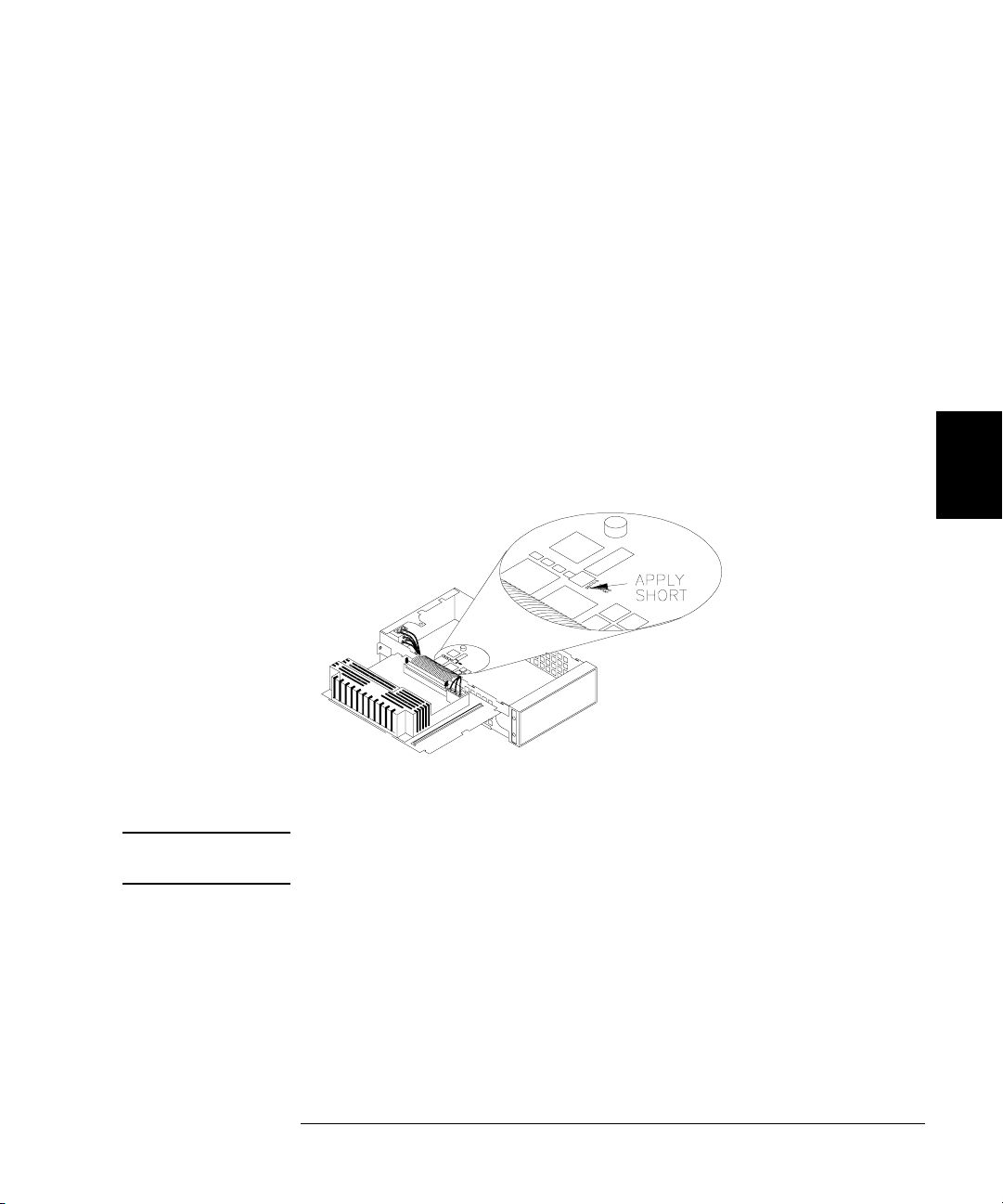

To Unsecure the Instrument Without the Security Code

To unsecure the instrument without the correct security code, follow the

steps below. See “To Unsecure and Secure for Calibration” on page 41.

See “Electrostatic Discharge (ESD) Precautions” on page 133 before

beginning this procedure.

1 Disconnect the power cord and all input connections.

2 Remove the instrument cover. See “Disassembly” on page 140.

3 Remove the main power supply.

4 Apply a temporary short between the two exposed metal pads on the

A1 assembly. The general location is shown in the figure below. On the

PC board, the pads are marked CAL ORIDE.

5 Apply power and turn on the instrument.

WARNING Be careful not to touch the power line connections or high voltages on the

power supply module.

4

4

6 The display will show the message “Calibration security has been

disabled”. The instrument is now unsecured.

7 Turn off the instrument and remove the power cord.

8 Reassemble the instrument.

Now you can enter a new security code, see “To Unsecure and Secure for

Calibration”, on page 41. Be sure you record the new security code.

69

4

Chapter 4 Calibration Procedures

Calibration Message

Calibration Message

The instrument allows you to store one message in calibration memory.

For example, you can store such information as the date when the last

calibration was performed, the date when the next calibration is due,

the instrument’s serial number, or even the name and phone number

of the person to contact for a new calibration.

You can record a calibration message only from the remote interface

and only when the instrument is unsecured.

You can read the message from either the front-panel or over the remote

interface. You can read the calibration message whether the instrument

is secured or unsecured. Reading the calibration message from the front

panel is described on “To Read the Calibration Information”, on page 40.

Calibration Count

You can query the instrument to determine how many calibrations have

been performed. Note that your instrument was calibrated before it left

the factory. When you receive your instrument, read the count to

determine its initial value. The count value increments by one for each

calibration point, and a complete calibration may increase the value by

many counts. See “To Read the Calibration Information”, on page 40.

70

Chapter 4 Calibration Procedures

General Calibration/Adjustment Procedure

General Calibration/Adjustment Procedure

The following procedure is the recommended method to complete an

instrument calibration. This procedure is an overview of the steps

required for a complete calibration. Additional details for each step in

this procedure are given in the appropriate sections of this chapter.

1 Read “Test Considerations” on page 54.