Page 1

5 OPERATING

f

‘\

AND SERVICE

GENERATOR

MANUAL

214A

HEWLETT

m

-meT&~c~~R~

Y

Page 2

COPYRIGHT AND DISCLAIMER NOTICE

Copyright - Agilent Technologies, Inc. Reproduced with the permission of Agilent

Technologies Inc. Agilent Technologies, Inc. makes no warranty of any kind with regard

to this material including, but not limited to, the implied warranties of merchantability

and fitness for a particular purpose. Agilent Technologies, Inc. is not liable for errors

contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this material or data.

Page 3

CERTIFICATION

The Hewlett-Packard Company certifies that this instrument was

thoroughly tested and inspected and found to meet its published

specifications when it was shipped from the factory. The Hewlett-

Packard Company further certifies that its calibration measurements

are traceable to the U. S. National Bureau

allowed by the Bureau’s calibration facility.

of

Standards to the extent

WARRANTY AND ASSISTANCE

All Hewlett-Packard products are warranted against defects in

materials and workmanship. This warranty applies for one year from

the date of delivery, or, in the case of certain major components listed

in the operating manual, for the specified period. We will repair or

replace products which prove to be defective during the warranty

period. No other warranty is expressed or implied. We are not liable

for consequential damages.

For any assistance contact your nearest Hewlett-Packard Sales and

Service Office. Addresses are provided at the back of this manual.

Page 4

OPERATING AND SERVICE MANUAL

MODEL 214A

PULSEGENERATOR

SERIALS PREFIXED: 812.

02056-7 PRINTED: APR 1968

Page 5

Table of Contents Model 214A

TABLE OF CONTENTS

Section Page

I GENERAL INFORMATION. ........... l-l

l-l. Instrument Description ......... l-l

l-5. Instrument Applications ........ 1-2

1-7.

Equipment and Accessories

Available ................ l-2

l-9. Differences Between Instruments . . l-2

II PREPARATION FOR USE

2-l. Initial Inspection .............

2-3. AC Power Considerations

............

.......

2 - 1

2 - 1

2-l

2-4. Power Source Requirements ... 2-l

2-6.

Three-Conductor Power Cable . . 2-l

2-8. Ventilation Requirements ....... 2 -1

2-11. Rack/Bench Conversion ........

2-l

2-15. Repackaging for Shipment ....... 2 -1

2-16. Packaging Suggestions ....... 2 -1

2-18.

Returning for Service or Repair . 2-2

III OPERATING INSTRUCTIONS .......... 3-l

3-l. General ................... 3-l

3-3. Operating Considerations ....... 3 - 1

3-4. Duty Cycle Limitation. .......

3-l

3-7. Pulse Position vs. Rate ...... 3-l

3-9. Minimum Spacing with Double

Pulses ................

3-3

3-11. Gating of Pulses ........... 3-3

3-13. Operating Procedures. .........

3-3

3-14. Manual Trigger Mode ........ 3-3

3-16. External Trigger Mode ....... 3-3

3-18. Internal Trigger Mode ....... 3-3

IV PRINCIPLES OF OPERATION

.........

4-1

4-l. General ................... 4-1

4-3. Input and Rate Generator. ....... 4-l

4-4. External Trigger Operation .... 4-1

4-7. Manual Trigger Operation ..... 4-l

4-9. Internal Trigger Operation

.... 4-1

4-11. Trigger Blocking Oscillator. ... 4-l

4-13.

Gate Input Circuit ............

4-2

4-15. Advance, Delay, Double Pulse

4-17.

Modes ..................

Pulse Position Circuit .......

4-2

4-2

4-20. Pulse Width Multivibrator ..... 4-2

4-22.

Trigger Output Blocking

Oscillator. ............. 4-2

4-24. Start-Stop Pulse Blocking

Oscillators ............. 4-2

4-27. Pulse Advance Timing Logic ...

4-2

APPENDIX I MANUAL CHANGES. * . * . * * . * . * . I-l

Section

Page

4-29. Pulse Delay Timing Logic ..... 4-2

4-31. Double Pulse Timing Logic

.... 4-3

4-33. Forming and Controlling Output

Pulse. .................. 4-3

4-35. Start Pulse Spiker .......... 4-3

4-37. Stop Pulse Spiker. .......... 4-4

4-39. Pulse Output Circuit. ........ 4-4

4-41.

Pulse Output Amplitude Controls. 4-4

4-43. Reversing Pulse Polarity. ..... 4-4

V MAINTENANCE .................. 5-l

5-l. Introduction ................ 5-l

5-3. Performance Check ........... 5-l

5-5.

External Gating ............

5-l

5-6. External Triggering ......... 5-l

5-7. Pulse Amplitude and Width

.... 5-l

5-8. Pulse Position. ............ 5-2

5-9.

Double Pulse and Manual

Triggering ............. 5-3

5-10. Internal Rep Rate. ..........

5-3

5-11. Duty Cycle ............... 5-3

5-12. Pulse Droop .............. 5-4

5-13.

Overshoot, Preshoot, and Pulse

Top Variation ........... 5-4

5-14.

Rise Time and Fall Time

..... 5-4

5-15. Rate and Width Jitter ........ 5-5

5-16. Output Pulse to Trigger Output

Jitter ................ 5-6

5-17. Adjustments ................ 5-6

5-21. Power Supply Adjustment ..... 5-6

5-23. Rate Multivibrator .......... 5 -6

5-24.

Pulse Position Multivibrator

... 5-7

5-25. Output Bias Current ......... 5-8

5-26.

Pulse Width and Amplitude

.... 5-8

5-27. Overload Relay Adjust ....... 5-10

5-28. Troubleshooting. .............

5-10

5-30. Trigger Mode Checks ........ 5-10

5-31. Pulse Control Checks

5-32.

Output Circuit Checks.

........ 5-10

....... 5-10

5-33. Power Supply Checks ........ 5-11

5-35. Repair and Replacement

....... .5- 11

5-36. General ................. 5-11

5-38. Servicing Etched Circuit Boards. . 5- 11

5-40. Periodic Maintenance .......... 5-11

5-41. General ................. 5-11

5-43. Cleaning Air Filter ......... 5-11

VI REPLACEABLE PARTS .............

6-l

6-l. Introduction ................ 6-l

6-4. Ordering Information .......... 6-l

ii

02056-3

Page 6

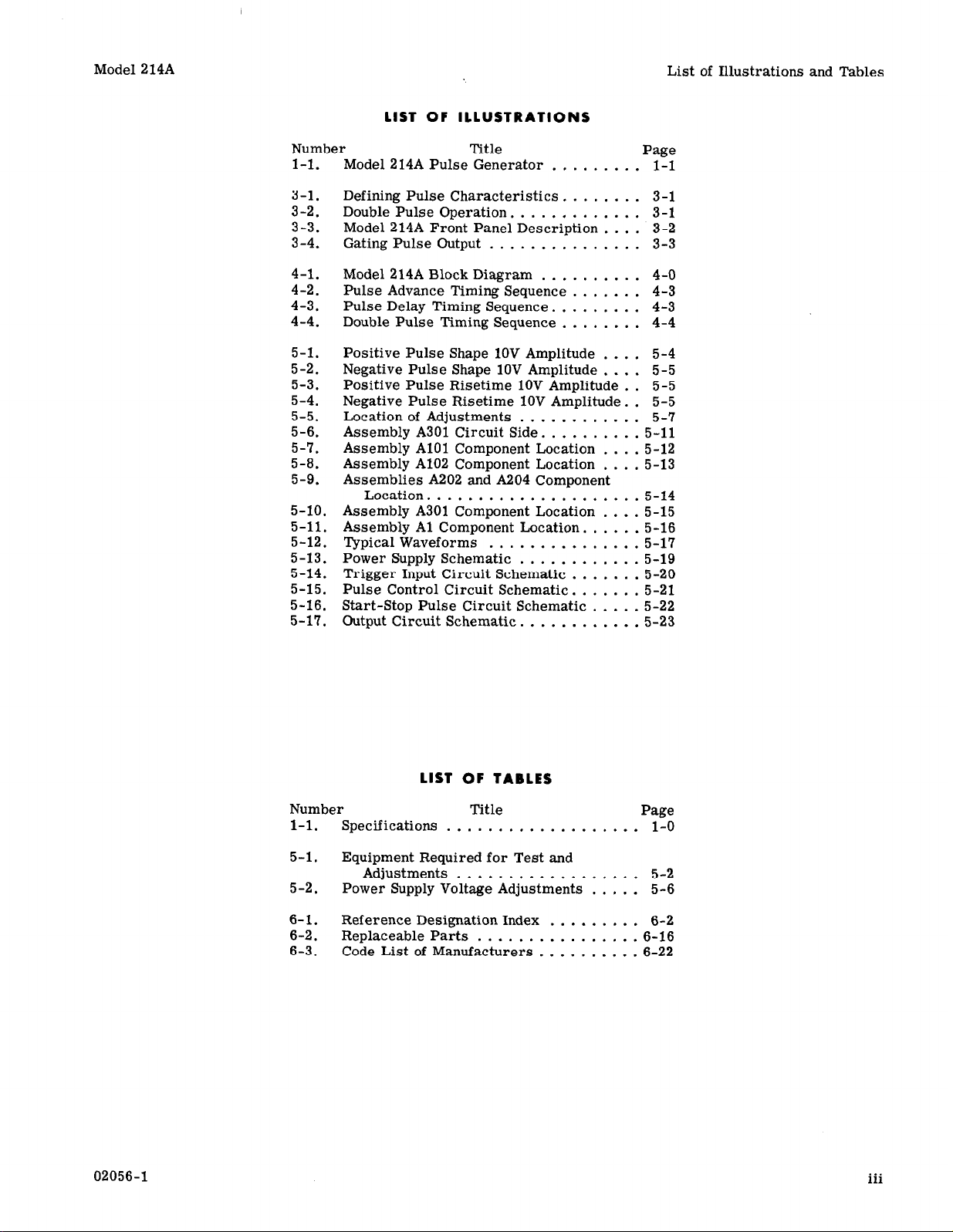

Model 214A List of Illustrations and Tables

LIST OF ILLUSTRATIONS

Number Title

Page

l-l. Model 214A Pulse Generator ......... l-1

3-1.

Defining Pulse Characteristics. ....... 3-l

3-2, Double Pulse Operation ............. 3 - 1

3-3. Model 214A Front Panel Description .... 3-2

3-4. Gating Pulse Output ............... 3-3

4-l. Model 214A Block Diagram ..........

4-O

4-2. Pulse Advance Timing Sequence ....... 4-3

4-3. Pulse Delay Timing Sequence. ........ 4-3

4-4. Double Pulse Timing Sequence ........ 4-4

5-l.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

5-8.

5-9.

5-10.

5-11.

5-12.

5-13.

5-14.

5-15.

5-16.

5-17.

Positive Pulse Shape 1OV Amplitude

Negative Pulse Shape 1OV Amplitude .... 5-5

Positive Pulse Risetime 1OV Amplitude . . 5-5

Negative Pulse Risetime 1OV Amplitude. . 5-5

Location of Adjustments ............

Assembly A301 Circuit Side. ......... 5-11

Assembly Al01 Component Location

Assembly Al02 Component Location .... 5-13

Assemblies A202 and A204 Component

Location.

....................

Assembly A301 Component Location

Assembly Al Component Location. ..... 5-16

Typical Waveforms ............... 5-17

Power Supply Schematic ............

Trigger Input Circuit Schematic ....... 5-20

Pulse Control Circuit Schematic.

Start-Stop Pulse Circuit Schematic ..... 5-22

Output Circuit Schematic. ...........

.... 5-4

5-7

.... 5-12

5-14

.... 5-15

5-19

...... 5-21

5-23

02056-l

LIST OF TABLES

Number Title Page

l-l. Specifications . . . . . . . . . . . . . . . . . . . 1-O

5-l. Equipment Required for Test and

Adjustments . . . . . . . . . . . . . . . . . . 5-2

5-2. Power Supply Voltage Adjustments . . , . . 5-6

6-l. Reference Designation Index . . . . . . . . . 6-2

6-2. Replaceable Parts . . . . . . . . . . . . . . . . 6-16

6-3. Code List of Manufacturers . . . . . . . . . . 6-22

. . .

111

Page 7

Section I

Table l-l

Model 214A

Table l- 1. Specifications

1

OUTPUT PULSE

Source Impedance:

lower ranges: approximately 1500 ohms on the

lOO-volt range.

Pulse Shape

Rise and Fall Time: <13 nsec on 20-volt and

lower ranges and the -50 volt range, < 15 nsec

on the +50 volt range.

with vernier set for maximum attenuation.

1OOV range typically 15 nsec.

Pulse Amplitude:

attenuator provides 0.2 to 100 volts in a 1,2,

5, 10 sequence (9 ranges). Vernier reduces

output of 0.2~ setting to 80 mv and provides

continuous adjustment between ranges.

Polarity: Positive or negative.

Overshoot: < 50/o, both leading and trailing edges.

Pulse Top Variations: < 4%.

Droop: < 6%.

Preshoot: < 2%.

Pulse Width: 50 nsec to 10 ms in 5 decade

ranges. Continuously adjustable vernier.

Width Jitter: < .05% of pulse width + 1 nsec.

50 ohms on the 50-volt and

Typically < 10 nsec

100 volts into 50 ohms. An

External

Repetition Rate: DC to 1 MC

Sensitivity: < 0.5~ pk

Slope: Positive or negative

Level: Adjustable from -40~ to +4Ov.

Delay: Delay between input trigger and leading

edge of pulse out is approximately 250 nsec in

Pulse Advance mode (approx. 420 nsec minimum in Pulse Delay mode).

External Gating: +8 volt signal gates pulse gen-

erator on. Maximum signal, +4Ov peak.

Double Pulse

Minimum Spacing: 1 usec on the .05 to lksec

pulse width range.

upper limit of Width range.

Trigger Output

Amplitude: > 1Ov open circuit.

Width: 0.05 psec, nominal.

Polarity: Positive or negative.

GENERAL

Maximum Duty Cycle: 10% on 100 and 50 volt

ranges; 25% on 20 volt range; 50% on 10 volt

and lower ranges.

Power: 115 or 23OvilO%, 50 to 60 cps,

Dimensions:

On all other ranges 25% of

325

watts.

Pulse Position: 0 to 10 ms advance or delay,

with respect to trigger output (5 decade ranges).

Continuously adjustable vernier.

Position Jitter: < 0.05% of advance or delay

setting +l ns (between trigger pulse and output

pulse).

REPETITION RATE AND TRIGGER

Internal

Repetition Rate:

continuously adjustable vernier.

Rate Jitter: < 0.5% of the period.

Manual: Push button single pulse, 2 cps maxi-

mum rate.

10 cps to 1 MC (5 ranges),

Weight:

(19,6 kg).

Net 35 lbs. (15,8 kg). Shipping 48 lbs.

J

1-o

02056-3

Page 8

Model 214A

Paragraphs l-l to l-4

Section I

SECTION I

GENERAL INFORMATION

l-l. INSTRUMENT DESCRIPTION.

1-2. The m@$ Model 214APulseGenerator (Figure l-l)

is a versatile instrument providing variable repetition rate, variable width, variable amplitude, positive or negative, pulses with a rise and fall time of

less than 15 nanoseconds. The complete specifications are given in Table l-l. Pulse power of up to

200 watts is available when using a 50-ohmload. The

Model 214A output impedance matches an external

system of 50 ohms on all ranges of 50 volts amplitude

and below, thus minimizing reflections. The maxi-

mum pulse amplitude is 100 volts (with a source

impedance of 1500 ohms) and the amplitude may be

set as low as 80 millivolts using the vernier and the

lowest range. For pulse amplitudes of 10 volts and

less, the duty cycle may be set as high as 50% (see

Table l-l for duty cycle limits at other amplitudes),

providing a square wave output.

l-3. Pulses may be obtained from the Model 214A

at a rate of dc to 1 MC using an external trigger source

or from 10 cps to 1 MC with an internal generator.

For external triggers, positive or negative signals

of 0.5 volt peak may be used and trigger slope and

level may be selected to determine the triggering

point on the waveform. A single pulse may be obtained

from an internal circuit each time a manual button

is pushed. Gating of pulses is done easily by applying

an external signal and an output occurs only when the

gating signal reaches a positive 8 volt level. Three

modes of pulse operation allow: (1) setting of the

output pulse to occur from 0 to 10 ms before (advance)

the trigger output, (2) setting of the output pulse to

occur from 0 to 10 ms after (delay) the trigger output,

or (3) a double pulse output with variable spacing

between the two pulses.

l-4. The Hewlett-Packard modular instrument enclosure system provides advantages in maintenance

and operation. Easy removal of instrument covers

allows access to all chassis and circuit components.

As a bench type instrument the modular design provides mechanical stability even when several instruments are stacked together. The bench type instrument is readily converted for use in standard width

02056-l

Figure l-l. Model 214A Pulse Generator

l-l

Page 9

Section I

Paragraphs l-5 to l-10

Model 214A

rack using hardware shipped with the instrument.

Paragraph 2-11 explains the details of converting to

either the rack or bench version,

l-5. INSTRUMENT APPLICATIONS.

l-6. With its variable pulse characteristics the

Model 214A is useful as a general purpose laboratory

or production line test instrument.

The high peak

current output available, 2 amps, is useful for testing

current driven devices such as magnetic memory

cores, high power modulators, and power amplifiers.

Fast rise and fall time combined with highpower out-

put pulses facilitate checking switching time of high

power semiconductors. The positiveor negative pulse

output, with identical characteristics, provides an

easy technique for checking either npn or pnp type

transistors. By gating the Model 214A output, a

burst of pulses may be obtained for making computer

logic measurements. The double pulse feature may

also be used for pulse resolution tests of amplifiers

and memory cores.

l-7. EQUIPMENT AND ACCESSORIES

AVAILABLE.

l-8. A complete line of electronic test equipment

is available from the Hewlett-Packard Company for

use in making test measurements with, or maintaining, the Model 214A. Also available are cables,

connectors, adapters and other accessory items for

use in various test or measurement applications.

For information on specific items, consult the &?

Catalog or your @ Field Engineer.

1-9. DIFFERENCES BETWEEN INSTRUMENTS.

l-10. The Hewlett-Packard Company uses a two-

section, eight-digit serial number to identify instruments (e.g. ~-00000). The serial number is located

on a plate attached to the instrument rear panel. The

first three digits are a serial prefix number, also

appearing on the first page of this manual, and the

last five digits identify a specific instrument. If the

serial prefix number of the instrument is higher than

that on the first page, change sheets included with the

manual will define differences between other instru-

ments and the Model 214A described herein. If the

change sheets are missing, your @J Field Engineer

can supply the information. Refer to Appendix I at

the back of this manual for changes required to adapt

this manual to an instrument with a lower serial

prefix.

Page 10

Model 2 14A

SECTION II

PREPARATION FOR USE

2-1.

INIT

IAL INSPECTION.

2-2.

Upon receipt of the Model 214A, verify that

the contents are intact and complete as ordered.

Inspect the instrument for any physical damage such

as a scratched panel surface, broken knob or connector,

possible reshipment,

material if reusable (see Paragraph 2-15), until a

satisfactory operational check (Paragraph 5-3) is

completed. If damage is found, file a claim with

the freight carrier and refer to the warranty page in

this manual. Section V outlines the recommended

adjustment and troubleshooting procedures needed

for normal maintenance or recalibration.

2-3. AC POWER CONSIDERATIONS.

2-4. POWER SOURCE REQUIREMENTS.

2-5. The Model 214A may be operated from an ac

source of 115 or 230 volts (&lO%), at 50 to 60 cps.

With the instrument power cord disconnected, move

the slide switch (located on the rear panel) until the

desired voltage numbers (115 or 230) are visible. A

narrow-blade screwdriver may be used to operate

the switch. Fuse Fl (holder on rear panel) should be

3.2 amperes, slow-blow for 115~ operation or 1.6

amperes, slow-blow for 230~ operation.

2-6. THREE-CONDUCTOR POWER CABLE.

2-7. To protect operating personnel, the National

Electrical Manufacturers’ Association (NEMA) re-

commends that the instrument and cabinet be grounded.

The Model 214A is supplied with a detachable three-

conductor power cable which, when plugged into an

appropriate receptacle, grounds the instrument to

the power line ground. The round pin on the power

cable is the ground connection. To retain the protection feature when operating the instrument from

a two-contact outlet, use a three-conductor to twoconductor adapter and connect the adapter wire to a

suitable ground.

2-B. VENTILATION REQUIREMENTS.

2-9.

GENERAL. The cooling fan and air filter are

located on the rear panel of the Model 214A. Leave

adequate clearance (at least 2 to 3 inches) behind and

at both sides of the instrument for free movement of

air. The path of air flow is through the filter and

intake fan then out of the perforated side covers. It

is important to keep the air intake area free of dust

and small particles which could clog the filter.

Section V provides maintenance information for fan

and filter. In a rack installation be sure that recirculation of warm air within the rack cabinet does

not produce an ambient temperature high enough to

affect instrument operation.

02056-l

incurred in shipping. To facilitate

etc.,

keep the original packing

Paragraphs 2-1 to 2-1’7

Section II

2-10. COATING FILTER. Before placing the instrument in use, the air filter should be coated with a

filter adhesive preparation. A recommended pre-

paration is No. 3 Filter Coat, made by Research

Products Company, and available in sprayer cans at

heating-supply stores. This may also be obtained by

contacting your @ Field Engineer (see maps at back

of this manual) or by ordering directly from @

Customer Service. Hewlett-Packard stock number

is 3150-0002.

2-11. RACK/BENCH CONVERSION.

2-12. The Model 214A is shipped as a bench-type

instrument (even when ordered as a rack type) with

plastic feet and tilt stand in place. The @ modular

instrument enclosure system allows easy conversion

to either bench or rack

mode.

Refer to the appropri-

ate following procedure for conversion.

2-13. CONVERSION TO RACK MODEL.

a. Detach the tilt stand and all the plastic feet.

Tilt stand removes by pressing away from the front

feet. Remove feet by depressing metal release

button and sliding feet free.

b. Using a thin-blade tool, loosen and remove the

plastic trim strip (with adhesive back) from eachside

of the instrument (directly behind front handles).

Removal of strip exposes threaded nuts pressed in

the side casting.

c. Attach the rack-mounting flanges, with the screws

provided, in the space where the trim strip was

adhered. Each flange extends slightly below the

front panel when attached correctly.

d. If the instrument is to be placed in a rack above

or below another @ modular instrument, attach the

filler strip between the front panels. Insert Model

214A in the rack and secure flanges to rack.

2-14. CONVERSION TO BENCH.

a. Remove instrument from rack, detach rackmounting flanges and filler strip, if used between

front panels.

b. Attach trim strip (in slots where rack flanges

were located), plastic feet, and tilt stand. A fifth

plastic foot at center-front of the instrument provides

extra stability when the Model 214A is stacked atop

another @ modular bench-type instrument.

2-15. REPACKAGING FOR SHIPMENT.

2-16. PACKAGING SUGGESTIONS.

2-17. To package an instrument for shipment, some

types of original packing materials may be reused,

or your @ Field Engineer will provide assistance in

obtaining suitable packaging. The types of original

2-l

Page 11

Section II

Paragraphs 2-18 to 2-19

Model 214A

packing materials which may be reused are: (1) foam

enclosure pads, (2) cardboard layers separated by

foam supports, and (3) laminated cardboard cut to

desired packing shape. Original packing materials

which are a cardboard “accordion-like” filler are

not recommended for shipment since the useful

cushioning qualities are usually gone after one use.

If packing materials listed above are not available,

first protect the instrument surfaces with heavy

paper or sheets of cardboard flat against the instru-

ment. Then place instrument in a durable carton,

pad all sides with approximately 4 inches of new

packaging material designed specifically for package

cushioning, mark carton clearly for proper handling,

and insure adequately before shipping.

2-18. RETURNING FOR SERVICE OR REPAIR.

2-19. Contact your Hewlett-Packard Company Field

Office for shipping instructions. All correspondence

should refer to an instrument by model number and the

full (eight-digit) serial number.

2-2

02056-l

Page 12

Model 214A

Section III

Paragraphs 3-l to 3-8

SECTION III

OPERATING INSTRUCTIONS

3-1. GENERAL.

3-2. The Model 214A is self-protected and no combination of front panel control settings or connections

to external circuits can damage the instrument, providing the overload relay circuitry is operating properly.

duty cycle specified in Table l-l are exceeded. The

limits and combinations of settings which result in an

overload indication are described in Paragraph 3-4.

Other specific operating considerations are given in

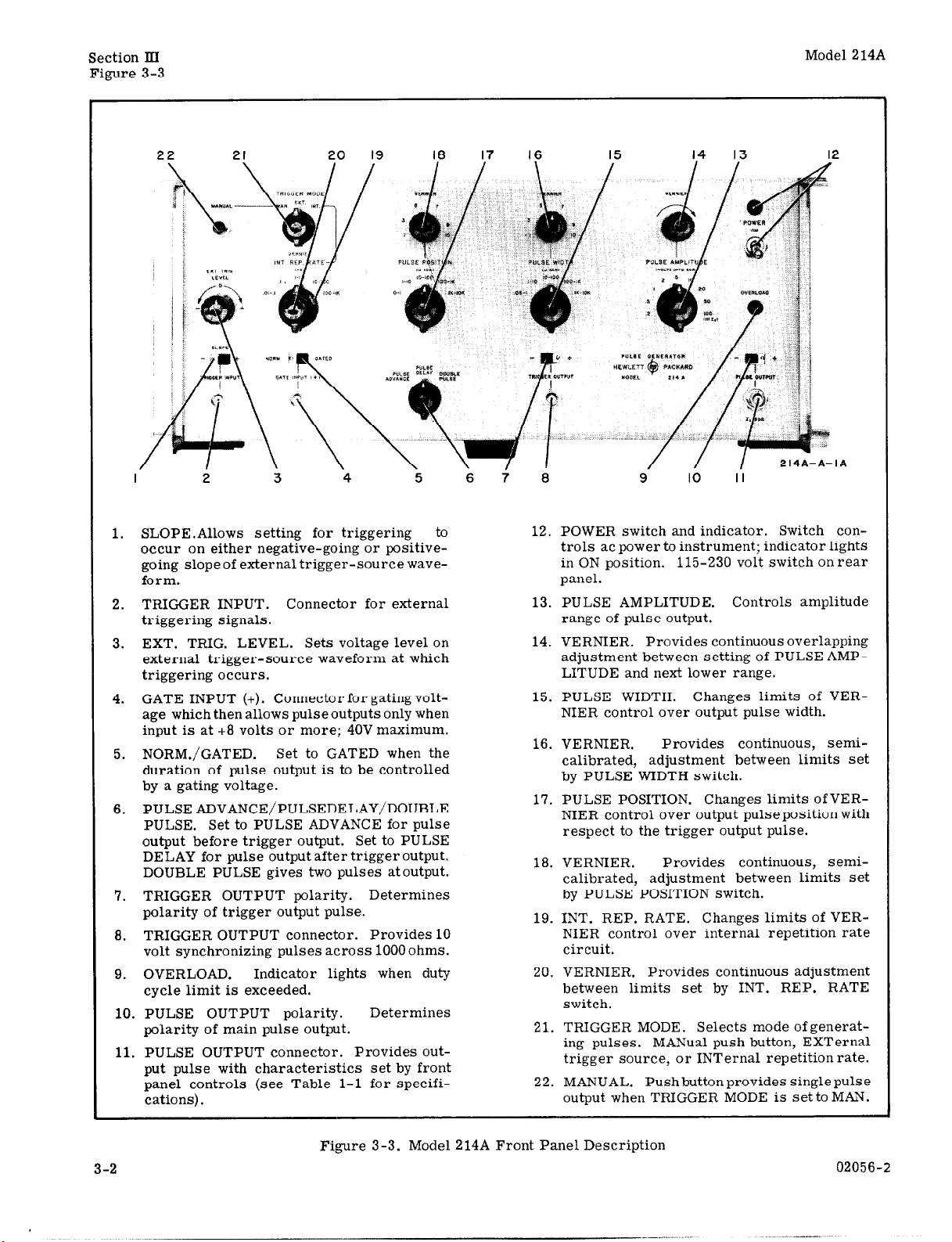

Paragraphs 3-7 and 3-9. Figure 3-3 illustrates and

explains the function of all the front panel fixtures.

The ac power connector, fuse, and line voltage switch

are on the rear panel. Proper fusesize is: 3.2 amps

slow-blow for 115~ and 1.6 amps slow-blow for 230~

operation. Setting line switch and other ac power

information is given in Paragraph 2-3.

3-3. OPERATING CONSIDERATIONS.

3-4. DUTY CYCLE LIMITATION.

3-5.

panel control settings. Duty cycle is defined as the

ratio of duration of pulse (i.e. pulse width) to the

total duration of one complete cycle. Figure 3-1

shows the relationship which determines the duty cycle.

The time for one cycle is defined as the period, and

the period is related to repetition rate by:

Thus the product of pulse width and frequency times

100 determines the percent duty cycle. For example

if INT. REP. RATE is set to l-10, VERNIER set to

give a rate of 6 kc (or if the external trigger rate is

6 kc), and PULSE WIDTH and VERNIER are set to

give a pulse 70 psec wide, the percent duty cycle is:

The same limits on duty cycle apply for external

An overload will be indicated if the limits on

Duty cycle of operation is determined by front

Period -

(70 x 10-6) (6 x 103) x 100 = 42%

1

Rep Rate

trigger operation or internal repetition rate. The

limits are 50% for PULSE AMPLITUDE settings of

10 volts or less, 25% on 20 volts amplitude, and 10%

on 50 to 100 volt amplitude. The maximum duty

cycle will decrease slightly at repetition rates slower

than 20 cps on the 5Ov and 100~ PULSE AMPLITUDE

ranges.

relay reacts if there were a higher average voltage

than that actually present.

3-6. If maximum duty cycle is exceeded for any

pulse amplitude, the front panel light, OVERLOAD,

will flash on and off and an internal relay will be heard

as a clicking sound. No damage will occur to the

instrument when this overload circuit is operating

properly. When an overload is indicated it may be

stopped by reducing either the frequency or the PULSE

WIDTH setting. Usually this may be done easiest by

turning the Width VERNIER counterclockwise, or by

reducing the Width range setting. In DOUBLE PULSE

operation the duty cycle limit is one half that for

PULSE ADVANCE or PULSE DELAY. The expression

for duty cycle using DOUBLE PULSE is given in

Figure 3-2.

At these slow repetition rates the overload

11 n r--/-

~-PEl%N--~

t------

P/EK&ENCY

-----I

r-------1

I

%DUTY CYCLE = ‘“‘&l”ob”‘” x 100

:

PULSE WIDTH X FREQUENCY X 100

Figure 3-l. Defining Pulse Characteristics

02056-l

I

I

I

I.--

z,..-.-

% DUTY CYCLE= 2 ’ PULSE W’DTH X 100

= 2 X PULSE WIDTH X FREOUENCY X 100

Figure 3-2. DOUBLE PULSE Operation

3-7. PULSE POSITION VS. RATE.

3-8. In either PULSE ADVANCE or PULSE DELAY

operation, the PULSE POSITION setting should always

be less than the period (i.e. 1 divided by the frequ ency) .

the period is:

and the PULSE POSITION range combined withVERNIER setting should not exceed40 psec. For DOUBLE

For example if the repetition rate is 25 kc,

Period = 25 kc = 40 ysec

PERIOD

2141--*-

1

3-l

Page 13

Section III

Figure 3-3

Model 214A

I- i

SLOPE.Allows setting for triggering to

1.

occur on either negative-going or positivegoing slope of external trigger-source waveform.

TRIGGER INPUT. Connector for external

2.

triggering signals.

3. EXT. TRIG. LEVEL. Sets voltage level on

external trigger-source waveform at which

triggering occurs.

4. GATE INPUT (+). Connector for gating volt-

age which then allows pulse outputs only when

input is at +8 volts or more; 40V maximum.

5. NORM./GATED. Set to GATED when the

duration of pulse output is to be controlled

by a gating voltage.

6. PULSE ADVANCE/PULSEDELAY/DOUBLE

PULSE. Set to PULSE ADVANCE for pulse

output before trigger output. Set to PULSE

DELAY for pulse output after trigger output.

DOUBLE PULSE gives two pulses atoutput.

7. TRIGGER OUTPUT polarity. Determines

polarity of trigger output pulse.

8. TRIGGER OUTPUT connector. Provides 10

volt synchronizing pulses across 1000 ohms.

9. OVERLOAD. Indicator lights when duty

cycle limit is exceeded.

10. PULSE OUTPUT polarity.

polarity of main pulse output.

11. PULSE OUTPUT connector. Provides output pulse with characteristics set by front

panel controls (see Table l-l for specifi-

cations).

3 4 6 i 6

Determines

IO II

12. POWER switch and indicator. Switch controls ac power to instrument; indicator lights

in ON position. 115-230 volt switch on rear

panel.

13. PULSE AMPLITUDE. Controls amplitude

range of pulse output.

14. VERNIER. Provides continuous overlapping

adjustment between setting of PULSE AMPLITUDE and next lower range.

15. PULSE WIDTH. Changes limits of VER-

NIER control over output pulse width.

16. VERNIER. Provides continuous, semicalibrated, adjustment between limits set

by PULSE WIDTH switch.

17. PULSE POSITION. Changes limits ofVERNIER control over output pulse position with

respect to the trigger output pulse.

18. VERNIER. Provides continuous, semi-

calibrated, adjustment between limits set

by PULSE POSITION switch.

19. INT. REP. RATE. Changes limits of VER-

NIER control over internal repetition rate

circuit.

20. VERNIER. Provides continuous adjustment

between limits set by INT. REP. RATE

switch.

21. TRIGGER MODE. Selects mode of generat-

ing pulses. MANual push button, EXTernal

trigger source, or INTernal repetition rate.

22. MANUAL. Pushbutton provides singlepulse

output when TRIGGER MODE is set to MAN.

3-2 02056-2

_--...

Page 14

Model 214A

Paragraphs 3-9 to 3-19

Section III

PULSE operation, the minimum allowable PULSE

POSITION setting depends on the PULSE WIDTHused;

this is explained in Paragraph 3-9.

3-9. MINIMUM SPACING WITH DOUBLE

PULSES.

3-10. In DOUBLE PULSE operation, the PULSE

POSITION control sets the spacing between the start

of the first pulse and the start of the second pulse.

For proper operation without affecting pulse shape,

there are minimum spacing limits between the two

pulses, and these limits depend on the PULSE WIDTH

setting.

between pulses is 1 psec. For other PULSE WIDTH

settings, the minimum spacing is 25% of the upper

limit of range selected. For example, if PULSE

WIDTH is set to 100-lK, the minimum spacing

between pulses is 25% of 1K microseconds, or 250

microseconds.

characteristics as set by the Model 214A controls in

DOUBLE PULSE mode. Note from Figure 3-2 that

the setting of PULSE POSITION and PULSE WIDTH

controls the actual spacing between pulses. The

spacing between pulses is then the PULSE POSITION

setting minus the PULSE WIDTH setting.

3-11. GATING OF PULSES.

3-12. By applying a positive signal voltage to the

GATE INPUT (+) connector and sliding the switch to

GATED, pulses will occur at the output only when the

gating signal is at +8 volts or greater. The maximum

gating signal amplitude is +40 volts. To ensure that

output pulses occur when the gate signal just reaches

+8v, a fast rise time input should be used. If a gating

sine wave signal is used, a larger amplitude (but less

than 40 volts peak) will generally provide better results.

and repetition rate must be locked together. Figure

3-4 illustrates the result of gating the pulse output.

3-13. OPERATING PROCEDURES.

3-14. MANUAL TRIGGER MODE.

3-15. When TRIGGER MODE is set to MAN. and the

MANUAL button is pushed, a single pulse output will

occur. Other front panel controls are set to obtain

For a 0.05-l setting the minimum spacing

Figure 3-2 shows the output pulse

For synchronized pulse trains, the gating signal

the desired pulse characteristics. The same operating

considerations apply as explained in Paragraphs 3-4,

3-7, and 3-9. The maximum rate for pushbutton

pulses is 2 cps.

3-16. EXTERNAL TRIGGER MODE.

3-17. With TRIGGER MODE set to EXT., an external

triggering signal from dc to 1 MC with 0.5 volts peak

amplitude is required to generate pulses in the Model

214A.

proceed as follows:

to TRIGGER INPUT.

gering level on input waveform. Polarity of EXT.

TRIG. LEVEL must agree with SLOPE setting.

using an external gating signal.

DELAY/DOUBLE PULSE. PULSE ADVANCE or

PULSE DELAY means the output pulse will occur

advanced or delayed in time, with respect to the

trigger output pulse. DOUBLE PULSE provides two

pulses out at a rate determined by the TRIGGER

MODE circuits.

nect coaxial cable to external circuit being triggered.

these amplitudes are volts into a 50 ohm load at the

PULSE OUTPUT connector. The 100 v range will not

produce a pulse without the 50 ohm termination.

NIER. Observe duty cycle limit for amplitude range.

coaxial cable to external test circuit.

NIER as desired. With PULSE ADVANCE or PULSE

DELAY operation. PULSE POSITION setting is the

spacing between the pulse output and the trigger output

pulse. With DOUBLE PULSE, PULSE POSITION sets

the spacing between the two pulses.

position, width, and amplitude characteristics.

Refer to Paragraphs 3-4, 3-7, and 3-9 and

a. Set TRIGGER MODE to EXT. and connect signal

b. Select + or - SLOPE setting.

c. Set EXT. TRIG. LEVEL to obtain desired trig-

d. Set GATED/NORM. switch to NORM. unless

e. Select setting for PULSE ADVANCE/PULSE

f. Select polarity of TRIGGER OUTPUT and con-

g. Select PULSE AMPLITUDE range. Note that

h. Select PULSE WIDTH range and adjust VER-

i. Select polarity of PULSE OUTPUT and connect

j. Select PULSE POSITION range and adjust VER-

k. Adjust VERNIERS if necessary to obtain exact

nnnnnnn nnn

MODEL 214A PULSE OUTPUT

2 I

GATE INPUT SIGNAL

Figure 3-4. Gating Pulse Output

02056-3

1

214*-*-

3-18. INTERNAL TRIGGER MODE.

3-19. With TRIGGER MODE set to INT.. the Model

214A will generate pulses at a rate set by the INT.

REP. RATE range and VERNIER. This repetition

rate is adjustable from 10 cps to 1 MC. Refer to

Paragraphs 3-4, 3-7? and 3-9 and proceed as follows:

a. Turn instrument POWER switch to ON and allow

several minutes for warmup.

b. Set TRIGGER MODE to INT.

c. Set INT. REP. RATE range and VERNIER to

approximate position for frequency desired (maximum frequency is fully clockwise).

d. Complete steps d through k of Paragraph 3-16.

3-3

Page 15

El 00,

.4 /iSEC

+

0,

DELAY

CIRCUIT

V2028 B DL201 --o V203 El T202

0,

\

\

POSITION POSITION

MONOSTABLE

b-+ MULTIVIBRATOR -

V20lA,V202A,

VI048

--oI \-

0

,-. l

\

\

BLOCKING

OSCILLATOR

VZOIB 8 T201

\

TRIGGER

OUTPUT

BLOCKING

OSCILLATOR

-\

\

\

\ ’

<

\

-c* DIODE

<

/

\

[PULSE DELAY 1

lDOuBLE PULSE 1

\

\

\

1

CR208

, DIODE -

CR207

PULSE ADVANCE

\

\

,-

0

START

1

1 v204A 8. DL202 1 1 V205A 8 T203 1 1 1

I

PULSE

Q’ “‘;KING

1ATl-N

1 I

STOP SIGNAL

Figure

,;;;iR

V301 8. T301

1

I

4-l. Model 214A Block Diagram

BISTABLE

MULTIVIBRATOR

AND POWER

AMPLIFIER

v304, v305,0301

POLARITY

AND

ATTENUATION

Page 16

Model 214A

Paragraphs 4-l to 4-12

SECTION IV

PRINCIPLES OF OPERATION

4-1. GENERAL. 4-7. MANUAL TRIGGER OPERATION.

4-2. The complete circuit operation is shown in

Figure 4-1.

lowing general sequence: a trigger pulse from the

rate circuit (VlOZ), functioning either as a Schmitt

trigger or an astable multivibrator, is applied to

blocking oscillator V103, which triggers both the

Position Multivibrator (V201A, VZOZA, V104B) and

blocking oscillator V203 for the trigger output pulse.

The position Multivibrator triggers Position Blocking

Oscillator V201B which in turn triggers both start

and stop pulse circuits.

are used to switch a bistable multivibrator-power

amplifier combination (V304, V305, Q301) which

forms the output pulse. The details of each block

are contained in the schematics, and the following

circuit description explains the operation of each

circuit, both as to basic type and to the part it plays

in the sequence of forming the output pulse.

4-3. INPUT AND RATE GENERATOR.

4-4. EXTERNAL TRIGGER OPERATION.

4-5. With TRIGGER MODE set to EXT. position, a

signal of at least 0.5 volts peak will cause Differential

Amplifier VlOl to amplify the difference between the

levels at the control grids, pins 2 and 7. TRIGGER

SLOPE switch SlOl routes the trigger input to one

grid of VlOl and also transfers the external trigger

level circuit of R105 to the other grid. Resistor R105

sets the grid bias which must be overcome by the

trigger input at the other grid to obtain an output at

the plate, pin 6 of V101. The output from VlOl is

coupled through S103A, through a low-impedance

network (DSlOl, R116, and C107), and S103B to R125

and the grid of V102.

The output pulse is formed by the fol-

The start and stop pulses

4-8. With TRIGGER MODE set to MAN. position,

V102 again functions as a Schmitt Trigger circuit as

in external operation, with the parallel RC network

R129-Cl10 coupling between plate and grid. When

MANUAL switch S102 is energized, the side of capacitor Cl06 toward the switch charges toward +150 volts

through R120. This positive-going, slow rising ex-

ponential voltage is coupled to the grid (pin 2) of V102

and the left half of the tube conducts. The right half

of V102 now cuts off and a positive pulse to +15OV is

the output coupled to the grid of V103.

4-9. INTERNAL TRIGGER OPERATION.

4-10. With TRIGGER MODE set toINT. position, V102

functions as an astable multivibrator. The free-

running rate of this circuit is controlled by range

capacitors, Cl13 through C117, couplingbetweenplate

(pin 1) and grid (pin 7), and by VERNIER, R137.

Breakdown diode CR101 sets the bias at the grid of

the left half of V102. This circuit has no stable state

and is always changing between two states: (1) lefthalf cutoff, right-half conducting or (2) left-half conducting, right-half cutoff. The rate at which this

changing of states occurs is primarily a function of

the capacitors between plate and grid since this determines the exponential rise and decay time of the

grid (pin 7). When the grid (pin 7) voltage rises

exponentially enough to cause the right half to conduct,

the output at pin 6 is about +125 volts. Then as the

voltage at pin 7 decays exponentially, the right half

cuts off and the output at pin 6 is at the supply voltage,

+15Ov. A regenerative action occurs as the right half

of V102 just starts to conduct and the left half starts

to cutoff: the increase in voltage at the plate (pin 1)

is coupled through the range capacitor to speed turn

on of the right half. Symmetry Adjust, R133, changes

the grid bias of pin 7 to nearly equal the bias at pin 2

making the two halves of the waveform equalin width,

Section IV

4-6. In external trigger operation, V102 functions

as a cathode-coupled binary, or Schmitt Trigger,

circuit. The plate to grid coupling network is from

pin 1 through S103B and the parallel RC combination,

R129-C110, to the grid, pin 7. The left half of V102

is normally off and the right half conducting so the

output at pin 6 is at a positive level (about 125 volts),

less than the +150 supply. As the signal at pin 2

becomes positive enough (upper hysteresis limit),

the left half of V102 conducts and regenerative action

cuts the right half off. When the input at pin 2 decreases enough (lower hysteresis limit), the left half

of V102 is cut off and the circuit returns to the original

state. The output at pin 6 then is a positive pulse each

time the signal at pin 2 causes the left half to conduct,

and the rate at which this occurs is exactly that of

the external trigger signal (1 MC limit on input frequency). The output pulse from pin 6 is coupled

through Cl22 to pin 2 of Blocking Oscillator V103.

02056-2

4-11. TRIGGER BLOCKING OSCILLATOR.

4-12.

Tube V103 and transformer TlOl function as an

amplifier-blocking oscillator, when the output of

V102 is not being gated by the circuit of V104A (see

Paragraph 4- 13). Normal operation of the blocking

oscillator is as a monostable circuit being triggered

by an amplified signal. The left half of V103 amplifies

the positive pulse at its grid and the resulting plate

pulse is coupled through transformer TlOl, reversed

in phase, to the grid of the right half. This puts the

right half of V103 in conduction and a regenerative

action drives the plate (pin 6) voltage down abruptly

and the grid voltage (pin 7) abruptly positive. Next

the action reverses and as the plate voltage becomes

more positive, the grid goes negative and regeneration

turns the tube off agian. The output is taken from the

cathode (pin 8) and the pulse drives other circuits de-

pending on which pulse mode (advance, delay, or

double) is used (see Paragraph 4-15).

4-l

Page 17

Section IV

Paragraphs 4-13 to 4-30

Model 214A

4-13. GATE INPUT CIRCUIT.

4-14. When switch S105 is in the NORM. position,

Gate Cathode Follower V104A is conducting enough so

CR103 is biased off, and the pulse at pin 2 of V103 is

unaffected in operation.

However, when S105 is moved

to GATED, V104A is cut off, biasing the cathode of

CR103 more negative than its anode and CR103 conducts, changing V103 input impedance so the rate pulse

does not develop enough signal to trigger the blocking

oscillator. By applying a positive signal of at least

8 volts (but less than 40) V104A will again conduct,

cutting off CR103 and the pulse at V103 triggers the

blocking oscillator (explained in Paragraph 4-l 1).

4-15. ADVANCE, DELAY, DOUBLE PULSE

MODES.

4-16. Three modes of pulse operation are obtained

by switching the timing pulse from the Trigger Blocking Oscillator V103 through combinations of circuits.

These circuits are described below first in terms of

general operation (Paragraphs 4-17 through 4-26)

and second, as each is used in either PULSE AD-

VANCE, PULSE DELAY, or DOUBLE PULSE (Para-

graphs 4-27 through 4-32).

4-17. PULSE POSITION CIRCUIT.

4-18. POSITION MULTIVIBRATOR. The circuits of

tubes V201A and V202A form a monostable multi-

vibrator which controls the position relationship between the output pulses and trigger output or between

both output pulses in DOUBLE PULSE operation. This

multivibrator substitutes cathode-coupling with a

common cathode resistor for the usual coupling between plate of V202A and grid of V201A, but still is

a monostable circuit. The width of the multivibrator

pulse is controlled by range capacitors, C201 through

C205, and the VERNIER control R207. By controlling

the time V202A is cut off, with the range capacitor

and VERNIER, the delay before triggering theposition

blocking oscillator V201B is also controlled (V201B

is triggered as V202A starts conducting; see Para-

graphs 4- 19). Tube V104B acts as a screen biasing

supply for V202A.

The output at pin 9 of V202A is a

variable width positive pulse which is coupledthrough

C209 to pin 6 of V201B.

4-19. POSITION BLOCKING OSCILLATOR. The signal from V202A triggers Position Blocking Oscillator V201B at the plate. This signal is coupled

through T201 to the grid (pin 7) and the circuit functions

in the same way as V103 right half, described in

Paragraph 4-11. The output is takenfromthe cathode

as a positive pulse about 30 volts in amplitude.

4-20. PULSE WIDTH MULTIVIBRATOR.

4-21.

The circuits of tubes V206A and V204B form a

monostable, cathode-coupled multivibrator, and the

circuit functions the same as that described in Paragraph 4-18. The time for whichV204Bremains cutoff

is determined by range capacitors C225 through C229

and VERNIER, R257. The output at pin 9 of V204B is

used to drive the stop pulse blocking oscillator V206B

(see Paragraph 4-26). The time delay obtained from

the width multivibrator thus determines how long since

4-2

the output pulse started before the stop pulse blocking

oscillator returns the pulse to zero (this time is the

pulse width).

4-22. TRIGGER OUTPUT BLOCKING

OSCILLATOR.

4-23. Tube V203 and transformer T202 function as an

amplifier-blocking oscillator in a nearly identical

circuit as described in Paragraph 4-11 for the circuit

of v103.

A signal at pin 2 of V203 is amplified and

coupled from the plate through T202 to the grid of the

right half. For a positive trigger output, S203 routes

the cathode signal to 5201 and for a negative trigger

out, S203 routes the signal from pin 1 of T202 to 5201.

4-24. START-STOP PULSE BLOCKING

OSCILLATORS.

4-25. START PULSE BLOCKING OSCILLATOR. The

circuit of V205A and T203 is another blocking oscillator working the same way as described in Paragraph 4-11. The signal which triggers V205A plate

has been amplified by V204A and delayed by 0.14

microseconds by DL202. The output from thecathode

of V205A is a positive pulse of about 35 volts which

drives the input to V301.

4-26. STOP PULSE BLOCKING OSCILLATOR. The

blocking oscillator of V206B and T204 also is of the

same type already described in Paragraph 4-11. The

signal to trigger V206B comes from the width multivibrator circuit when V204B starts conducting. The

output from the cathode of V206B is a positive pulse

of about 35 volts and it drives the input to V303, the

Stop Pulse Spiker.

4-27. PULSE ADVANCE TIMING LOGIC.

4-28. Figure 4-2 shows the timing logic for PULSE

ADVANCE mode of operation. The timing pulse from

V103 goes directly through diode CR207 to the start-

stop pulse circuits (through V204A to V205A, and

through the width multivibrator to V206B). The timing

pulse also goes through CR201 to the grid of V201A

to operate the position multivibrator. The resulting

waveform from the position blocking oscillator is

coupled through C216 to pin 2 of V203. Now the posi-

tion multivibrator is used to effectively delay the trig-

ger output, i.e. the main pulse output occurs in

advance of the trigger.

The pulse width multivibrator

and start-stop pulse blocking oscillators function the

same as described previously.

4-29. PULSE DELAY TIMING LOGIC.

4-30. Figure 4-3 shows the timing logic for PULSE

DELAY mode of operation. The V103 timing pulse

goes directly to Cathode Follower V202B andis taken,

delayed by 0.4 microseconds by DL201, throughS202B

to the trigger output blocking oscillator, to cause a

trigger output pulse. The timing pulse has also triggered theposition multivibrator circuit throughCR201.

The output from V201B goes through CR208 and S202B

to the width multivibrator and start-stop blocking

oscillators.

This time the position multivibrator has

been used to effectively delay the start of the pulse

output with respect to the trigger output.

02056-l

Page 18

Model 214A

Section TV

Paragraphs 4-31 to 4-36

RATE

GVEi%%R.

POSITION

V%A

P”X!oN

V2blB

TRIGGER

OUT PUT

PULSE

WIDTH

M.V.

V204B

STOP

svp:oK3E

PULSE

OUTPUT

OUTPUT

AS SEEN

)N SCOPE

SEQUENCE OF EVENTS

PULSE ADVANCE

t‘l

1

I

I

I

,

I

I

I

h

r

1

l

t

1

l

t

t

w

t

SEQUENCE OF EVENTS

PULSE DELAY

to

RATE

GvEIYiRR.

Rk%:

VI03

rRLGGER

DUTPUT

‘OSITION

M.V.

V202A

‘“sB!To!oN

V201B

ssTp?KRET

v30 I

2%

M.V.

V204B

STOP

SPIKE

v303

PULSE

OUTPUT

OUTPUT

AS SEEN

IN SCOPE

b

t5

1 1

h

h

f

h

l

t

b

t

c

b

t

t

b

t

b

Figure 4-2. PULSE ADVANCE Timing Sequence Figure 4-3. PULSE DELAY Timing Sequence

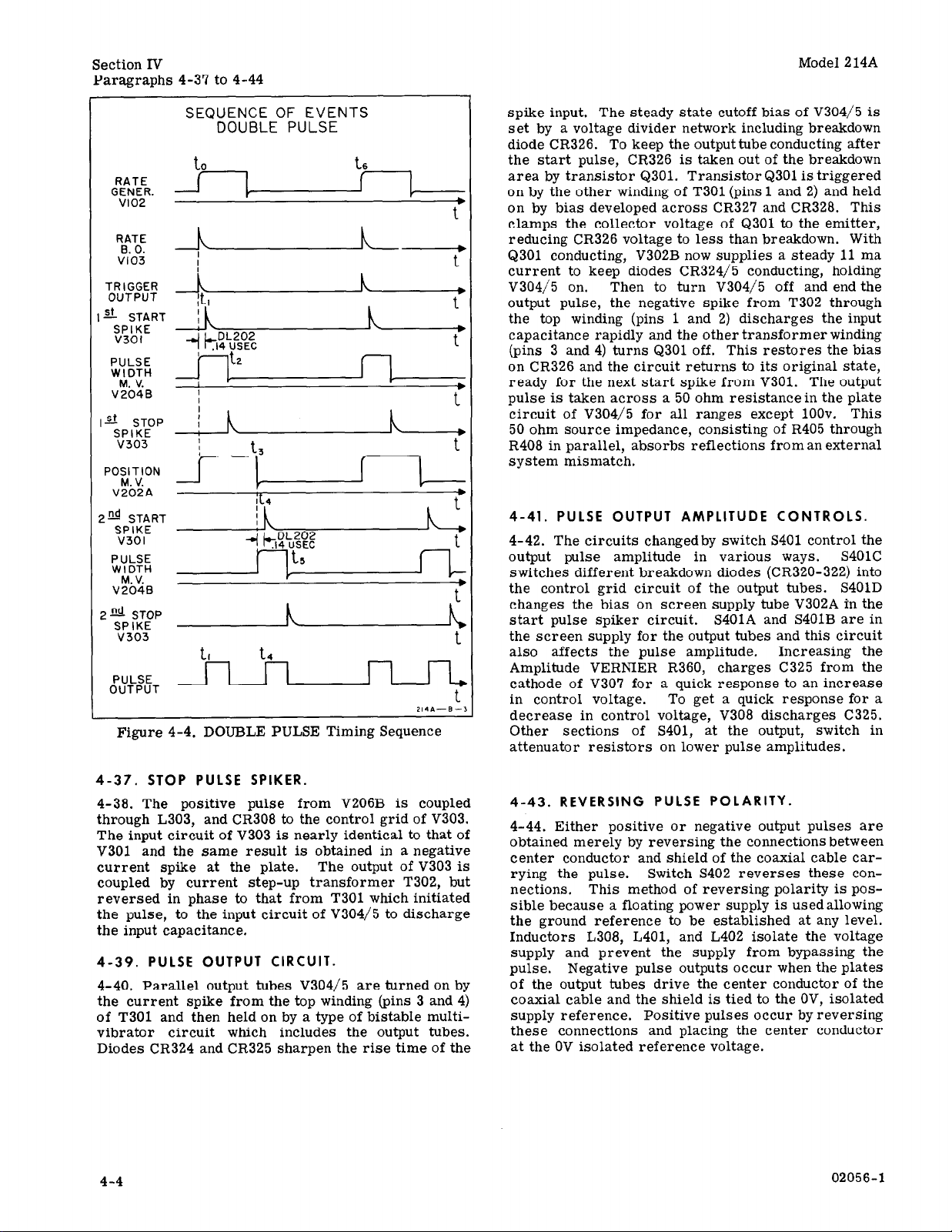

4-31. DOUBLE PULSE TIMING LOGIC.

4-32. Figure 4-4 shows the timing logic for DOUBLE

PULSE mode of operation. The V103 timingpulse goes

directly through CR201 to the position multivibrator

and directly through CR207 to the start pulse and stop

pulse circuitry (i.e. through V204A and also through

the width multivibrator). This causes one pulse output. Then the delayed timing pulse from the position

multivibrator and blocking oscillator comes through

CR208 to trigger the start-pulse circuitry a second

time and another pulse output is formed. The delayed

timing pulse from V201B determines the position in

time at which the second pulse occurs (i.e. the time

between leading edge of pulses). The pulses have the

same variable width since both are controlled by the

width multivibrator.

4-33. FORMING AND CONTROLLING

OUTPUT PULSE.

4-34. The fast rise and fall time of the output pulse is

achieved by rapid charging of the input capacitance

represented by the grid of tubes V304 and V305, then

02056-l

rapidly discharging this capacitance to end the pulse.

A large current spike waveform is used and the output

tubes are held on during the pulse by a bistable type

multivibrator circuit. The amplitude of the output

pulse is controlled by varying the output tube screen

supply, by changing the bias levels of the output circuits, and some attenuation at the output,

4-35. START PULSE SPIKER.

4-36. The positive pulse from V205A is coupled

through L301, C301, and CR301 to the control grid of

v301. The input circuit of V301 changes the dc level

of the start pulse and smoothes the transition from

triggered on state to the steady stateduring the output

pulse. Diode CR301 discharges the input circuit after

the start spike occurs and C302 discharges through

R301 to increase the fall time of the spike. The rise

time of the spike is sharpened by clipping diode CR303.

Tube V302A is a screen supply for V301. The output

of V301 is a current spike which is increased to about

0.5 amp by current step-up transformer T301 and

coupled to the input circuit of V304/5 to charge

input capacitance.

up

the

4-3

Page 19

Section IV

Paragraphs 4-37 to 4-44

Model 214A

SEQUENCE OF EVENTS

DOUBLE PULSE

h

P°K!oN

I

2@ START

SVP21E

PULSE

*K”

v2oie

2~~~r:p h L

v303

PULSE

OUTPUT

Figure 4-4. DOUBLE PULSE Timing Sequence

1

I

214&--B-,

spike input. The steady state cutoff bias of V304/5 is

set by a voltage divider network including breakdown

diode CR326. To keep the output tube conducting after

the start pulse, CR326 is taken out of the breakdown

area by transistor Q301. Transistor Q301 is triggered

on by the other winding of T301 (pins 1 and 2) and held

on by bias developed across CR327 and CR328. This

clamps the collector voltage of Q301 to the emitter,

reducing CR326 voltage to less than breakdown. With

Q301 conducting, V302B now supplies a steady 11 ma

current to keep diodes CR324/5 conducting, holding

V304/5 on.

Then to turn V304/5 off and end the

output pulse, the negative spike from T302 through

the top winding (pins 1 and 2) discharges the input

capacitance rapidly and the other transformer winding

(pins 3 and 4) turns Q301 off. This restores the bias

on CR326 and the circuit returns to its original state,

ready for the next start spike from V301. The output

pulse is taken across a 50 ohm resistancein the plate

circuit of V304/5 for all ranges except 100~. This

50 ohm source impedance, consisting of R405 through

R408 in parallel, absorbs reflections from an external

system mismatch.

4-41. PULSE OUTPUT AMPLITUDE CONTROLS.

4-42. The circuits changedby switch S401 control the

output pulse amplitude in various ways. s401c

switches different breakdown diodes (CR320-322) into

the control grid circuit of the output tubes. S401D

changes the bias on screen supply tube V302A in the

start pulse spiker circuit. S401A and S401B are in

the screen supply for the output tubes and this circuit

also affects the pulse amplitude.

Increasing the

Amplitude VERNIER R360, charges C325 from the

cathode of V307 for a quick response to an increase

in control voltage. To get a quick response for a

decrease in control voltage, V308 discharges C325.

Other sections of S401, at the output, switch in

attenuator resistors on lower pulse amplitudes.

4-37. STOP PULSE SPIKER.

4-38. The positive pulse from V206B is coupled

through L303, and CR308 to the control grid of V303.

The input circuit of V303 is nearly identical to that of

V301 and the same result is obtained in a negative

current spike at the plate. The output of V303 is

coupled by current step-up transformer T302, but

reversed in phase to that from T301 which initiated

the pulse, to the input circuit of V304/5 to discharge

the input capacitance.

4-39. PULSE OUTPUT CIRCUIT.

4-40. Parallel output tubes V304/5 are turned on by

the current spike from the top winding (pins 3 and 4)

of T301 and then held on by a type of bistable multivibrator circuit which includes the output tubes.

Diodes CR324 and CR325 sharpen the rise time of the

4-4

4-43. REVERSING PULSE POLARITY.

4-44. Either positive or negative output pulses are

obtained merely by reversing the connections between

center conductor and shield of the coaxial cable carrying the pulse. Switch S402 reverses these connections. This method of reversing polarity is

pas-

sible because a floating power supply is usedallowing

the ground reference to be established at any level.

Inductors L308, L401, and L402 isolate the voltage

supply and prevent the supply from bypassing the

pulse.

Negative pulse outputs occur when the plates

of the output tubes drive the center conductor of the

coaxial cable and the shield is tied to the OV, isolated

supply reference. Positive pulses occur by reversing

these connections and placing the center conductor

at the OV isolated reference voltage.

02056-l

.l.-l-_. .--”

-_

Page 20

Model 214A

Paragraphs 5-l to 5-7

Section V

SECTION V

MAINTENANCE

5-1. INTRODUCTION.

5-2. This section covers maintenance, troubleshooting, and adjustment of the Model 214A Pulse

Generator. The performance check, Paragraph 5-3,

may be used in incoming inspection or after adjustments have been made to verify that the instrument

meets its specifications (Table l- 1).

5-3. PERFORMANCE CHECK.

5-4. The performance check is intended to determine whether or not the instrument is operating within

its specifications.

to Paragraph 5-17.

If adjustment is necessary, refer

Test equipment recommended

for the performance check is listed in Table 5-1,

items 1 through 13. Similar instruments having the

listed characteristics may be substituted.

5-5. EXTERNAL GATING.

a. Connect Model 214A PULSE OUTPUT to High

Frequency Oscilloscope Channel A INPUT,

b.

Connect external Power Supply to Model 214A

GATE

INPUT.

C.

Set Model 214A:

INT. REP RATE. . . . . . . . . . . . . l-10

Int. Rep. Rate VERNIER

fully cw

TRIGGER MODE. . . . . : : : : : : . . . INT

GATE INPUT . . . . . . . . . . . . . GATED

PULSE WIDTH. . . . . . . . lo- 100

Width VERNIER . . . . . . . : : : : Midrange

PULSE AMPLITUDE . . . . . . .

PULSE POSITION . . . . . . . . . .

2 VOLTS

lo- 100

Position VERNIER. . . . . . . . . . fully cw

d.

Set Oscilloscope and Plug-In:

SWEEP TIME. , . ,

Channel A SENSITIVITY : : : .

TRIGSOURCE . . . . . . . . . : : . . .

20 &SEC/CM

1 V/CM

INT

e. Increase voltage output of Power Supply from 0

volts until 214A gates on. Gating voltage should be

8 volts or less.

5-6. EXTERNAL TRIGGERING.

Connect output of Audio Oscillator to Model 2 14A

a.

TRIGGER INPUT.

b. Connect Model 214A PULSE OUTPUT to Oscillo-

scope Plug-In Channel A INPUT.

c. Set Model 214A:

PULSE AMPLITUDE. . . . . . .

10 VOLTS

Amplitude VERNIER . . . . . . . . . . . . cw

TRIGGER MODE . . . . . . . . . . . . . EXT

PULSE WIDTH . . . .

.05-l

WidthVERNIER . . . . . ...:::... 3

d. Set Oscilloscope and Plug-In:

Channel A SENSITIVITY 2v/cm with 50 ohm-

load or 5v/cm without 50 ohmload

SWEEP TIME . . . . . . . . . . 0.1 psec/cm

TRIG SOURCE . . . . . . . . . . . . . . INT

e. Set Oscillator frequency to 200 kc andOscillator

amplitude for l/2 volt peak-to-peak.

f. Model 214A shouldtrigger on both + and - slope

by adjusting EXT TRIG LEVEL.

5-7. PULSE AMPLITUDE AND WIDTH.

a. Connect aBNC Tee to High Frequency Oscillo-

scope Plug-In Channel A INPUT. A 50-ohm, 1%

resistor witharating of at least 10 watts (such as the

hp 50-ohm load recommended in Table 5-1, Item 10)

should be connected as a load to the Tee. Connect the

Tee to the Model 214A PULSE OUTPUT with a BNC

to BNC cable.

b. Connect Oscilloscope TRIGGERINPUT toMode

214A TRIGGER OUTPUT with BNC to BNC cable.

c. Set Model 214A:

INT REP RATE. . . . . . . . . . .

. Ol-. 1

Int. Rep. Rate VERNIER. . . . . . Midrange

PULSE POSITION . . . . . . . . . . . l-10

Position VERNIER . . . . . . . . . . . . . 1

PULSE WIDTH . . . . . . . . . . . lK- 10K

Width VERNIER. . . . . . . . . . . fully ccw

PULSE AMPLITUDE . . . . . .

100 VOLTS

Amplitude VERNIER . . . . . . . . . fully cw

TRIG MODE. . . . . . . . . . . . . . . . INT

d. Set Oscilloscope and Plug-In:

Channel Selector . . . . . . . . CHANNEL A

Channel A SENSITIVITY . . . . .

SWEEP TIME . . . . . . .

20 V/CM

0.1 MSEC/CM

Int SWEEP MAGNIFIER . . . . . . . . . . Xl

TRIG SOURCE . . . . . . . . . . . . . . EXT

e. There should be at least 100 volts (5 cm) of

vertical display.

f. Set Model 214A PULSE WIDTH to .05-l.

PULSE POSITION . . . . . . . . . . . . O-l

Pulse Position VERNIER . . . . . . . . CCW

g. Set Oscilloscope:

SWEEP TIME. . . . . . . . . 0.1 /JSEC/CM

Int SWEEP MAGNIFIER . . . . , . . . . X10

h. There should be at least 50 nanoseconds (5 cm)

of horizontal display measured at half amplitude of

pulse.

i. Set Model 214A:

PULSE AMPLITUDE , . . . . . 0.2 VOLTS

PULSE WIDTH . . . . . . . . . . .

lK- 10K

Width VERNIER . . . . . . . . . . . fully cw

Rep Rate VERN . . . . . . . . . . . fully ccw

j. Set Oscilloscope and Plug-In:

Channel A SENSITIVITY . . . . . 05 V/CM

SWEEP TIME. . . . . . . . .

2 I&EC/CM

Int SWEEP MAGNIFIER . . . . . . . . . . Xl

k. There should be at least lOmilliseconds (5 cm)

of horizontal display.

m. Set Model 214A Amplitude VERNIER fully ccw.

02056-3

5-l

Page 21

Section V

Paragraph 5-8

Model 214A

Table 5-l. Equipment Required for Tests and Adjustments

Item

Equipment Name or Part Req’d Required Ref. Para.

1 Power Supply

Model

‘@ 723A

No.

1 Performance 5-5

Check

Audio Oscillator c@ 200CD 1 Performance 5-6 0.5 volt peak-to-peak,

Check 200 kc

Variable Attenuator @ 355D

1 Performance 5-12 thru 5-14 50-ohms,

Check

Sampling Oscillo- @ 185B

scope and Plug-in

‘@ 187B

5 50 -ohm Load ~$3 908A 1

1 Performance 5-13 thru 5-16 800 MC Bandwidth, dual

1. Check

Performance 5-13, 5-14 Type N connector, 50

Check & Adj ohms, SWR<l. 05, l/2 W

6 50-ohm Tee @ 10204B

1

Performance 5-13 thru 5-16 Type N 50 ohm Tee for

Check

7 BNC to Type N @10122A 1 Performance

Cable

Check male, 50 ohms * l/2 ohm

8 BNC to Dual Banana @llOOlA 1 Performance 5-6

Cable

Check 50 ohm cable

Required

Characteristics

At least 8V output

120 db attenuation

channel, Sensitivity

5 mv/cm

Sampling Oscilloscope

Probe

5-13 thru 5-16 Type N male to BNC fe-

BNC male to dual banana

9 BNC Female to Type N@ 1250- 1 Performance 5-15 BNC female to Type N

N Male Adapter

0067 Check male

10 50-ohm Load @5060- 1 Performance 5-7 thru 5-12 50 ohms, l%, 20watts

0426 Check

11 50 ohm Tee @1250- 1 Performance 5-7 thru 5-11; BNC male to BNC female

0072 Check and 5-26 to BNC female

Adjustments

12 BNC to BNC Cable @10503A 2 Performance 5-7 thru 5-14; BNC male to BNC male

Check and 5-26, 5-2’7 50 ohm Cable

Adjustments

13

High Frequency @ 175A 1

Oscilloscope, Plug- c@ 1750B 1

Ins and Probes

14

DC Voltmeter @412A

@1780A 1

Performance 5-5 thru 5-12; 40 MC Bandwidth, dual

Check and 5-23 thru5-27 channel

Adjustments

1

Adjustments 5-21, 5-26 Range 0 - 600 volts,

accuracy 1%

15 DC Milliammeter ~$3 428B 1 Adjustments 5-25 Range 0 - 50 ma, clip on

Probe, + 3% accuracy

n, There should be 1. 6 cm ( 80 mv ) or less of

vertical display.

5-8. PULSE POSITION.

a. Connect a BNC Tee to Oscilloscope Plug-in

Channel A INPUT. Connect 50-ohm load (at least

10 W) to Tee. Connect the Tee to the Model 214A

PULSE OUTPUT with a BNC to BNC cable.

b. Connect a BNC Tee Oscilloscope TRIGGER

INPUT. Connect the Tee to the Model 214A TRIGGER

OUTPUT with BNC to BNC cable. Connect the Tee to

Oscilloscope PLUG-in Channel B INPUT with BNC to

BNC cable.

5-2

c. Set Model 214A:

PULSE AMPLITUDE ......

a ... 10 VOLTS

Amplitude VERNIER ........... fully

PULSE WIDTH ............... lo- 100

Width VERNIER .............. fully ccw

TRIGGER OUTPUT .... ,

........ , , .. +

PULSE OUTPUT.. ................. +

PULSE POSITION .............. lo-100

Position VERNIER ............. fully ccw

ADVANCE/DELAY/DOUBLE . . PULSE DELAY

INT. REP. RATE ...............

Int. Rep. Rate VERNIER ......... fully

02056- 3

ccw

l-10

ccw

---._-- --

Page 22

Model 214A

Section V

Paragraphs 5-Q to 5-11

d. Set Oscilloscope and Plug-In:

Channel A SENSITIVITY , . . . . . . . . 1 V/CM

Channel B SENSITIVITY . , . , . . . . . 5 V/CM

Channel Selector . . . . . . . . . . . ALTERNATE

TRIGGERSOURCE............. EXTAC

TRIGGER SLOPE. . . . . . . . . . . . . . . . . . . +

SWEEP TIME . . . . . . . . . . . . . 10 @EC/CM

Int SWEEP MAGNIFIER . . . . . . . . . . . . . Xl

e. Position Channel A and Channel B traces on

Oscilloscope graticule.

f. By adjusting Model 214A Position VERNIER

from fully ccw to fully cw, the pulse on Channel A

should sweep 100 p set (10 cm).

g. Reverse cables to Model 214A PULSE OUTPUT

and TRIGGER output.

h. Set ADVANCE/DELAY/DOUBLE to PULSE AD-

VANCE.

i. By adjusting Model 214A Position VERNIER

from fully ccw to fully cw the trigger spike displayed

on Channel A should sweep 100 p set (10 cm).

j. Reverse cables to Model 214A PULSE OUTPUT

and TRIGGER OUTPUT (original position).

5-9. DOUBLE PULSE AND MANUAL

TRIGGERING.

a. Connect a BNC Tee to Oscilloscope Plug-in Chan-

nel A INPUT. Connect 50-ohm load (10 ,W) to Tee.

Connect the Tee to the Model 214A PUISE OUTPUT

with a BNC to BNC cable.

b. Connect Oscilloscope TRIGGER INPUT to the

Model 214A TRIGGER OUTPUT with BNC to BNC

cable.

c. Set Model 214A:

PULSE AMPLITUDE . . . . . . . , . . . . .

10 V

Amplitude VERNIER. . . . . . . . . . , . . fully cw

TRIG. MODE. . . . . . . . . . . . . . . . . . . . INT.

PULSE WIDTH . . . . , . . . . . . . . . . . . .05- 1

Width VERNIER. . . . . . . . . . . . . . . . . . . 3

PULSE POSITION . . . . . . . . . . . . . . l-10

Position VERNIER . . . , . . . . . . . . . fully cw

ADVANCE/DELAY/DOUBLE . DOUBLE PULSE

d. Set Oscilloscope and Plug-In:

Channel Selector . . . . . . . . . . . CHANNEL A

Channel A SENSITIVITY . . . . , . . . . 2 V/CM

SWEEP TIME . . . . . . . . . . . , . . 1 pSEC/CM

Int SWEEP MAGNIFIER . . . . . . . . . . . . . Xl

e. Adjust Model 214A Position VERNIER fully ccw.

Spacing between pulses should be 1 psec (lcm) or

less.

f. Set Model 214A TRIGGER MODE to MAN.

position.

g. One complete cycle should be observed on oscil-

loscope CRT each time MANUAL push button is

pressed.

5-10. INTERNAL REP RATE.

a. Connect a BNC Tee to Oscilloscope Plug-In

Channel A INPUT. Connect 50-ohm load (.lO W) to Tee.

Connect the Tee to the Model 214A PULSE OUTPUT

with a BNC to BNC cable.

02056- 4

b. Connect Oscilloscope TRIGGER INPUT to the

Model 214A TRIGGER OUTPUT with BNC to BNC

cable.

Set Model 214A:

PULSE AMPLITUDE.

Amplitude VERNIER.

PULSE WIDTH.

Width VERNIER.

...............

............... fully cw

...........

........... fully cw

10 VOLT

lK- 10K

PULSE OUTPUT.. ................. +

INT. REP. RATE. .............

Rate VERMER

PULSE POSITION

...............

................

.Ol - .l

fully ccw

Q-1

Position VERNIER ............. fully ccw

ADV/DELAY/DOUBLE ..... PULSE DELAY

Set Oscilloscope and Plug-In:

Channel Selector . . . . . . . . . . . CHANNEL A

Channel A SENSITIVITY . . . . . . . , . . XV/CM

SWEEP TIME . . . . . . . . . . . . . 20 MSEC/CM

There should be no more than 2 pulses displayed

in 10 cm of sweep.

f.

Set Model 214A:

PULSE WIDTH . . . . . . . . . . . . . . . .05 - 1

Width VERNIER. . . . . . . . . . . . . . . . . . .

INT. REP. RATE. . . . . , . . . . . . . . 100 - 1K

Int. Rep. Rate VERNIER . . . . . . . . . . fully cw

Set Oscilloscope SWEEP TIME to 1 ysec/cm.

g.

h.

At least 10 pulses should be displayed in 10 cm

of sweep.

5-11. DUTY CYCLE.

a. Connect a BNC Tee to Oscilloscope Pl<g-in

Channel A INPUT. Connect 50-ohm load (10 W) to

Tee. Connect the Tee to the Model 2 144 PULSE OUTPUT with a BNC to BNC cable.

b. Connect Oscilloscope TRIGGER INPUT to the

Model 214A TRIGGER OUTPUT with BNC to BNC

CABLE.

C.

Set Model 214A.

TRIGGER OUTPUT

TRIGGER MODE

PULSE WIDTH.

..................

.................

INT.

................ 10-100

Width VERNIER. .............. fully ccw

INT. REP. RATE

Rate VERNIER

............... 1 - 10

...............

fully ccw

PULSE OUTPUT ...................

PULSE AMPLITUDE

Amplitude VERNIER,

PULSE POSITION

Position VERNIER

d.

Set Oscilloscope and Plug-in:

Channel Selector

Channel A SENSITIVITY

Channel A INPUT.

TRIGGER SLOPE.

TRIGGER SOURCE.

SWEEP TIME

.............

Int SWEEP MAGNIFIER

Adjust Position VERNIER until leading edge of

e.

pulse lines up with first vertical line of Oscil-

first

.......... 10 VOLTS

...........

fully cw

............. 10 - 100

.............

fully ccw

........... CHANNEL A

..........

.................

2V/CM

DC

..................

...............

EXT.

16 @KC/CM

............. Xl

loscope graticule.

5-3

3

+

-

+

Page 23

Section V

Paragraphs 5-12 to 5-14

Model 214A

f. Adjust Int. Rep. Rate VERNIER until leading

edge of second pulse lines up with last vertical line

of Oscilloscope graticule.

g. Adjust width VERNIER; no overload should

occur until pulse width is at least 50 psec (5 cm).

h. Set:

Model 214A Width VERNIER . . . . . . fully ccw

Model 214A PULSE AMPLITUDE . . 20 VOLTS

Oscilloscope Channel A SENSITIVITY

. . . . . . . ..**............

5 V/CM

i. Adjust width VERNIER; no overload should

occur until pulse width is at least 25 psec (2.5 cm).

j. Set:

Model 214A Width VERNIER. . . . . , , fully ccw

Model 214A PULSE AMPLITUDE . . 50 VOLTS

Oscilloscope Channel A SENSITIVITY

. . . .

10 V/CM

Osciil&cbpd &V&&‘&ME : : . . . 2 kSEC/CM

k. Adjust width VERNIER; no overload shouldoccur

until pulse width is at least 10 psec (5 cm).

m. Set Model 214A PULSE AMPLITUDE to 1OOV.

With pulse width at 10 psec (5 cm) the Model 214A

should not overload.

TRIGGER SLOPE. . . . . . . . . . . . . . . . . . . -

TIME SCALE. . . . . . . . . . . . . . . 1 @EC/CM

TIME SCALE MAGNIFIER . . . . . . . . . . Xl0

c. Connect PULSE OUTPUT to the 120 db Variable

Attenuator with BNC to BNC cable.

d. Connect the Attenuator output to the Model

10204B 50-ohm Tee with a BNC to type N cable.

e. Connect the Tee to Channel A probe of Sampling

Oscilloscope.

f. Terminate the Tee with 50-ohm load (I/2 watt).

g. Connect Model 214A TRIGGER OUTPUT to

Sampling Oscilloscope trigger INPUT.

h. Set Attenuator to 20 db.

i. Obtain 10 cm of vertical deflection by adjusting

Attenuator and Sampling Oscilloscope vertical sensitivity controls.

j. Adjust DELAY control of Sampling Oscilloscope

for 3 cm of delay on screen as shown in Figures 5-I

and 5-2.

OVERSHOOT,

,PULSE TOP VARIATIONS

5-12. PULSE DROOP.

a. Set Model 214A:

INT. REP. RATE . . . . . . . . . . . . . . .

Rate VERNIER . . . . . . . . . . . . . . . . . .

PULSE AMPLITUDE . . . . . . . . . . . . . .

Amplitude VERNIER . . . . . . . . .

.Ol-.1

ccw

50V

5ov output

PULSE WIDTH . . . . . . . . . . . . . . . . lK-1OK

b. Set Oscilloscope and Plug-in:

SWEEP TIME 0 . . . . . . . . . . . .

VERTICAL SENSITIVITY . . . . . . .

I MSEC/CM

5 V/CM

c. Connect the Model 214A PULSE OUTPUT to the

Oscilloscope vertical INPUT using BNC to BNC cables

and terminated with a 50 ohm (1Ow) load.

d. Adjust Oscilloscope SENSITIVITY VERNIER to

obtain 6 cm of vertical deflection.

e. Adjust Model 214A width VERNIER until the

pulse width is 5 msec (5 cm).

f. Pulse droop should be less than 3.6 mm.

5-13. OVERSHOOT, PRESHOOT, AND PULSE

TOP VARIATION.

a. Set Model 214A:

PULSE AMPLITUDE . . . . . . . . . . 10 VOLT,C:

Amplitude VERNIER

PULSE WIDTH . . . . . . . . . . . . . . . .

1ov output

.05- 1

Width VERNIER. . . . . . . . . . . . . . . Midrange

MT. REP. RATE . . . . . . . . . . . . . . . lo-100

Rate VERNIER . . . . . . . . . . . . . . . . . . ccw

TRIGGER OUTPUT . . . . . . . . . . . . . . . . . -

b. Set Sampling Oscilloscope:

CHANNEL SELECTOR .,......CHANNELA

VERTICAL SENSITIVITY. . . . . . . 100 MViCM

TRIGGER . . . , . . . . . . . , . . . EXT NORMAL

5-4

J-i++

PRESHOOT

Figure 5-l. Positive Pulse Shape 1OV Amplitude

k. Positive and Negative pulse overshoot should be

less than 5 mm (5%).

m. Positive and Negative pulse preshoot should be

less than 2 mm (2%~).

n. Positive and Negative pulse top variation should

be less than 4 mm (4%).

5-14. RISE TIME AND FALL TIME.

a. Connect PULSE OUTPUT to Attenuator with

BNC to BNC cable.

b. Connect the attenuator output to the Model 10204B

50-ohm Tee with a BNC to type N cable.

c. Connect the Tee to Channel A probe of Sampling

Oscilloscope.

02056- 5

Page 24

Model 214A

Section V

Paragraph 5 - 15

Figure 5-2. Negative Pulse Shape 1OV Amplitude

d. Terminate the Tee with 50-ohm load (l/2 W).

e. Connect Model 214A TRIGGER OUTPUT to

Sampling Oscilloscope trigger INPUT.

f. Set Model 214A:

PULSE WIDTH . . . . . . . . . . . . . . . .

Width VERNIER. . . . . . . . . . . . . . . midrange

INT. REP. RATE.. . . . . . . . . . . . . .

lo-100

Rate VERNIER . . . . . . . . . . . . . . . Midrange

TRIGGER OUTPUT . . . . . . . . . . . . . . . . . +

PULSE AMPLITUDE . . . . . . . . . . 50 VOLTS

Amplitude VERNIER . . . . . . . . .

5ov output

PULSE POSITION . . . . . . . . . . . . . . l- 10

Pulse Position VERNIER . . . . . . . . . . ccw

g. Set Sampling Oscilloscope:

CHANNEL SELECTOR . . . . . . ..CHANNELA

VERTICAL SENSITIVITY

200 MV/CM

TRIGGER . . . . . . . . . . . : : : : ‘EXT NORMAL

TRIGGERSLOPE................... -

TIME SCALE

TIMESCALEMAGNI&Ek:::::.....

100 NSEC/CM

. x20

h. Set Attenuator to 30 db.

i. Obtain 10 cm of vertical signal as shown in

Figures 5-3 and 5-4.

j. Rise and fall time of positive pulse should be

less than 15 nsec (3 cm).

k. Rise and fall time of negative pulse should be

less than 13 nsec (2.6 cm).

m. Set:

PULSE AMPLITUDE . . . . . . . . . . 20 VOLTS

Amplitude VERNIER . * * * * * . * * . 20V output

Sampling Oscilloscope VERTICAL

SENSITIVITY . . . . . . . . . . . . . 200 MV/CM

n. Rise and fall time of both positive and negative

pulses should be less than 13 nsec.

p. Set:

PULSE AMPLITUDE . . . . . . . . . . 10 VOLTS

Amplitude VERNIER . . - * * * - a . . 1OV

OUtpUt

Sampling Oscilloscope VERTICAL

SENSITIVITY. . . . . . . . . . . . . . 100 MV/CM

02056-4

.05-l

Figure 5-3. Positive Pulse Risetime 1OV Amplitude

Figure 5-4.

Negative Pulse Risetime 1OVAmplitude

q. Rise and fall time of both positive and negative

pulses should be less than 13 nsec.

5-15. RATE AND WIDTH JITTER.

a. Connect PULSE OUTPUT of Model 214A to

Model 10204B 50-ohm Tee with BNC to type N cable.

b. Connect 50-ohm Tee to Sampling Oscilloscope

trigger INPUT using type N to BNC adapter.

c. Set Model 214A:

INT. REP. RATE.. . . . . . . . . . . . . . 100-IK

Rate VERNIER. . . . . . . . . . . . . . . . Midrange

PULSE AMPLITUDE . . , . . . . . . . . . 1 VOLT

Amplitude VERNIER . . . . . . . . . . . . . . . cw

PULSE OUTPUT . . . . . . . . . . . . . . ..a . . -

PULSE POSITION , . . . . . . . . , . . . . . . . ccw

Position VERNIER. . . . . . . . . . . . . . . . . ccw

PULSE WIDTH . . . . . . . . . . . . . . . . . .05-l

Width VERNIER. . . . . . . . . . . . . . . . . . . 10

5-5

Page 25

Section V

Paragraphs 5-16 to 5-23

Model 214A

d. Set Sampling Oscilloscope:

TRIGGER SLOPE . . . . . . . . . . . . . . . . . . -

TIME SCALE . . . . . . . . . . . . .

TIME SCALE MAGNIFIER . . . . . . . . . . . X50

e. Looking at leading edge of second pulse, rate

jitter should be less than 10 nsec (1 cm).

f. Set Sampling Oscilloscope:

TIME SCALE . . . . . . . . . . . . 100 NSEC/CM

TIME SCALE MAGNIFIER. . . . , . . . . . . X100

g. Looking at trailing edge of pulse, width jitter

should be less than 1.5 nsec (1.5 cm).

5-16. OUTPUT PULSE TO TRIGGER OUTPUT

JITTER.

a. Connect Model 214A PULSE OUTPUT to Model

10204B 50-ohm tee with BNC to type N cable.

b. Connect Sampling probe to Tee.

c. Connect Model 214A TRIGGER OUTPUT to

Sampling Oscilloscope trigger INPUT.