Page 1

Agilent 16800 Series

Portable Logic Analyzers

Data Sheet

Quickly debug, validate,

and optimize your digital

system – at a price that

fits your budget.

Features and benefits

• 250 ps resolution (4 GHz) timing

zoom to find elusive timing problems

quickly, without double probing

• 15” display, with available touch

screen, allows you to see more data

and navigate quickly

• View Scope – time-correlated

measurements and displays of your

logic analyzer and oscilloscope data

let you effectively track down

problems across the analog and

digital portions of your design

• Eight models with

34/68/102/136/204 channels,

up to 32 M memory depth and

models with a pattern generator

provide the measurement flexibility

for any budget

• Application support for every aspect

of today’s complex designs – FPGA

dynamic probe, digital VSA (vector

signal analysis) and broad processor

and bus support

Table of Contents

Selection Guide for 16800 Series Portable Logic Analyzers . . . . . . . . . . . . . . . . . . . . . . . . 2

Logic Analysis for Tracking Real-time System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Agilent 16800 Series Logic Analyzer Specifications and Characteristics . . . . . . . . . . . . 5

A Built-in Pattern Generator Gives You Digital Stimulus and Response in a

Single Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pattern Generator Specifications and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Unleash the Complementary Power of a Logic Analyzer and an Oscilloscope . . . . . . . 23

Get Instant Insights into your Design with Multiple Views and Analysis Tools . . . . . . 24

16800 Series Instrument Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

16800 Series Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

16800 Series Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

16800 Series Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Support, Services, and Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Page 2

2

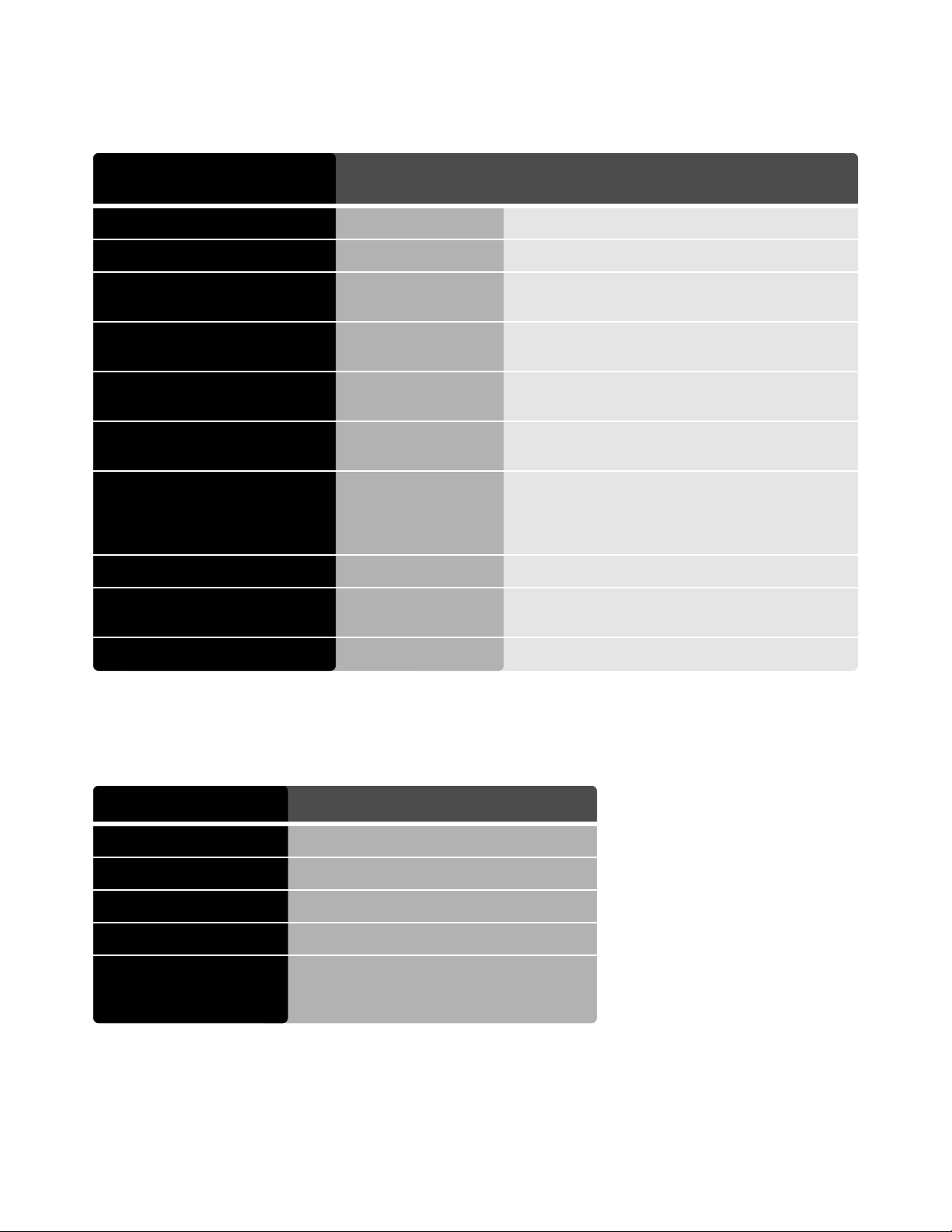

Selection Guide for 16800 Series Portable Logic Analyzers

Agilent Model Number 16821A, 16822A, 16823A

Half Channel Full Channel

Maximum clock 300 MHz 180 MHz

Data channels 24 48

Memory depth in vectors 16 M 8 M

Logic levels supported 5 V TTL, 3-state TTL, 3-state TTL/CMOS,

3-state 1.8 V, 3-state 2.5 V, 3-state 3.3 V, ECL,

5 V PECL, 3.3 V LVPECL, LVDS

Models with a built-in pattern generator give you more

measurement flexibility

16801A, 16802A, 16803A, 16804A 16806A

Agilent Model Number 16821A

1

16822A

1

16823A

1

Logic analyzer channels 34 68 102 136 204

Pattern generator channels

1

48 48 48 N/A N/A

High-speed timing zoom 4 GHz (250 ps) with 4 GHz (250 ps) with 64 K depth

64 K depth

Maximum timing sample rate 1.0 GHz (1.0 ns) / 1.0 GHz (1.0 ns) / 500 MHz (2.0 ns)

(Half/full ch) 500 MHz (2.0 ns)

Maximum state clock rate 250 MHz with 450 MHz with option 500

option 250 250 MHz with option 250

Maximum state data rate 250 Mb/s with 500 Mb/s with option 500

option 250 250 Mb/s with option 250

Maximum memory depth 1 M with option 001 1 M with option 001

4 M with option 004 4 M with option 004

16 M with option 016 16 M with option 016

32 M with option 032 32 M with option 032

Supported signal types Single-ended Single-ended

Automated threshold/sample position Ye s Ye s

Simultaneous eye diagrams, all channels

Probe compatibility 40-pin cable connector 40-pin cable connector

1 Pattern generator available with 16821A, 16822A and 16823A.

Choose from eight models to get the measurement capability for your specific application

Probes are ordered separately. Please

specify probes when ordering to ensure

the correct connection between your

logic analyzer, pattern generator, and

the device under test.

Page 3

3

Logic Analysis for Tracking Real-time System Operation

Agilent 16800 Series portable logic

analyzers offer the performance,

applications, and usability your

digital development team needs

to quickly debug, validate, and

optimize your digital system – at

a price that fits your budget.

The logic analyzer’s timing and

state acquisition gives you the

power to:

• Accurately measure precise

timing relationships using

4 GHz (250 ps) timing zoom

with 64 K depth

• Find anomalies separated in

time with memory depths

upgradeable to 32 M

• Buy what you need today and

upgrade in the future. 16800

Series logic analyzers come

with independent upgrades for

memory depth and state speed

• Sample synchronous buses

accurately and confidently

using eye finder. Eye finder

automatically adjusts

threshold and setup and

hold to give you the highest

confidence in measurements

on high-speed buses

• Track problems from symptom

to root cause across several

measurement modes by

viewing time-correlated data

in waveform/chart, listing,

inverse assembly, source code,

or compare display

• Set up triggers quickly and

confidently with intuitive,

simple, quick, and advanced

triggering. This capability

combines new trigger

functionality with an intuitive

user interface

• Access the signals that hold

the key to your system’s

problems with the industry’s

widest range of probing

accessories with capacitive

loading down to 0.7 pF

• Monitor and correlate multiple

buses with split analyzer

capability, which provides

single and multi-bus support

(timing, state, timing/state or

state/state configurations)

Accurately measure precise

timing relationships

16800 Series logic analyzers let

you make accurate high-speed

timing measurements with 4 GHz

(250 ps) high-speed timing zoom. A

parallel acquisition architecture

provides high-speed timing

measurements simultaneously

through the same probe used for

state or timing measurements.

Timing zoom stays active all the

time with no tradeoffs. View data

at high resolution over longer

periods of time with 64-K-deep

timing zoom.

Figure 1. With eight models to choose from, you can get a

logic analyzer with measurement capabilities that meet

your needs.

Page 4

4

Logic Analysis for Tracking Real-time System Operation

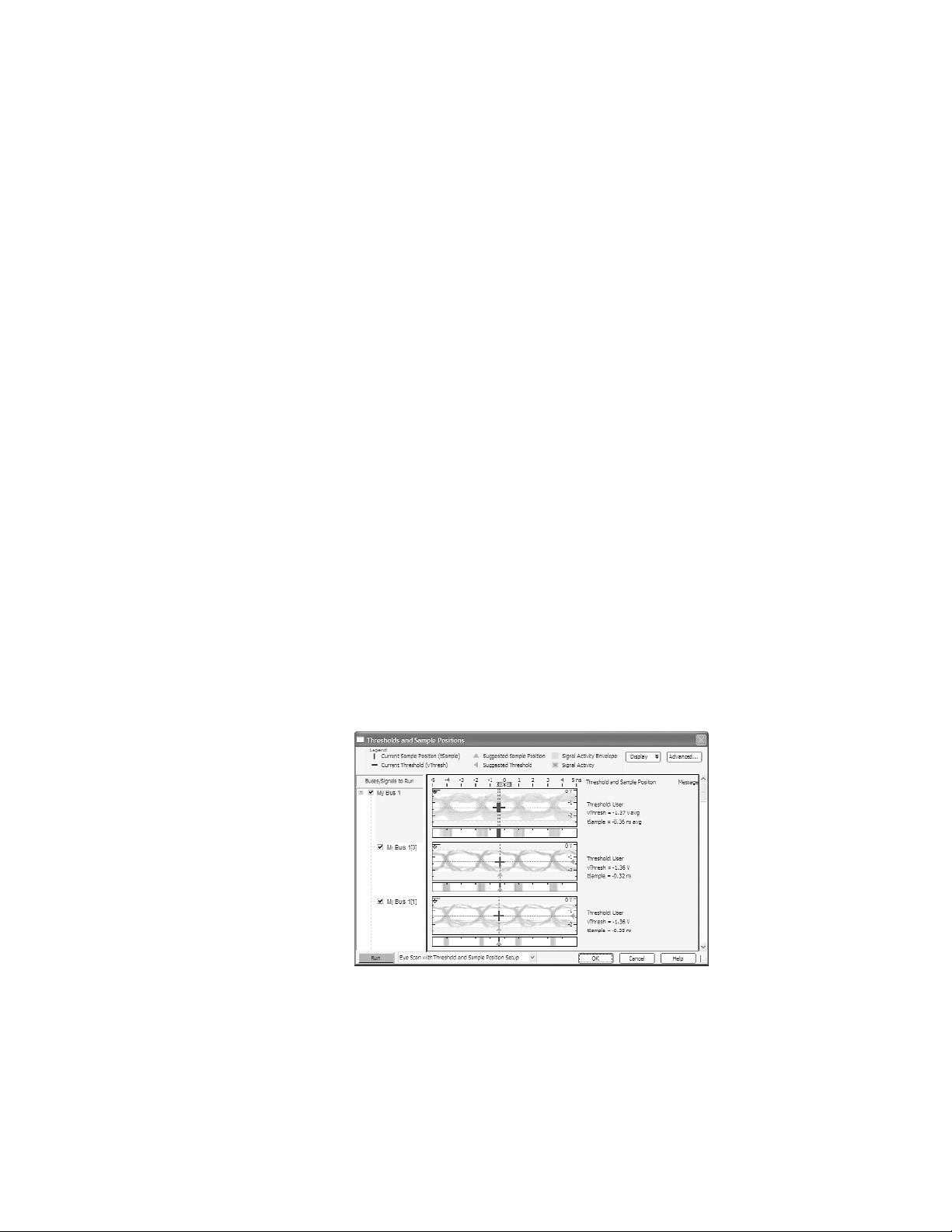

Automate measurement setup and

quickly gain diagnostic clues

16800 Series logic analyzers make

it easy for you to get up and

running quickly by automating

your measurement setup process.

In addition, the logic analyzer’s

setup/hold window (or sampling

position) and threshold voltage

settings are automatically

determined so you can capture

data on high-speed buses with the

highest accuracy. Auto Threshold

and Sample Position mode allow

you to...

• Obtain accurate and reliable

measurements

• Save time during measurement

setup

• Gain diagnostic clues and

identify problem signals

quickly

• Scan all signals and buses

simultaneously or just a few

• View results as a composite

display or as individual signals

• See skew between signals

and buses

• Find and fix inappropriate

clock thresholds

• Measure data valid windows

• Identify signal integrity

problems related to rise times,

fall times, data valid window

widths

Identify problem signals over

hundreds of channels simultaneously

As timing and voltage margins

continue to shrink, confidence

in signal integrity becomes an

increasingly vital requirement

in the design validation process.

Eye scan lets you acquire signal

integrity information on all

the buses in your design, under

a wide variety of operating

conditions, in a matter of

minutes. Identify problem signals

quickly for further investigation

with an oscilloscope. Results can

be viewed for each individual

signal or as a composite of

multiple signals or buses.

Extend the life of your equipment

Easily upgrade your 16800 Series

logic analyzer. “Turn on”

additional memory depth and

state speed when you need more.

Purchase the capability you

need now, then upgrade as your

needs evolve.

Figure 2. Identify problem signals quickly by viewing eye

diagrams across all buses and signals simultaneously.

Page 5

5

Agilent 16800 Series Logic Analyzer Specifications and Characteristics

Channel count per measurement mode

16801A/16821A 16802A/16822A 16803A/16823A 16804A 16806A

State analysis [1] 32 data + 2 clocks 64 data + 4 clocks 98 data + 4 clocks 132 data + 4 clocks 200 data + 4 clocks

Conventional timing 34 68 102 136 204

Transitional timing for 34 68 102 136 204

sample rates < 500 MHz

Transitional timing for – 34 68 102 170

500 MHz sample rate

[1] Unused clock channels can be used as data channels.

Timing zoom

(simultaneous state and timing without double probing – all channels,

all the time)

Timing analysis sample rate 4 GHz (250 ps)

Time interval accuracy

Within a pod pair ± (1.0 ns + 0.01% of time interval reading)

Between pod pairs ± (1.75 ns +0.01% of time interval reading)

Memory depth 64 K samples

Trigger position Start, center, end, or user-defined

Minimum data pulse width 1 ns

Other

Voltage threshold –5 V to 5 V (10 mV increments)

Threshold accuracy ± 50 mV + 1% of setting

Page 6

6

Agilent 16800 Series Logic Analyzer Specifications and Characteristics

Option 500 (available on 16802A, 16803A,

State (synchronous) analysis mode Option 250 16804A, 16806A, 16822A and 16823A)

tWidth* [1] 1.5 ns 1.5 ns

tSetup 0.5 tWidth 0.5 tWidth

tHold 0.5 tWidth 0.5 tWidth

tSample range [2] –3.2 ns to +3.2 ns –3.2 ns to +3.2 ns

tSample adjustment resolution 80 ps typical 80 ps typical

Maximum state data rate on each channel 250 Mb/s 500 Mb/s

Memory depth [4] Option 001: 1 M samples Option 001: 1 M samples

Option 004: 4 M samples Option 004: 4 M samples

Option 016: 16 M samples Option 016: 16 M samples

Option 032: 32 M samples Option 032: 32 M samples

Number of independent analyzers [5] 2 (1 for 16801A or 16821A) 1

Number of clocks [6] 4 (2 for 16801A or 16821A) 1

Number of clock qualifiers [6] 4 (2 for 16801A or 16821A) N/A

Minimum time between active 4.0 ns 2.0 ns

clock edges* [7]

Minimum master-to-slave clock time 1 ns N/A

Minimum slave-to-master clock time 1 ns N/A

Minimum slave-to-slave clock time 4.0 ns N/A

Minimum state clock pulse width

Single edge 1.0 ns 1.0 ns

Multiple edge 1.0 ns 2.0 ns

* Items marked with an asterisk (*) are specifications. All others are characteristics.

“Typical” represents the average or median value of the parameter based on measurements from a significant number of units.

[1] Minimum eye width in system under test.

[2] Sample positions are independently adjustable for each data channel input. A negative sample position causes the input to be synchronously sampled by that amount before

each active clock edge. A positive sample position causes the input to be synchronously sampled by that amount after each active clock edge. A sampling position of zero

causes the input to be synchronously sampled coincident with each clock edge.

[3] Use of eye finder is recommended in 450 MHz and 500 Mb/s state mode.

[4] In 250 Mb/s state mode, with all pods assigned, memory depth is half the maximum memory depth. With one pod pair (34 channels) unassigned, the memory depth is full. One

pod pair (34 channels) must remain unassigned for time tags in 500 Mb/s state mode.

[5] Independent analyzers may be either state or timing. When the 500 Mb/s state mode is selected, only one analyzer may be used.

[6] In the 250 Mb/s state mode, the total number of clocks and qualifiers is 4(2 for 16801A or 16821A).

[7] Tested with input signal Vh = +1.3 V, Vl = +0.7 V, threshold = +1.0 V, tr/tf = 180 ps ± 30 ps (10%, 90%).

Individual

Data Channel

tSetup tHold

Sampling Position

Clock Channel

tWidth

Data EyevHeight

vThreshold

OV

tSample

Page 7

7

Agilent 16800 Series Logic Analyzer Specifications and Characteristics

Option 500 (available on 16802A, 16803A,

State (synchronous) analysis mode Option 250 16804A, 16806A, 16822A and 16823A)

Clock qualifier setup time 500 ps N/A

Clock qualifier hold time 0 N/A

Time tag resolution 2 ns 1.5 ns

Maximum time count between stored states 32 days 32 days

Maximum trigger sequence speed 250 MHz 500 MHz

Maximum trigger sequence levels 16 16

Trigger sequence level branching Arbitrary 4-way if/then/else 2-way if/then/else

Trigger position Start, center, end, or user-defined Start, center, end, or user-defined

Trigger resources 16 patterns evaluated as =, =/, >, ≥, <, ≤ 14 patterns evaluated as =, =/, >, ≥, <, ≤

14 double-bounded ranges evaluated as 7 double-bounded ranges evaluated as

in range, not in range in range, not in range

1 timer for every 34 channels 1 occurrence counter per sequence level

2 global counters 4 flags

1 occurrence counter per sequence level

4 flags

Trigger resource conditions Arbitrary Boolean combinations Arbitrary Boolean combinations

Trigger actions Go To Go To

Trigger, send e-mail, and fill memory Trigger and fill memory

Trigger and Go To

Store/don’t store sample

Turn on/off default storing

Timer start/stop/pause/resume

Global counter increment/decrement/reset

Occurrence counter reset

Flag set/clear

Store qualification Default (global) and per sequence level Default (global)

Maximum global counter 2E+24 N/A

Maximum occurrence counter 2E+24 2E+24

Maximum pattern width Smaller of 128 bits or maximum number Smaller of 128 bits or maximum number

of channels of channels

Maximum range width Smaller of 64 bits or maximum number Smaller of 64 bits or maximum number

of channels of channels

Timers range 60 ns to 2199 seconds N/A

Timer resolution 2 ns N/A

Timer accuracy ± (5 ns +0.01%) N/A

Timer reset latency 60 ns N/A

Page 8

8

Agilent 16800 Series Logic Analyzer Specifications and Characteristics

Timing (asynchronous) analysis mode Conventional timing Transitional timing [8]

Sample rate on all channels 500 MHz 500 MHz

Sample rate in half channel mode 1 GHz N/A

Number of independent analyzers [5] 2 (1 for 16801A or 16821A) 2 (1 for 16801A or 16821A)

Sample period (half channel) 1.0 ns N/A

Minimum sample period (full channel) 2.0 ns 2.0 ns

Minimum data pulse width 1 sample period + 1.0 ns 1 sample period + 1.0 ns

Time interval accuracy ± (1 sample period + 1.25 ns + 0.01% of ± (1 sample period + 1.25 ns + 0.01% of

time interval reading) time interval reading)

Memory depth in full channel mode Option 001: 1 M samples Option 001: 1 M samples

Option 004: 4 M samples Option 004: 4 M samples

Option 016: 16 M samples Option 016: 16 M samples

Option 032: 32 M samples Option 032: 32 M samples

Memory depth in half channel mode Option 001: 2 M samples N/A

Option 004: 8 M samples

Option 016: 32 M samples

Option 032: 64 M samples

Maximum trigger sequence speed 250 MHz 250 MHz

Maximum trigger sequence levels 16 16

Trigger sequence level branching Arbitrary 4-way if/then/else Arbitrary 4-way if/then/else

Trigger position Start, center, end, or user-defined Start, center, end, or user-defined

[5] Independent analyzers may be either state or timing. When the 500 Mb/s state mode is selected, only one analyzer may be used.

[8] Transitional timing speed and memory depth are halved unless a spare pod pair (34 channels) is unassigned.

Page 9

9

Agilent 16800 Series Logic Analyzer Specifications and Characteristics

Timing (asynchronous) analysis mode Conventional timing Transitional timing

Trigger resources 16 patterns evaluated as =, =/, >, ≥, <, ≤ 15 patterns evaluated as =, =/, >, ≥, <, ≤

14 double-bounded ranges evaluated as 14 double-bounded ranges evaluated as

in range, not in range in range, not in range

3 edge/glitch 3 edge/glitch

1 timer for every 34 channels 1 timer for every 34 channels

(no timer for 16801A or 16821A) (no timer for 16801A or 16821A)

2 global counters 2 global counters

1 occurrence counter per sequence level 1 occurrence counter per sequence level

4 flags 4 flags

Trigger resource conditions Arbitrary Boolean combinations Arbitrary Boolean combinations

Trigger actions Go To Go To

Trigger, send e-mail, and fill memory Trigger, send e-mail, and fill memory

Trigger and Go To Trigger and Go To

Turn on/off default storing Turn on/off default storing

Timer start/stop/pause/resume Timer start/stop/pause/resume

Global counter increment/decrement/reset Global counter increment/decrement/reset

Occurrence counter reset Occurrence counter reset

Flag set/clear Flag set/clear

Maximum global counter 2E+24 2E+24

Maximum occurrence counter 2E+24 2E+24

Maximum range width 32 bits 32 bits

Maximum pattern width Smaller of 128 bits or maximum number Smaller of 128 bits or maximum number

of channels of channels

Timer value range 60 ns to 2199 seconds 60 ns to 2199 seconds

Timer resolution 2 ns 2 ns

Timer accuracy ± (5 ns +0.01%) ± (5 ns +0.01%)

Greater than duration 4.0 ns to 67 ms in 4.0 ns increments 4.0 ns to 67 ms in 4.0 ns increments

Less than duration 8.0 ns to 67 ms in 4.0 ns increments 8.0 ns to 67 ms in 4.0 ns increments

Timer reset latency 60 ns 60 ns

Page 10

10

A Built-in Pattern Generator Gives You Digital Stimulus and Response

in a Single Instrument

Selected 16800 Series models

(16821A, 16822A and 16823A)

also include a 48-channel pattern

generator to drive down risk early

in product development. With a

pattern generator you can:

• Substitute for missing boards,

integrated circuits (ICs) or

buses instead of waiting for

missing pieces

• Write software to create

infrequently encountered test

conditions and verify that the

code works – before complete

hardware is available

• Generate patterns necessary to

put a circuit in a desired state,

operate the circuit at full speed

or step the circuit through a

series of states

• Create a circuit initialization

sequence

Agilent 16800 Series portable

logic analyzers with a pattern

generator offer a variety of

features that make it easier for you

to create digital stimulus tests.

Vectors up to 48 bits wide

Vectors are defined as a “row” of

labeled data values, with each

data value from one to 48 bits

wide. Each vector is output on

the rising edge of the clock.

Create stimulus patterns for the

widest buses in your system.

Depth up to 16 M vectors

With the pattern generator, you

can load and run up to 16 M

vectors of stimulus. Depth on this

scale is most useful when coupled

with powerful stimulus generated

by electronic design automation

tools, such as SynaptiCAD’s

WaveFormer and VeriLogger.

These tools create stimulus using

a combination of graphically

drawn signals, timing parameters

that constrain edges, clock signals,

and timing and Boolean equations

for describing complex signal

behavior. The stimulus also can

be created from design simulation

waveforms. The SynaptiCAD tools

allow you to convert .VCD files

into .PGB files directly, offering

you an integrated solution that

saves you time.

Synchronized clock output

You can output data synchronized

to either an internal or external

clock. The external clock is input

via a clock pod, and has no

minimum frequency (other than

a 2 ns minimum high time).

The internal clock is selectable

between 1 MHz and 300 MHz in

1-MHz steps. A Clock Out signal is

available from the clock pod and

can be used as an edge strobe with

a variable delay of up to 8 ns.

Initialize (INIT) block for

repetitive runs

When running repetitively, the

vectors in the initialize (init)

sequence are output only once,

while the main sequence is

output as a continually repeating

sequence. This “init” sequence is

very useful when the circuit or

subsystem needs to be initialized.

The repetitive run capability

is especially helpful when

operating the pattern generator

independent of the logic analyzer.

“Send Arm out to…” coordinates

activity with the logic analyzer

Verify how your system responds

to a specific stimulus sequence by

arming the logic analyzer from

the pattern generator. A “Send

Arm out to…” instruction acts as a

trigger arming event for the logic

analyzer or other test equipment

to begin measurements. Arm

setup and trigger setup of the

logic analyzer determines the

action initiated by “Send Arm

out to…”.

Figure 3. Models with a built-in pattern generator give you

more measurement flexibility.

Page 11

11

“Wait for External Event…” for

input pattern

The clock pod also accepts a 3-bit

input pattern. These inputs are

level-sensed so that any number

of “Wait for External Event”

instructions can be inserted into

a stimulus program. Up to four

pattern conditions can be defined

from the OR-ing of the eight

possible 3-bit input patterns. A

“Wait for External Event” also can

be defined to wait for an Arm. This

Arm signal can come from the

logic analyzer. “Wait for External

Event…” allows you to execute

a specific stimulus sequence

only when the defined external

event occurs.

Simplify creation of stimulus programs

with user-defined macros and loops

User macros permit you to define

a pattern sequence once, then

insert the macro by name

wherever it is needed. Passing

parameters to the macro will

allow you to create a more

generic macro. For each call to

the macro you can specify unique

values for the parameters.

Loops enable you to repeat a

defined block of vectors for a

specified number of times. Loops

and macros can be nested, except

that a macro cannot be nested

within another macro. At compile

time, loops and macros are

expanded in memory to a

linear sequence.

Convenient data entry and

editing feature

You can conveniently enter

patterns in hex, octal, binary,

decimal, and signed decimal

(two’s complement) bases. To

simplify data entry, you can view

the data associated with an

individual label with multiple

radixes. Delete, Insert, and Copy

commands are provided for easy

editing. Fast and convenient

Pattern Fills give the programmer

useful test patterns with a few

key strokes. Fixed, Count, Rotate,

Toggle, and Random patterns are

available to help you quickly

create a test pattern, such

as “walking ones.” Pattern

parameters, such as step size and

repeat frequency, can be specified

in the pattern setup.

ASCII input file format: your design

tool connection

The pattern generator supports

an ASCII file format to facilitate

connectivity to other tools in your

design environment. Because the

ASCII format does not support the

instructions listed earlier, they

cannot be edited into the ASCII

file. User macros and loops also

are not supported, so the vectors

need to be fully expanded in the

ASCII file. Many design tools will

generate ASCII files and output

the vectors in this linear sequence.

Data must be in hex format, and

each label must represent a set of

contiguous output channels.

Configuration

The pattern generator operates

with the clock pods, data pods,

and lead sets described later in

this document. At least one clock

pod and one data pod must be

selected to configure a functional

system. You can select from a

variety of pods to provide the

signal source needed for your logic

devices. The data pods, clock pods

and data cables use standard

connectors. The electrical

characteristics of the data cables

are described for users with

specialized applications who want

to avoid the use of a data pod.

Direct connection to your

target system

You can connect the pattern

generator pods directly to a

standard connector on your target

system. Use a 3M brand #2520

Series or similar connector. The

clock or data pods will plug right

in. Short, flat cable jumpers can

be used if the clearance around

the connector is limited. Use a 3M

#3365/20, or equivalent, ribbon

cable; a 3M #4620 Series or

equivalent connector on the

pattern generator pod end of the

cable, and a 3M #3421 Series or

equivalent connector at your

target system end of the cable.

Probing accessories

The probe tips of the

Agilent 10474A, 10347A, 10498A,

and E8142A lead sets plug

directly into any 0.1-inch grid

with 0.026-inch to 0.033-inch

diameter round pins or 0.025-inch

square pins. These probe tips

work with the Agilent 5090-4356

surface mount grabbers and

with the Agilent 5959-0288

through-hole grabbers, providing

compatibility with industry

standard pins.

A Built-in Pattern Generator Gives You Digital Stimulus and Response

in a Single Instrument

Page 12

12

Pattern Generator Specifications and Characteristics

(16821A, 16822A, and 16823A)

Pattern generator characteristics

Maximum memory depth 16 MVectors

Number of output channels at > 180 MHz and 24

≤ 300 MHz clock

Number of output channels at ≤ 180 MHz clock 48

Number of different macros Limited only by the pattern

Maximum number of lines in a macro

generator’s available

Maximum number of parameters in a macro

memory depth

Maximum number of macro invocations

Maximum loop count in a repeat loop

Maximum number of repeat loop invocations 1000

Maximum number of “Wait” event patterns 4

Number of input lines to define a pattern 3

Maximum width of a label 48 bits

Maximum number of labels Limited only by system memory

Maximum number of vectors in all formats 16 MVectors

Minimum number of vectors in binary format 4096

when loading into hardware

Lead set characteristics

Agilent 10474A 8-channel Provides most cost effective lead set for clock and data

probe lead set* pods. Grabbers are not included. Lead wire length is

12 inches.

Agilent 10347A 8-channel Provides 50 Ω coaxial lead set for unterminated signals,

probe lead set required for 10465A ECL Data Pod (unterminated).

Grabbers are not included.

Agilent 10498A 8-channel Provides most cost effective lead set for clock and data

probe lead set* pods. Grabbers are not included. Lead wire length is

6 inches.

Agilent E8142A 8-channel Provides lead set for LVDS clock and data pods. Grabbers

probe lead set are not included. Lead wire length is 6 inches.

* For all clock and data pods except 10465A unterminated ECL Data Pod and E8140A/E8141A clock and data pods.

Page 13

13

Pattern Generator Specifications and Characteristics

(16821A, 16822A, and 16823A)

Data pod characteristics

Note: Data pod output parametrics depend on the output driver and

the impedance load of the target system. Check the device data

book for the specific drivers listed for each pod.

Agilent 10461A TTL data pod

Output type 10H125 with 100 Ω series

Maximum clock 200 MHz

Skew [1] Typical < 2 ns; worst case = 4 ns

Recommended lead set Agilent 10474A

Agilent 10462A 3-state TTL/CMOS data pod

Output type 74ACT11244 with 100 Ω series;

10H125 on non 3-state channel 7 [2]

3-state enable Negative true, 100 KΩ to GND, enabled

on no connect

Maximum clock 100 MHz

Skew [1] Typical < 4 ns; worst case = 12 ns

Recommended lead set Agilent 10474A

Agilent 10464A ECL data pod (terminated)

Output type 10H115 with 330 Ω pulldown, 47 Ω series

Maximum clock 300 MHz

Skew [1] Typical < 1 ns; worst case = 2 ns

Recommended lead set Agilent 10474A

[1] Typical skew measurements made at pod connector with approximately

10 pF/50 KΩ load to GND; worst case skew numbers are a calculation of worst

case conditions through circuits. Both numbers apply to any channel within the

pattern generator.

[2] Channel 7 on the 3-state pods has been brought out in parallel as a non 3-state

signal. By looping this output back into the 3-state enable line, the channel can be

used as a 3-state enable.

ECL/TTL

10H125

74ACT11244

100 Ω

100 Ω

10H115

348 Ω

42 Ω

– 5.2 V

Page 14

14

Pattern Generator Specifications and Characteristics

(16821A, 16822A, and 16823A)

Agilent 10465A ECL data pod (unterminated)

Output type 10H115 (no termination)

Maximum clock 300 MHz

Skew [1] Typical < 1 ns; worst case = 2 ns

Recommended lead set Agilent 10347A

Agilent 10466A 3-state TTL/3.3 volt data pod

Output type 74LVT244 with 100 Ω series;

10H125 on non 3-state channel 7 [2]

3-state enable Negative true, 100 KΩ to GND, enabled

on no connect

Maximum clock 200 MHz

Skew [1] Typical < 3 ns; worst case = 7 ns

Recommended lead set Agilent 10474A

[1] Typical skew measurements made at pod connector with approximately

10 pF/50 KΩ load to GND; worst case skew numbers are a calculation of worst

case conditions through circuits. Both numbers apply to any channel within the

pattern generator.

[2] Channel 7 on the 3-state pods has been brought out in parallel as a non 3-state

signal. By looping this output back into the 3-state enable line, the channel can be

used as a 3-state enable.

10H115

100 Ω

74LVT244

Page 15

15

Pattern Generator Specifications and Characteristics

(16821A, 16822A, and 16823A)

Agilent 10469A 5 volt PECL data pod

Output type 100EL90 (5 V) with 348 ohm pulldown to

ground and 42 ohm in series

Maximum clock 300 MHz

Skew [1] Typical < 500 ps; worst case = 1 ns

Recommended lead set Agilent 10498A

Agilent 10471A 3.3-volt LVPECL data pod

Output type 100LVEL90 (3.3 V) with 215 ohm pulldown

to ground and 42 ohm in series

Maximum clock 300 MHz

Skew [1] Typical < 500 ps; worst case = 1 ns

Recommended lead set Agilent 10498A

Agilent 10473A 3-State 2.5-volt data pod

Output type 74AVC16244

3-state enable Negative true, 38 KΩ to GND, enabled

on no connect

Maximum clock 300 MHz

Skew [1] Typical < 1.5 ns; worst case = 2 ns

Recommended lead set Agilent 10498A

[1] Typical skew measurements made at pod connector with approximately

10 pF/50 KΩ load to GND; worst case skew numbers are a calculation of worst

case conditions through circuits. Both numbers apply to any channel within the

pattern generator.

[2] Channel 7 on the 3-state pods has been brought out in parallel as a non 3-state

signal. By looping this output back into the 3-state enable line, the channel can be

used as a 3-state enable.

100EL90

100LVEL90

42 Ω

348 Ω

42 Ω

215 Ω

74AVC16244

Page 16

16

Pattern Generator Specifications and Characteristics

(16821A, 16822A, and 16823A)

Agilent 10476A 3-state 1.8-volt data pod

Output type 74AVC16244

3-state enable Negative true, 38 KΩ to GND, enabled

on no connect

Maximum clock 300 MHz

Skew [1] Typical < 1.5 ns; worst case = 2 ns

Recommended lead set Agilent 10498A

Agilent 10483A 3-state 3.3-volt data pod

Output type 74AVC16244

3-state enable Negative true, 38 KΩ to GND, enabled

on no connect

Maximum clock 300 MHz

Skew [1] Typical < 1.5 ns; worst case = 2 ns

Recommended lead set Agilent 10498A

Agilent E8141A LVDS data pod

Output type 65LVDS389 (LVDS data lines)

10H125 (TTL non-3-state channel 7)

3-state enable Positive true TTL; no connect=enabled

Maximum clock 300 MHz

Skew Typical < 1 ns; worst case = 2 ns

Recommended lead set E8142A

Recommended lead set Agilent 10498A

[1] Typical skew measurements made at pod connector with approximately

10 pF/50 KΩ load to GND; worst case skew numbers are a calculation of worst

case conditions through circuits. Both numbers apply to any channel within the

pattern generator.

74AVC16244

74AVC16244

3.3 V

10 KΩ

65LVDS389

ENABLE

LVDS DATA OUT

3-STATE IN TTL

Page 17

17

Pattern Generator Specifications and Characteristics

(16821A, 16822A, and 16823A)

Data cable characteristics without a data pod

The pattern generator data cables without a data pod provide an ECL terminated (1 KΩ to

–5.2 V) differential signal (from a type 10E156 or 10E154 driver). These are usable when

received by a differential receiver, preferably with a 100 Ω termination across the lines.

These signals should not be used single ended due to the slow fall time and shifted voltage

threshold (they are not ECL compatible).

Pattern generator cable pin outs

Data cable

(Pod end)

Clock cable

(Pod end)

–3.25 V

470 Ω

10E156

or

10E154

Differential

Output

470 Ω

–3.25 V

Page 18

18

Pattern Generator Specifications and Characteristics

(16821A, 16822A, and 16823A)

Clock cable characteristics without a clock pod

The pattern generator clock cables without a clock pod provide an ECL terminated (1 KΩ to

–5.2 V) differential signal (from a type 10E164 driver). These are usable when received by a

differential receiver, preferably with a 100 Ω termination across the lines. These signals

should not be used single ended due to the slow fall time and shifted voltage threshold

(they are not ECL compatible).

7

10E116

10H125

–3.25 V

100 Ω

100 Ω

215 Ω

Clock in

8

11, 13, 15

Wait 1, 2, 3 IN

12, 14, 16

10E164

Clock out

215 Ω

–3.25 V

Page 19

19

Pattern Generator Specifications and Characteristics

(16821A, 16822A, and 16823A)

Clock pod characteristics

10460A TTL clock pod

Clock output type 10H125 with 47 Ω series; true & inverted

Clock output rate 100 MHz maximum

Clock out delay Approximately 8 ns total in 14 steps

Clock input type TTL – 10H124

Clock input rate DC to 100 MHz

Pattern input type TTL – 10H124 (no connect is logic 1)

Clock-in to clock-out Approximately 30 ns

Pattern-in to Approximately 15 ns + 1 clk period

recognition

Recommended lead set Agilent 10474A

10463A ECL clock pod

Clock output type 10H116 differential unterminated; and

differential with 330 Ω to –5.2V and

47 Ω series

Clock output rate 300 MHz maximum

Clock out delay Approximately 8 ns total in 14 steps

Clock input type ECL – 10H116 with 50 KΩ to –5.2v

Clock input rate DC to 300 MHz

Pattern input type ECL – 10H116 with 50 KΩ (no connect is

logic 0)

Clock-in to clock-out Approximately 30 ns

Pattern-in to Approximately 15 ns + 1 clk period

recognition

Recommended lead set Agilent 10474A

10H125

10H124

10H116

10H116

VBB

–5.2 V

CLKin

–5.2 V

330 W

47 Ω

WAIT

CLKin

CLKout

50 kΩ

47 Ω

CLKout

Page 20

20

Pattern Generator Specifications and Characteristics

(16821A, 16822A, and 16823A)

10468A 5-volt PECL clock pod

Clock output type 100EL90 (5V) with 348 ohm pulldown to

ground and 42 ohm in series

Clock output rate 300 MHz maximum

Clock out delay Approximately 8 ns total in 14 steps

Clock input type 100EL91 PECL (5V), no termination

Clock input rate DC to 300 MHz

Pattern input type 100EL91 PECL (5V), no termination (no

connect is logic 0)

Clock-in to clock-out Approximately 30 ns

Pattern-in to Approximately 15 ns + 1 clk period

recognition

Recommended lead set Agilent 10498A

10470A 3.3-volt LVPECL clock pod

Clock output type 100LVEL90 (3.3V) with 215 ohm pulldown

to ground and 42 ohm in series

Clock output rate 300 MHz maximum

Clock out delay Approximately 8 ns total in 14 steps

Clock input type 100LVEL91 LVPECL (3.3V), no termination

Clock input rate DC to 300 MHz

Pattern input type 100LVEL91 LVPECL (3.3V), no termination

(no connect is logic 0)

Clock-in to clock-out Approximately 30 ns

Pattern-in to Approximately 15 ns + 1 clk period

recognition

Recommended lead set Agilent 10498A

100EL90

100EL91

348 Ω

42 Ω

CLKout

CLKin

100LVEL90

100LVEL91

215 Ω

42 Ω

CLKout

CLKin

Page 21

21

Pattern Generator Specifications and Characteristics

(16821A, 16822A, and 16823A)

10472A 2.5-volt clock pod

Clock output type 74AVC16244

Clock output rate 200 MHz maximum

Clock out delay Approximately 8 ns total in 14 steps

Clock input type 74AVC16244 (3.6V max)

Clock input rate DC to 200 MHz

Pattern input type 74AVC16244 (3.6V max; no connect is

logic 0)

Clock-in to clock-out Approximately 30 ns

Pattern-in to Approximately 15 ns + 1 clk period

recognition

Recommended lead set Agilent 10498A

10475A 1.8-volt clock pod

Clock output type 74AVC16244

Clock output rate 200 MHz maximum

Clock out delay Approximately 8 ns total in 14 steps

Clock input type 74AVC16244 (3.6V max)

Clock input rate DC to 200 MHz

Pattern input type 74AVC16244 (3.6V max; no connect is

logic 0)

Clock-in to clock-out Approximately 30 ns

Pattern-in to Approximately 15 ns + 1 clk period

recognition

Recommended lead set Agilent 10498A

74AVC16244

CLKout

74AVC16244

74AVC16244

74AVC16244

WAIT

CLKin

CLKout

WAIT

CLKin

Page 22

22

Pattern Generator Specifications and Characteristics

(16821A, 16822A, and 16823A)

10477A 3.3-volt clock pod

Clock output type 74AVC16244

Clock output rate 200 MHz maximum

Clock out delay Approximately 8 ns total in 14 steps

Clock input type 74AVC16244 (3.6V max)

Clock input rate DC to 200 MHz

Pattern input type 74AVC16244 (3.6 V max; no connect is

logic 0)

Clock-in to clock-out Approximately 30 ns

Pattern-in to Approximately 15 ns + 1 clk period

recognition

Recommended lead set Agilent 10498A

E8140A LVDS clock pod

Clock output type 65LVDS179 (LVDS) and 10H125 (TTL)

Clock output rate 200 MHz maximum (LVDS and TTL)

Clock out delay Approximately 8 ns total in 14 steps

Clock input type 65LVDS179 (LVDS with 100 ohm)

Clock input rate DC to 150 MHz (LVDS)

Pattern input type 10H124 (TTL) (no connect = logic 1)

Clock-in to clock-out Approximately 30 ns

Pattern-in to Approximately 15 ns + 1 clk period

recognition

Recommended lead set Agilent 10498A

74AVC16244

CLKout

74AVC16244

WAIT

CLKin

10H125

65LBDS179

65LVDS179

10H124

CLK OUT TTL

CLK OUT LVDS

CLK IN LVDS

100 Ω

CLK IN LVDS

WAIT IN TTL

Page 23

23

Unleash the Complementary Power of a Logic Analyzer and an Oscilloscope

Seamless scope integration

with View Scope

Easily make time-correlated

measurements between Agilent

logic analyzers and oscilloscopes.

The time-correlated logic analyzer

and oscilloscope waveforms are

integrated into a single logic

analyzer waveform display for

easy viewing and analysis. You

can also trigger the oscilloscope

from the logic analyzer (or vice

versa), automatically de-skew the

waveforms and maintain marker

tracking between the two

instruments. Perform the

following more effectively:

• Validate signal integrity

• Track down problems caused

by signal integrity

• Validate correct operation of

A/D and D/A converters

• Validate correct logical and

timing relationships between

the analog and digital portions

of a design

Connection

The Agilent logic analyzer and

oscilloscope can be physically

connected with standard BNC

and LAN connections. Two BNC

cables are connected for cross

triggering, and the LAN

connection is used to transfer

data between the instruments.

The View Scope correlation

software is standard in the logic

analyzer’s application software

version 3.50 or higher. The View

Scope software includes:

• Ability to import some or all

of the captured oscilloscope

waveforms

• Auto scaling of the scope

waveforms for the best fit in

the logic analyzer display

Feature Benefit

Automated setup Quickly get to your first measurement using the logic analyzer’s

help wizard for easy setup, regardless of which supported

Agilent oscilloscope you connect to.

Integrated waveform Instantly validate the logical and timing relationships between

display the analog and digital portions of your design. View oscilloscope

and logic analyzer waveforms integrated into a single logic

analyzer waveform display.

Automatic Save time and gain confidence in measurement results with

measurement de-skew measurements that are automatically de-skewed in time.

Cross trigger the Start your debug approach from either the analog or digital

logic analyzer and domain with the flexibility to trigger the oscilloscope from the

oscilloscope logic analyzer (or vice versa).

Tracking markers Precisely relate information on the oscilloscope’s display to the

corresponding point in time on the logic analyzer display with

tracking markers. The oscilloscope’s time markers automatically

track adjustments of the logic analyzer's global markers.

Table 1. Key features and benefits of integrating Agilent oscilloscope and

logic analyzer capabilities

Compatibility

Agilent logic analyzers 16800 Series portable logic analyzers (ver 3.50 or higher)

16900 Series modular logic analysis systems (ver 03.20 or higher)

1680 Series standalone logic analyzers (ver 03.20 or higher)

1690 Series PC-hosted logic analyzers (ver 03.20 or higher)

Agilent oscilloscopes DSO80000 Series (ver 3.90 or higher)

Infiniium 8000 Series (ver A.04.90 or higher)

Infiniium 54800 Series (ver 3.90 or higher)

6000 Series (ver 3.90 or higher)

Figure 4. View Scope seamlessly integrates your scope

and logic analyzer waveforms into a single display.

Page 24

24

Get Instant Insights into your Design with Multiple Views and Analysis Tools

Acquisition and analysis tools

provide rapid insight into your

toughest debug problems

You have unique measurement

and analysis needs. When you

want to understand what your

target is doing and why, you need

acquisition and analysis tools

that rapidly consolidate data into

displays that provide insight into

your system’s behavior.

Optional analysis and automated measurement packages

B4655A FPGA dynamic probe Gain unprecedented visibility into your FPGA’s internal activity. Make incremental real-time

measurements in seconds without stopping the FPGA, changing the design or modifying design

timing. Quickly set up the logic analyzer with automatic pin mapping and signal bus naming by

leveraging work you did in your design environment. www.agilent.com/find/fpga

89601A-300 digital vector signal analysis, Perform time-domain, spectrum, and modulation quality analysis on digital Baseband and

hardware connectivity for logic analyzers IF signals. www.agilent.com/find/dvsa

B4601C serial-to-parallel analysis package Eliminate the tedious, time-consuming, and error-prone task of sifting through thousands of

analysis package serial bits by looking at long vertical columns of captured 1’s and 0’s. The

B4601C serial-to-parallel analysis package is general-purpose software that allows easy

viewing and analysis of serial data.

B4606A advanced customization Tailor your logic analyzer interface with a wide range of control, analysis and display

environment – development and capabilities specific to your measurement application. Create integrated dialogs, graphical

runtime package displays and analysis functions to quickly manipulate measurement data into a format that

provides additional insight and answers. www.agilent.com/find/logic-customview

B4607A advanced customization Run the macros and graphical views created with a B4606A development package or obtain

environment – runtime package and run a variety of commonly requested tools from Agilent and it's partners to help customize

your measurement environment.

B4608A ASCII remote programming Remotely control a 16900-, 16800-, 1680-, or 1690-Series logic analysis system by issuing

interface ASCII commands. This interface is designed to be as similar as possible to the RPI on the

16700 Series logic analysis system, so that you can reuse existing programs. Requires either

B4606A or B4607A to be enabled. You can also use the B4606A to customize and add RPI

commands.

B4610A data import package Use the logic analyzer GUI to view data obtained from tools other than a logic analyzer.

B4630A MATLAB

®

connectivity and Make an easy connection to MATLAB and transfer your logic analyzer measurement data for

analysis package processing. Display the results on the logic analyzer in an XY scattergram chart.

Figure 5. Perform in-depth time, frequency and modulation

domain analysis on your digital baseband and IF signals

with Agilent’s 89600 Vector Signal Analysis software.

Page 25

25

Available device support

Microprocessors /

microcontrollers FPGAs I/O buses Memory buses Serial buses Graphics buses

AMD, Analog Devices, Xilinx Virtex 5, PCI, PCI-X

®

, DDR1, DDR2, Fibre Channel, AGP2x, AGP4x,

ARM, AT&T, Dallas, DEC, Virtex 4, PCI Express

®

, PC-100/133, I2C, IEEE-1394, AGP3.0,

Freescale, GTE, IBM, IDT, Virtex-II Pro series, Serial ATA GDDR3, Fully Serial ATA PCI Express

Infineon, Intel, LSI Logic, Virtex-II series, (SATA 1 and 2), Buffered DIMM (SATA 1 and 2),

McDonnell Douglas, MIPS, Spartan-3 series SCSI, Serial (FB-DIMM), USB 2.0/1.1,

Motorola, National, NEC, Attached SCSI Rambus PCI Express,

PACE, PMC Sierra/QED, (SAS), RS-232, CAN,

Rockwell, Siemens, HyperTransport IEEE-488

Texas Instruments,

Toshiba, Zilog

Get Instant Insights into your Design with Multiple Views and Analysis Tools

Save time analyzing your unique

design with a turnkey setup

Agilent Technologies and our

partners provide an extensive

range of bus and processor

analysis probes. They provide

non-intrusive, full-speed,

real-time analysis to accelerate

your debugging process.

• Save time making busand processor-specific

measurements with

application specific analysis

probes that quickly and

reliably connect to your

device under test

• Display processor mnemonics

or bus cycle decode

• Get support for a

comprehensive list of

industry-standard processors

and buses

Page 26

26

16800 Series Instrument Characteristics

Standard data views

Waveform Integrated display of data as digital waveforms, analog waveforms imported from an external oscilloscope,

and/or as a chart of a bus’ values over time

Listing Displays data as a state listing

Compare Compares data from different acquisitions and highlights differences

Source code Displays time-correlated source code and inverse assembly simultaneously in a split display

Define the trigger event by simply clicking on a line of source code

Obtain source-code-level views of dynamically loaded software or code moved from ROM to RAM during a

boot-up sequence using address offsets

Requires access to source files via the LAN or instrument hard drive to provide source code correlation

Source correlation does not require any modification or recompilation of your source code

Eye scan Displays eye diagrams across all buses and signals simultaneously, allowing you to identify problem signals

quickly

Numeric bases for data display

Binary, hex, octal, decimal, signed decimal (two’s complement),ASCII, symbols, and processor mnemonics

Symbolic support/object file format compatibility

Number of symbols/ranges – Unlimited (limited only by amount of virtual memory available on 16800 Series logic analyzers)

IEEE-695, Aout, Omf86, Omf96, Omf386, Sysrof, ELF/DWARF1,* ELF/DWARF2*, ELF/Stabs1, ELF/Stabs2, ELF/Mdebug Stabs, TICOFF/COFF,

TICOFF/Stabs

GPA (general purpose ASCII)

User defined – specify a mnemonic for a given bit pattern for a label or bus

* Supports C++ name de-mangling

Available data/file formats

ala Contains information to reconstruct the display appearance, instrument settings, and trace data (optional)

that were present when the file was created

xml Extensible markup language for configuration portability and programmability

csv CSV (comma-separated values) format for transferring data to other applications like Microsoft®Excel

mfb Export logic analyzer data for post-processing. Mfb data can be parsed using programming tools

Standard analysis tools

Filter/colorize

Find (next/previous)

Page 27

27

16800 Series Instrument Characteristics

16800 Series PC characteristics

Operating system Microsoft Windows®XP Professional

Processor Intel Celeron™ 2.93 GHz

Chipset Intel 915G

System memory 1 GB SDRAM

Hard disk drive 80 GB (or higher)

Installed on hard drive Operating system, latest revision of the logic analyzer application software, optional application software

ordered with the logic analyzer

16800 Series instrument controls

LCD display Large 38.1-cm (15-in.) display makes is easy to view a large number of waveforms or states

(Touch screen available via option 103)

Front-panel hot keys Dedicated hot keys for selecting run mode and disabling touch screen (if ordered)

Front-panel knob General-purpose knob adjusts viewing and measurement parameters

Keyboard and mouse PS/2 keyboard and mouse (shipped standard)

16800 Series video display modes

Available touch-screen Size 38.1 cm (15 in.) diagonal

display

Resolution 1024 x 768

External display Simultaneous Front panel and external display can be used simultaneously at 1024 x 768 resolution

display capability

Supports up to four external monitors at up to 1600x1200 (with PCI video card)

Page 28

28

Programmability

You can write programs to

control the logic analyzer

application from remote

computers on the local area

network using COM or ASCII.

The COM automation server

is part of the logic analyzer

application. This software

allows you to write programs to

control the logic analyzer. All

measurement functionality is

controllable via the COM interface.

The B4608A Remote Programming

Interface (RPI) lets you remotely

control a 16800 Series logic

analyzer by issuing ASCII

commands to the TCP socket

on port 6500. This interface is

designed to be as similar as

possible to the RPI on 16700

Series logic analysis systems,

so that you can reuse existing

programs.

The remote programming

interface works through the COM

automation objects, methods,

and properties provided for

controlling the logic analyzer

application. RPI commands are

implemented as Visual Basic

modules that execute COM

automation commands, translate

their results, and return proper

values for the RPI. You can use the

B4606A advanced customization

environment to customize and

add RPI commands.

Figure 6. 16800 Series programming overview

16800 Series Instrument Characteristics

Computer with

Windows 2000/XP

Logic analyzer

(16900/16800/1680)

or PC running Agilent

logic analyzer application

Distributed COM

LAN connection

Instrument COM

automation server

Page 29

29

16800 Series Interfaces

Peripheral interfaces

Display 15-pin VGA connector

Keyboard PS/2

Mouse PS/2

Parallel 25-pin D-sub

Serial 9-pin D-sub

PCI card expansion slot 1 full profile

USB Six 2.0 ports, two in front, four in rear

Connectivity interfaces

LAN 10/100 Mb/s

Connector RJ-45

Interface with external instrumentation

Trigger or arm external devices or receive signals that can be used to arm measurement hardware within the logic analyzer with

Trigger In/Out

Trigger In

Input Rising edge or falling edge

Action taken When received, the logic analyzer takes the actions described in the trigger sequence step

Input signal level ± 5 V max

Threshold level Selectable: ECL , LVPECL, LVTTL, PECL, TTL

User defined (± 5 V in 50 mV increments)

Minimum signal amplitude 200 mV

Connector BNC

Input resistance 4 k ohm nominal

Trigger Out

Trigger Rising edge or falling edge. OR of selected events that cause Trigger Out (logic analyzer trigger or flags)

Output signal V

OH

(output high level) 2.0 V min

V

OL

(output low level) 0.5 V max

Pulse width approx. 80-160 ns

Threshold level LVTTL (3.3 V logic)

Signal load 50 ohm (For good signal quality, the trigger out signal should be terminated in 50 ohms to ground)

Connector BNC

Page 30

30

Figure 9. 16800 Series back panel

Full profile PCI card

expansion slot

External display port

Parallel port

Serial port

10/100 Base T LAN

2.0 USB ports (4)

Clock in

Trigger out

Trigger in

Keyboard

Mouse

AC power

Figure 8. 16800 Series front panel

On/Off power switch

15 inch built-in

color LCD display,

Touch Screen

available

General purpose knob

Run/stop keys

Touch screen on/off (if ordered)

16800 Series Physical Characteristics

Dimensions

Power

16801A 115/230 V, 48-66 Hz, 605 W max

16802A 115/230 V, 48-66 Hz, 605 W max

16803A 115/230 V, 48-66 Hz, 605 W max

16804A 115/230 V, 48-66 Hz, 775 W max

16806A 115/230 V, 48-66 Hz, 775 W max

16821A 115/230 V, 48-66 Hz, 775 W max

16822A 115/230 V, 48-66 Hz, 775 W max

16823A 115/230 V, 48-66 Hz, 775 W max

Weight Max net Max shipping

16801A 12.9 kg 19.7 kg

(28.5 lbs) (43.5 lbs)

16802A 13.2 kg 19.9 kg

(28.9 lbs) (43.9 lbs)

16803A 13.7 kg 20.5 kg

(30.3 lbs) (45.3 lbs)

16804A 14.2 kg 21.0 kg

(31.3 lbs) (46.3 lbs)

16806A 14.6 kg 21.4 kg

(32.1 lbs) (47.1 lbs)

16821A 14.2 kg 20.9 kg

(31.2 lbs) (46.2 lbs)

16822A 14.2 kg 21.1 kg

(31.6 lbs) (46.6 lbs)

16823A 14.5 kg 21.3 kg

(32.0 lbs) (47.0 lbs)

Instrument operating environment

Temperature 0˚ C to 50˚ C (32˚ F to 122˚ F)

Altitude To 3000 m (10,000 ft)

Humidity 8 to 80% relative humidity

at 40˚ C (104˚ F)

Figure 7. 16800 Series exterior dimensions

Figure 10. 16800 Series side view

330.32

(13.005)

Dimensions: mm (inches)

28.822

(11.347)

443.23

(17.450)

Page 31

31

16800 Series Accessories

Agilent 1184A Testmobile

The Agilent 1184A testmobile

gives you a convenient means of

organizing and transporting your

logic analyzer and accessories.

The testmobile includes the

following:

• Drawer for accessories

(probes, cables, power cords)

• Keyboard tray with adjustable

tilt and height

• Mouse extension on keyboard

tray for either right or left

hand operation

• Locking casters for stability

on uneven surfaces

• Strap to stabilize the monitor

• Load limits:

Top tray: 68.2 kg (150.0 lb.)

Lower tray: 68.2 kg (150.0 lb.)

Total: 136.4 kg (300.0 lb.)

Figure 11. Agilent 1184A testmobile cart

Figure 12. Agilent 1184A testmobile cart dimensions

Weight

Max net Max shipping

1184A 48.0 kg 59.0 kg

(106.0 lbs) (130.0 lbs)

Dimensions: mm (inches)

772.2

(30.4)

482.6

(19.0)

254

(10.0)

243.8

(9.6)

774.7

(30.5)

866.1

(34.1)

116.8

(4.6)

594.4

(23.4)

190.5

(7.5)

469.9

(18.5)

652.8

(25.7)

584.2

(23.0)

Page 32

32

16800 Series Accessories

Stationary shelf

This light-duty fixed shelf is

designed to support 16800 Series

logic analyzers. The shelf can be

used in all standard Agilent

racks. The stationary shelf is

mounted securely into place

using the supplied hardware and

is designed to sit at the bottom of

the EIA increment. Features of

the stationary shelf include:

• Snap-in design for easy

installation

• Smooth edges

Specifications

J1520AC J1526AC

Material Cold-rolled steel Cold-rolled steel

Weight 8 kg (17.6 lbs) 9.9 kg (22 lbs)

Color Quartz gray Quartz gray

Length 678 mm (26.7 in) 723.9 mm (28.5 in)

Height 44 mm (1.73 in) 44.5 mm (1.75 in)

Width 444 mm (17.5 in) 482.6 mm (19 in)

Load Capacity 68 kg (150 lbs) Capacity 68 kg (150 lbs)

EIA Units 1 2

Contains 1 stationary shelf 1 sliding shelf

2 rear brackets 2 rear brackets

Mounting hardware 1 cable strap

Mounting hardware

Rack accessories

Sliding shelf

The sliding shelf provides a

flat surface with full product

accessibility. It can be used in all

Agilent racks to support 16800

Series logic analyzers. The shelf

and slides are preassembled for

easy installation. Features of the

sliding shelf include:

• Snap-in design for easy

installation

• Smooth edges

Consider purchasing the steel

ballast (C2790AC) to use with the

sliding shelf. The ballast provides

anti-tip capability when the shelf

is extended.

Figure 15. Sliding shelf (J1526AC)

Figure 14. Stationary shelf (J1520AC)

Figure 13. Sliding shelf installed in rack

Page 33

33

Ordering Information

Each 16800 Series portable logic

analyzer comes with one PS/2

keyboard, one PS/2 mouse,

accessory pouch, power cord and

1-year warranty standard.

Additional 16800 Series options

Agilent product or

option number Description Ordering information

<Model number>-103 Add touch screen Must be ordered at time of purchase

<Model number>-109 External removable hard drive Must be ordered at time of purchase

E5862A Additional external hard drive

Choose measurement Choose the channel count

capability

34 channels 68 channels 102 channels 136 channels 204 channels

Logic analyzer 16801A 16802A 16803A 16804A 16806A

Logic analyzer with 16821A 16822A 16823A – –

48-channel pattern generator

1 2

Choose the memory depth and state speed

Memory depth 1 M: <Model number>-001

4 M: <Model number>-004

16 M: <Model number>-016

32 M: <Model number>-032

State speeds 250 MHz: <Model number>-250

450 MHz: <Model number>-500*

* Applies to 68, 102, 136 and 204 channel models

3

Selecting a logic analyzer to meet your application and budget is as easy as 1, 2, 3

Page 34

34

16800 Series probing options

16800 Series logic analyzer probes

Logic analyzer probes are ordered separately. General-purpose flying lead

Please specify probes when ordering to ensure • 17-ch E5383A

the correct connection between your logic Connector probes

analyzer and the device under test. • Mictor: 34-ch E5346A

• Samtec: 34-ch E5385A

Connectorless probes

• 34-ch E5394A soft touch

• 17-ch E5396A soft touch

• 34-ch E5404A pro-series soft touch

Pattern generator clock and data pods

For models with a pattern generator, order at TTL/CMOS

least one clock pod and at least one data pod • 16720A-011 TTL clock pod and lead set

for every 8 output channels. • 16720A-012 3-state TTL/3.3-V data pod and lead set

• 16720A-013 3-state TTL/CMOS data pod and lead set

• 16720A-014 TTL data pod and lead set

2.5 V

• 16720A-015 2.5-V clock pod and lead set

• 16720A-016 2.5-V data pod and lead set

3.3 V

• 16720A-017 3.3-V clock pod and lead set

• 16720A-018 3.3-V 3-state data pod and lead set

ECL

• 16720A-021 ECL clock pod and lead set

• 16720A-022 ECL data pod and lead set

• 16720A-023 ECL unterminated data pod and lead set

5 V PECL

• 16720A-031 5-V PECL clock pod and lead set

• 16720A-032 5-V PECL data pod and lead set

LVPECL

• 16720A-033 LVPECL clock pod and lead set

• 16720A-034 LVPECL data pod and lead set

1.8 V

• 16720A-041 1.8-V clock pod and lead set

• 16720A-042 1.8-V data pod and lead set

LVDS

• 16720A-051 LVDS clock pod and lead set

• 16720A-052 LVDS data pod and lead set

Ordering Information

Page 35

35

Related Literature

Publication Title Publication Type Publication Number

Agilent Technologies 16800 Series Color brochure 5989-5062EN

Logic Analyzers

Considerations When Selecting a Application note 5989-5138EN

Logic Analyzer

Agilent Technologies 16900 Series Logic Color brochure 5989-0420EN

Analysis Systems

Agilent Technologies Measurement Modules Data sheet 5989-0422EN

for the 16900 Series

Agilent Technologies B4655A FPGA Data sheet 5989-0423EN

Dynamic Probe

Probing Solutions for Agilent Technologies Catalog 5968-4632E

Logic Analyzers

Processor and Bus Support for Agilent Catalog 5966-4365E

Technologies Logic Analyzers

MATLAB®is a U.S. registered trademark of Math Works, Inc.

Windows

®

is a U.S. registered trademark of Microsoft Corporation.

Intel

®

is a U.S. registered trademark of Intel Corporation.

Celeron

®

is a U.S. trademark of Intel Corporation.

PCI Express

®

and PCI-X®are registered trademarks of PCI-SIG.

Upgrade memory depth or state speed after purchase

Logic analyzer channels 34 68 102 136 204

Logic analyzer models 16801A 16802A 16803A 16804A 16806A

16821A 16822A 16823A

After purchase upgrade models E5876A E5877A E5878A E5879A E5880A

Memory depth 1 M: <Model number>-001

4 M: <Model number>-004

16 M: <Model number>-016

32 M: <Model number>-032

State speed 450 MHz: <Model number>-500*

* Applies to 68, 102, 136 and 204 channel models

Ordering Information

Page 36

Agilent Technologies’ Test and Measurement Support, Services, and Assistance

Agilent Technologies aims to maximize the value you receive, while minimizing your risk and

problems. We strive to ensure that you get the test and measurement capabilities you paid

for and obtain the support you need. Our extensive support resources and services can help

you choose the right Agilent products for your applications and apply them successfully.

Every instrument and system we sell has a global warranty. Two concepts underlie Agilent’s

overall support policy: “Our Promise” and “Your Advantage.”

Our Promise

Our Promise means your Agilent test and measurement equipment will meet its advertised

performance and functionality. When you are choosing new equipment, we will help you

with product information, including realistic performance specifications and practical

recommendations from experienced test engineers. When you receive your new Agilent

equipment, we can help verify that it works properly and help with initial product operation.

Your Advantage

Your Advantage means that Agilent offers a wide range of additional expert test and

measurement services, which you can purchase according to your unique technical and

business needs. Solve problems efficiently and gain a competitive edge by contracting with

us for calibration, extra-cost upgrades, out-of-warranty repairs, and on-site education and

training, as well as design, system integration, project management, and other professional

engineering services. Experienced Agilent engineers and technicians worldwide can

help you maximize your productivity, optimize the return on investment of your Agilent

instruments and systems, and obtain dependable measurement accuracy for the life of

those products.

For more information on Agilent Technologies’

products, applications or services, please

contact your local Agilent office. The complete

list is available at:

www.agilent.com/find/contactus

Phone or Fax

United States:

(tel) 800 829 4444

(fax) 800 829 4433

Canada:

(tel) 877 894 4414

(fax) 800 746 4866

China:

(tel) 800 810 0189

(fax) 800 820 2816

Europe:

(tel) 31 20 547 2111

Japan:

(tel) (81) 426 56 7832

(fax) (81) 426 56 7840

Korea:

(tel) (080) 769 0800

(fax) (080) 769 0900

Latin America:

(tel) (305) 269 7500

Taiwan:

(tel) 0800 047 866

(fax) 0800 286 331

Other Asia Pacific Countries:

(tel) (65) 6375 8100

(fax) (65) 6755 0042

Email: tm_ap@agilent.com

Contacts revised: 05/27/05

Product specifications and descriptions in this

document subject to change without notice.

© Agilent Technologies, Inc. 2006

Printed in USA, May 31, 2006

5989-5063EN

www.agilent.com/find/emailupdates

Get the latest information on the products and applications you select.

www.agilent.com

t

www.agilent.com/find/agilentdirect

Quickly choose and use your test equipment solutions with confidence.

www.agilent.com/find/open

Agilent Open simplifies the process of connecting and programming test systems to

help engineers design, validate and manufacture electronic products. Agilent offers open

connectivity for a broad range of system-ready instruments, open industry software,

PC-standard I/O and global support, which are combined to more easily integrate test

system development.

Agilent Open

Agilent Email Updates

Agilent Direc

Loading...

Loading...