Page 1

Help Volume

© 2000-2001 Agilent Technologies Inc. All rights reserved.

Instrument: Agilent

Technologies 16720A 300 M

Vectors/s Pattern Generator

Page 2

Using the Agilent Technologies 16720A Pattern Generator

The Agilent 16720A Pattern Generator is used by digital design teams

to emulate digital signals in circuits under development. The pattern

generator can take the place of missing devices, or can act as a

stimulus to functionally test prototypes.

Getting Started • “Overview of the Agilent Technologies 16720A Pattern Generator” on

page 10

• “A Beginner's Exercise” on page 17

Creating the Program • “Building an Initialization Sequence” on page 21

• “Building a Main Sequence” on page 23

• “Building a User Macro” on page 25

• “Importing Agilent 16522A ASCII Files” on page 28

• “Importing Agilent 16720A PattGen Binary Files” on page 39

• “Importing System Data Files” on page 58

• “Loading and Saving Pattern Generator Configurations” on page 61

See Also “Selecting the Correct Probe Pod” on page 62

“Connecting the Probe Pods” on page 71

“Editing Sequences” on page 73

“Working with Instruction Types” on page 78

“Working with Labels and Pods” on page 85

“Working with Macro Parameters” on page 98

“Working with Automatic Pattern Fills” on page 101

2

Page 3

Using the Agilent Technologies 16720A Pattern Generator

“Printing the Pattern Generator Window” on page 108

“Printing Vector Sequences to a File” on page 109

“Viewing a Compiled Sequence” on page 116

Using the Intermodule Window (see the Agilent Technologies 16700A/BSeries Logic Analysis System help volume)

“Key Characteristics” on page 111

Main System Help (see the Agilent Technologies 16700A/B-Series Logic

Analysis System help volume)

Glossary of Terms (see page 117)

3

Page 4

Using the Agilent Technologies 16720A Pattern Generator

4

Page 5

Contents

Using the Agilent Technologies 16720A Pattern Generator

1 Using the Agilent Technologies 16720A Pattern Generator

Overview of the Agilent Technologies 16720A Pattern Generator 10

Mapping Probe Pods to the Interface 11

Vector Output Mode 12

Clock Source 13

Building a Sequence of Test Vectors 15

Running the Pattern Generator 16

A Beginner’s Exercise 17

Configure Format 17

Configure Sequence 18

Set up the Workspace 19

View the Results 19

Building an Initialization Sequence 21

Building a Main Sequence 23

Building a User Macro 25

Importing Agilent 16522A ASCII Files 28

Creating an ASCII File 30

ASCII Disk File Identifier 32

ASCII File Commands 32

Importing Agilent 16720A PattGen Binary Files 39

Creating a PattGen Binary File 40

Binary File Commands 42

5

Page 6

Contents

Importing System Data Files 58

Data Sets 59

Data Set Labels 59

Data Set Range 60

Loading and Saving Pattern Generator Configurations 61

Selecting the Correct Probe Pod 62

Data Pod Descriptions 63

Clock Pod Descriptions 67

Connecting the Probe Pods 71

Editing Sequences 73

Cutting, Copying, Pasting, and Deleting Sequence Lines 73

Deleting Sequence Lines 74

Inserting Blank Sequence Lines 75

Go to a Line Number 76

Positioning the Sequence 76

Using Ditto " values 77

Working with Instruction Types 78

The Break Instruction 79

The Signal IMB Instruction 79

The Wait IMB Event Instruction 80

The Wait External Event Instruction 80

The User Macro Instruction 81

The Repeat Loop Instruction 82

6

Page 7

Contents

Working with Labels and Pods 85

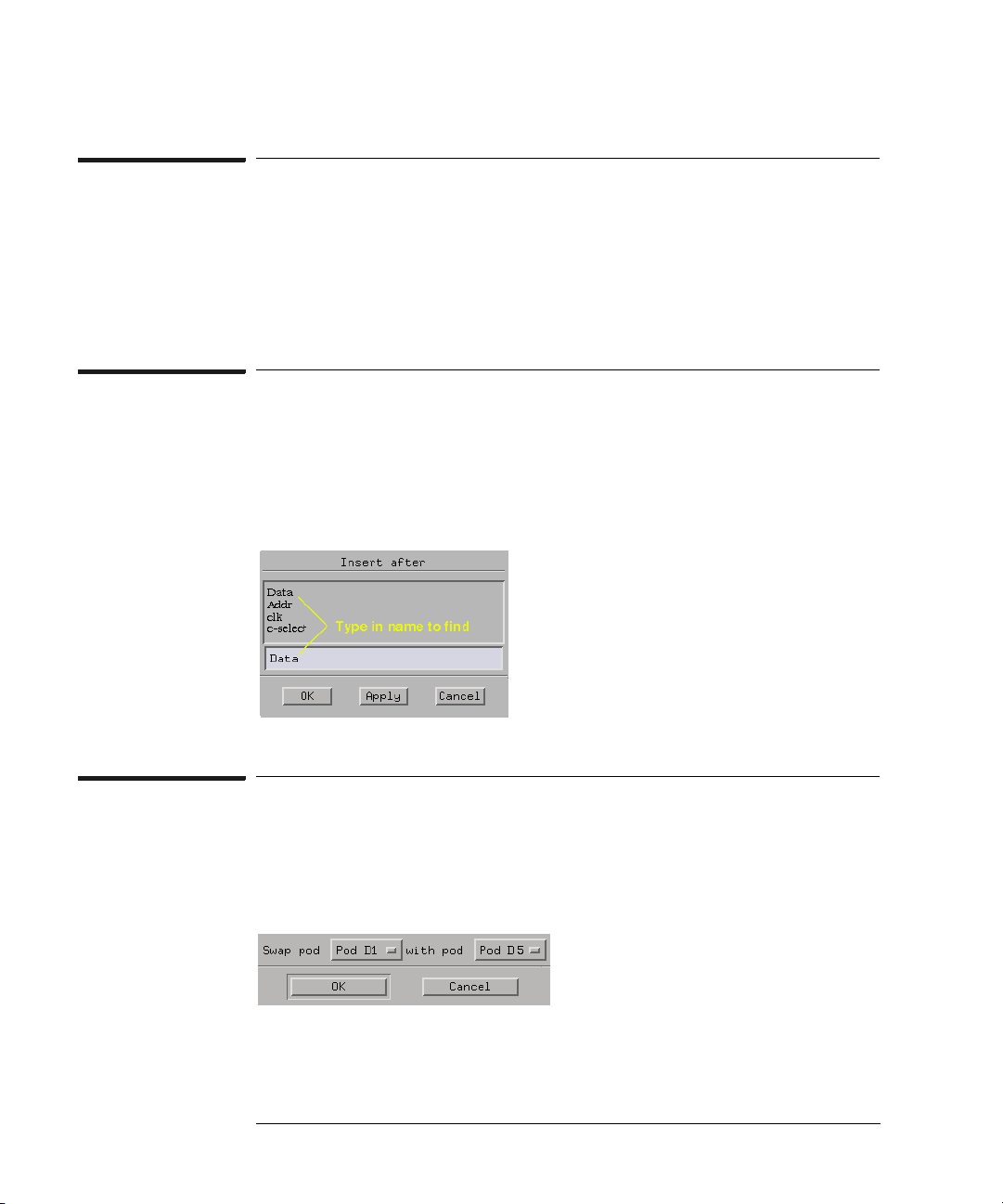

Creating and Inserting New Labels 86

Deleting Labels 87

Inserting Pre-assigned Labels 88

Renaming Existing Labels 88

Reordering a Label’s Pod Bits 89

Turning Labels On/Off 89

Clearing Format Labels 90

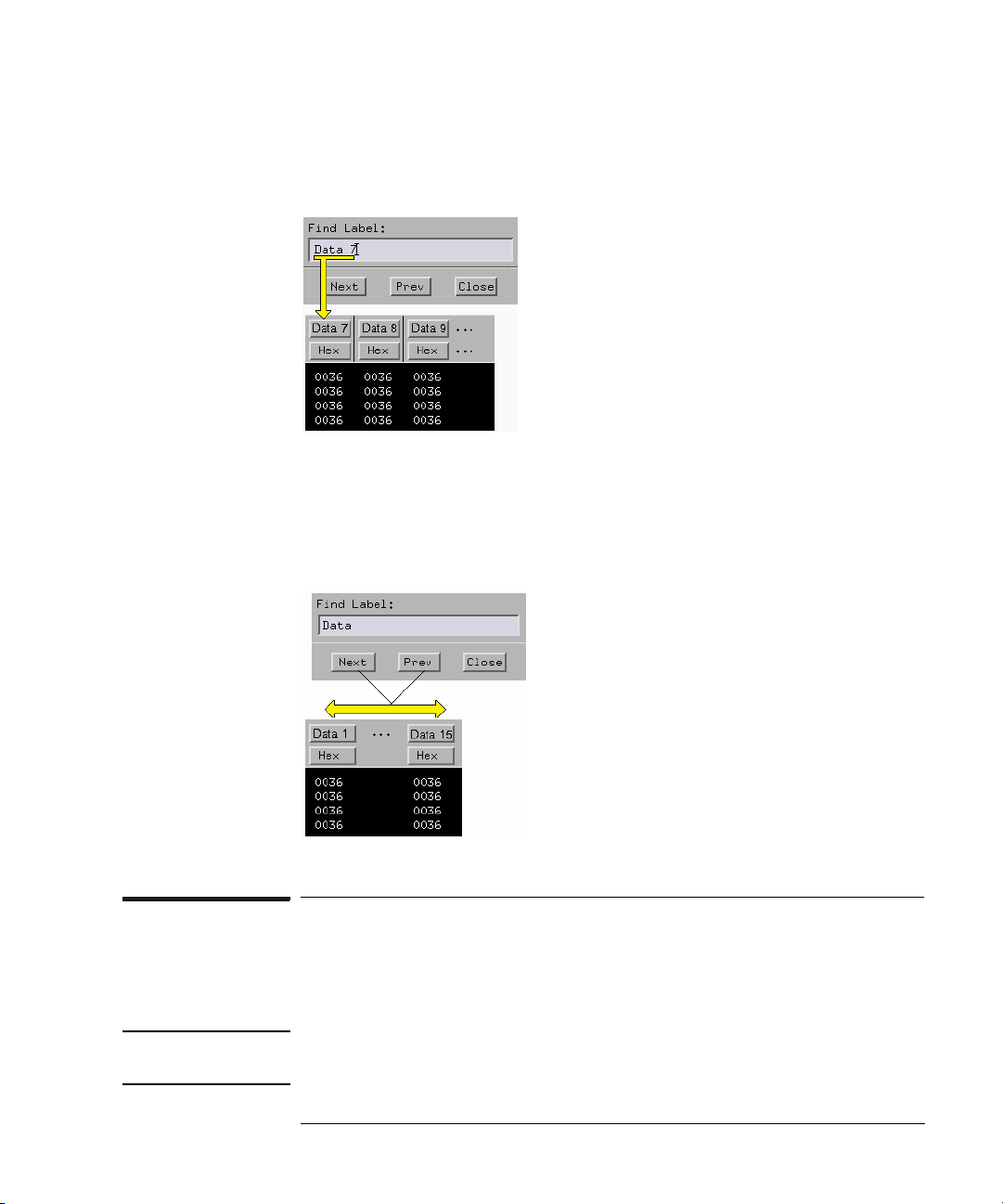

Searching for Labels 90

Swap Pods 90

Clear Pods 91

Assigning Bits to a Label 91

Label Polarity 92

Finding a label 92

Replace Labels 93

Appending Labels 94

Insert All Labels 95

Delete All Labels 95

Setting the Label Font Size 95

Adjusting Column Width 96

Setting Column Color 96

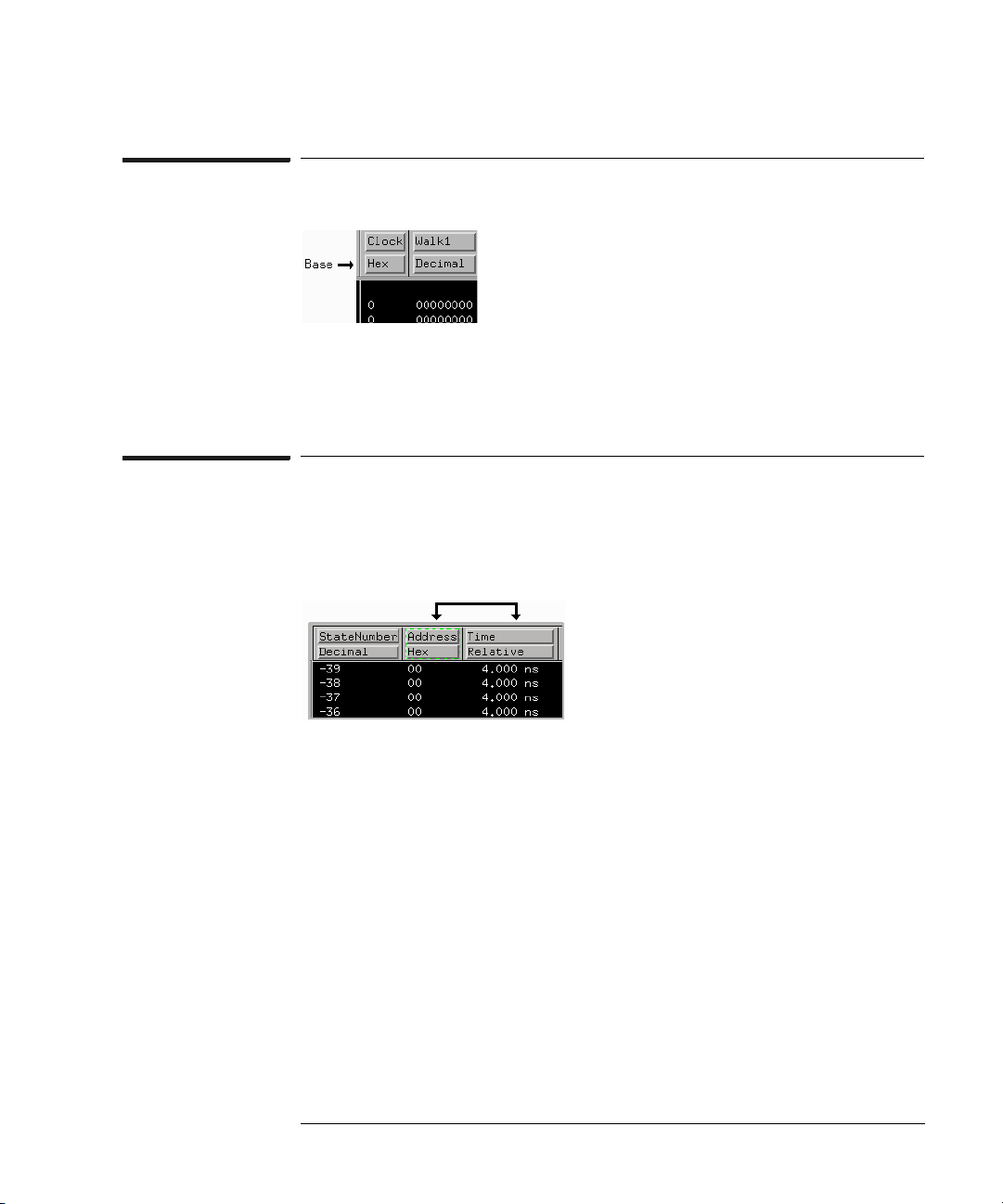

Setting the Numeric Base 97

Rearranging the Label Order 97

Working with Macro Parameters 98

Turning Parameters On 98

Inserting Parameters into a Macro 99

Assigning Parameter Values 99

Removing Parameters from a Macro 100

Working with Automatic Pattern Fills 101

Generating a Fixed Pattern Fill 101

Generating a Count Pattern Fill 102

Generating a Rotate Pattern Fill 103

Generating a Toggle Pattern Fill 105

Generating a Random Pattern Fill 106

7

Page 8

Contents

Printing the Pattern Generator Window 108

Printing Vector Sequences to a File 109

Key Characteristics 111

Automatic Cursor Wrap 113

Recalling Macros 114

Copying Macros 115

Viewing a Compiled Sequence 116

Glossary

Index

8

Page 9

1

Using the Agilent Technologies 16720A Pattern Generator

9

Page 10

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Overview of the Agilent Technologies 16720A Pattern Generator

Overview of the Agilent Technologies 16720A

Pattern Generator

Description of the Agilent 16720A Pattern Generator

The Agilent 16720A Pattern Generator is a tool that generates digital

signals. It is used in applications that require an external source to

simulate digital circuitry or generate digital signals for functionally

testing prototype hardware.

Combined with the analog and digital measurement capabilities of the

logic analysis system, you have a tightly integrated solution to your

digital stimulus and response measurement needs.

A Conceptual Measurement Example

The exact output pattern, clock type and speed, and number of

required signals depends on your specific application. How you

configure the pattern generator and what kind of signal generation

sequence you create will vary. However, from a procedural standpoint,

the steps are the same each time to set up, create a sequence, and run

the pattern generator.

1. Select the probing (see page 62) that is compatible with your target

circuit.

2. Set the Vector Output mode (see page 12) and the Clock Source (see

page 13) parameters.

3. Connect the probes (see page 71) to your circuit and map the probe

channels (see page 11) into the interface of the pattern generator.

4. Build a sequence of test vectors (see page 15) to generate the desired

output signals.

5. Run (see page 16) the pattern generator and measure the active target

circuit or prototype for the desired results.

Re-using Pattern Generator Programs

After you set up a pattern generator configuration, you may want to

store it away so you can use it again. Perhaps you want to create a set

10

Page 11

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Overview of the Agilent Technologies 16720A Pattern Generator

of test routines or circuit simulators. There are three ways to handle

re-usable configurations.

• You can reload previously saved (see page 61) pattern generator

configurations.

• You can import an Agilent 16522A ASCII file (see page 28) (can only be

used for vector sets <= 1048576 vectors)

• You can import a Agilent 16720A PattGen Binary file (see page 39) (must

be used for vector sets >1048576 vectors)

See Also “A Beginner's Exercise” on page 17

“Key Characteristics” on page 111

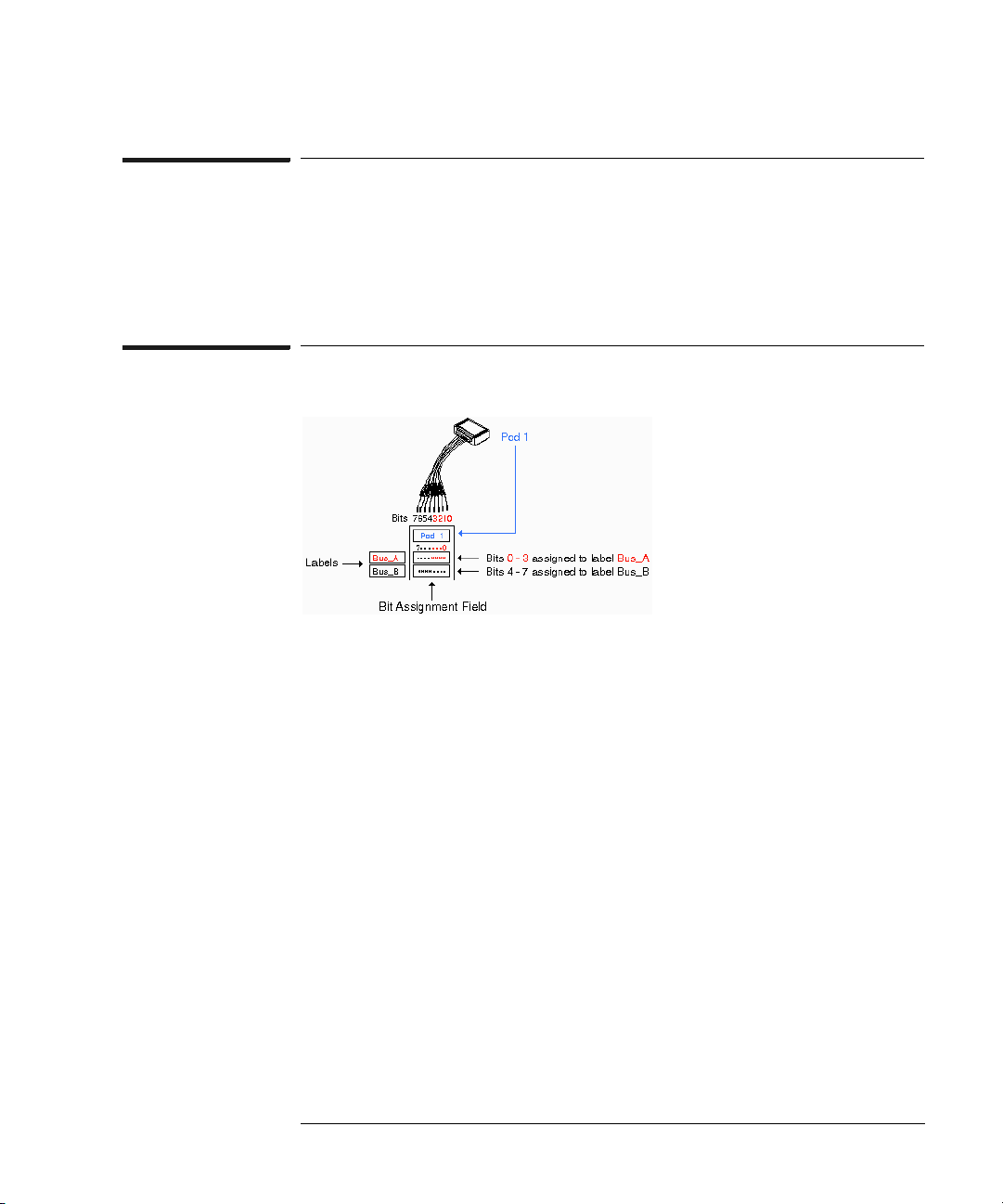

Mapping Probe Pods to the Interface

While the probes make the physical connection to your target circuit, a

software connection is also made within the interface which routes

generated signals to the proper probe output lines. This software

connection is done within the Format tab and is called mapping.

The mapping process consists of logically grouping output signals that

have a similar purpose to a label (see page 85) with a unique name. To

add to or delete signals from a group, you simply turn On/Off the bits

(see page 91) beside the label.

Example

This example shows eight channels (or bits) on probe pod 1 mapped to

two labels in the interface. Bits 0-3 are assigned to label Bus_A, and

bits 4-7 are assigned to label Bus_B. When a bit is assigned, an asterisk

"*" appears in the bit assignment field, verifying the software

connection.

11

Page 12

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Overview of the Agilent Technologies 16720A Pattern Generator

NOTE: After you set up your first measurement, use the ribbon cable ID clips to mark

the data cable numbers for future reference.

Vector Output Mode

The Vector Output Mode determines the channel width, available pods,

and the frequency range for both the internal and external clock. The

choice you make may be determined by trade-offs between clock speed

and channel width.

Because the output mode affects clock frequency ranges, available

pods, and channel width, keep your mode selection in mind when

designing the circuit’s hardware interface and when mapping probe

connections between the test circuit and the labels of the pattern

generator.

This table shows the difference between the Full-Channel 180 MBits/s

mode and the Half-Channel 300 MBits/s mode.

12

Page 13

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Overview of the Agilent Technologies 16720A Pattern Generator

Clock Source

The Clock Source field toggles between internal and external. The

internal clock source is supplied by the pattern generator and controls

the frequency used to output the vectors to the system under test. The

external clock is provided by the user or the system under test, and is

input to the pattern generator through the CLK IN probe of a clock

pod.

An advantage of using an external clock is that you synchronize the

vector output of the pattern generator to the system under test. No

matter which clock source is used, vectors are always output on the

rising edge of the clock.

Internal Clock Source

Use an internal clock source when you want to have control over the

frequency of the output vectors and it is not important for the output

vectors to be synchronized to the system under test.

You select clock frequencies in steps of 1. If you use the keypad to

select a value between the step intervals, the value is rounded to the

nearest interval.

13

Page 14

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Overview of the Agilent Technologies 16720A Pattern Generator

NOTE: If you use the keypad to change the the clock frequency value, you must press

the Enter key to register the new value. You are not required to type "Hz", you

may use only a metric prefix or you may enter a floating point number, i.e.

"50M" and "5e7" will both be displayed as "50MHz" after you select enter. You

may also enter the value as a period, i.e. "20n" and "2e-8" will both be

displayed as "50MHz".

The minimum clock period available with Vector Output Mode at Full

Channel 180Mbit/s is 1MHz. Maximum clock frequency for Full Channel

Mode is 180MHz. The minimum clock frequency available with Vector

Output Mode at Half Channel 300Mbit/s is 1MHz. Maximum clock

frequency for Half Channel Mode is 300MHz.

External Clock Source

Use an external clock source when you want to synchronize the

frequency of the output vectors to the system under test. With this

mode selected, you do not have direct control over the frequency of

the output vectors. Output vector frequency will be the same as the

external clock.

When using an external clock source the maximum clock period for the

Vector Output Mode at Full Channel 180Mbit/s is 180 MHz. The

maximum clock period for the Vector Output Mode at Half Channel

300Mbit/s is 300 MHz.

CAUTION: If the external clock is faster than the maximum period, the Agilent 16720A

will produce erroneous output vectors.

Clock Out Delay

The clock out delay setting lets you position the output clock with

respect to the data. The zero setting is uncalibrated and should be

measured to determine the initial position with respect to the data.

14

Page 15

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Overview of the Agilent Technologies 16720A Pattern Generator

Each numerical change of one on the counter results in an approximate

change of 500 ps.

Building a Sequence of Test Vectors

Test vectors determine the pattern output at each clock cycle. Test

vectors are positioned in a list called a sequence. When a sequence is

run (see page 16), the list of vectors is executed in order of first vector

to last vector. Vectors are always output on the rising edge of the clock.

In every pattern generator application, you have two sequences. An

INIT SEQUENCE (initialization sequence) is used to place your circuit

or subsystem in a known state. The initialization sequence is followed

by the MAIN SEQUENCE. The main sequence is used for the actual

pattern generation that stimulates your circuit under test. The INIT

sequence is only run once, while the MAIN sequence loops if you select

a repetitive run.

Using Hardware and Software Instructions

In addition to test vectors, both INIT and MAIN sequences can include

predefined instruction (see page 78) elements. Instructions can create

Breaks, Loops, and Wait, and can even signal the Intermodule Bus. The

most useful instruction is "User Macro". With a User Macro instruction,

you can create reusable sequences that accept parameters. This

flexibility is very useful in prototype turn-on and environmental

testing.

For more information on INIT and MAIN sequences and how to create

them, see the following topics.

“Building an Initialization Sequence” on page 21

“Building a Main Sequence” on page 23

“Building a User Macro” on page 25

“Working with Instruction Types” on page 78

15

Page 16

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Overview of the Agilent Technologies 16720A Pattern Generator

Running the Pattern Generator

If you are not changing the run options, simply select the Run icon to

run a measurement. Select the Stop icon to stop a measurement.

See Also “What Happens when Run is Selected” on page 16

“What Happens when Stop is Selected” on page 16

What Happens when Run is Selected

In single run mode, the vectors are output from the first vector in the

initialization sequence to the last vector of the main sequence. The last

vector of the main sequence will be held at the outputs until you run

again.

In repetitive run mode, the vectors in the initialization sequence will be

output from first to last, one time, then the main sequence will

repetitively output the vectors in that sequence until you select the

Stop icon.

What Happens when Stop is Selected

When the pattern generator acknowledges stop, the vector currently

being output will be held at the outputs until you run again.

16

Page 17

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

A Beginner’s Exercise

A Beginner’s Exercise

This exercise begins with the pattern generator Format tab active. If it

is not active, select Format in the pattern generator window now.

In this exercise, you will create a label with eight output channels

assigned to it. You will then create a "Walking Ones" output pattern

using one of the automatic pattern fill functions.

NOTE: This exercise does NOT require you to connect the probes or view the output.

The intent of this exercise is to give you practice configuring the pattern

generator interface. A timing analyzer display of the results is furnished for

you.

1. Configure Format (see page 17) with a label called "Walk1" and all eight

bits of Pod 6 assigned.

2. Select Sequence.

3. Configure Sequence (see page 18) with a Walking Ones sequence.

4. Set up the Workspace. (see page 19)

5. View the results. (see page 19)

Configure Format

1. In the pattern generator’s Format area, select the label Label1, then select

Rename. In the Rename dialog, enter "Walk1", then select OK.

2. Select the bit assignment field under Pod 6 and select the menu item with

all eight bits set to "*" (on).

17

Page 18

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

A Beginner’s Exercise

Configure Sequence

1. In the pattern generator’s Sequence window, select Hex and set the

numeric base to Binary.

2. Select the first sequence line. This positions the cursor.

3. Select Rotate, and configure the Rotate Pattern Fill dialog as shown. Select

Fill.

4. Select Close.

18

Page 19

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

A Beginner’s Exercise

Set up the Workspace

1. Open the system Workspace window.

2. Drag and drop a waveform icon onto the pattern generator icon.

3. Select the waveform icon, then select Display.

4. Select the Run icon.

View the Results

1. Select Walk 1 all in the waveform display, then select Expand.

2. Set the Samples/div to 1.

19

Page 20

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

A Beginner’s Exercise

20

Page 21

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Building an Initialization Sequence

Building an Initialization Sequence

The initialization (INIT) sequence is the first of two vector sequences

that appear in the Sequence display. Use the INIT sequence to put the

circuit or subsystem into a known starting condition. You can also use

the INIT sequence to arm a logic analyzer or oscilloscope with the

Signal IMB instruction to begin a measurement when the MAIN

sequence begins. If you leave the INIT sequence empty, it will be

ignored.

What Happens when Run is Selected

In single run mode, the vectors are output from the first vector in the

initialization sequence to the last vector of the main sequence. The last

vector of the main sequence will be held at the outputs until you

execute run again.

In repetitive run mode, the vectors in the initialization sequence will be

output from first to last, one time, then the main sequence will

repetitively output the vectors in that sequence until you select the

Stop icon.

Building the INIT Sequence

The INIT sequence can contain hardware and software instructions

(see page 78) as well as vector data. However, instructions are not

allowed on the first two vector lines.

1. Select the Sequence tab, then select INIT START.

2. Select Insert After, then select Vector.

3. Repeat for each new vector line you want to insert.

4. Select the left-most character in the new vector line.

5. Select Edit.

6. Enter in the desired vector data. As you enter the information, the default

cursor wrap (see page 113) setting will roll the cursor left-to-right and top

line to bottom line.

21

Page 22

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Building an Initialization Sequence

7. Optional - If applicable, insert an instruction (see page 78) instead of

entering vector data.

See Also “Working with Labels and Pods” on page 85

“Editing Sequences” on page 73

“Working with Instruction Types” on page 78

“Building a User Macro” on page 25

“Automatic Cursor Wrap” on page 113

22

Page 23

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Building a Main Sequence

Building a Main Sequence

The MAIN sequence is the second of two vector sequences that appear

in Sequence. Use the MAIN sequence as the primary signal generation

sequence. The MAIN sequence must contain at least two vectors to

output.

What Happens when Run is Selected

In single run mode, the vectors are output from the first vector in the

initialization sequence to the last vector of the main sequence. The last

vector of the main sequence will be held at the outputs until you select

run again.

In repetitive run mode, the vectors in the initialization sequence will be

output from first to last, one time, then the main sequence will

repetitively output the vectors in that sequence until you select the

Stop icon.

Building the Main Sequence

The MAIN sequence can contain hardware and software instructions

(see page 78) as well as vector data. However, instructions are not

allowed on the first two vector lines or the last vector line.

1. Select the Sequence tab, then select MAIN START.

2. Select Insert After, then select Vector.

3. Repeat for each new vector line you want to insert.

4. Select the left-most character in the new vector line.

5. Select Edit.

6. Enter in the desired vector data. As you enter the information, the default

cursor wrap (see page 113) setting will roll the cursor left-to-right and top

line to bottom line.

7. Optional - If applicable, insert an instruction (see page 78) instead of

entering vector data.

23

Page 24

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Building a Main Sequence

See Also “Working with Labels and Pods” on page 85

“Editing Sequences” on page 73

“Working with Instruction Types” on page 78

“Building a User Macro” on page 25

“Automatic Cursor Wrap” on page 113

24

Page 25

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Building a User Macro

Building a User Macro

A User Macro is a vector sequence defined by a custom name, then

inserted by name into a sequence wherever the macro is needed.

Macros may be inserted into the INIT or MAIN sequences of the vectors

in Sequence, or into other macros. Using macros gives you the benefit

of keeping INIT or MAIN sequences generic. By simply interchanging

macros, you change the pattern generator output.

NOTE: Care should be taken to avoid infinite loops. For example, if macro 0 calls

macro 1, and macro 1 calls macro 0, this will cause an infinite loop.

Macros can also accept parameters (see page 98). A major benefit in

using parameters is that you keep a macro’s functionality generic and

still direct specific action identified by parameters. Think of a

parameter as the only part of a macro that changes as the macro is

reused. Each macro can accept a maximum of 10 unique parameters.

Typically, you create a macro first under the Macro tab, then insert it

into sequences under the Sequence tab. You can create 100 different

macros for use in one or more pattern generator sequences.

Differences between User Macros and the INIT and MAIN sequences

are that macros cannot use any instruction that interacts with the

intermodule bus (IMB). The reason is that these instructions can only

be included once into the sequence. Since macros may be called as

many times as desired, allowing these instructions within macros

would violate this restriction. You remove macros from sequences by

using the Delete Line(s) function.

Creating the Macro

A macro sequence can contain hardware and software instructions

(see page 78) as well as vector data. However, instructions are not

allowed on the first vector line.

1. In Macro, recall (see page 114) the macro that you want to create.

2. Select MACRO START.

3. Select Insert After, then select Vector.

25

Page 26

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Building a User Macro

4. Repeat for each new vector line you want to insert.

5. Select left-most character in the new vector line.

6. Enter in the desired vector data. As you enter the information, the default

cursor wrap (see page 113) setting will roll the cursor left-to-right and top

line to bottom line.

7. Optional - Insert an instruction (see page 78) instead of entering vector

data.

8. Enter in a name for the new macro.

9. Optional - Select Parameters and turn on any parameters you plan to use.

Inserting the Macro

1. In Sequence or Macro, select the vector line directly above where you

want to insert the User Macro instruction.

2. Select Insert After, then select User Macro.

3. Select the User Macro instruction.

4. From the Macro Selection dialog that appears, select the desired macro

name you want to insert.

5. Select OK.

26

Page 27

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Building a User Macro

NOTE: See The User Macro Instruction (see page 81) for restrictions on User Macro

instruction usage.

See Also “Recalling Macros” on page 114

“Copying Macros” on page 115

“Working with Macro Parameters” on page 98

“Working with Instruction Types” on page 78

“Editing Sequences” on page 73

“Working with Labels and Pods” on page 85

27

Page 28

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16522A ASCII Files

Importing Agilent 16522A ASCII Files

You can create an ASCII text file and import it as a complete pattern

generator program. In general, the ASCII file consists of a block of

setup information, a block of label and channel information, and a block

of pattern generator vector data. The file must be saved in ASCII

format and organized as shown in step 1 of the procedure below.

1. Create the ASCII file (see page 30) in a text editor.

2. Save the file as Te x t On l y or ASCII Format in a directory on your

analyzer’s hard drive.

3. In the Sequence menu bar, select File, then Import 16522A ASCII File.

See the caution below.

4. From the file selection dialog that appears, select the desired path and

ASCII file name.

5. Select Import.

CAUTION: Importing an Agilent 16522A ASCII file causes all current Format and

Sequence information to be overwritten. Be sure to save the pattern generator

configuration before you begin the import process.

NOTE: Importing a 1048576 line 16522A ASCII file may take approximately two

minutes. If a 1048576 sequence is in memory when you begin an import, it

may take up to a minute to clear the current data and up to two minutes to

import the new data.

28

Page 29

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16522A ASCII Files

This figure shows Format after the ASCII file example shown in step 1

was imported.

29

Page 30

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16522A ASCII Files

Creating an ASCII File

You can create an ASCII file using any Windows, MS-DOS, or UNIX text

editor. An ASCII file consists of a file identifier and three blocks of

information. Each block must follow the specified order.

• ASCII 000000 - required file identifier ("ASCII" followed by 5 spaces and

6 zeros).

ASCDown - optional. Retained for backwards compatibility.

• 1st block (optional)

FORMat - clock, channel mode, and delay information.

• 2nd block

LABel - names and number of channels.

• 3rd block

VECTor - vector data and Repeat indicators.

File Requirements and Precautions

• The file must contain only specified pattern generator commands (see

page 32), and in the order and format shown in the example below.

• The file must be saved in "ASCII" or "text only" format.

• Vector data is assumed to be entirely hexadecimal base.

• No pattern generator instructions are allowed in the data.

• No pattern generator macros are defined or invoked in the data.

• All labels consist of adjacent bits.

• The file must end with a line termination character (line feed "<lf>" or a

carriage return and line feed "<CR><lf>".

• Comments can be included after the first line (ASCII 000000). Comments

begin with a slash '/' and terminate at the end of the line.

30

Page 31

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16522A ASCII Files

ASCII File Example

NOTE: In this example, the underlined links are added for documentation purposes

only, and would NOT be part of an actual disk file’s text. Line feeds "<lf>" are

shown for example purposes only, and depending on the computer and text

editor used, could actually be a carriage return followed by a line feed

"<CR><lf>".

ASCII 000000 (see page 32)<lf>

/

/ This is a test of the ascii file

/

ASCDown (see page 33)<lf>

FORMat:MODE FULL (see page 36)<lf>

FORMat:CLOCk INTernal, 10E-9 (see page 36)<lf>

LABel LAB1,8 (see page 33)<lf>

LABel DATA,8<lf>

LABel TEST,9<lf>

LABel CLK,3<lf>

LABel BIG,12<lf>

/*

/* This is the beginning of the vector part

/*

VECTor (see page 34)<lf>

12 34 056 7 89A<lf> / Some vectors

0 22 007 0 FFF<lf>

A0 33 000 1 111<lf> /* Some more vectors */

*M<lf>

92 6F 000 1 FF0<lf>

CA CA 000 1 00F<lf> // Even more vectors

*R 3<lf>

00 10 011 0 ABC<lf>

NOTE: The LABel sequence specified in the 8th through 12th lines results in a

specific bit assignment. A different ordering of the LABel commands would

give a different ordering to the bits.

31

Page 32

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16522A ASCII Files

ASCII Disk File Identifier

The first line of a disk file must contain the text string "ASCII

000000". It consists of the text "ASCII" followed by 5 blanks, then 6

zeros. The purpose of this string is to uniquely identify the file as an

ASCII disk file.

Example

ASCII File Commands

The following commands are used in the ASCII file to configure

Sequence and Format. Commands are not case sensitive. Lowercase

letters in an illustrated command simply show the long and short form

difference.

The uppercase letters of the command show the mandatory portions of

each command.

Commands

“ASCDown Command” on page 33

FORMat Commands

MODe (see page 36)

CLOCk (see page 36)

32

Page 33

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16522A ASCII Files

DELay (see page 37)

ASCII Disk File Indentifier (see page 32)

“LABel Command” on page 33

“VECTor Command” on page 34

ASCDown Command

The ASCDown command was formerly used to signal the start of an

ASCII file load. It causes the current pattern generator label and

sequence structures to be cleared and reset to a default state. The

Agilent 16720A pattern generator now does this automatically.

Example

LABel Command

The LABel command is a special means of specifying labels for use by

an ASCII file. The label bits are assigned from most to least significant

bits across the output pods. You must specify the label string

(quotation marks on the string are optional) and the width of the field.

The label base defaults to hexadecimal. There are a maximum of 126

labels. No label may be more than 32 bits wide. If a label is too wide

(too many bits) for the remaining unused pattern generator bits, it will

be discarded.

Command Syntax

LABel <name_str>,<width>

33

Page 34

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16522A ASCII Files

<name_str> = label string a maximum of 20 characters in length.

<width> = integer number of bits in the label (1 through 32).

Example

VECTor Command

The VECTor command is used after the end of the header/setup

commands to signal the start of the actual pattern generator data in an

ASCII file. No data is allowed in the same line as the VECTor command.

Example

Vector Data

The data portion of the ASCII file is an array of hexadecimal data fields.

Each row of the array corresponds to a single line of the main program.

Each column of the array corresponds to a single label as defined under

34

Page 35

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16522A ASCII Files

the pattern generator Format tab.

Data fields are separated by one or more blank characters. A line

termination (line feed or carriage return + line feed) signals the end of

a line and the start of a new line. If a data field has more data than the

label width would indicate, only the least significant bits of the data

field are used. If there are more data fields in a row than there are

labels, the extra data fields (last data fields in the row) are ignored. If

there are fewer data fields in a row than there are labels, the data for

the extra (right-most) labels will be zero.

The MAIN sequence must have at least two data lines. In the ASCII

data file, a row consisting of only "*M" signals the start of the MAIN

sequence. If there is to be no data in the INIT sequence, the first row of

the file after the VECTor command must be "*M". Note that the

quotation marks in "*M" are not really in the file.

CAUTION: Any character that is not a valid hexadecimal digit (that is, 0 through 9, or

upper/lower case A through F) are ignored and treated as field separators.

This could cause problems if a mistyped character appears in the middle of a

data value. For example, "12R4" will be assigned to two labels as "12" and "4".

Either of the INIT or MAIN sequences can include multiple Repeat

indicators specified by "*R <count>". Note that the quotation marks

around the Repeat indicator are not part of the indicator, and like the

"*M", the "*R <count>" must be located on a separate line.

The Repeat indicator specifies that the previous data vector is repeated

<count> more times, where <count> is a positive integer. The Repeat

indicator must follow a sequence line containing a data vector or

another Repeat indicator. Placing the Repeat indicator after the

VECTor command or the "*M" will cause an error message to appear.

The last data row of the file must end with a line termination character.

The line termination character is the flag to load the data row into the

data structure. Failure to do this will result in the last data row not

being loaded.

The ASCII file import mechanism assumes correctness in the data file

and any header commands. Error handling is basic, and treating

unexpected characters as field separators could create bizarre results

when parsing the file. Error messages point to the line number where

35

Page 36

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16522A ASCII Files

the parser finds the error.

Serious problems will cause the default main program to be loaded in

an effort to avoid locking up the logic analysis system.

FORMat:MODe Command

The FORMat:MODe command is optional. The existing mode scheme is

used if nothing is specified. FULL channel output mode limits the data

rate to a maximum of 180 MHz, but allows 48 channels per card. HALF

channel output mode allows an output rate of greater than 180 MHz,

but limits the number of channels to 24 per card.

Command Syntax

FORMat:MODe [FULL|HALF]

Example

FORMat:CLOCk Command

The FORMat:CLOCk command is optional. The existing clock scheme

is used if nothing is specified. The CLOCk command specifies the clock

source for the pattern generator.

Command Syntax

FORMat:CLOCk INTernal, <clk_period>

= a real number value that corresponds to the interface selectable

clock period values (example = 5E-9).

36

Page 37

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16522A ASCII Files

FORMat:CLOCk EXTernal, [LEFifty|GTFifty|GTONe]

[LEFifty] = Less than or equal to 50 MHz.

[GTFifty] = Greater than 50 MHz and less than or equal to 180 MHz.

[GTONe] = Greater than 180 MHz.

NOTE: The maximum clock rate is limited by the channel mode. See FORMat:MODe

(see page 36) command.

Example

FORMat:DELay Command

The FORMat:DELay command is optional. The existing delay scheme is

used if nothing is specified. The DELay command specifies the clock

out delay. The clock out delay setting allows positioning of the clock

with respect to the data. Delay setting range is 0 - 14 with each

increment delaying the clock approximately 500 ps per step.

NOTE: The delay setting that corresponds to zero is uncalibrated. You must measure

it to determine the basic clock/data timing.

Command Syntax

FORMat:DELay <delay_arg>

<delay_arg> = an integer from 0 to 14 with each increment delaying

the clock by approximately 500 ps.

37

Page 38

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16522A ASCII Files

Example

38

Page 39

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

Importing Agilent 16720A PattGen Binary Files

You can create a PattGen Binary file and import it as a complete

pattern generator program. In general, the PattGen Binary file consists

of a set of ASCII commands followed by a binary representation of the

vectors. The file must be organized as shown in step 1 of the procedure

below.

1. Create the PattGen Binary file (see page 40).

2. Make the file available in a directory on your logic analysis system hard

drive using the various connectivity methods available from the logic

analysis system. These include FTP, NFS, or PC file sharing.

3. Under the Format tab, select File, then select Import PattGen Binary

File. See the Caution Below

4. From the file selection dialog, select the desired path and PattGen Binary

file name.

5. Select Import.

CAUTION: Importing an Agilent 16720 PattGen Binary file causes all current Format

and Sequence information to be overwritten. Be sure to save the pattern

generator configuration before you begin the import process.

When a PattGen Binary file is loaded, the GUI changes in the following

ways:

• The Sequence and Macro tabs are disabled.

• The Output Mode (full channel/half channel) button is disabled.

• Channel assignments can not be edited.

The reason for each of these changes is the same. When a PattGen

Binary file is loaded, it is loaded directly into the 16720A hardware.

Because PattGen Binary files can be very large there is no internal

representation that can be edited and/or displayed as there is for the

16522A ASCII or System Date files.

Changing among Full and Half channel modes requires memory to be

reloaded. Changing channel assignments or adding labels with channel

39

Page 40

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

assignments also requires memory to be reloaded.

If you save a configuration after loading a PattGen file, the

configuration will not contain the binary data. You will have to reload

the original PattGen Binary file.

Vectors that are loaded from a PattGen Binary file can be viewed in a

Listing Window attached to the output of the 16720A icon on the

Workspace. The Listing Window displays vectors by reading them from

memory on 16720A card.

You can exit the Binary Mode (where editing is disabled) either by

loading a non-binary file (i.e. 16522A ASCII) or by selecting Enable

Sequence Tab in the File menu. This causes the vectors that were

loaded from the binary file to be replaced by the default vectors, which

are two vectors of all zero values.

Creating a PattGen Binary File

The PattGen Binary is primarily designed for deep (>1048576) vector

sets and the various other formats (i.e. 16522A ASCII) will be used for

shorter sets. The deep vector sets can be generated from tools, such as

Verilog simulators, and translated to PattGen Binary by third party

tools or customer-developed translation utilities. The changes to

vectors, labels, etc. should be made in the tool that originally generated

the vectors (i.e. Verilog).

Example

C/C++ code for generating PattGen Binary is available on the logic

analysis system in the directory /logic/demo/pattgen which contains

these files.

• simple_pg.c- A very simple example of how to generate PattGen Binary.

• simple pgb- The PattGen Binary file created by simple_pg.c

• pattgen.c- A more extensive example with command line options.

• binary_yacc.y- A simple utility that will parse and print PattGen Binary.

40

Page 41

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

• binary_lex.1- A simple utility that will parse and print PattGen Binary.

• makefile- Rules for building the examples with typical C/C++ compilers.

• ToolDevKit - A directory containing instructions for installing a Workspace

Tool that will generate a PattGen Binary file from vectors captured with a

logic analyzer. See the README file in that directory for details.

• fastReader - A utility that will translate Fast Binary files to PattGen Binary

files. Source code and a .exe file are included. See the README file in that

directory for details.

File Requirements and Precautions

• The file must contain only specified pattern generator commands (see

page 42), and in the order and format shown in the example below.

• The file must be created in binary byte-stream format.

• Vector data must be entirely in binary.

• No pattern generator instructions are allowed in the data.

• No pattern generator macros are defined or invoked in the data.

• Labels may consist of adjacent bits or arbitrarily ordered bits.

• Each ACSII command must end with a line termination character (line

feed "<lf>" or a carriage return and line feed "<CR><lf>"

• Comments can be included after the first command (PGBINARY).

• Comments begin with a slash '/' and terminate at the end of the line.

PattGen Binary Example

NOTE: In this example only the ASCII pattern generator commands are shown. The

binary vector data is not illustrated. This example is available on the logic

analysis system in the file /logic/pattgen/demo/simpe.pgb.

PGBINARY

MODE FULL

CLOCK INTERNAL 5e7

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

41

Page 42

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

WIDTH 6

DEPTH 4096

BEGIN

NOTE: The LABEL sequence specified in the 5th through 10th lines results in a

specific bit assignment. Different POD assignments in those LABEL

commands would give a different ordering to the bits.

PattGen Binary File Identifier

The first line of a PattGen Binary file must contain the text string

"PGBINARY". The purpose of this string is to uniquely identify the file

as a PattGen Binary file.

Example

PGBINARY

MODE FULL

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0}

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

WIDTH 6

DEPTH 4096

BEGIN

Binary File Commands

The following ASCII commands are used in the PattGen Binary file to

configure Sequence and Format. Commands may be all uppercase or

42

Page 43

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

all lowercase, but not mixed. Commands may not be abbreviated or

truncated.

Commands

PattGen Binary File Identifier (see page 42)

CLOCK (see page 43)

DELAY (see page 44)

MODE (see page 45)

RMODE (see page 46)

LABEL (see page 46)

ORDER (see page 49)

WIDTH (see page 50)

DEPTH (see page 50)

BREAK (see page 52)

EVENT (see page 52)

WAIT (see page 53)

SIGNAL (see page 54)

MAIN (see page 55)

BEGIN (see page 56)

Binary Data (see page 57)

CLOCK Command

The CLOCK command is optional. The existing clock scheme is used if

nothing is specified. The CLOCK command specifies the clock source

for the pattern generator.

Command Syntax

CLOCK EXTERNAL

Set the clock mode to externally clocked.

43

Page 44

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

NOTE: The maximum clock rate is limited by the channel mode. See MODE

command.

Example

PGBINARY

MODE FULL

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

WIDTH 6

DEPTH 4096

BEGIN

DELAY Command

The DELAY command is optional. The existing delay scheme is used if

nothing is specified. The DELAY command specifies the clock out

delay. The clock out delay setting allows positioning of the clock with

respect to the data. Delay setting range is 0 - 14 with each increment

delaying the clock approximately 500 ps per step.

NOTE: The delay setting that corresponds to zero is uncalibrated. You must measure

it to determine the basic clock/data timing.

Command Syntax

DELAY <delay_arg>

<delay_arg> = an integer from 0 to 14 with each increment delaying

the clock by approximately 500 ps.

Example

PGBINARY

MODE FULL

44

Page 45

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

CLOCK INTERNAL 5e7 // 50 MHz

DELAY 6

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

WIDTH 6

DEPTH 4096

BEGIN

MODE Command

The MODE command is optional. The existing mode scheme is used if

nothing is specified. FULL channel output mode limits the data rate to

a maximum of 180 MHz, but allows 48 channels per card. HALF

channel output mode allows an output rate of up to 300 MHz, but limits

the number of channels to 24 per card.

Command Syntax

MODE [FULL|HALF]

Example

PGBINARY

MODE FULL

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

WIDTH 6

DEPTH 4096

BEGIN

45

Page 46

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

RMODE Command

The RMODE command is optional. The existing run mode scheme is

used if nothing is specified. SINGLE indicates that a run will output the

INIT part followed by the MAIN part one time each. REPETITIVE

indicates that a run will output the INIT part once followed by the

MAIN part repeating until the STOP icon is selected.

Command Syntax

RMODE [SINGLE][REPETITIVE]

Example

PGBINARY

MODE FULL

RMODE SINGLE

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

WIDTH 6

DEPTH 4096

BEGIN

LABEL Command

The LABEL command is a special means of specifying labels for use by

a PattGen Binary file. The first <integer> following the POD keyword is

the pod number. Pods are numbered from 0...N where N is the

maximum number pods in a logic analysis system minus 1. In the

16720A the number of pods would be 0...29 in Full channel mode or

0...14 in Half channel mode when five cards are connected as a master

card and four expander cards. The pods are numbered from left to

right. By using index numbers rather than the names they would have

in the logic analysis system (i.e. B6 for Pod 6 in Slot B) the command is

independent of how the logic analysis system is configured. Bit

46

Page 47

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

assignment are from Most Significant Bit to Least Significant Bit.

Command Syntax

LABEL <name> { POD <integer> { <integer> | [ <integer> : <integer> ]

}}

<name_str> = label string a maximum of 20 characters in length. The

name string must begin with a letter (A-Z, a-z) or underscore (_) and

can be followed by letters, underscores, or digits (0-9). A label may not

be a keyword (see page 48). If you wish to use a keyword as a label,

you may do so by enclosing it in quotes.

<integer> = POD index or bit number.

Example

PGBINARY

MODE FULL

RMODE SINGLE

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

WIDTH 6

DEPTH 4096

BEGIN

47

Page 48

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

Example

PGBINARY

MODE FULL

RMODE SINGLE

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Select0 POD 0 7

LABEL Select1 POD 0 6

LABEL IN_BUS0 POD 0 [5:2]

LABEL IN_BUS1 POD 0 [1:0] POD 1 [7:6]

LABEL IN_BUS2 POD 1 [5:2]

LABEL IN_BUS3 POD 1 [1:0] POD 2 [7:6]

LABEL OUT_BUS POD 2 [5:2]

WIDTH 7

DEPTH 4096

BEGIN

Keywords

The following are keywords in the PattGen Binary file and may not be

used as labels.

48

Page 49

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

ORDER Command

The Order command provides an optional means for specifying the

order that data for labels will appear. If the order is not specified it is

assumed to be the order in which labels were defined. If the ORDER

command contains only a subset of the labels that have been defined,

then the subsequent BEGIN command refers only to the labels named

in the ORDER command.

Command Syntax

ORDER { <name_str> }

<name_str> = label string a maximum of 20 characters in length.

Example

PGBINARY

MODE FULL

RMODE SINGLE

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

ORDER Label 0 Label1 Label2 Label3 Label4 Label5

WIDTH 6

DEPTH 4096

BEGIN

49

Page 50

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

WIDTH Command

The WIDTH command defines how wide, in number of bytes, the

binary data will be. The width is determined by summing the size,

rounded up to full bytes, of every label that is defined or named in an

ORDER command. The total number of data bytes in the file must be

(DEPTH * WIDTH). WIDTH must be defined before the binary data

part begins. The binary data part also contains the width. This

redundant information is used as one verification of the binary data.

Command Syntax

WIDTH <integer>

<integer> = number of bytes wide the binary data will be.

Example

PGBINARY

MODE FULL

RMODE SINGLE

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

WIDTH 6

DEPTH 4096

BEGIN

DEPTH Command

The DEPTH command defines how may vectors will appear in the

binary data. The total number of bytes in the binary data part of the file

must be (DEPTH * WIDTH). DEPTH must be defined before the binary

data part begins. The binary data part also contains the depth. This

redundant information is used as one verification of the binary data.

The DEPTH has the following restrictions based on the MODE (FULL

50

Page 51

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

or HALF) that the instrument will be in.

FULL Channel Mode

• INIT part must be an even number of vectors.

• MAIN part must be an even number of vectors.

• Total depth can be no more than 8,388,608.

• Total depth can be no less than 4, 096.

HALF Channel Mode

• INIT part must be a multiple of 4 vectors.

• MAIN part must be a multiple of 4 vectors.

• Total depth can be no more than 16,777,216.

• Total depth can be no less than 4,096.

Command Syntax

DEPTH <integer>

<integer> = number of vectors in the binary data.

Example

PGBINARY

MODE FULL

RMODE SINGLE

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

WIDTH 6

DEPTH 4096

BEGIN

51

Page 52

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

BREAK Command

The BREAK command places a hardware BREAK instruction on a

vector number <integer>. Vectors are numbered from 0 to DEPTH - 1.

Command Syntax

BREAK <integer>

<integer> = the vector where a hardware BREAK instruction is to be

placed.

Example

PGBINARY

MODE FULL

RMODE SINGLE

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

BREAK 100

WIDTH 6

DEPTH 4096

BEGIN

NOTE: A BREAK instruction can go on any vector except the first vector or the last

vector. The last vector instruction is used to implement single and repetitive

run modes and is not available for other instructions. Attempting to place an

instruction on or beyond the last vector is an error.

EVENT Command

The EVENT command sets a pattern into one of the four external

event registers. These event registers can be specified in WAIT

instructions. If the pattern is NONE then a wait on this event will

always wait. If the pattern is an integer, its value is interpreted

according to the following table.

52

Page 53

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

Values can be ORed together, i.e. a value of #H22 would indicate

patterns of ( 101 + 001 ).

Command Syntax

EVENT [ A | B | C | D ] [ NONE | <integer> ]

A, B, C, D = four external wait event registers.

NONE - value that indicates "always wait".

<integer> = the event pattern from the table above.

Example

PGBINARY

MODE FULL

RMODE SINGLE

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

EVENT A #H01

WAIT A 100

WIDTH 6

DEPTH 4096

BEGIN

WAIT Command

The WAIT command places a hardware instruction on vector number

53

Page 54

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

<integer>. Vectors are numbered from 0 to DEPTH -1. There can only

be one WAIT INB instruction in a configuration.

Command Syntax

WAIT [ IMB | A | B | C | D ] <integer>

IMB = Inter-Module Bus.

A, B, C, D = external wait events.

<integer> = the vector where a hardware WAIT instruction is to be

placed.

Example

PGBINARY

MODE FULL

RMODE SINGLE

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

EVENT A #H01

WAIT A 100

WAIT IMB 200

WIDTH 6

DEPTH 4096

BEGIN

NOTE: A WAIT instruction can go on any vector except the first vector or the last

vector. The last vector instruction is used to implement single and repetitive

run modes and is not available for other instructions. Attempting to place an

instruction on or beyond the last vector is an error.

SIGNAL Command

The SIGNAL command places a hardware SIGNAL IMB instruction on

vector number <integer>. Vectors are numbered from 0 to DEPTH -1.

54

Page 55

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

There can only be one SIGNAL instruction in a configuration.

PGBINARY

MODE FULL

RMODE SINGLE

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

SIGNAL 100

WIDTH 6

DEPTH 4096

BEGIN

NOTE: A SIGNAL instruction can go on any vector except the first vector or the last

vector. The last vector instruction is used to implement single and repetitive

run modes and is not available for other instructions. Attempting to place an

instruction on or beyond the last vector is an error.

MAIN Command

The MAIN command gives the vector number where the MAIN part of

the vector set begins. The vectors prior to the MAIN vector comprise

the INIT part. This is defaulted to zero (no INIT part). Vectors are

numbered from 0 to DEPTH -1.

Command Syntax

MAIN <integer>

<integer> = the vector number where the MAIN part of the vector set

begins.

Example

PGBINARY

55

Page 56

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

MODE FULL

RMODE SINGLE

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

WIDTH 6

DEPTH 4096

BEGIN

BEGIN Command

The BEGIN command is the last command in the ASCII part of the file.

It is terminated with a newline or a comment like all other commands.

The binary data immediately follows the newline.

Command Syntax

BEGIN

<binary data>

Example

PGBINARY

MODE FULL

RMODE SINGLE

CLOCK INTERNAL 5e7 // 50 MHz

MAIN 0

LABEL Label0 POD 0 [7:0]

LABEL Label1 POD 1 [7:0]

LABEL Label2 POD 2 [7:0]

LABEL Label3 POD 3 [7:0]

LABEL Label4 POD 4 [7:0]

LABEL Label5 POD 5 [7:0]

WIDTH 6

DEPTH 4096

56

Page 57

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing Agilent 16720A PattGen Binary Files

BEGIN

Binary Data

The Binary Data begins with a simple eight byte header that gives the

DEPTH and WIDTH in binary. These values must match the DEPTH

and WIDTH given as ASCII commands earlier in the file. These values

must be written as 32 bit integers in big-endian order, i.e. the first byte

is the most significant byte. This is followed by the binary data itself.

• 4 bytes = number of vectors.

• 4 bytes = number of bytes per vector.

• (WIDTH * DEPTH) bytes = the binary data.

Each vector is comprised of one value for each LABEL that has been

defined or named in an ORDER command. The number of bytes for

each label is the lowest possible integer number of bytes given the bit

width of the label. For example, a 17 bit label will require 3 bytes

(24bits), a 16 bit label will require 2 bytes (16 bits).

The bytes are taken to be in big-endian order. If a label is comprised of

a smaller number of bits than are written for that label (i.e. a 17 bit

label that receives 24 bit data) the least significant bits are used and

the excess most significant bits are discarded. This number must

match the number of bytes required for the labels that have been

defined or named in an ORDER command.

The remaining length of the file after the newline following “BEGIN”

must be (8 + DEPTH + WIDTH).

If a LABEL is defined for pods that are not in the current hardware (i.e.

POD 7 for a 1 board system) the configuration is truncated to what fits

and a warning is emitted.

57

Page 58

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing System Data Files

Importing System Data Files

If you store logic analyzer data using the File Out tool, in either

Internal, ASCII, or Fast Binary format, you can import these files into

the pattern generator’s INIT or MAIN sequences.

The "Import System Data File" dialog will only load files saved using the

File Out tool. For ASCII files created in a PC or UNIX text editor, use

Import 16522A ASCII File (see page 28). For PattGen Binary files

created in a PC or UNIX program, use Import 16720A PattGen Binary

File (see page 39).

CAUTION: Importing a File Out tool file causes all current Format and Sequence

information to be overwritten. Be sure to save the pattern generator

configuration before you begin the import process.

NOTE: Importing a 1048576 line System Data file may take approximately two

minutes. If a 1048576 sequence is in memory when you begin an import, it

may take up to a minute to clear the current data and up to two minutes to

import the new data.

1. Select the Sequence tab.

2. Select File from the menu bar, then Import System Data File.

3. From the Import System Data File dialog, load the desired File Out tool

file. See the note below.

4. Select the desired data set (see page 59).

5. Select the desired labels (see page 59).

6. Select a data set range (see page 60) to import. If you select "Partial", the

range integers you specify will correspond to state numbers found in a

state listing of the same data set.

7. Select the location to insert the samples. Samples are inserted at the

beginning of the selected sequence. See the caution below.

8. Select Import.

58

Page 59

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing System Data Files

NOTE: If in step 3 you entered the file name into the text entry field using a keyboard,

you must press the Return key on your keyboard to start the file import

process instead of selecting the Import field.

Data Sets

A data set is defined as data captured from a single source. For

example, the data captured from analyzer one of a logic analyzer is a

single source. Because the File Out tool allows multiple analyzers

worth of data to be stored within the same file, you pick only one data

set to import into the pattern generator.

Data Set Labels

All labels in a single data set are listed along with each label’s

corresponding channel width. If a label is wider than the pattern

59

Page 60

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Importing System Data Files

generator’s maximum allowable channel width (32 channels), the label

is marked "unavailable". Labels wider than 32 channels cannot be

selected.

Data Set Range

When you select a data set, the "from" and "to" fields update to the

minimum and maximum values of the state listing. Both positive and

negative integers are valid.

CAUTION: If the range of data samples is too large for the pattern generator sequence

(1048576 vectors), a message will appear giving you the choice to continue or

not. If you continue, data will be imported starting from the beginning of the

file. At the point where you run out of vectors, data will be missing. To solve

this problem, reduce the range of samples you are importing.

60

Page 61

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Loading and Saving Pattern Generator Configurations

Loading and Saving Pattern Generator

Configurations

You can save pattern generator settings and data to a configuration file.

You can also save any tools connected to the pattern generator. Later,

you can restore your data and settings by loading the configuration file.

• Loading Configuration Files (see the Agilent Technologies 16700A/B-

Series Logic Analysis System help volume)

• Saving Configuration Files (see the Agilent Technologies 16700A/B-

Series Logic Analysis System help volume)

61

Page 62

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Selecting the Correct Probe Pod

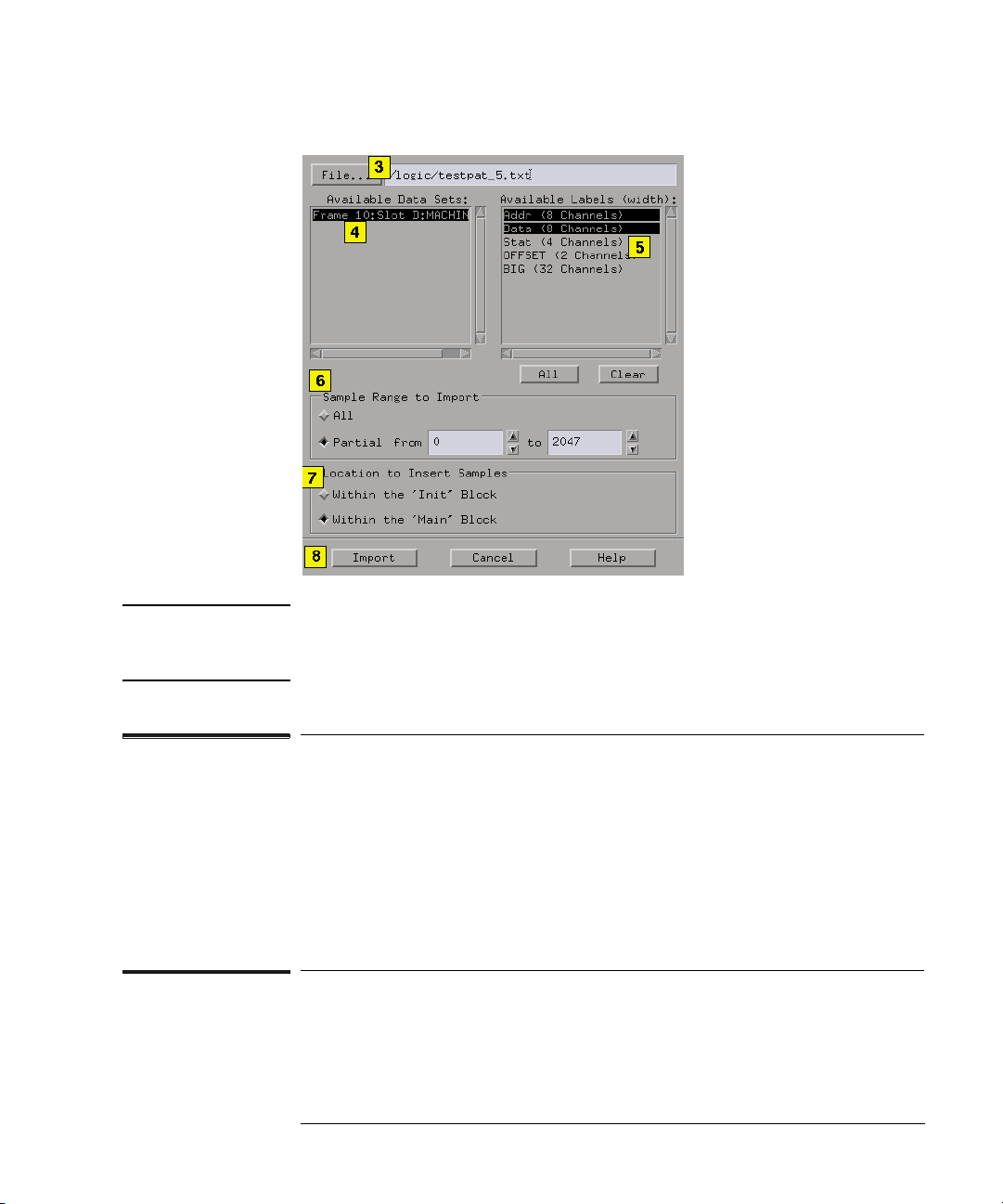

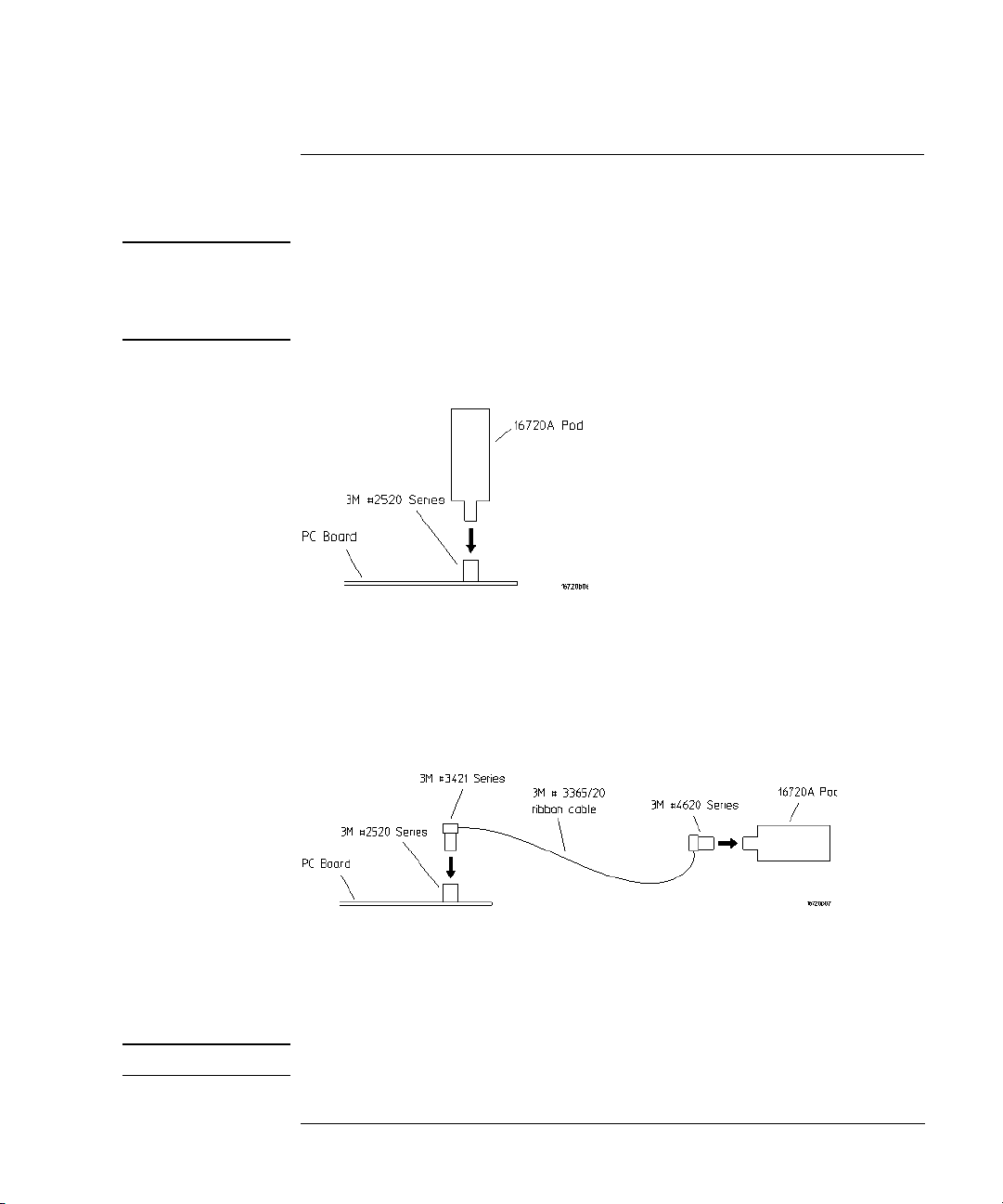

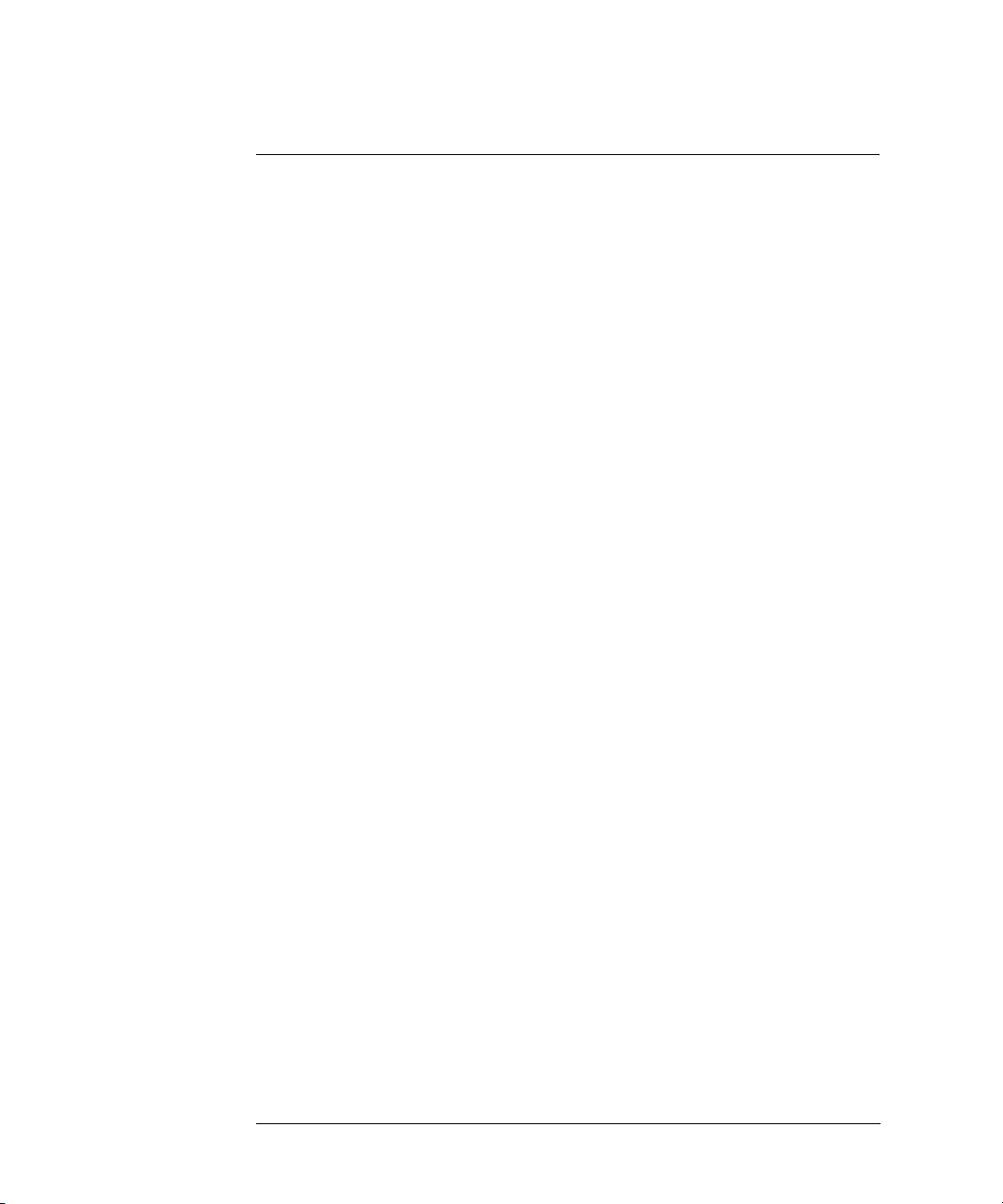

Selecting the Correct Probe Pod

The following equivalent circuit information is provided to help you

select the appropriate clock and data pods for your application.

“Data Pod Descriptions” on page 63

“Clock Pod Descriptions” on page 67

Data Cable Characteristics without a Data Pod

The data cables without a data pod provide an ECL-terminated (470

ohm; to -3.25V) differential signal. These signals are usable when

received by a differential receiver, preferably with a 100 ohm

termination across the lines. These signals should not be used singleended due to the slow fall time and shifted voltage threshold; they are

not ECL compatible.

62

Page 63

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Selecting the Correct Probe Pod

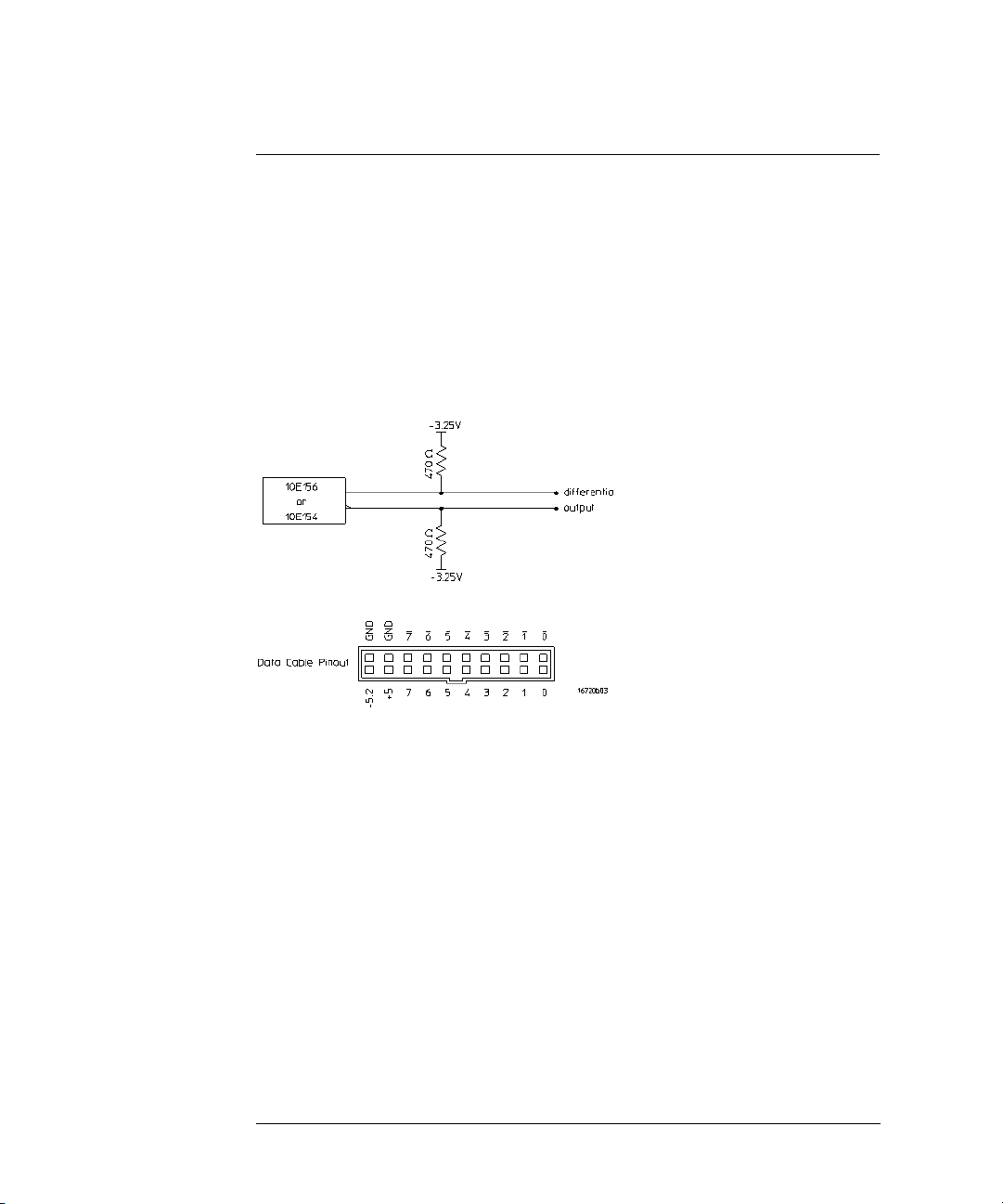

Clock Cable Characteristics without a Clock Pod

The clock out signals (CLKOUT and not-CLKOUT) without a clock pod

provide an ECL-terminated (215 ohm to -3.25V) differential signal.

These signals are usable when received by a differential receiver,

preferably with a 100 ohm termination across the lines. These signals

should not be used single-ended due to the slow fall time and shifted

voltage threshold; they are not ECL compatible.

See Also “Connecting the Probe Pods” on page 71

Data Pod Descriptions

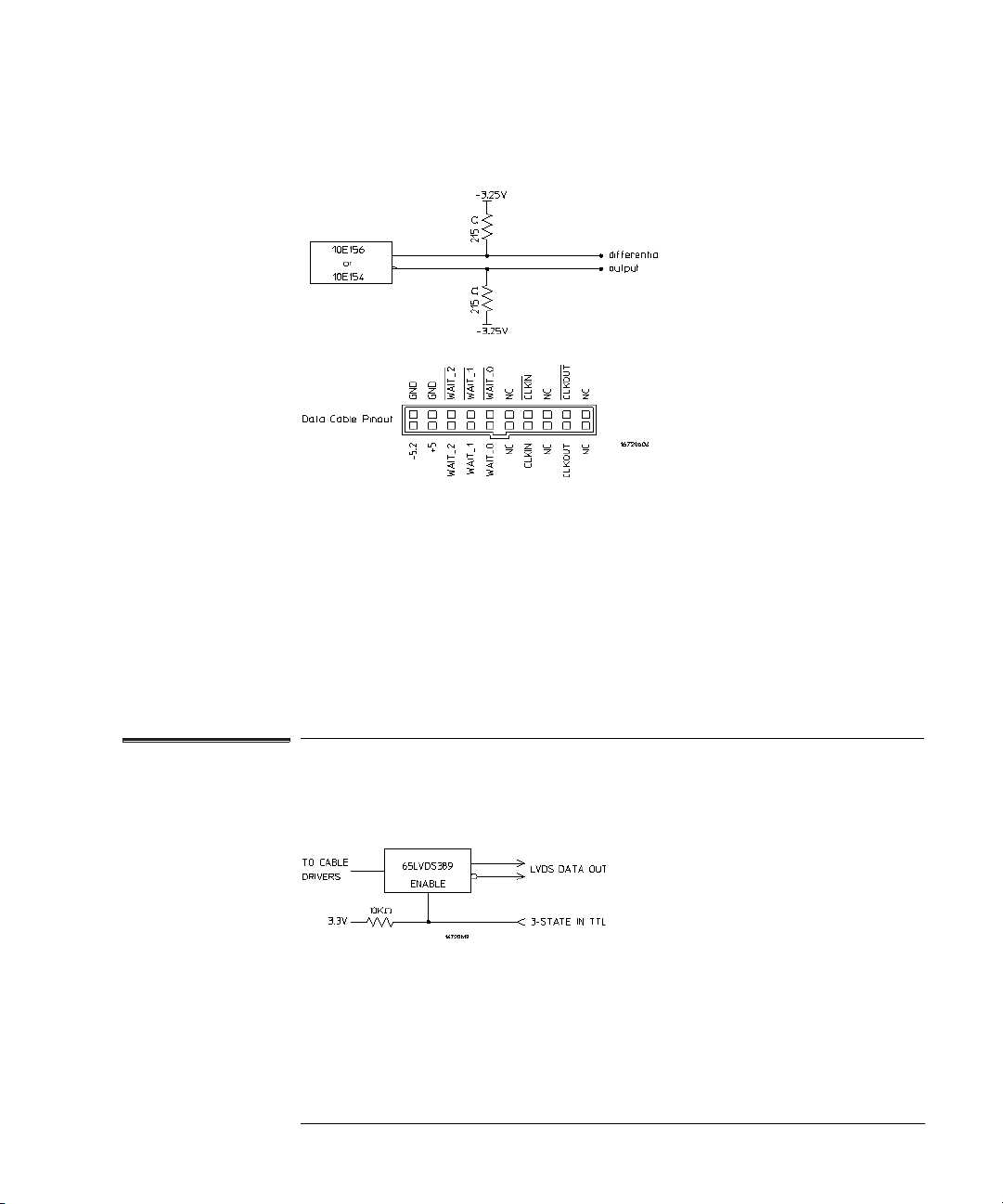

E8141A LVDS Data Pod

Output type 65LVDS389 (LVDS data lines)

10H125 (TTL non-3-state channel 7)

3-state enable positive true TTL; no connect=enabled

Maximum clock 300 MHz

Skew Typical less than 1 ns, worst case 2 ns

Recommended lead set E8142A

63

Page 64

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Selecting the Correct Probe Pod

10473A 3-State 2.5 V Data Pod

Output type 74AVC16244

3-state enable negative true, no connect=enabled

Maximum clock 300 MHz

Skew Typical less than 1 ns, worst case 2 ns

Recommended lead set 10498A

10476A 3-State 1.8 V Data Pod

Output type 74AVC16244

3-state enable negative true, no connect=enabled

Maximum clock 300 MHz

Skew Typical less than 1.5 ns, worst case 2.5 ns

Recommended lead set 10498A

10483 3-State 3.3V Data Pod

Output type 74AVC16244

3-state enable negative true, no connect=enabled

Maximum clock 300 MHz

Skew Typical less than 1 ns, worst case 2 ns

Recommended lead set 10498A

64

Page 65

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Selecting the Correct Probe Pod

10469A PECL Data Pod

Output type 100EL09 (5V) with 348 pulldown to ground and

42 ohm in series

Maximum clock 300 MHz

Skew Typical less than 500 ps, worst case 1 ns

Recommended lead set 10498A

10471A LVPECL Data Pod

Output type 100LVEL90 (3.3V) with 215 ohm pulldown to

ground and 42 ohm in series

Maximum clock 300 MHz

Skew Typical less than 500 ps, worst case 1 ns.

Recommended lead set 10498A

10461A TTL Data Pod

Output type 10H125 with 100 ohm in series

Maximum clock 200 MHz

Skew Typical less than 2 ns; worst case 4 ns (note 1)

Recommended lead set 10498A

10462A 3-State TTL/CMOS Data Pod

Output type 74ACT11244 with 100 ohm in series

10H125 on non 3-state channel 7 (note 2),

3-state enable negative true, 100K ohm to GND, enabled

on no connect.

Maximum clock 100 MHz

Skew Typical less than 4 ns; worst case 12 ns (note 1)

Recommended lead set 10498A

65

Page 66

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Selecting the Correct Probe Pod

10464A ECL Data Pod (terminated)

Output type 10H115 with 348 ohm pulldown, 42 ohm in series

Maximum clock 300 MHz

Skew Typical less than 1 ns; worst case 2 ns (note 1)

Recommended lead set 10498A

10465A ECL Data Pod (unterminated)

Output type 10H115 (no termination)

Maximum clock 300 MHz

Skew Typical less than 1 ns; worst case 2 ns (note 1)

Recommended lead set 10347A

10466A 3-State TTL/3.3 volt Data Pod

Output type 74LVT244 with 100 ohm in series

10H125 on non 3-state channel 7 (see note 2)

3-state enable negative true, 100K ohm to GND, enabled on no

connect.

Maximum clock 200 MHz

Skew Typical less than 3 ns; worst case 7 ns (note 1)

Recommended lead set 10498A

Note 1

Typical skew measurements made at the pod connector with approximately

10 pF/50K ohm load to GND; worst case skew numbers are a calculation of

worst case conditions through circuits. Both numbers apply to any channel

within a single or multiple module system.

Note 2

Channel 7 on the 3-state pods has been brought out in parallel as a

non 3-state signal. By looping this output back into the 3-state enable

line, the channel can be used as a 3-state enable.

See Also “Clock Pod Descriptions” on page 67

66

Page 67

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Selecting the Correct Probe Pod

“Connecting the Probe Pods” on page 71

Clock Pod Descriptions

E8140A LVDS Clock Pod

Clock output type 65LVDS179 (LVDS) and 10H125 (TTL)

Clock output rate 200 MHz maximum (LVDS and TTL)

Clock out delay approximately 8 ns total in 14 steps

Clock input type 65LVDS179 (LVDS with 100 ohm)

Clock input rate DC to 150 MHz (LVDS)

Pattern input rate 10H124 (TTL) (no connect=logic 1)

Clock in to clock out approximately 30 ns

Patt in to recognition approximately 15 ns + 1 clock period

Recommended lead set 10498A

10472A 2.5 V Clock Pod

Clock output type 74AVC16244

Clock output rate 200 MHz maximum

Clock out delay approximately 8 ns total in 14 steps

Clock input type 74AVC16244 (3.6 V maximum)

Clock input rate DC to 200 MHz

Pattern input rate 74AVC16244 (3.6 V maximum; no connect=logic 0)

Clock in to clock out approximately 30 ns

Patt in to recognition approximately 15 ns + 1 clock period

Recommended lead set 10498A

67

Page 68

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Selecting the Correct Probe Pod

10475A 1.8 V Clock Pod

Clock output type 74AVC16244

Clock output rate 200 MHz maximum

Clock out delay approximately 8 ns total in 14 steps

Clock input type 74AVC16244 (3.6 V maximum)

Clock input rate DC to 200 MHz

Pattern input rate 74AVC16244 (3.6 V maximum; no connect=logic 0)

Clock in to clock out approximately 30 ns

Patt in to recognition approximately 15 ns + 1 clock period

Recommended lead set 10498A

10477A 3.3 V Clock Pod

Clock output type 74AVC16244

Clock output rate 200 MHz maximum

Clock out delay approximately 8 ns total in 14 steps

Clock input type 74AVC16244 (3.6 V maximum)

Clock input rate DC to 200 MHz

Pattern input rate 74AVC16244 (3.6 V maximum; no connect=logic 0)

Clock in to clock out approximately 30 ns

Patt in to recognition approximately 15 ns + 1 clock period

Recommended lead set 10498A

68

Page 69

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Selecting the Correct Probe Pod

10468A PECL Clock Pod

Clock output type 100EL90 (5V0 with 348 ohm pulldown to ground

and 42 ohm in series

Clock output rate 300 MHz maximum

Clock input delay approximately 8 ns total in 14 steps

Clock input type 100EL91 PECL (5V), no termination (no connect

is logic 0)

Clock input rate DC to 300 MHz

Pattern input type 100EL91 PECL (5V), no termination (no connect

is logic 0)

Recommended lead set 10498A

10470A LVPECL Clock Pod

Clock output type 100LVEL90 (3.3V) with 215 ohm pulldown to

ground and 42 ohm in series

Clock output rate 300 MHz maximum

Clock out delay approximately 8 ns in 14 steps

Clock input type 100LVEL91 PECL (3.3V), no termination

Clock input rate DC to 300 MHz

Pattern input type 100LVEL91 PECL (3.3V), no termination

Clock in to clock out approximately 30 ns

Patt in to recognition approximately 15 ns + up to 1 clock period

Recommended lead set 10498A

69

Page 70

Chapter 1: Using the Agilent Technologies 16720A Pattern Generator

Selecting the Correct Probe Pod

10460A TTL Clock Pod

Clock output type 10H125 with 42 ohm series; true & inverted

Clock output rate 100 MHz maximum

Clock out delay 8 ns maximum in 14 steps

Clock input type TTL - 10H124

Clock input rate DC to 100 MHz

Pattern input type TTL - 10H124 (no connect is logic 1)

Clk-in to clk-out Approx. 30 ns

Patt-in to recognition Approx. 15 ns + up to 1 clk period

Recommended lead set 10498A

10463A ECL Clock Pod

Clock output type 10H116 differential unterminated; differential

with 348 ohm to -5.2v and 42 ohm series

Clock output rate 300 MHz maximum

Clock out delay 11 ns maximum in 9 steps

Clock input type ECL - 10H116 with 50K ohm to -5.2v

Clock input rate DC to 300 MHz

Pattern input type ECL - 10H116 with 50K ohm (no connect is logic 0)

Clk-in to clk-out Approx. 30 ns

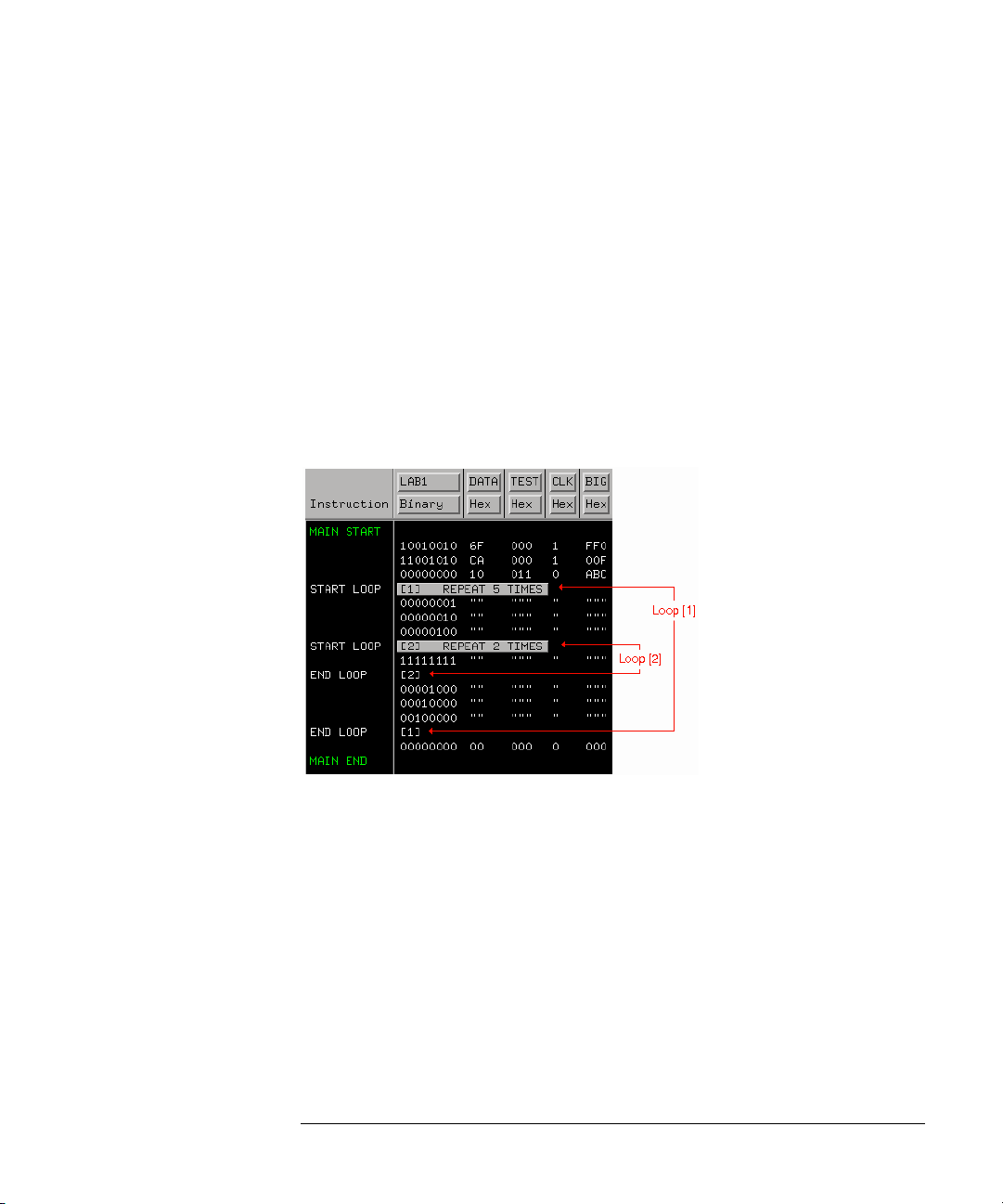

Patt-in to recognition Approx. 15 ns + up to 1 clk period