Installation Guide

16700B

Measurement

Modules

16allp01

Publication Number 16700-97014

© Copyright Agilent Technologies 2000

All Rights Reserved

16702B

Logic Analysis Systems

Contents

System Overview Agilent 16700B

System Overview Agilent 16702B

Mouse and Keyboard

Monitor Connection

Proper Cooling

Monitor Configuration 16700B

Monitor Configuration 16702B 10

Changing Monitors

LAN

Printers

External Disk Drive 15

External Disk Drive & CD-ROM Drive

Software Installation

16701A/B Expander Frame

Probing

Self-Test

Specifications & Characteristics

Disaster Recovery

Saving System Settings

4

5

6

7

8

9

11

12

13

19

21

24

25

31

32

33

35

16allp02

Reloading System Settings

Multiframe

Proper Cleaning

General Installations

16517/18A

16522A

16533/34A

16557D

16710/11/12A

16715-19A /50-52A

16720A

36

37

40

42

43

50

54

64

69

72

77

16700B Overview

16700B Mainframe

Power Cable

Making Basic

Measurements

(If ordered)

Monitor

Monitor Cable

Monitor Power Cable

Training Board and Training Kit

Additional Connections

External Disk Drive and Cable

(Data Drive - Option 008)

(Boot Drive - Option 009)

16allp04

Keyboard

and

Mouse

16701A/B

Expander Frame

Printer

and

Cable

4

16702B Overview

16702B

Mainframe

Power Cable

Additional Connections

Making Basic

Measurements

Training Board and

Training Kit

Mouse and

Keyboard

16allp05

Monitor

Monitor Cable and

Monitor Power Cable

(If ordered)

External Disk Drive and Cable

(Data Drive - Option 008)

(Boot Drive - Option 009)

Printer and

Cable

16701A/B Expander Frame

5

Mouse & Keyboard

for 16700B/ 16702B

The 16700B must have the system mouse and keyboard connected for the system to boot

up properly.

Once enabled on the LAN, the system can be operated remotely without a keyboard or

mouse.

16700B

or

16702B

16allp06

Target

Target

Control

Control

To16701 Expansion FrameTo 16701 Expansion Frame

Keyboard Mouse

Keyboard

Mouse

6

Monitor Connection

for 16700B /16702B

If applicable, international versions of the power cables can be found in the accessories

box.

16allp07

Monitor & Power Cable

(Optional for 16702B)

16700B

or

16702B

Target

Target

Control

Control

To16701 Expansion FrameTo 16701 Expansion Frame

Keyboard Mouse

7

Proper Cooling

for 16700B/ 16702B/ Measurement Modules

Allow a minimum of 5 cm spacing between instruments for proper cooling.

Power

Busy

>5cm

16700B

>5cm

16allp08

Power

Busy

>5cm

>5cm

16702B

8

Monitor Configuration

for 16700B

If you ordered the optional monitor with your logic analyzer, the monitor resolution setting is preconfigured for 1280 x 1024 at the factory.

If you already have a monitor and ordered your logic analysis system without the optional

monitor, you will need to configure your monitor. The display will change on the screen every

few seconds as the system cycles through the monitor resolution choices. Make the appropriate

selection when it appears.

(Your monitor)

16700B

System power

Monitor power

1

2

Monitor choice.

16allp09

(Cycling choices)

Clear

Images

Press ENTER to select the

monitor choice and "Y" to

confirm.

Enter

3

9

Monitor Configuration

for 16702B

Use this procedure if you wish to configure an optional monitor to an 16702B.

Ta bTa b

Ta b

Ta b

Ta b

Ta b

Ta b

Ta b

Ta b

Ta b

Ta b

Press ENTER to select the

4

3

monitor choice and "Y" to

confirm.

Enter

Monitor power

1

Immediately press the

TAB key about ten times.

Monitor choice.

System power

2

(Cycling choices)

Images

Clear

16allp10

10

Changing Monitors

for 16700B/ 16702B

(Different Monitor)

Monitor power

1

2

16700B

Ta b

Ta b

Ta b

Ta b

Ta b

Ta b

Ta b

Ta b

Ta b

Ta b

Press ENTER to select the

4

3

monitor choice and "Y" to

confirm.

Enter

System power

Immediately press the

TAB key about ten times.

(Cycling choices)

Monitor choice.

16702B

Clear

Images

16allp11

11

LAN

for 16700B/ 16702B

Help

10Base-T /100Base-TX

Target

Target

Control

Control

To16701Expansion FrameTo16701 Expansion Frame

KeyboardKeyboard Mouse

16700B or 16702B

16allp12

12

Printers

for 16700B/ 16702B

(Your printer)

Target

Target

Control

Control

To16701 Expansion FrameTo 16701 Expansion Frame

Keyboard Mouse

16700B or 16702B

16allp13

13

Printers

for 16700B/ 16702B

(Your printer)

16allp14

14

Refer to “ the

online help for networked printers.

Network Printer Setup” in

Printer Setup

Done

Done

External Disk Drive

for 16700A/ 16700B/ 16702A/ 16702B

as External Data Drive (Option 008)

Set the External Disk drive

address to 3 or 4.

Termination Plug

(68 pin)

Removable Drive

Power Cable

(68 pin)

External Disk Drive

Cable

(50 pin)

16allp34

Target

Target

Control

Control

To16701Expansion FrameTo16701 Expansion Frame

Keyboard Mouse

16700A/B or 16702A/B

15

External Disk Drive

for 16700A/ 16700B/ 16702A/ 16702B

as External Data Drive (Option 008)

To power up the system.......

Disk Drive

1

Power

2

Monitor Power

(If applicable)

16700A

LogicAnalysisSystem

System power

3

16700A/B or 16702A/B

Power

Busy

To power down the system.......

16700A

LogicAnalysisSystem

Power

Busy

System power

1

16700A/B or 16702A/B

16allp32

2

Monitor Power

(If applicable)

16

3

Disk Drive

Power

Data Drive

Done

Done

External Disk Drive

for 16700B/ 16702B

as Removable Boot Drive (Option 009)

Set the External Disk Drive

address to 6.

Termination Plug

(68 pin)

Removable Drive

Power Cable

(68 pin)

External Disk Drive

Cable

(50 pin)

16allp36

Target

Target

Control

Control

To16701Expansion FrameTo16701 Expansion Frame

Keyboard Mouse

16700B or 16702B

17

External Disk Drive

for 16700B/ 16702B

as Removable Boot Drive (Option 009)

To power up the system.......

Disk Drive

1

Power

2

Monitor Power

(If applicable)

16700A

LogicAnalysisSystem

System power

3

16700B or 16702B

Power

Busy

To power down the system.......

16700A

LogicAnalysisSystem

Power

Busy

System power

1

16700B or 16702B

16allp37

2

Monitor Power

(If applicable)

18

3

Disk Drive

Power

External Disk Drive & CD-ROM

for 16700B/ 16702B

A CD-ROM drive and an external hard drive(s) may

Termination Plug

(68 pin)

be connected to the SCSI-II port at the same time.

(68 pin)

(68 pin)

External Hard Drive

Cable

SCSI

(50 pin to 68 pin)

(50 pin)

(50 pin)

1

CAUTION

A CD-ROM drive address

setting of 6 or 7 could damage

your hard drive. Set the CDROM drive address to 2.

(50 pin)

External Disk Drive

CD-ROM Drive

(50 pin)

External Disk Drive

Cable

SCSI

16allp31

Target

Target

Control

Control

To16701Expansion FrameTo16701 Expansion Frame

Keyboard Mouse

16700B or 16702B

19

External Disk Drive & CD-ROM

for 16700B/ 16702B

When a system is shipped, the factory installs the current operating system

and ordered processor support packages and tools.

External Disk Drive

1

Power

2

CD-ROM Drive

Power

Monitor Power

(If applicable)

16allp33

3

System power

4

20

16700B

16702B

Done

Done

Software Installation

for 16700B/ 16702B/ Measurement Modules

When a system is shipped, the factory installs the current operating system

and ordered processor support packages and tools.

16allp17

21

Software Installation

for 16700B/ 16702B/ Measurement Modules

Select

Media

Type

Additional

Tools

System

Software

AUXILIARY-SW

HP1670X

PROC-SUPPORT

Processor

Support

16allp18

167XXB

Install

22

Software Installation

for 16700B/ 16702B/ Measurement Modules

AUXILIARY-SW

HP 1670X

PROC-SUPPORT

Select desired

package or

packages.

The system will

automatically reboot if it

is required by the newly

installed package.

16allp19

(Selected Package)

(Selected Package)

(Selected Package)

(Selected Package)

Install

23

Software Installation

Done

Done

16701A/B Expander Frame

for 16700B/ 16702B/ Measurement Modules

16700B or 16702B

Install your measurement modules

1

in the 16701A/B expander frame.

Target

Connect the desired length

2

interconnect cable and tighten the

connector screws with the screw

driver provided.

Connect the power cable to the

3

16701A/B.

Power up the 16700B

4

or 16702B system.

Target

Control

Control

To16701 Expansion FrameTo16701 Expansion Frame

Keyboard Mouse

16701A/B Interconnect Cable

Choose from the 30cm (12 inch) length,

or the 90 cm (36 inch) length.

16allp20

16701A/B

24

Probing

for 16700B/ 16702B/ Measurement Modules

General-Purpose Probing

Logic Analyzer

Pod

Ground Lead

(Short)

Ground Lead

(Long)

Probe Tip

Probe Tip

Assembly

Assembly

01650-61608

01650-61608

Probe

Housing

Probe Tip

Probe Lead

General-purpose probing requires connecting probe leads to individual signal lines. It is

generally the most cumbersome method, but it is also the most flexible. Because of the

passive design of the probe, there are no active circuits at the outer end of the cable.

Tip RC Network

90.9k

250

ohm

Signal Signal

Ground Ground

ohm

8.2pF

To Logic

Analyzer

Pod

The advantages of this are:

High input impedance. (See Equivalent Load.)

Signal ground at the probe tip for high-speed timing signals.

Inexpensive, removable probe tip assemblies.

16allp22

25

Equivalent Load

370

ohm

7.4pF1.5pF

Includes logic analyzer

100k

ohm

Probing

for 16700B/ 16702B/ Measurement Modules

General-Purpose Probing

The signal and ground leads can be connected directly to the target system. This requires

installing 0.63 mm (0.025 inch) square pins, or round pins with a diameter between 0.66 and

0.84 mm (0.026 and 0.033 inch) directly on the board. You can also use an IC test clip with pins

with those dimensions.

You can also connect the leads using through-hole grabbers, which have small enough hooks

to fit around adjacent IC pins, or by using surface-mount grabbers designed for fine surfacemount component leads.

Proper grounding will improve the signal quality and is essential for high speed measurements.

Each pod has a pod ground lead, which must be used. You can use only this ground, but signal

quality for high speed signals will be poor.

For better results, ground not only the pod, but every third or fourth lead.

For best results, and when probing signals with rise and fall times of 1 ns or less, ground each

probe lead with no more than a 2-inch ground lead as well as grounding the pod with the pod

ground lead.

16allp23

You can replace damaged leads. Disconnect individual probe leads by pushing on the

latch at the lead base with a ball-point pen.

Connect grabbers to the leads by slipping the end of the lead over the recessed pin

located in the side of the grabber.

The minimum input overdrive is the greater of 250 mV or 30% of signal amplitude. The

maximum probe input voltage of each logic analyzer probe is 40 volts peak.

26

Probing

for 16700B/ 16702B/ Measurement Modules

Termination Adapter

The logic analyzer cable must have the proper

RC network at its input in order to acquire data

correctly. The optional Termination Adapter

incorporates the RC network into a convenient

package. It also reduces the number of pins

required for the header on the target board

from 40 pins to 20.

Logic Analyzer

Pod

16allp24

+5V 1

3CLK1

5D14

7D12

9D10

11D8

13D6

15D4

17D2

19D0

Target Connector Pinout

(Top View)

N/C2

4 D15

6 D13

8D11

10 D9

12 D7

14 D5

16 D3

18 D1

20 GND

Termination

Adapter

Connector

Tip RC Network

250

90.9k

ohm

Signal Signal

Ground Ground

ohm

8.2pF

To Logic

Analyzer

Pod

27

Target

Equivalent Load

370

ohm

Includes logic analyzer

7.4pF4.6pF

100k

ohm

Probing

for 16700B/ 16702B/ Measurement Modules

Connecting Probes to a Target System Directly

You can connect the logic analyzer cable directly to a 40-pin connector, but you must install the

proper RC network directly onto the target system board. Agilent Technologies recommends

three types of which are described in detail in the Application Note:RC networks Probing

Solutions for Agilent Logic Analysis Systems.

Logic Analyzer

Pod

Suggested On Board RC Network

250

90.9k

ohm

Signal Signal

Ground Ground

ohm

8.2pF

To Logic

Analyzer

Pod

+5V

CLK1

N/C

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

+5V

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

2 Power GND

4 Signal GND

6 Signal GND

8 Signal GND

10 Signal GND

12 Signal GND

14 Signal GND

16 Signal GND

18 Signal GND

20 Signal GND

22 Signal GND

24 Signal GND

26 Signal GND

28 Signal GND

30 Signal GND

32 Signal GND

34 Signal GND

36 Signal GND

38 Signal GND

40 Power GND

Target Connector Pinout

(Top View)

Equivalent Load

370

ohm

7.4pF0.3pF

100k

ohm

Includes on board RC network and logic analyzer

CAUTION

Do not exceed 0.33 amps per cable, or the cable will be damaged. The cable ground lines

are chasis (earth) grounds and not "floating" grounds. All the lines are woven into a flat

ribbon that is 4.5 feet long.

For more information, contact your Agilent Technologies Sales office and ask for the

Application Note:

download from the web at: http://www.agilent.com/find/go/LA-AppNotes/ )

16allp25

Probing Solutions for Agilent Logic Analysis Systems. (Or

28

Probing

for 16700B/ 16702B/ Measurement Modules

High Density Adapter

E5346A (With Tip RC Network)

The E5346A high-density adapter provides a convenient and easy way to connect an Agilent

logic analyzer to the signals on your target system for packages that are difficult to probe, such

as BGAs. An Amp "Mictor 38" connector must be installed on your target system board.

Logic Analyzer

Pod

High-density

Adapter Cable

AMP "Mictor 38" Connector Pinout

+5VDC

GND DC

CLK

D15

D14

D13

D12

D11

D10

D9

D8

D7

Even Pod

D6

D5

D4

D3

D2

D1

D0

(Top View)

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

SCL

2

SDA

4

CLK

6

D15

8

D14

10

D13

12

D12

14

D11

16

D10

18

D9

20

D8

22

D7

24

26

28

30

32

34

36

38

D6

D5

D4

D3

D2

D1

D0

Odd Pod

Shroud

Tip RC Network

250

90.9k

ohm

Signal Signal

Ground Ground

16allp29

ohm

10pF

To Logic

Analyzer

Pod

29

Amp "Mictor 38"

Connector

Equivalent Load

370

ohm

9pF3pF

Includes logic analyzer

100k

ohm

Probing

for 16700B/ 16702B/ Measurement Modules

High Density Adapter

E5351A (No Tip Network)

The E5351A high-density adapter provides a convenient and easy way to connect an Agilent

logic analyzer to the signals on your target system for packages that are difficult to probe, such

as BGAs. The proper RC networks and an AMP "Mictor 38" connector must be installed on

your target system board. See Application Note: Probing Solutions for Agilent Logic

Analysis Systems.

Logic Analyzer

Pod

AMP "Mictor 38" Connector Pinout

+5VDC

GND DC

CLK

D15

D14

D13

D12

D11

D10

D9

D8

D7

Even Pod

D6

D5

D4

D3

D2

D1

D0

(Top View)

High-density

Adapter Cable

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

SCL

2

SDA

4

CLK

6

D15

8

D14

10

D13

12

D12

14

D11

16

D10

18

D9

20

D8

22

D7

24

26

28

30

32

34

36

38

D6

D5

D4

D3

D2

D1

D0

Odd Pod

Signal

Equivalent Load

370

ohm

9pF0.3pF

Shroud

100k

ohm

Ground

16allp30

Includes on board RC network and logic analyzer

Suggested On Board RC Network

250

90.9k

ohm

Signal

Ground

ohm

10pF

To

High Density

Adapter Cable

Amp "Mictor 38"

Connector

HP E5351A High Density

Adapter Cable

To Logic

Analyzer

Pod

Must be terminated on-board.

30

Self-Test

for 16700B/ 16702B/ all Measurement Modules

16allp26

(Measurement Modules)

Choose a module and select

the desired test.

31

Specifications & Characteristics

for 16700B/ 16702B/ all Measurement Modules

Select on the

Main Menu

Select an

instrument

16allp28

32

Disaster Recovery

Reinstalling the Operating System.

CAUTION

A batch process is used to autoload the software and then reboot the instrument. The batch process waits

for only a short timeout period for user interaction to abort the process. Otherwise, the hard drive will be

initialized, the operating system will be uploaded, and the instrument will reboot.

The reinstallation process takes approximately one hour depending on the speed of the attached CD-ROM.

If required, follow the steps in "Saving System Settings” and “Reloading System

1

Settings" to create a backup file of your system settings and license passwords.

If required, follow the steps in this book to setup the instrument and CD-ROM drive.

2

Insert the CD-ROM containing the instrument operating software into the CD-ROM

drive. Allow a couple of moments for the media to settle after inserting the media.

If the LAN cable is connected, disconnect it from the instrument. If needed, turn on the

3

system and initiate the monitor selection mode. ( Otherwise,

proceed to step 4.

Read this section carefully before you attempt to reinstall the operating system

from the CD-ROM using this procedure.

overwritten, including user configuration, data files, and license passwords.

To save your system's license information, as well as other system settings,

refer to “Saving System Settings” and “Reloading System Settings" in this

section.

You will need to connect a keyboard to your 16702B in order to execute disaster

recovery procedures.

Everything on the hard drive will be

See the section in this book.)

Turn on the instrument and repeatedly press the [ESC] key on the keyboard to terminate

4

the boot process. When the boot process is terminated, a prompt will be displayed.

Main Menu: Enter command >

Press:

Type:

The instrument will search for all viable boot devices on the bus, including the CD-ROM

drive. The display will then show the boot devices:

Path Number Device Path Device Type

------------ ------------ -----------------P0 SESCSI.6.0 IBM DNES-309170W

P1 SESCSI.1.0 PLEXTOR CD-ROM PX-40TS

disasbk

<Enter>

SEA <Enter>

33

Disaster Recovery

Reinstalling the Operating System.

At the prompt:

5

Main Menu: Enter command >

Type:

BO P1 <Enter>

Interact with IPL (Y, N, Q) ?>

Type:

After about 30 seconds you will see the message:

6

WARNING: The configuration information calls for a non-interactive

installation.

Press <Return> within 10 seconds to cancel batch mode

installation:

To abort the reinstallation process at this point:

7

Press the [Return] key on the keyboard within 10 seconds. (If you do nothing within the 10

second timeout, the reinstallation process will begin. The instrument will completely reload

the operating system software onto the hard disk drive.)

Processor Support Packages, Auxiliary Software, and user files must be installed manually

8

once the operating system has been reinstalled.

Follow the steps in “Reloading System Settings” to restore any license passwords and

9

system settings saved in step 1.

N <Enter>

disasbk

34

Done

Done

Saving System Settings

By saving your system settings to a flexible disk or a mounted directory, you create a backup file that can

be used to quickly setup systems, or restore current system settings after the Disaster Recovery procedure.

1

2

4

disas

3

5

6

My.Backup

Disk

7

35

Reloading System Settings

2

3

1

disasbk

4

My.Backup

Disk

5

If an item is not valid, or was not initially saved to the file, the selection will be greyed out in the

interface. Also, if no file extension is added, a “set” extension is automatically added for you.

36

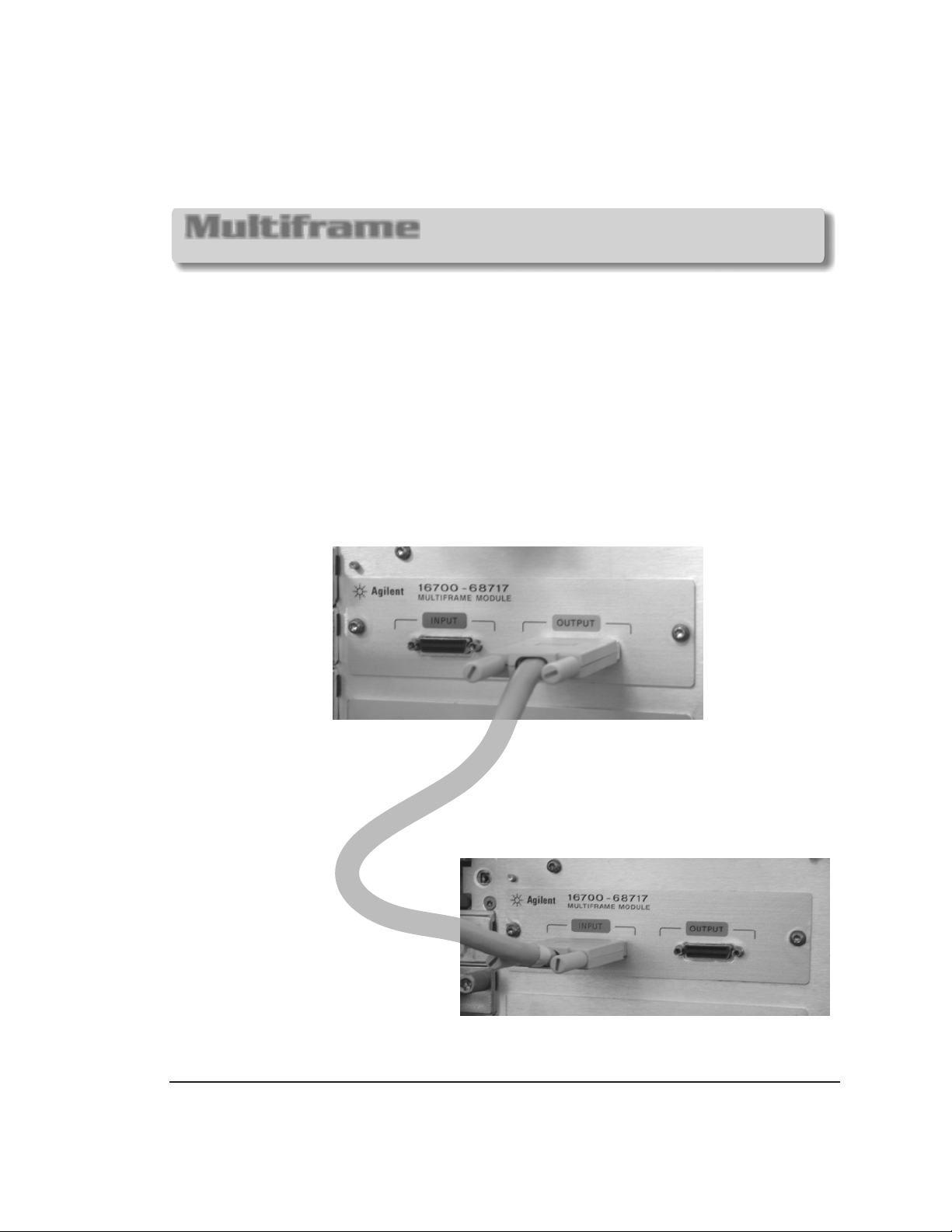

Multiframe

for 16700B/ 16702B

As many as eight 16700B’s and/or 16702B’s with

modules installed

The frame at the beginning of the series must have its port open and the

last frame in the series must have its port open.

Multiframe requires software Rev. A.02.00.00 or higher.

16702B logic analysis systems ordered with the multi

have the current operating system software installed.

may be connected together.

OUTPUT

Agilent 16700-68717 multiframe

INPUT

Agilent 16700B and

frame option installed will

16allp35

37

Multiframe

for 16700B/ 16702B

Install the Multiframe Modules into 16700B or 16702B frames.

CAUTION

Be sure to unplug the power cable before beginning this procedure.

1

16allp39

2

38

Multiframe

for 16700B/ 16702B

3

Multiframe Module

16allp40

4

39

Proper Cleaning

for 16700B/ 16702B/ all Measurement Modules

Instrument Cabinet and Module Front Panels

CAUTION

With the instrument unplugged, use mild soap and water to clean the cabinet of the

instrument or the front of the modules. Harsh soap might damage the water-based

paint. Do not immerse the instrument or modules in water.

16allp27

40

Measurement Modules

16517/18A

16522A

16533/34A

16557D

16710/11/12A

16715/16/17/18/19A

16720A

16750/51/52A

16533/34A

16557D 16522A

16710/11/12A

16720A

16715/

16/17/18/19A

for 16700A/B

16517/18A

16allp21

16702A/B

16701A/B

Measurement Modules

General Installation

Power

Busy

Power down

1

the system.

3

Remove

4

(Other or

or filler panels.

modules

filler panels.)

CAUTION

modules

5

Be sure the frame is unplugged before

removing or installing modules.

Disconnect the

2

power cable.

Insert

modules

or filler panels.

(Other or

modules

filler panels.)

CAUTION

Use a grounded wrist strap and mat when handling the . Gently apply pressure to

the center of the module or filler panel while tightening the thumb screws. Use filler panels in

empty slots for proper cooling.

Carefully slide the into the frame and hand tighten the thumb screws. If you are

inserting more than one , the tightening order is bottom to top .module module module

A single-module configuration can be installed in any available slot.

Some require calibration if they are moved to a different slot. For calibration

modules

information, refer to the online help for the individual .

modgen

module

modules

modules

42

16517A/18A

2-Card Module

Expander

2 Connector

OR

Cable

Master

Expander

Master

EXPANDER

MASTER

(16518A)

(16517A)

MASTER

EXPANDER

16517p08

2 Connector

Cable

(16517A)

(16518A)

43

16517A/18A

3-Card Module

Master

Expander

Expander

3 Connector

Cable

MASTER

EXPANDER

EXPANDER

16517p07

(16517A)

(16518A)

(16518A)

44

16517A/18A

3-Card Module

2 Connector

Cable

Expander

Master

Expander

2 Connector

EXPANDER

MASTER

EXPANDER

Cable

16517p06

(16518A)

(16517A)

(16518A)

45

16517A/18A

3-Card Module

Expander

Expander

Master

3 Connector

Cable

EXPANDER

EXPANDER

MASTER

16517p05

(16518A)

(16518A)

(16517A)

46

16517A/18A

4-Card Module

2 Connector

Cable

Expander

Master

Expander

Expander

3 Connector

EXPANDER

MASTER

EXPANDER

EXPANDER

Cable

16517p04

(16518A)

(16517A)

(16518A)

(16518A)

47

16517A/18A

4-Card Module

Expander

Expander

Master

Expander

3 Connector

Cable

2 Connector

EXPANDER

EXPANDER

MASTER

EXPANDER

Cable

16517p03

(16518A)

(16518A)

(16517A)

(16518A)

48

16517A/18A

5-Card Module

Expander

Expander

Master

Expander

Expander

3 Connector Cables

(Need 2)

EXPANDER

EXPANDER

MASTER

EXPANDER

EXPANDER

16517p02

(16518A)

(16518A)

(16517A)

(16518A)

(16518A)

49

16517/18

Done

Done

16522A

Single-Card Module

Each 16522A shipped stand alone has

the connected in the

2x10 cable

single-card module configuration.

2x10 cable

2x10 cable connection

for a single-card

16522p02

Master

J12 J11 J10 J9

CAUTION

J7 J8

A single-card module configuration can be

installed in any available slot.

Be sure the frame is unplugged before

removing or installing modules.

The following pages will show you how to

connect the to configure two,

three, four, and five-card modules.

2x10 cables

50

16522A

2-Card Module

EXPANDER

MASTER

2x10 Cable

Expander

Master

3-Card Module

Expander

J12 J11 J10 J9

J12 J11 J10 J9

EXPANDER

MASTER

EXPANDER

J12 J11 J10 J9

J7 J8

J7 J8

2x10 Cable

J7 J8

16522p03

Master

Expander

J12 J11 J10 J9

J12 J11 J10 J9

51

J7 J8

J7 J8

16522A

4-Card Module

Carefully slide the four cards half way into the mainframe slots.

Cable the bottom Expander to the Master Card first.

Cable the upper two Expanders to the Master Card.

Gently slide the cabled assembly fully into the frame and

tighten.

2x10 Cable

EXPANDER

EXPANDER

MASTER

EXPANDER

16522p04

Expander

Expander

Master

Expander

J12 J11 J10 J9

J12 J11 J10 J9

J12 J11 J10 J9

J12 J11 J10 J9

52

J7 J8

J7 J8

J7 J8

J7 J8

16522A

5-Card Module

Carefully slide the five cards half way into the mainframe slots.

Cable the bottom two Expanders to the Master first.

Cable the upper two Expanders to the Master.

Gently slide the cabled assembly fully into the frame and

tighten.

2x10 Cable

EXPANDER

EXPANDER

MASTER

EXPANDER

EXPANDER

Expander

Expander

Master

Expander

Expander

J12 J11 J10 J9

J12 J11 J10 J9

J12 J11 J10 J9

J12 J11 J10 J9

J12 J11 J10 J9

J7 J8

J7 J8

J7 J8

J7 J8

J7 J8

16522A

16522p05

53

Done

Done

16533/34A Calibration

Single-Card Module

Power down the mainframe.

1

Remove the module from the

2

mainframe and set the

PROTECTED / UNPROTECTED

switch to UNPROTECTED.

16702A/B

16600A Series

16700A/B

UNPROTECTED

PROTECTED

If you calibrate this module without unprotecting the memory, the new calibration settings will

not be saved when the system is shut down. The system will default to the previous settings.

The new calibration settings would be effective for the current active session only.

16533p01

54

16533/34A Calibration

Single-Card Module

Target

Out - Port - In

Out - Port - In

Target

Keyboard Mouse

Keyboard Mouse

Control

Control

RS232 Monitor Parallel Printer

RS232 Monitor Parallel Printer

SCSI-2Single Ended

LAN

LAN

10Base-T

10Base-T

SCSI-2Single Ended

LAN

LAN

10Base2

10Base2

Target

Target

Target

3

Target

Control

Control

Control

Control

To16701Expansion FrameTo16701 Expansion Frame

To16701Expansion FrameTo16701 Expansion Frame

Reinstall the 16533A/34A module

into the mainframe and reconnect

the power cable.

KeyboardKeyboard MouseMouse

KeyboardKeyboard MouseMouse

16533p02

Monitor power ON.

(If applicable)

4

5

55

16600A Series

System

power

ON

16700A/B

16702A/B

15

16533/34A Calibration

Single-Card Module

0

15

30

7

Connect the BNC Tee and the

(equal length) BNC cables to the

module.

For more accurate calibration, allow the system

6

30 minutes to warm up.

16533p03

56

16533/34A Calibration

Single-Card Module

Select -

16534A

>

16533p04

RUN

57

16533/34A Calibration

Single-Card Module

16533p05

58

16533/34A Calibration

Single-Card Module

Connect the BNC Tee, adapter, and

the (equal length) BNC cables to the

module.

16533p06

59

16533/34A Calibration

Single-Card Module

RUN

16533p07

Remember to set the PROTECTED/UNPROTECTED switch back to

PROTECTED.

If you just calibrated this card as one of a multi-card set, you must leave

the PROTECTED/UNPROTECTED switch in the UNPROTECTED position

until you have completed the multi-card calibration procedure on the

following pages.

Single Module

Calibration

Done

Done

60

16533/34A Calibration

Multi-Card Module

Each of the individual boards of a multi-card module must first be calibrated as a single.

(See previous pages: .)

The following example is of a two board arrangement. Up to four cards may be

configured in a 16700A, 16700B, 16702A, or 16702B mainframe.

Master

1

Connect the module cables.

Exit the current session and restart.

2

16533/34A Single-Card Module

1

2

3

16533p08

61

16533/34A Calibration

Multi-Card Module

3

Select -

16534A

>

4

Connect the (equal length) BNC calibration between channel 1, AC/DC cal,

5

and channel 1 of the second card. (Channel 1 of the third card next time etc.

up to four cards.)

Chan. 1

Chan. 1

Chan. 1Chan. 1

Chan. 1Chan.

Chan. 2

Chan. 2

Chan. 2Chan.

2

1

Chan. 2Chan.

2

16533p09

62

16533/34A Calibration

Multi-Card Module

7

6

RUN

Repeat steps 3 through 7 for

each additional card in your

multi-card module.

Select the appropriate

combination for each

additional card.

16533p10

63

Remember to set the

PROTECTED/UNPROTECTED

switch back to

PROTECTED.

Multi-Module

Calibration

Done

Done

16557D

Single-Card Module

When ordered as a single card, the 16557D is

shipped with the factory configured

as a single card module.

2x10 cable

2x10 Cable

2x10 Cable

Master

16557p03

J6J8 J5J7 J4

64

J3J9J10

16557D

2-Card Module

EXPANDER

MASTER

Find the required two connector

and connect the cables as shown.

2x25 Cables

(Need 2)

Expander

Master

Expander

2x25 cables

J8

Connect the on the

Expander to the Master.

2x10 cables

2x10 Cables

J6

J7

J5

J4

J3J9J10

Master

16557p04

J8

J7

65

J6

J5

J4

J3J9J10

16557D

3-Card Module

Find the required three connector

and connect the cables as shown.

2x25 cables

EXPANDER

MASTER

EXPANDER

Expander

Master

2x25 Cables

Expander

Master

Expander

J10

(Need 2)

J9

J8

J8

Connect the on the

Expanders to the Master.

2x10 cables

2x10 Cables

J6

J6

J5

J5

J4

J4

J7

J7

J3

J3J9J10

Expander

16557p05

J10

J9

J8

J7

66

J6

J5

J4

J3

16557D

4-Card Module

Find the required four connector

and connect the cables as shown.

2x25 Cables

(Need 2)

Expander

Expander

Master

Expander

Expander

J10

2x25 cables

J8

J9

EXPANDER

EXPANDER

MASTER

EXPANDER

Connect the on the

Expanders to the Master.

2x10 cables

2x10 Cables

J6

J7

J5

J4

J3

Expander

Master

Expander

16557p06

J10

J10

J9

J9

J8

J8

J8

J7

J7

J7

67

J6

J6

J6

J5

J5

J5

J4

J4

J4

J3

J3J9J10

J3

16557D

5-Card Module

Find the required five connector

and connect the cables as shown.

2x25 Cables

(Need 2)

Expander

Expander

Master

Expander

Expander

Expander

Expander

J10

J10

2x25 cables

J8

J9

J8

J9

Connect the on the

Expanders to the Master.

2x10 cables

2x10 Cables

J6

J6

J5

J5

J4

J4

J7

J7

EXPANDER

EXPANDER

MASTER

EXPANDER

EXPANDER

J3

J3

Master

Expander

Expander

16557p07

J10

J10

J9

J9

J8

J8

J8

J7

J7

J7

68

J6

J6

J6

J5

J5

J5

J4

J4

J4

J3J9J10

J3

J3

16710/ 11/ 12A

Single-Card Module

The 16700A, 16700B, 16702A and 16702B require Rev.

A.01.20.00 or higher. See the Software Installation chapter in

the book. Select 1660X-70XA.

A single 16710A, 16711A, and 16712A will have the cable

connected in the single-card configuration.

Master

2x40

J7

2x40 Cable

J9

J8

16710P01

69

16710/ 11/ 12A

Multi-Card Module

J5

Master

J6

2x40

Cable

J7

J9

J8

16710P03

2x25

Cable

J6

J5

Expander

2x25

Cable

70

J7

J9

J8

2x40

Cable

16710/ 11/ 12A

Multi-Card Module

J5

J5

Other modules or

filler panels.

J6 J7 J9

J6 J7 J9

J8

J8

16710P04

71

Multi-Card

Module

Done

Done

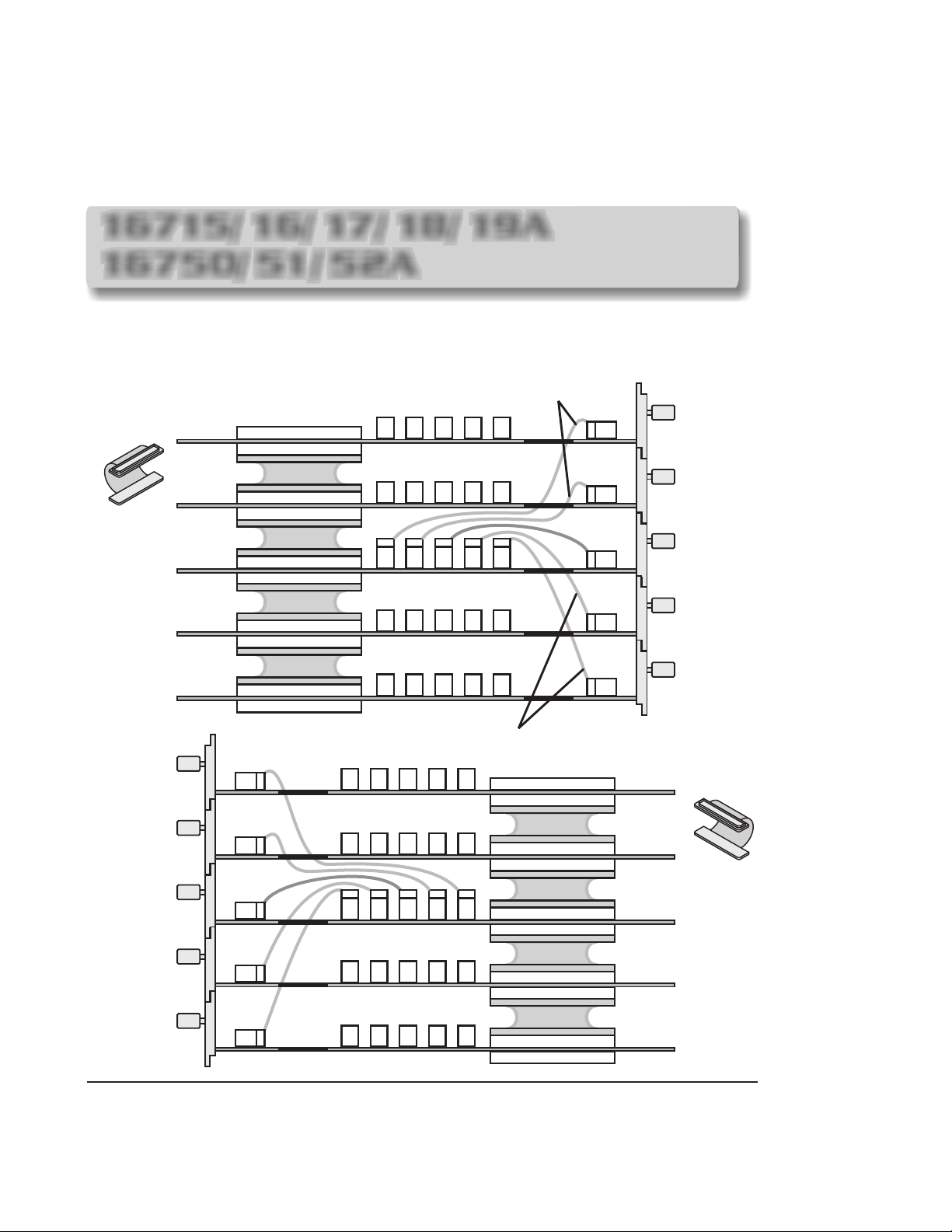

16715/ 16/ 17/ 18/ 19A 16750/ 51/ 52A

Single-Card Module

A single 16715/ 16/ 17/ 18/ 19A or 16750/ 51/ 52A will have the cable

connected in the single-card configuration.

Master

The require software Rev. A.01.40.00 or higher

16715/ 16/ 17A's .

J6J8 J5J7 J4

2x40

2x10 Cable

J3

16717p06

The 16718/ 19A's

The 16750/ 51/ 52A

See the Software Installation chapter in this book.

require software Rev. A.01.50.00 or higher.

require software Rev. A.02.00.00 or higher.

72

16715/ 16/ 17/ 18/ 19A

16750/ 51/ 52A

2-Card Module

Connect the of the Expander

to the Master.

Expander

Master

2x10 cable

2x40

Cable

Open the accessory pouch and

find two of the required

cables the

on the modules as shown.

. Connect

2x40

2x40 cables

J8

J8

EXPANDER

J7

J7

J6

J6

2x10 Cable

J5

J4

J5

J4

J3

J3

16717p05

2x40

Cable

2x40

Cable

MASTER

73

16715/ 16/ 17/ 18/ 19A

16750/ 51/ 52A

3-Card Module

Connect the of the Expanders to the Master. Find the in the

2x10 cables 2x40 cables

accessory pouch and connect them between the modules.

2x10 Cable

J6

J6

J6

J7

J5

J4

J5

J4

J5

J4

2x10 Cable

J8

J3

J3

J3

Expander

J7

J7

J7

J6

2x40

Cable

Expander

Master

Expander

2x40 Cable

2x40 Cable

J3

J8

J8

J8

J5

J4

16717p14

2x40 Cable

J3

J3

J4

J6

J5

J4

J6

J5

J8

J7

2x40 Cable

J8

J7

Master

2x40

Cable

Expander

74

16715/ 16/ 17/ 18/ 19A

16750/ 51/ 52A

4-Card Module

Connect the of the Expanders to the Master. Find the in the

2x10 cables 2x40 cables

accessory pouch and connect them between the modules.

2x10 Cables

J6

J7

J7

J7

J7

J5

J4

J6

J5

J4

J6

J5

J4

J6

J5

J4

J3

J3

J3

J3

2x10 Cable

J6

J8

J7

Expander

2x40

Cable

Expander

Expander

Master

Expander

2x40 Cable

2x40 Cable

2x40 Cable

J3

J8

J8

J8

J8

J5

J4

16717p13

2x40 Cable

J3

J4

J6

J5

J8

J7

Expander

2x40

2x40 Cable

J3

J4

J6

J5

J8

J7

Master

Cable

2x40 Cable

J3

J4

J6

J5

J8

J7

Expander

75

16715/ 16/ 17/ 18/ 19A

16750/ 51/ 52A

5-Card Module

Connect the of the Expanders to the Master. Find the in the

2x10 cables 2x40 cables

accessory pouch and connect them between the modules.

2x10 Cables

J7

J7

J7

J7

J7

J6

J6

J5

J6

J5

J6

J5

J6

J5

J6

J5

2x10 Cables

J8

J7

J4

J4

J4

J4

J4

J3

J3

J3

J3

J3

Expander

2x40

Cable

Expander

Expander

Master

Expander

Expander

2x40 Cable

2x40 Cable

2x40 Cable

2x40 Cable

J3

J8

J8

J8

J8

J8

J5

J4

16717p12

2x40 Cable

J3

J4

J6

J5

J8

J7

Expander

2x40

2x40 Cable

J3

J4

J6

J5

J8

J7

Master

Cable

2x40 Cable

J3

J4

J6

J5

J8

J7

Expander

2x40 Cable

J3

J4

J6

J5

J8

J7

Expander

76

16720A

Single-Card Module

Each 16720A shipped stand alone has

the connected in the

2x10 cable

single-card module configuration.

2x10 cable

2x10 cable connection

for a single-card

16720p02

Master

J13 J12 J11 J10

CAUTION

77

J9 J8

A single-card module configuration can be

installed in any available slot.

Be sure the frame is unplugged before

removing or installing modules.

The 16720A requires software Rev.

A.02.00.00 or higher.

The following pages will show you how to

connect the to configure two,

three, four, and five-card modules.

2x10 cables

16720A

2-Card Module

EXPANDER

MASTER

2x10 Cable

Expander

Master

3-Card Module

Expander

J13 J12 J11 J10

J13 J12 J11 J10

EXPANDER

MASTER

EXPANDER

J13 J12 J11 J10

J9 J8

J9 J8

2x10 Cable

J9 J8

16720p03

Master

Expander

J13 J12 J11 J10

J13 J12 J11 J10

78

J9 J8

J9 J8

16720A

4-Card Module

Carefully slide the four cards half way into the mainframe slots.

Cable the bottom Expander to the Master Card first.

Cable the upper two Expanders to the Master Card.

Gently slide the cabled assembly fully into the frame and

tighten.

2x10 Cable

EXPANDER

EXPANDER

MASTER

EXPANDER

16720p04

Expander

Expander

Master

Expander

J13 J12 J11 J10

J13 J12 J11 J10

J13 J12 J11 J10

J13 J12 J11 J10

79

J9 J8

J9 J8

J9 J8

J9 J8

16720A

5-Card Module

Carefully slide the five cards half way into the mainframe slots.

Cable the bottom two Expanders to the Master first.

Cable the upper two Expanders to the Master.

Gently slide the cabled assembly fully into the frame and

tighten.

2x10 Cable

EXPANDER

EXPANDER

MASTER

EXPANDER

EXPANDER

Expander

Expander

Master

Expander

Expander

J13 J12 J11 J10

J13 J12 J11 J10

J13 J12 J11 J10

J13 J12 J11 J10

J13 J12 J11 J10

J9 J8

J9 J8

J9 J8

J9 J8

J9 J8

16720A

16720p05

80

Done

Done

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer's Name:

Manufacturer's Address:

declares, that the product

Product Name:

Model Number(s):

Product Options(s):

Is in conformity with:

EMC:

IEC 61326-1:1997+A1:1998/EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011:1991 - Group 1, Class A*

IEC 61000-4-2:1995+A1:1998/EN 61000-4-2:1995 (ESD 4kV CD, 8kV AD)

IEC 61000-4-3:1995/EN 61000-4-3:1995 (3V/m 80% AM)

IEC 61000-4-4:1995/EN 61000-4-4:1995 (0.5kV line-line, 1kV line-earth)

IEC 61000-4-6:1996/EN61000-4-6:1996 (3V 80% AM, power line)

Australia/New Zealand: AS/NZS 2064.1

Safety:

IEC 61010-1:1990+A1:1992+A2:1995/EN61010-1:1994+A2:1995

Canada: CSA C22.2 No. 1010-1:1992

USA: UL 3111-1:1994

Agilent Technologies, Inc.

1900 Garden of the Gods Road

Colorado Springs, CO 80907 USA

Logic Analyzer System Mainframe

16700B, 16701B, 16702B

All options based on the above

Additional Information:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC

and the EMC Directive 89/336/EEC (including 93/68/EEC) and carries the CE marking accordingly.

(European Union)

*This product was tested in a typical configuration with Agilent Technologies test systems.

Date: 11/18/99

Ken Wyatt / Product Regulations Manager

For further information, please contact your local Agilent Technologies sales office, agent, or distributor.

dconframes

Definitions

Installation category (overvoltage category) Signal level, special equipment or parts of

equipment, telecommunication, electronic etc., with smaller transient overvoltages than

installation (overvoltage category)

II.

I:

Enviromental

Conditions

Temperature

Humidity

Power

Installation category (overvoltage category) Local level, appliances, portable

equipment etc., with smaller transient overvoltages than installation category

Indoor use only.

Altitude up to 3000 m. (10,000 ft.)

Instrument - 0 degrees C to 50 degrees C (32 degrees F to 122 degrees F)

Disk Media - 10 degrees C to 40 degrees C (50 degrees F to 104 degrees F)

Probes/cables - 0 degrees C to 65 degrees C (32 degrees F to 149 degrees F)

Relative humidity 8 to 80% at 40 degrees C (104 degrees F)

CAT , Pollution degree 2

II

All Frames: ~Line 115/230 volts ± 20%, 48-66 Hz, 610 Watts max.

II:

III.

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer's Name:

Manufacturer's Address:

Agilent Technologies

Colorado Springs Division

1900 Garden of the Gods Road

Colorado Springs, CO 80907 USA

declares, that the product

Product Name:

Model Number(s):

Measurement Modules

16517A, 16518A, 16522A, 16533A, 16534A,

16557D, 16710A, 16711A, 16712A, 16715A,

16716A, 16717A, 16718A, 16719A

Product Options(s):

All

conforms to the following Product Specifications:

Safety:

IEC 1010-1:1990+A1 / EN 61010-1:1993

UL 3111

CSA-C22.2 No. 1010.1:1993

EMC:

CISPR 11:1990 / EN 55011:1991 Group 1, Class A

IEC 801-2:1991 / EN 50082-1:1992 4 kV CD, 8 kV AD

IEC 801-3:1984 / EN 50082-1:1992 3 V/m,{1kHz 80% AM, 27-1000 MHz}

IEC 801-4:1988 / EN 50082-1:1992 0.5 kV Sig. Lines, 1kV Power Lines

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC

and the EMC Directive 89/336/EEC, and carries the CE marking accordingly.

This product was tested in a typical configuration with Agilent Technologies test systems.

Colorado Springs, 10/03/96

Ken Wyatt / Product Regulations Manager

For further information, please contact your local Agilent Technologies sales office, agent, or distributor.

dconoldmods

Definitions

Installation category (overvoltage category) Signal level, special equipment or parts of

equipment, telecommunication, electronic etc., with smaller transient overvoltages than

installation (overvoltage category)

II.

I:

Enviromental

Conditions

Temperature

Humidity

Power

Installation category (overvoltage category) Local level, appliances, portable

equipment etc., with smaller transient overvoltages than installation category

Indoor use only.

Altitude up to 3000 m. (10,000 ft.)

Instrument - 0 degrees C to 50 degrees C (32 degrees F to 122 degrees F)

Disk Media - 10 degrees C to 40 degrees C (50 degrees F to 104 degrees F)

Probes/cables - 0 degrees C to 65 degrees C (32 degrees F to 149 degrees F)

Relative humidity 8 to 80% at 40 degrees C (104 degrees F)

(From host frame.)

II:

III.

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer's Name:

Manufacturer's Address:

declares, that the product

Product Name:

Model Number(s):

Product Options(s):

Is in conformity with:

EMC:

IEC 61326-1:1997+A1:1998/EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011:1991 - Group 1, Class A*

IEC 61000-4-2:1995+A1:1998/EN 61000-4-2:1995 (ESD 4kV CD, 8kV AD)

IEC 61000-4-3:1995/EN 61000-4-3:1995 (3V/m 80% AM)

IEC 61000-4-4:1995/EN 61000-4-4:1995 (0.5kV line-line, 1kV line-earth)

IEC 61000-4-6:1996/EN61000-4-6:1996 (3V 80% AM, power line)

Australia/New Zealand: AS/NZS 2064.1

Safety:

IEC 61010-1:1990+A1:1992+A2:1995/EN61010-1:1994+A2:1995

Canada: CSA C22.2 No. 1010-1:1992

USA: UL 3111-1:1994

Agilent Technologies, Inc.

1900 Garden of the Gods Road

Colorado Springs, Colorado 80907 USA

Measurement Modules

16720A, 16750A, 16751A, and 16752A

All options based on the above

Additional Information:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC

and the EMC Directive 89/336/EEC (including 93/68/EEC) and carries the CE marking accordingly.

(European Union)

*This product was tested in a typical configuration with Agilent Technologies test systems.

Date: 02/08/2000

Ken Wyatt / Product Regulations Manager

For further information, please contact your local Agilent Technologies sales office, agent, or distributor.

dconnewmods

Definitions

Installation category (overvoltage category) Signal level, special equipment or parts of

equipment, telecommunication, electronic etc., with smaller transient overvoltages than

installation (overvoltage category)

II.

I:

Enviromental

Conditions

Temperature

Humidity

Power

Installation category (overvoltage category) Local level, appliances, portable

equipment etc., with smaller transient overvoltages than installation category

Indoor use only.

Altitude up to 3000 m. (10,000 ft.)

Instrument - 0 degrees C to 50 degrees C (32 degrees F to 122 degrees F)

Disk Media - 10 degrees C to 40 degrees C (50 degrees F to 104 degrees F)

Probes/cables - 0 degrees C to 65 degrees C (32 degrees F to 149 degrees F)

Relative humidity 8 to 80% at 40 degrees C (104 degrees F)

(From host frame.)

II:

III.

C

Copyright

Agilent Technologies Inc. 2000

All Rights Reserved.

Reproduction, adaptation, or

translation without prior written

permission is prohibited, except

as allowed under the copyright

laws.

Restricted Rights Legend.

Use, duplication or disclosure by

the U.S.Government is subject to

restrictions as set forth in

subparagraph (c)(1)(ii) of the

Rights in Technical Data and

Computer Software clause at

DFARS 252.227-7013.

Agilent Technologies

3000 Hanover Street

Palo Alto, California 94304

U.S.A.

Rights for no- DOD U.S.

Government Departments and

Agencies are set forth in FAR

52.227-19(c) (1,2).

Inc.

Document Warranty

The information contained in this

document is subject to change

without notice.

Agilent Technologies Inc. makes

no warranty of any kind with

regard to this material,

including, but not limited to,

the implied warranties of

merchantability or fitness for a

particular purpose.

Agilent Technologies Inc. shall

not be liable for errors contained

herein or for damages in

connection with the furnishing,

performance, or use of this

material.

Safety

This apparatus has been designed

and tested in accordance with IEC

Publication 1010, Safety

Requirements for Measuring

Apparatus, and has been supplied

in a safe condition. This is a

Safety Class I instrument

(provided with terminal for

protective earthing). Before

applying power, verify that the

correct safety precautions are

taken (see the following

warnings). In addition, note the

external markings on the

instrument that are described

under "Safety Symbols."

Warning

Before turning on the

instrument, you must connect the

protective earth terminal of the

instrument to the protective

conductor of the (mains) power

cord. The mains plug shall only

be inserted in a socket outlet

provided with a protective earth

contact. You must not negate the

protective action by using an

extension cord (power cable)

without a protective conductor

(grounding). Grounding one

conductor of a two-conductor

outlet is not sufficient protection.

Only fuses with the required

rated current, voltage, and

specified type (normal blow, time

delay, etc.) should be used. Do

not use repaired fuses or shortcircuited fuseholders. To do so

could cause a shock or fire

hazard.

Service instructions are for

trained service personnel. To

avoid dangerous electric shock,

do not perform any service unless

qualified to do so. Do not

attempt internal service or

adjustment unless another person,

capable of rendering first aid and

resuscitation, is present.

If you energize this instrument

by an auto transformer (for

voltage reduction), make sure the

common terminal is connected to

the earth terminal of the power

source.

Whenever it is likely that the

ground protection is impaired,

you must make the instrument

inoperative and secure it against

any unintended operation.

Do not operate the instrument

in the presence of flammable

gasses or fumes. Operation of

any electrical instrument in such

an environment constitutes a

definite safety hazard.

Do not install substitute parts or

perform any unauthorized

modification to the instrument.

Capacitors inside the instrument

may retain a charge even if the

instrument is disconnected from

its source of supply.

Use caution when exposing or

handling the CRT. Handling or

replacing the CRT shall be done

only by qualified maintenance

personnel.

Safety Symbols

Instruction manual symbol: the

product is marked with this

symbol when it is necessary for

you to refer to the instruction

manual in order to protect against

damage to the product.

Hazardous voltage symbol.

Earth terminal symbol: Used to

indicate a circuit common

connected to grounded chassis.

WARNING

The Warning sign denotes a

hazard. It calls attention to a

procedure, practice, or the like,

which, if not correctly performed

or adhered to, could result in

personal injury. Do not proceed

beyond a Warning sign until the

indicated conditions are fully

understood and met.

CAUTION

The Caution sign denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like, which, if not correctly

performed or adhered to, could

result in damage to or destruction

of part or all of the product. Do

not proceed beyond a Caution

symbol until the indicated

conditions are fully understood or

met.

Agilent Technologies

P.O. Box 2197

1900 Garden of the Gods Road

Colorado Springs, CO. 80901

Product Warranty

Agilent Technologies

This Inc.

product has a warranty against

defects in material and

workmanship for a period of one

year from date of shipment. Some

newly manufactured

Technologies Inc.

contain remanufactured parts which

are equivalent to new in

performance. During the warranty

Agilent Technologies Inc.

period,

will, at its option, either repair or

replace products that prove to be

defective.

For warranty service or repair, this

product must be returned to a

service facility designated by

Agilent Technologies Inc.

For products returned to

Technologies Inc.

service, the Buyer shall prepay

shipping charges to

Technologies Inc. Agilent

Technologies Inc.

shipping charges to return the

product to the Buyer. However, the

Buyer shall pay all shipping

charges, duties, and taxes for

products returned to

Technologies

Agilent Technologies warrants that

its software and firmware

designated by Agilent Technologies

for use with an instrument will

execute its programming

instructions when properly installed

on that instrument. Agilent

Technologies does not warrant that

the operation of the instrument

software, or firmware will be

uninterrupted or error free.

Agilent

products may

Agilent

for warranty

Agilent

and

shall pay

Agilent

from another country.

No other warranty is

expressed or implied.

TechnologiesInc.

Agilent

specifically

disclaims the implied

warranties of

merchantability or fitness for

a particular purpose.

Exclusive Remedies

The remedies provided herein are

the buyer's sole and exclusive

Agilent Technologies

remedies.

Inc.

shall not be liable for any

direct, indirect, special, incidental,

or consequential damages, whether

based on contract, tort, or any

other legal theory.

Assistance

Product maintenance agreements

and other customer assistance

agreements are available for

Agilent Technologies Inc.

products. For any assistance,

contact your nearest

Technologies

Agilent

Sales Office.

Certification

Agilent Technologies Inc.

that this product met its published

specifications at the time of

shipment from the factory.

Technologies Inc.

that its calibration measurements

are traceable to the United States

National Institute of Standards and

Technology, to the extent allowed

by the Institute's calibration

facility, and to the calibration

facilities of other International

Standards Organization members.

certifies

Agilent

further certifies

About this edition

Publication number

16700-97014, Apr. 2000

Printed in USA.

New editions are complete

revisions of the manual. Many

product updates do not require

manual changes; and, conversely,

manual corrections may be done

without accompanying product

changes. Therefore, do not expect

a one-to-one correspondence

between product updates and

manual updates.

Limitation ofWarranty

The foregoing warranty shall not

apply to defects resulting from

improper or inadequate

maintenance by the Buyer, Buyersupplied software or interfacing,

unauthorized modification or

misuse, operation outside of the

environmental specifications for the

product, or improper site

preparation or maintenance.

Loading...

Loading...