User’s Reference

Publication number 16557-97000

First edition, March 1998

For Safety information, Warranties, and Regulatory information, see the

pages behind the Index.

© Copyright Hewlett-Packard Company 1992–1998

All Rights Reserved

HP 16557D 135-MHz State/

500-MHz Timing Logic Analyzer

ii

In This Book

The User’s Reference manual contains

field and feature definitions. Use this

manual to learn what the menu fields do,

what they are used for, and how the

features work.

The manual is divided into chapters

covering general product information,

probing, and separately tabbed chapters

for each analyzer menu. Chapters on

error messages and instrument

specifications are also provided.

In the Configuration menu, you have the

choice of configuring an analyzer as

either a State analyzer or a Timing

analyzer. Some menus in the analyzer

will change depending on the analyzer

type you choose. For example, because a

Timing analyzer does not use external

clocks, the clock assignment fields in the

Format menu will not be available.

If a menu field is only available to a

particular analyzer type, the field is

designated (Timing only) or (State only)

after the field name. If no designation is

shown, the field is available for both

types.

1

General Information

2

Probing

3

The Configuration Menu

4

The Format Menu

5

The Trigger Menu

6

The Listing Menu

7

The Waveform Menu

8

The Chart Menu

9

The Compare Menu

10

The Mixed Display Menu

11

The SPA Menu

12

Error Messages

Specifications and

13

Characteristics

14

Installation and Service

Index

iii

iv

Contents

1 General Information

User Interface 1–3

Configuration Capabilities 1–4

Key Features for the HP 16557D 1–5

Accessories Supplied 1–6

Accessories Available 1–7

2 Probing

General-Purpose Probing System Description 2–17

Assembling the Probing System 2–21

Connecting the External Reference Clock 2–25

3 The Configuration Menu

Analyzer Name Field 3–3

Analyzer Type Field 3–4

Pod Fields 3–6

Activity Indicators 3–8

4 The Format Menu

State Acquisition Mode Field (State, State Compare, and SPA only) 4–3

Timing Acquisition Mode Field (Timing only) 4–4

Data on Clocks Display 4–5

Pod Field 4–6

Pod Clock Field (State only) 4–7

Pod Threshold Field 4–11

Master and Slave Clock Fields (State modes only) 4–12

Setup/Hold Field (State only) 4–14

Symbols Field 4–16

Label Assignment Fields 4–16

Rolling Labels and Pods 4–16

Label Polarity Fields 4–17

Bit Assignment Fields 4–18

Contents–1

Contents

5 The Trigger Menu

Predefined Trigger Macros 5–3

Timing Trigger Macro Library 5–5

State Trigger Macro Library 5–7

Sequence Levels 5–9

Sequence Level Number Field 5–10

Sequence Instruction Menu 5–11

Resource Terms 5–17

Resource Term Fields 5–18

Bit Pattern Terms 5–21

Range Terms 5–23

Timer Terms 5–25

Edge Terms (Timing only) 5–27

Combination of Terms 5–29

Control Fields 5–31

Arming Control Field 5–32

Count Field (State and State Compare only) 5–35

Acquisition Control Field 5–37

Modify Trigger Field 5–42

6 The Listing Menu

Markers Field 6–3

Pattern Markers 6–4

Find X-pattern / O-pattern Field 6–5

Pattern Occurrence Fields 6–6

From Trigger / Start / X Marker Field 6–7

Specify Patterns Field 6–8

Label / Base Roll Field 6–11

Contents–2

Stop Measurement Field 6–12

Clear Pattern Field 6–14

Time Markers 6–15

Trig to X / Trig to O Fields 6–16

Statistics Markers 6–17

Data Roll Field 6–19

7 The Waveform Menu

Basic Controls 7–3

Acquisition Control Field 7–4

Accumulate Field 7–5

States Per Division Field (State and State Compare only) 7–6

Seconds Per Division Field (Timing only) 7–7

Delay Field 7–8

Sample Period Display (Timing only) 7–9

Markers Field 7–11

Contents

Pattern Markers 7–12

X-pat / O-pat Occurrence Fields 7–13

From Trigger / Start / X Marker Field 7–14

Center Screen Field 7–15

Specify Patterns Field 7–16

Time Markers 7–17

Trig to X / Trig to O Fields 7–18

Marker Label / Base and Display 7–19

Statistics Markers 7–20

Contents–3

Contents

Waveform Display 7–22

Display Location Reference Line 7–23

Blue Bar Field 7–24

Channel Mode Field 7–26

Module and Label Fields 7–27

Action Insert/Replace Field 7–28

Delete and Delete All Fields 7–29

Waveform Size Field 7–30

8 The Chart Menu

The Y Markers 8–4

The X Markers and the Markers Field 8–5

Sample 8–5

Pattern 8–6

Rescale 8–13

Axis Control Field 8–15

Accumulate Field 8–18

Cancel Field 8–18

9 The Compare Menu

Reference Listing Field 9–4

Difference Listing Field 9–5

Copy Listing to Reference Field 9–7

Find Error Field 9–8

Compare Full / Compare Partial Field 9–9

Mask Field 9–10

Specify Stop Measurement Field 9–11

Data Roll Field 9–14

Bit Editing Field 9–15

Label and Base Fields 9–16

Label / Base Roll Field 9–16

Contents–4

10 The Mixed Display Menu

Intermodule Configuration 10–3

Inserting Waveforms 10–4

Interleaving State Listings 10–4

Time-Correlated Displays 10–5

Markers 10–5

11 The SPA Menu

System Performance Analysis Software 11–2

What is System Performance Analysis? 11–4

Getting Started 11–6

SPA Measurement Processes 11–8

Using State Overview, State Histogram, and Time Interval 11–21

Using SPA with other features 11–30

Contents

12 Error Messages

Error Messages 12–3

Warning Messages 12–4

Advisory Messages 12–7

13 Specifications and Characteristics

Specifications 13–3

Supplemental Characteristics 13–4

14 Installation and Service

To configure a single-card module 14–2

To configure a multi-card module 14–3

To install modules 14–8

Preparing for Use 14–9

To inspect the module 14–10

To clean the logic analyzer module 14–10

Index

Contents–5

Contents–6

1

General Information

Logic Analyzer Description

The HP 16557D State/Timing Analyzer module is part of a new

generation of general-purpose logic analyzers. It is used with the HP

16500C Logic Analysis System mainframe, which is designed as a

standalone instrument for use by digital and microprocessor hardware

and software designers. The HP 16557D logic analyzer is not

compatible with earlier models of the HP 16500 logic analysis system.

The HP 16500C mainframe has HP-IB and RS-232-C interfaces for

hard copy printouts and control by a host computer.

The State/Timing Analyzer module has 64 data channels and four

clock/data channels. Two additional HP 16557D cards can be added

to expand the module to 200 data and 4 clock/data channels. Up to

two more HP 16557D cards can be added to expand the module to

336 data and 4 clock/data channels, but the state speed decreases to

100 MHz.

Memory depth on the HP 16557D is 2M in all pod pair groupings, or

4M on just one pod (timing half-channel mode). All available resource

terms can be assigned to either configured state or timing analyzer

machine.

Measurement data is displayed as data listings or waveforms.

The 135-MHz state analyzer has master, slave, and demultiplexed

clocking modes available. Measurement data can be stamped with

either state or time tags. For triggering and data storage, the state

analyzer uses 12 sequence levels with two-way branching, 10 pattern

resource terms, 2 range terms, and 2 timers/counters.

The 500-MHz conventional timing analyzer has variable width, depth,

and speed selections. Sequential triggering uses 10 sequence levels

with two-way branching, 10 pattern resource terms, 2 range terms,

2 timers/counters and 2 edge/glitch terms.

1–2

General Information

User Interface

User Interface

The HP 16500C Logic Analysis System has four easy-to-use user interface

devices: the knob, the touchscreen, the mouse, and the optional keyboard.

The knob on the front panel is used to move the cursor on certain menus, to

increment or decrement numeric fields, and to roll the display.

The touchscreen fields can be selected by touch or with the mouse or

keyboard. To activate a touchscreen field by touch, simply press the screen

over any dark blue box on the display with your finger until the field changes

color. Then remove your finger from the screen to activate your selection.

To activate a field with the mouse, position the cursor (+) of the mouse over

the desired field and press the button on the upper-left corner of the mouse.

The optional keyboard can control all instrument functions by using special

function keys, the arrow keys, and the ENTER key. Alphanumeric entry is

simply typed in.

All user interface devices are discussed in more detail in the HP 16500C

User’s Reference.

1–3

General Information

Configuration Capabilities

Configuration Capabilities

The HP 16557D can be configured as a single card, two-card, three-card,

four-card, or five-card module. The number of data channels ranges from 68

channels using just one card, to 340 channels when five cards are installed. A

half-channel acquisition mode is available for timing analyzers which reduces

the channel width by half, but doubles memory depth from 2M-deep to

4M-deep per channel.

Modules are made of cards cabled together to form a single timebase. An HP

16557D module may use from one to five HP 16557D cards. Because the

clock is common to all cards in a module, the data is always synchronized.

For tightly coupled measurements involving multiple HP 16557D modules,

your analyzer module provides an external reference clock. The reference

clock prevents large data samples from becoming unsynchronized towards

the end of a measurement. Because the internal clock on each logic analyzer

card is accurate to 100 parts per million, in a 2M timing measurement using

two modules, the last sample of each may be separated as much as 100 times

the sample period. The external reference clock prevents this by having

multiple modules share the same clock. There is no limit to how many

modules may share the clock.

See Also "Connecting the External Reference Clock" in chapter 2, Probing, for

information on configuring the external reference clock.

1–4

General Information

Key Features for the HP 16557D

Key Features for the HP 16557D

Lightweight passive probes for easy hookup and compatibility with

•

previous HP logic analyzers and preprocessors.

HP-IB and RS-232-C interface for programming and hard copy printouts.

•

Variable setup/hold time, 3.0-ns window.

•

External arming to and from other modules through the intermodule bus.

•

2-M deep memory on all channels with 4 Mbytes in half-channel modes.

•

Marker measurements.

•

12 levels of trigger sequencing for State and 10 levels of sequential

•

triggering for Timing.

Both state and timing analyzers can use 10 pattern resource terms, two

•

range terms, and two timer/counters to qualify and trigger on data. The

timing analyzer also has two edge terms available.

Time (8-ns resolution) and number-of-qualified-states tagging.

•

Full programmability.

•

Mixed State/Timing and State/State (interleaved) display.

•

Waveform display.

•

One, Two, or Three-Card HP 16557D

135-MHz state and 500-MHz timing acquisition speed.

•

64 data channels/4 clocks expandable to 200 data/4 clock channels.

•

Four or Five-Card HP 16557D

100-MHz state and 500-MHz timing acquisition speed.

•

268 data/4 clock channels or 336 data/4 clock channels.

•

1–5

General Information

Accessories Supplied

Accessories Supplied

The table below lists the accessories supplied with your logic analyzer. If any

of these accessories are missing, contact your nearest Hewlett-Packard Sales

Office. If you need additional accessories, refer to the Accessories for

HP Logic Analyzers brochure.

Table 1-1

Accessories Supplied

Accessory HP Part No. Quantity

Probe tip assemblies 01650-61608 4

Probe cables 16557-61601 2

Cable kit for multicard 16555-68705 1

Grabbers (20 per pack) 5090-4356 4 pkgs

Extra probe leads (5 per pack) 5959-9333 1 pkg

Probe cable and pod labels 01650-94312 1

Double probe adapter 16542-61607 1

External reference cable 16555-61608 1

Probe grounds (5 per pack) 5959-9334 4

Operating system dis ks Call 1

User’s Reference Call 1

1–6

General Information

Accessories Available

Accessories Available

There are a number of accessories available that will make your measurement

tasks easier and more accurate. You will find these listed in Accessories for

HP Logic Analyzers, available from your Hewlett-Packard Sales Office.

Preprocessor Modules

The preprocessor module accessories enable you to quickly and easily

connect the logic analyzer to your microprocessor under test.

Included with each preprocessor module is a 3.5-inch disk which contains a

configuration file and an inverse assembler file. When you load the

configuration file, it configures the logic analyzer for making state

measurements on the microprocessor for which the preprocessor is designed.

Configuration files from other analyzer modules can also be loaded. For

information on translating other configuration files into the analyzer, refer to

"Preprocessor File Configuration Translation and Pod Connections" in

chapter 2, "Probing".

The inverse assembler file is a software routine that will display captured

information in a specific microprocessor’s mnemonics. The DATA field in the

State Listing is replaced with an inverse assembly field. The inverse

assembler software is designed to provide a display that closely resembles

the original assembly language listing of the microprocessor’s software. It also

identifies the microprocessor bus cycles captured, such as Memory Read,

Interrupt Acknowledge, or I/O write.

Many of the preprocessor modules require the HP 10269C General Purpose

Probe Interface. The HP 10269C accepts the specific preprocessor PC board

and connects it to five connectors on the general purpose interface to which

the logic analyzer probe cables connect.

A list of preprocessor modules is found in the Accessories for HP Logic

Analyzers brochure. Descriptions of the preprocessor modules are found

with the preprocessor module accessories.

1–7

1–8

2

Probing

Probing

This chapter contains a description of the probing system for the logic

analyzer. It also contains the information you need for connecting the

probe system components to each other, to the logic analyzer, and to

the system under test.

Probing Options

You can connect the logic analyzer to your system under test in one of

the following ways:

• The standard general purpose probing (provided).

• HP E2445A User-Definable Interface (optional).

• Direct connection to a 20-pin, 3M-Series type header connector

using the termination adapter (optional).

• Microprocessor and bus specific interfaces (optional).

General-Purpose Probing

General-purpose probing involves connecting the logic analyzer

probes directly to your target system without using any interface.

General purpose probing does not limit you to specific hook up

schemes, as for example, the probe interface does. General-purpose

probing uses grabbers that connect to both through hole and surface

mount components.

General-purpose probing is the standard probing option provided with

the logic analyzer. There is a full description of its components and

use later in this chapter.

2–2

Probing

The HP E2445A User-Definable Interface

The optional HP E2445A User-Definable Interface allows you to

connect the logic analyzer to the microprocessor in your target

system. The HP E2445A includes a breadboard that you custom-wire

for your system.

You will find additional information about the HP E2445A in the

Accessories for HP Logic Analyzers brochure.

The Termination Adapter

The optional termination adapter allows you to connect the logic

analyzer probe cables directly to test ports on your target system

without the probes.

The termination adapter is designed to connect to a 20-pin (2x10),

4-wall, low-profile header connector, 3M-Series 3592 or equivalent.

Termination Adapter

2–3

Probing

Microprocessor and Bus-Specific Interfaces

There are a number of microprocessor and bus-specific interfaces

available as optional accessories which are listed in Microprocessor

and Bus Interfaces and Software Accessories for HP Logic

Analyzers. Microprocessors are supported by Universal Interfaces or

Preprocessor Interfaces, or in some cases both.

Preprocessor interfaces are aimed at hardware turn-on and

hardware/software integration, and will provide the following:

• All clocking and demultiplexing circuits needed to capture the

system’s operation.

• Additional status lines to further decode the operation of the CPU.

• Inverse assembly software to translate logic levels captured by the

logic analyzer into microprocessor mnemonics.

• Bus interfaces to support bus analysis for HP-IB, RS-232-C, RS-449,

SCSI, VME, VXI, ISA, EISA, MCA, FDDI, Futurebus+, JTAG, SBus,

PCI, and PCMCIA.

Universal Interfaces are aimed at initial hardware turn-on, and will

provide fast, reliable, and convenient connections to the

microprocessor system. Universal Interfaces do not provide inverse

assembly of software instructions.

2–4

Probing

Preprocessor File Configuration Translation and Pod Connections

Configuration files for the HP 16554, HP 16555A/D, and HP 16556A/D

logic analyzers can be used by the HP 16557D. For the HP 16554-6 to

the HP 16557D, no pod translation is necessary. Preprocessor

configuration files from an HP 16550A can be used by the HP 16557D

logic analyzer. However, some pods must be connected differently in

order for the configuration files to work properly. The tables on the

next several pages provide information on what configuration files to

load and the required connections between the preprocessor interface

and the HP 16557D pods.

In the tables, expansion and master card pods are referred to as either

A or B pods. Those designations are done for convenience. The letter

designation of pods in your module will depend on the slots in which

your cards reside. They may use any letter from A through E for the

16500 Logic Analysis System mainframe, or F through J for the

16501A Expander Frame

In a five-card module, for example, the master card pods would be

labeled C. The expansion card pods then would be labeled A, B, D,

and E. Look at the Format menu for the slot designators for

expansion cards in your system.

The following three tables provide configuration file names and pod

connections for older microprocessors. Look in the microprocessorspecific preprocessor manual for configuration and connection

information for newer microprocessors.

2–5

Probing

Software and Hardware Translation Information

Table 2-1

Single-card HP16550A configuration loaded into single-card HP 16557D

Master Card

16550A Config

HP Model Processor

10300B Z80 FZ80 -- P2 -- P1 J+L No

Inverse Assembler Labels: P1=DATA/STAT.clk

P2=ADDR.clk

10304B 8085 C8085_IF -- P3 P2 P1 J, K No

Inverse Assembler Labels: P1=DATA/STAT.master_clk

P2=ADDR.slave_clk

Filename

Pods

B4 B3 B2 B1 Clocks Drop Pods

mclk, sclk

10305 B 8086 F8086_I P3 P2 -- P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=ADDR P3=ADDR/STAT

10305 B 8088 F8088_I P3 P2 -- P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=ADDR P3=ADDR/STAT

10315G/H 68HC11 F68HC11 -- P2 -- P1 L, J Timing

mclk, sclk P3, P4

Inverse Assembler Labels: P1=ADDR/DATA.slave_clk P2=ADDR/STAT.master_clk

10341B 1553 F1553 -- P2 -- P1 J Timing

Inverse Assembler Labels: P1=DATA.clk (no Inverse Assembler capability) P3

10342B RS232 FRS232 -- P3 P4 P1 K No

Inverse Assembler Labels: P1=DATA/STAT P4=.clk

10342B HPIB FHPIB . P3 P2 J No

Inverse Assembler Labels: P2=DATA/STAT.clk P3=DATA

2–6

Table 2-1 (continued)

Single-card HP16550A configuration loaded into single-card HP 16557D

Master Card

HP Model Processor

10342 G HPIB FHPIB -- J2 -- J2 J No

Inverse Assembler Labels: J2=DATA/STAT.clk

E2409B 80286 F80286S P3 P2 -- P1 J Timing

Inverse Assembler Labels: P1=Data.clk P2=ADDR P3=ADDR/STAT P4, P5

E2409B 80286 F80286T P3 P2 -- P4 Timing Timing

Inverse Assembler Labels: n/a P5

16550A Config

Filename

Pods

B4 B3 B2 B1 Clocks Drop Pods

Probing

E2413B 68331/2 F68332 P4 P3 P5 P1 J State

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P4=ADDR P5=STAT P2, P6

E2414B 68302 F68302 -- P4 P3 P1 J No

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P4=ADDR/STAT

E2415A MCS-51 FMCS51 -- P2 P3 P1 J State

Inverse Assembler Labels: P1=DATA.clk P2=ADDR P3=STAT P5

E2416A MCS-96 FMCS96 -- P3 P2 P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=ADDR

P3=STAT

E2418A 320C20/25 F320C25 J3 J1 -- J2 J No

Inverse Assembler Labels: J1=DATA J2=ADDR.clk J3=STAT

E2419A 68HC16 FHC16 P4 P3 P5 P1 J State

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P5=STAT (P4=ADDR not required) P2, P6

2–7

Probing

Table 2-1 (continued)

Single-card HP16550A configuration loaded into single-card HP 16557D

Master Card

HP Model Processor

E2423A SCSI-2 FSCSI2 P4 P3 P2 P1 J No

Inverse Assembler Labels: P1=STAT.clk P2=ADDR/DATA

E2424B 68340 F68340 P4 P3 P5 P1 K N o

Inverse Assembler Labels: P1=DATA P3=ADDR P5=STAT.clk (P4=ADDR_B not required)

E2424B 68340 FEV340 P4 P3 P5 P1 J No

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P5=STAT (P4=ADDR not required)

16550A Config

Filename

Pods

B4 B3 B2 B1 Clocks Drop Pods

E2431A 320C30/31 P_320C3X P4 P3 P2 P1

Inverse Assembler Labels: P1=DATA.clk P2=DATA P3=ADDR P4=ADDR/STAT

E2431A 320C30/31 Q_320C30 P6 P5 -- P7

Inverse Assembler Labels: P5=DATA P6=DATA P7=ADDR/STAT.clk

Note: A single-card HP 16557D is not recommended for this preprocessor because it does not allow simultaneous

viewing of both the primary and expansion microprocessor buses.

E2434A 80186XL/88 C186EA09 P4 P3 -- P1 J No

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P4=ADDR/STAT

E2434A 80186XL/88 C186EA10 P6 P5 P4 P2 Timing No

Inverse Assembler Labels: n/a

E2434B 80186/88EB C186EB_7 P4 P3 -- P1 J No

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P4=ADDR/STAT

E2434B 80186/88EB C186EB_8 P6 P5 P4 P2 Timing Timing

Inverse Assembler Labels: n/a P7

J↕

J↕

No

No

2–8

Table 2-1 (continued)

Single-card HP16550A configuration loaded into single-card HP 16557D

Master Card

HP Model Processor

16550A Config

Filename

Pods

B4 B3 B2 B1 Clocks Drop Pods

Probing

E2434C 80186/88EC C186EC_7 P4 P3 P6 P1

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P4=ADDR/STAT

E2434C 80186/88EC C186EC_8 P5 P6 P7 P2 Timing Timing

Inverse Assembler Labels: n/a P8

E2442A TMS320C5X D_320C5X P5 P2 P3 P1 J+K+L State

Inverse Assembler Labels: P1=DATA.clk P2=STAT.clk P3=ADDR.clk P4, P6

E2447AA 68000 F68000 P6 P1 P4 P3 K No

Inverse Assembler Labels: P1=DATA P3=ADDR P4=ADDR/STAT.clk

E2447AA 68010 F68010 P6 P1 P4 P3 K No

Inverse Assembler Labels: P1=DATA P3=ADDR P4=ADDR/STAT.clk

E2447AB 68EC000 FEC000 P6 P1 P4 P3 K No

Inverse Assembler Labels: P1=DATA P3=ADDR P4=ADDR/STAT.clk

E2451A Ethernet CETH_4 P4 P3 P2 P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=ADDR/ DATA_B P3=ADDR/DATA_B P4=STAT

E2453A DS1 C_DS1_6 . -- xx

Inverse Assembler Labels: Carrier/Customer=ADDR/DATA/STAT.clk

E2453A DS1 C_DS1_7 -- Cu -- Ca

mach2 mach1 mach1 mach2

Inverse Assembler Labels: Carrier=ADDR/DATA/STAT.clk Customer=ADDR/DATA/STAT.clk

J

J↕

J↕ L↕

No

No

No

2–9

Probing

Table 2-2

Single-card HP16550A configuration loaded into multi-card HP 16557D

16550A

HP Model Processor

10300B Z80 FZ80 -- P2 -- P1 J+L No

Inverse Assembler Labels: P1=DATA/STAT.clk P2=ADDR.clk

10304B 8085 C8085_IF . -- P3 . P2 P1 J, K No

Inverse Assembler Labels: P1=DATA/STAT.master_clk P2=ADDR.slave_clk

10305 B 8086 F8086_I . P3 P2 . -- P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=ADDR P3=ADDR/STAT

10305 B 8088 F8088_I . P3 P2 . -- P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=ADDR P3=ADDR/STAT

10315G/H 68HC11 F68HC11 -- P2 -- P1 L, J Timing

Inverse Assembler Labels: P1=ADDR/DATA.slave_clk P2=ADDR/STAT.master_clk

10341 B 1553 F1553 . -- P2 -- P3 -- P1 J No

Inverse Assembler Labels: P1=DATA.clk (no Inverse Assembler capability)

Config

Filename

Expansion

Card Pods

A4 A3 A2 A1

Master Card

Pods

B4 B3 B2 B1 Clocks Drop Pods

mclk, sclk

mclk, sclk P3, P4

10342B RS232 FRS232 -- P3 P4 P1 K No

Inverse Assembler Labels: P1=DATA/STAT P4=.clk

10342B HPIB FHPIB . P3 P2 J No

Inverse Assembler Labels: P2=DATA/STAT.clk P3=DATA

10342G HPIB FHPIB -- J2 --- J2 J No

Inverse Assembler Labels: J2=DATA/STAT.clk

2–10

Table 2-2 (continued)

Single-card HP16550A configuration loaded into multi-card HP 16557D

Probing

16550A

HP Model Processor

E2409B 80286 F80286S P5 P4 P3 P2 . -- P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=ADDR P3=ADDR/STAT

E2409B 80286 F80286T . P5 P4 P3 P2 Timing No

Inverse Assembler Labels: n/a

E2413B 68331/2 F68332 P6 P5 P4 P3 . P2 P1 J No

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P4=ADDR P5=STAT

E2414B 68302 F68302 -- P4 -- P3 . -- P1 J No

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P4=ADDR/STAT

E2415A MCS-51 FMCS51 P5 P3 -- P2 . -- P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=ADDR P3=STAT

E2416A MCS-96 FMCS96 . -- P3 . P2 P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=ADDR P3=STAT

Config

Filename

Expansion

Card Pods

A4 A3 A2 A1

Master Card

Pods

B4 B3 B2 B1 Clocks Drop Pods

E2418A 320C20/25 F320C25 -- J3 -- J1 . -- J2 J No

Inverse Assembler Labels: J1=DATA J2=ADDR.clk J3=STAT

E2419A 68HC16 FHC 16 P6 P5 P4 P3 . P2 P1 J No

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P5=STAT (P4=ADDR not required)

E2419A 68HC16EVB FHC16 P6 P5 P3 P1 . P4 P2 J No

Inverse Assembler Labels: P2=DATA.clk P1=ADDR P5=STAT (P3=ADDR not required)

2–11

Probing

Table 2-2 (continued)

Single-card HP16550A configuration loaded into multi-card HP 16557D

16550A

HP Model Processor

E2423A SCSI- 2 FSCSI2 P4 P3 P2 P1 J No

Inverse Assembler Labels: P1=STAT.clk P2=ADDR/DATA

E2424B 68340 F68340 P4 P3 -- P1 . -- P5 J No

Inverse Assembler Labels: P1=DATA P3=ADDR P5=STAT.clk (P4=ADDR_B not required)

E2424B 68340 FEV340 -- P5 P4 P3 . -- P1 J No

Inverse Assembler Labels P1=DATA.clk P3=ADDR P5=STAT (P4=ADDR not required)

E2431A 320C30/31 O_320C30 -- P7 P2 P1 P4 P3

Inverse Assembler Labels: P1=DATA.clk P2=DATA P3=ADDR.clk P4=ADDR/STAT P7=STAT

Note: This is actually an HP 16510 configuration file.

E2434A 80186XL/88 C186EA09 . P4 P3 . -- P1 J No

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P4=ADDR/STAT

E2434A 80186XL/88 C186EA10 . P6 P5 P4 P2 Timing No

Cable Mapping: 1-B3 2-B4 3-A1 4-A2 5-B1 6-B2

Inverse Assembler Labels: n/a

Config

Filename

Expansion

Card Pods

A4 A3 A2 A1

Master Card

Pods

B4 B3 B2 B1 Clocks Drop Pods

J↕+L↕

No

E2434B 80186/88EB C186EB_7 . P4 P3 . -- P1 J No

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P4=ADDR/STAT

E2434B 80186/88EB C186EB_8 -- P7 P6 P5 P4 P2 Timing No

Inverse Assembler Labels: n/a

E2434C 80186/88EC C186EC_7 . P4 P3 . P6 P1 J No

Inverse Assembler Labels: P1=DATA.clk P3=ADDR P4=ADDR/STAT

E2434C 80186/88EC C186EC_8 -- P8 P5 P6 P7 P2 Timing No

Inverse Assembler Labels: n/a

2–12

Table 2-2 (continued)

Single-card HP16550A configuration loaded into multi-card HP 16557D

Probing

16550A

HP Model Processor

E2442A TMS320C5X D_320 C5X . -- P4 P5 P2 P3 P1 J+K+L No

Inverse Assembler Labels: P1=DATA.clk P2=STAT.clk P3=ADDR.clk

E2447AA 68000 F68000 . P6 P1 . P4 P3 K No

Inverse Assembler Labels: P1=DATA P3=ADDR P4=ADDR/STAT.clk

E2447AA 68010 F68010 . P6 P1 . P4 P3 K No

Inverse Assembler Labels: P1=DATA P3=ADDR P4=ADDR/STAT.clk

E2447AB 68EC000 FEC000 . P6 P1 . P4 P3 K No

Inverse Assembler Labels: P1=DATA P3=ADDR P4=ADDR/STAT.clk

E2451A Ethernet CETH_4 . P4 P3 . P2 P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=ADDR/ DATA_B P3=ADDR/DATA_B P4=STAT

E2453A DS1 C_DS1_6 . -- xx

Inverse Assembler Labels: Carrier/Customer=ADDR/DATA/STAT.clk

E2453A DS1 C_DS1_7 -- Cu -- Ca

Inverse Assembler Labels: Carrier=ADDR/DATA/STAT.clk Customer=ADDR/DATA/STAT.clk

Config

Filename

Expansion

Card Pods

A4 A3 A2 A1

Master Card

Pods

B4 B3 B2 B1 Clocks Drop Pods

J↕

J↕ L↕

mach2 mach1 mach1 mach2

No

No

2–13

Probing

Table 2-3

Two-card HP16550A configuration loaded into multi-card HP 16557D (or single-card HP 16550 which

requires more than four pods for inverse assembly)

16550A

HP Model Processor

E2401A R3000 FR3KA -- P7 P6 P5 P4 P3 P2 P1

Inverse Assembler Labels: P1=STAT.clk P2=DATA P3=D ATA P4=ADDR/STAT P5=ADDR P6=ADDR P7=STAT

FR3KB Same as FR3KA

FR3KC Same as FR3KA

E2403A 80486 UI_486_21 -- J4 J6 J7 J3 J5 J1 J2 J No

E2406A 68030 C68030_4 . P5 P4 -- P3 P2 P1 K+L No

Inverse Assembler Labels: P1=DATA P2=DATA.clk P3=S TAT.clk P4=ADDR P5=ADDR

E2411C 80486 F486S2 -- P7 P6 P5 P4 P3 P2 P1 (J)*(K=1) No

Inverse Assembler Labels: P1=STAT.clk P2=STAT.clk P3=DATA P4=DATA P5=ADDR P6=AD DR

E2412A I860XP F_I860XP P6 P5 P9 P8 P3 P2 P7 P1 J No

Inverse Assembler Labels: P1=STAT.clk P2=DATA P3=DATA P5=DATA_B P6=DAT A_B P7=STAT P8=ADDR P9=ADDR

E2420A 68040 F68040 P4 P3 P2 P1 . -- P5 J No

Inverse Assembler Labels: P1=ADDR P2=ADDR P3=DATA P4=DATA P5=STAT.clk

Config

Filename

Expansion

Card Pods

A4 A3 A2 A1

Master Card

Pods

B4 B3 B2 B1 Clocks Drop Pods

J↕

No

E2426A/B 68020 F68020E P6 P5 P2 P1 . P4 P3 J No

Inverse Assembler Labels:

P1=DATA P2=DATA P3=ADDR.clk P4=ADDR P5 =STAT (P6=STAT_B not acces sed by inverse assembler)

E2426A/B 68EC020 FEC020E P6 P5 P2 P1 . P4 P3 J No

Inverse Assembler Labels:

P1=DATA P2=DATA P3=ADDR.clk P4=ADDR P5 =STAT (P6=STAT_B not acces sed by inverse assembler)

2–14

Table 2-3 (continued)

Two-card HP16550A configuration loaded into multi-card HP 16557D (or single-card HP 16550 which

requires more than four pods for inverse assembly)

Probing

16550A

HP Model Processor

E2432A 80960CA PI960CA_06 -- P7 P5 P4 P3 P2 P6 P1

Inverse Assembler Labels: P1=STAT.clk P2=DATA P3=DATA P4=ADDR P5=ADDR

E2435A I860XR I860XR3 -- P7 P6 P5 P3 P2 P4 P1 J No

Inverse Assembler Labels: P1=STAT.clk P2=ADDR P3=ADDR P4=DATA_B P5=DATA P6=DATA P7=DATA_B

E2438A R4000 F_R4K P6 P5 P4 P3 P8 P7 P2 P1

P9

Inverse Assembler Labels:

P1=STAT.clk P2=S TAT.clk P3=DATA P4=DATA P5=AD DR P6=ADDR P7=DATA_B P8=DATA_B

E2441B VME/VXI FE2441 P6 P5 P4 P3 . P2 P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=DATA P3=ADDR P4=ADDR P5=STAT

E2443B Pentium CPENT_2 P6 P5 P4 P3 P8 P7 P2 P 1 (J)*(K=0) State

P9, P10

Inverse Assembler Labels:

P1=STAT.clk P2=S TAT.clk P3=ADDR P4=ADDR P5=DA TA P6=DATA P7=DATA_B P8=DATA_B

Config

Filename

Expansion

Card Pods

A4 A3 A2 A1

Master Card

Pods

B4 B3 B2 B1 Clocks Drop Pods

J↕

J↕+K

No

State

E2444A 80386DX PI386_04 -- P5 P4 P3 . P2 P1 J No

Inverse Assembler Labels: P1=DATA.clk P2=DATA P3=ADDR P4=ADDR P5=STAT

2–15

Probing

Table 2-3 (continued)

Two-card HP16550A configuration loaded into multi-card HP 16557D (or single-card HP 16550 which

requires more than four pods for inverse assembly)

16550A

HP Model Processor

E2448A 68360 C68360_0 P6 P5 P4 P3 . P2 P1 J No

Inverse Assembler Labels: P1=STAT.clk P2=STAT P3=DATA P4=DATA P5=ADDR P6=ADDR

E2448A 68360 C68360_4 . P4 P3 P6 P5 P2 P1 J+L,K No

Inverse Assembler Labels:

P1=STAT.master_clk P2=STAT.slave_clk P3=DATA P4=DATA P5=ADDR.master_clk P6=ADDR

E2457A P54C CP54C_2 P6 P5 P4 P3 P8 P7 P2 P1 (J)*(K=0) State

P9, P10

Inverse Assembler Labels:

P1=STAT.clk P2=S TAT.clk P3=ADDR P4=ADDR P5=DA TA P6=DATA P7=DATA_B P8=DATA_B

Config

Filename

^ Asynch ronous Operation

^Synchronous Operation

Expansion

Card Pods

A4 A3 A2 A1

Master Card

Pods

B4 B3 B2 B1 Clocks Drop Pods

2–16

Probing

General-Purpose Probing System Description

General-Purpose Probing System Description

The standard probing system provided with the logic analyzer consists of a

probe tip assembly, probe cable, and grabbers. Because of the passive design

of the probes, there are no active circuits at the outer end of the cable.

The passive probing system is similar to the probing system used with

high-frequency oscilloscopes. It consists of a series RC network (90 kΩ in

parallel with 8 pF) at the probe tip, and a shielded resistive transmission line.

The advantages of this system include the following:

250 Ω in series with 8-pF input capacitance at the probe tip for minimal

•

loading.

Signal ground at the probe tip for higher speed timing signals.

•

Inexpensive removable probe tip assemblies.

•

Probe Tip Assemblies

Probe tip assemblies allow you to connect the logic analyzer directly to the

target system. This general-purpose probing is useful for discrete digital

circuits. Each probe tip assembly, or pod, contains 16 probe leads (data

channels), one clock lead, a pod ground lead, and a ground tap for each of

the 16 probe leads.

Probe Tip Assembly

2–17

Probing

General-Purpose Probing System Description

Probe and Pod Grounding

Each pod is grounded by a long black pod ground lead. You can connect the

ground lead directly to a ground pin on your target system or use a grabber.

To connect the ground lead directly to grounded pins on your target system,

you must use 0.63 mm (0.025 in) square pins, or use round pins with a

diameter of 0.66 mm (0.026 in) to 0.84 mm (0.033 in). The pod ground lead

should always be used.

Each probe can be individually grounded with a short black extension lead

that connects to the probe tip socket. You can then use a grabber or the

grounded pins on your target system in the same way you connect the data

lines.

When probing signals with rise and fall times of 1 ns, grounding each probe

lead with the 2-inch ground lead is recommended. In addition, always use

the probe ground on a clock probe.

Probe ground lead

Probe Grounds

2–18

Probe lead connector

Probing

General-Purpose Probing System Description

Probe Leads

The probe leads consists of a 12-inch twisted pair cable, a ground tap, and

one grabber. The probe lead, which connects to the target system, has an

integrated RC network with an input impedance of 100 kΩ in parallel with

approximately 8 pF, and all in series with 250 Ω.

The probe lead has a two-pin connector on one end that snaps into the probe

housing.

Probe Lead

Grabbers

The grabbers have a small hook that fits around the IC pins and component

leads. The grabbers have been designed to fit on adjacent IC pins on either

through-hole or surface-mount components with lead spacing greater than or

equal to 0.050 in.

2–19

CAUTION

WARNING

Probing

General-Purpose Probing System Description

Probe Cable

The probe cable contains 18 signal lines, 17 chassis ground lines, and two

power lines for preprocessor use. The cables are woven together into a flat

ribbon that is 4.5 feet long. The probe cable connects the logic analyzer to

the pods, termination adapter, HP 10269C General-Purpose Probe Interface,

or preprocessor. Each cable is capable of carrying 0.33 amps for

preprocessor power.

DO NOT exceed this 0.33 amps per cable or the cable will be damaged.

Preprocessor power is protected by a current limiting circuit. If the current

limiting circuit is activated, the fault condition must be removed. After the

fault condition is removed, the circuit will reset in one minute.

Minimum Signal Amplitude

Any signal line you intend to probe with the logic analyzer probes must

supply a minimum voltage swing of 500 mV to the probe tip. If you measure

signal lines with a voltage swing of less than 500 mV, you may not obtain a

reliable measurement.

Maximum Probe Input Voltage

The maximum input voltage of each logic analyzer probe is 40 volts peak.

Pod Thresholds

Logic analyzer pods have two preset thresholds and a user-definable

threshold. The two preset thresholds are ECL (– 1.3 V) and TTL (+1.5 V).

The user-definable threshold can be set anywhere between – 6.0 volts and

+6.0 volts in 0.05-volt increments.

All pod thresholds are set independently.

2–20

Probing

Assembling the Probing System

Assembling the Probing System

The general-purpose probing system components are assembled as shown

below to make a connection between the measured signal line and the pods

displayed in the Format menu.

Connecting Probe Cables to the Logic Analyzer

2–21

Probe tip assembly

Probing

Assembling the Probing System

Connecting Probe Cables to the Logic Analyzer

All probe cables are installed at Hewlett-Packard. If you need to replace a

probe cable, refer to the HP 16557D Logic Analyzer Service Guide,

available from your HP Sales Office.

Connecting the Probe Tip Assembly to the Probe Cable

To connect a probe tip assembly to a cable, align the key on the cable

connector with the slot on the probe housing and press them together.

Probe cable

Connecting Probe Tip Assembly

2–22

Probing

Assembling the Probing System

Disconnecting Probe Leads from Probe Tip Assemblies

When you receive the logic analyzer, the probe leads are already installed in

the probe tip assemblies. To keep unused probe leads out of your way during

a measurement, you can disconnect them from the pod.

To disconnect a probe, insert the tip of a ball-point pen into the latch

opening. Push on the latch while gently pulling the probe out of the pod

connector as shown in the figure below.

To connect the probes to the pods, insert the double pin end of the probe

into the probe housing. Both the double pin end of the probe and the probe

housing are keyed so they will fit together only one way.

Installing Probe Leads

2–23

Probing

Assembling the Probing System

Connecting the Grabbers to the Probes

Connect the grabbers to the probe leads by slipping the connector at the end

of the probe onto the recessed pin located in the side of the grabber. If you

need to use grabbers for either the pod or the probe grounds, connect the

grabbers to the ground leads in the same manner.

Connecting Grabbers to Probes

Connecting the Grabbers to the Test Points

The grabbers have a hook that fits around the IC pins and component leads.

Connect the grabber to the test point by pushing the rear of the grabber to

expose the hook. Hook the lead and release your thumb as shown.

Connecting Grabbers to Test Points

2–24

Connecting the External Reference Clock

Connecting the External Reference Clock

The external reference clock synchronizes deep-memory logic analyzer

modules. Within a module, the individual cards all share a common clock and

are thus automatically synchronized. However, each module clock is

accurate only to 100 parts per million. So, two deep-memory logic analyzers

with identical settings may capture their trigger at the same time but show

discrepancies in the final sample. Sharing an external reference clock

prevents this.

To Connect the External Reference Clock

You can either supply your own external reference clock, or choose one of

the logic analyzer modules to supply the clock signal. Either method keeps

all connected modules synchronized.

If you are supplying the clock signal, connect it to the "reference

1

clock in" of the master card of the top module.

Probing

CAUTION

The Reference Clock field lets you specify whether to use the internal clock

provided on the card, or an external clock. If you select the external clock,

you must connect a clock signal to the card using the Reference Clock In/Out

ports on the back of the analyzer.

Do not exceed 1 V, peak-to-peak, at a maximum voltage offset of 20 V on the

Reference Clock In/Out ports.

2 Cable the top module’s "reference clock out" to the "reference clock

in" of the master card of the next module.

3 Continue connecting the modules in this manner.

2–25

Probing

Connecting the External Reference Clock

Connecting the External Reference Clock

Note that only the master card of a module should be connected. Connecting

the clocks of the expander cards will not synchronize the module. Any

number of modules may be synchronized together. Any modules that have

external reference clock ports may be connected together.

2–26

3

The Configuration Menu

The Configuration Menu

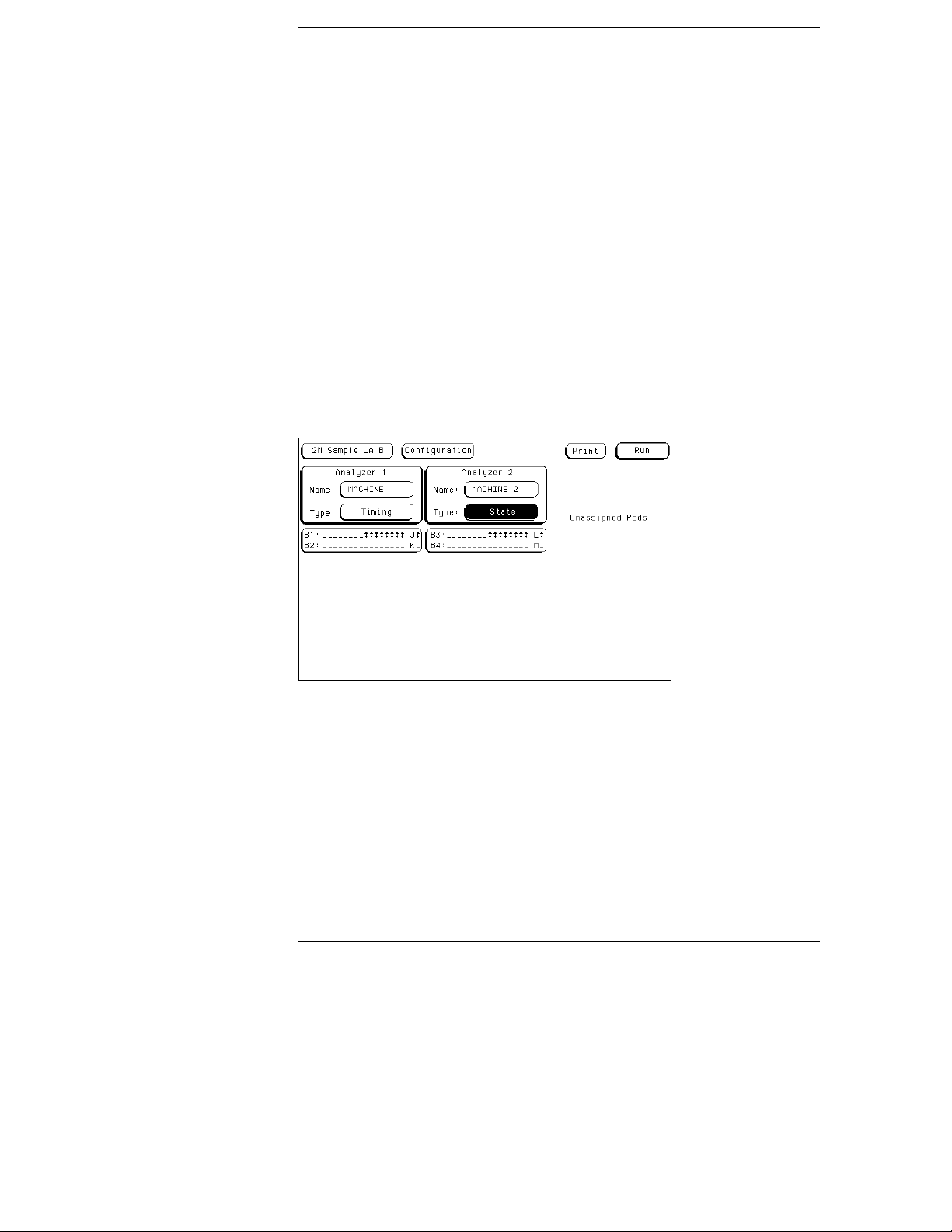

The Configuration menu allows you to set module level parameters.

You can partition the module into one or two independent analyzers.

You can also assign pods to either analyzer, select the type of clocking

needed (state or timing), and provide names for each analyzer.

The fields on this menu are:

• Analyzer Name Field

• Analyzer Type Field

• Pod Fields

• Activity Indicators

Configuration Menu

3–2

Name field

Keypad pop-up

appears when you

select the name

field.

The Configurat ion Menu

Analyzer Name Field

Analyzer Name Field

The Name field lets you assign a specific name to the analyzer machine. Use

the pop-up alphanumeric keypad to enter the name. When you have stored

several configurations to disk and later reload them, having assigned a

specific name to an analyzer can help identify the measurement setup.

Name Field

3–3

The Configuration Menu

Analyzer Type Field

Analyzer Type Field

The Type field allows you to configure each analyzer as either a state or

timing analyzer. When the Type field is selected, the following choices are

available.

Off

•

Timing

•

State

•

State Compare

•

SPA

•

Timing

When you select Timing, the analyzer uses its own internal clock to clock

measurement data into the acquisition memory. This clock is asynchronous

to the signals in the target system. When this option is selected, some fields

specific to external clocks will not appear in the analyzer menus.

You can configure the machine with only one timing analyzer. If you select

both analyzers as timing analyzers, the first will be turned off.

State

When you select State, the analyzer uses a clock from the system under test

to clock measurement data into acquisition memory. This clock is

synchronous with the signals in the target system. You can configure both

analyzers as state analyzers. State mode does not allow you to access the

Compare menu.

State Compare

When State Compare is selected, the Compare menu is available in the main

menu selection. For more details on Compare, see chapter 9, "The Compare

Menu." State Compare mode functions much like State mode, except that

total memory is reduced by one-fourth.

3–4

Type field

Type pop-up menu

The Configurat ion Menu

Analyzer Type Field

SPA

SPA stands for System Performance Analysis. It uses an external clock like a

state analyzer but measures overall system performance rather than

recording discrete activity. For more details, see Chapter 11.

Type Field

3–5

The Configuration Menu

Pod Fields

Pod Fields

The list of unassigned pods in the Configuration menu shows the available

pods for the module configuration. Pod grouping and assignment is by pod

pairs. When you want to assign a pod pair to an analyzer, touch the pod field.

From the assignment menu, select a destination for the pod pair. Use the

same procedure to reassign pod pairs that have previously been assigned to

an analyzer.

Pod field

Unassigned Po ds Display

3–6

Pod assignment

pop-up menu

The Configurat ion Menu

Pod Fields

When both analyzers are turned on, the pods of the master card cannot be

assigned to the same analyzer. If you attempt to assign them to the same

analyzer, you’ll get an error message when you try to exit the configuration

menu. The error message gives an explanation of the problem and provides

selection fields with options for reassigning one of the pod pairs.

Pod Reassignment Menu

3–7

The Configuration Menu

Activity Indicators

Activity Indicators

Within each pod pair you’ll notice activity indicators for each bit of each pod.

These indicators appear in two places. One is in the pod pair displays of this

Configuration menu. The other place is in the bit reference line in the

Format menu just above the pod bit numbers.

When the logic analyzer is properly connected to an active target system,

you’ll see either a high-level dash, a low-level dash, or a transitional arrow in

the Activity Indicator displays for each pod pair. These indicators are very

useful in showing proper probe connections and that the logic levels are as

expected.

See Also The "Bit Assignment Fields" in chapter 4, "The Format Menu," for more

information on the activity indicators.

Activity Indicators

3–8

4

The Format Menu

The Format Menu

Use the Format menu to select which data channels are measured and

to set up the clocking arrangement to capture valid data. It allows you

to group and label the data channels from the system under test to fit

your particular measurement. In addition, for your convenience in

recognizing bit groupings, you can specify symbols to represent them.

If the analyzer is configured as a state analyzer, there are master and

slave clocks, clock qualifiers, and a variable clock setup and hold to

further qualify what data is captured. In addition, you can set

individual pod clock threshold levels. The Format menu contains the

following fields:

• State Acquisition Mode Field (State, State Compare, and SPA only)

• Timing Acquisition Mode Field (Timing only)

• Data on Clocks Display

• Pod Field

• Pod Clock Field (State only)

• Master and Slave Clock Field (State only)

• Setup/Hold Field (State only)

• Symbols Field

• Label Assignment Field

• Rolling Labels and Pods Field

• Label Polarity Fields

• Bit Assignment Fields

• Pod Threshold Field

4–2

The Format Menu

State Acquisition Mode Field (State, State Compare, and SPA only)

State Acquisition Mode Field (State, State Compare,

and SPA only)

The State Acquisition Mode field identifies the speed and memory depth of

the acquisition mode. In four or five-card systems, speed is reduced to 100

MHz. In State Compare mode, some memory depth is used for information

needed to perform a comparison.

135 MHz [100 MHz]/2M State

The State Acquisition Mode uses both pods in a pod pair. If time or state tags

are turned on, the total memory is split between data acquisition storage and

time or state tag storage. To maintain the full 2M per channel depth, leave

one pod pair unassigned. State clock speed is 135 MHz [100 MHz for four or

five-card configurations].

Acquisition mode field

Acquisition Mode Field

4–3

The Format Menu

Timing Acquisition Mode Field (Timing only)

Timing Acquisition Mode Field (Timing only)

The Timing Acquisition Mode field displays the acquisition type, the channel

width, and sampling speed of the present acquisition mode. In timing

acquisition mode, the analyzer stores measurement data at each sampling

interval. Use the Timing Acquisition Mode field to access an acquisition mode

selection menu.

2M Sample Full Channel 250MHz

The total memory depth is 2M, with data being sampled and stored at most

every 4 ns.

4M Sample Half Channel 500MHz

The total memory depth is 4M, with data being sampled and stored at most

every 2 ns.

4–4

The Format Menu

Data on Clocks Display

Data on Clocks Display

This display shows the clock input channels available for the present

configuration. There are four clock input channels (J, K, L, and M) for each

card of a module, one for each pod. This display shows only the clock input

channels for those pods that are assigned in the present configuration.

A single-card module has four clock input channels, each of which may be

used as a state clock (when the machine is configured for state mode) or as a

data channel (in either state or timing modes). In a multi-card module, only

the four clock input channels connected to the Clock Master card of the

module are available for use as state clocks, but all of the clock input

channels of the module (there are four for each card in the module) may be

used as data channels. A clock input channel, when used as a data channel,

is treated as an ordinary data channel, except it cannot be included in a

Range resource.

In the display panel, the clock input channels of the Clock Master card are

grouped on the right, underneath the slot letter of the Clock Master card,

with the clock input channels of the other cards displayed to the left of those

of the Clock master card. If any clock input channel is used as a data

channel, that bit must be assigned. Activity indicators above the clock

identifier show signal activity on that clock input channel.

Data on Clocks

display

Data on Clocks Display

4–5

The Format Menu

Pod Field

Pod Field

The Pod field identifies which pod of a pod pair is affected by the settings of

the bit assignment field, pod threshold field, and pod clock fields. In the

full-channel modes, this field is simply an identifier and is not selectable.

However, in the half-channel mode, the Pod field turns dark, which means it

is selectable. In the half-channel mode, one pod of a pod pair is selectable

and all pod settings affect the selected pod.

Pod clock field

Pod field

Pod Field

4–6

The Format Menu

Pod Clock Field (State only)

Pod Clock Field (State only)

There is one Pod Clock field for each pod in the machine, and it is used to

indicate whether that pod’s data lines are to be strobed into memory by the

Master clock, Slave clock, or both, in the Demultiplex mode of operation.

When the Pod Clock field is selected, a clock menu appears with the

following choices:

Master

•

Slave

•

Demultiplex

•

The Master and Slave clock events are specified in the Master and Slave clock

fields. These clock functions are available only in a state analyzer.

See Also The "Master and Slave Clock Field" later in this chapter for information about

configuring a clocking arrangement.

Pod Clock Field

4–7

The Format Menu

Pod Clock Field (State only)

Master

This option specifies that data on all pods designated "Master Clock," in a

single analyzer, are strobed into memory when the status of the clock lines

matches the clocking arrangement specified under the Master Clock.

Slave

This option specifies that data on a pod designated "Slave Clock" is latched

when the status of the state clock inputs meets the requirements of the slave

clocking arrangement. Then, followed by a match of the master clock and

the master clock arrangement, the slave data is strobed into analyzer memory

along with the master data. If multiple slave clocks occur between master

clocks, only the data latched by the last slave clock prior to the master clock

is strobed into analyzer memory.

Analyzer Memory

latches on Master Clock

latches on

Slave Clock

Data on Master

Latching Slave Data

Slave Latch

Data on Slave

4–8

The Format Menu

Pod Clock Field (State only)

Demultiplex

The Demultiplex mode is used to store two different sets of data that occur at

different times on the same channels. In Demultiplex mode, only one pod of

the pod pair is used, and that pod is selectable. Both the master and slave

clocks are used in the Demultiplex mode. Channel assignments are displayed

as Demux Master and Demux Slave. For easy recognition of the two sets of

data, assign slave and master data to separate labels.

Demultiplex Clocking Mode

4–9

The Format Menu

Pod Clock Field (State only)

When the analyzer sees a match between the state clock inputs and the slave

clock specification, Demux Slave data is latched. Then, followed by a match

of the state clocks and the master clock specification, the slave data is

strobed into analyzer memory along with the master data. If multiple slave

clocks occur between master clocks, only the data latched by the last slave

clock prior to the master clock is strobed into analyzer memory.

Analyzer Memory

latches on Master Clock

latches on

Slave Clock

Same pod

Data on Master

Latching Slave Data in Demultiplex Mode

Slave Latch

Data on Slave

4–10

The Format Menu

Pod Threshold Field

Pod Threshold Field

Use the Pod Threshold field to set a voltage level the data must reach before

the analyzer recognizes and displays it as a change in logic levels. You specify

a threshold level for each pod. The level specified for each pod is also

assigned to the pod’s clock threshold. When the Pod Threshold field is

touched, a threshold selection pop-up menu appears with the following

choices:

TTL

When TTL is selected as the threshold level, the data signals must reach +1.5

volts.

ECL

When ECL is selected as the threshold level, the data signals must reach –1.3

volts.

Pod threshold field

Pod threshold pop-up

menu

USER

When USER is selected as the threshold level, the data signals must reach a

user selectable value between –6.0 volts to +6.0 volts.

Pod Threshold Field

4–11

The Format Menu

Master and Slave Clock Fields (State only)

Master and Slave Clock Fields (State only)

The Master and Slave Clock fields are used to construct a clocking

arrangement. A clocking arrangement is the assignment of appropriate

clocks, clock edges, and clock qualifier levels which allow the analyzer to

synchronize itself on valid data.

When the Master or Slave Clock field is selected, a clock/qualifier selection

menu appears showing the available clocks and qualifiers for a clocking

arrangement. There are four clocks available (J, K, L, M), and four clock

qualifiers available (Q1 through Q4).

A single-card module can use any of its four clocks as a state clock for

specifying Master and Slave clocking arrangements. For a multi-card module,

only the four clocks of the Clock Master board are available for use as state

clocks. Any unassigned clocks may be used as data channels.

See Also The "Pod Clock Field" earlier in this chapter for information on selecting

clocking arrangement types such as Master, Slave, or Demultiplex.

Master Clock Field

4–12

Master Clock field

The Format Menu

Master and Slave Clock Fields ( State only)

All combinations of the J and K clock and Q1 and Q2 qualifiers are ORed to

the clock combinations of the L and M clocks and Q3 and Q4 qualifiers. Clock

edges are ORed to clock edges, clock qualifiers are ANDed to clock edges,

and clock qualifiers can be either ANDed or ORed together. The clock

threshold level is the same as the level assigned in the Pod Threshold field.

Clock Edges and Levels

4–13

The Format Menu

Setup/Hold Field (State only)

Setup/Hold Field (State only)

Setup/Hold adjusts the relative position (in time) of the clock edge with

respect to the time period that data is valid. When the Setup/Hold field is

selected, a configuration menu appears. Use this Setup/Hold configuration

menu to select each pod in the analyzer and assign a Setup/Hold selection

from the selection list.

With a single clock edge assigned, the choices range from 3.0 ns Setup/0.0 ns

Hold to -0.5 ns Setup/3.5 ns Hold. With both edges of a single clock assigned,

the choices are from 3.5 ns Setup/0.0 ns Hold to -0.5 ns Setup/4.0 ns Hold. If

the analyzer has multiple clock edges assigned, the choices range from 4.0 ns

Setup/0.0 ns Hold to -0.5 ns Setup/4.5 ns Hold.

Setup and Hold Menu

4–14

The Format Menu

Setup/Hold Field (State only)

The relationship of the clock signal and valid data under the default setup

and hold is shown below.

Default Setup and Hold

If the relationship of the clock signal and valid data is such that the data is

valid for 1 ns before the clock occurs and 3 ns after the clock occurs, you

could use 1.0/2.0 or 0.5/2.5 or 0.0/3.0, but 0.5/2.5 would be the best choice.

Clock Position in Valid Data

4–15

The Format Menu

Symbols Field

Symbols Field

See Also Symbols Assignment in "Common Module Operations" in the HP 16500C

User’s Reference for complete information on using symbols.

Label Assignment Fields

See Also Labels Assignment in "Common Module Operations" in the HP 16500C

User’s Reference for complete information on using labels.

Rolling Labels and Pods

The rolling function is the same for all items that are stored offscreen.

See Also Labels Assignment in "Common Module Operations" in the HP 16500C

User’s Reference for complete information about rolling labels and pods.

4–16

The Format Menu

Label Polarity Fields

Label Polarity Fields

Use the Label Polarity fields to assign a polarity to each label. The default

polarity for all labels is positive ( + ). Change the label polarity by touching

the polarity field. This toggles between positive ( + ) and negative ( – )

polarity.

When the polarity is inverted, all data, as well as bit pattern specific

configurations used for identifying, triggering, or storing data, reflect the

change of polarity. In a timing analyzer with the data inverted, the waveform

display does not change.

Polarity field

Polarity Field

4–17

The Format Menu

Bit Assignment Fields

Bit Assignment Fields

The bit assignment fields are used to assign bits (channels) to labels. The

convention for bit assignment is as follows:

* (asterisk) indicates an assigned bit.

•

. (period) indicates an unassigned bit.

•

To change a bit assignment, select the bit assignment field and, using the

knob, move the cursor to the bit you want to change, then select an asterisk

or a period. When the bits are assigned as desired and you close the pop-up

menu, the screen displays the new bit assignment.

See Also "Activity Indicators" in chapter 3, "The Configuration Menu," for more

information on the bit reference line and the activity indicators on the bit

reference line.

Bit assignment field

Bit Assignment Field

4–18

The Format Menu

Bit Assignment Fields

Labels may have from 1 to 32 channels assigned to them. If you try to assign

more than 32 channels to a label, the logic analyzer will beep and a message

will appear at the top of the screen telling you that 32 channels per label is

the maximum. Channels assigned to a label are numbered from right to left,

with the least significant bit on the far right, numbered 0.

Although labels can contain split fields, assigned channels are always

numbered consecutively within a label.

Bit Assignment Example

4–19

4–20

5

The Trigger Menu

The Trigger Menu

The Trigger menu is used to specify when the analyzer triggers and

what the analyzer stores in acquisition memory. The Trigger menu

can be viewed as having four functionally different sections:

• Automatic Sequence Levels, located in the large light blue center

box

• Manual Sequence Levels, also located in the large light blue center

box

• Resource Terms, located at the bottom of the menu

• Control Fields, located at the right side of the display

The Trigger Menu

5–2

Predefined Trigger Macros

The state and timing acquisition modes each have a macro library

containing predefined trigger macros. Each macro will require at least

one sequence level, and in some cases, several levels. Macros can be

branched to by combining a user-defined level with a macro level. To

use these predefined trigger macros, see "Using Macros to Create a

Trigger Specification" on the next page. The macro libraries are as

follows:

Timing Trigger Macro Library:

• User Mode (user-defined macro)

• Basic Macros

• Pattern/Edge Combination Macros

• Time Violation Macros

• Delay Macros

State Trigger Macro Library:

• User Mode (user-defined macro)

• Basic Macros

• Sequence Dependent Macros

• Time Violation Macros

• Delay Macros

5–3

The Trigger Menu

Using Macros to Create a Trigge r Specification

1. From the Trigger menu, enter the desired sequence level by selecting the

Modify Trigger field or by selecting a sequence level number.

See Also "Modify Trigger Field" for information on accessing levels.

2. From within the sequence level, select the Select New Macro field

3. Scroll to highlight the macro you want, then select the Done field.

4. Select the appropriate assignment fields and insert the desired predefined

resource terms, numeric values, and other parameter fields required by the

macro. Select the Done field.

See Also "Resource Terms" for information on using predefined resource terms.

5–4

Timing Trigger Macro Library

The following list contains the macros in the Timing Trigger Macro Library.

They are listed in the order in which they appear on the screen.

User Mode User level - custom combinations, branching

The User level lets you manually design a sequence level. It uses one internal

sequence level.

Basic Macros 1. Find anystate n times

This macro becomes true with the nth state it sees. It uses one internal

sequence level.

2. Find pattern present/absent for > duration

This macro becomes true when it finds a pattern you have designated that

has been present or absent for greater than or equal to the set duration. It

uses one internal sequence level.

The Trigger Menu

Timing Trigger Macro Library

3. Find pattern present/absent for < duration

This macro becomes true when it finds a pattern you have designated that

has been present or absent for less than the set duration. It uses four or five

internal sequence levels.

4. Find edge

This macro becomes true when the edge you have designated is seen. It uses

one internal sequence level.

5. Find Nth occurrence of an edge

This macro becomes true when it finds the occurrence of an edge you have

designated. It uses one internal sequence level. The 500-MHz trigger

sequencer may not count edges captured closer than 2 ns apart.

5–5

The Trigger Menu

Timing Trigger Macro Library

Pattern/Edge

Combinations

Time Violations 1. Find 2 edges too close together

1. Find edge within a valid pattern

This macro becomes true when a selected edge type is seen within the time

window defined by a pattern you have designated. It uses one internal

sequence level.

2. Find pattern occurring too soon after edge

This macro becomes true when a pattern you have designated is seen

occurring within a set duration after a selected edge type is seen. It uses

three or four internal sequence levels.

3. Find pattern occurring too late after edge

This macro becomes true when one edge type you have selected occurs and,

for a designated period after that first edge is seen, a pattern is not seen. It

uses two internal sequence levels.

This macro becomes true when a second selected edge is seen occurring

within a period you have designated after the occurrence of a first selected

edge. It uses three or four internal sequence levels.

2. Find 2 edges too far apart

This macro becomes true when a second selected edge occurs beyond a

period you have designated after the first selected edge. It uses two internal

sequence levels.

3. Find width violations on a pattern/pulse

This macro becomes true when the width of a pattern violates minimum and

maximum width settings you have designated. It uses four or five internal

sequence levels.

Delay 1. Wait t sec

This macro becomes true after a period you have designated has expired. It

uses one internal sequence level.

5–6

State Trigger Macro Library

The following list contains the macros in the State Trigger Macro Library.

They are listed in the order in which they appear on the screen.

User Mode User Level - custom combinations, loops

The User level lets you manually design a sequence level. It uses one internal

sequence level.

Basic Macros 1. Find anystate n times

This macro becomes true with the nth state it sees. It uses one internal

sequence level.

2. Find event n times

This macro becomes true when it sees an event you have specified occurring

a designated number of times. The events may occur consecutively, but does

not have to. It uses one internal sequence level.

The Trigger Menu

State Trigger Macro Library

Sequence

Dependent Macros

3. Find event n consecutive times

This macro becomes true when it sees an event you have specified occurring

a designated number of consecutive times. It uses one internal sequence

level.

4. Find event2 immediately following event1

This macro becomes true when the first event you have specified is seen

immediately followed by a second designated event. It uses two internal

sequence levels.

1. Find event2 n times after event1, before event3 occurs

This macro becomes true when it first finds a designated event1, followed by

a selected number of occurrences of a designated event2. In addition, if a

designated event3 is seen anytime while the sequence is not yet true, the

sequence starts over. If event2’s nth occurrence is coincident with event3,

the sequence starts over. It uses two internal sequence levels.

5–7

The Trigger Menu

State Trigger Macro Library

2. Find too few states between event1 and event2

This macro becomes true when a designated event1 is seen, followed by a

designated event2, and with less than a selected number of states occurring

between the two events. It uses three or four internal sequence levels.

3. Find too many states between event1 and event2

This macro becomes true when a designated event1 is seen, followed by more

than a selected number of states, before a designated event2. It uses two

internal sequence levels.

4. Find n-bit serial pattern

This macro becomes true when a specified serial pattern of n bits is found.

Time Violations 1. Find event2 occurring too soon after event1

This macro becomes true when a designated event1 is seen, followed by a

designated event2, and with less than a selected period occurring between

the two events. It uses two internal sequence levels.

2. Find event2 occurring too late after event1

This macro becomes true when a designated event1 is seen, followed by at

least a selected period, before a designated event2 occurs. It uses two

internal sequence levels.

Delay 1. Wait n external clock states

This macro becomes true after a number of user clock states you have

designated has occurred. It uses one internal sequence level.

5–8

Sequence Levels

The Sequence Levels section controls when the analyzer triggers,

what the analyzer triggers on, and what data is stored in memory

before and after triggering occurs. By using sequence levels, you

create a sequence of instructions for the analyzer to follow. The

instructions contain user-defined resource terms representing such

things as timers, ranges, edges, and bit patterns.

As the resource terms are evaluated and acted upon by the analyzer,

all subsequent branching and storing within the sequence flow is

directed by your instructions. The path taken resembles a flow chart,

and the end result is the storage of only the data you need.

The state analyzer has 12 sequence levels available. The timing

analyzer has 10 sequence levels available.

5–9

The Trigger Menu

Sequence Level Number Field

Sequence Level Number Field

The Sequence Level Number field identifies an instruction to be evaluated by

the analyzer. In addition, use the number field to access the Sequence

Instruction menu, which allows you to define the automated trigger macros

and to manually construct sequence instructions.

The sequence instruction for each level is displayed in text and located just

to the right of the level number. The timer status in each level is also

displayed to the right of the instruction text.

Sequence Level Roll Field

The field rolls offscreen sequence levels back on screen by using the knob

when the Sequence Levels field is light blue. If the field is dark blue, select it,

turning it light blue.

Sequence Level Roll field

Sequence Level Number

field

Sequence Level Number

5–10

The Trigger Menu

Sequence Instruction Menu

Sequence Instruction Menu

When a Sequence Level Number field is selected, a Sequence Instruction

menu appears. Use this menu to create instructions for the Sequence Level

Number, to insert adjacent sequence levels, select a new macro, or to delete

the current level. The instruction you create will read like a sentence, with

the assigned resource terms directing how the analyzer qualifies and stores

the desired data. This Sequence Instruction Menu contains the following

fields to help you set up trigger conditions:

Insert Level and Delete Level Fields

•

Select New Macro field

•

Term assignment fields

•

Occurrence counter fields

•

Branching fields

•

Duration counter field (Timing only)

•

Timer Control field

•

Insert Level and Delete Level Fields

The Insert Level field is used to add another sequence level. When this field

is selected, depending on the analyzer configuration, you are given choices to

add a field before or after the current sequence level. A message appears

letting you know when all available sequence levels are inserted. The Delete

Level field is used to delete a selected sequence level.

See Also "Resource Term Fields" later in this chapter for information on assigning a

value to the Resource Terms.

Select New Macro Field

The Select New Macro field brings up a list of triggers that have been built

with predefined macros. There are separate libraries of predefined triggers

for State and Timing acquisition.

See Also "Predefined Trigger Macros" in this chapter for more information on

predefined trigger macros.

5–11

The Trigger Menu

Sequence Instruction Menu

Term Assignment Fields

The Term Assignment fields hold user-defined bit patterns, ranges, timers,

and logical combination resource terms. You can logically combine different

resource terms to form the kind of instruction needed to qualify the trigger

and store operations.

Occurrence Counter Field

The Occurrence Counter field indicates the number of times the analyzer

must see the resource term before it is allowed to advance to the next

sequence level. To assign an occurrence number, simply turn the knob, or

select the Occurrence Counter field and use the keypad that appears. The

maximum number of occurrences is 1048575. If the "Else on" term is seen

before all specified occurrences have taken place, the flow of the sequence

instruction goes to the sequence level designated in the Branching field.

See Also For information on selecting resource term choices and how to assign a value

to a resource term, refer to the term types, such as bit pattern, range, or

timers in this chapter.

Term assignment field

Occurrence Coun ter Field

5–12

The Trigger Menu

Sequence Instruction Menu

Branching Field

Each sequence level has two-way branching. If the first resource term is

found, the branch is to the next sequence level. If the first resource term is

not found, the analyzer evaluates the "Else on" secondary branching term.

If the "Else on" term is found, the secondary branch taken is to the

designated sequence level in the Branching field. If the "Else on" term is not

found, the analyzer continues to loop within the sequence level until one of

the two branches is found. If the "Else on" branch is taken, the occurrence

counter is reset even if the "go to level" branch is to the same level.

If both terms are found at the same time, the branch is to the next sequence

level after the required number of first term occurrences.

Branching across trigger levels is possible. If this occurs, the sequence level