User’s Guide

Agilent 16442A Test Fixture

Agilent Part No. 16442-90000

Printed in Japan January 2000

Edition 3

Legal Notice

The information contained in this document is subject to change without notice.

Copyright © 1994 - 2000 Agilent Technologies

This document contains information which is protected by copyright. All rights are

reserved. Reproduction, adaptation, or translation without prior written permission

is prohibited, except as allowed under the copyright laws.

• Product Warranty

Agilent Technologies warrant Agilent Technologies hardware, accessories and

supplies against defects in materials and workmanship for the period of one year

from the warranty start date specified below. If Agilent Technologies receive

notice of such defects during the warranty period, Agilent Technologies will, at

its option, either repair or replace products which prove to be defective.

Replacement products may be either new or like-new.

Warranty service of this product will be performed at Agilent Technologies.

Buyer shall prepay shipping charges to Agilent Technologies and Agilent

Technologies shall pay shipping charges to return the product to Buyer.

However, Buyer shall pay all shipping charges, duties, and taxes for products

returned to Agilent Technologies from another country.

Agilent Technologies do not warrant that the operation of Agilent Technologies

products will be uninterrupted or error free. If Agilent is unable, within a

reasonable time, to repair or replace any product to a condition as warranted,

customer will be entitled to a refund of the purchase price upon prompt return of

the product.

The Agilent Technologies products may contain remanufactured parts

equivalent to new in performance or may have been subject to incidental use.

The warranty period begins on the date of delivery or on the date of installation

if installed by Agilent Technologies. If customer schedules or delays Agilent

Technologies installation more than 30 days after delivery, warranty begins on

the 31st day from delivery.

Warranty does not apply to defects resulting from (a) improper or inadequate

maintenance or calibration, (b) software, interfacing, parts or supplies not

supplied by Agilent Technologies, (c) unauthorized modification or misuse, (d)

operation outside of the published environmental specifications for the product,

or (e) improper site preparation or maintenance.

2 Agilent 16442A User’s Guide, Edition 3

To the extent allowed by local law, the above warranties are exclusive and no

other warranty or condition, whether written or oral, is expressed or implied and

Agilent Technologies specifically disclaim any implied warranties or conditions

of merchantability, satisfactory quality, and fitness for a particular purpose.

Agilent Technologies will be liable for damage to tangible property per incident

up to the greater of $300,000 or the actual amount paid for the product that is the

subject of the claim, and for damages for bodily injury or death, to the extent

that all such damages are determined by a court of competent jurisdiction to

have been directly caused by a defective Agilent Technologies product.

To the extent allowed by local law, the remedies in this warranty statement are

customer’s sole and exclusive remedies. Expect as indicated above, in no event

will Agilent Technologies or its suppliers be liable for loss of date or for direct,

special, incidental, consequential (including lost profit or date), or other damage,

whether based in contract, tort, or otherwise.

For consumer transactions in Australia and New Zealand: the warranty terms

contained in this statement, except to the extent lawfully permitted, do not

exclude, restrict or modify and are in addition to the mandatory statutory rights

applicable to the sale of this product to you.

• Assistance

Product maintenance agreements and other customer assistance agreements are

available for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales Office.

• Certification

Agilent Technologies Inc. certifies that this product met its published

specifications at the time of shipment from the factory. Agilent further certifies

that its calibration measurements are traceable to the National Institute of

Standards and Technology (NIST), to the extent allowed by the Institute’s

calibration facility, and to the calibration facilities of other International

Standards Organization members.

• Safety Summary

The following general safety precautions must be observed during all phases of

operation, service, and repair of this instrument. Failure to comply with these

precautions or with specific warnings elsewhere in this manual may impair the

protections provided by the equipment. In addition, it violates safety standards

of design, manufacture, and intended use of the instrument. Agilent

Technologies Inc. assumes no liability for customer’s failure to comply with

these requirements.

Agilent 16442A User’s Guide, Edition 3 3

• GROUND THE INSTRUMENT

This is Safety Class I instrument. To minimize shock hazard, the instrument

chassis and cabinet must be connected to an electrical ground. The power

terminal and the power cable must meet International Electrotechnical

Commission (IEC) safety standards.

• DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a

definite safety hazard.

• KEEP AWAY FROM LIVE CIRCUITS

Operation personnel must not remove instrument covers. Component

replacement and internal adjustments must be made by qualified

maintenance personnel. Do not replace components with power cable

connected. Under certain conditions, dangerous voltages may exist even

with the power cable removed. To avoid injuries, always disconnect power

and discharge circuits before touching them.

• DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another person, capable

of rendering first aid and resuscitation, is present.

• DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Because of the danger of introducing additional hazards, do not install

substitute parts or perform any unauthorized modification to the instrument.

Return the instrument to a Agilent Technologies Sales and Service Office for

services and repair to ensure that safety features are maintained.

• DANGEROUS PROCEDURE WARNINGS

Warnings, such as example below, precede potentially dangerous procedures

throughout this manual. Instructions contained in the warnings must be

followed.

WARNING Dangerous Voltage, capable of causing death, are present in this instrument.

Use extreme caution when handling, testing, and adjusting.

4 Agilent 16442A User’s Guide, Edition 3

• Safety Symbols

The general definitions of safety symbols used on equipment or in manuals are

listed below.

Instruction manual symbol: the product will be marked with this symbol when it

is necessary for the user to refer to the instruction manual in order to protect

against damage to the instrument.

Indicates dangerous voltage and potential for electrical shock. Do not touch

terminals that have this symbol when instrument is on.

Protective conductor terminal. For protection against electrical shock in case of

a fault. Used with field wiring terminals to indicate the terminal which must be

connected to ground before operating equipment.

Frame or chassis terminal. A connection to the frame (chassis) of the equipment

which normally includes all exposed metal structures.

Indicates earth (ground) terminal.

Alternating current.

Direct current.

ON (Supply).

OFF (Supply).

STANDBY (Supply).

CAT 1

Means INSTALLATION CATEGORY I. Measurement terminals on the rear

panel comply with INSTALLATION CATEGORY I.

WARNING The warning sign denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to, could result in

injury or death to personal.

CAUTION The caution sign denotes a hazard. It calls attention to an operating procedure,

practice, condition or the like, which, if not correctly performed or adhered to, could

result in damage to or destruction of part or all of the product.

Agilent 16442A User’s Guide, Edition 3 5

• Herstellerbescheinigung

GEÄUSCHEMISSION

Lpa < 70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 T. 19

• Manufacturer’s Declaration

ACOUSTIC NOISE EMISSION

Lpa < 70dB

operator position

normal operation

per ISO 7779

Printing History

Edition 1: February 1994

Edition 2: August 1997

Edition 3: January 2000

6 Agilent 16442A User’s Guide, Edition 3

User's Guide

Agilent 16442A User’s Guide, Edition 3

User's Guide

Agilent 16442A test fixture is designed for testing electronic devices. You mount

the suitable socket module on the 16442A, which allows you to easily connect

various devices (DUTs) to measurement units.

The 16442A has thirteen channels:

• 6 source/monitor unit (SMU) channels

Up to 3 channels can be connected to SMUs by Kelvin connections.

• 2 voltage source unit (VSU) channels

• 2 voltage monitor unit (VMU) channels

• 2 pulse generator unit (PGU) channels

• 1 ground unit (GNDU) channel

This manual provides the following information.

• Introduction

• Operation

• Installation

• Maintenance

• Specifications

2 Agilent 16442A User’s Guide, Edition 3

Introduction

Agilent 16442A test fixture contains the following accessories:

User's Guide

Introduction

Description

1 test fixture 16442-60001 1

2 stabilizer (with two flathead screws) 16442-60002 2

3 carrying case for socket modules 16442-60101 1

4 miniature banana to pin plug connection

cable (black)

5 miniature banana to pin plug connection

cable (red)

6 miniature banana to pin plug connection

cable (blue)

7 pin plug to pin plug connection cable

(black)

8 pin plug to pin plug connection cable (red) 16442-61604 3

Agilent 16442A User’s Guide, Edition 3 3

Agilent

Part Number

16442-61600 4

16442-61601 4

16442-61602 4

16442-61603 3

Quantity

User's Guide

Introduction

Description

Agilent

Part Number

9 pin plug to pin plug connection cable (blue) 16442-61605 3

10 miniature banana to miniature clip

16442-61606 3

connection cable (black)

11 miniature banana to miniature clip

16442-61607 3

connection cable (red)

12 miniature banana to miniature clip

16442-61608 3

connection cable (blue)

13 miniature banana to miniature banana

16442-61609 3

connection cable (black)

14 miniature banana to miniature banana

16442-61610 3

connection cable (red)

15 miniature banana to miniature banana

16442-61611 3

connection cable (blue)

16

blank Teflon

TM

board

16058-60004 1

17 dual-in-line package socket module (28-pin) 16088-60002 1

18 axial lead package socket module 16088-60009 1

Quantity

19 TO-package socket module (12-pin) 16088-60006 1

20 User's Guide (this document) 16442-90000 1

NOTE Inspecting the 16442A upon Receiving

When the 16442A arrives at your site, make sure that nothing is missing or

damaged. Unpack the carton, then check the contents against figure and table above.

(For details about furnished and optional accessories, refer to “Specifications”.)

If anything is missing or damaged, contact your nearest Agilent Technologies sales

office.

4 Agilent 16442A User’s Guide, Edition 3

User's Guide

Operation

Operation

This section is organized into the following two sections:

• Attaching a socket module onto the 16442A.

• Mounting and wiring DUT on the socket module.

Select the proper environment to execute the measurements. Place the 16442A on a

flat surface. The 16442A shields from electromagnetic interference, but Agilent

Technologies recommend that the measurement is performed in as noiseless

environment as possible for more stable and accurate measurement results.

You place the DUT into the provided socket modules in the 16442A, then measure

the dc characteristics by using the connected measurement units.

WARNING To prevent electric shock, be sure to connect the cable between the interlock

(Intlk) terminals of measurement instrument and the 16442A before

performing measurements.

WARNING Do not operate the 16442A while the High Voltage indicator is lit. Dangerous

voltages of up to 200 V may be present on the connection between measurement

units and DUT.

WARNING Do not get connection cables caught in the lid of the 16442A during

measurements. Dangerous voltage of up to 200 V may be present on the

connection cables.

CAUTION To prevent damage to instrument or DUT, do not remove or attach DUT in the

16442A when voltage or current is present.

CAUTION Do not touch any metal surface that is in the circuit path. Oil, perspiration, and dirt

prevent good electric contact and degrade measurement accuracy.

NOTE After setting up the 16442A and DUT, confirm that the connections are correct. Shut

lid of the 16442A to close switches of the interlock (Intlk) terminal.

Agilent 16442A User’s Guide, Edition 3 5

User's Guide

Operation

Circuit Schematic of the 16442A

The following figure shows the circuit schematic of the 16442A test fixture.

The 16442A is equipped with an interlock (Intlk) terminal, which prevents the user

from getting an electric shock during operation.

If more than 40 V will be forced to the 16442A, be sure to connect Intlk terminal of

the 16442A to Interlock terminal of measurement instrument using an

Interlock/LED cable (the 16493J option 001 for 1.5 m, the 16493J option 002 for

3.0 m).

When the lid of the 16442A is open, two switches of the Intlk terminal are open. The

instrument recognizes that the lid of the 16442A is not closed and does not output

high voltage (more than ±40 V).

6 Agilent 16442A User’s Guide, Edition 3

The following figure shows pin assignment of the Intlk terminal.

User's Guide

Operation

Agilent 16442A User’s Guide, Edition 3 7

User's Guide

Operation

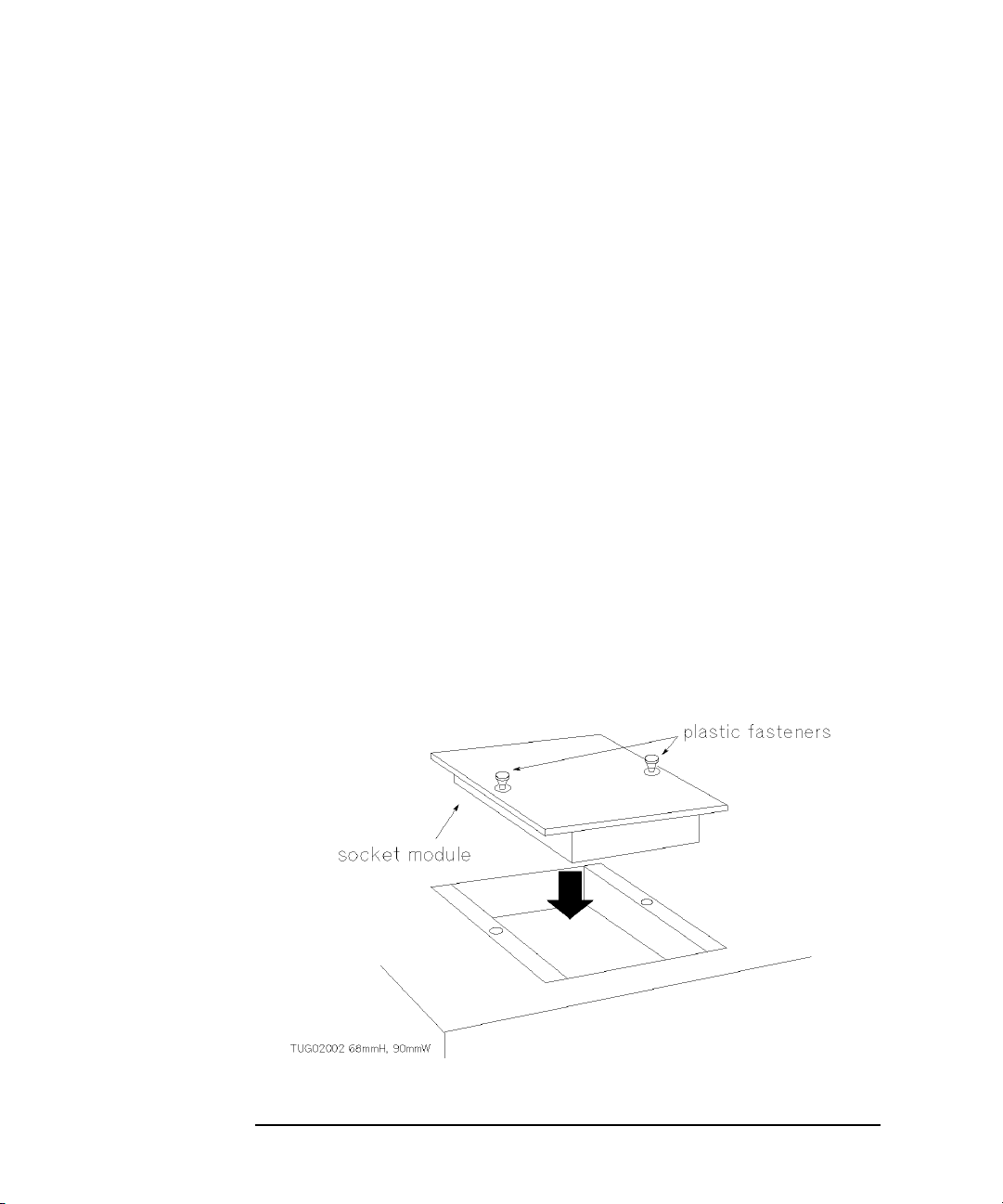

Attaching a Socket Module onto the 16442A

After choosing correct socket module for DUT, install the socket module into the

16442A. The following figure shows how to attach socket module to the 16442A.

Use the following procedure to attach the socket module:

1. Confirm that voltage or current is not forced to the 16442A.

2. Open the lid of the 16442A.

3. Check that the black plastic fasteners of the socket module are unlocked (pulled

up).

4. Push the socket module onto the 16442A.

5. Press the black fasteners down to lock the socket module into place.

Use the following procedure to remove a socket module from the 16442A:

1. Confirm that voltage or current is not forced to the 16442A.

2. Open the lid of the 16442A.

3. Disconnect the connection cables.

4. Pull up the black plastic fasteners on both sides of the socket module.

5. Lift the socket module from the 16442A.

8 Agilent 16442A User’s Guide, Edition 3

User's Guide

Operation

Mounting and Wiring the DUT on the Socket Module

Thirteen types of socket modules are available for mounting the DUTs:

• Three socket modules for power devices.

• Six socket modules for small signal devices.

• Three universal socket modules and a blank Teflon board module for uniquely

shaped devices.

Non-Kelvin Connections

Use connection cables to connect the FORCE terminals on the 16442A to the

FORCE terminals on the socket module.

Kelvin Connections

• Socket Modules for Power Devices

The three socket modules for power devices have separate FORCE and SENSE

terminals for Kelvin connections. As shown in the example in the following

figure, use miniature banana to miniature banana connection cables to connect

the FORCE and SENSE terminals of the 16442A to the FORCE and SENSE

terminals on the socket module.

Agilent 16442A User’s Guide, Edition 3 9

User's Guide

Operation

• Socket Modules for Small Signal Devices

The six socket modules for small signal devices have FORCE terminals only. Up

to 3 SMU channels can be connected to DUT by Kelvin Connection. As shown

in the example in the following figure, use miniature banana to pin plug

connection cables to connect both FORCE and SENSE terminals of the 16442A

to the FORCE terminal on the socket module as follows: insert one pin plug into

the FORCE terminal of the socket module, then insert the other pin plug into the

tail hole of the inserted pin plug.

To connect sense terminals as near as possible to the DUT, connect the SENSE

terminals of the 16442A directly to the DUT with the miniature banana to

miniature clip connection cables as shown in following figure.

10 Agilent 16442A User’s Guide, Edition 3

User's Guide

Operation

Connections for a Uniquely Shaped Device

If there is no socket module suitable for a uniquely shaped DUT, you can connect

the device by using the blank Teflon board or the universal socket module:

Blank Teflon Board

Connect all the terminals directly to the DUT on the blank Teflon board with the

miniature banana to miniature clip connection cables, as shown in the following

figure. Make sure to place the DUT on the blank Teflon board.

Universal Socket Module

The following figure shows an example of a universal socket module. You solder

the connection pins into the universal socket, then insert the pin plug of the

connection cable into the connection pin.

Note that hydrochloric acid residue deposited by solder may cause electrical

problems. Agilent Technologies recommend that you solder the wiring on the

universal board using low hydrochloric acid solder (Agilent part number:

8090-0433).

Do not use the universal socket module for low-current measurements (less than

1 nA) that require low leakage current.

Agilent 16442A User’s Guide, Edition 3 11

User's Guide

Installation

Installation

You can make the 16442A stable by installing stabilizers as shown in the following

figure.

1. Put a stabilizer on both sides of test fixture.

2. Screw a flathead screw into hole of each stabilizer.

After installing stabilizers, connect terminals on the rear panel to the desired

measurement units.

NOTE When you attach the 16442A to Agilent 16440A SMU/Pulse Generator Selector or

Agilent 16441A R-Box, you do not need to install stabilizers. For attaching to

selector or R-Box procedure, see the User's Guide for selector or R-Box.

12 Agilent 16442A User’s Guide, Edition 3

User's Guide

Maintenance

Maintenance

This section provides the following maintenance information:

• Cleaning

• Performing test

• Servicing

Cleaning the 16442A Test Fixture

To maintain high performance, the 16442A must be kept clean. Oil, perspiration,

hair, dust, and dirt degrade board insulation, which increases leakage current and

decreases measurement accuracy.

Agilent Technologies recommend the following cleaning procedure:

• Chassis, lid, inner plate, and socket modules:

1. Make sure that voltage or current is not forced to the 16442A.

2. Disconnect all cables from the 16442A.

3. Using lint-free paper, gently wipe the chassis, lid, inner plate, and socket

module. For any area that will not come clean, dip the lint-free paper into

alcohol and wipe the area gently.

• Connection cables:

1. Make sure that voltage or current is not forced to the 16442A.

2. Disconnect the connection cables from the 16442A.

3. Dip lint-free paper into alcohol and gently wipe the metal contacts of the

connection cables.

Agilent 16442A User’s Guide, Edition 3 13

User's Guide

Maintenance

Performing the Interlock Circuit Test

To confirm that interlock circuit test, do as follows:

1. Connect the Intlk terminal of Agilent 4155/4156 to your interlock circuit.

2. Press

3. In the CALIB/DIAG field, select DIAG secondary softkey.

4. In the CATEGORY field, select I/O PERIPH secondary softkey.

5. Move pointer to the 403 (INT.) Interlock LED field.

6. Select EXECUTE secondary softkey.

7. Confirm the following:

8. To stop the interlock test, select STOP secondary softkey.

System front-panel key, then select CALIB/DIAG primary softkey to

display the SYSTEM: SELF-CALIBRATION/DIAGNOSTICS page.

• LED turns on within 1 sec from when interlock circuit is shorted.

• LED turns off within 1 sec from when interlock circuit is open.

Servicing the Test Fixture

This section provides information for trained service personnel to repair the test

fixture.

“Replaceable Parts” provides the Agilent part numbers of replaceable parts. When a

part needs to be replaced, order the parts from the nearest Agilent Technologies

Sales and Service Office.

WARNING High voltages may be present in the test fixture when voltage or current is

added to the test fixture. Dangerous voltage may be generated on wires or parts

and the danger of electric shock exists.

14 Agilent 16442A User’s Guide, Edition 3

User's Guide

Maintenance

Make sure that terminals are not connected to the instruments before you repair the

test fixture. When you remove the bottom cover, loosen the four flathead screws

using a screwdriver, as shown in the following figure.

When wiring the test fixture and socket modules, use low hydrochloric acid solder

(Agilent part number: 8090-0433) to prevent the flux in the solder from spreading

unnecessarily. When soldering, make sure the terminals do not make contact with

each other. After soldering, make sure that there are no lint bridges so that leakage

current is minimal.

Keep the following items in mind when repairing socket modules:

• Place a ferrite bead at the 8 mm point of the terminal on the socket side and fix

the bead using epoxy adhesive.

• Never allow the ferrite beads to make contact with each other.

• For the three socket modules used for power devices, wrap the contact of the

wire and socket terminal using heat-shrink tube (Agilent part number:

0890-1496).

Agilent 16442A User’s Guide, Edition 3 15

User's Guide

Maintenance

Replaceable Parts

16 Agilent 16442A User’s Guide, Edition 3

User's Guide

Maintenance

Reference

Designation

(1) 3101-3241 2 Sense Switch

(2) 1450-0641 1 LED

(3) 8150-0459 40cm´1 Wire 24 White/Red

(4) 8150-0460 40cm´2 Wire 24 White/Orange

(5) 0535-0031 4 Nut

(6) 8150-4684 32cm´1 Wire 24 Orange

(7) 8150-4682 32cm´1 Wire 24 Brown

(8) 8150-4683 32cm´1 Wire 24 Red

(9) 8150-4685 32cm´1 Wire 24 Yellow

(10) 8120-0102 22cm´2, 15cm´6 Coaxial Cable 50 W

(11) 8150-0462 40cm´1 Wire 24 White/Green

(12) 8150-0458 30cm´8 Wire 24 White/Brown

(13) 8150-0462 32cm´1 Wire 24 White/Yellow

Agilent

Part Number

Quantity Description

(14) 8120-0122 16cm´1 Coaxial Cable

(15) 8120-0122 16cm´1 Coaxial Cable

(16) 8150-0456 5cm´4 Wire 24 White

(17) 41422-24099 1 Soldering Pipe

Agilent 16442A User’s Guide, Edition 3 17

User's Guide

Maintenance

Installing Triaxial and BNC Connectors:

Reference

Designation

(1) 1250-1906 7 Triaxial Connector

(2) 1250-0083 6 BNC Connector

(3) 2190-0016 6 Lock Washer

(4) 0360-1190 2 Terminal Washer

(5) 2950-0001 6 Nut

(6) 5000-4218 1 Terminal Washer

(7) 1252-1419 1 6-pin Connector

18 Agilent 16442A User’s Guide, Edition 3

Agilent

Part Number

Quantity Description

Connections between Lid and Body:

User's Guide

Maintenance

Reference

Designation

(1) 16442-24001 1 Sleeve

(2) 0515-1973 1 Bolt M4

(3) 16442-61624 1 Cable Assy

(4) 0515-1550 1 Screw M3-L 8 P-H

(5) 16442-23001 1 Pin

Agilent 16442A User’s Guide, Edition 3 19

Agilent

Part Number

Quantity Description

User's Guide

Maintenance

TO-3 or TO-66 Package Socket Module

In-Line Package Socket Module

20 Agilent 16442A User’s Guide, Edition 3

Axial Lead Package Socket Module

User's Guide

Maintenance

TO- (4-pin) Package Socket Module

Agilent 16442A User’s Guide, Edition 3 21

User's Guide

Maintenance

Dual-In-Line (28-pin) Package Socket Module

Dual-In-Line (18-pin) Package Socket Module

22 Agilent 16442A User’s Guide, Edition 3

TO- (8-, 10-, and 12-pin) Package Socket Module

User's Guide

Maintenance

Universal Socket Module

Agilent 16442A User’s Guide, Edition 3 23

User's Guide

Specifications

Specifications

The "supplemental information" and "typical" entries, in the following

specifications are not warranted, but provide useful information about the functions

and performance of the instruments.

The following specifications data is specified at 23 ± 5 °C and 50 % relative

humidity.

Functions

Agilent 16442A lets you test various shaped DUTs. The 16442A has:

• 6 SMU channels (when using non-Kelvin connections).

3 SMU channels (when using Kelvin connections).

• 2 VSU channels.

• 2 VMU channels.

• 2 PGU channels.

• 1 GNDU channel.

• interlock (Intlk) 6-pin connector.

Voltage and current range

Channel Maximum Voltage Maximum Current

SMU 200 V 1 A

VSU 40 V 100 mA

VMU 40 V

PGU 40 V 200 mA (AC peak)

GNDU 40 V 1.6 A

24 Agilent 16442A User’s Guide, Edition 3

Furnished Accessories

User's Guide

Specifications

Agilent

Part Number

16442-60101 1 carrying case for socket modules

16442-60002 2 stabilizer (with two flathead screws)

16442-61600 4 miniature banana - pin plug connection cable

16442-61601 4 miniature banana - pin plug connection cable

16442-61602 4 miniature banana - pin plug connection cable

16442-61603 3 pin plug - pin plug connection cable (black)

16442-61604 3 pin plug - pin plug connection cable (red)

16442-61605 3 pin plug - pin plug connection cable (blue)

16442-61606 3 miniature banana - miniature clip connection

16442-61607 3 miniature banana - miniature clip connection

16442-61608 3 miniature banana - miniature clip connection

Quantity Description

(black)

(red)

(blue)

cable (black)

cable (red)

cable (blue)

16442-61609 3 miniature banana - miniature banana connection

cable (black)

16442-61610 3 miniature banana - miniature banana connection

cable (red)

16442-61611 3 miniature banana - miniature banana connection

cable (blue)

16058-60004 1

16088-60002 1 dual-in-line package socket module (28-pin)

16088-60009 1 axial lead package socket module

16088-60006 1 TO-package socket module (12-pin)

16442-90000 1 User's Guide (this document)

Agilent 16442A User’s Guide, Edition 3 25

blank Teflon

TM

board

User's Guide

Specifications

Connection Cables (furnished)

• Miniature Banana - Pin Plug

• Pin Plug - Pin Plug

26 Agilent 16442A User’s Guide, Edition 3

• Miniature Banana - Miniature Clip

User's Guide

Specifications

• Miniature Banana - Miniature Banana

Agilent 16442A User’s Guide, Edition 3 27

User's Guide

Specifications

Socket Modules (furnished)

• Blank Teflon Board

• Dual-In-Line Packages (28-pin)

28 Agilent 16442A User’s Guide, Edition 3

• Axial lead package

User's Guide

Specifications

• TO-Package (12-pin)

Agilent 16442A User’s Guide, Edition 3 29

User's Guide

Specifications

Available Accessories (options)

Option

Number

010 adds 1.5 m triaxial cable (16058-61603), 4 ea.

and triaxial cap (1250-1708), 4 ea.

011 adds 3.0 m triaxial cable (04145-61622), 4 ea.

and triaxial cap (1250-1708), 4 ea.

800

801 adds universal socket module, 0.1 inch pitch (16088-60010), 1 ea.

802 adds universal socket module, 0.075 inch pitch (16442-60011), 1 ea.

803 adds universal socket module, 0.05 inch pitch (16442-60012), 1 ea.

810 adds connection pin (16088-60013), 10 ea.

811 adds 6 miniature banana pin plug connection cables

812 adds 6 pin plug pin plug connection cables

813 adds 6 miniature banana miniature clip connection cable

814 adds 6 miniature banana miniature banana connection cables

adds blank Teflon

and connection pin (16088-60013), 10 ea.

and connection pin (16088-60013), 10 ea.

and connection pin (16088-60013), 10 ea.

black (16442-61600), 2 ea.

red (16442-61601), 2 ea.

blue (16442-61602), 2 ea.

black (16442-61603), 2 ea.

red (16442-61604), 2 ea.

blue (16442-61605), 2 ea.

black (16442-61606), 2 ea.

red (16442-61607), 2 ea.

blue (16442-61608), 2 ea.

black (16442-61609), 2 ea.

red (16442-61610), 2 ea.

blue (16442-61611), 2 ea.

TM

Description

board (16058-60004)

30 Agilent 16442A User’s Guide, Edition 3

User's Guide

Specifications

Option

Number

821 adds TO-packages socket module, 4-pin (16088-60001)

822 adds dual-in-line package socket module, 18-pin (16088-60003)

823 adds dual-in-line package socket module, 28-pin (16088-60002)

824 adds TO-packages socket module, 8-pin (16088-60004)

825 adds TO-packages socket module, 10-pin (16088-60005)

826 adds TO-packages socket module, 12-pin (16088-60006)

830 adds TO-packages socket module, TO-3 or TO-66 (16088-60007)

831 adds in-line packages socket module (3-pin) (16088-60008)

832 adds axial lead package socket module (16088-60009)

890 adds carrying case for socket modules (16442-60101)

Connection pins (optional)

Description

Socket modules (optional)

• TO-package (TO-3 or TO-66)

Agilent 16442A User’s Guide, Edition 3 31

User's Guide

Specifications

• In-Line package (3-pin)

• Dual-In-Line package (18-pin)

32 Agilent 16442A User’s Guide, Edition 3

• TO-package (4-pin)

User's Guide

Specifications

• TO-package (8-pin)

Agilent 16442A User’s Guide, Edition 3 33

User's Guide

Specifications

• TO-package (10-pin)

• Universal socket module

34 Agilent 16442A User’s Guide, Edition 3

General Specifications

• Environment

Operating temperature 5 °C to 40 °C

Storage temperature -40 °C to 70 °C

Operating Humidity 5% to 80% relative humidity (at no condensation)

Storage Humidity 5% to 90% relative humidity at 65 °C

• Weight

Approximately 2.5 kg

• Dimensions (W ´ H ´ D)

260 mm ´ 140 mm ´ 260 mm (not including stabilizers)

260 mm ´ 140 mm ´ 320 mm (including stabilizers)

User's Guide

Specifications

Agilent 16442A User’s Guide, Edition 3 35

User's Guide

Specifications

Supplemental Information

The following reference data is specified at 23 ± 5 °C and 50 % relative humidity.

• SMU channel

Leakage Current

(force or sense to common) 10 pA maximum at 200 V

Stray Capacitance

(force or sense to common) 15 pF maximum

Stray Capacitance

(force or sense to other SMUs) 3 pF typical

Residual Resistance (force) 60 mW typical

Residual Resistance (sense) 60 mW typical

Guard Capacitance (force or

sense guard) 70 pF maximum

• VSU channel

Residual Resistance 60 mW typical

• VMU channel

Residual Resistance 60 mW typical

• PGU channel

Characteristic Impedance 50 W typical

• GNDU channel

Residual Resistance (force) 40 mW typical

Residual Resistance (sense) 40 mW typical

36 Agilent 16442A User’s Guide, Edition 3

• Socket Board

User's Guide

Specifications

Agilent

Part number

16088-60001 2 Tr 200 V

16088-60002 28pin DIP 230 V

16088-60003 18pin DIP 230 V

16088-60004 8pin TO 230 V

16088-60005 10pin TO 200 V

16088-60006 12pin DIP 230 V

16088-60007 TO-3,TO-66 1000 V 20 mW

16088-60008 3pin Kelvin 1000 V 20 mW

16088-60009 axial Kelvin 1000 V 20 mW

16088-60010 Universal module

16442-60011 Universal module

16442-60012 Universal module

Connection wire residual resistance : 20 mW typical

Description Max Voltage

Resistance

Residual

Agilent 16442A User’s Guide, Edition 3 37

Loading...

Loading...