Page 1

Agilent 140/240/280

Series AA

Service Manual

Agilent Confidential

Agilent Technologies

Page 2

Notices

WARNING

CAUTION

NOTE

No part of this manual may be reproduced in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Agilent Technologies, Inc. as governed by United States

and international copyright laws.

Manual Part Number

G8434-90050

Edition

Rev. B, July 2017

Agilent Technologies

679 Springvale Road

MULGRAVE Victoria 3170, Australia

Printed in Australia

© Agilent Technologies, Inc. 2017

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection

with the furnishing, use, or performance of this document or of any information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

Restricted Rights Legend

If software is for use in the performance of a

U.S. Government prime contract or subcontract, Software is delivered and licensed as

“Commercial computer software” as defined

in DFAR 252.227-7014 (June 1995), or as a

“commercial item” as defined in FAR

2.101(a) or as “Restricted computer software” as defined in FAR 52.227-19 (June

1987) or any equivalent agency regulation or

contract clause. Use, duplication or disclosure of Software is subject to Agilent Technologies’ standard commercial license

terms, and non-DOD Departments and Agencies of the U.S. Government will receive no

greater than Restricted Rights as defined in

FAR 52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater than

Limited Rights as defined in FAR 52.227-14

(June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any technical data.

Safety Notices

A WARNING notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in personal

injury or death. Do not proceed

beyond a WARNING notice until

the indicated conditions are fully

understood and met.

A CAUTION notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like that,

if not correctly performed or adhered

to, could result in damage to the

product or loss of important data. Do

not proceed beyond a CAUTION

notice until the indicated conditions

are fully understood and met.

A NOTE contains helpful information on usage - it does not denote a

hazard.

Confidentiality Notice:

Export License Restrictions apply to

the information in this Service Manual

and require that it only be made available to and be used by qualified Agilent

AA System Field Service Engineers.

The information contained in the Agilent 140/240/280 AA Series Service

Manual is for use only by Agilent

trained Field Service Engineers.

Do NOT disclose this information to any

other parties.

Agilent Confidential

Page 3

Foreword

NOTE

About this Manual

This manual contains information relating to the structure of the 140/240/280 Series

AA system, as well as information relating to maintenance, troubleshooting, peripheral

equipment, and service support parts. Step- by- step explanations are also provided to

enable efficient installation.

In Feb 2012, Agilent rationalized the AA product from 25 models with over 400

possible configurations to 14 models which included the most popular configurations

including as standard; auto lamp selection, double beam for all flame instruments, and

GTA camera on all GFAA models. Current available models are:

G8430A Agilent 55B AA Spectrometer

G8430AA Agilent 55B AA Spectrometer Bundle

G8431AA Agilent 240 AA Spectrometer Bundle

G8432AA Agilent 240FS AA Spectrometer

G8433AA Agilent 240FS AA Spectrometer with GTA Camera

G8434AA Agilent 280FS AA Spectrometer

G8435AA 240Z AA Spectrometer, no UltrAA Control

G8436AA Agilent 240Z AA Spectrometer

G8437AA Agilent 280Z AA Spectrometer

G8447AA 240FS/GTA120/PSD120/UltrAA System

G8448AA 240FS/SPS3/SIPS20 AA System

G8449AA AA Duo 240FS/240Z/UltrAA System

G8450AA AA Duo 55B/240Z/UltrAA System

G8442AA AA Duo 280FS/280Z/UltrAA System

Note that the contents included in this manual are subject to change without notice due to modifications

made to the product. Check the Support Portal or SubscribeNet regularly.

Using this Manual

The Agilent 140/240/280 Series AA Service Manual provides information which allows

Agilent Field Service Engineers (FSE) to install, maintain, and service the Agilent AA

system. This manual contains the following chapters:

Chapter 1, “General Information”

This chapter describes precautions for handling the Agilent AA system, specifications,

names and functions of key components, and explanations on the structure of each

system.

You should be aware of the general safety practices outlined in the Precaution section.

Chapter 2, “Removal/Installation, Replacement and Adjustment”

This chapter describes the methods for removal/installation, disassembly/assembly,

replacement and adjustment of the components of the AA system.

Agilent Confidential

Page 4

Chapter 3, “Troubleshooting”

NOTE

This chapter describes the instrument power-on self- tests and available diagnostics for

troubleshooting. Technical information on the electronics used in the AA system is

also provided as an aid to troubleshooting.

This chapter also contains explanations for error codes and error messages, as well as

causes and remedies for handling them.

Chapter 4, “Peripheral Equipment”

This chapter contains overviews of the optional equipment used with the 140/240/280

Series AA system components.

Chapter 5, “Service Parts”

This chapter provides assistance in searching for parts to be ordered based on

diagrams, and in specifying the part numbers.

Chapter 6, “Installation and Preventative Maintenance Guide”

This chapter describes the procedures for installing and setting up the Agilent AA

system.

Appendix A, “Technical Theory”

This appendix describes the technical theory behind the AA system.

Most information contained in this publication is relevant to the Agilent 140/240/280

AA instruments. Where information applies only to one instrument model, it shall be

clearly identified.

Agilent Confidential

Page 5

Contents

Foreword 3

About this Manual 3

Using this Manual 3

1 General Information

Precautions 16

General 16

Verifying Safe State 16

Electrical Hazards 17

High Voltage Devices 17

Heat, Vapors, and Fumes 18

Compressed Gas Hazards 18

Ultraviolet Radiation 19

Hazardous Materials 20

Other Precautions 20

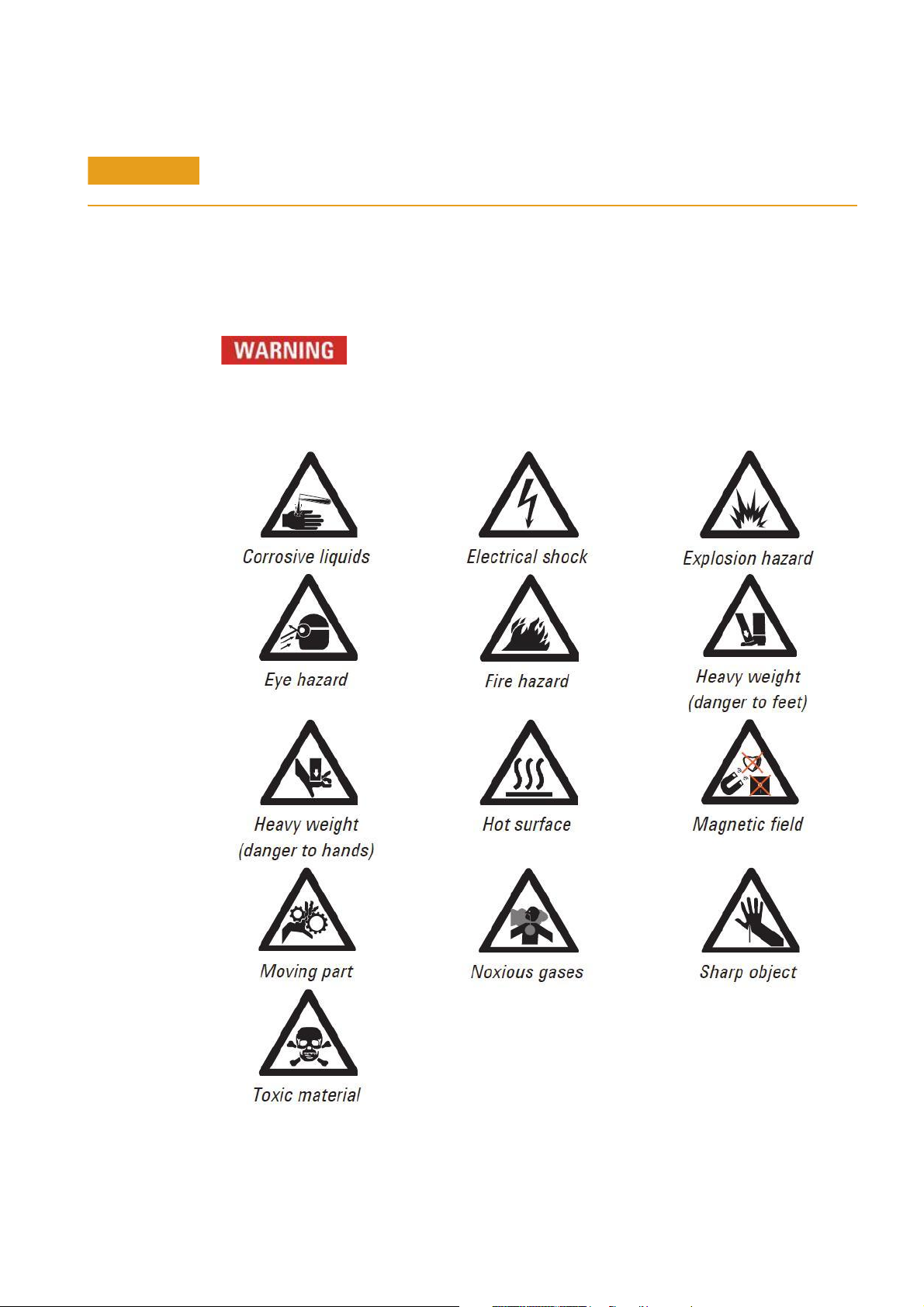

Warning Symbols 21

Color Coding 22

CE Compliance 22

Electromagnetic Compatibility 23

EN55011/CISPR11 23

ICES/NMB-001 23

Flame Operation 24

Flammable Solvents 24

Compressed Gases and Cylinders for Flame Operation 25

Acetylene 25

Nitrous Oxide 26

Burners 26

Nebulizer 27

Liquid Trap 27

Heat Hazards 27

Perchloric Acid 28

Flashbacks 28

Furnace and Zeeman Operation 30

Gases 30

Heat Hazards 30

Vapors and Fumes 30

UV Radiation 31

Magnetic Field (Zeeman only) 31

Specifications 32

Weights and Dimensions 32

Optics 32

Primary Light Sources (Not supplied) 32

140/240/280 Series AA Service Manual Agilent Confidential 5

Page 6

Contents

Beam Arrangement 32

Background Correction (where fitted) 32

Monochromator 33

Gas Supplies (for flame instruments only) 33

Sample Introduction (flame instruments only) 34

Electrical Specifications 35

Electrical Supply 35

Agilent SpectrAA Windows software 37

Methods and Sequence 37

Performance 39

Environmental Conditions 39

Flame Performance 40

Furnace Performance 40

PC Requirements 40

Outline of Agilent AA System 41

Agilent AA Features 41

Instrument Overview 43

Flame Instruments Front View 43

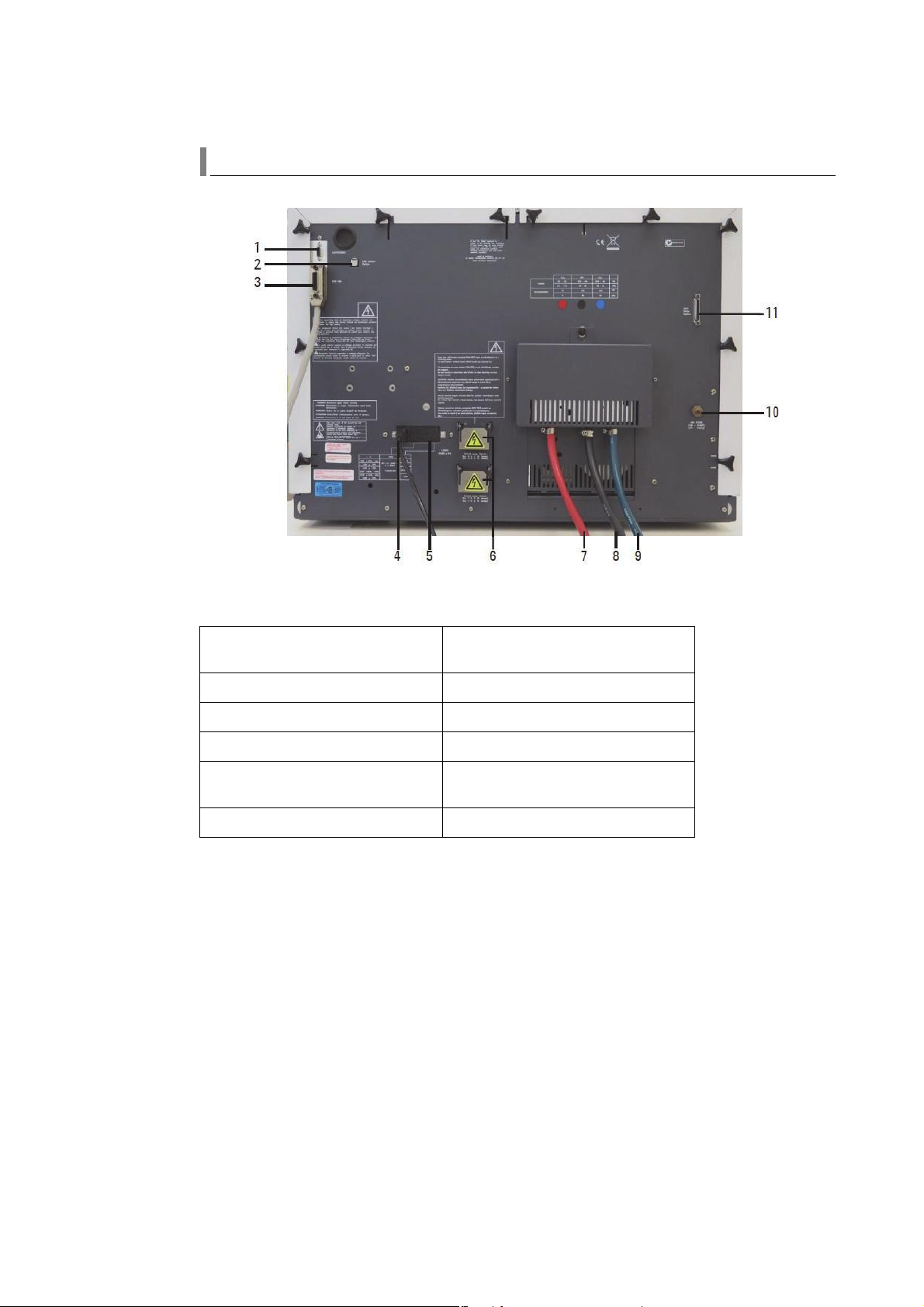

Flame Instruments Rear View 44

Zeeman Instruments Front View 45

Zeeman Instrument Rear View 46

Furnace Instruments Front View (D

Furnace Instruments Rear View (D

- non Zeeman) 47

2

- non Zeeman) 48

2

System Structure and Key Components 49

Sample Introduction 50

Nebulizer 50

Nebulizer Block and Impact Bead 51

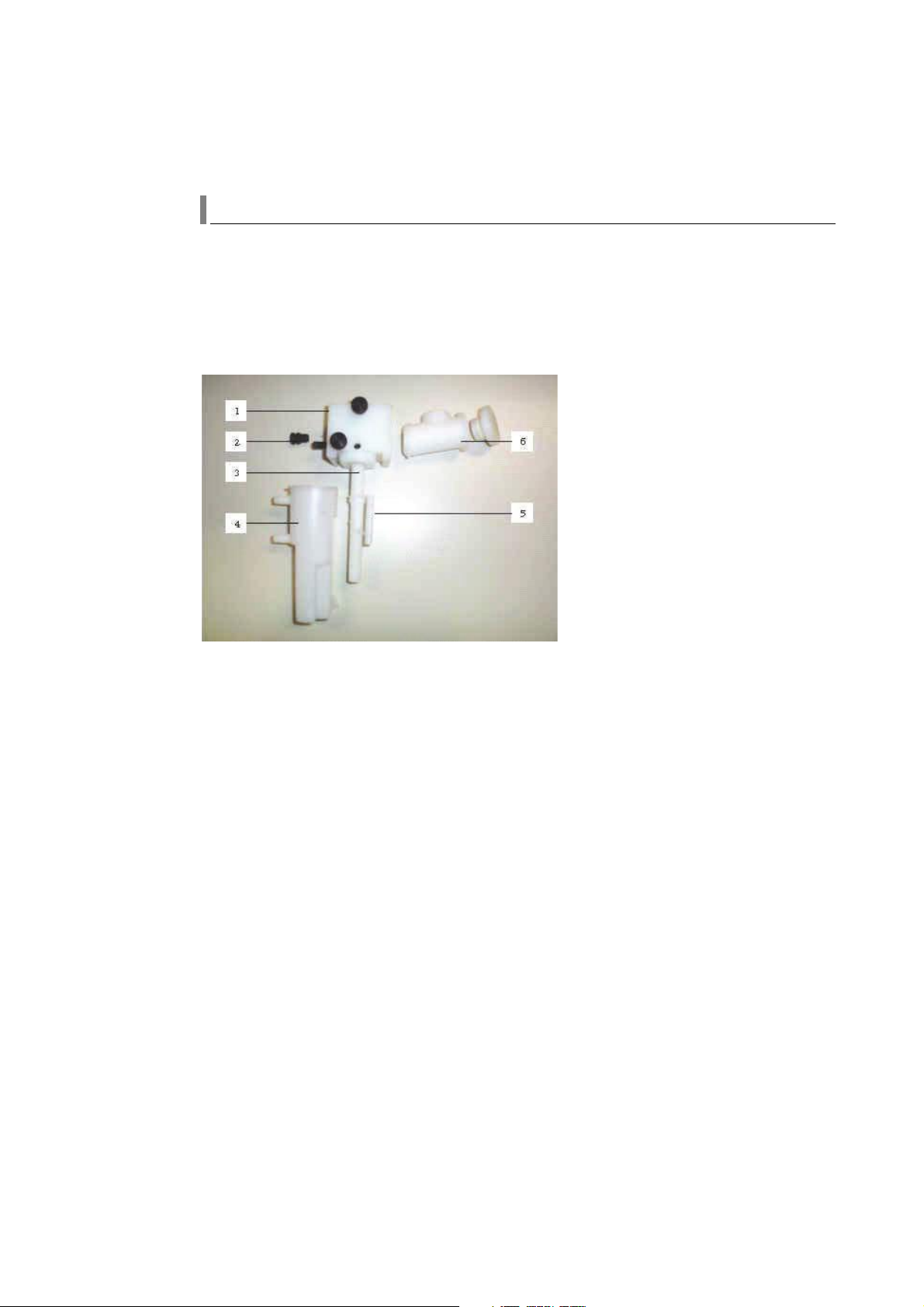

Liquid Trap 52

Spray Chamber 53

Burner 53

Burner Adjuster Assembly 56

Optics 58

Monochromator 59

Peaking on Spectral Lines 60

Slits 60

Background Correction 61

Lamp Selection 61

Lamp Recognition 62

Optics Chassis 63

UltrAA lamp Control Module 65

Gas Control 67

Programmable Gas Control Unit (PGCU) 67

Automatic Gas Control Unit (AGCU) 69

Ignition Interlocks 71

6 Agilent Confidential 140/240/280 Series AA Service Manual

Page 7

Oxidant Reservoir 72

Specifications 72

Gas Control Unit Flow Diagram 74

Accessories 76

2 Removal/Installation, Replacement and Adjustment

Tools and Supplies 79

Main Frame Covers 81

Replacing the Chimney 81

Removal 81

Installation 81

Replacing the Flame Shield/Viewing Window Assembly 82

Removal 82

Installation 82

Replacing the Flame Sample Compartment Front Panel (140/240/280) 82

Removal 82

Installation 82

Replacing the Flame Sample/Burner Compartment Heat Shield 82

Removal 82

Installation 83

Replacing the Left Front Molding/Panel 83

Removal 83

Installation 83

Replacing the Left Side Cover 84

Removal 84

Installation 84

Replacing the HCL Compartment Cover/Door 85

Removal 85

Installation 85

Replacing the Right Side Cover 85

Removal 85

Installation 86

Contents

Sample Introduction 88

Replacing the Burner 88

Removal 88

Installation 89

Replacing the Nebulizer Block/Spray Chamber Assembly 90

Removal 90

Installation 91

Replacing the Spray Chamber 91

Removal 91

Installation 92

Replacing the Pressure Relief Bung 92

Removal 92

140/240/280 Series AA Service Manual Agilent Confidential 7

Page 8

Contents

Installation 92

Replacing the Mixing Paddles 92

Removal 93

Installation 93

Replacing the Liquid Trap 93

Removal 93

Installation 94

Replacing the Nebulizer Block 94

Disassembling the Nebulizer 94

Cleaning a Blocked Nebulizer 95

Reassembling the Nebulizer 96

Replacing the Impact Bead 97

Removal 97

Replacing the Burner Adjuster Assembly 99

Removal 99

Installation 100

Replacing the Carriage from AGCU/PGCU Burner Adjuster 101

Removal 101

Installation 102

Replacing the Carriage from Automatic Burner Adjuster 103

Removal 103

Installation 106

Replacing the Ignition Interlocks 108

Removal 108

Installation 108

Optics 109

Replacing the Monochromator 110

Replacing the Slit/Motor Assembly 112

Replacing the Grating Assembly 114

Agilent AA140/240 114

Agilent AA280 114

Replacing the Micrometer Assembly 115

Agilent AA140/240 115

Agilent AA280 116

Replacing the Collimator Assembly 118

Replacing the Chopper Mirror Assembly 119

Replacing the UltrAA Lamp Module 120

Wavelength Calibration 122

Correcting Wavelength Using the Firmware 122

Zero Order Peaking 122

Slit Calibration 123

Wavelength Calibration 123

Optical Alignment 125

Preparation 126

8 Agilent Confidential 140/240/280 Series AA Service Manual

Page 9

Installing the Back-Lighting Tool 126

Sample Beam Alignment 127

For Zeeman Instruments 128

Reference Beam Alignment 128

M5D2 Alignment 130

Auto Lamp Select Mirror Alignment 132

Beam Balance 139

Dynamic Beam Balance Alignment 139

An Alternative to Using the Oscilloscope 139

Dynamic Beam Balance - SVD method 140

Beam Coincidence Check 141

Cleaning Mirrors 142

Gas Control Unit 143

Primary Service Position 143

Secondary Service Position 144

Replacing the Gas Control Unit 145

Removal 145

Installation 145

Gas Calibration 147

Kit Contents 147

Installing the Calibration Manifold 147

Performing Gas Calibration Using Air 148

AGCU (Automatic Gas Control Unit) Calibration 149

PGCU (Programmable Gas Control Unit) Calibration 152

Flow Measurements 157

Measuring Gas Flows 157

Installing Flow Gauge 157

Oxidant Flow 159

Acetylene Flow 160

Leak Checking 162

Contents

Electronics 163

Mains Input and Distribution 163

Replacing the Power Cable Inlet Connector (Corcom Module) 163

Removal 163

Installation 164

Replacing the PC Power Module 164

Removal 164

Installation 165

Replacing the Mains Transformer 166

Removal 166

Installation 167

Replacing the Monochromator Interface PCA 168

Removal 168

Installation 168

140/240/280 Series AA Service Manual Agilent Confidential 9

Page 10

Contents

Replacing the Main Control PCA 169

Removal 170

Installation 170

Replacing the Photomultiplier Interface PCA 172

Removal 173

Installation 173

Replacing the RBA Opto 174

Removal 174

Installation 174

Replacing the Triac Control PCA (Zeeman Instruments) 175

Removal 175

Installation 176

Replacing the SIPS Control and Power Module 177

Removal 177

Installation 177

Replacing the Flame Detector 178

Removal 178

Installation 178

3 Troubleshooting

Diagnostics 180

Power-on Self-Test 180

Main Control PCA, G8434-65750 180

Firmware Start Up Sequence 181

Service Diagnostic Program (SVD) 187

Executing Service Diagnostics 188

Menus 188

Startup Page 190

Instrument Configuration Tab 190

Optical Tests 195

Mechanical Tests Tab 202

Lamps 203

Miscellaneous 205

Zeeman Magnet Calibration 208

UltrAA Lamp Module Diagnostics 219

Diagnostic LEDs 219

Te s t P oi nt s 220

Troubleshooting 222

Minimum Information 222

Troubleshooting Chart 222

Error Messages 230

Structure 230

Format 230

Examples 231

10 Agilent Confidential 140/240/280 Series AA Service Manual

Page 11

Error Coding 231

Error Message Ranges 231

Error Message Help ID. 232

Help ID Description 256

Electronics 278

Overview 278

Mains Input and Distribution 279

PC Power Module 279

Setting the Supply Voltage 280

Zeeman Instruments 280

PC Power Module - Zeeman Instruments 281

Main Control PCA (G8434-65750) 282

History of the AA Control PCA 282

What happens if an AA control PCA configuration is wrong? 283

Configuring AA Control PCAs 284

Additional Information 287

Photomultiplier Interface PCA (G8434-65030) 288

Test Points and Links 288

Instrument Photometric Gain 289

Low Voltage Supplies 290

EHT Supply 290

Signal Processing 290

Flame Emission Compensation (FEC) 291

Voltage-to-Frequency Converter 291

Indicator LEDs, Switches, and Test Points 291

Low Voltage Supplies 293

Motor Drives 293

Digital to Analog Converters 294

Timing Generator 294

Diagnostics, Accessory Control and EEPROM 295

Board Revision Level 296

Gas Control 296

Igniter 297

Flow Control (PGCU) 297

Flame Sensor 297

Hollow Cathode Lamp Supplies 298

+30, +310, +550 Volt Supplies 299

D

Lamp Supply 299

2

Lamp Recognition 300

Upgrading Firmware (FLASH) 301

Updating the Instrument Operating Block 301

Sample Oscilloscope Traces and Timing Diagrams 302

PMT Interface PCA 302

Main Control PCA 303

Contents

140/240/280 Series AA Service Manual Agilent Confidential 11

Page 12

Contents

Timing Diagrams 306

Mono Interface PCA 308

4 HCL PCA (210177690) - Agilent-AA280 309

UltrAA Lamp Module (210142790) - Zeeman 310

4 Peripheral Equipment

Dynavac Air Compressor 314

Specifications 315

Installation 316

At Start-up 316

Air Pressure Calibration 317

Maintenance 318

Cleaning the Compressor Air Intake Filter 318

Cleaning the Air Service Unit Filter 319

Spare Parts 320

5 Service Parts

Mainframe Fitting Parts 322

Optics 324

Optical bench – 240/240FS/280FS 324

Optical bench – 140/240Z/280Z 325

Monochromator – AA280FS/Z 326

Monochromator – AA140/240/240FS 327

Monochromator – AA240Z 328

Auto Lamp Select – AA280 329

Auto Lamp Select – AA140/240 330

Manual Lamp Select – AA140/240 331

Photomultiplier Tube – AA140/240/280 331

Optics cover – AA140/240/280 332

Others 333

Electronics 335

PCA/Board 335

Wiring Looms 337

Gas Control 338

Gas Control Unit 338

Igniter 340

Burner Adjusters 341

Sample Introduction 343

Spray Chamber Mk 7, complete 343

Spray Chamber / Nebulizer Supplies 345

Others 346

12 Agilent Confidential 140/240/280 Series AA Service Manual

Page 13

Panel Hardware 346

Special Tools 347

Upgrade Kits 348

Miscellaneous 348

Parts Index 349

6 Installation and Preventative Maintenance Guide

Before You Start 352

Installing and Maintaining AA 140/240/280 Instruments 353

Installation and Preventative Maintenance References 353

AA Series Spectrometers Installation Checklist 354

AA Series Spectrometers Installation Scope of Work 363

AA Series Spectrometers Familiarization Checklist 386

AA Series Spectrometers Familiarization Scope Of Work 390

AA Accessories Installation Checklist 416

AA Accessories Installation Scope of Work 435

AA Series Accessories Familiarization Checklist 485

AA Series Accessories Familiarization Scope Of Work 496

AA Series Spectrometers PM Checklist 569

AA Series PM Scope Of Work 579

Contents

Water Hose Connection 609

Water Hose Fitting 611

A Technical Theory

Introduction 614

Basic Principles of Atomic Absorption 615

Nature of Atomic and Ionic Spectra 617

Ionization 619

Atomic Emission 620

The Absorbance - Concentration Relationship 621

Atomization 622

Flame Atomization 622

Elements by Air-Acetylene Flame 624

Elements by Nitrous Oxide - Acetylene Flame 624

Elements By Both Flame Types 625

Graphite Furnace Atomization 626

Platform Atomization 627

Chemical Modifiers 628

Use of Alternate Gases 629

Injection Modes 629

140/240/280 Series AA Service Manual Agilent Confidential 13

Page 14

Contents

Vapor Generation 630

Other Vapor Generation Designs 632

Cell Heating 632

Background Correction 632

Deuterium Technique 633

Smith Heiftje Technique 635

Zeeman Technique 636

Calibration Roll-over 639

Sensitivity Loss for Some Elements 640

Comparison of Background Correction Techniques 640

Optics 642

Lenses 642

Lamps 642

Mirrors 644

Slit Width 645

Monochromator 646

Gratings 649

Detectors 650

Single vs Double Beam Configurations 652

Single Beam Optics 652

Double Beam Optics 653

Glossary of Technical Terms in AA 655

Bibliography and Further Reading 662

References 662

14 Agilent Confidential 140/240/280 Series AA Service Manual

Page 15

Agilent 140/240/280 Series AA

Service Manual

1

General Information

This chapter provides an overview of the Agilent AA System and

contains important information on:

Precautions 16

General 16

Verifying Safe State 16

High Voltage Devices 17

Heat, Vapors, and Fumes 18

Compressed Gas Hazards 18

Ultraviolet Radiation 19

Hazardous Materials 20

Other Precautions 20

Warning Symbols 21

Color Coding 22

CE Compliance 22

Electromagnetic Compatibility 23

Furnace and Zeeman Operation 30

Specifications 32

Weights and Dimensions 32

Optics 32

Gas Supplies (for flame instruments only) 33

Sample Introduction (flame instruments only) 34

Electrical Specifications 35

Agilent SpectrAA Windows software 37

Performance 39

PC Requirements 40

Outline of Agilent AA System 41

Agilent AA Features 41

Instrument Overview 43

System Structure and Key Components 49

Sample Introduction 50

Optics 58

Gas Control 67

Accessories 76

Agilent Confidential 15

Agilent Technologies

Page 16

General Information

WARNING

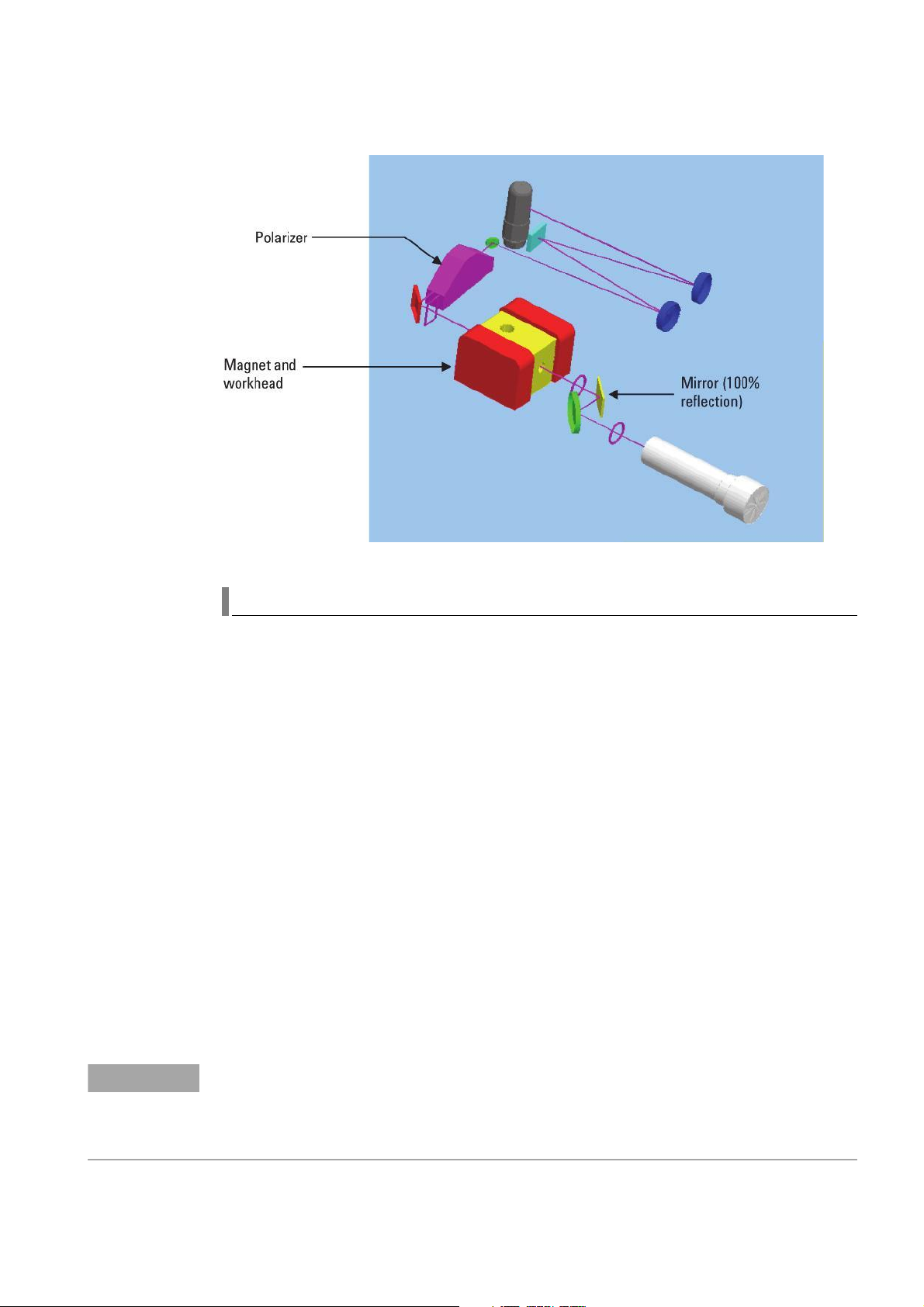

CAUTION

NOTE

Precautions

General

.

An Atomic Absorption Spectrometer uses compressed gases and high voltages and

generates radiant energy and hazardous wastes including corrosive fluids and

flammable liquids. Careless, improper or unskilled use of this spectrometer can cause

death or serious injury to personnel, or severe damage to equipment and property.

All users of an Atomic Absorption (AA) instrument must be familiar with the correct

operating procedures.

Before servicing the various components of the Agilent AA instrument, observe the

following safety precautions.

A WARNING notice denotes a hazard. It calls attention to an operating procedure, practice, or the

like that, if not correctly performed or adhered to, could result in personal injury or death. Do not

proceed beyond a WARNING notice until the indicated conditions are fully understood and met.

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or adhered to, could result in damage to the product or loss of

important data. Do not proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

.

A NOTE contains helpful information on usage - it does not denote a hazard.

Verifying Safe State

The following general safety precautions must be observed during all phases of

operation, maintenance, and service of this instrument.

To ensure continued safe use of the instrument after maintenance or service

procedures, verify the instrument is returned to a safe state for the user. This includes

running performance checks to verify the instruments safety systems are functioning

correctly. Check the general condition of the instrument during operation for wear or

signs of corrosion that are likely to inhibit function or safety.

Failure to comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and intended use of the

instrument. Agilent Technologies assumes no liability for the customer’s failure to

comply with these requirements.

16 Agilent Confidential 140/240/280 Series AA Service Manual

Page 17

General Information

WARNING

WARNING

WARNING

Electrical Hazards

Panels or covers that are secured by screws on the spectrometer and accessories may

be opened only by Agilent field service engineers. Consult the manuals or product

labels supplied with your computer, monitor, printer, water circulating system, and air

compressor to determine which parts are operator- accessible.

Replace blown fuses with ones of the size and rating shown in the text near to the

fuse holder.

Electrical Shock Hazard

To avoid electric shock this equipment must be disconnected from the mains supply before

servicing.

Electrical Shock Hazard

Do not touch electrical circuits, devices, and components of the spectrometer system and some

accessories. They operate at dangerous voltages. Contact with them can cause death, serious

injury, or painful electric shock.

Fire Hazard, Electrical Shock Hazard

• The spectrometer uses interlocks and covers that are designed to prevent accidental contact

with any potential hazards. If the instrument is used in any manner not specified by Agilent,

this protection provided by the equipment may be impaired. It is good practice to develop safe

working habits that do not depend upon the correct operation of the interlocks for safe

operation. It is essential that no interlock or cover is bypassed, damaged, or removed.

• Application of the wrong supply voltage, connection of the instrument to an incorrectly wired

supply outlet, or lack of proper electrical grounding can create a fire hazard or a potentially

serious shock hazard. This could seriously damage the instrument and any attached ancillary

equipment.

• Always use a 3-wire outlet with ground connection that is adequately rated for the load. The

installation must comply with local and national safety regulations. Use only an Agilent

supplied power cord.

Replace the power cord only with a cord equivalent to the one specified in the Site Preparation

Guide.

• Do not connect the instrument to the mains power supply until you have made sure that the

operating voltage is correctly set for the mains power supply in the specific outlet in the

laboratory in which the instrument is connected.

High Voltage Devices

140/240/280 Series AA Service Manual Agilent Confidential 17

The photomultiplier tube, deuterium (D2), hollow cathode lamps, and the UltrAA lamp

module operate at high voltages.

Appropriate warning labels are attached to the instrument in easily visible locations to

warn of the dangers in that area. This equipment has been designed to prevent

electric shock by using interlocks and/or covers on high voltage compartments to

restrict access to powered circuitry.

Page 18

General Information

WARNING

WARNING

WARNING

WARNING

WARNING

Electrical Shock Hazard

Do not touch the drive circuitry of the photomultiplier tube, deuterium (D

and UltrAA lamp module. Contact with the drive circuitry can cause death, serious injury, or

painful electric shock.

Electrical Shock Hazard

Never attempt to override or disable interlocks. Failure to observe this warning can result in death

or serious injury.

Always disconnect the mains power when you need direct access to the electronics.

Magnetic Hazard

The Zeeman magnet generates a variable magnetic field of 0.8 Tesla (at mains frequency) in the

workhead. Pacemakers and magnetic storage media must be kept at least 300 mm from the

magnet.

), hollow cathode lamps,

2

Heat, Vapors, and Fumes

Heat, ozone, vapors, and fumes generated by flame, furnace, and vapor generation

methods can be hazardous, and must be extracted from the instrument by an exhaust

system.

Health Hazard, Asphyxiation Hazard

Ensure that an exhaust system of the appropriate type is fitted (as specified in the Site Preparation

Guide and Checklist). The exhaust system must be vented to the outside air in accordance with

local regulations and never within the building. Regularly check the exhaust system by smoke test

to ensure that the exhaust system is functioning correctly. The exhaust fan must always be

switched on before lighting the flame.

Compressed Gas Hazards

Health Hazard, Asphyxiation Hazard

All compressed gases other than air can create a hazard if they leak into the atmosphere. Even

small leaks in gas supply systems can be dangerous. Any leak other than air can result in an

oxygen-deficient atmosphere which can cause death, serious injury, asphyxiation, or

anaesthesia. The area in which cylinders are stored and the area surrounding the instrument must

be adequately ventilated to prevent accumulations of gas.

18 Agilent Confidential 140/240/280 Series AA Service Manual

Page 19

General Information

WARNING

CAUTION

NOTE

WARNING

WARNING

Fire Hazard, Explosion Hazard

• Gas cylinders must be stored and handled strictly in accordance with local safety codes and

regulations. Cylinders must be used and stored only in a vertical position and secured to an

immovable structure or a properly constructed cylinder stand. Move cylinders only on a

properly constructed trolley. Never locate gas cylinders near a source of ignition or in a

position that is subject to direct heat.

• Keep cylinders cool. This rule applies to every cylinder of compressed gas. Cylinders have

pressure relief devices that release the contents of the cylinder if the temperature exceeds 52

°C (125 °F).

• Ensure that all cylinders are clearly labeled so that there can be no doubt about the contents. If

the cylinder label is not legible, do not use the cylinder - return it to your supplier. Always

ensure that you have the right cylinder before connecting the cylinder to the instrument.

• If air is supplied from a compressor, all moisture must be extracted from the air before it is

supplied to the gas control module. Moisture can affect the internal components of the gas

control system and create a potentially hazardous situation.

• Use only approved regulator and hose connectors - refer to the gas supplier’s instructions.

Keep gas cylinders cool and properly labeled. All cylinders are fitted with a pressure relief

device that will rupture and empty the cylinder if the internal pressure rises above the safe

limit. Ensure that you have the correct cylinder before connecting it to the instrument.

Use only ‘Instrument Grade’ gases with the spectrometer.

.

• Shut-off valves should be installed and easily accessible.

• Always ensure that the gas supplies are turned off at the cylinders or tanks after completing an

analytical procedure and at the end of the working day.

Ultraviolet Radiation

Flames, hollow cathode lamps, and deuterium lamps emit hazardous ultraviolet

radiation. This radiation can cause serious damage to eyes and skin.

Eye Hazard

Always wear safety glasses conforming to an approved standard, and certified or otherwise

warranted to protect the eyes from ultraviolet radiation. Never look directly at the light emitted by

a hollow cathode lamp.

Eye Hazard

The deuterium lamp used for background correction emits high levels of UV radiation. Never

operate the deuterium lamp unless it is correctly mounted in its holder and fitted in its operating

position. Always wear UV absorbing safety glasses when you do any visual alignments involving

an energized deuterium lamp.

140/240/280 Series AA Service Manual Agilent Confidential 19

Page 20

General Information

WARNING

WARNING

WARNING

WARNING

WARNING

Chemical Hazard

When using a flame, always operate the instrument with the flame shield closed, and the sample

compartment front panel and chimney in place.

Hazardous Materials

Before attempting any work on the sample compartment area, you must know exactly

what matrix of solutions has been running through the instrument and particularly

what types of solvents are involved.

Chemical Hazard

Always check that the sample introduction system has been thoroughly flushed out with distilled

water and that the contents of the drain or waste container are known and properly disposed of if

necessary before touching any part.

Health Hazard

Wash your hands and gloves thoroughly during sample compartment work. Avoid contact

between hands and eyes at all times during servicing of the instrument.

Other Precautions

Fire Hazard, Explosion Hazard, Toxic Hazard

• Use of the spectrometer and accessories may involve materials, solvents, and solutions that

are flammable, corrosive, toxic or otherwise hazardous. Careless, improper, or unskilled use of

such materials, solvents, and solutions can create explosion hazards, fire hazards, toxicity, and

other hazards which can result in death, serious personal injury, and damage to equipment and

property.

• Always ensure that laboratory safety practices governing the use, handling, and disposal of

such materials are strictly observed. These safety practices should include appropriate safety

clothing and safety glasses.

• Cooling air flow to the spectrometer and accessories must be unobstructed. Do not block the

ventilation grills on the spectrometer and accessories. Consult the manuals supplied with your

computer, monitor, printer, water circulating system, and air compressor for their specific

ventilation requirements.

20 Agilent Confidential 140/240/280 Series AA Service Manual

Personal Injury Hazard

• Take great care when working with glass or quartz parts to prevent breakage and cuts. This is

especially important when attaching plastic tubing to glass barbs.

• The spectrometer weighs approximately 69 kg (152 lb). To avoid injury to personnel or damage

to the instrument or property, always use a forklift or other suitable mechanical lifting device to

move the instrument. If a forklift is not available, the instrument will need to be lifted by two

people.

Page 21

General Information

CAUTION

Use only Agilent-supplied or approved spares with your instrument.

.

Warning Symbols

The following is a list of symbols that appear in conjunction with warnings in this

manual and on the spectrometer. The hazard they describe is also shown. The

beginning of the warning text is noted by a warning icon:

A triangular symbol indicates a warning. The meanings of the symbols that may

appear alongside warnings in the documentation or on the instrument itself are as

follows:

140/240/280 Series AA Service Manual Agilent Confidential 21

Page 22

General Information

The following symbol may be used on warning labels attached to the instrument. When

you see this symbol, refer to the relevant operation or service manual for the correct

procedure referred to by that warning label.

The following symbols appear on the instrument for your information.

Mains power on

Mains power off

Fuse

Single phase alternating current

Flame off

Flame on

Indicates lamp present

Disconnect all power plugs.

Caution, disconnect all supplies, risk of electric shock

Color Coding

The various indicator lights on the instrument and associated accessories are color

coded to represent the status of the instrument or accessory.

• A green light indicates the instrument is in normal/standby mode.

• An orange light indicates that a potential hazard is present.

• A blue light indicates that operator intervention is required.

• A red light warns of danger or an emergency.

CE Compliance

Your Agilent AA instrument has been designed to comply with the requirements of the

Electromagnetic Compatibility (EMC) Directive and the Low Voltage (electrical safety)

Directive (commonly referred to as the LVD) of the European Union. Agilent has

confirmed that each product complies with the relevant Directives by testing a

prototype against the prescribed EN (European Norm) standards.

Proof that a product complies with these directives is indicated by:

• The CE Marking appearing on the rear of the product, and

• The documentation package that accompanies the product containing a copy of the

Declaration of Conformity. The Declaration of Conformity is the legal declaration by

Agilent that the product complies with the directives listed above, and shows the

EN standards to which the product was tested to demonstrate compliance.

22 Agilent Confidential 140/240/280 Series AA Service Manual

Page 23

General Information

Electromagnetic Compatibility

EN55011/CISPR11

Group 1 ISM equipment: group 1 contains all ISM equipment in which there is

intentionally generated and/or used conductively coupled radio- frequency energy that

is necessary for the internal functioning of the equipment itself.

Class A equipment is equipment suitable for use in all establishments other than

domestic and those directly connected to a low voltage power supply network that

supplies buildings used for domestic purposes.

This device complies with the requirements of CISPR11, Group 1, Class A as radiation

professional equipment. Therefore, there may be potential difficulties in ensuring

electromagnetic compatibility in other environments, due to conducted as well as

radiated disturbances.

Operation is subject to the following two conditions:

1 This device may not cause harmful interference.

2 This device must accept any interference received, including interference that may

cause undesired operation.

If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged

to try one or more of the following measures:

1 Relocate the radio or antenna.

2 Move the device away from the radio or television.

3 Plug the device into a different electrical outlet, so that the device and the radio or

television are on separate electrical circuits.

4 Make sure that all peripheral devices are also certified.

5 Make sure that appropriate cables are used to connect the device to peripheral

equipment.

6 Consult your equipment dealer, Agilent Technologies, or an experienced technician

for assistance.

Changes or modifications not expressly approved by Agilent Technologies could void

the user’s authority to operate the equipment.

ICES/NMB-001

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB- 001 du Canada.

140/240/280 Series AA Service Manual Agilent Confidential 23

Page 24

General Information

Flame Operation

Unskilled, improper, or careless use of flammable solvents in or near an atomic

absorption spectrometer can create explosion hazards and fire hazards. This can result

in death, severe personal injury, or burns.

The combination of a flame and flammable solvents can present a serious hazard. All

relevant safety practices governing the use of flammable solvents must be strictly

followed.

To reduce the possibility of fire or explosion:

• When selecting an organic solvent, choose a solvent that has the highest flash point

• Never use a solvent with a specific gravity lower than 0.75.

• Never leave uncovered containers of flammable solvent standing near the burner.

• Always use solvent-resistant tubing such as nitrile rubber for the drainage system

• Use small, wide- necked waste vessels and empty them frequently - do not

• When your analytical program is completed, or at the end of the working day,

• When your analytical program is completed, or at the end of the working day,

• Do not mix nitric or perchloric acid residues with organic solvent residues.

• Keep the burner slot, spray chamber, and liquid trap clean.

• Always use the internal igniter to light the flame as the flame will not operate

Flammable Solvents

consistent with your analytical requirements.

When aspirating such solvents, always use a covered container and feed the

capillary tubing through a 2- mm diameter hole in the cover. Always use the

smallest volume of solvent consistent with your analytical requirements.

and the vapor vent. Lead the drainage tube to a suitable wide- necked waste vessel

(as described in the next paragraph). The standard plastic laboratory tubing

supplied with your instrument is not suitable for draining organic solvents or

venting organic vapors. If organic or toxic solutions are used in the spray chamber,

vent tubing must be connected to the vapor vent on the liquid trap, run parallel to

the drain tubing, and led to an active exhaust system. Do not lead the vapor tubing

to the waste vessel. If you are not using toxic or hazardous liquids in the spray

chamber, leave the vapor vent uncovered.

accumulate large volumes of flammable solvent. Do not use glass waste vessels -

use vessels made of a material that will not shatter in the event of a flashback.

Metal vessels will corrode and it is difficult to determine the level of liquid in them.

Ensure that your waste vessel is below the instrument and located in an open,

well- ventilated position where you can see it. Never locate the vessel in a confined

space.

always empty and rinse the waste vessel.

always empty, clean, and refill the liquid trap.

unless all the safety interlocks are in enabled.

24 Agilent Confidential 140/240/280 Series AA Service Manual

Page 25

Figure 1 System setup diagram

General Information

Compressed Gases and Cylinders for Flame Operation

This spectrometer must only be used with air, nitrous oxide, and acetylene for flame

operation.

Never use oxygen or oxygen- enriched air as the oxidant because this results in an

explosion.

Never use any gas except acetylene as the fuel gas.

Acetylene

Unskilled, improper, or careless use of acetylene can create explosion hazards and fire

hazards that can result in death, severe personal injury, or burns.

Use acetylene at pressures lower than 105 kPa (15 psig). At pressures above this level,

acetylene can explode spontaneously. Your Agilent AA is designed to operate at fuel

supply pressures between 65 and 100 kPa (9.5.14.5 psig). Refer to the ‘Specifications’

section or the rear of the instrument for the exact range and recommended pressure.

Do not use any tubing or connector that reacts chemically with acetylene. Never pass

acetylene through copper tubing, or brass tubing or fittings containing more than 65%

copper, as this may cause an explosion. Never bring acetylene into direct contact with

copper, silver, liquid mercury, gaseous chlorine, or grease, this may cause an

explosion.

Use only acetylene that is packed in acetone. Some gas suppliers offer acetylene

packed in material other than acetone. While these alternatives may overcome some of

the disadvantages of acetone, they may also introduce the more serious problem of

corrosion in the gas control module and must not be used with Agilent atomic

absorption spectrometers.

If the pressure in the acetylene cylinder is allowed to fall below 700 kPa (100 psig), or

the consumption is greater than 1/7 of the cylinder contents per hour, acetone may be

carried over from the cylinder and into the spectrometer. Acetone in the spectrometer

can damage seals, O- rings, and hoses, degrade analytical performance and precipitate

flashbacks.

140/240/280 Series AA Service Manual Agilent Confidential 25

Page 26

General Information

Minimize the amount of acetone that is carried over with the acetylene by:

• Replacing cylinders when the pressure of the contents drops below 700 kPa

• Ensuring that the rate of acetylene drawn off from each cylinder is not excessive.

If there are high rates of consumption, connect two or more cylinders in parallel to a

manifold. This reduces the rate at which acetylene is drawn from each cylinder.

To reduce the possibility of fire or explosion:

• Test the supply ‘plumbing’ regularly for leaks with a brush and soapy water or a

• ‘Crack’ the cylinder before use by gently opening the valve to check for any drops

Use ‘Instrument Grade’ acetylene that is at least 99.5% pure.

Turn off fuel gas at the cylinder when you have completed your flame analysis.

Refer also to your local regulations governing the use of acetylene.

(100 psi)

proprietary leak- detecting solution (never use a naked flame when testing for leaks)

or spray of acetone. Any cylinder showing acetone should be returned to the

supplier for replacement.

Nitrous Oxide

The decompression of high- pressure N2O gas at the regulator can cause excessive

cooling and eventual freezing of the regulator. To prevent regulator malfunction and

possible flashback, the gas should be heated with an in- line or wrap- around heater.

Burners

Improper or careless use of burners can create explosion hazards and fire hazards

that can cause death, serious injury, and damage to equipment and property.

Whenever you handle burners, remember that the burner may be very hot. Always use

protective gloves to handle burners.

Burners are clearly identified by the fuel/oxidant combination for which they are

intended. Always fit the correct burner. Never attempt to use an air- acetylene burner

for nitrous oxide-acetylene, as this causes a flashback.

Use only acetylene as the fuel gas.

Use only air or nitrous oxide as the oxidant. Never attempt to use oxygen or

oxygen- enriched air, as this causes a flashback.

Burner interlocks are used to minimize the possibility of using the wrong burner.

Never interfere with or attempt to bypass any interlock fitted to this instrument.

To minimize the rate of burner blockage, the burner slot must be cleaned and polished

as described in the ‘Maintenance and Troubleshooting’ chapter of the User’s Guide.

Never allow burners to become blocked. Progressive burner blockage can increase the

static pressure in the liquid trap to the point at which the liquid seal is breached.

This can cause a flashback and create an explosion hazard or a fire hazard.

Never allow carbon to build up on the slot, as glowing particles can dislodge and fall

through the slot, causing a flashback.

Always turn off the flame before attempting to clean the burner slot. Never clean the

slot of a burner while a flame is running.

Never leave a flame unattended.

26 Agilent Confidential 140/240/280 Series AA Service Manual

Page 27

General Information

Never disassemble or modify a burner. Never use a damaged burner.

Nebulizer

Incorrect assembly and fitting of nebulizers to an atomic absorption spectrometer can

create explosion hazards and fire hazards that can cause serious injury and damage to

equipment and property.

Ensure that the nebulizer is correctly assembled and correctly fitted to the spray

chamber before lighting the flame. Nebulizers should be correctly adjusted before

lighting the flame.

Never remove a nebulizer from the spray chamber while the flame is on, and do not

use a mechanical device (for example, a wire) to clean the capillary of a nebulizer

while a flame is operating. Always extinguish the flame before removing the nebulizer

from the spray chamber.

Regularly test all connections for leaks. Fix all leaks before lighting the flame.

Liquid Trap

Improper use of the liquid trap can create explosion hazards, fire hazards, and toxic

vapor hazards that can result in death or serious injury.

The liquid trap interlock is used to minimize the possibility of operating the

instrument with an empty trap. Never interfere with this interlock. Never attempt to

bypass this interlock.

Always fill the liquid trap with the same solvent that is being used for your samples.

The trap is designed to provide a liquid seal under all normal conditions for solutions

with a specific gravity greater than 0.75. Never use a solution or solvent with a

specific gravity lower than 0.75, otherwise the liquid seal can be breached. This can

create a flashback and create an explosion hazard or a fire hazard.

A length of tubing must be connected to the drain outlet on the trap and led to a

suitable waste vessel. The free end of the tubing must remain above the liquid in the

waste vessel. Do not use glass waste vessels, use vessels made of a material that will

not shatter in the event of a flashback.

A length of tubing should be connected to the vapor vent (the upper nipple) on the

liquid trap when you are analyzing organic or toxic liquids. This tubing should be led

out from the sample compartment, parallel to the drain tubing, and must slope

downwards to enable any liquid overflow to drain out and prevent the tubing from

becoming blocked. Do not lead the vapor tubing to the waste vessel. If necessary, an

active exhaust system should be used to draw away toxic vapors. If you are not

analyzing solutions of a toxic nature, leave the vapor outlet uncovered.

Heat Hazards

An open flame, burners, and other hot surfaces can present heat hazards that can

result in severe burns.

When operating a flame system, always operate your spectrometer with the flame

shield closed, and the sample compartment front panel in place. Keep your hands out

of the sample compartment while a flame is burning.

When operating a flame system make sure that the chimney is in place with the

cutaway skirt (if present) to the back. Before you touch the instrument chimney, turn

off the flame and allow the chimney to cool.

140/240/280 Series AA Service Manual Agilent Confidential 27

Page 28

General Information

NOTE

When you change burners, remember that the burner may be very hot. Always use

protective gloves when removing a burner from the instrument.

Aspiration of perchloric acid perchlorates into a nitrous oxide- acetylene flame and can

create an explosion hazard that can result in death or serious injury, including

temporary or permanent impairment of hearing.

Do not use perchloric acid unless it is absolutely essential for sample preparation. If

perchloric acid must be used, you may be able to reduce the risk of explosion by

taking the following measures:

• Use an air-acetylene flame instead of a nitrous oxide- acetylene flame.

• Reduce the concentration of perchloric acid and metal in all analytical solutions to

• Aspirate all solutions for the shortest practicable period.

• Aspirate distilled water between samples. Minimize the aspiration of air.

• Use separate spray chamber/liquid trap and drain assemblies for perchloric acid

Perchloric Acid

the lowest practicable level. The concentration of perchloric acid should be reduced

in the digestion stage and further reduced by extending the fuming stage.

analyses and organic solvent analyses to prevent perchloric acid from mixing with

organic solvent residues.

When solvent extractions of perchloric solutions are performed, some of the acid may dissolve in the

organic solvent that is subsequently aspirated. Also, if the organic solution is aspirated while floating on

the surface of the acid, do not allow the capillary tube to drop below the organic layer and suck up

aqueous perchloric acid.

When using perchloric acid, wear approved ear protectors and approved safety glasses

and ensure that all instrument safety covers are in position.

Flashbacks

A flashback is an explosion of the gas mixture in the spray chamber, which can occur

for several reasons. For more details, refer to the SpectrAA software Help.

Agilent AA spectrometers have several safety features in place to prevent flashbacks,

and flashbacks are very rare in circumstances where instruments are properly

maintained.

In the rare event that a flashback does occur, the Agilent AA instrument safety

features are designed to safely relieve the pressure and minimize damage. In addition

to reading the list below, refer to the ‘Maintenance and Troubleshooting’ chapter of

the User’s Guide and the SpectrAA software Help for recommended maintenance

procedures to prevent flashbacks.

Analysis over many years has shown that in most cases, flashbacks are associated

with one or more of the following points. If you experience a flashback, check this list

to see if any of the points are relevant, and take steps to remedy the situation.

1 Keep the burner clean. Deposits must not be allowed to build up in or on the

burner slot because they can partially block it (thus causing the pressure to build

up in the spray chamber and breach the seal provided by the liquid trap), or

glowing particles can fall down through the slot into the spray chamber and ignite

the combustible gas mixture inside.

The use of a hard object to brush off glowing carbon particles during flame

28 Agilent Confidential 140/240/280 Series AA Service Manual

Page 29

General Information

operation is not recommended because of the increased risk of knocking one of the

particles down the slot. When using an organic solvent, a reduced uptake rate

should be used to restrict the amount of liquid fuel that is fed to the flame.

2 The width of the burner slot must not exceed the maximum design specification

[Mark VIA: 0.47 mm (0.0185 in) for N2O; Mark 7 0.46 mm (0.0181 in) for N2O; or

0.54 mm (0.021 in) for air]. Even a small increase in width can greatly increase the

possibility of a flashback occurring.

The burner slot must be regularly cleaned according to the instructions included in

the ‘Maintenance and Troubleshooting’ chapter of the User’s Guide.

3 Ensure that the spray chamber and liquid trap are kept clean. If dirty solutions are

being analyzed (for example, engine oils), ensure that the spray chamber, liquid

trap, float, and drain tube are regularly cleaned and flushed with a suitable solvent

so that sludge does not build up in the parts.

4 Ensure that the correct O- rings are used on the burner, nebulizer block, and

nebulizer, and that they remain undamaged.

Damage to O- rings in the spray chamber can result in gas leaks that can be ignited

by the flame and in turn set fire to the spray chamber.

Damage to O- rings in the nebulizer can result in oxidant leaks that can reduce the

total flow of gas through the burner slot and so increase the possibility of a

flashback occurring.

5 The liquid trap must be filled with the same solution as the matrix used for the

standards and samples.

6 The drain tube must be attached to the lower nipple of the liquid trap, and it must

slope downwards all the way to the drain vessel so that the waste liquid drains

smoothly.

The end of the drain tube must not be allowed to drop below the level of the liquid

in the vessel. (Also, the level of liquid must not be allowed to rise above the end of

the tube.)

When using organic or toxic liquids in the spray chamber, a vent tube must be

attached to the upper vent nipple of the liquid trap. It must slope downwards

(running parallel to the drain tube) to prevent it becoming blocked should any

liquid drain out, and be vented to an active exhaust system.

All the above points must be observed because a sudden surge of waste liquid can

affect the pressure in the spray chamber and result in a flashback.

7 Since N

O is stored in the cylinder under pressure as a liquid, when it expands

2

through the regulator it can cool the regulator sufficiently to form ice on the

outside and prevent it from operating correctly.

Prevent freezing by using a heater on the N

O regulator on the supply cylinder.

2

Contact the supplier of the regulator for a suitable heater.

8 As free acetylene is unstable at elevated pressure, it has to be stored in the

cylinder by dissolving it in acetone. If the gas is withdrawn too quickly, or the

cylinder pressure is allowed to drop below 700 kPa, acetone may be drawn off in

sufficient quantities to affect analytical performance, damage seals, O- rings, and

hoses, or even cause a flashback. Observe the recommendations concerning the use

of acetylene.

9 Where possible, do not perform digests with perchloric acid. As this acid is known

for forming unstable salts, operators using this acid should ensure that the

minimum amount is allowed to reach the spectrometer, and that the burner, spray

chamber, and liquid trap are thoroughly cleaned after each analysis to ensure that

unstable salts are not allowed to build up. Failure to do this can result in

unpredictable flashbacks.

140/240/280 Series AA Service Manual Agilent Confidential 29

Page 30

General Information

10 Aspirating solutions (especially alkaline/ammoniacal ones) that contain high

If a flashback or flame event occurs,

• Immediately press the red flame- off button to turn off gas f low to the instrument.

• Turn off the gas supply.

• Turn off power to the instrument.

• Inspect the sample introduction components including the burner, spray chamber,

• Check burner condition and O- rings for damage.

• Check O- rings for the spray chamber, especially the pressure relief bung for

• Check the nebulizer for damage.

• Check the windows on either side of the flame area for damage.

• Clean up any spills in the sample introduction area or on the instrument.

• Follow the Agilent Product Safety procedures for flashbacks. These procedures can

concentrations of Ag and Cu can lead to the formation of acetylides that can

spontaneously decompose and cause a flashback.

and nebulizer and clean or replace as necessary.

damage.

be found in two documents:

• Product Safety Event (PSE)

• AA Flashback Incident Questionaire

For further details refer to Service Note Number: AA- 275, AA Flashback Incident

Questionaire and Product Safety Event (PSE)

(The following SPARK website may also be useful:

https://spark.it.agilent.com/message/27517#27517)

Furnace and Zeeman Operation

Gases

The graphite tube atomizer (GTA120) gas supply system is designed for use with inert

gases and air. For more details and service information about the GTA120, refer to the

GTA120-120Z and PSD120 service manual.

Do not use pure hydrogen with the graphite tube atomizer since this could result in

leakage and potentially explosive accumulation of hydrogen. You can use a proprietary,

prepackaged mixture of 95% argon (or nitrogen) and 5% hydrogen. Do not attempt to

create your own mixture of hydrogen and an inert gas for use with the GTA system.

Heat Hazards

A hot furnace atomizer can present heat hazards that can result in severe burns.

Never put your hands in the sample compartment while you are operating your

furnace.

Allow the furnace atomizer to cool before removing it from the sample compartment.

Vapors and Fumes

Do not place your head over the graphite tube atomizer while it is operating. This

could cause inhalation of hazardous or toxic fumes, or your skin and eyes could be

injured by corrosive vapors or fumes.

30 Agilent Confidential 140/240/280 Series AA Service Manual

Page 31

General Information

The chimney or the optional exhaust accessory must be in place for furnace operation

to ensure that toxic vapors and heat are exhausted.

UV Radiation

When viewing the sample during the drying stage, use only a rear coated mirror (as

supplied) or the optional Tube- CAM. Do not look directly at the furnace during either

the ash or atomize stages.

Magnetic Field (Zeeman only)

The magnet produces a variable magnetic field of up to 0.8 Tesla peak at mains

frequency in the workhead during the read stage.

To avoid interference with heart pacemakers or magnetic storage media, keep them at

least 300 mm from the magnet.

140/240/280 Series AA Service Manual Agilent Confidential 31

Page 32

General Information

Specifications

Weights and Dimensions

System unit Width Depth Height Weight

240 AA spectrometer 790 mm (31 in) 580 mm (23 in) 590 mm (23 in) 56 kg (123 lb)

240Z AA spectrometer. Also

requires GTA 120Z

240 AA shipping dimensions 1215 mm (46 in) 820 mm (35 in) 870 mm (35 in) 97 kg (214 lb)

240Z AA shipping dimensions 1215 mm (46 in) 820 mm (35 in) 870 mm (35 in) 86 kg (190 lb)

280FS AA spectrometer 790 mm (31 in) 580 mm (23 in) 590 mm (29 in) 75 kg (165 lb)

280Z AA spectrometer. Also

requires GTA 120Z

280FS/Z AA shipping dimensions 1210 mm (48 in) 820 mm (32 in) 1020 mm (40 in) 106 kg (234 lb)

790 mm (31 in) 580 mm (23 in) 590 mm (23 in) 56 kg (123 lb)

790 mm (31 in) 580 mm (23 in) 740 mm (29 in) 61 kg (135 lb)

Optics

Primary Light Sources (Not supplied)

Hollow Cathode Lamps (HCL) Standard

UltrAA lamps Optional for AA140/240/240FS/240Z/ 280FS

Standard for AA280Z

* Refer to brochures for the full range of available lamps.

** All HCLs are available with recognition-coded bases.

Eight fixed-position lamps

Automatic lamp selection

Lamps are individually adjustable to the optical path

** On the AA280 Fast Sequential, 8 HCLs can be simultaneously powered up to 90 mA (45 mA per bank of 4 lamps) and

on the 280Z, 1 operating HCL and 1 on standby.

Beam Arrangement

Non-Zeeman Double/single beam

Zeeman Single beam

Reflective surfaces are designed for constant focus at all wavelengths and are hard–dielectric coated for high

performance and corrosion resistance.

Background Correction (where fitted)

Non- Zeeman

Continuum source Deuterium (D

Wavelength range 180 to 423 nm approx

lamp supply Switch-mode, current regulated, 40 mA (avg) approx

D

2

D2 duty cycle 20% at 50 Hz, 24% at 60 Hz

) lamp

2

32 Agilent Confidential 140/240/280 Series AA Service Manual

Page 33

General Information

WARNING

Zeeman

Magnetically separated and polarized sample beam pair generated in the workhead by the Zeeman effect with

rejection of one polarized component by a polarizer in the sample beam. The Zeeman effect background corrector

corrects to greater than 2.0 Abs background from 185 to 900 nm.

Monochromator

Instrument Agilent AA140/240 Agilent AA280

Type Czerny–Turner Czerny–Turner

Dispersing method Grating, 27 x 35 mm, 1200 lines/mm Grating, 30 x 35 mm, 1800 lines/mm

Focal length 252 mm 331.8 mm

Reciprocal linear dispersion 3 nm/mm at 250 nm 1.6 nm/mm at 250 nm

Blaze wavelength 250 nm 250 nm

Wavelength range 185 to 900 nm (and zero order) 185 to 900 nm (and zero order)

Wavelength accuracy ±0.37 nm ±0.37 nm

Wavelength repeatability ±0.04 nm ±0.035 nm

Wavelength drive Software controlled motor drive Software controlled motor drive

Slew rate 2000 nm/min 2025 nm/min

Scan direction Decreasing wavelength Decreasing wavelength

Wavelength readout Four digit display on PC screen Four digit display on PC screen

Slits, normal height 0.2, 0.5, 1.0 nm (flame atomizer) 0.1, 0.2, 0.5, 1.0 nm (flame atomizer)

Slits, reduced height 0.5 nm (furnace atomizer) 0.5 nm (furnace atomizer)

Slit drive Software controlled motor drive Software controlled motor drive

Slit repeatability To ±2% of nominal energy To ±2% of nominal energy

Gas Supplies (for flame instruments only)

The Agilent AA flame instrument is to be used only with air or nitrous oxide and acetylene for

flame operation.

Do not use oxygen or oxygen–enriched air as a combustion support gas. This will cause an

explosion. Do not use hydrogen as the fuel gas as it may leak into the instrument and cause an

explosion. Explosion hazards may also result from the use of other unspecified gas mixtures.

140/240/280 Series AA Service Manual Agilent Confidential 33

Compressed air supply Air supply must be clean, dry, and oil free

Air filter Recommended if a compressor is being used

Recommended pressure 350 kPa (50 psi)

Pressure range 245 to 455 kPa (35 to 65 psi)

Maximum flow rate 20 L/min

Page 34

General Information

CAUTION

Nitrous oxide supply Instrument grade (99.5% pure)

Recommended pressure 350 kPa (50 psi)

Pressure range 245 to 455 kPa (35 to 65 psi)

Maximum flow rate 16 L/min

Acetylene supply Instrument grade (99.0% pure). Must be packed in acetone

Recommended pressure 75 kPa (11 psi) at the instrument

Pressure range 65 to 100 kPa (9.5 to 14.5 psi) at the instrument

Maximum flow rate 10 L/min

Pressure in the acetylene storage cylinder must be maintained in excess of 700 kPa (100 psi) to

prevent acetone entering the gas lines.

Refer to “Gas Control” on page 67 for complete gas specifications.

Sample Introduction (flame instruments only)

Nebulizer

Platinum/iridium capillary

PEEK venturi

Adjustable to hi–vac and hi–solids positions

Burner

Mark 7 Air/Acetylene burner

Mark 7 Nitrous oxide/Acetylene burner

Flame ignition

Tongue of flame, spark ignition

Burner adjuster

Manual/Automatic vertical motion

Manual horizontal motion

Manual rotation

Spray chamber

Mark 7 polypropylene standard

Twin head mixing paddles

Externally finger-adjustable impact bead

Safety interlocks

Burner present

Burner type

Flame sensor

Flame shield

Pressure relief bung

Liquid trap level

Oxidant/safety tank pressure

Mains power

Gas control

34 Agilent Confidential 140/240/280 Series AA Service Manual

Page 35

General Information

NOTE

Programmable flame stoichiometry (gas mix)

On demand display of gas parameters

Interlocked ignition sequencing

Automatic flame changeover

Automatic dilution of combustible mixtures for safe flameout

Electrical Specifications

The installation of electrical power supplies must comply with the rules and/or

regulations imposed by the local authorities responsible for the use of electrical energy

in the work place.

All Agilent AA instruments are supplied with a 2 meter (6' 6") mains power cord

terminated as indicated in Table 1.

All power supplies should be single phase AC, 3 wire system (active, neutral and

ground, or two actives and ground) and should be terminated at an appropriate

connection receptacle that is within reach of the system power cable assembly. In

areas where 208/220/240 Volt supplies are not normally available in a single phase

configuration, supplies may be taken from two phases and ground using a three phase

system.

A separate connection receptacle should be provided for each unit in the system. Do

not use double adapters or extension cords.

A separate mains circuit individually protected by fuses or circuit breakers must be

used for the GTA accessory. It is preferable for the GTA and the instrument to share

the same phase.

If the system being installed is a Zeeman system, then two separate mains circuits individually protected

by fuses or circuit breakers must be used — one each for the instrument and the Zeeman GTA accessory.

It is preferable for the GTA and the instrument to share the same phase but separate power supply

circuits.

Avoid using power supplies from a source that may be subject to electrical interference from other

services (large electric motors, elevators, welders, air conditioning units, etc.).

Electrical Supply

Tab l e 1 Electrical specifications for Agilent AA systems

System unit Required supply voltage Rating

55B AA spectrometer 100, 120, 220 or 240 VAC, 50/60 Hz 170 VA

240 AA spectrometer 100, 120, 220 or 240 VAC, 50/60 Hz 170 VA

280 AA spectrometer 100, 120, 220 or 240 VAC, 50/60 Hz 230 VA

240 Z AA spectrometer 208-240 VAC, 50/60 Hz 1000 VA*

280 Z AA spectrometer 208-240 VAC, 50/60 Hz 1000 VA*

GTA Graphite Tube Atomizer (GTA 120) 208/220/240 VAC, 50/60 Hz 15 A*

SIPS 10/20 Sample Introduction Pump System 100-240 VAC 70 W

SPS 4 Autosampler 100-240 VAC, 50/60 Hz 24 VDC, 2.5 A

VGA 77 Vapor Generation Accessory 100, 120, 220 or 240 VAC, 50/60 Hz 20 VA

140/240/280 Series AA Service Manual Agilent Confidential 35

Page 36

General Information

Tab l e 1 Electrical specifications for Agilent AA systems

System unit Required supply voltage Rating

ETC 60 Electrothermal Temperature Controller 110-120, 220-240 VAC, 50/60 Hz 755 VA maximum

UltrAA Boosted Lamp Supply 100, 120, 220 or 240 VAC, 50/60 Hz 150 VA

* In normal operation, the Zeeman and GTA units will draw surge currents in excess

of the nominal rating. Power supplies to these units must be isolated from other

supplies to the system, and should include delayed action protection devices such as

circuit breakers or motor start fuses.

The VA and current figures above are the typical continuous VA and current drawn by

AA and GTA. During the atomize cycle, surge currents for very short spans of time

(between 1 and 5 second) may be drawn by AA (up to 48 A) and by GTA (up to

40 A).

Tab l e 2 Agilent AA spectrometer power connections

Standard GTA 120 or Zeeman

Plug supplied

Australia -00 10 A, 250 VAC. Complies with AS3112. Clipsal 439D15M

USA -01 Complies with NEMA 5-15P Complies with NEMA L6-30P (Hubbell

#2621)

Canada -01 Complies with NEMA 5-15P 20 A, 250 VAC. Complies with NEMA

L6-20P (Hubbell #2321+).

Europe -02 Perena 3410. Complies with CEE 7 Sheet

VII or NFC 61.303.

Required wall socket type

Australia -00 General purpose 10 A 250 V outlet (HPM

787, Clipsal 15)

USA -01 Complies with NEMA 5-15R (15 A supply)

(Hubbell IG 5262)

Canada -01 Complies with NEMA 5-15R (15 A supply)

(Hubbell IG 5262)

Europe -02 Complies with CEE 7 standard No.7 Sheet

VII, or Norma Francais C61.303 Sheet V.A.

Power supply, current

rating and overload

protection

Between 5 and 20 A Between 30 and 40 A

Kaiser CEBEC 616 VDE. Complies with

DIN 49441R2.

Dedicated circuit, 15 A 250 V outlet (HPM

787/15, Clipsal 15/15

Complies with NEMA L6-30R (30 A

supply) (Hubbell #2626)

20 A, 250 VAC. Complies with NEMA

L6-20R (Hubbell #2326+)

No standard known (Kaiser CEBEC 702

type 31/131.5)

Power supply Single phase Single phase

36 Agilent Confidential 140/240/280 Series AA Service Manual

Page 37

General Information

NOTE

NOTE

Agilent SpectrAA Windows software

SpectrAA software is based on a spreadsheet concept that mimics the analyst’s

workbook.

Refer to the on-line Help or the Agilent AA140/240/280 operation manuals for detailed information on

software use.

System software for Flame, Furnace, Vapor and limited (non EPA- compliant) QC

operation is supplied as standard.

Refer to the AA Site Preparation Guide for recommended PC configuration and Windows operating

system.

Methods and Sequence

Methods

All previous Worksheet features have been retained, and new ones added, so

developing Methods and Sequence information will be familiar.

The Index has been retained as a very useful feature for the operator. The Cookbook

is now accessible directly from the Index.

The element tabs at the base of method pages are retained, one for each element

selected for the sequence. Clicking on the tab will display the parameters for each

element for that particular page, enabling immediate comparison of parameters for the

elements selected.

Sequence

This contains four pages:

• Control is the standard Agilent SpectrAA software layout

•Options contains Error Protocols and Signal Graphics storage

•Reports is used to define data reported and to set up data export

•Notes can be used by the operator to add further information for the report.

QC Operation

A range of QC tests is provided as standard:

• QC Check Standard

• QC Check Blank

• Sample Spike

• Duplicate

• Matrix Spike

• Lab Control Sample (LCS)

• Replicate %RSD

• Required Detection Limit (RDL)

• Instrument Detection Limit (IDL)

140/240/280 Series AA Service Manual Agilent Confidential 37

Page 38

General Information

• Correlation Coefficient

• Date and Time Stamping

As in all Agilent SpectrAA software, you can set QC operation to ON or OFF..

Results Display

The final concentration result is displayed in a cell in the spreadsheet. This

concentration result can be optionally selected as weight/volume corrected.

The Datalog displays all data relevant to an autorun. Data from each solution -

concentration, %RSD, mean Abs, replicate Abs, and any error and status messages.

All flame, furnace, and vapor signal graphics can be stored. Calibration graphics are

also a standard feature.

Both have separate graphical display windows.

Zoom facilities are provided as standard.

A reference calibration graph may be overlaid on the current calibration graph for

comparison.

Operational Display (Instrument)

The operator can select up to four windows for display. These are sized to the

available screen area. The four windows are:

• Spreadsheet

• Calibration

• Signal graphics

• Datalog

These can be selected either by scrolling using the F6 function key or from the VIEW

drop- down menu.

Large characters show results for the current solution. The normal SpectrAA Status

Block is shown at the base of the screen together with the Autorun Status block,

Message line and Instrument Status line.

Six large buttons and four tabs enable the operator to control the system from this

page.

Buttons:

• Select

• Optimize

• Start/Pause/Continue

• Stop

• Read

• Help

Tabs:

• Filing - to develop, recall, or store worksheets and templates

• Develop - to develop or change all worksheet parameters

• Labels - to enter solution labels and weight/volume data

• Instrument - to access and change all instrument parameters

38 Agilent Confidential 140/240/280 Series AA Service Manual

Page 39

General Information

CAUTION

‘Status’

The operator is kept continuously informed about the system.

The Status block shows the current Method and basic parameters.

The Autorun status block shows what is happening with the autorun.

The Message line is used for several purposes. When developing

Methods it describes the parameters and valid numeric range, as well as displaying

hints. During autorun it displays any warning messages.

Error Messages appear in a popup window in the center of the screen.

The Instrument status line shows what the instrument/accessory is currently doing.

Data Export

Data can be exported in PRN format and can be sent to a LIMS system.

Administration

This allows you to set a password to limit access to the software. When a password is

active ‘Simple’ operation mode is activated which allows the operator only to recall a