Page 1

User’s Guide

Publication number 01159-92000

February 2000

s1

For Safety information, Warranties, Regulatory information, and publishing information,

see the pages at the back of this book.

© Copyright Agilent Technologies 2000

All Rights Rese rved.

1159A 1GHz Active Differential Probe

Page 2

Contents

Inspect the Probe 3

1159A Active Differential Probes Introduction 4

Probe Accessories Supplied 5

Attaching External Attenuators to the Probe 7

!

Specifications and Characteristics 8

To Connect the Probe to the Circuit under Test 12

Recommended Probe Configurations 14

Safety Considerations 17

Service Strategy 18

Performance Verification 19

Adjustment of 10:1 and 20:1 Attenuators 33

Performance Test Record 37

2

Page 3

1159A 1GHz Active Differential Probe

Inspect the Probe

Inspect the Probe

❏ Inspect the shipping container for damage.

Keep a damaged shipping container or cushioning material until the contents of

the shipment have been checked for completeness and the probe has been

checked mechanically and electrically.

❏ Check the accessories.

Any accessories that were supplied with the probe are listed in “Probe

Accessories Supplied” on page 5.

• If the contents are incomplete or damaged notify your Agilent Sales Office.

❏ Inspect the instrument.

• If there is mechanical damage or defect, or if the probe does not operate

properly or pass performance tests, notify your Agilent Sales Office.

• If the shipping container is damaged, or the cushioning materials show signs

of stress, notify the carrier as well as your Agilent Sales Office. Keep the

shipping materials for the carrier’s inspection. The Agilent office will arrange

for repair or replacement at Agilent’s option without waiting for claim

settlement.

3

Page 4

1159A 1GHz Active Differential Probe

1159A Active Differential Probes Introduction

1159A Active Differential Probes Introduction

The 1159A is a wide-band differential active probe. The probe features low noise,

low input capacitance, high common mode rejection, and Field Effect Transistor

(FET) buffered inputs in the probe head. User-selectable offset gives the probe

flexibility to measure a large range of signal types. Plug-on attenuators and AC

coupling accessories further extend the application range. Included interconnect

accessories allow connection to surface mount and through-hole components

with minimal signal degradation. The input receptacles in the probe head are

compatible with standard 0.025" (0.635 mm) square pins, which provide a

convenient low-cost method of creating device characterization test fixtures.

The 1159A is ideal for acquiring high speed differential signals such as those

found in disk drive read channels, differential LAN, video, and so on. The high

impedance characteristics of both inputs allow you to use the probe as a FET

probe to make single-ended measurements in digital systems without

introducing a ground loop as a conventional FET probe would.

Differential Amplifiers and CMRR

The 1159A Differential Probe is a high input impedance amplifier. A

characteristic of differential amplifiers is the ability to reject signals that are

common to the two inputs. The common mode rejection ratio (CMRR) is the

measurement of this ability. It is expressed as the ratio between the amplitudes

of the common mode and differential signals that produce equal outputs. If the

differential gain is known, these measurements can be referred to the probe

input. CMRR is usually expressed in dB:

V common mode input Gain×

CMRR in dB 20

The ability to reject common mode signals depends on the balance designed into

the probe amplifier. As the frequency of the common mode signal increases, it

becomes harder to balance the amplifier parasitic parameters. This leads to

degradation of the CMRR.

The CMRR of the 1159A Differential probe is specified from the probe tip. This

method of specifying the probe CMMR eliminates the effects of source

impedance, provided the connections from the probe tip to the signal source are

symmetrical.

-------------------------------------------------------------------------

log=

V common mode output

4

Page 5

1159A 1GHz Active Differential Probe

Probe Accessories Supplied

Probe Accessories Supplied

The following diagram and table show the accessories supplied with the 1159A

Differential Probe.

1

4

5

Probe Accessories

Item Description Qty. Part Number

1 AC coupler 1 01154-82101

2 10:1 Attenuator 1 01159-82104

3 20:1 Attenuator 1 01159-82105

4 Header 1 N/A

5 Offset Pin 4 N/A

6 0.5 Grabber 2 N/A

7 0.8 Grabber 3 N/A

8 Ground Wire 1 N/A

9SMT Lead 4 N/A

10 Wire Lead 1 N/A

2

7

6

3

10

9

8

5

Page 6

1159A 1GHz Active Differential Probe

Probe Accessories Supplied

To Order Replaceable Parts

To order a replaceable part, in the United States and Canada call our toll-free

hotline at 1-877-447-7278, or call your local Agilent Technologies Sales Office.

Replaceable Parts

Item Description Qty. Part Number

1 AC coupler 1 01154-82101

2 10:1 Attenuator

3 20:1 Attenuator

4 Header 1 N/A

5 Offset Pin 4 N/A

6 0.5 Grabber 2 N/A

7 0.8 Grabber 3 N/A

8 Ground Wire 1 N/A

9SMT Lead 4N/A

10 Wire Lead 1 N/A

(includes an adjustment tool)

(includes an adjustment tool)

Connection Kit 1 01154-60004

Trimmer Tool

(0.635 mm square head)

1 01159-82104

1 01159-82105

1 5063-2196

Using the Accessories

The 1159A Differential Probe and accessories provide a variety of ways to

connect to circuitry under test. Any method used to connect the probe signal

inputs to the circuit under test degrades the performance of the probing solution.

Take the following precautions to optimize common mode rejection.

• Maintain tip connection lead length as short as possible and the same

length.

• Follow the same path for wires used to connect the inputs of the probe

to the circuit under test.

• Probes do not have infinite input impedance and do load the circuit

under test. If the impedance of the test points is not identical, unequal

loading will occur. This degrades common mode rejection.

• The ground lead length is not usually critical with a differential probe.

• Carefully consider the ground potential relative to the oscilloscope

ground potential. The potential difference must be within the common

mode range of the probe.

• The DC potential between the AC coupling adapter and the oscilloscope

ground must not exceed 42 Vpk.

• Do not cascade the external attenuators.

• Cascade the external AC coupling adapter in the following order: probe,

attenuator, and AC coupling adapter.

6

Page 7

1159A 1GHz Active Differential Probe

Attaching External Attenuators to the Probe

Other Probe Accessories

The Agilent Wedge was designed to interface directly with the differential probe.

These devices simplify connections to surface mount integrated circuits and have

output pins compatible with the probe tip and attenuator sockets.

Attaching External Attenuators to the Probe

The external attenuators plug directly on to the probe tip. They are calibrated

at the factory to provide the optimum common mode rejection and should not

be swapped between probes.

1159A Attenuator

Div-By-10 1 GHz

Div-By-20 1 GHz

1159A AC Coupler

Always Install Last

The 1159A probe’s best performance is achieved when the probe attenuation is set

to /10 in the Infiniium’s Probes Setup dialog box.

7

Page 8

1159A 1GHz Active Differential Probe

Specifications and Characteristics

Specifications and Characteristics

Specifications

Input Configuration Ground Connector

Input Coupling DC AC coupling obtained by installing an AC coupling

Gain Accuracy at 1 kHz 2%

!

Maximum Input Voltage

Either input from ground

CMRR at 70 Hz: 80dB

True Differential (+ and inputs), with shield

adapter

< ±42 V

at 1 MHz: 40dB

at 100 MHz: 25dB

at 500 MHz: 19dB

at 1 GHz: 13dB

–

Range

Mode No attenuator ÷10 attenuator ÷20 attenuator

Differential < ±400 mV < ±4 V < ± 8V

Common < ±16 V < ±42 V < ±42 V

Offset (Common) < ±1.6 V < ±16 V < ±32 V

8

Page 9

1159A 1GHz Active Differential Probe

Specifications and Characteristics

The following characteristics are valid for the 1159A probe after the probe has

reached operating temperature, which is 20 minutes with power applied in a

environment with stable ambient temperature. The probe must be operating

within the environmental conditions listed in the “Environmental Specifications”

section on page 11, and must have been calibrated within the past 12 months in

a ambient temperature of 23 5 C.

±°

Performance Characteristics

Probe Bandwidth (-3 dB) DC to 1 GHz

Offset Range 1.6 V

Rise Time (Probe only)

1:1 Attenuation

Internal switched attenuation only

Input Resistance

(each side to ground)

Input Capacitance (between inputs)

1:1 Attenuation

No external attenuators

Input Capacitance (each side to ground)

1:1 Attenuation

No external attenuators

±

<350 ps

1 M

Ω

<0.85 pF

<1.5 pF

9

Page 10

1159A 1GHz Active Differential Probe

Specifications and Characteristics

Typical CMRR versus Frequency (Hz)

Typical Noise

10

Page 11

1159A 1GHz Active Differential Probe

Specifications and Characteristics

Environmental Specifications

Operating Non-operating

Temperature 0 to 50 C -40 to 75 C

Humidity Up to 80% RH at 40 C Up to 80% RH at 75 C

Altitude Up to 4,600 meters

Vibration Random vibration 5 to

Weight Approximately 226 g

Dimensions Refer to the drawing shown below

Dimensions

°°

°°

(15,000 feet)

500 Hz, 10 minutes per axis,

0.3 g

rms

Up to 15,000 meters

(50,000 feet)

Random vibration 5 to

500 Hz, 10 minutes per axis, 2.41

g

. Resonant search 5 to 500 Hz

rms

swept sine, 1 octave/min. sweep

rate, (0.75 g), 5 minutes resonant

dwell at 4 resonance’s per axis.

11

Page 12

1159A 1GHz Active Differential Probe

To Connect the Probe to the Circuit under Test

To Connect the Probe to the Circuit under Test

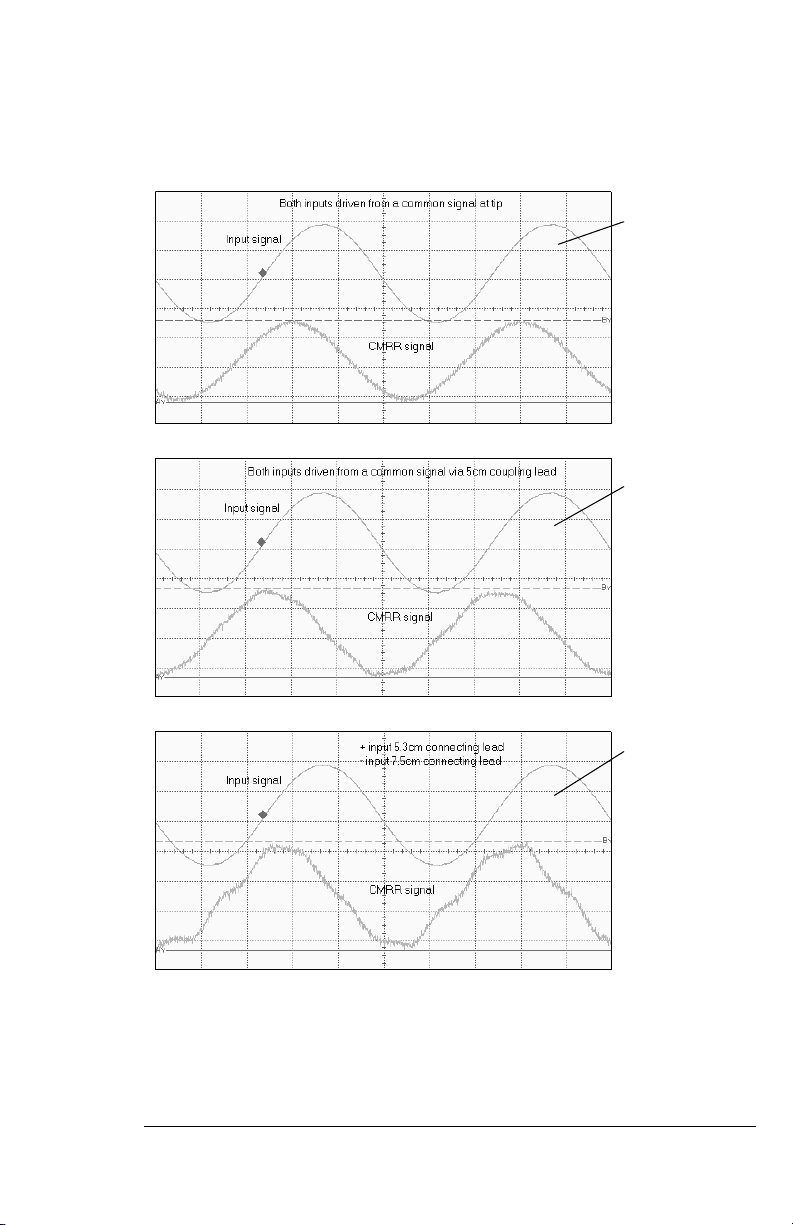

The method you use to connect the probe to the circuit under test is critical for

ensuring accurate measurements. The following examples examine the effect of

using different lengths of wire at 100MHz to connect the signal source to the

probe tip.

The Impedance of the Source

This is another instance where the symmetry of the differential circuit is

important. The impedance of the source forms a network with the input

impedance of the connection and the probe. This network determines the

frequency response for the measurement. If each side of the differential source

has a different impedance, the frequency response of each side will be different.

This lack of balance is reflected in reduced CMRR. The higher the impedance

of the source, the more critical these parasitic effects.

The Ground Connection

A poorly located ground connection allows ground loops to add to the common

mode signal. The differential probe measures the potential difference between

two locations on a PC board. Usually, it is not necessary to ground the probe.

Whether to ground the probe depends on the magnitude and frequency of the

voltage difference between the oscilloscope ground and the board ground. It is

good practice to maintain a board ground. Without this ground reference, you

could easily exceed the common mode range of the probe.

Probe Offset

The amplifiers in the 1159A probe limit the Differential Mode Range to 400mV.

If the input to the probe is approaching 400mV, there is little offset range available

for positioning the trace on screen. There are two solutions to this problem:

• Attenuate the signal into the probe with the 1/10 or 1/20 attenuator. This

mode of operation will induce some small loss in CMRR.

•Use Position to position the trace on screen.

The added feature of position control independent of Offset allows trace

positioning without calculating how much probe offset range is available. The

trace can be positioned by dragging the trace or positioning the trace under the

Probe menu.

12

Page 13

1159A 1GHz Active Differential Probe

To Connect the Probe to the Circuit under Test

Both inputs derived

from a common signal

at probe tip.

CMRR = 35.6dB

Both inputs derived

from a common signal

via 5cm coupling lead.

CMRR = 35dB

Probe coupli ng leads

of different length.

Positive input 5.3cm.

Negative input 7.5cm.

CMRR = 33dB

13

Page 14

1159A 1GHz Active Differential Probe

Recommended Probe Configurations

Recommended Probe Configurations

For best performance, use the following configurations. They are presented in

the recommended order from the most desirable to the least.

Note The use of the ground connection is optional for all configurations.

Direct Connection

1159A Probe Tip

Test Point Layout

See the “Test Point

Layout” section for

more information

AC Adapter/Attenuator

Use the attenuator shipped with the probe and marked with the same serial

number for accurate measurements. Do not use the attenuators with other

probes.

1159A Attenuator

Div-By-10 1 GHz

Div-By-20 1 GHz

1159A AC Coupler

Always Install Last

Test Point Layout

See the “Test Point

Layout” section for

more information

14

Page 15

1159A 1GHz Active Differential Probe

Recommended Probe Configurations

Offset Pins

You may use offset pins with any of the tip adapters.

Offset Pins Rotate to

Adjust Spacing

SMT Lead

You may use SMT leads with any of the tip adapters.

SMT Leads

Maintain

Equal Length

Solder Leads

to Test Points

Ground

Ground

Lead Opt

15

Page 16

1159A 1GHz Active Differential Probe

Recommended Probe Configurations

Wire Leads

You may use wire leads with any of the tip adapters.

Connect Leads

to Test Points

Ground

Opt

Grabbers

Using grabbers and wire leads results in significant lead length. Expect

measurement quality degradation with fast signals.

0.5 mm or 0.8 mm Grabbers

Opt

Ground

16

Page 17

1159A 1GHz Active Differential Probe

Safety Considerations

Test Point Layout

Safety Considerations

Read the Safety summary in the warranty pages at the back of this guide before

servicing the instrument. Before performing any procedure, review the safety

information for cautions and warnings.

WARNING Only trained service personnel aware of the hazards involved (for example, fire

!

and electric shock) should perform maintenance on the instrument. When

maintenance can be performed without power applied, the power cord must be

removed from the instrument.

17

Page 18

1159A 1GHz Active Differential Probe

Service Strategy

Service Strategy

To return the 1159A 1 GHz Differential Probe to optimum performance requires

factory repair. Return all probes to the service group for repair and calibration.

If the probe is under warranty, normal warranty services apply. If the probe is

not under warranty, you can exchange a failed probe for a reconditioned one at

a nominal cost.

To Return the Probe to Agilent for Service

Call (877) 447-7278 for further details and the location of your nearest Agilent

Service Office.

1

Write the following information on a tag and attach it to the probe.

• Name and address of owner.

• Probe model number.

• Probe serial number.

• Description of the service required or failure indications.

2 Return the following accessories with the probe:

• Attenuators

• AC coupling adapter

Retain all other accessories.

3

Return the probe in its case or pack the probe in foam or other shock

absorbing material and place it in a strong shipping container.

You can use the original shipping materials or order materials from an Agilent

Sales Office. If neither are available, place 3 to 4 inches of shock-absorbing

material around the instrument and place it in a box that does not allow

movement during shipping.

4

Seal the shipping container securely.

5 Mark the shipping container as FRAGILE.

In all correspondence, refer to the instrument by model number and full serial

number.

18

Page 19

1159A 1GHz Active Differential Probe

Performance Verification

Performance Verification

Use this procedure to verify the warranted characteristics of the 1159A 1 GHz

Differential Probe. The recommended performance verification interval for the

1159A is one year. Perform the complete performance verification procedure as

the first step of annual certification. You can complete performance verification

without removing the probe covers. There are no user adjustments available for

calibration. Use the equipment shown in the “Test Equipment Required” section

to complete the performance verification procedures.

1

Perform the steps listed in the “Preliminary Procedure” section on

page 20.

2 Perform the steps listed in the “Test Gain Accuracy at 1 kHz” section

on page 25.

3 Perform the steps listed in the “Test Offset” section on page 26.

4 Perform the steps listed in the “Test Differential Mode Range” section

on page 26.

5 Perform the steps listed in the “CMRR Test Introduction” section on

page 27.

Test Equipment Required

Description Minimum Requirements Part Number

Infinium Oscilloscope 1.5 GHz 54845A

Digital AC/DC Voltmeter DC: 0.1% accuracy

AC: 0.2% accuracy

200 mV @ 1 kHz

5 1/2 digit resolution

Function Generator Sine Wave and Square Wave output

Sine Wave Generator 50 MHz to 1 GHz

BNC T E9625A

Probe Tip BNC Adapter 5063-2143

Calibration Fixture 01154-63801

Intelligent Interface 01154-63401

High Frequency 10:1 Resistor

Divider Probe

10:1 Resistor Divider Probe

(provided with the 54845A)

Trimmer Tools

(included when attenuators are

purchased separately)

waveforms

into 1 M

20 V

pp

70 Hz to 10 MHz

500 1163A

Ω

10 M 1161A

Ω

Flat blade 0.04” (1 mm) wide

Square Head 0.025” (0.635 mm) 5063-2196

Ω

34401A

33120A

19

Page 20

1159A 1GHz Active Differential Probe

µ

Performance Verification

Preliminary Procedure

1

Turn on the oscilloscope, the 1159A, and the other test equipment.

Allow 30 minutes for all test equipment to warm up.

2

Press Default Setup.

3 Perform Probe Tip Cal on the 1161A connected to CH4 of the

oscilloscope (54845A).

4 Save the setup files listed in the “Performance Verification Setup Files”

section on page 20 to the C drive of the 54845A.

These setups can also be saved to drive A and filed for future use.

Performance Verification Setup Files

Save the setup information shown below for the various performance verification

tests to the specified file names on the C drive of the 54845A or to a floppy disk

in drive A. Connect the probes to the specified channels before creating and

storing the setup files.

Setup for Differential Mode Range

File Name: 1159CAL0

Probe Connected to CH1 1159A

Probe Connected to CH4 1161A

CH1 and CH4 Sensitivity 200 mV/div

CH2 and CH3 Off

Offset and Position CH1, CH2, CH3 and CH4 0 V

Measurements: CH1 and CH4 V amplitude under Measure Voltage

Timebase 500 Sec/div

Timebase Delay 0 Sec

Setup Acquisition Equivalent time: 8 averages

Trigger CH4; level 0 V + ve edge

20

Page 21

1159A 1GHz Active Differential Probe

Setup for CMRR at 70 Hz

File Name: 1159CAL1

Probe Connected to CH1 1159A

Probe Connected to CH4 1161A

CH1 Sensitivity 2 mV/div

CH4 Sensitivity 5 V/div

Measure Amplitude CH1 and CH4

CH2 and CH3 Off

Offset and Position CH1, CH2, CH3 and CH4 0 V

Timebase 10 mSec/div

Timebase Delay 0 Sec

Setup Acquisition Equivalent time: 64 averages

Trigger CH4; level 0 V + ve edge

Setup for CMRR at 1 MHz

File Name: 1159CAL2

Probe Connected to CH1 1159A

Probe Connected to CH4 1161A

CH1 Sensitivity 10 mV/div

CH4 Sensitivity 5 V/div

CH2 and CH3 Off

Offset and Position CH1, CH2, CH3 and CH4 0 V

Measure Amplitude CH1 and CH4

Timebase 500 nSec/div

Timebase Delay 0 Sec

Setup Acquisition Equivalent time: 64 averages

Trigger CH4; level 0 V + ve edge

Performance Verification

21

Page 22

1159A 1GHz Active Differential Probe

Performance Verification

Setup for CMRR at 100 MHz

File Name: 1159CAL3a

Probe Connected to CH1 None

Probe Connected to CH4 1163A

CH1 Sensitivity 200 mV/div; 50

CH4 Sensitivity 200 mV/div; 50

CH2, CH3, and CH4 Off

Offset and Position CH1, CH2, CH3 and CH4 0 V

Measure Amplitude CH1

Timebase 5 nSec/div

Timebase Delay 0 Sec

Setup Acquisition Equivalent time: 64 averages

Trigger CH4; 0 V + ve edge

Ω

Ω

Setup for CMRR at 100 MHz

File Name: 1159CAL3b

Probe Connected to CH1 1159A

Probe Connected to CH4 1163A

CH1 Sensitivity 5 mV/div

CH4 Sensitivity 200 mV

CH2, CH3, and CH4 Off

Offset and Position CH1, CH2, CH3 and CH4 0 V

Measure Amplitude CH1

Timebase 5 nSec/div

Timebase Delay 0 Sec

Setup Acquisition Equivalent time: 64 averages

Trigger CH4; 0 V+ ve edge

22

Page 23

1159A 1GHz Active Differential Probe

Setup for CMRR at 500 MHz

File Name: 1159CAL4a

Probe Connected to CH4 1163A

CH1 Sensitivity 200 mV/div; 50

CH4 Sensitivity 200 mV/div; 50

Offset and Position CH1, CH2, CH3 and CH4 0 V

Measure Amplitude CH1

Timebase 1 nSec/div

Timebase Delay 0 Sec

Setup Acquisition Equivalent time: 64 averages

Trigger CH4; 0 V

Ω

Ω

Setup for CMRR at 500 MHz

File Name: 1159CAL4b

Probe Connected to CH1 1159A

Probe Connected to CH4 1163A

CH1 Sensitivity 20 mV/div

CH4 Sensitivity 200 mV/div; 50

Offset and Position CH1, CH2, CH3 and CH4 0 V offset

Measure Amplitude CH1

Timebase 1 nSec/div

Timebase Delay 0 Sec

Setup Acquisition Equivalent time: 16 averages

Trigger CH4; 0 V

Ω

Performance Verification

23

Page 24

1159A 1GHz Active Differential Probe

Performance Verification

Setup for CMRR at 1 GHz

File Name: 1159CAL5a

Probe Connected to CH1 None

Probe Connected to CH4 1163A

CH1 Sensitivity 200 mV/div; 50

CH4 Sensitivity 200 mV/div; 50

CH2, CH3, and CH4 Off

Offset and Position CH1, CH2, CH3 and CH4 0 V

Measure Amplitude CH1

Timebase 500 pSec/div

Timebase Delay 0 Sec

Setup Acquisition Equivalent time: 16 averages

Trigger CH4; 0 V

Ω

Ω

Setup for CMRR at 1 GHz

File Name: 1159CAL5b

Probe Connected to CH1 1159A

Probe Connected to CH4 1163A

CH1 Sensitivity 50 mV/div

CH4 Sensitivity 200 mV/div; 50

CH2, CH3, and CH4 Off

Offset and Position CH1, CH2, CH3 and CH4 0 V

Measure Amplitude CH1

Timebase 500 pSec/div

Timebase Delay 0 Sec

Setup Acquisition Equivalent time: 16 averages

Trigger CH4; 0 V

Ω

24

Page 25

1159A 1GHz Active Differential Probe

Performance Verification

Test Gain Accuracy at 1 kHz

Setup the test equipment as shown in the following diagram.

1

Select Auto Zero on the probe menu.

The probe tip must not be connected to a signal source when Auto Zero is

performed.

2

Set the function generator as shown in the following table.

RMS (Sine wave) as measured with DVM.

Setting Value

Frequency 1 kHz

Output Amplitude 200 mV

Connect the 1159A via Intelligent Interface to the oscilloscope.

3

4 Connect the function generator to BNC A of the calibration fixture.

5 Connect the probe tip to the probe input A of the calibration fixture.

6 Set and measure with DVM (RMS mode) output of the function

Sine Wave

rms

generator at the calibration fixture.

Record V1: ___________________ .

7

Measure the probe output with the same DVM at Intelligent Interface.

Record V2: ___________________ .

8

Calculate the % gain error.

(% Gain Error = 100(V2 - V1)/V1). Record % Gain Error: ___________________ .

25

Page 26

1159A 1GHz Active Differential Probe

Performance Verification

9 Record the % Gain Error in the Performance Test Record on page 37.

Note Probe voltages at the calibration fixture and the output of the Intelligent

Interface.

Test Offset

This is an important step in the performance verification process. It should be

performed, even though no data is recorded in the Performance Test Record.

1

Disconnect the probe tip from the calibration fixture.

2 Select Auto Zero under the probe menu.

3 Measure the probe output (at BNC T of the Intelligent Interface) with

DVM DC mode.

Note The DVM reading should be approximately 2mV or less. This is not a warranted

specification.

Test Differential Mode Range

Use setup file 1159CAL0 for this test. Set up the test equipment as shown in the

following diagram.

1

Disconnect the intelligent interface.

2 Connect the 1159A to CH1 of the oscilloscope.

3 Load 1159CAL0.

26

Page 27

1159A 1GHz Active Differential Probe

Performance Verification

4

Connect the 1161A to the output of the function generator and CH4 of

the oscilloscope.

5 Setup the test equipment as shown in the following table. Connect the

1161A probe to CH4 of the oscilloscope. Measure the amplitude on CH4.

Test Equipment Setting

1161A Offset: 0

Function Generator Frequency: 1 kHz

Output Amplitude: 800 mV

6 Select Auto Zero under the probe menu.

Do not connect the probe tip to the fixture when Auto Zero is performed.

7

Connect a coaxial cable from the function generator to BNC A on the

pp

calibration fixture.

8 Connect the 1159A probe to the output of the calibration fixture CH A.

9 Record “Pass” in the “Differential Mode Range” section of the

Performance Test Record on page 37 if no clipping occurs. Record

“Fail” if visible clipping occurs.

CMRR Test Introduction

You will use setup files 1159CAL1 through 1159CAL5b to perform the CMRR

tests.

1

Set the output of the function generator to 20 Vpp.

2 Connect the 1161A probe to the output of the function generator using

BNC T.

27

Page 28

1159A 1GHz Active Differential Probe

Performance Verification

The instrument setup is shown in the following diagram.

3

Follow the steps in the “Test CMRR at 70 Hz” section on page 28.

4 Follow the steps in the “Test CMRR at 1 MHz” section on page 29.

5 Follow the steps in the “Test CMRR at 100 MHz” section on page 30.

6 Follow the steps in the “Test CMRR at 500 MHz” section on page 31.

7 Follow the steps in the “Test CMRR at 1 GHz” section on page 31.

Test CMRR at 70 Hz Use setup file 11 59CAL1 in this test. If only a short time

has elapsed from the last AUTO-ZERO calibration this step may be omitted.

1

Set the function generator as shown in the following table.

Setting Value

Output Level 20 V

Frequency 70 Hz

2 Connect the 1161A to the function generator output and CH4 of the

pp

oscilloscope.

3 Connect the 1159A probe to the CH C probe input of the calibration

fixture.

4 Load setup file 1159CAL1.

5 Select Auto Zero under the probe menu.

Do not connect the probe tip to the fixture during Auto Zeroing.

28

Page 29

6 Connect the function generator to Channel C BNC of the calibration

fixture.

7 Measure the amplitude of the function generator output (CH4).

Record V1:_____________

8

Measure the maximum value of CH1.

Record V2:_____________

9

Calculate CMRR.

CMRR in dB 20

10 Record CMRR in the “CMRR at 70 Hz” section of the Performance Test

Record on page 37.

Note CMRR must 80dB or greater.

Test CMRR at 1 MHz Use setup file 1159CAL2 in this test.

1

Set the function generator as shown in the following table.

Setting Value

Output Level 20 V

Frequency 1 MHz

pp

1159A 1GHz Active Differential Probe

V2 amplitude

--------------------------------

log=

V1 amplitude

Performance Verification

2 Disconnect the function generator from the BNC calibration fixture.

3 Load setup file 1159CAL2.

4 Perform Auto Zero under the probe menu.

Do not connect the probe tip to the calibration fixture during Auto Zeroing.

5

Connect the function generator to CHANNEL C BNC on the calibration

fixture.

6 Measure the amplitude of the function generator output (CH4).

Record V1:_____________

7

Measure the maximum value of CH1.

Record V2:_____________

8

Calculate CMRR.

V2 amplitude

--------------------------------

CMRR in dB 20

log=

V1 amplitude

29

Page 30

1159A 1GHz Active Differential Probe

Performance Verification

9 Record CMRR in the “CMRR at 1 MHz” section of the Performance Test

Record on page 37.

Note CMRR must 40dB or greater.

Test CMRR at 100 MHz Use setup files 1159CAL3a and 1159CAL3b in this

test.

1

Set the signal generator as shown in the following table.

Setting Value

Output Level 5 dBm

Frequency 100 MHz

2 Disconnect the 1159A probe from CH1 and connect it to CH2 to maintain

a constant temperature.

3 Load setup file 1159CAL3a.

4 Connect the signal generator to CH1 on the oscilloscope.

5 Measure the amplitude of the signal generator output.

Record V1:_____________

6

Remove the signal generator from CH1.

7 Remove the 1159A probe from CH2 and connect it to CH1.

8 Select Auto Zero under the probe menu.

Do not connect the probe tip to the calibration fixture during Auto Zeroing.

9

Connect the signal generator to BNC D of the calibration fixture.

10 Load setup file 1159CAL3b.

11 Connect the 1159A probe to D on the calibration fixture.

12 Measure the maximum value of CH1.

Record V2:_____________

13

Calculate CMRR.

CMRR in dB 20

14 Record CMRR in the “CMRR at 100 MHz” section of the Performance

Test Record on page 37.

V2 amplitude

--------------------------------

log=

V1 amplitude

Note CMRR must 25dB or greater.

30

Page 31

1159A 1GHz Active Differential Probe

Performance Verification

Test CMRR at 500 MHz Use setup files 1159CAL4a and 1159CAL4b in this

test.

1

Set the signal generator as shown in the following table.

Setting Value

Output Level 5 dBm

Frequency 500 MHz

2 Disconnect the 1159A probe from the CH1 and connect it to CH2 to

maintain a constant temperature.

3 Load setup file 1159CAL4a.

4 Connect the signal generator to CH1 on the oscilloscope.

5 Measure the amplitude of the signal generator output.

Record V1:_____________

6

Remove the signal generator from CH1.

7 Remove the 1159A probe from CH2 and connect it to CH1.

8 Select Auto Zero under the probe menu.

Do not connect the probe tip to the calibration fixture during Auto Zeroing.

9

Connect the signal generator to BNC C of the calibration fixture.

10 Load setup file 1159CAL4b.

11 Connect the 1159A probe to D of the calibration fixture.

12 Measure the maximum value of CH1.

Record V2:_____________

13

Calculate CMRR.

V2 amplitude

--------------------------------

CMRR in dB 20

14 Record CMRR in the “CMRR at 500 MHz” section of the Performance

log=

V1 amplitude

Test Record on page 37.

Note CMRR must 19dB or greater.

Test CMRR at 1 GHz Use setup files 1159CAL5a and 1159CAL5b in this test.

1

Set the signal generator as shown in the following table.

Setting Value

Output Level 5 dBm

Frequency 1 GHz

2 Disconnect the 1159A probe from the CH1 and connect it to CH2 to

maintain a constant temperature.

31

Page 32

1159A 1GHz Active Differential Probe

Performance Verification

3 Load setup file 1159CAL5a.

4 Connect the signal generator to CH1 on the oscilloscope.

5 Measure the amplitude of the signal generator output.

Record V1:_____________

6

Remove the signal generator from CH1.

7 Remove the 1159A probe from CH2 and connect it to CH1.

8 Select Auto Zero under the probe menu.

Do not connect the probe tip to the calibration fixture during Auto

Zeroing.

9

Connect the signal generator to BNC C of the calibration fixture.

10 Load setup file 1159CAL5b.

11 Measure the maximum value of CH1.

Record V2:_____________

12

Calculate CMRR.

CMRR in dB 20

13 Record CMRR in the “CMRR at 1 GHz” section of the Performance Test

Record on page 37.

Note CMRR must 13dB or greater.

V2 amplitude

--------------------------------

log=

V1 amplitude

32

Page 33

1159A 1GHz Active Differential Probe

Adjustment of 10:1 and 20:1 Attenuators

Adjustment of 10:1 and 20:1 Attenuators

10:1 and 20:1 attenuators are supplied with the 1159A probe. This attenuator is

matched to the probe and should require no further adjustment. Each attenuator

is labeled with a serial number that matches the last four digits of the probe serial

number. Identify matching probes and attenuators using this number. If you

purchase new attenuators for the probe, you must adjust them to match the

probe.

Optimizing CMRR for an Attenuator

For optimum CMRR when the attenuator is connected to the probe, the DC and

HF attenuation should be the same for both active inputs of the probe. Three

trimmers are provided in the attenuator to match the two active inputs. The

adjustments are located under the serial number label. Apply a new label after

calibration and mark this label with the last four digits of the probe’s serial

number. Only adjust an attenuator if it is not the original attenuator shipped with

the probe.

33

Page 34

1159A 1GHz Active Differential Probe

Adjustment of 10:1 and 20:1 Attenuators

The attenuator’s plastic covers may be removed. You must take care not to

damage the probe attenuator pins.

10:1 and 20:1 Attenuator Adjustment Procedure

Use the following steps to adjust the 10:1 or 20:1 attenuators.

1

Connect the function generator, probe and oscilloscope as shown.

Connect the + active probe input to the function generator output for these tests.

Connect the active input to ground with the probe ground socket.

–

2

Connect the 1159A Probe to CH1 of the oscilloscope.

3 Turn on the test equipment.

Allow 30 minutes for the probe to warm up.

34

Page 35

1159A 1GHz Active Differential Probe

Adjustment of 10:1 and 20:1 Attenuators

4

Place the 10:1 or 20:1 attenuator on the 1159A probe.

Do not connect a signal to the probe at this time.

5

Set the function generator as shown in the following table.

Use a function with a flat top for this test.

Setting Value

Square Wave Output Amplitude 1 V

Frequency 5 kHz

Offset 0

6

Select Auto Zero on the probe menu.

7 Connect the 1159A probe as shown.

Use the clips to make these connections. The frequency being considered has a

fundamental of 5 kHz. Connect the + input of the probe to the signal source.

Connect the input to ground.

8

Set the oscilloscope time base to 500 nS/div.

9 Press Auto Scale.

The 54845A triggers off CH 4.

10

Use the square head trimmer tool to adjust the + LF comp to achieve

–

the best square corner and flat top of the displayed waveform.

Adjust the compensation to achieve the best waveform characteristics when you

remove the tool.

11

Connect the + and probe inputs to the function generator output while

–

the probe ground is connected.

You can use the calibration fixture BNC to make these connections.

12

Set the function generator to 50Hz and the output to 10V amplitude.

The 1161A CH 4 will show this amplitude.

13

Set the oscilloscope time base to 5 mS/div.

14 Set CH1 sensitivity to maximum.

15 Adjust DC Att. Balance for the minimum square wave amplitude.

The phase of the signal will change by 180 as you adjust the balance control

through zero.

16

Set the function generator to 5 kHz and amplitude to 1 Vpp.

17 Connect the Probe input to function generator’s output and the +

–

°

input to the ground. You can use BNC A on the calibration fixture.

Maintain the probe ground.

18

Press Auto Scale.

35

Page 36

1159A 1GHz Active Differential Probe

Adjustment of 10:1 and 20:1 Attenuators

19

Use the square head trimmer tool to set the + LF compensation for a

minimum of overshoot and undershoot at the leading edge of the

waveform.

Adjust the compensation to achieve the best waveform characteristics when you

remove the tool.

20

Set the oscilloscope time base to 500 nS/div

21 Connect the probe + and inputs to the function generator output.

You can use BNC C on the calibration fixture. Connect the probe ground to the

function generator ground.

22

Set the amplitude of the function generator to 10 V and the frequency

–

to 5 kHz.

23 Set the oscilloscope sensitivity to maximum.

24 Use the square head trimmer tool to adjust the LF compensation for

–

minimum signal amplitude.

It is not possible to make the trace completely flat.

36

Page 37

Performance Test Record

1159A 1GHz Active Differential Probe

Performance Test Record

Agilent Technologies

Recommended Test Interval: 1 Year

Recommended Date of Next Certification:_________

Certification Temperature:_____________________

1159A 1 GHz Differential Probe

Serial No.:_______________________

Certification Date:_________________

Tested By:_______________________

_______________________________

_______________________________

Test Limit Minimum Results Limit Maximum

Accuracy at 1 kHz into 50

input of 54845 A

Differential Mode Range

Att 1; Gain 1

Att 10; Gain 10

CMRR at 70 Hz 80 dB N/A

CMRR at 1 MHz 40 dB N/A

CMRR at 100 MHz 25 dB N/A

CMRR at 500 MHz 19 dB N/A

CMRR at 1 GHz 13 dB N/A

Min Gain 98% Max Gain 102%

Ω

No Clipping

Pass

_____

_____

Fail

_____

_____

N/A

37

Page 38

38

Page 39

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: Agilent Technologies

Manufacturer’s Address: Colorado Springs Division

declares, that the product

Product Name: Active Differential Voltage Probe

Model Number(s): 1159A

Product Option(s): All

conforms to the following Product Specifications:

Safety: IEC 1010-1:1990+A1 / EN 61010-1:1993

UL 3111

CSA-C22.2 No. 1010.1:1993

EMC: CISPR 11:1990 / EN 55011:1991 Group 1, Class A

IEC 555-2:1982 + A1:1985 / EN60555-2:1987

IEC 555-3:1982 + A1:1990 / EN 60555-2:1987 + A1:1991

IEC 801-2:1991 / EN 50082-1:1992 4 kV CD, 8 kV AD

IEC 801-3:1984 / EN 50082-1:1992 3 V/m, {1kHz 80% AM, 27-1000 MHz}

IEC 801-4:1988 / EN 50082-1:1992 0.5 kV Sig. Lines, 1 kV Power Lines

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC

and the EMC Directive 89/336/EEC, and carries the CE-marking accordingly.

This product was tested in a typical configuration with Agilent test systems.

1900 Garden of the Gods Road

Colorado Springs, CO 80907, U.S.A.

Colorado Springs, 1/12/2000

Ken Wyatt, Quality Manager

European Contact: Your local Agilent Technologies Sales and Service Office

Page 40

Page 41

© Copyright

Agilent Technologies 2000.

All Rights Reserved.

Reproduction, ad aptation,

or translation without prior

written permission is

prohib ited, except as

allowed under the copyright

laws.

Restric ted Rights

Legend.

Use, duplication or

disclo sure by the U.S .

Government is subject to

restrictions as set forth in

subparagraph (c) (1) (ii) of

the Rights in Technical Data

and Computer Software

clause at DFARS 252.2277013 for DOD agencies, and

subparagraphs (c) (1) and

(c) (2) of the Commercial

Computer Software

Restricted Rights clause at

FAR 52.227-19 for other

agencies.

Agilen t Technologies

3000 Hanover Street

Palo Alto, California 94304

U.S.A.

Document Warranty

The information contained

in this document is subject

to change without notice.

Agilent makes no

warranty of any kind

with regard to this

material, including, but

not limited to, the

implied warranties of

merchantability or

fitness for a particular

purpose.

Agilen t sha ll not be liabl e

for errors contained herein

or for damages in

connection with the

furnishing, perfo rmance, or

use of this mate rial.

Product Warranty

This Agilent product has a

warranty against defects in

material and workmanship

for a period of one year

from date o f shipment.

During the warranty period,

Agilent Technologies will, at

its option, either repair or

replace products that prove

to be defective.

For warranty service or

repair, this product must be

returned to a service facility

designated by Agilen t.

For products retur ned to

Agilent for warranty

service, the Buyer shall

prepay shipping charges to

Agilent and Agilent shall

pay shipping charges to

return the product to the

Buyer. However, the Buyer

shall pay all shipping

charges, duties, and taxes

for products returned to

Agilent from another

country.

Agilent warrants that its

software and firmware

designated by Agilen t for

use with an instrument will

execute its programming

instructions when properly

installed on that

instrument. Agilent does

not warrant that the

operation of the instrument

software, or firmware will

be uninterru pted or erro r

free.

Limitation of Warranty

The for egoin g warranty

shall not apply to defects

resulting from improper or

inadequate maintenance by

the Buye r, Buyer-supplied

software or interfacing,

unauthorized modification

or misuse, operation outside

of the environ mental

specifications for the

product, or improper site

preparation or

maintenance.

No other warranty i s

expressed or implied.

Agilent specifically

disclaims the implied

warranties of

merchantability or

fitness for a particular

purpose.

Exclusive Remedies

The remedies provided

herein are the buyer's sole

and exclusive remedies.

Agilent shall not be liable

for any direct, indirect,

special, incidental, or

consequential damages,

whether based on contract,

tort, or any other legal

theory.

Assistance

Product maintenance

agreements and other

customer assistance

agreements are available for

Agilent products .

For any assistance, contact

your nearest Agilent Sales

Office.

Certification

Agilent Technologies

certifies that this product

met its published

specifications at the time of

shipment from the factory.

Agilent fur ther certifies that

its cal ibrat ion

measurements are traceable

to the United States

National Institute of

Standards and Technology,

to the extent allowed by the

Institute's calib ration

facility, and to the

calibration facilities of other

International S tandards

Organization m embers.

Agilen t Technologies

P.O. Box 2197

1900 Garden of the Gods Road

Colorado Springs, CO 80901

Page 42

Safety

This apparatus has been

designed and tested in

accordance with IEC

Publication 1010, Safe ty

Requirements for

Measuring Apparat us, and

has been supplied in a safe

condition. To ensure safe

operation and to keep the

product safe, the

information, cautions, and

warnings in this operating

manual must be heeded. In

addition, note the external

markin gs on the instrument

that are described under

"Safet y Symbols."

Safety Symbols

!

Instruction manual symbol:

the product is marked with

this symbol when it is

necessary for you to refer to

the instruction manual in

order to protect against

damage to the product.

Hazardous voltage symbol.

Earth terminal symbol:

Used to indicate a circuit

common connected to

grounded chassis.

WARNING

The Warning sign denotes a

hazard . It calls at tention to

a procedure, practice, or

the like, which, if not

correctly performed or

adhered to, could result in

personal injury. Do not

proceed beyon d a Warning

sign until the indicated

conditions are fully

understood and met.

CAUTION

The Caution sign denotes a

hazard . It calls at tention to

an operating procedure,

practice, or the like, which,

if not correctly performe d

or adhered to, could result

in damage to or destruction

of part or all of the product.

Do not proceed beyond a

Caution symbol until the

indicated conditions are

fully understood or met.

About this edition

This is the 1159 Active

Differential Voltage Probe

User’s Guide.

Publication number

01159-92000, Feb. 2000

Printed in USA.

Print history is as follows:

01159-92000, Feb. 2000

New editions are complete

revisions of the manual.

Many product updates do

not require manual

changes; and, conversely,

manual corrections may be

done without accompanying

product changes.

Therefore, do n ot expect a

one-to-one correspondence

between product updates

and manual updates.

Page 43

Page 44

s1

Agilent Technologies

Printed in the USA

Manual Part Number

01159-92000

Loading...

Loading...