Page 1

User and Service Guide

Publication number 01144-97001

September 2002

For Safety and Regulatory information, and publishing information, see the pages

at the back of this book.

© Copyright Agilent Technologies Company 1993-2002

All Rights Reserved.

1144A Active Probe

Page 2

Contents

Specifications 4

Characteristics 4

General Characteristics 5

Operating the Probe 6

Probe Power Connection 8

Cleaning the Probe 8

Service Strategy 8

To return the probe for service 9

Calibration Testing Procedures 9

Calibration Test Record 14

2

Page 3

1144A Active Probe

The 1144A Active Probe is a 10:1 probe with an 800 MHz bandwidth. An FET at

the input allows a high input resistance and low input capacitance which

minimizes the loading of the circuit under test. The output impedance of the

probe is 50 Ω which allows the probe cable to be extended with a 50 Ω coaxial

cable. The probe can be powered by the probe power outputs of the 54520A,

54522A, 54540A, or 54542A oscilloscopes. To use the probe with other

instruments you can use the 1142A power supply.

Accessories Supplied

The following accessories are supplied with the 1144A probe.

1

2

3

4

5

1 Retractable pincher tip 6 Ground lead

2 Alligator clip ground lead 7 Dual lead adapter

3 BNC adapter 8 Mini-pincher tip

4 IC tip 9 Mini-pincher tip

5 Ground bayonet

6

7

8

9

(black)

(red)

You can order a kit of accessory parts from Agilent Technologies, part number

01144-68702.

3

Page 4

1144A Active Probe

Specifications

Accessories Available

The following accessories are available and can be ordered separately.

• Fan-out adapter, Agilent Technologies part number 01144-61604, to operate

two probes from one supply connector.

Specifications

The following specifications apply to the 1144A.

1

Bandwidth

Rise Time

Attenuation

≥800 MHz

1,2

≤440 ps

3

10:1 ±2%

Input Resistance 1 MΩ, ±5%

Maximum Input Voltage ±40 V (dc + peak ac)

1. Above 35 °C, bandwidth and risetime degrade approximately 1/2%/°C

2. Rise time figure calculated from tr = 0.35/Bandwidth.

3. When connected to an instrument input of 50 Ω, ±0.5%

Characteristics

The following are characteristics of the 1144A.

Input Capacitance 2 pF (typical)

Overshoot and Ringing 1 ±10% for the first 6 ns, ±4% from 6 ns to 20 ms,

±1.5% thereafter

Output Voltage Offset <±15 mV

2

Input Dynamic Range

0 to ±7.0 V

Output Load Requirement 50 Ω ±0.5%

1. When used with a 3 GHz oscilloscope (oscilloscope characteristics excluded).

2. When connected to an instrument input of 50 Ω, ±0.5%

4

Page 5

General Characteristics

The 1144A Active Probe has the following general characteristics.

Environmental

Conditions

Temperature 0 C to +55 °C (32 °F to

Humidity up to 95% relative humidity

Altitude up to 4,600 meters

Vibration Random vibration 5 to 500

Power

Requirements

!

Weight Net: approximately 180 g (~6.5 oz), probe body 35 g (~1.25

Dimensions Refer to the outline drawing below.

Operating Non-operating

-40 °C to +70 °C (-40 °F to

+131 °F)

(non- condensi ng) at +40 °C

(+104 °F)

(15,000 ft)

Hz, 10 minutes per axis,

.

0.3g

rms

dc ±12 V to ±15 V ±5% (at approximately 75 mA each

supply)

oz) Shipping: approximately 0.8 kg (1.75 lb)

+158 °F)

up to 90% relative humidity

at +65°C (+149 °F)

up to 15,300 meters

(50,000 ft)

Random vibration 5 to 500

Hz, 10 min. per axis,

2.41 g

5 to 500 Hz swept sine,

1octave/min. sweep rate,

(0.75g), 5 min. resonant

dwell at 4 resonances per

axis.

. Resonant search

rms

1144A Active Probe

General Characteristics

1144A Dimensions.

.

5

Page 6

1144A Active Probe

Operating the Probe

Operating the Probe

The following information will help you get the most out of your measurement

when operating the probe.

Operating Voltage Derating

6

Page 7

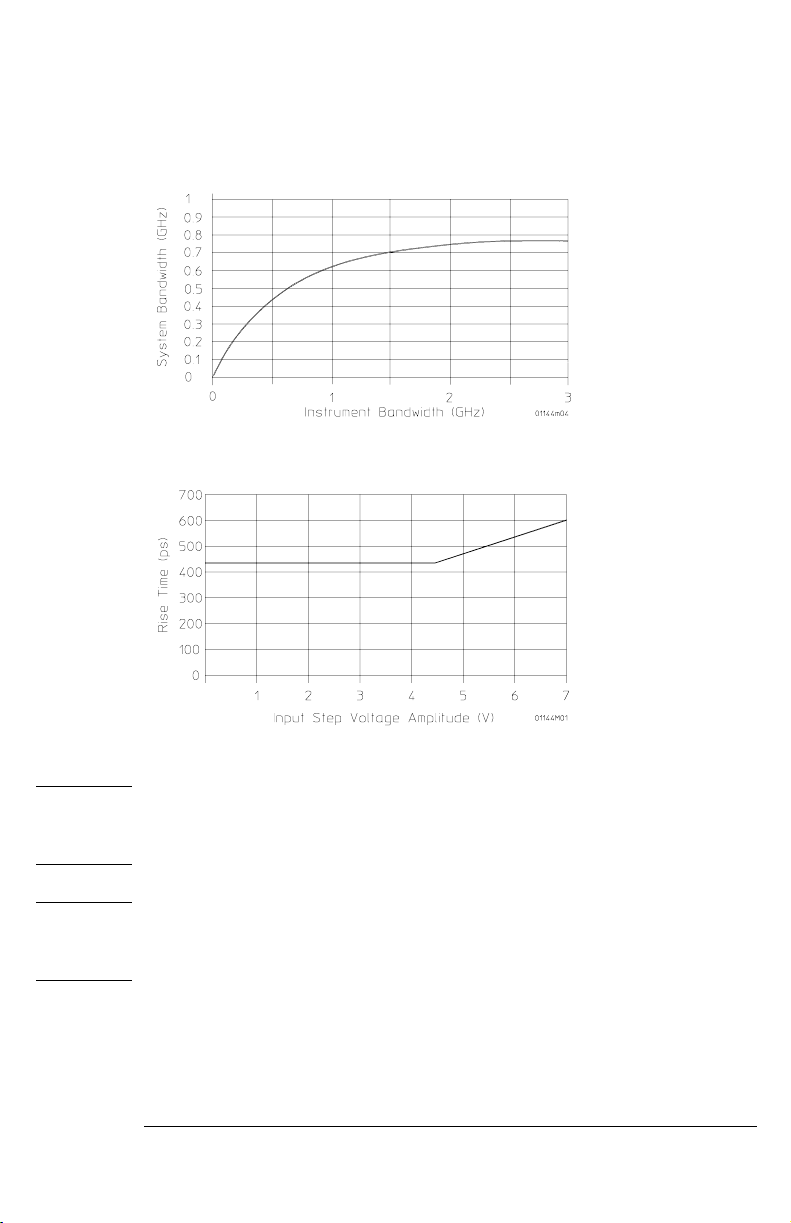

Typical Input Impedance vs. Frequency

System Bandwidth

1144A Active Probe

Operating the Probe

Typical Risetime vs. Input Voltage

CAUTION Be sure to limit the input of this probe to voltages within the specified working

voltage. Though the probe is designed with safeguards against static electricity

and noise, the input is sensitive to and may be damaged by excessive voltage.

CAUTION This probe is a sophisticated and delicate device. Please handle it with care.

Dropping it or exposing it to strong vibration or shock can damage it and cause

a malfunction.

7

Page 8

1144A Active Probe

Probe Power Connection

Probe Power Connection

The following drawing shows the input power connections. The power

requirements are given in the General Characteristics.

Pin 4, -15 V

Pin 6, +15 V

Pin 7, Ground

Shell, Cable Sheild

Cleaning the Probe

Do not use petroleum based solvents to clean the probe. Clean the probe with

a neutral detergent in water and immediately wipe the probe with a dry cloth.

Service Strategy

Other than the accessories, there are no replaceable parts on the 1144A Active

Probe. If your probe fails during warranty, normal warranty services apply. If the

probe is not under warranty when it fails, it can be exchanged for a reconditioned

probe at a nominal cost. The reconditioned probe is Agilent Technologies part

number 01144-69701. Contact your Agilent Technologies representative for

further information.

8

Page 9

1144A Active Probe

To return the probe for service

To return the probe for service

Before shipping the instrument to Agilent Technologies, contact your nearest

Agilent Technologies sales office for additional details.

1

Write the following information on a tag and attach it to the instrument.

• Name and address of owner

• Instrument model number

• Description of the service required or failure indications

2

Remove all accessories from the instrument.

Accessories include all cables. Do not include accessories unless they are

associated with the failure symptoms.

3

Protect the instrument by wrapping it in plastic or heavy paper. Antistatic wrapping or packaging is strongly recommended.

4 Pack the instrument in foam or other shock absorbing material and

place it in a strong shipping container.

You can use the original shipping materials or order materials from an Agilent

Technologies Sales Office. If neither are available, place 3 to 4 inches of shockabsorbing material around the instrument and place it in a box that does not

allow movement during shipping.

Seal the shipping container securely.

5

6 Mark the shipping container as FRAGILE.

In any correspondence, refer to instrument by model number and full serial

number.

Calibration Testing Procedures

These procedures are used to test the warranted specifications for the 1144A

Active probe. Use the equipment listed in the “Test Equipment Required” section

to complete the Testing Procedures.

Testing Interval

The calibration test procedures may be performed for incoming inspection of the

instrument and should be performed periodically thereafter to ensure and

maintain peak performance. The recommended test interval is yearly or every

2,000 hours of operation. Amount of use, environmental conditions, and the

user’s experience concerning need for testing will contribute to verification

requirements.

9

Page 10

1144A Active Probe

Calibration Testing Procedures

Equipment Required

The equipment required for the calibration tests is listed at the test. Any

equipment satisfying the critical specifications listed may be substituted for the

recommended model.

CAUTION Allow the probe to warm up for at least 15 minutes prior to beginning calibration

Input

Resistance

tests. Failure to allow warm-up may cause the probe to fail tests.

This test checks the input resistance of the active probe.

Specification 1.0 MΩ ±5%

Equipment Required

Equipment Critical Specification Recommended

Digital Multimeter Resistance ±1% 34401A

1

Connect the DMM between the probe tip and the ground shell at the

Model/Part

front of the probe.

2 Set up the DMM to measure resistance.

The resistance should read 1.0 MΩ ±50 kΩ.

Gain

Accuracy

This test checks the gain accuracy of the probe

Specification 0.1 ±2% (into 50 Ω ±0.5%)

Equipment Required

Equipment Critical Specification Recommended

Model/Part

Signal Generator 1 kHz and 1 Vrms 3312A

Digital Multimeter Better than 0.1% accuracy at 1 kHz 34401A

Power Supply Power for probe under test Oscilloscope or

1142A

Blocking cap 0.18 mF (or 0.1 mF fixed capacitor) 10240B

Adapter BNC(f)-to-probe (suppl’d with probe) 5081-7705

Adapter N(f)-to-BNC(m) 1250-0077

Termination BNC feed-through, 50 Ω ±0.5% 10100C (test to 0.5%)

Adapter BNC (f) to banana (m) 1251-2277

10

Page 11

1

Connect the power connector of the active probe to the oscilloscope or

1142A.

2 Connect the 50 Ω feedthrough to the output of the probe.

If your termination is not accurate to 0.5%, you will need to adjust your test

results accordingly, about 0.05% for each 0.1% error in the load.

3

AC couple the voltmeter by connect the blocking capacitor in series

with the voltmeter input.

This is to insure that there is no dc component in the signal measurement.

4

Set the signal generator for 1 kHz and 1.000 Vrms ±0.5% (±5.0mV). Use

the DVM to measure the signal.

Generator voltage __________

5

Using the BNC-to-probe adapter, connect the probe input to the output

of the signal generator.

6 Use the voltmeter to measure the signal at the output of the probe.

Connect the feedthrough termination to the blocking capacitor.

Probe output voltage ___________

7

Calculate the ac gain.

ac Gain

The ac gain should be between 0.098 and 0.102 (0.10 ±2.0%).

Bandwidth This test checks the probe bandwidth.

Specification down less than 3 dB, dc to 800 MHz

Probe output voltage

------------- ------------- ------------ ------------=

Generator voltage

1144A Active Probe

Calibration Testing Procedures

Equipment Required

Equipment Critical Specification Recommended

Signal Generator 50 MHz to 800 MHz 8663A

Power Meters (2)

or one DualChannel

Power Sensor (2) 50 MHz to 800 MHz, 300 mW 8482A

Power Splitter Type-N, dc to 800 MHz, ≤0.2 dB tracking 11667A

Power Supply Power for probe under test Oscilloscope or

Adapter (2) Type N(m) to BNC(f), 50 Ω 1250-0780

Termination BNC feedthrough, 50 Ω 10100C

Adapter BNC(f)-to-probe (suppl’d with probe) 5081-7705

50 MHz to 800 MHz, ±3% accuracy 436A (2),

Model/Part

437A (2), or

438A (1)

1142A

11

Page 12

1144A Active Probe

Calibration Testing Procedures

Equipment Critical Specification Recommended

Adapter N(f-f), 50 Ω 1250-0772

Adapter N(m-m), 50 Ω 1250-0778

1

Zero and calibrate the power meters with the power sensors.

2 Connect the equipment as in the drawing below.

Model/Part

3 Connect the probe power input to the oscilloscope or 1142A.

4 Set the signal generator for 50 MHz at 0.0 dBm.

5 Set the power meter calibration factors to the 50 MHz value on the

power sensors.

6 Adjust the signal generator power output for exactly -6.0 dBm as read

on the input power meter.

7 Note the power level reading on the output power meter. 50 MHz power

level _______________ dBm.

The output power level will be approximately -26 dBm. This corresponds to the

10:1 division ratio of the probe.

12

Page 13

1144A Active Probe

Calibration Testing Procedures

8

Change the signal generator frequency to 800 MHz.

9 Set the power meter calibration factors to the 800 MHz value on the

power sensors.

10 Re-level the signal generator output power for a -6.0 dBm reading on

the input power meter.

11 Note the power level reading on the output power meter. 800 MHz

power level _______________ dBm

12 Subtract the reading in step 7 from the reading in step 11.

The difference should be ≤3.0 dB

13

Page 14

1144A Active Probe

Calibration Test Record

Calibration Test Record

Agilent Technologies

Recommended Test Interval: 1 Year

Recommended Date of Next Certification:_________

Certification Temperature:_____________________

1144A 800 MHz Differential Probe

Serial No.:_______________________

Certification Date:_________________

Tested By:_______________________

_______________________________

_______________________________

Test Limits Results

Input Resistance 1.0 MΩ ±5%

Gain Accuracy 0.1 ±2% (into 50 Ω ±5%)

Bandwidth Down less than 3dB, dc to 800 MHz

14

Page 15

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer's Name: Agilent Technologies, Inc.

Manufacturer's Address: 1900 Garden of the Gods Road

Declares, that the product

Product Name: Active Probe

Model Number(s): 1144A

Product Option(s): This declaration covers all options of the above product(s).

Conforms with the following product standards:

EMC: Standard

IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011:1991

IEC 61000-4-2:1995+A1:1998 /EN 61000-4-2:1995

IEC 61000-4-3:1995 / EN 61000-4-3:1995

IEC 61000-4-4:1995 / EN 61000-4-4:1995

IEC 61000-4-5:1995 / EN 61000-4-5:1995

IEC 61000-4-6:1996 / EN 61000-4-6:1996

IEC 61000-4-11:1994 / EN 61000-4-11:1994

Canada: ICES-001:1998

Australia/New Zealand: AS/NZS 2064.1

Safety: IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

Supplementary Information:

Colorado Springs, CO

80907, U.S.A.

Limit

Group 1 Class A

4kV CD, 8kV AD

3 V/m, 80-1000 MHz

0.5kV signal lines, 1kV power lines

0.5 kV line-line, 1 kV line-ground

3V, 0.15-80 MHz

1 cycle, 100%

[1]

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC

and the EMC Directive 89/336/EEC (including 93/68/EEC, and carries the CE-marking accordingly

(European Union).

[1]

This product was tested in a typical configuration with Agilent Technologies test systems.

Date: 08/21/2000

Ken Wyatt / Product Regulations Manager

For further information, please contact your local Agilent Technologies sales office, agent or distributor.

Page 16

Product Regulations

Performance

Criteria

EMC IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011:1991

IEC 61000-4-2:1995+A1:1998 /EN 61000-4-2:1995

IEC 61000-4-3:1995 / EN 61000-4-3:1995

IEC 61000-4-4:1995 / EN 61000-4-4:1995

IEC 61000-4-5:1995 / EN 61000-4-5:1995

IEC 61000-4-6:1996 / EN 61000-4-6:1996

IEC 61000-4-11:1994 / EN 61000-4-11:1994

A

B

A

A

A

A

Canada: ICES-001:1998

Safety IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

Addtional Information

The product herewtih complies with the requirements of the Low Voltage Directive 73/23/EEC

and the EMC Directive 89/336/EEC (including 93/68/EEC) and carries the CE Marking

accordingly (European Union).

1

Performance Codes:

A PASS - Normal operation, no effect.

B PASS - Temporary degradation, self recoverable.

C PASS - Temporary degradation, operator intervention required.

D FAIL - Not recoverable, component damage.

Notes:

Sound Pressure Level N/A

Regulatory Information for Canada

ICES/NMB-001

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est confomre à la norme NMB-001 du Canada.

Regulatory Information for Australia/New Zealand

This ISM device complies with Australian/New Zealand AS/NZS 2064.1

Page 17

Safety

Notices

This apparatus has been

designed and tested in accordance with IEC Publication

1010, Safety Requirements for

Measuring Apparatus, and

has been supplied in a safe

condition. This is a Safety

Class I instrument (provided

with terminal for protective

earthing). Before applying

power, verify that the correct

safety precautions are taken

(see the following warnings).

In addition, note the external

markings on the instrument

that are described under

"Safety Symbols."

Warnings

• Before turning on the instrument, you must connect the

protective earth terminal of

the instrument to the protective conductor of the (mains)

power cord. The mains plug

shall only be inserted in a

socket outlet provided with a

protective earth contact. You

must not negate the protective action by using an extension cord (power cable)

without a protective conductor (grounding). Grounding

one conductor of a two-conductor outlet is not sufficient

protection.

• Only fuses with the required

rated current, voltage, and

specified type (normal blow,

time delay, etc.) should be

used. Do not use repaired

fuses or short-circuited fuseholders. To do so could cause

a shock or fire hazard.

• If you energize this instrument by an auto transformer

(for voltage reduction or

mains isolation), the common

terminal must be connected to

the earth terminal of the

power source.

• Whenever it is likely that the

ground protection is impaired,

you must make the instrument

inoperative and secure it

against any unintended operation.

• Service instructions are for

trained service personnel. To

avoid dangerous electric

shock, do not perform any service unless qualified to do so.

Do not attempt internal service or adjustment unless

another person, capable of

rendering first aid and resuscitation, is present.

• Do not install substitute parts

or perform any unauthorized

modification to the instrument.

• Capacitors inside the instrument may retain a charge

even if the instrument is disconnected from its source of

supply.

• Do not operate the instrument in the presence of flammable gasses or fumes.

Operation of any electrical

instrument in such an environment constitutes a definite

safety hazard.

• Do not use the instrument in

a manner not specified by the

manufacturer.

To clean the instrument

If the instrument requires

cleaning: (1) Remove power

from the instrument. (2) Clean

the external surfaces of the

instrument with a soft cloth

dampened with a mixture of

mild detergent and water. (3)

Make sure that the instrument is completely dry before

reconnecting it to a power

source.

Safety Symbols

!

Instruction manual symbol:

the product is marked with

this symbol when it is necessary for you to refer to the

instruction manual in order to

protect against damage to the

product..

Hazardous voltage symbol.

Earth terminal symbol: Used to

indicate a circuit common

connected to grounded chassis.

Agilent Technologies

P.O. Box 2197

1900 Garden of the Gods Road

Colorado Springs, CO 80901

Page 18

Notices

© Agilent Technologies, Inc.

2002

No part of this manual may be

reproduced in any form or by

any means (including electronic storage and retrieval or

translation into a foreign language) without prior agreement and written consent

from Agilent Technologies,

Inc. as governed by United

States and international copyright laws.

Manual Part Number

01144-97001, September 2002

Print History

01144-90901, June 1993

01144-97000, July 2000

01144-97001, July 2002

Agilent Technologies, Inc.

1900 Garden of the Gods Road

Colorado Springs, CO 80907

USA

Restricted Rights Legend

If software is for use in the

performance of a U.S. Government prime contract or subcontract, Software is

delivered and licensed as

“Commercial computer software” as defined in DFAR

252.227-7014 (June 1995), or as

a “commercial item” as

defined in FAR 2.101(a) or as

“Restricted computer software” as defined in FAR

52.227-19 (June 1987) or any

equivalent agency regulation

or contract clause. Use, duplication or disclosure of Software is subject to Agilent

Technologies’ standard commercial license terms, and

non-DOD Departments and

Agencies of the U.S. Government will receive no greater

than Restricted Rights as

defined in FAR 52.227-19(c)(1-

2) (June 1987). U.S. Government users will receive no

greater than Limited Rights as

defined in FAR 52.227-14 (June

1987) or DFAR 252.227-7015

(b)(2) (November 1995), as

applicable in any technical

data.

ual and any information

contained herein, including but not limited to the

implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for

incidental or consequential damages in connection with the furnishing,

use, or performance of

this document or of any

information contained

herein. Should Agilent

and the user have a separate written agreement

with warranty terms covering the material in this

document that conflict

with these terms, the warranty terms in the separate agreement shall

control.

Technology Licenses

The hardware and/or software described in this document are furnished under a

license and may be used or

copied only in accordance

with the terms of such license.

WARNING

A WARNING notice

denotes a hazard. It

calls attention to an

operating procedure,

practice, or the like

that, if not correctly

performed or adhered

to, could result in

personal injury or

death. Do not proceed

beyond a WARNING

notice until the

indicated conditions

are fully understood

and met.

CAUTION

A CAUTION notice

denotes a hazard. It

calls attention to an

operating procedure,

practice, or the like

that, if not correctly

performed or adhered

to, could result in

damage to the product

or loss of important

data. Do not proceed

beyond a CAUTION

notice until the

indicated conditions

are fully understood

and met.

Document Warranty

The material contained in

this document is provided

“as is,” and is subject to

being changed, without

notice, in future editions.

Further, to the maximum

extent permitted by applicable law, Agilent disclaims all warranties,

either express or implied,

with regard to this man-

Page 19

Page 20

sA

Agilent Technologies

Printed in Malaysia

Part Number

01144-97001

*01144-97001*

User’s Guide

Loading...

Loading...