AGF Manufacturing Inc.

Pr o d u c t

In f o r m a t I o n

V008.0

Reliability, Versatility, Code Compatibility

BK002

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

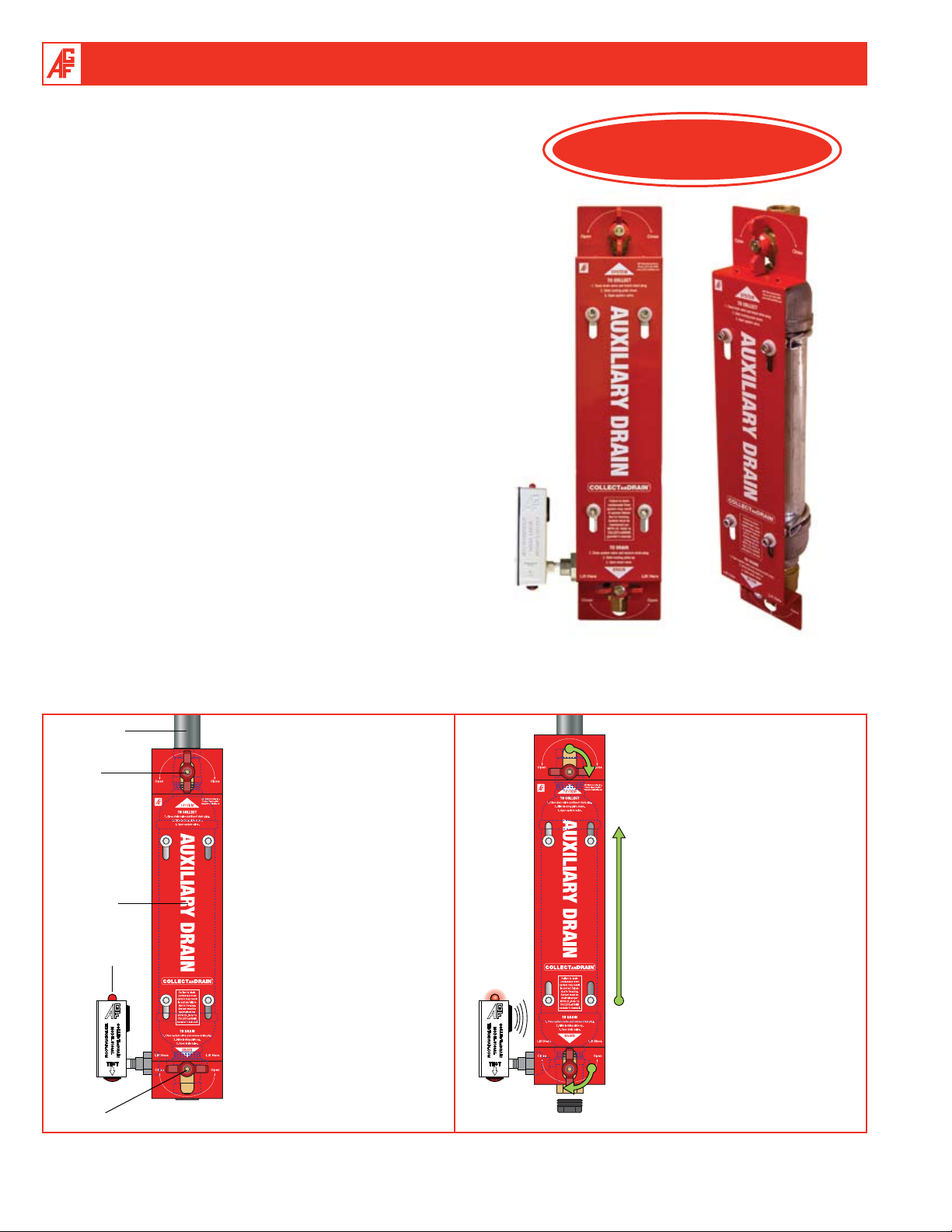

™

coLLEcta n draIn

The coLLEcta n draIn™ family of products are anti-trip drum drips

that prevent the accidental tripping and filling of dry pipe and pre-action

fire sprinkler systems during maintenance or as a result of vandalism.

The coLLEct

opening of either the upper or lower valve on the drum drip unless the

opposite valve is in the closed position, preventing an accidental tripping

and filling of the system and ensuring that the drum drip is operated per

NFPA 25 specifications.

The steel Anti-Trip Plate features a durable red powder coated finish that

has been silkscreened with “AUXILIARY DRAIN” for easy identification,

fulfilling NFPA signage requirements. The plate also includes operating

instructions for easy use.

The Model 5100 coLLEct

on the lower ball valve that indicates when maintenance is required.

When water is present in the drum drip, a red blinking light and beeping

alarm are activated, alerting you whenever the drum drip needs to be

drained.

A locking option is also available for added security.

The Model 5100 with alarm is available in three versions:

• Model 5100A Complete Assembly

• Model 5100K Field Assembly Kit (Includes ball valves, water detector,

and Anti-Trip Plate with mounting hardware)

• Model 5100ALBV Ball Valve with Water Detector only

The Model 5200 without alarm is available in two versions:

• Model 5200A Complete Assembly

• Model 5200K Field Assembly Kit (Includes ball valves and Anti-Trip

Plate with mounting hardware)

a n draIn’s

™

patent pending Anti-Trip Plate prevents the

a n draIn

™

includes a water detection alarm

NEW PRODUCT!

TO SYSTEM

UPPER

VALVE

ANTI-TRIP

PLATE

ALARM

LOWER

VALVE

COLLECT

COLLECTa n DRaIn™ provides

a method to drain water from

isolated sections of dry pipe and

preaction sprinkler systems that

prevents accidental discharge of

the system. When in the “COLLECT” position, the upper valve

is open and the Anti-Trip Plate is

in its lower position, preventing

the lower ball valve from being

completely opened. While in this

position, water in the system

collects in the condensate nipple.

MODEL 5100

COLLECTa n DRaIn

™

DRAIN

The alarm will blink and sound

when water has collected and

draining is required (Model 5200

only). To drain the collected water,

the upper valve must be completely

closed and the Anti-Trip Plate slid

to its upper position, allowing the

lower valve to be opened. To return

the COLLECTa n DRaIn™ to the

“COLLECT” position after draining,

the lower valve must be completely

closed and the Anti-Trip Plate slid

to its lower position for the upper

valve to be opened. This prevents

both valves from being completely

open at the same time, which could

accidentally release the air in the

system.

2

Product Information V008.0

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

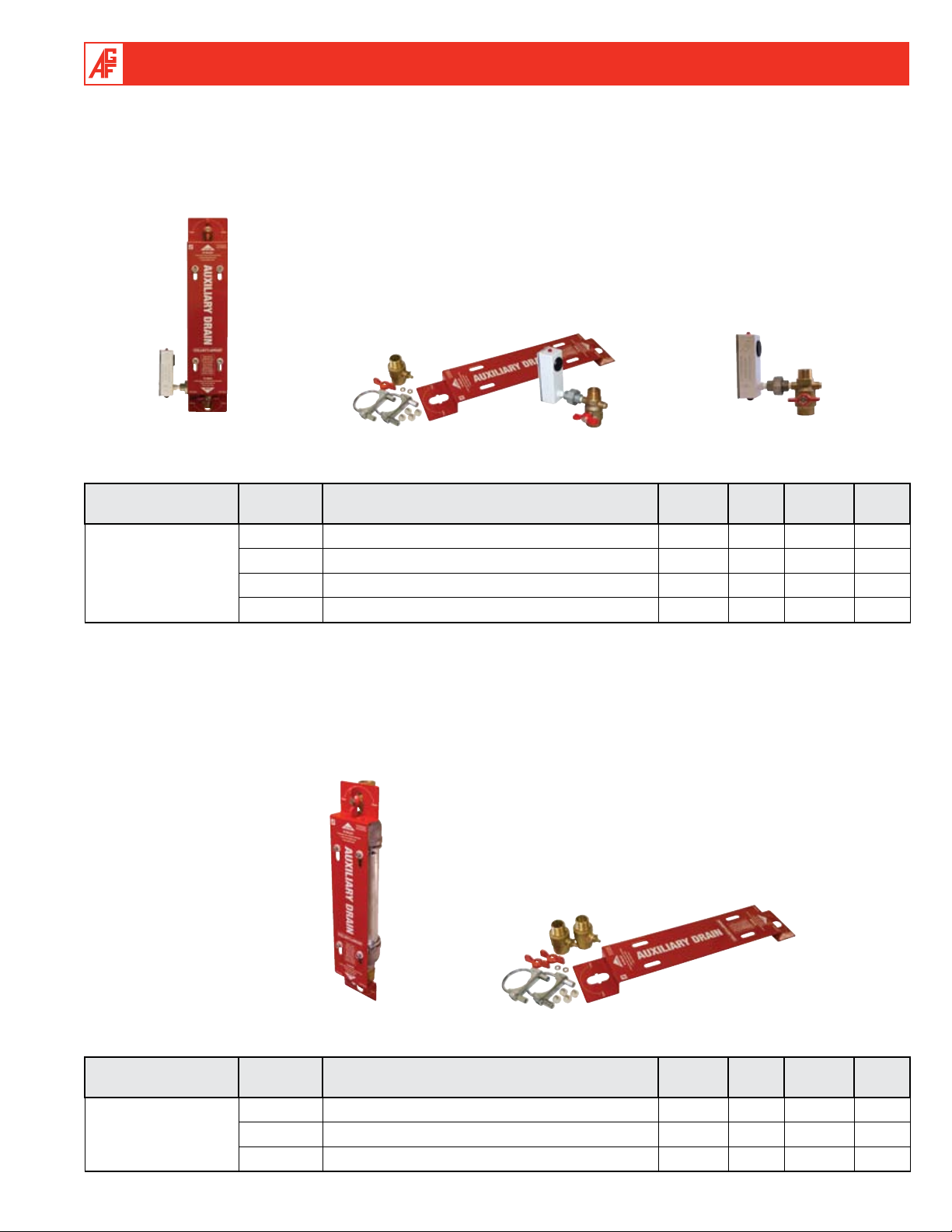

Model 5100 coLLEcta n draIn™ Anti-Trip Auxiliary Drain and Condensation Collection

Assembly with Water Detection Alarm for Dry Pipe and Preaction Fire Sprinkler Systems

Complete assembly includes pre-assembled condensation collection assembly (drum drip) with condensate nipple and reducers, 1"

ball valve, 1" M5100ALBV ball valve with water detection alarm, 1" plug, and anti-trip plate.

Field assembly kit includes 1" ball valve, 1" M5100ALBV ball valve with water detection alarm, and anti-trip plate with mounting

hardware.

Model 5100A

Complete Assembly

w/Water Detector Alarm

AGF Item ID Item Description

Model 5100K

Field Assembly Kit

w/Water Detector Alarm

Model 5100ALBV

Ball Valve w/Water Detector Alarm

Item

Class

Master

Carton

Minimum

Order Qty.

Unit

5100A M5100A Complete Assembly Special N/A 1 EACH

5100K M5100K Field Assembly Kit Special N/A 1 EACH

M5100

5100ALBV M5100ALBV Ball Valve w/Water Detector Alarm Special N/A 1 EACH

870 Optional Locking Kit Special N/A 1 EACH

Model 5200 coLLEcta n draIn™ Anti-Trip Auxiliary Drain and Condensation Collection

Assembly for Dry Pipe and Preaction Fire Sprinkler Systems

Complete assembly includes pre-assembled condensation collection assembly (drum drip) with condensate nipple and reducers,

two 1" ball valves, 1" plug, and anti-trip plate.

Field assembly kit includes two 1" ball valves and anti-trip plate with mounting hardware.

M5200

Product Information V008.0

Model 5200A

Complete Assembly

AGF Item ID Item Description

Model 5200K

Field Assembly Kit

Item

Class

Master

Carton

Minimum

Order Qty.

5200A M5200A Complete Assembly Special N/A 1 EACH

5200K M5200K Field Assembly Kit Special N/A 1 EACH

870 Optional Locking Kit Special N/A 1 EACH

Unit

3

tESta n draIn

®

Model 1000

Page 5

Model 2511A

Pages 9 – 10

tESta n draIn

®

Locking Plate Kits

Page 11

In S P E c t o r ’StESt

Model 2500

Page 6

Model 2511T

Pages 9 – 10

KI t S & ac c E S S o r I E S

®

Valve Repair Kits

Page 12

Model 1011A

Pages 6 – 8

Model 1500

draIna n tESt

Page 10

Model 1011T

Pages 7 – 8

Model 1200

®

rE m o t E tESt

®

Page 11

Pressure Relief Valves & Trim Kits

Page 13

Model 3011A

Page 14

rI S E r PacK

®

Model 8000 Residential

Pages 15 – 16

Model 8011 Commercial

Bronze Riser

Pages 20 – 21

4

Model 3011BV

Page 14

Model 8011 Residential

Model 8000 Commercial

Powder Coated Steel Riser

Pages 17 – 19

Pages 21 – 22

Model 3011SG

Page 14

Model 3011ASG

Page 14

Model 8000 Commercial

Bronze Riser

Pages 19 – 20

Model 8011 Commercial

Powder Coated Steel Riser

Pages 22 – 23

Product Information V008.0

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

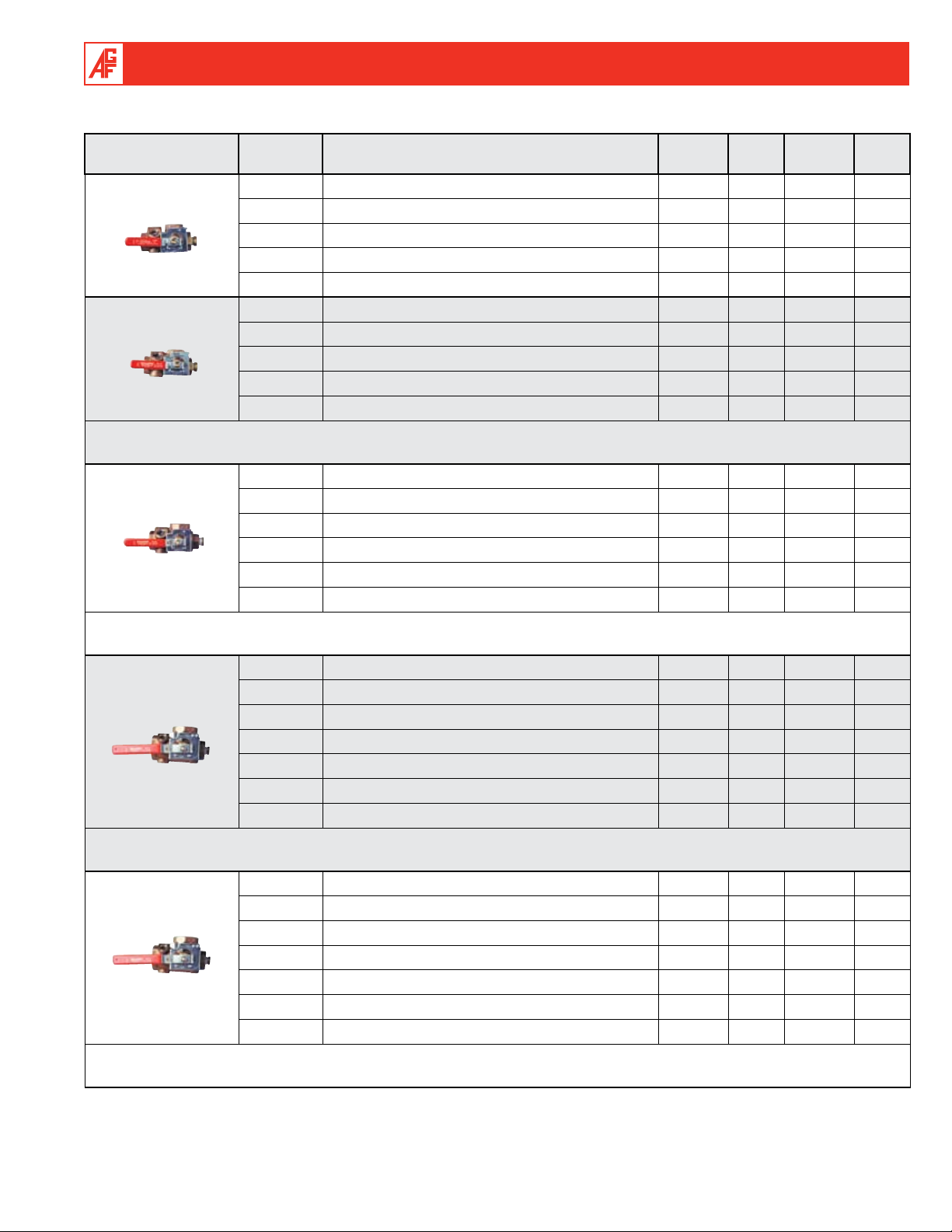

Model 1000 tESta n draIn® Sectional Floor Control Test and Drain Valve

¾" M1000

AGF Item ID Item Description

Item

Class

100 ¾" M1000 x 3⁄8" Orifice Special 10 1 EACH

Master

Carton

Minimum

Order Qty.

101 ¾" M1000 x 7⁄16" Orifice Special 10 1 EACH

102 ¾" M1000 x ½" Orifice Stock 10 1 EACH

17

⁄32" Orifice Special 10 1 EACH

5

⁄8" ELO Orifice Special 10 1 EACH

7

⁄16" Orifice Stock 10 1 EACH

1" M1000

103 ¾" M1000 x

104 ¾" M1000 x

110 1" M1000 x 3⁄8" Orifice Stock 10 1 EACH

111 1" M1000 x

112 1" M1000 x ½" Orifice Stock 10 10 EACH

17

113 1" M1000 x

⁄32" Orifice Stock 10 1 EACH

114 1" M1000 x 5⁄8" ELO Orifice Stock 10 1 EACH

NOTE: The 1" x ½" orifice Model 1000 TEST

a n DRaIn

®

Valve is available with British Standard Pipe Threads (BSPT). Please order using AGF

Item ID #412, price is the same as listed above for NPT. For 1" BSPT with orifice sizes other then ½" please call for availability.

1¼" M1000

120 1¼" M1000 x 3⁄8" Orifice Stock 10 1 EACH

7

121 1¼" M1000 x

⁄16" Orifice Stock 10 1 EACH

122 1¼" M1000 x ½" Orifice Stock 10 10 EACH

123 1¼" M1000 x 17⁄32" Orifice Stock 10 1 EACH

5

124 1¼" M1000 x

⁄8" ELO Orifice Stock 10 1 EACH

125 1¼" M1000 x ¾" ESFR Orifice Stock 10 1 EACH

NOTE: The 1¼" x ½" orifice Model 1000 TEST

a n DRaIn

®

Valve is available with British Standard Pipe Threads (BSPT). Please order using AGF

Item ID #422, price is the same as listed above for NPT. For 1¼" BSPT with orifice sizes other then ½" please call for availability.

1½" M1000

130 1½" M1000 x 3⁄8" Orifice Special 6 1 EACH

131 1½" M1000 x 7⁄16" Orifice Special 6 1 EACH

132 1½" M1000 x ½" Orifice Stock 6 1 EACH

17

133 1½" M1000 x

134 1½" M1000 x

⁄32" Orifice Special 6 1 EACH

5

⁄8" ELO Orifice Special 6 1 EACH

135 1½" M1000 x ¾" ESFR Orifice Special 6 1 EACH

136 1½" M1000 x K25 Orifice Special 6 1 EACH

NOTE: The 1½" x ½" orifice Model 1000 TEST

a n DRaIn

®

Valve is available with British Standard Pipe Threads (BSPT). Please order using AGF

Item ID #432, price is the same as listed above for NPT. For 1½" BSPT with orifice sizes other then 1/2" please call for availability.

2" M1000

140 2" M1000 x 3⁄8" Orifice Stock 6 1 EACH

141 2" M1000 x 7⁄16" Orifice Stock 6 1 EACH

142 2" M1000 x ½" Orifice Stock 6 6 EACH

17

143 2" M1000 x

144 2" M1000 x

⁄32" Orifice Stock 6 1 EACH

5

⁄8" ELO Orifice Stock 6 1 EACH

145 2" M1000 x ¾" ESFR Orifice Stock 6 1 EACH

146 2" M1000 x K25 Orifice Stock 6 1 EACH

NOTE: The 2" x ½" orifice Model 1000 TEST

a n DRaIn

®

Valve is available with British Standard Pipe Threads (BSPT). Please order using AGF

Item ID #442, price is the same as listed above for NPT. For 2" BSPT with orifice sizes other then ½" please call for availability.

Unit

Product Information V008.0

5

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

Model 2500 tESta n draIn® Sectional Floor Control Test and Drain Valve

1" M2500

1¼" M2500

2" M2500

Groove x Groove

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

404-0 1" M2500 x 3⁄8" Orifice Special 10 1 EACH

404-1 1" M2500 x 7⁄16" Orifice Special 10 1 EACH

404-2 1" M2500 ½" Orifice Stock 10 1 EACH

17

404-3 1" M2500

404-4 1" M2500

⁄32" Orifice Special 10 1 EACH

5

⁄8" ELO Orifice Special 10 1 EACH

405-0 1¼" M2500 x 3⁄8" Orifice Special 10 1 EACH

7

405-1 1¼" M2500 x

⁄16" Orifice Special 10 1 EACH

405-2 1¼" M2500 ½" Orifice Stock 10 1 EACH

17

405-3 1¼" M2500

⁄32" Orifice Special 10 1 EACH

405-4 1¼" M2500 5⁄8" ELO Orifice Special 10 1 EACH

405-5 1¼" M2500 ¾" ESFR Orifice Special 10 1 EACH

408-0 2" M2500 x 3⁄8" Orifice (GRV) Special 6 1 EACH

7

408-1 2" M2500 x

⁄16" Orifice (GRV) Special 6 1 EACH

408-2 2" M2500 ½" Orifice (GRV) Stock 6 1 EACH

17

408-3 2" M2500

⁄32" Orifice (GRV) Special 6 1 EACH

408-4 2" M2500 5⁄8" ELO Orifice (GRV) Special 6 1 EACH

408-5 2" M2500 ¾" ESFR Orifice (GRV) Special 6 1 EACH

408-6 2" M2500 K25 Orifice (GRV) Special 6 1 EACH

Unit

Model 1011 tESta n draIn® Sectional Floor Control Test and Drain Valve for Systems

Requiring Pressure Relief

M1011A valves are packaged with a trim kit. The trim kit includes a 175 PSI rated M7000 PRV and drain trim. M7000 valves are also

available in PSI ratings of 165, 185, 195, 205, 225 and 250.

Note: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and closing of the valve. Standard relief

valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves are required to CLOSE at a pressure above 80% of that rating. The

relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the

system is operational. A relief valve should NEVER have a shutoff valve or a plug downstream of its outlet.

¾" M1011

No PRV Trim

¾" M1011A

AGF Item ID Item Description

Item

Class

200 ¾" M1011 x 3⁄8" Orifice Special 10 1 EACH

7

201 ¾" M1011 x

⁄16" Orifice Special 10 1 EACH

202 ¾" M1011 x ½" Orifice Special 10 1 EACH

17

203 ¾" M1011 x

⁄32" Orifice Special 10 1 EACH

204 ¾" M1011 x 5⁄8" ELO Orifice Special 10 1 EACH

200A ¾" M1011A x 3⁄8" Orifice Special 10 1 EACH

7

201A ¾" M1011A x

⁄16" Orifice Special 10 1 EACH

202A ¾" M1011A x ½" Orifice Stock 10 1 EACH

203A ¾" M1011A x 17⁄32" Orifice Special 10 1 EACH

5

204A ¾" M1011A x

⁄8" ELO Orifice Special 10 1 EACH

Master

Carton

Minimum

Order Qty.

Unit

6

Product Information V008.0

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

¾" M1011T

1" M1011

No PRV Trim

1" M1011A

1" M1011T

1¼" M1011

No PRV Trim

1¼" M1011A

1¼" M1011T

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

200T ¾" M1011T x 3⁄8" Orifice Special 5 1 EACH

201T ¾" M1011T x 7⁄16" Orifice Special 5 1 EACH

202T ¾" M1011T x ½" Orifice Special 5 1 EACH

17

203T ¾" M1011T x

204T ¾" M1011T x

⁄32" Orifice Special 5 1 EACH

5

⁄8" ELO Orifice Special 5 1 EACH

210 1" M1011 x 3⁄8" Orifice Special 10 1 EACH

7

211 1" M1011 x

⁄16" Orifice Special 10 1 EACH

212 1" M1011 x ½" Orifice Special 10 1 EACH

17

213 1" M1011 x

⁄32" Orifice Special 10 1 EACH

214 1" M1011 x 5⁄8" ELO Orifice Special 10 1 EACH

210A 1" M1011A x 3⁄8" Orifice Stock 10 1 EACH

211A 1" M1011A x 7⁄16" Orifice Stock 10 1 EACH

212A 1" M1011A x ½" Orifice Stock 10 10 EACH

17

213A 1" M1011A x

214A 1" M1011A x

⁄32" Orifice Stock 10 1 EACH

5

⁄8" ELO Orifice Stock 10 1 EACH

210T 1" M1011T x 3⁄8" Orifice Special 5 1 EACH

7

211T 1" M1011T x

⁄16" Orifice Special 5 1 EACH

212T 1" M1011T x ½" Orifice Stock 5 1 EACH

17

213T 1" M1011T x

⁄32" Orifice Special 5 1 EACH

214T 1" M1011T x 5⁄8" ELO Orifice Special 5 1 EACH

220 1¼" M1011 x 3⁄8" Orifice Special 10 1 EACH

7

221 1¼" M1011 x

⁄16" Orifice Special 10 1 EACH

222 1¼" M1011 x ½" Orifice Special 10 1 EACH

223 1¼" M1011 x 17⁄32" Orifice Special 10 1 EACH

5

224 1¼" M1011 x

⁄8" ELO Orifice Special 10 1 EACH

225 1¼" M1011 x ¾" ESFR Orifice Special 10 1 EACH

220A 1¼" M1011A x 3⁄8" Orifice Stock 10 1 EACH

7

221A 1¼" M1011A x

⁄16" Orifice Stock 10 1 EACH

222A 1¼" M1011A x ½" Orifice Stock 10 10 EACH

17

223A 1¼" M1011A x

⁄32" Orifice Stock 10 1 EACH

224A 1¼" M1011A x 5⁄8" ELO Orifice Stock 10 1 EACH

225A 1¼" M1011A x ¾" ESFR Orifice Stock 10 1 EACH

220T 1¼" M1011T x 3⁄8" Orifice Special 5 1 EACH

7

221T 1¼" M1011T x

⁄16" Orifice Special 5 1 EACH

222T 1¼" M1011T x ½" Orifice Special 5 1 EACH

17

223T 1¼" M1011T x

⁄32" Orifice Special 5 1 EACH

224T 1¼" M1011T x 5⁄8" ELO Orifice Special 5 1 EACH

225T 1¼" M1011T x ¾" ESFR Orifice Special 5 1 EACH

Unit

Product Information V008.0

7

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

1½" M1011

No PRV Trim

1½" M1011A

1½" M1011T

2" M1011

No PRV Trim

2" M1011A

2" M1011T

8

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

230 1½" M1011 x 3⁄8" Orifice Special 6 1 EACH

231 1½" M1011 x 7⁄16" Orifice Special 6 1 EACH

232 1½" M1011 x ½" Orifice Special 6 1 EACH

17

233 1½" M1011 x

234 1½" M1011 x

⁄32" Orifice Special 6 1 EACH

5

⁄8" ELO Orifice Special 6 1 EACH

235 1½" M1011 x ¾" ESFR Orifice Special 6 1 EACH

236 1½" M1011 x K25 Orifice Special 6 1 EACH

230A 1½" M1011A x 3⁄8" Orifice Special 6 1 EACH

7

231A 1½" M1011A x

⁄16" Orifice Special 6 1 EACH

232A 1½" M1011A x ½" Orifice Stock 6 1 EACH

17

233A 1½" M1011A x

⁄32" Orifice Special 6 1 EACH

234A 1½" M1011A x 5⁄8" ELO Orifice Special 6 1 EACH

235A 1½" M1011A x ¾" ESFR Orifice Special 6 1 EACH

236A 1½" M1011A x K25 Orifice Special 6 1 EACH

230T 1½" M1011T x 3⁄8" Orifice Special 6 1 EACH

7

231T 1½" M1011T x

⁄16" Orifice Special 6 1 EACH

232T 1½" M1011T x ½" Orifice Special 6 1 EACH

233T 1½" M1011T x 17⁄32" Orifice Special 6 1 EACH

5

234T 1½" M1011T x

⁄8" ELO Orifice Special 6 1 EACH

235T 1½" M1011T x ¾" ESFR Orifice Special 6 1 EACH

236T 1½" M1011T x K25 Orifice Special 6 1 EACH

240 2" M1011 x 3⁄8" Orifice Special 6 1 EACH

241 2" M1011 x 7⁄16" Orifice Special 6 1 EACH

242 2" M1011 x ½" Orifice Special 6 1 EACH

17

243 2" M1011 x

244 2" M1011 x

⁄32" Orifice Special 6 1 EACH

5

⁄8" ELO Orifice Special 6 1 EACH

245 2" M1011 x ¾" ESFR Orifice Special 6 1 EACH

246 2" M1011 x K25 Orifice Special 6 1 EACH

240A 2" M1011A x 3⁄8" Orifice Stock 6 1 EACH

7

241A 2" M1011A x

⁄16" Orifice Stock 6 1 EACH

242A 2" M1011A x ½" Orifice Stock 6 6 EACH

17

243A 2" M1011A x

⁄32" Orifice Stock 6 1 EACH

244A 2" M1011A x 5⁄8" ELO Orifice Stock 6 1 EACH

245A 2" M1011A x ¾" ESFR Orifice Stock 6 1 EACH

246A 2" M1011A x K25 Orifice Stock 6 1 EACH

240T 2" M1011T x 3⁄8" Orifice Special 6 1 EACH

7

241T 2" M1011T x

⁄16" Orifice Special 6 1 EACH

242T 2" M1011T x ½" Orifice Special 6 1 EACH

17

243T 2" M1011T x

⁄32" Orifice Special 6 1 EACH

244T 2" M1011T x 5⁄8" ELO Orifice Special 6 1 EACH

245T 2" M1011T x ¾" ESFR Orifice Special 6 1 EACH

246T 2" M1011T x K25 Orifice Special 6 1 EACH

Product Information V008.0

Unit

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

Model 2511 tESta n draIn® Sectional Floor Control Test and Drain Valve for Systems

Requiring Pressure Relief

M2511A valves are packaged with a trim kit. The trim kit includes a 175 PSI rated M7000 PRV and drain trim. M7000 valves are also

available in PSI ratings of 165, 185, 195, 205, 225, and 250.

Note: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and closing of the valve. Standard relief

valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves are required to CLOSE at a pressure above 80% of that rating. The

relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the

system is operational. A relief valve should NEVER have a shutoff valve or a plug downstream of its outlet.

1" M2511

No PRV Trim

1" M2511A

1" M2511T

1¼" M2511

No PRV Trim

1¼" M2511A

1¼" M2511T

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

406-0 1" M2511 x 3⁄8" Orifice Special 10 1 EACH

7

406-1 1" M2511 x

⁄16" Orifice Special 10 1 EACH

406-2 1" M2511 ½" Orifice Stock 10 1 EACH

17

406-3 1" M2511

⁄32" Orifice Special 10 1 EACH

406-4 1" M2511 5⁄8" ELO Orifice Special 10 1 EACH

406A-0 1" M2511A x 3⁄8" Orifice Special 10 1 EACH

406A-1 1" M2511A x 7⁄16" Orifice Special 10 1 EACH

406A-2 1" M2511A ½" Orifice Stock 10 1 EACH

17

406A-3 1" M2511A

406A-4 1" M2511A

⁄32" Orifice Special 10 1 EACH

5

⁄8" ELO Orifice Special 10 1 EACH

406T-0 1" M2511T x 3⁄8" Orifice Special 5 1 EACH

7

406T-1 1" M2511T x

⁄16" Orifice Special 5 1 EACH

406T-2 1" M2511T ½" Orifice Stock 5 1 EACH

17

406T-3 1" M2511T

⁄32" Orifice Special 5 1 EACH

406T-4 1" M2511T 5⁄8" ELO Orifice Special 5 1 EACH

407-0 1¼" M2511 x 3⁄8" Orifice Special 10 1 EACH

407-1 1¼" M2511 x 7⁄16" Orifice Special 10 1 EACH

407-2 1¼" M2511 ½" Orifice Stock 10 1 EACH

17

407-3 1¼" M2511

407-4 1¼" M2511

⁄32" Orifice Special 10 1 EACH

5

⁄8" ELO Orifice Special 10 1 EACH

407-5 1¼" M2511 x ¾" ESFR Orifice Special 10 1 EACH

407A-0 1¼" M2511A x 3⁄8" Orifice Special 10 1 EACH

7

407A-1 1¼" M2511A x

⁄16" Orifice Special 10 1 EACH

407A-2 1¼" M2511A ½" Orifice Stock 10 1 EACH

17

407A-3 1¼" M2511A

⁄32" Orifice Special 10 1 EACH

407A-4 1¼" M2511A 5⁄8" ELO Orifice Special 10 1 EACH

407A-5 1¼" M2511A x ¾" ESFR Orifice Special 10 1 EACH

407T-0 1¼" M2511T x 3⁄8" Orifice Special 5 1 EACH

7

407T-1 1¼" M2511T x

⁄16" Orifice Special 5 1 EACH

407T-2 1¼" M2511T ½" Orifice Stock 5 1 EACH

17

407T-3 1¼" M2511T

⁄32" Orifice Special 5 1 EACH

407T-4 1¼" M2511T 5⁄8" ELO Orifice Special 5 1 EACH

407T-5 1¼" M2511T x ¾" ESFR Orifice Special 5 1 EACH

Unit

Product Information V008.0

9

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

2" M2511

No PRV Trim

Groove x Groove

2" M2511A

Groove x Groove

2" M2511T

Groove x Groove

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

409-0 2" M2511 x 3⁄8" Orifice (GRV) Special 6 1 EACH

409-1 2" M2511 x 7⁄16" Orifice (GRV) Special 6 1 EACH

409-2 2" M2511 ½" Orifice (GRV) Stock 6 1 EACH

17

409-3 2" M2511

409-4 2" M2511

⁄32" Orifice (GRV) Special 6 1 EACH

5

⁄8" ELO Orifice (GRV) Special 6 1 EACH

409-5 2" M2511 ¾" ESFR Orifice (GRV) Special 6 1 EACH

409-6 2" M2511 K25 Orifice (GRV) Special 6 1 EACH

409A-0 2" M2511A x 3⁄8" Orifice (GRV) Special 6 1 EACH

7

409A-1 2" M2511A x

⁄16" Orifice (GRV) Special 6 1 EACH

409A-2 2" M2511A ½" Orifice (GRV) Stock 6 1 EACH

17

409A-3 2" M2511A

⁄32" Orifice (GRV) Special 6 1 EACH

409A-4 2" M2511A 5⁄8" ELO Orifice (GRV) Special 6 1 EACH

409A-5 2" M2511A ¾" ESFR Orifice (GRV) Special 6 1 EACH

409A-6 2" M2511A K25 Orifice (GRV) Special 6 1 EACH

409T-0 2" M2511T x 3⁄8" Orifice (GRV) Special 6 1 EACH

7

409T-1 2" M2511T x

⁄16" Orifice (GRV) Special 6 1 EACH

409T-2 2" M2511T ½" Orifice (GRV) Special 6 1 EACH

409T-3 2" M2511T 17⁄32" Orifice (GRV) Special 6 1 EACH

5

409T-4 2" M2511T

⁄8" ELO Orifice (GRV) Special 6 1 EACH

409T-5 2" M2511T ¾" ESFR Orifice (GRV) Special 6 1 EACH

409T-6 2" M2511T K25 Orifice (GRV) Special 6 1 EACH

Unit

Model 1500 DRAINa n tESt® Alarm Main Drain and Test Valve

Iron Body without Sight Glasses

AGF Item ID Item Description

2" BSPT M1500

290 2" BSPT M1500 x 3⁄8" Orifice Special 6 1 EACH

291 2" BSPT M1500 x 7⁄16" Orifice Special 6 1 EACH

292 2" BSPT M1500 x ½" Orifice Special 6 6 EACH

17

293 2" BSPT M1500 x

⁄32" Orifice Special 6 1 EACH

294 2" BSPT M1500 x 5⁄8" ELO Orifice Special 6 1 EACH

295 2" BSPT M1500 x ¾" ESFR Orifice Special 6 1 EACH

296 2" BSPT M1500 x K25 Orifice Special 6 1 EACH

Item

Class

Master

Carton

Minimum

Order Qty.

Unit

10

Product Information V008.0

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

Model 1200 rE m o t E tESt® Remote

Operated tESt

Energizing the solenoid incorporated into the TESTa n DRaIn® valve

allows system water to flow through a test orifice. After the preset

time delay, the water flow alarm is activated confirming system

integrity. R

panel or wired to an independent panel, allowing ONE person to

activate each specific system or a group of systems from ONE

central location. An optional bypass drain loop kit is also available.

E m o T E TEST

a n draIn

®

is designed to be integrated into an existing

®

Valve

With Optional Bypass

Drain Loop Kit

1" M1200

1¼" M1200

1½" M1200

2" M1200

Bypass Kit

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

270-350 1" M1200 x ½" Orifice w/1" Solenoid Valve 24V Special 1 1 EACH

270-351 1" M1200 x ½" Orifice w/1" Solenoid Valve 110V Special 1 1 EACH

3

Note: Other orifice sizes are also available (

⁄8", 7⁄16", 17⁄32", 5⁄8" ELO)

272-350 1¼" M1200 x ½" Orifice w/1" Solenoid Valve 24V Special 1 1 EACH

272-351 1¼" M1200 x ½" Orifice w/1" Solenoid Valve 110V Special 1 1 EACH

3

Note: Other orifice sizes are also available (

Special

Order

Special

Order

1½" M1200 x ½" Orifice w/1" Solenoid Valve 24V Special 1 1 EACH

1½" M1200 x ½" Orifice w/1" Solenoid Valve 110V Special 1 1 EACH

Note: Other orifice sizes are also available (

⁄8", 7⁄16", 17⁄32", 5⁄8" ELO, ¾" ESFR)

3

⁄8", 7⁄16", 17⁄32", 5⁄8" ELO, ¾" ESFR)

274-350 2" M1200 x ½" Orifice w/1" Solenoid Valve 24V Special 1 1 EACH

274-351 2" M1200 x ½" Orifice w/1" Solenoid Valve 110V Special 1 1 EACH

3

Note: Other orifice sizes are also available (

⁄8", 7⁄16", 17⁄32", 5⁄8" ELO, ¾" ESFR, K25)

365 Model 1200 1" Bypass Kit Special 1 1 EACH

365 Model 1200 1¼" Bypass Kit Special 1 1 EACH

365 Model 1200 1½" Bypass Kit Special 1 1 EACH

365 Model 1200 2" Bypass Kit Special 1 1 EACH

Unit

Locking Plate Kits

Provide protection and vandal-resistance for Models 1000, 1011,

2500, 2511 TESTa n DRan®, Model 1200 RE m o T E TEST®, and Model

1500 DRaIna n TEST®. Includes locking plate, hex key, lock, and (2)

keys. Please indicate valve size when ordering.

AGF Item ID Item Description

Locking Plate Kit

Product Information V008.0

870 Locking Plate Kit (Specify Valve Size When Ordering) Special 1 1 EACH

Item

Class

Master

Carton

Minimum

Order Qty.

Unit

11

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

Valve Repair Kits

Repair kits are available for all Models 1000, 1011, 2500, 2511 TESTa n DRaIn®;

1200 RE m o T E TEST®; and 1500 DRaIna n TEST® valves. Repair kits include: (1)

replacement adapter gasket, (1) replacement ball, (2) replacement valve seats,

(1) replacement stem packing, and (1) replacement stem washer. For more

information visit testandrain.com and click on the “SUPPORT” button.

Repair Kit for ¾"

and 1" Models

1000, 1011, 1200

Repair Kit for 1¼"

Models 1000,

1011, 1200

Repair Kit for 1½"

and 2" Models

1000, 1011, 1200

Repair Kit for 1"

Models 2500, 2511

Repair Kit for 1¼"

Models 2500, 2511

Repair Kit for 2"

Models 2500,

2511, 1500

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

9700A Repair Kit for ¾" and 1" Valves; 3⁄8" Orifice Assembly 1 1 EACH

7

9701A Repair Kit for ¾" and 1" Valves;

⁄16" Orifice Assembly 1 1 EACH

9702A Repair Kit for ¾" and 1" Valves; ½" Orifice Assembly 1 1 EACH

17

9703A Repair Kit for ¾" and 1" Valves;

⁄32" Orifice Assembly 1 1 EACH

9704A Repair Kit for ¾" and 1" Valves; 5⁄8" ELO Orifice Assembly 1 1 EACH

9710A Repair Kit for 1¼" Valves; 3⁄8" Orifice Assembly 1 1 EACH

7

9711A Repair Kit for 1¼" Valves;

⁄16" Orifice Assembly 1 1 EACH

9712A Repair Kit for 1¼" Valves; ½" Orifice Assembly 1 1 EACH

17

9713A Repair Kit for 1¼" Valves;

⁄32" Orifice Assembly 1 1 EACH

9714A Repair Kit for 1¼" Valves; 5⁄8" ELO Orifice Assembly 1 1 EACH

9715A Repair Kit for 1¼" Valves;

¾" ESFR Orifice Assembly 1 1 EACH

9730A Repair Kit for 1½" and 2" Valves; 3⁄8" Orifice Assembly 1 1 EACH

7

9731A Repair Kit for 1½" and 2" Valves;

⁄16" Orifice Assembly 1 1 EACH

9732A Repair Kit for 1½" and 2" Valves; ½" Orifice Assembly 1 1 EACH

17

9733A Repair Kit for 1½" and 2" Valves;

9734A Repair Kit for 1½" and 2" Valves;

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

9735A Repair Kit for 1½" and 2" Valves; ¾" ESFR Orifice Assembly 1 1 EACH

9736A Repair Kit for 1½" and 2" Valves; K25 Orifice Assembly 1 1 EACH

9741A Repair Kit for 1" Valves; 3⁄8" Orifice Assembly 1 1 EACH

7

9742A Repair Kit for 1" Valves;

⁄16" Orifice Assembly 1 1 EACH

9743A Repair Kit for 1" Valves; ½" Orifice Assembly 1 1 EACH

17

9744A Repair Kit for 1" Valves;

9745A Repair Kit for 1" Valves;

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

9750A Repair Kit for 1¼" Valves; 3⁄8" Orifice Assembly 1 1 EACH

7

9751A Repair Kit for 1¼" Valves;

⁄16" Orifice Assembly 1 1 EACH

9752A Repair Kit for 1¼" Valves; ½" Orifice Assembly 1 1 EACH

17

9753A Repair Kit for 1¼" Valves;

⁄32" Orifice Assembly 1 1 EACH

9754A Repair Kit for 1¼" Valves; 5⁄8" ELO Orifice Assembly 1 1 EACH

9755A Repair Kit for 1¼" Valves;

¾" ESFR Orifice Assembly 1 1 EACH

9760A Repair Kit for 2" Valves; 3⁄8" Orifice Assembly 1 1 EACH

7

9761A Repair Kit for 2" Valves;

⁄16" Orifice Assembly 1 1 EACH

9762A Repair Kit for 2" Valves; ½" Orifice Assembly 1 1 EACH

17

9763A Repair Kit for 2" Valves;

9764A Repair Kit for 2" Valves;

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

9765A Repair Kit for 2" Valves; ¾" ESFR Orifice Assembly 1 1 EACH

9766A Repair Kit for 2" Valves; K25 Orifice Assembly 1 1 EACH

Unit

12

Product Information V008.0

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

Model 1011 Kits - Pressure Relief Valve Trim Kits

Pressure relief valve and trim kits for Model 1000 and 2500 TESTa n DRaIn® and Model 1500 DRaIna n TEST® include M7000 pressure

relief valve, bypass tubing, (2) barbed elbows, and (2) hose clamps. 1011T kits also include M7500 pressure gauge, M7600 3-way

globe valve, and (2) nipples. Kits are shipped with 175PSI rated relief valve standard. Other PSI options are available (165, 185, 195,

205, 225, 250) and may be exchanged at no additional charge.

Note: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and closing of the valve. Standard relief

valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves are required to CLOSE at a pressure above 80% of that rating. The

relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the

system is operational. A relief valve should NEVER have a shutoff valve or a plug downstream of its outlet.

M1011 Kit

AGF Item ID Item Description

Item

Class

260 Model 1011 ¾" Kit Parts Kit 1 1 EACH

Master

Carton

Minimum

Order Qty.

Unit

260 Model 1011 1" Kit Parts Kit 1 1 EACH

261 Model 1011 1¼" Kit Parts Kit 1 1 EACH

262 Model 1011 1½" Kit Parts Kit 1 1 EACH

262 Model 1011 2" Kit Parts Kit 1 1 EACH

M1011T Kit

263 Model 1011T ¾" Kit Parts Kit 1 1 EACH

263 Model 1011T 1" Kit Parts Kit 1 1 EACH

264 Model 1011T 1¼" Kit Parts Kit 1 1 EACH

265 Model 1011T 1½" Kit Parts Kit 1 1 EACH

265 Model 1011T 2" Kit Parts Kit 1 1 EACH

Model 7000 Pressure Relief Valve - 7500 Gauge - 7600 Gauge Valve

Note: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and closing of the valve. Standard relief

valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves are required to CLOSE at a pressure above 80% of that rating. The

relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the

system is operational. A relief valve should NEVER have a shutoff valve or a plug downstream of its outlet.

M7000 / M7200

AGF Item ID Item Description

Item

Class

600 M7000 ½" Relief Valve 175PSI Stock 50 50 EACH

601 M7000 ½" Relief Valve 165PSI Stock 50 1 EACH

602 M7000 ½" Relief Valve 185PSI Stock 50 1 EACH

603 M7000 ½" Relief Valve 195PSI Stock 50 1 EACH

605 M7000 ½" Relief Valve 205PSI Stock 50 1 EACH

606 M7000 ½" Relief Valve 225PSI Stock 50 1 EACH

607 M7000 ½" Relief Valve 250PSI Stock 50 1 EACH

604 Special Relief Valve Stock 25 1 EACH

610 M7200 ¾" Relief Valve Stock 50 1 EACH

Master

Carton

Minimum

Order Qty.

Unit

M7500 M7600

Product Information V008.0

650 M7500 3½" Pressure Gauge Stock 60 1 EACH

660 M7600 ¼" 3-Way Globe Valve Stock 100 1 EACH

13

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

Model 3011 In S P E c t o r S tESt® Connection for Single Story and Other Applications

M3011A and M3011ASG valves are packaged with a trim kit. The trim kit includes a 175 PSI rated M7000 PRV and drain trim.

M7000 valves are also available in PSI ratings of 165, 185, 195, 205, 225, 250.

Note: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and closing of the valve. Standard relief

valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves are required to CLOSE at a pressure above 80% of that rating. The

relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the

system is operational. A relief valve should NEVER have a shutoff valve or a plug downstream of its outlet.

M3011A

M3011BV

M3011SG

M3011ASG

M3011

Accessories

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

300A M3011A x 3⁄8" Orifice Stock 10 1 EACH

301A M3011A x 7⁄16" Orifice Stock 10 1 EACH

302A M3011A x ½" Orifice Stock 10 10 EACH

17

303A M3011A x

304A M3011A x

⁄32" Orifice Stock 10 1 EACH

5

⁄8" ELO Orifice Stock 10 1 EACH

300BV M3011BV x 3⁄8" Orifice Stock 10 1 EACH

7

301BV M3011BV x

⁄16" Orifice Stock 10 1 EACH

302BV M3011BV x ½" Orifice Stock 10 1 EACH

17

303BV M3011BV x

⁄32" Orifice Stock 10 1 EACH

304BV M3011BV x 5⁄8" ELO Orifice Stock 10 1 EACH

300SG M3011SG x 3⁄8" Orifice Special 10 1 EACH

7

301SG M3011SG x

⁄16" Orifice Special 10 1 EACH

302SG M3011SG x ½" Orifice Special 10 1 EACH

17

303SG M3011SG x

⁄32" Orifice Special 10 1 EACH

304SG M3011SG x 5⁄8" ELO Orifice Special 10 1 EACH

300ASG M3011ASG x 3⁄8" Orifice Special 10 1 EACH

301ASG M3011ASG x 7⁄16" Orifice Special 10 1 EACH

302ASG M3011ASG x ½" Orifice Special 10 1 EACH

17

303ASG M3011ASG x

304ASG M3011ASG x

⁄32" Orifice Special 10 1 EACH

5

⁄8" ELO Orifice Special 10 1 EACH

305 M3011 1" Sight Glass Stock 1 1 EACH

306 Model 3011 1" Kit Assembly 1 1 EACH

Unit

14

Product Information V008.0

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

N

e

w

N

o

s

.

Model 8000 rE S I d E n t I a L rI S E r PacK® Pre Assembled Riser for NFPA 13D Systems

Assembly includes: bronze riser body w/ imprinted signage, water flow alarm switch w/ retard, 3½" pressure gauge, appropriately

sized drain valve w/ specific TEST orifice, sight glass option available, non retard flow switch special order

1" M8000

Thread

1¼" M8000

Thread

1½" M8000

Thread

1½" M8000

Thread x Groove

1½" M8000

Groove

2" M8000

Thread

2" M8000

Thread x Groove

2" M8000

Groove

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

8100D 1" M8000 x 3.0k-A Orifice Assembly 1 1 EACH

8101D 1" M8000 x 3.7k-B Orifice Assembly 1 1 EACH

8102D 1" M8000 x 4.3k-C Orifice Assembly 1 1 EACH

8103D 1" M8000 x 5.5k-D Orifice Assembly 1 1 EACH

8110D 1¼" M8000 x 3⁄8" Orifice Assembly 1 1 EACH

8111D 1¼" M8000 x 7⁄16" Orifice Assembly 1 1 EACH

8112D 1¼" M8000 x ½" Orifice Assembly 1 1 EACH

17

8113D 1¼" M8000 x

⁄32" Orifice Assembly 1 1 EACH

8114D 1¼" M8000 x 5⁄8" ELO Orifice Assembly 1 1 EACH

8120D 1½" M8000 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

8121D 1½" M8000 (THD) x 7⁄16" Orifice Assembly 1 1 EACH

8122D 1½" M8000 (THD) x ½" Orifice Assembly 1 1 EACH

17

8123D 1½" M8000 (THD) x

8124D 1½" M8000 (THD) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8125D 1½" M8000 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8126D 1½" M8000 (THD x GRV) x

⁄16" Orifice Assembly 1 1 EACH

8127D 1½" M8000 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

17

8128D 1½" M8000 (THD x GRV) x

8129D 1½" M8000 (THD x GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8130D 1½" M8000 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8131D 1½" M8000 (GRV) x

⁄16" Orifice Assembly 1 1 EACH

8132D 1½" M8000 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8133D 1½" M8000 (GRV) x

8134D 1½" M8000 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8140D 2" M8000 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

7

8141D 2" M8000 (THD) x

⁄16" Orifice Assembly 1 1 EACH

8142D 2" M8000 (THD) x ½" Orifice Assembly 1 1 EACH

17

8143D 2" M8000 (THD) x

⁄32" Orifice Assembly 1 1 EACH

8144D 2" M8000 (THD) x 5⁄8" ELO Orifice Assembly 1 1 EACH

8145D 2" M8000 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8146D 2" M8000 (THD x GRV) x 7⁄16" Orifice Assembly 1 1 EACH

8147D 2" M8000 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

17

8148D 2" M8000 (THD x GRV) x

⁄32" Orifice Assembly 1 1 EACH

8149D 2" M8000 (THD x GRV) x 5⁄8" ELO Orifice Assembly 1 1 EACH

8150D 2" M8000 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8151D 2" M8000 (GRV) x 7⁄16" Orifice Assembly 1 1 EACH

8152D 2" M8000 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8153D 2" M8000 (GRV) x

8154D 2" M8000 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

Unit

Product Information V008.0

15

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

N

e

w

N

o

s

.

Model 8011 rE S I d E n t I a L rI S E r PacK® Pre Assembled Riser for NFPA 13D Systems

Requiring Pressure Relief

Assembly includes: bronze riser body w/ imprinted signage, water flow alarm switch w/ retard, 3½" pressure gauge, appropriately

sized drain valve w/ specific TEST orifice, pressure relief valve w/ drain trim, sight glass option available, non retard flow switch

special order

M8011 valves are packaged with a trim kit. The trim kit includes a 175 PSI rated M7000 PRV and drain trim. M7000 valves are also

available in PSI ratings of 165, 185, 195, 205, 225, and 250.

Note: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and closing of the valve. Standard relief

valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves are required to CLOSE at a pressure above 80% of that rating. The

relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the

system is operational. A relief valve should NEVER have a shutoff valve or a plug downstream of its outlet.

1" M8011

Thread

1¼" M8011

1½" M8011

1½" M8011

1½" M8011

2" M8011

Thread

Thread

Thread x

Groove

Groove

Thread

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

8200D 1" M8011 x 3.0k-B Orifice Assembly 1 1 EACH

8201D 1" M8011 x 3.7k-E Orifice Assembly 1 1 EACH

8202D 1" M8011 x 4.3k-F Orifice Assembly 1 1 EACH

8203D 1" M8011 x 5.5k-F Orifice Assembly 1 1 EACH

8210D 1¼" M8011 x 3⁄8" Orifice Assembly 1 1 EACH

8211D 1¼" M8011 x 7⁄16" Orifice Assembly 1 1 EACH

8212D 1¼" M8011 x ½" Orifice Assembly 1 1 EACH

17

8213D 1¼" M8011 x

⁄32" Orifice Assembly 1 1 EACH

8214D 1¼" M8011 x 5⁄8" ELO Orifice Assembly 1 1 EACH

8220D 1½" M8011 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

8221D 1½" M8011 (THD) x 7⁄16" Orifice Assembly 1 1 EACH

8222D 1½" M8011 (THD) x ½" Orifice Assembly 1 1 EACH

17

8223D 1½" M8011 (THD) x

8224D 1½" M8011 (THD) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8225D 1½" M8011 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8226D 1½" M8011 (THD x GRV) x

⁄16" Orifice Assembly 1 1 EACH

8227D 1½" M8011 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

17

8228D 1½" M8011 (THD x GRV) x

8229D 1½" M8011 (THD x GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8230D 1½" M8011 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8231D 1½" M8011 (GRV) x

⁄16" Orifice Assembly 1 1 EACH

8232D 1½" M8011 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8233D 1½" M8011 (GRV) x

8234D 1½" M8011 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8240D 2" M8011 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

7

8241D 2" M8011 (THD) x

⁄16" Orifice Assembly 1 1 EACH

8242D 2" M8011 (THD) x ½" Orifice Assembly 1 1 EACH

17

8243D 2" M8011 (THD) x

⁄32" Orifice Assembly 1 1 EACH

8244D 2" M8011 (THD) x 5⁄8" ELO Orifice Assembly 1 1 EACH

Unit

16

Product Information V008.0

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

N

e

w

N

o

s

.

N

e

w

N

o

s

.

2" M8011

Thread x

Groove

AGF Item ID Item Description

Item

Class

8245D 2" M8011 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8246D 2" M8011 (THD x GRV) x

⁄16" Orifice Assembly 1 1 EACH

8247D 2" M8011 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

17

8248D 2" M8011 (THD x GRV) x

⁄32" Orifice Assembly 1 1 EACH

Master

Carton

Minimum

Order Qty.

Unit

8249D 2" M8011 (THD x GRV) x 5⁄8" ELO Orifice Assembly 1 1 EACH

2" M8011

Groove

8250D 2" M8011 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8251D 2" M8011 (GRV) x 7⁄16" Orifice Assembly 1 1 EACH

8252D 2" M8011 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8253D 2" M8011 (GRV) x

8254D 2" M8011 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

Model 8000 rE S I d E n t I a L rI S E r PacK® Pre Assembled Riser for NFPA 13R Systems

Assembly includes: bronze riser body w/ imprinted signage, water flow alarm switch w/ retard, 3½" pressure gauge with ¼" 3-way

valve, appropriately sized drain valve w/ specific TEST orifice, sight glass option available, non retard flow switch special order

1¼" M8000

Thread

1½" M8000

Thread

1½" M8000

Thread x

Groove

1½" M8000

Groove

2" M8000

Thread

AGF Item ID Item Description

Item

Class

8110R 1¼" M8000 x 3⁄8" Orifice Assembly 1 1 EACH

8111R 1¼" M8000 x 7⁄16" Orifice Assembly 1 1 EACH

8112R 1¼" M8000 x ½" Orifice Assembly 1 1 EACH

17

8113R 1¼" M8000 x

8114R 1¼" M8000 x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8120R 1½" M8000 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

7

8121R 1½" M8000 (THD) x

⁄16" Orifice Assembly 1 1 EACH

8122R 1½" M8000 (THD) x ½" Orifice Assembly 1 1 EACH

17

8123R 1½" M8000 (THD) x

8124R 1½" M8000 (THD) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8125R 1½" M8000 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8126R 1½" M8000 (THD x GRV) x

⁄16" Orifice Assembly 1 1 EACH

8127R 1½" M8000 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

17

8128R 1½" M8000 (THD x GRV) x

⁄32" Orifice Assembly 1 1 EACH

8129R 1½" M8000 (THD x GRV) x 5⁄8" ELO Orifice Assembly 1 1 EACH

8130R 1½" M8000 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8131R 1½" M8000 (GRV) x

⁄16" Orifice Assembly 1 1 EACH

8132R 1½" M8000 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8133R 1½" M8000 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

8134R 1½" M8000 (GRV) x 5⁄8" ELO Orifice Assembly 1 1 EACH

8140R 2" M8000 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

8141R 2" M8000 (THD) x 7⁄16" Orifice Assembly 1 1 EACH

8142R 2" M8000 (THD) x ½" Orifice Assembly 1 1 EACH

17

8143R 2" M8000 (THD) x

⁄32" Orifice Assembly 1 1 EACH

8144R 2" M8000 (THD) x 5⁄8" ELO Orifice Assembly 1 1 EACH

Master

Carton

Minimum

Order Qty.

Unit

Product Information V008.0

17

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

N

e

w

N

o

s

.

N

e

w

N

o

s

.

2" M8000

Thread x

Groove

2" M8000

Groove

AGF Item ID Item Description

Item

Class

8145R 2" M8000 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8146R 2" M8000 (THD x GRV) x 7⁄16" Orifice Assembly 1 1 EACH

8147R 2" M8000 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

17

8148R 2" M8000 (THD x GRV) x

8149R 2" M8000 (THD x GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8150R 2" M8000 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8151R 2" M8000 (GRV) x

⁄16" Orifice Assembly 1 1 EACH

Master

Carton

Minimum

Order Qty.

Unit

8152R 2" M8000 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8153R 2" M8000 (GRV) x

8154R 2" M8000 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

Model 8011 rE S I d E n t I a L rI S E r PacK® Pre Assembled Riser for NFPA 13R Systems

Requiring Pressure Relief

Assembly includes: bronze riser body w/ imprinted signage, water flow alarm switch w/ retard, 3½" pressure gauge with ¼" 3-way

valve, appropriately sized drain valve w/ specific TEST orifice, pressure relief valve w/ drain trim, sight glass option available, non

retard flow switch special order

M8011 valves are packaged with a trim kit. The trim kit includes a 175 PSI rated M7000 PRV and drain trim. M7000 valves are also

available in PSI ratings of 165, 185, 195, 205, 225, and 250.

Note: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and closing of the valve. Standard relief

valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves are required to CLOSE at a pressure above 80% of that rating. The

relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the

system is operational. A relief valve should NEVER have a shutoff valve or a plug downstream of its outlet.

1¼" M8011

Thread

1½" M8011

Thread

1½" M8011

Thread x

Groove

1½" M8011

Groove

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

8210R 1¼" M8011 x 3⁄8" Orifice Assembly 1 1 EACH

8211R 1¼" M8011 x 7⁄16" Orifice Assembly 1 1 EACH

8212R 1¼" M8011 x ½" Orifice Assembly 1 1 EACH

17

8213R 1¼" M8011 x

8214R 1¼" M8011 x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8220R 1½" M8011 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

7

8221R 1½" M8011 (THD) x

⁄16" Orifice Assembly 1 1 EACH

8222R 1½" M8011 (THD) x ½" Orifice Assembly 1 1 EACH

17

8223R 1½" M8011 (THD) x

⁄32" Orifice Assembly 1 1 EACH

8224R 1½" M8011 (THD) x 5⁄8" ELO Orifice Assembly 1 1 EACH

8225R 1½" M8011 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8226R 1½" M8011 (THD x GRV) x

⁄16" Orifice Assembly 1 1 EACH

8227R 1½" M8011 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

17

8228R 1½" M8011 (THD x GRV) x

⁄32" Orifice Assembly 1 1 EACH

8229R 1½" M8011 (THD x GRV) x 5⁄8" ELO Orifice Assembly 1 1 EACH

8230R 1½" M8011 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8231R 1½" M8011 (GRV) x

⁄16" Orifice Assembly 1 1 EACH

8232R 1½" M8011 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8233R 1½" M8011 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

8234R 1½" M8011 (GRV) x 5⁄8" ELO Orifice Assembly 1 1 EACH

Unit

18

Product Information V008.0

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

N

e

w

N

o

s

.

2" M8011

Thread

AGF Item ID Item Description

Item

Class

8240R 2" M8011 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

8241R 2" M8011 (THD) x 7⁄16" Orifice Assembly 1 1 EACH

Master

Carton

Minimum

Order Qty.

Unit

8242R 2" M8011 (THD) x ½" Orifice Assembly 1 1 EACH

17

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

7

⁄16" Orifice Assembly 1 1 EACH

17

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

7

⁄16" Orifice Assembly 1 1 EACH

2" M8011

Thread x

Groove

2" M8011

Groove

8243R 2" M8011 (THD) x

8244R 2" M8011 (THD) x

8245R 2" M8011 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8246R 2" M8011 (THD x GRV) x

8247R 2" M8011 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

8248R 2" M8011 (THD x GRV) x

8249R 2" M8011 (THD x GRV) x

8250R 2" M8011 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8251R 2" M8011 (GRV) x

8252R 2" M8011 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8253R 2" M8011 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

8254R 2" M8011 (GRV) x 5⁄8" ELO Orifice Assembly 1 1 EACH

Model 8000 co m m E r c I a L rI S E r PacK® Pre Assembled Riser for NFPA 13 Sectional Floor

Control Assembly, Cast Bronze 1¼" – 2"

Assembly includes: bronze riser body w/ imprinted signage, water flow alarm switch w/ retard, 3½" pressure gauge with ¼" 3-way

valve, appropriately sized TEST

a n DRaIn

®

valve w/ specific TEST orifice,

1¼" M8000

Thread

1½" M8000

Thread

1½" M8000

Thread x

Groove

1½" M8000

Groove

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

8310A 1¼" M8000 x 3⁄8" Orifice Assembly 1 1 EACH

8311A 1¼" M8000 x 7⁄16" Orifice Assembly 1 1 EACH

8312A 1¼" M8000 x ½" Orifice Assembly 1 1 EACH

17

8313A 1¼" M8000 x

8314A 1¼" M8000 x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8320A 1½" M8000 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

7

8321A 1½" M8000 (THD) x

⁄16" Orifice Assembly 1 1 EACH

8322A 1½" M8000 (THD) x ½" Orifice Assembly 1 1 EACH

8323A 1½" M8000 (THD) x 17⁄32" Orifice Assembly 1 1 EACH

5

8324A 1½" M8000 (THD) x

⁄8" ELO Orifice Assembly 1 1 EACH

8325A 1½" M8000 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8326A 1½" M8000 (THD x GRV) x 7⁄16" Orifice Assembly 1 1 EACH

8327A 1½" M8000 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

17

8328A 1½" M8000 (THD x GRV) x

8329A 1½" M8000 (THD x GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8330A 1½" M8000 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8331A 1½" M8000 (GRV) x

⁄16" Orifice Assembly 1 1 EACH

8332A 1½" M8000 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8333A 1½" M8000 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

8334A 1½" M8000 (GRV) x 5⁄8" ELO Orifice Assembly 1 1 EACH

Unit

Product Information V008.0

19

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

2" M8000

Thread

AGF Item ID Item Description

Item

Class

8340A 2" M8000 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

8341A 2" M8000 (THD) x 7⁄16" Orifice Assembly 1 1 EACH

Master

Carton

Minimum

Order Qty.

Unit

8342A 2" M8000 (THD) x ½" Orifice Assembly 1 1 EACH

17

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

7

⁄16" Orifice Assembly 1 1 EACH

17

⁄32" Orifice Assembly 1 1 EACH

2" M8000

Thread x

Groove

8343A 2" M8000 (THD) x

8344A 2" M8000 (THD) x

8345A 2" M8000 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8346A 2" M8000 (THD x GRV) x

8347A 2" M8000 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

8348A 2" M8000 (THD x GRV) x

8349A 2" M8000 (THD x GRV) x 5⁄8" ELO Orifice Assembly 1 1 EACH

2" M8000

Groove

8350A 2" M8000 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8351A 2" M8000 (GRV) x 7⁄16" Orifice Assembly 1 1 EACH

8352A 2" M8000 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8353A 2" M8000 (GRV) x

8354A 2" M8000 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

Model 8011 co m m E r c I a L rI S E r PacK® Pre Assembled Riser for NFPA 13 Sectional Floor

Control Assembly Requiring Pressure Relief, Cast Bronze 1¼" – 2"

Assembly includes: bronze riser body w/ imprinted signage, water flow alarm switch w/ retard, 3½" pressure gauge with ¼" 3-way

valve, appropriately sized TEST

M8011 valves are packaged with a trim kit. The trim kit includes a 175 PSI rated M7000 PRV and drain trim. M7000 valves are also

available in PSI ratings of 165, 185, 195, 205, 225, and 250.

Note: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and closing of the valve. Standard relief

valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves are required to CLOSE at a pressure above 80% of that rating. The

relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the

system is operational. A relief valve should NEVER have a shutoff valve or a plug downstream of its outlet.

a n DRaIn

®

valve w/ specific TEST orifice, pressure relief valve w/ drain trim.

1¼" M8011

Thread

1½" M8011

Thread

1½" M8011

Thread x

Groove

20

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

8410A 1¼" M8011 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

8411A 1¼" M8011 (THD) x 7⁄16" Orifice Assembly 1 1 EACH

8412A 1¼" M8011 (THD) x ½" Orifice Assembly 1 1 EACH

17

8413A 1¼" M8011 (THD) x

⁄32" Orifice Assembly 1 1 EACH

8414A 1¼" M8011 (THD) x 5⁄8" ELO Orifice Assembly 1 1 EACH

8420A 1½" M8011 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

7

8421A 1½" M8011 (THD) x

⁄16" Orifice Assembly 1 1 EACH

8422A 1½" M8011 (THD) x ½" Orifice Assembly 1 1 EACH

8423A 1½" M8011 (THD) x 17⁄32" Orifice Assembly 1 1 EACH

5

8424A 1½" M8011 (THD) x

⁄8" ELO Orifice Assembly 1 1 EACH

8425A 1½" M8011 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8426A 1½" M8011 (THD x GRV) x 7⁄16" Orifice Assembly 1 1 EACH

8427A 1½" M8011 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

17

8428A 1½" M8011 (THD x GRV) x

8429A 1½" M8011 (THD x GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

Product Information V008.0

Unit

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

1½" M8011

Groove

2" M8011

Thread

2" M8011

Thread x

Groove

2" M8011

Groove

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

8430A 1½" M8011 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8431A 1½" M8011 (GRV) x 7⁄16" Orifice Assembly 1 1 EACH

8432A 1½" M8011 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8433A 1½" M8011 (GRV) x

8434A 1½" M8011 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8440A 2" M8011 (THD) x 3⁄8" Orifice Assembly 1 1 EACH

7

8441A 2" M8011 (THD) x

⁄16" Orifice Assembly 1 1 EACH

8442A 2" M8011 (THD) x ½" Orifice Assembly 1 1 EACH

17

8443A 2" M8011 (THD) x

⁄32" Orifice Assembly 1 1 EACH

8444A 2" M8011 (THD) x 5⁄8" ELO Orifice Assembly 1 1 EACH

8445A 2" M8011 (THD x GRV) x 3⁄8" Orifice Assembly 1 1 EACH

8446A 2" M8011 (THD x GRV) x 7⁄16" Orifice Assembly 1 1 EACH

8447A 2" M8011 (THD x GRV) x ½" Orifice Assembly 1 1 EACH

17

8448A 2" M8011 (THD x GRV) x

8449A 2" M8011 (THD x GRV) x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8450A 2" M8011 (GRV) x 3⁄8" Orifice Assembly 1 1 EACH

7

8451A 2" M8011 (GRV) x

⁄16" Orifice Assembly 1 1 EACH

8452A 2" M8011 (GRV) x ½" Orifice Assembly 1 1 EACH

17

8453A 2" M8011 (GRV) x

⁄32" Orifice Assembly 1 1 EACH

8454A 2" M8011 (GRV) x 5⁄8" ELO Orifice Assembly 1 1 EACH

Unit

Model 8000 co m m E r c I a L rI S E r PacK® Pre Assembled Riser for NFPA 13 Sectional Floor

Control Assembly, Fabricated Schedule 40 Steel 2½" – 6"

Assembly includes: schedule 40 fabricated steel body w/ 3 mil powder coat red finish and grooved ends, water flow alarm switch w/

retard, 3½" pressure gauge with ¼" 3-way valve, appropriately sized TEST

AGF Item ID Item Description

2½" M8000

8360A 2½" M8000 x 3⁄8" Orifice Assembly 1 1 EACH

a n DRaIn

8361A 2½" M8000 x 7⁄16" Orifice Assembly 1 1 EACH

8362A 2½" M8000 x ½" Orifice Assembly 1 1 EACH

17

8363A 2½" M8000 x

⁄32" Orifice Assembly 1 1 EACH

8364A 2½" M8000 x 5⁄8" ELO Orifice Assembly 1 1 EACH

8365A 2½" M8000 x ¾" ESFR Orifice Assembly 1 1 EACH

3" M8000

8370A 3" M8000 x 3⁄8" Orifice Assembly 1 1 EACH

8371A 3" M8000 x 7⁄16" Orifice Assembly 1 1 EACH

8372A 3" M8000 x ½" Orifice Assembly 1 1 EACH

17

8373A 3" M8000 x

8374A 3" M8000 x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8375A 3" M8000 x ¾" ESFR Orifice Assembly 1 1 EACH

®

valve w/ specific TEST orifice.

Item

Class

Master

Carton

Minimum

Order Qty.

Unit

Product Information V008.0

21

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

4" M8000

AGF Item ID Item Description

Item

Class

8380A 4" M8000 x 3⁄8" Orifice Assembly 1 1 EACH

Master

Carton

Minimum

Order Qty.

Unit

8381A 4" M8000 x 7⁄16" Orifice Assembly 1 1 EACH

8382A 4" M8000 x ½" Orifice Assembly 1 1 EACH

17

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

7

⁄16" Orifice Assembly 1 1 EACH

Utilizes M2500 Groove x

Groove TEST

a n DRaIn

®

6" M8000

8383A 4" M8000 x

8384A 4" M8000 x

8385A 4" M8000 x ¾" ESFR Orifice Assembly 1 1 EACH

8386A 4" M8000 x K25 Orifice Assembly 1 1 EACH

8390A 6" M8000 x 3⁄8" Orifice Assembly 1 1 EACH

8391A 6" M8000 x

8392A 6" M8000 x ½" Orifice Assembly 1 1 EACH

17

8393A 6" M8000 x

⁄32" Orifice Assembly 1 1 EACH

8394A 6" M8000 x 5⁄8" ELO Orifice Assembly 1 1 EACH

Utilizes M2500 Groove x

Groove TESTa n DRaIn

®

8395A 6" M8000 x ¾" ESFR Orifice Assembly 1 1 EACH

8396A 6" M8000 x K25 Orifice Assembly 1 1 EACH

Model 8011 co m m E r c I a L rI S E r PacK® Pre Assembled Riser for NFPA 13 Sectional Floor

Control Assembly Requiring Pressure Relief, Fabricated Schedule 40 Steel 2½" – 6"

Assembly includes: schedule 40 fabricated steel body w/ 3 mil powder coat red finish and grooved ends, water flow alarm switch w/

retard, 3½" pressure gauge with ¼" 3-way valve, appropriately sized TEST

valve w/ drain trim.

M8011 valves are packaged with a trim kit. The trim kit includes a 175 PSI rated M7000 PRV and drain trim. M7000 valves are also

available in PSI ratings of 165, 185, 195, 205, 225, and 250.

*Note: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and closing of the valve. Standard relief

valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves are required to CLOSE at a pressure above 80% of that rating. The

relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the

system is operational. A relief valve should NEVER have a shutoff valve or a plug downstream of its outlet.

a n DRaIn

®

valve w/ specific TEST orifice, pressure relief

2½" M8011

22

3" M8011

AGF Item ID Item Description

Item

Class

Master

Carton

Minimum

Order Qty.

8460A 2½" M8011 x 3⁄8" Orifice Assembly 1 1 EACH

8461A 2½" M8011 x 7⁄16" Orifice Assembly 1 1 EACH

8462A 2½" M8011 x ½" Orifice Assembly 1 1 EACH

17

8463A 2½" M8011 x

⁄32" Orifice Assembly 1 1 EACH

8464A 2½" M8011 x 5⁄8" ELO Orifice Assembly 1 1 EACH

8465A 2½" M8011 x ¾" ESFR Orifice Assembly 1 1 EACH

8470A 3" M8011 x 3⁄8" Orifice Assembly 1 1 EACH

8471A 3" M8011 x 7⁄16" Orifice Assembly 1 1 EACH

8472A 3" M8011 x ½" Orifice Assembly 1 1 EACH

17

8473A 3" M8011 x

8474A 3" M8011 x

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

8475A 3" M8011 x ¾" ESFR Orifice Assembly 1 1 EACH

Product Information V008.0

Unit

AGF Manufacturing Inc. • Phone: 610.240.4900 • Fax: 610.240.4906 • www.testandrain.com

4" M8011

AGF Item ID Item Description

Item

Class

8480A 4" M8011 x 3⁄8" Orifice Assembly 1 1 EACH

Master

Carton

Minimum

Order Qty.

Unit

8481A 4" M8011 x 7⁄16" Orifice Assembly 1 1 EACH

8482A 4" M8011 x ½" Orifice Assembly 1 1 EACH

17

⁄32" Orifice Assembly 1 1 EACH

5

⁄8" ELO Orifice Assembly 1 1 EACH

7

⁄16" Orifice Assembly 1 1 EACH

Utilizes M2500 Groove x

Groove TEST

a n DRaIn

®

6" M8011

8483A 4" M8011 x

8484A 4" M8011 x

8485A 4" M8011 x ¾" ESFR Orifice Assembly 1 1 EACH

8486A 4" M8011 x K25 Orifice Assembly 1 1 EACH

8490A 6" M8011 x 3⁄8" Orifice Assembly 1 1 EACH

8491A 6" M8011 x

8492A 6" M8011 x ½" Orifice Assembly 1 1 EACH

17

8493A 6" M8011 x

⁄32" Orifice Assembly 1 1 EACH

8494A 6" M8011 x 5⁄8" ELO Orifice Assembly 1 1 EACH

Utilizes M2500 Groove x

Groove TESTa n DRaIn

®

8495A 6" M8011 x ¾" ESFR Orifice Assembly 1 1 EACH

8496A 6" M8011 x K25 Orifice Assembly 1 1 EACH

Model 6000 and 6100 Center of Tile System Fittings

The AGF Center of Tile fittings are designed to provide adjustability in the final piping connection between a water supply line and a

wet system fire sprinkler head. This adjustability permits fast and easy placement of the sprinkler head exactly where it needs to go

in any type or style of ceiling system or treatment including Drop, Slat, Cloud, Tin and many other innovative architectural designs.

By rotating any combination of two 6000 series offset fittings to the desired position, a sprinkler head can be placed at any point

within a 12" diameter from the center of the first fitting connection. By rotating any one 6000 series offset fitting to the desired position, a sprinkler head can be placed at any point on the perimeter of a 6" diameter.

Center of Tile fittings are easy to install, and do not require extra hangers, ceiling T-bar brackets, ceiling grids, or special tools. Precise sprinkler head placement can be accomplished in half the normal time with reduction in material cost.

6100B

6000B 6000C 6000D 6000E 6000F

Minimum

Order Qty.

Unit

Models 6000 and

6100

AGF Item ID Item Description

6000B 1" Female IPS x 1" Plain End; 2" Length 1 EACH

6000C 1" Plain End Socket x 1" Female IPS; 2" Length 1 EACH

6000D 1" Plain End Socket x ½" Female IPS; 2" Length x 2" Length 1 EACH

6000E 1" Female IPS x 1" Female IPS; 2" Length 1 EACH

6000F 1" Female IPS x ½" Female IPS; 2" Length x 2" Length 1 EACH

6100B 1" Female IPS x 1" Plain End Elbow 1 EACH

Terms and Conditions:

All orders must be received by AGF in a written format transmitted to AGF via fax (610-240-4906) or e-mail (orders@testandrain.com).

No order will be processed unless prices listed meet current published prices. Freight allowance for domestic shipment is $5,000.00

utilizing AGF shipping vendors. Stipulations of alternate shipping vendors may result in additional surcharges. Minimum order

quantities must meet those listed on published Product Information. No returns will be accepted without an AGF Manufacturing Inc.

Return Goods Authorization (RGA) number. AGF does not accept customer issued debit memos.

Product Information V008.0

23

Since our founding, AGF Manufacturing, Inc. has been committed to providing a unique line of products for the

fire sprinkler industry. We strive to maintain a close working relationship with our customers in order to meet the

ever increasing demands of our industry. Over the years, this has helped us introduce many innovative products

designed to meet a wide variety of needs. In filling these needs we have built a strong reputation for providing the

best products backed by an unwavering commitment to customer satisfaction. We continually work in the field to

improve existing products as well as invent new items.

At AGF our mission is to design and manufacture unique products that engineers and architects can specify with

confidence based on a proven record of reliability and fiscal accountability and that make the contractor’s job

more efficient and competitive by providing cost-effective labor savings.

Our entire product line is manufactured to the highest quality and meets or exceeds ISO 9002 standards. Our

valves are approved by Underwriters Laboratories and FM Approvals, LLC. This commitment to quality enhances

product reliability and end-user satisfaction.

AGF Manufacturing, Inc.

100 Quaker Lane, Malvern, PA 19355

Phone: 610-240-4900 • Fax: 610-240-4906

www.testandrain.com

© 2011 AGF Manufacturing Inc. TESTANDRAIN, DRAINANTEST, REMOTETEST, INSPECTOR’STEST, and RISERPACK are all registered trademarks of AGF Manufacturing Inc.

Loading...

Loading...