AGF Manufacturing 8011, 8000 Installation Manual

A

B

CD

A

B

C D

A

B

C

D

A

B

C

D

A

B

CD

A

B

C D

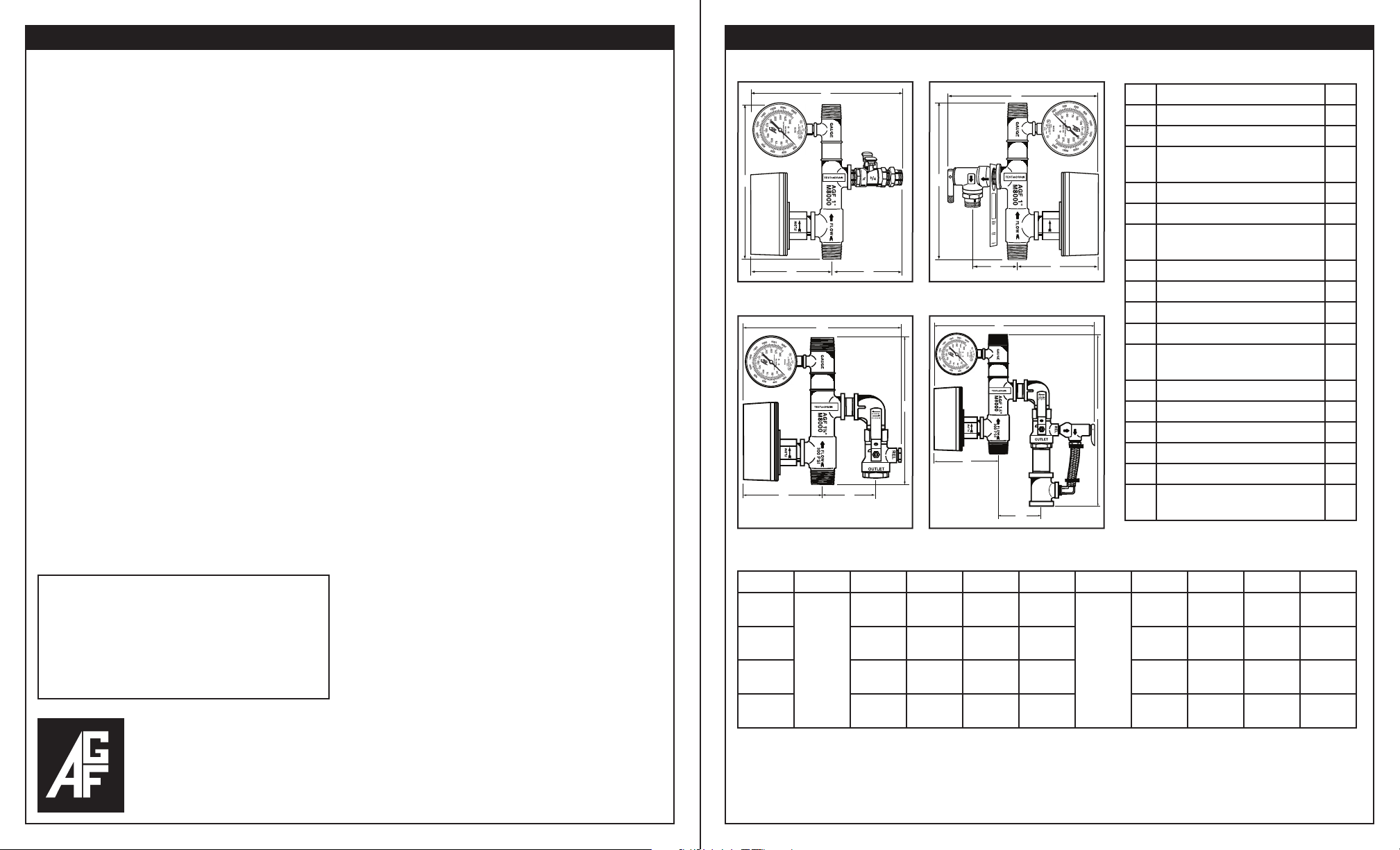

Mo d e l 8000/8011 Re s i d e n t i a l Ri s e R PaCK® as s e M b l yMo d e l 8000/8011 Re s i d e n t i a l Ri s e R PaCK® in s t a l l a t i o n in s t R u C t i o n s

WARNING: System must be flushed clean of any debris or pipe chips. Failure to flush the system clean can damage

the valve and will void the warranty. NOTE: This unit may be shipped in a semi-assembled state. IF A RELIEF VALVE IS

INCLUDED DO NOT INSTALL THE RELIEF VALVE BEFORE THE SYSTEM INTEGRITY TEST. SYSTEM CANNOT BE PRESSURE

TESTED WITH RELIEF VALVE INSTALLED.

Installing Ri s e R PACK

1. Determine installation location and orientation of Model

8000/8011 Ri s e R PACK®: drain to right, drain to left,

horizontal, or vertical.

2. If necessary, tighten AGF Model 7500 Pressure Gauge

and attached ball valve so that gauge face and valve

handle are accessible when Ri s e R PACK® is in desired

position.

3. Install preassembled Ri s e R PACK® to sprinkler system

inlet as directed by code and AHJ. Confirm flow arrow

direction. NOTE: Some local codes require the use of a

meter, a backflow preventer, and/or a check valve prior

to the inlet of the Ri s e R PACK®.

4. Attach outlet of Ri s e R PACK® to system supply piping and

complete system installation. NOTE: Local codes will

dictate riser drain requirements. 1" Ri s e R PACK® includes

a ¾" Male NPT x ½" Female NPT/Male Garden Hose

adaptor that can be used to access system for pressure

testing through the ¾" ball valve prior to completing

assembly of either a hard pipe or hose drain line. 1¼"

through 2" Ri s e R PACK®s include a 1" drain valve with

a ½" system access port that can be used for system

pressure testing.

®

Installing Pressure Relief Valve (Model 8011)

NOTE: SYSTEM CANNOT BE TESTED WITH RELIEF VALVE

INSTALLED.

1. The optional pressure relief valve should be installed

after the completion of system installation and integrity testing. The 1" Model 8011 Ri s e R PACK® includes a

¾" Model 7200 Pressure Relief Valve. 1¼" through 2"

Model 8011 Ri s e R PACK® are shipped with a ½" Model

7000 Pressure Relief Valve.

2. For 1" Ri s e R PACK®: with the hose adaptor attached to

the ¾" M/F ball valve, drain system and then remove

¾" ball valve. Using appropriate sealant, install Model

7200 ¾" Pressure Relief Valve to Ri s e R PACK®. Install

hose adaptor to outlet of relief valve and complete drain

assembly. Local code will dictate drain requirements.

Adaptor will accept either ½" Male NPT hard pipe or a

standard hose connection.

3. For 1¼" through 2" Ri s e R PACK® it is not necessary to

drain system to install the Model 7000 Pressure Relief

Valve. Shut off supply valve and depressurize system.

Open Model 3011 in s P e C t o R ’stest® Ball Valve. Remove

system access port ½" plug. Using appropriate sealant,

install Model 7000 Pressure Relief Valve to Model 3011

in s P e C t o R ’stest® Ball Valve and then close ball valve.

LIMITED WARRANTY: AGF Manufacturing Inc. warrants each product against defects

in material for a period of one year from the date of the original shipment. In the event

of such defects within the warranty period, the Company will, at its option, replace or

recondition the product without charge. This shall constitute the exclusive remedy for

breach of contract, and the Company shall not be responsible for any incidental or con-

sequential damages, including, without limitation, damages or other costs resulting from

labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage

from adverse water conditions, chemicals, or any other circumstances over which

the Company has no control. This warranty shall be invalidated by any abuse, misuse,

misapplication, or improper installation of the product. THE COMPANY MAKES NO OTHER

WARRANTIES EXPRESS OR IMPLIED EXCEPT AS PROVIDED IN THIS WARRANTY.

AGF Manufacturing Inc.

100 Quaker Lane, Malvern, PA 19355

Phone: 610-240-4900

Fax: 610-240-4906

www.testandrain.com

4. Install straight male X-barb to outlet of Model 7000

Pressure Relief Valve and install nylobraid tube to barb

end. Remove plastic plug from bypass tee and install

male X-barb elbow into the bypass tee, rolling the barb

elbow into the tubing on the last turn of the elbow.

5. Slide one plastic clamp over each barb fitting and secure

with pliers.

6. Return supply valve to fully open position.

Thank You For Using Our Products!

For our complete family of products,

visit us online at www.testandrain.com.

RISERPACK and INSPECTOR’STEST are registered trademarks of AGF Manufacturing Inc.

1" mo D e l 8000

1" mo D e l 8011

Co m p o n e n t s

No. Part Qty.

1

Ri s e R PACK® - Bronze Casting 1

2

4

5

1

1¼" – 2" mo D e l 8000

1

4

5

9

1

7

6

2

6

4

5

1¼" – 2" mo D e l 8011

1

4

10

5

3

11

9

10

3

8

14

12

13

16

17

16

15

¾" Male x Female Ball Valve 1

1" M3011BV in s P e C t o R ’stest®

3

Ball Valve

4

M7500 Pressure Gauge 1

5

Water Flow Alarm Switch 1

¾" MNPT x ½" FNPT Hose

6

Adaptor Orifice

7

M7200 ¾" Pressure Relief Valve 1

8

M7000 ½" Pressure Relief Valve 1

9

1" Brass Nipple 1

10

1" Brass Street Elbow 1

½" Brass System Access Port

11

Plug

12

1" Relief Valve Bypass Nipple 1

13

1" Relief Valve Bypass Tee 1

14

½" NPT X-Barb Straight Fitting 1

15

½" NPT X-Barb Elbow Fitting 1

16

Clamps 2

Nylobraid Relief Valve Drain

17

Tubing

Di m e n s i o n s

SIZE Model A B C D Model A B C D

1"

11⁄4"

1½"

2"

101⁄2"

(267 mm)

11"

(279 mm)

12"

(305 mm)

Model 8000

12"

(305 mm)

* Additional space may be necessary to allow for hard drain fitting if required.

** Valve handle clearance required — add 2".

*** Lift handle clearance required — add 31⁄8".

121⁄4"

(311 mm)

43⁄4" *

(121 mm)

121⁄4" **

(311 mm)4"(102 mm)

121⁄2" **

(317 mm)

13"

(329 mm)

41⁄8"

(105 mm)

43⁄8"

(111 mm)

61⁄4"

(159 mm)

61⁄2"

(165 mm)

65⁄8"

(168 mm)

67⁄8"

(174 mm)

101⁄2"

(267 mm)

143⁄4"

(375 mm)

151⁄4"

(387 mm)

Model 8011

151⁄4"

(387 mm)

121⁄4"

(317 mm)

27⁄8" ***

(73 mm)

15"

(381 mm)4"(102 mm)

151⁄4"

(387 mm)

153⁄4"

(399 mm)

41⁄8"

(105 mm)

43⁄8"

(111 mm)

1

1

1

1

61⁄4"

(159 mm)

61⁄2"

(165 mm)

65⁄8"

(168 mm)

67⁄8"

(174 mm)

Loading...

Loading...