AGF Manufacturing Inc.

Model 7900A & 7950A

Owner’s Manual

INST-PURGEnVENT

Model 7900A

Model 7950A

Air Venting Valves

Air Venting Valves

Air Venting Valves

for Wet Pipe Fire Sprinkler Systems

NFPA 13 code requires venting the excess air from wet fire sprinkler systems to

help prevent corrosion.

Table of Contents

Recommended Installation Locations ...........................................................3

Installation Instructions

Model 7900A ........................................................................................................4

Model 7950A .................................................................................................... 4-5

Filling the System .............................................................................................5

Cleaning the Vent Screen

Quick Clean ..........................................................................................................5

Full Clean ..............................................................................................................6

AGF Manufacturing Inc.

100 Quaker Lane • Malvern, PA 19355

Phone: 610-240-4900

Fax: 610-240-4906

www.agfmanufacturing.com

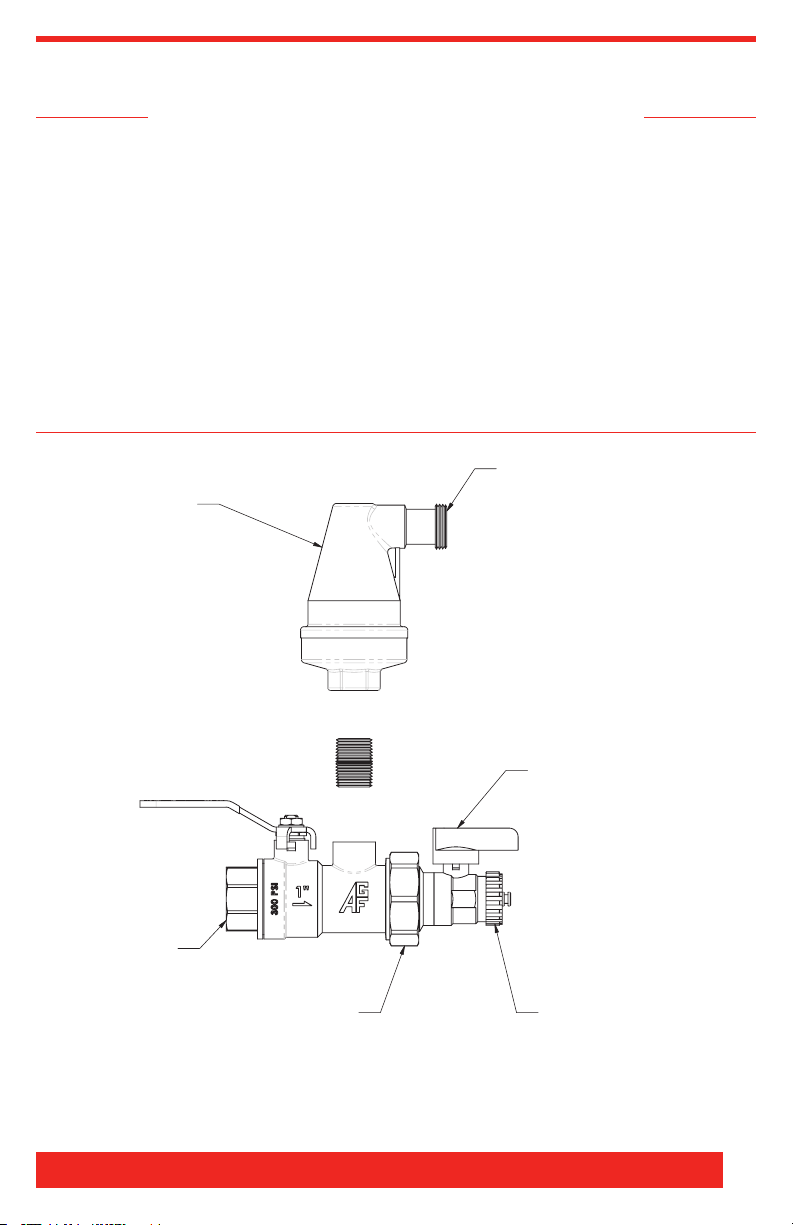

Recommended Installation Locations

,1/(7137

9(17

385*(9$/9(

&211(&7,1*187

6+2:123(1

*$5'(1+26(7+5($'

&$3

287/(7137

M7900A Valve

Near high points in system per NFPA 13 (2016). Examples are the top of a •

vertical riser, elevated branch lines, and under roof peaks.

At the end of branch lines.•

Locations which have previously experienced internal pipe corrosion due to •

pockets of trapped air.

M7950A Valve

Near the floor control assembly•

Model 7900AAV

MinimumPSIG:2.9•MaximumPSIG:175

AGF Manufacturing Inc. • Phone: 610-240-4900 • Fax: 610-240-4906 • www.agfmanufacturing.com

3

PURGEnVENT Owner’s Manual

Installation Instructions

M7900A Installation

Ensure vent will be vertical (plumb) when finished.1.

Remove plastic shipping plug from the ½” port of valve and discard.2.

Apply PTFE tape to the 1” pipe thread where the M7900A will be mounted.3.

Install valve using a wrench on the inlet flats. Ensure the valve’s ½” outlet port 4.

is oriented in the up position.

Apply PTFE tape to both halves of the provided nipple.5.

Install nipple into the valve’s outlet port.6.

Thread inlet of air vent onto nipple. Tighten using 17.

as desired.

OPTIONAL:

The purge valve may be reoriented as needed by loosening (not removing) •

the nut which connects it to the main M7900A valve. After the purge valve is

rotated to the desired position, ensure the connecting nut is tight.

The Mist Collection Assembly may be connected to the ¾” outlet of the vent.•

A standard drain line may be connected to the ¾” outlet of the vent.•

1

⁄16” wrench on flats; position

M7950A Installation

Ensure vent will be vertical (plumb) when finished.1.

Create required cutout length for the pipe section.2.

Verify flow arrow direction of preassembled PURGE3. nVENT pipe.

Install into sprinkler pipe as directed by code and AHJ.4.

Apply PTFE tape to both halves of the provided nipple.5.

Install nipple into the M7900A valve’s outlet port.6.

Thread inlet of air vent onto nipple. Tighten using 17.

1

⁄16” wrench on flats; position

as desired.

M7950A Alternate Installation

Turn main pipe section 45˚.1.

Install M7900A ensuring vent is positioned vertically.2.

4

OPTIONAL:

The purge valve may be reoriented as needed by loosening (not removing) •

the nut which connects it to the main M7900A valve. After the purge valve is

rotated to the desired position, ensure the connecting nut is tight.

The Mist Collection Assembly may be connected to the ¾” outlet of the vent.•

A standard drain line may be connected to the ¾” outlet of the vent.•

Filling the System

Open the M7900A valve handle to the “Vent” position.1.

Open the purge valve (small handle).2.

Remove the cap from the purge valve and connect a drain line (garden hose) 3.

to it’s port.

Fill the system with water.4.

Monitor the discharge from the drain line and close the purge valve when a 5.

steady stream of water is achieved.

Disconnect the drain line and reinstall the cap onto the purge port.6.

Keep the M7900A valve handle in the “Vent” position to allow any residual air 7.

to escape the system through the automatic air vent.

Cleaning the Vent Screen

If the internal vent screen becomes clogged with debris it can be cleaned using

one of the following methods:

Quick Clean

Close the M7900A valve.1.

Remove the cap from the purge valve and connect a drain (garden hose) to 2.

it’s port.

Open the purge valve.3.

Flush the screen by quickly and repeatedly opening and closing the M7900A 4.

valve.

Close the M7900A valve and allow the residual water to drain out.5.

Close the purge valve.6.

Disconnect the drain hose and reinstall the cap.7.

Slowly open the M7900A valve to vent.8.

AGF Manufacturing Inc. • Phone: 610-240-4900 • Fax: 610-240-4906 • www.agfmanufacturing.com

5

PURGEnVENT Owner’s Manual

Full Cleaning

Close the M7900A valve.1.

If needed, place a bucket under the PURGE2. nVENT to capture the small

amount of residual water which will come out during the next steps.

Using a wrench, loosen the nut which connects the purge valve to the M7900A 3.

valve.

Remove the purge valve from the M7900A valve. Set the purge valve and it’s 4.

flat gasket aside.

Remove the vent screen from the M7900A valve and clean as needed.5.

Place the vent screen back into the M7900A valve. 6.

Reinstall the purge valve making sure the screen is centered and the flat 7.

gasket is properly captured between the two halves of the assembly. DO NOT

apply grease to the at gasket.

Position the purge valve handle as desired and tighten.8.

Make sure that the purge valve is closed.9.

Slowly open the M7900A valve to vent.10.

Check for leaks and tighten the connecting nut if needed.11.

Thank You For Using Our Products!

For our complete family of products, visit

us online at www.agfmanufacturing.com

6

Corrosion Monitors

for Wet or Dry Pipe Fire Sprinkler Systems

M7700

M7800

www.corrinsite.com

AGF Manufacturing Inc.

100 Quaker Lane • Malvern, PA 19355

Phone: 610-240-4900

Fax: 610-240-4906

www.agfmanufacturing.com

Loading...

Loading...