AGF Manufacturing Inc.

Corrosion Monitors

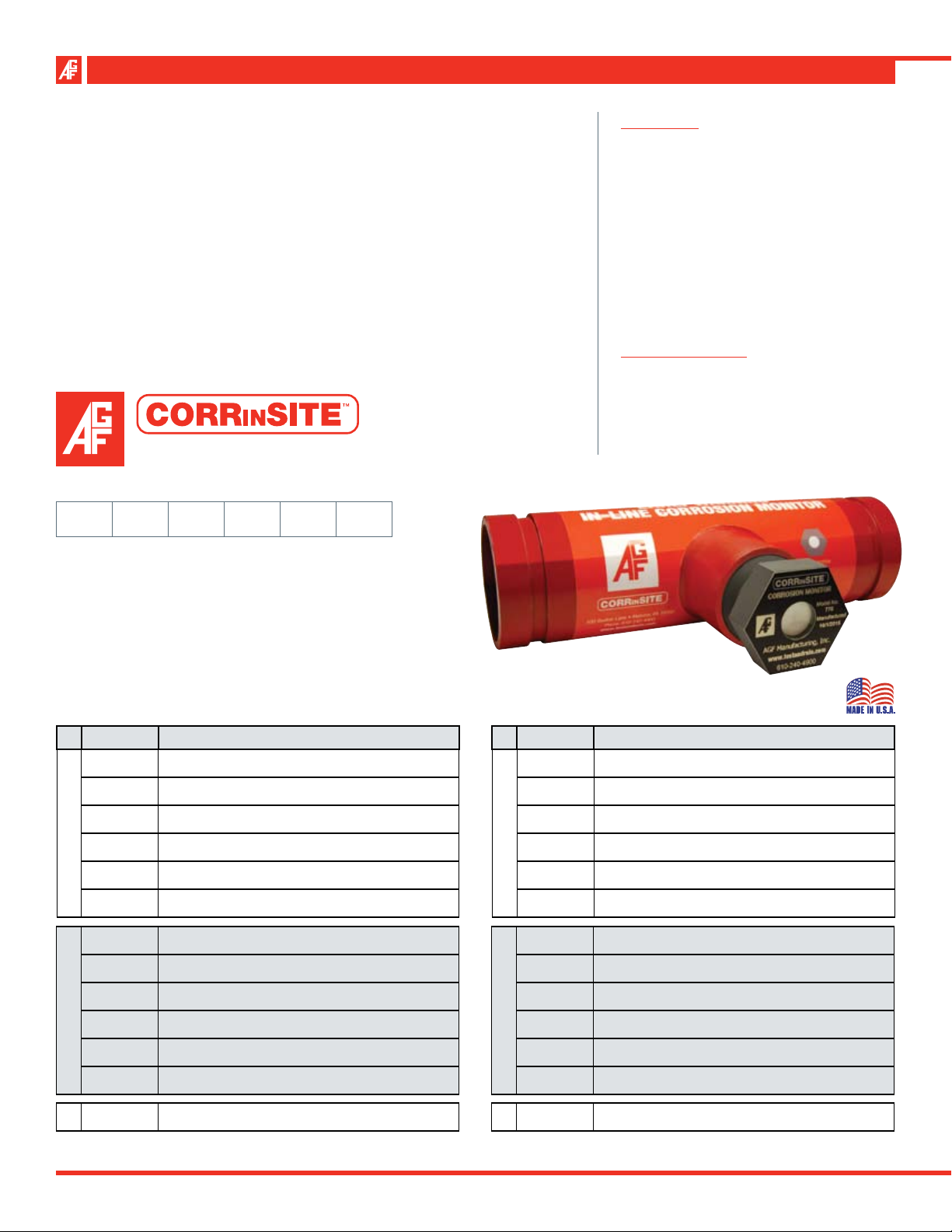

In-Line Pipe and Mechanical Tee

BR-COREin SITE_2017 1/17

Reliability, Versatility, Code Compatibility

CORRi n SITE

™

Corrosion Monitors

AGF’s CORRi n SITE™ Corrosion Monitors were developed in response to

the increase of corrosion-related failures in both wet and dry fire protection

systems. CORRin SITE™, available in an in-line pipe or mechanical tee,

provides a simple to install, maintenance-free, and inexpensive method to

monitor for hidden corrosion problems in any fire protection system.

The CORRin SITE™ is manufactured from the same mild carbon steel as the

system’s piping and its surface corrodes as the pipe corrodes. When the

monitor corrodes beyond it’s limit, moisture penetrates the sealed chamber

and transforms the brilliant white sight glass to a fluorescent orange color,

indicating a corrosion problem and need for further investigation.

Model 7700 In-Line Pipe

Sizes:

2” 2½” 3” 4” 6” 8”

Other sizes available upon request

Features

Low Cost•

Easy Installation and Maintenance•

Horizontal or Vertical Installation•

Continuous Corrosion Monitoring•

Easy-to-Read Visual Notification•

Direct Installation into the System•

No Power Required•

No Coupons•

Specifications

Service Pressure ...... 300 PSI

Operating Temp ....... -40° to 200° F

Material .................... Mild Carbon Steel

Wear Dimension ...... 0.040”

™

The CORR

Monitor is suitable for new construction and can be

retrofitted into existing fire protection systems. It is

available in schedule 10 or 40, powder-coated black steel

or galvanized pipe.

i nSITE

Model 7700 In-Line Pipe Corrosion

Powder-Coated Galvanized

Item ID Item Description

7720P-10 2” Powder Coated SCH 10 Pipe Assembly

7725P-10 2.5” Powder Coated SCH10 Pipe Assembly

7730P-10 3” Powder Coated SCH 10 Pipe Assembly

7740P-10 4” Powder Coated SCH 10 Pipe Assembly

Schedule 10

7760P-10 6” Powder Coated SCH 10 Pipe Assembly

7780P-10 8” Powder Coated SCH 10 Pipe Assembly

7720P-40 2” Powder Coated SCH 40 Pipe Assembly

7725P-40 2.5” Powder Coated SCH 40 Pipe Assembly

7730P-40 3” Powder Coated SCH 40 Pipe Assembly

7740P-40 4” Powder Coated SCH 40 Pipe Assembly

Schedule 40

7760P-40 6” Powder Coated SCH 40 Pipe Assembly

Item ID Item Description

7720G-10 2” Galvanized SCH 10 Pipe Assembly

7725G-10 2.5” Galvanized SCH 10 Pipe Assembly

7730G-10 3” Galvanized SCH 10 Pipe Assembly

7740G-10 4” Galvanized SCH 10 Pipe Assembly

Schedule 10

7760G-10 6” Galvanized SCH 10 Pipe Assembly

7780G-10 8” Galvanized SCH 10 Pipe Assembly

7720G-40 2” Galvanized SCH 40 Pipe Assembly

7725G-40 2.5” Galvanized SCH 40 Pipe Assembly

7730G-40 3” Galvanized SCH 40 Pipe Assembly

7740G-40 4” Galvanized SCH 40 Pipe Assembly

Schedule 40

7760G-40 6” Galvanized SCH 40 Pipe Assembly

7780P-40 8” Powder Coated SCH 40 Pipe Assembly

770 CORRin SITE Replacement Plug

7780G-40 8” Galvanized SCH 40 Pipe Assembly

770 CORRin SITE Replacement Plug

Model 7800 Mechanical Tee

Sizes:

2” 2½” 3” 4” 6” 8”

Other sizes available upon request

The CORRin SITE™ Model 7800 Mechanical Tee Corrosion

Monitor is suitable for retrofitting into existing fire protection

systems and is available with a painted red or galvanized

steel mechanical tee.

Painted

Item ID Item Description

7820MTP 2” Painted Mechanical Tee

7825MTP 2.5” Painted Mechanical Tee

7830MTP 3” Painted Mechanical Tee

7840MTP 4” Painted Mechanical Tee

7860MTP 6” Painted Mechanical Tee

7880MTP 8” Painted Mechanical Tee

770 CORRin SITE Replacement Plug

Installation Locations

Wet System

Office Building

Floor Control

Galvanized

Item ID Item Description

7820MTG 2” Galvanized Mechanical Tee

7825MTG 2.5” Galvanized Mechanical Tee

7830MTG 3” Galvanized Mechanical Tee

7840MTG 4” Galvanized Mechanical Tee

7860MTG 6” Galvanized Mechanical Tee

7880MTG 8” Galvanized Mechanical Tee

770 CORRin SITE Replacement Plug

End of Line

Water Main

The CORRi n SITE™ Model 7700 and 7800 can be

installed virtually anywhere on a wet or dry fire

system. AGF recommends the above locations

for monitoring the most important areas of the

AGF Manufacturing Inc. • Phone: 610-240-4900 • Fax: 610-240-4906 • www.testandrain.com

Dry System

Parking Garage

Branch Line

system. When installing horizontally on a wet

system, the monitor’s sight glass should be facing

up (dark blue area) and on a dry system, the sight

glass should face down (light blue area).

Dimensions

Model 7700 In-Line Pipe

All Models

Item ID Pipe Size A B C

7720 2”

7725 2 1/2”

7730 3”

7740 4”

7760 6”

7780 8”

2 3/8”

[60mm]

2 7/8”

[73mm]

3 1/2”

[89mm]

4 1/2”

[114mm]

6 5/8”

[168mm]

8 5/8”

[219mm]

4”

[102mm]

4 1/4”

[108mm]

4 9/16”

[116mm]

5 1/16”

[129mm]

6 1/8”

[156mm]

7 1/8”

[181mm]

5 3/16”

[132mm]

5 11/16”

[144mm]

6 5/16”

[160mm]

7 5/16”

[186mm]

9 7/16”

[240mm]

11 7/16”

[290mm]

Model 7800 Mechanical Tee

Item ID Pipe Size A B C D

7820 2”

7825 2 1/2”

7830 3”

7840 4”

7860 6”

7880 8”

3 15/16”

[100mm]

4 3/16”

[106mm]

4 5/8”

[117mm]

5 5/16”

[134mm]

6 7/16”

[163mm]

8 3/16”

[208mm]

1 11/16”

[43mm]

1 7/8”

[47mm]

2 1/4”

[56mm]

2 5/8”

[67mm]

3 3/4”

[95mm]

4 7/8”

[124mm]

5 5/16”

[135mm]

5 7/8”

[150mm]

6 3/16”

[160mm]

7 3/8”

[187mm]

9 3/4”

[247mm]

12 5/8”

[320mm]

3 1/4”

[82mm]

3 5/8”

[91mm]

3 3/4”

[95mm]

3 13/16”

[96mm]

3 13/16”

[96mm]

4 1/8”

[105mm]

AGF Manufacturing Inc.

100 Quaker Lane • Malvern, PA 19355

Phone: 610-240-4900

Fax: 610-240-4906

www.testandrain.com

Loading...

Loading...