Model 3011

In s p e c t o r ’stest

Remote Inspector’s Test for Single Story and Other Applications

Including Systems Requiring Pressure Relief Valve

1"

®

3011A

3011BV

• The AGF Manufacturing Inc. Model 3011 In s p e c t o r ’stest® family of valves are designed to perform

the remote inspector’s test function on single story and other applications with the benet of locating

the orice indoors.

• The Model 3011 I

- Model 3011BV ball valve only

- Model 3011SG ball valve with sight glass

- Model 3011A ball valve with Model 7000 Pressure Relief Valve and drainage piping

- Model 3011ASG ball valve with sight glass, Model 7000 Pressure Relief Valve, and drainage piping

• Available with test orice sizes of ³⁄

• The Models 3011A and 3011ASG have the added feature of a Model 7000 Pressure Relief Valve

with drainage piping designed to relieve excess system pressure caused by surges or temperature

changes as well as solve the difcult problem of providing the relief valve with a drainage piping outlet.

• The Models 3011A and 3011ASG comply with the requirements of NFPA-13 for the installation of a

pressure relief valve on all gridded systems and downstream of all pressure reducing valves.

• The included UL/FM Model 7000 Pressure Relief Valve features a ushing handle and is rated at 175

PSI. Other pressure settings are also available. (see note below)

• To expedite system testing, the unit is shipped semi-assembled with relief valve and bypass drain

ports plugged.

NOTE: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and

closing of the valve. Standard relief valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves

are required to CLOSE at a pressure above 80% of that rating. The relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the system is operational. A relief valve

should NEVER have a shutoff valve or a plug downstream of its outlet.

n s p e c t o r ’stest

®

is available in four different models:

8" (2.8K),

7

⁄16" (4.2K), ½" (5.6K), 17⁄32" (8.0K), and 5⁄8" (11.2K, ELO).

3011SG

3011ASG

Reliability, Versatility, Code Compatibility

CS3011 3/08INSPECTORSTEST is a registered trademark of AGF Manufacturing Inc.

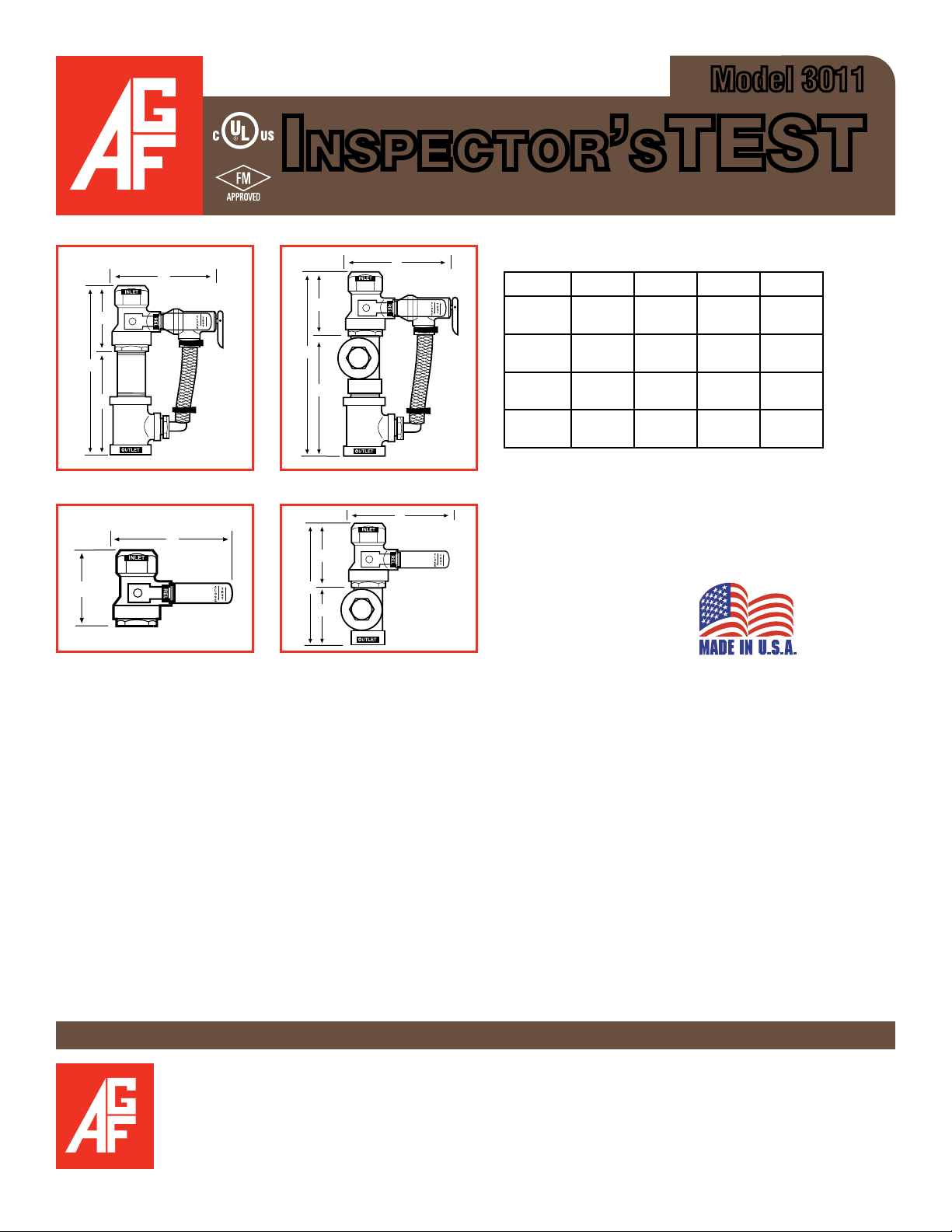

Model 3011

C

D

A

B

C

D

A

B

C

D

A

B

A

B

In s p e c t o r ’stest

Model 3011 300 PSI Bronze Ball Valve, Available with Model 7000 Pressure

Relief Valve Factory Rated at 175 PSI with other settings available

®

mo D e l 3011A

mo D e l 3011ASG

Di m e n S i o n S

Orice Size Available: 3⁄8", 7⁄16", 1⁄2", 17⁄32", ELO (5⁄8")

Model A B C D

mo D e l 3011BV

mo D e l 3011SG

3011A

3011ASG

3011BV

3011SG

31⁄16"

(75 mm)

31⁄16"

(75 mm)

31⁄16"

(75 mm)

1

⁄16"

3

(75 mm)

mA t e r i A l S

Handle: Steel

Stem: Rod Brass

Ball: C.P. Bronze

Body: Bronze

Valve Seat: Virgin Teon

Relief Valve: Bronze

Bypass Fittings: Brass

Bypass Tubing: Nylobraid

Sight Glass: Bronze & Glass

411⁄16"

(118 mm)

411⁄16"

(118 mm)

411⁄16"

(118 mm)

411⁄16"

(118 mm)

®

77⁄8"

(200 mm)

95⁄16"

(237 mm)

47⁄8"

(124 mm)

61⁄4"

(159 mm)

— —

63⁄16"

(157 mm)

31⁄8"

(79 mm)

Ap p r o V A l S

UL and ULC Listed:

[EX4019(N) & EX4533(N)]

FM Approved

NYC-BSA No. 720-87-SM

Fr o m t h e nFpA 13 2007 eD i ti o n

Models 3011BV, 3011SG, 3011A, & 3011ASG, depending on the variant chosen, provide some or all of the requirements listed below:

Chapter 8.16.2.4.1* Provisions shall be made to properly drain all parts of the system.

Chapter 8.16.2.4.2 Drain connections, Interior sectional or oor control valve(s) – shall be provided with a drain connection

& 8.16.2.4.3

Chapter 8.16.2.4.4 Drains shall discharge outside or to a drain capable of handling the ow of the drain.

Chapter 8.16.2.4.6 The test connection shall be permitted to be used as main drain connection.

Chapter A.8.17.4.2 (Wet Pipe System) test connection is permitted to terminate into a drain capable of accepting full ow …

Chapter 8.17.4.2.2 The test connection valve shall be readily accessible

Chapter 8.17.4.2.4 shall be permitted to be installed in any location …downstream of the waterow alarm.

Chapter 7.1.2 - a gridded wet pipe system shall be provided with a relief valve set to operate at 175 PSI or 10 PSI in excess

Chapter 8.16.1.2.3* A relief valve of not less than ½" in size shall be provided on the discharge side of the pressure-reducing valve

Chapter A8.16.1.2.3 - consideration should be given to piping the discharge from the (pressure relief) valve

Chapter 8.17.4.3.1 (Dry Pipe System) a trip test connection not less than 1" in diameter, terminating in a smooth bore corrosion-

Chapter 8.17.4.3.2 The trip test connection…with a shutoff valve and plug not less than 1", at least one of which shall be brass.

having a minimum size as shown in Table 8.16.2.4.2.

using an approved sight test connection containing a smooth bore corrosion-resistant orice giving a ow

equivalent to one sprinkler... (M3011SG and M3011ASG only)

of the maximum system pressure, whichever is greater.

set to operate at a pressure not exceeding 175 psi.

resistant orice, to provide a ow equivalent to one sprinkler…

USA Patent # 4971109 and Other Patents Pending

AGF Manufacturing Inc.

100 Quaker Lane, Malvern, PA 19355

Phone: 610-240-4900

Fax: 610-240-4906

www.testandrain.com

Job Name:__________________________________

Architect: ___________________________________

Engineer: ___________________________________

Contractor: _________________________________

Loading...

Loading...