AGF Manufacturing 3011 Installation Manual

INSTALLATION INSTRUCTIONS

MODEL 3011 PATENTED AND OTHER PATENTS PENDING 1" SIZE

INSPECTORS TEST

THE 3011 SUBASSEMBLY, CONSISTING OF THE MODEL 3011 INSPECTORS TEST VALVE (WITH THE

RELIEF VALVE PORT PLUGGED), THE CONNECTION NIPPLE AND THE BYPASS TEE (WITH THE BYPASS

BRANCH PLUGGED) SHOULD BE INSTALLED AS THE INSPECTORS TEST VALVE AT THE END OF A

GRIDDED SYSTEM OR WHEN A REGULATING VALVE IS USED IN A SINGLE STORY BUILDING.

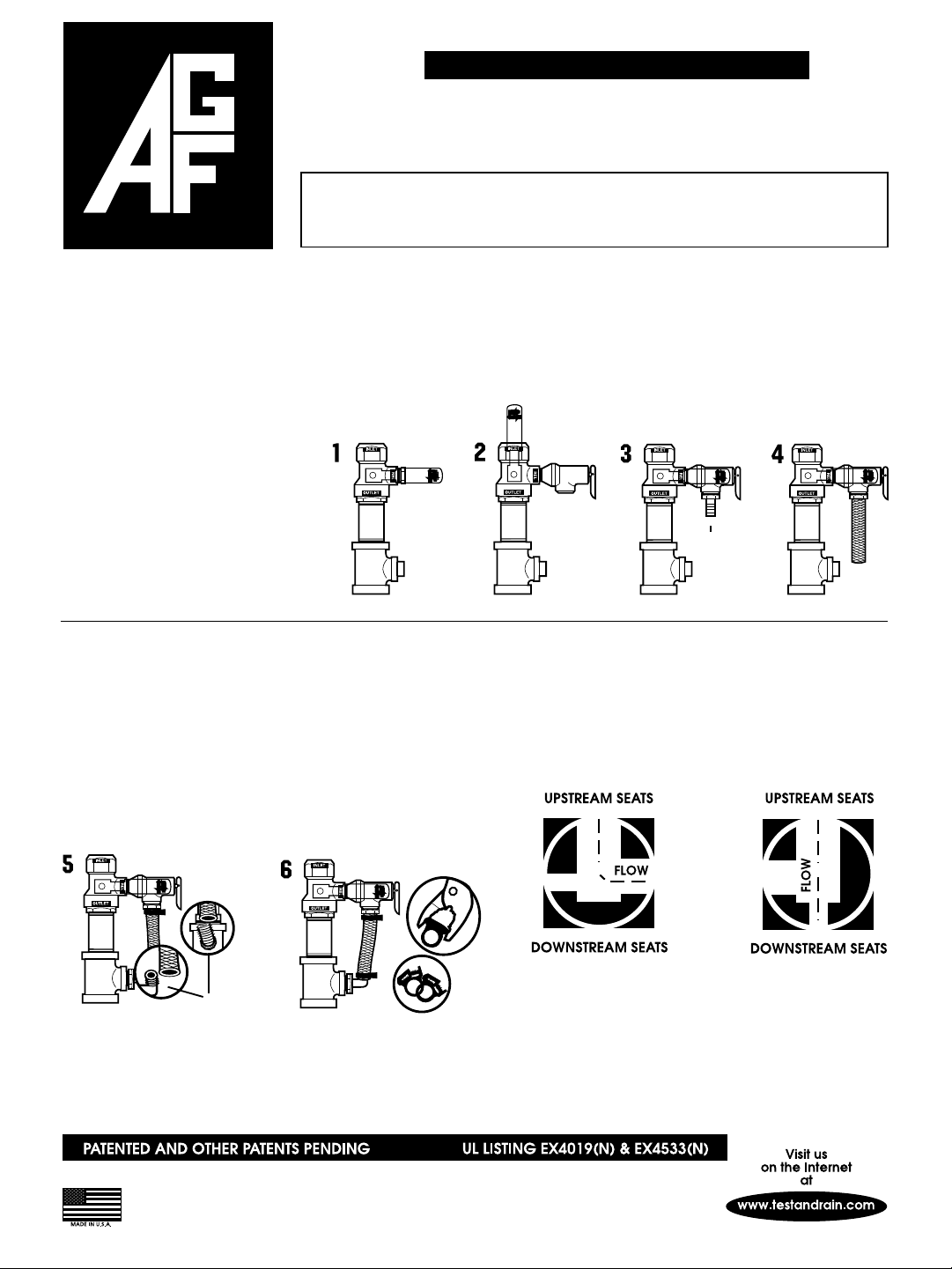

1. Turn the Model 3011 valve handle

to the ”CLOSED” position for the

hydrostatic test of the system

(see drawing 1).

2. Hydrostatically test the system.

3. To install the relief valve and

drain assembly follow this

procedure:

A. Shut off the system at the

supply valve.

B. Turn the Model 3011 valve

handle to the "test" position to

drop the system pressure (see

drawing 2).

C. After the system pressure is

dropped, remove the relief

valve port plug while the

system is draining (see

drawing 2).

H. Remove the plastic plug from the

bypass tee branch and install the

male X-barb elbow into the bypass

tee branch, rolling the barb elbow

into the flexible tubing on the last

turn of the elbow (see drawing 5).

I. Full assembly requires tightening

two pipe clamps on hose barb

fittings (see drawing 6). Clamps

provided.

D. Install the Model 7000 relief

valve in the relief valve port

with the relief valve outlet

pointed toward the bypass tee

branch inlet (see drawing 2).

E. Return the Model 3011 valve

handle to the “closed”

position (see drawing 3).

J. Repressurize the system.

Figure "A" shows the assembly in

the "OFF" position. There is no flow

THROUGH the valve. There is flow

from the inlet into the Relief Valve

providing pressure relief to the

system as required under

Paragraph 5-1.3 of NFPA13.

F. Install the straight male X-

barb adaptor into the outlet

of the Model 7000 relief valve.

G. Install the flexible tubing on

the male X-barb adaptor

(see drawing 4).

X-BARB

The valve in the "TEST" position as

shown in Figure "B" allows flow from

the inlet through the orifice in the

ball providing a testing facility as

required in Paragraph 3-4.1.1 of the

NFPA specifications.

side view

front view

X-BARB

Valve seated in

"OFF" position.

Flow from inlet of

valve to side outlet

into relief valve.

AGF MANUFACTURING INC.

100 Quaker Lane • Malvern, PA 19355

Telephone: (610) 240-4900 • Fax: (610) 240-4906

Figure A

Figure B

Valve seated in

""TEST" position.

Flow from inlet of

to straight

valve

outlet of valve

through orifice

in ball.

Loading...

Loading...