Model 1011A

TESTa n DRaIn®

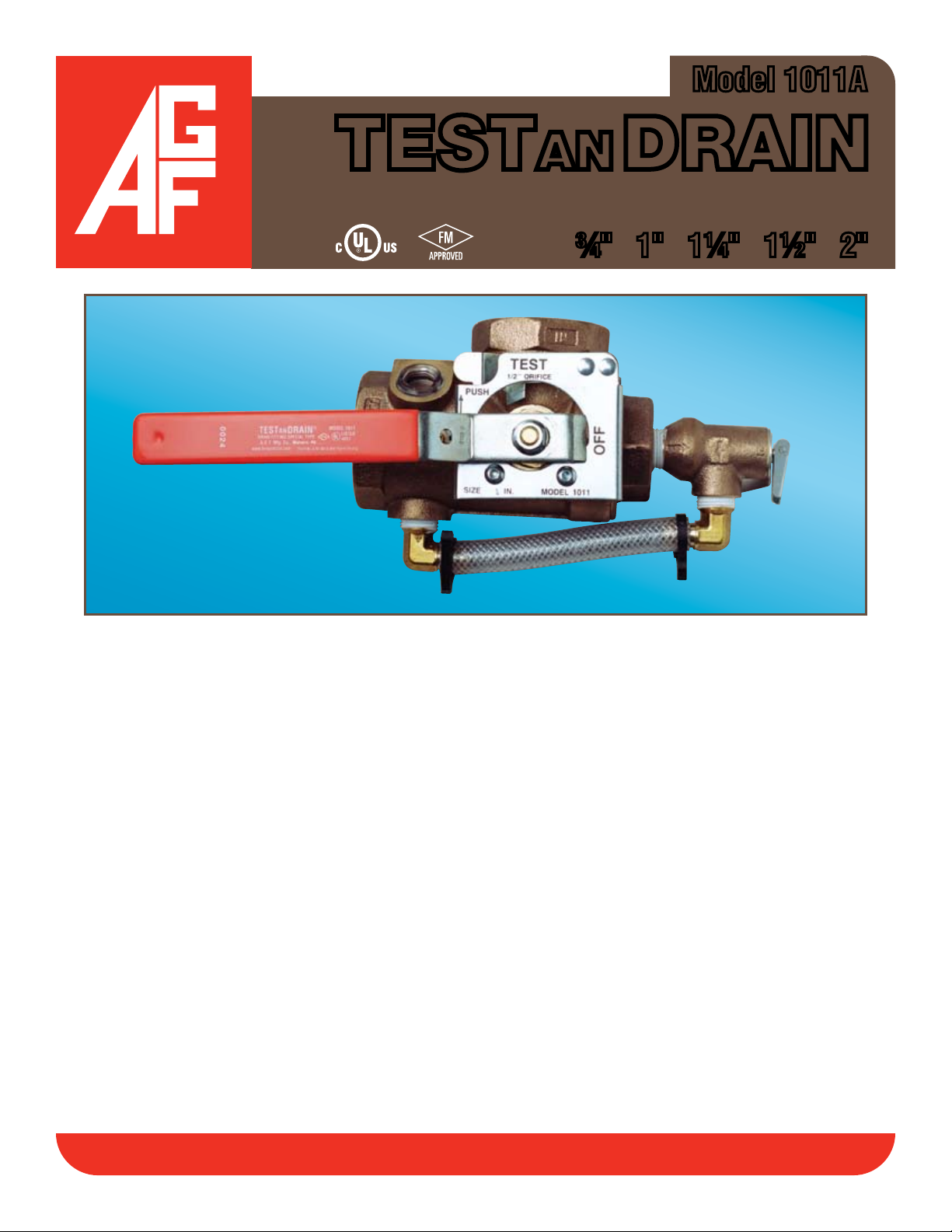

Sectional Floor Control Test and Drain Valve

for Systems Requiring Pressure Relief Valve

¾" 1" 1¼" 1½" 2"

• The AGF Manufacturing Inc. Model 1011A TESTa n DRaIn® matches all the features and benets of our Model

1000 by providing both the test function and the express drain function in a multistory installation for a wet re

sprinkler system, with the added feature of an integral Model 7000 Pressure Relief Valve with drainage piping.

• The Model 1011A complies with the requirements of NFPA-13 that stipulate a pressure relief valve be installed

on all gridded systems and downstream of all pressure reducing valves (see reverse).

• The Model 1011A TESTa n DRaIn® is a compact single handle ball valve which includes a tamper resistant

test orice and integral tamper resistant sight glasses, and is 300 PSI rated.

• Available in a full range of sizes from ¾" to 2" NPT and BSPT, with all speciable orice sizes ³⁄8" (2.8K), 7⁄16"

(4.2K), ½" (5.6K), 17⁄32" (8.0K), 5⁄8" (11.2K, ELO), ¾" (14.0K, ESFR), and K25 as required by NFPA 13, 2007 Edition (see reverse).

• The included UL/FM Model 7000 Pressure Relief Valve features a ushing handle and is factory rated for 175

PSI. Other pressure settings are available and may be substituted.

• Designed to relieve excess system pressure caused by surges or temperature changes as well as solve the difcult problem of providing the relief valve with a convenient drainage-piping outlet.

• Shipped with relief valve and bypass drain ports plugged to expedite pressure testing the system.

• A locking kit is available and can be ordered with the valve to provide vandal resistance or prevent unintentional alarm activation.

• Repair kits including (1) adapter gasket, (1) ball, (2) valve seats, (1) stem packing, and (1) stem washer are available for all TESTa n DRaIn® valves. Valve and orice size must be specied when ordering.

NOTE: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and

closing of the valve. Standard relief valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves

are required to CLOSE at a pressure above 80% of that rating. The relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the system is operational. A relief valve

should NEVER have a shutoff valve or a plug downstream of its outlet.

Reliability, Versatility, Code Compatibility

CS1011A 10/09TESTANDRAIN is a registered trademark of AGF Manufacturing Inc.

Model 1011A

TO

DRAIN

TO

DRAIN

H

F

G

E

A

A

INLET

D

B

C

TESTa n DRaIn®

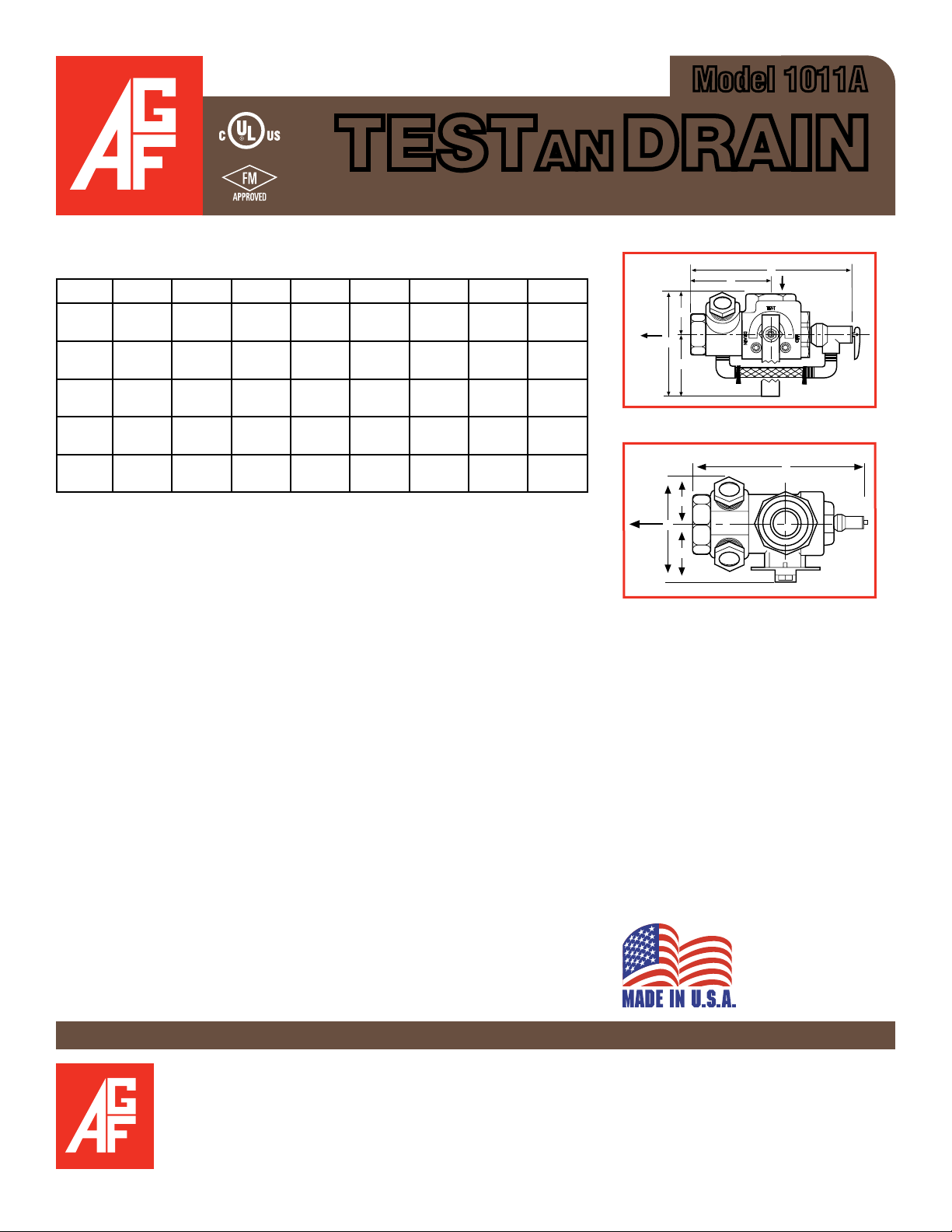

Model 1011A 300 PSI Bronze Ball Valve, Model 7000 Pressure Relief Valve

Factory Rated at 175 PSI with other settings available

Di m e n s i o n s

Orice Size Available: 3⁄8", 7⁄16", 1⁄2", 17⁄32", ELO (5⁄8")*, ESFR (3⁄4")*, & K25**

SIZE A B C D E F G H

¾"

1"

11⁄4"

1½"

2"

* Available on 11⁄4" to 2" size units only ** Available on 11⁄2" and 2" size units only

79⁄16"

(191 mm)

79⁄16"

(191 mm)

715⁄16"

(201 mm)

815⁄16"

(227 mm)

815⁄16"

(227 mm)

11⁄2"

(37.5 mm)

11⁄2"

(37.5 mm)

111⁄16"

(43 mm)

113⁄16"

(45 mm)

113⁄16"

(45 mm)

23⁄16"

(57 mm)

23⁄16"

(57 mm)

29⁄16"

(65 mm)

31⁄4"

(81.5 mm)

31⁄4"

(81.5 mm)

35⁄8"

(93 mm)

35⁄8"

(93 mm)

41⁄4"

(108 mm)

51⁄16"

(127 mm)

51⁄16"

(127 mm)

33⁄8"

(86 mm)

33⁄8"

(86 mm)

35⁄8"

(91 mm)

37⁄8"

(99 mm)

37⁄8"

(99 mm)

113⁄16"

(46 mm)

113⁄16"

(46 mm)

115⁄16"

(51 mm)

25⁄8"

(67 mm)

25⁄8"

(67 mm)

49⁄16"

(117 mm)

49⁄16"

(117 mm)

59⁄16"

(141 mm)

81⁄4"

(207 mm)

81⁄4"

(207 mm)

th e mo D e l 1011A p r o v i D e s A l l o F t h e F o l l o w i n g …

From the 2007 Edition of NFPA 13

Chapter 8.16.2.4.1* Provisions shall be made to properly drain all parts of the system.

Chapter 8.16.2.4.2 Drain connections, interior sectional or oor control valve(s) –

& 8.16.2.4.3

Chapter 8.16.2.4.4 Drains shall discharge outside or to a drain capable of handling

Chapter A.8.17.4.2 (Wet Pipe System) test connection is permitted to terminate into

Chapter 8.17.4.2.2 The test connection valve shall be readily accessible.

Chapter 8.17.4.2.4 shall be permitted to be installed in any location… downstream

Chapter 8.17.4.3.1 (Dry Pipe System) a trip test connection not less than 1" in

Chapter 8.17.4.3.2 The trip test connection… with a shutoff valve and plug not less

Chapter 7.1.2 - a gridded wet pipe system shall be provided with a relief valve

Chapter 8.16.1.2.3* A relief valve of not less than ½" in size shall be provided on the

Chapter A.8.16.1.2.3 - consideration should be given to piping the discharge from the

shall be provided with a drain connection having a minimum size

as shown in Table 8.16.2.4.2.

the ow of the drain.

a drain capable of accepting full ow… using an approved sight

test connection containing a smooth bore corrosion-resistant

orice giving a ow equivalent to one sprinkler…

of the waterow alarm.

diameter, terminating in a smooth bore corrosion-resistant orice,

to provide a ow equivalent to one sprinkler…

than 1", at least one of which shall be brass.

set to operate at 175 PSI or 10 PSI in excess of the maximum

system pressure, whichever is greater.

discharge side of the pressure-reducing valve set to operate at a

pressure not exceeding 175 PSI.

(pressure relief) valve

63⁄8"

(162.5 mm)

63⁄8"

(162.5 mm)

51⁄2"

(192 mm)

107⁄8"

(274 mm)

107⁄8"

(274 mm)

mo D e l 1011A - Fr o n t vi e w

mo D e l 1011A - pl A n vi e w

mA t e r i A l s

Handle: Steel

Stem: Rod Brass

Ball: C.P. Brass

Body: Bronze

Valve Seat: Impregnated Teon

Indicator Plate: Steel

Relief Valve: Bronze

Bypass Fittings: Brass

Bypass Tubing: Nylobraid

®

Ap p r o v A l s

UL and ULC Listed: (EX4019

& EX4533)

FM Approved

NYC-BSA No. 720-87-SM

USA Patent # 4741361 and Other Patents Pending

AGF Manufacturing Inc.

100 Quaker Lane, Malvern, PA 19355

Phone: 610-240-4900

Fax: 610-240-4906

www.testandrain.com

Job Name:__________________________________

Architect: ___________________________________

Engineer: ___________________________________

Contractor: _________________________________

Loading...

Loading...