Page 1

查询D2526G17供应商

D2570, D2526, D2555 Wa velength-Selected

Direct Modulated Isolated DFB Laser Module

Data Sheet, Rev. 3

July 2001

Applications

■

Three direct-modulated DWDM families available

to meet a number of OC-48/STM-16 applications:

—Extended reach (100 km)

—Very long reach (170 km)

—Metro DWDM

—Digital video

The 1.5 µm D2570, D2526G, and D2555 Laser Modules are

available in a 14-pin, hermetic, butterfly package.

Features

■

ITU wavelengths available from

1528.77 nm —1610.06 nm

■

SONET/SDH compatible up to OC-48/STM-16

■

Temperature tunable for precise wavelength

selection

■

Integrated optical isolator

■

High-performance, multiquantum well (MQW)

distributed-feedback (DFB) laser

■

Industry-standard, 14-pin butterfly package

■

Characterized at 2.488 Gbits/s (NRZ)

■

InGaAs, PIN photodetector back-facet monitor

■

Low threshold current

■

High-reliability, hermetic packaging

■

Excellent long-term wavelength stability can eliminate the need for external wavelength locker

■

Qualified to meet the intent of

gies

* 468

*

Telcordia Technologies

Inc.

is a trademark of Telcordia Technologies,

Telcordia Technolo-

Product Codes

Product

Code

D2570H 10 mW 1800 ps/nm (100 km)

D2526G 2 mW 1800 ps/nm (100 km)

D2555G 2 mW 3000 ps/nm (170 km)

Peak

Power

Dispersion

Performance

Description

The Direct Modulated Isolated DFB Laser Module

contains an internally cooled, InGaAs, MQW, distributed-feedback (DFB) laser designed for 1.5 µm applications. The f ollowing three d irect-modulation D WDM

product families have been established to meet various OC-48/STM-16 system applications:

■

D2526-type: designed to be used in OC-48/

STM-16 (2.488 Gbits/s) for extended reach, dense

WDM applications (1800 ps/nm). The wavelength

of the laser can be temperature-tuned for precise

wavelength selection by adjusting the temperature

of the internal thermoelectric cooler.

■

D2555-type: high-perf ormance device designe d for

very low dispersion; used in fi ber sp ans exceeding

170 km (3000 ps/nm).

■

D2570-type: high-power, direct-modulated laser

eliminates the need for optic al amplifier s in DWDM

many applications.

Page 2

D2570, D2526G, D2555 Wavelength-Selected Data Sheet, Rev. 3

Direct Modulated Isolated DFB Laser Module July 2001

Description

(continued)

Controlled Feedback

The module contains an internal optical isolator that

suppresses optical fee dbac k in l aser-based, fi ber-opt ic

systems. Light reflected back to the laser is attenuated

a minimum of 30 dB.

Controlled Temperature

An integral thermoelectric cooler (TEC) provides stab le

thermal characteristics. The TEC allows for heating

and cooling of the laser chip to mai ntain a te mper ature

of 25 °C for case temperatures from –40 °C to +70 °C .

The laser temperature is monitored by the internal

thermistor, which can be used wi th external circuitry to

control the laser chip temperature.

Controlled Power

An internal, InGaAs, PIN photodiode functions as the

back-f a ce t moni tor. The photodiode monitors emission

from the rear facet of the laser and, when used in conjunction with control circuitry, can control optical power

launched into the fiber. Normally, this configuration is

used in a feedback arr angement to maintain consistent

laser output power.

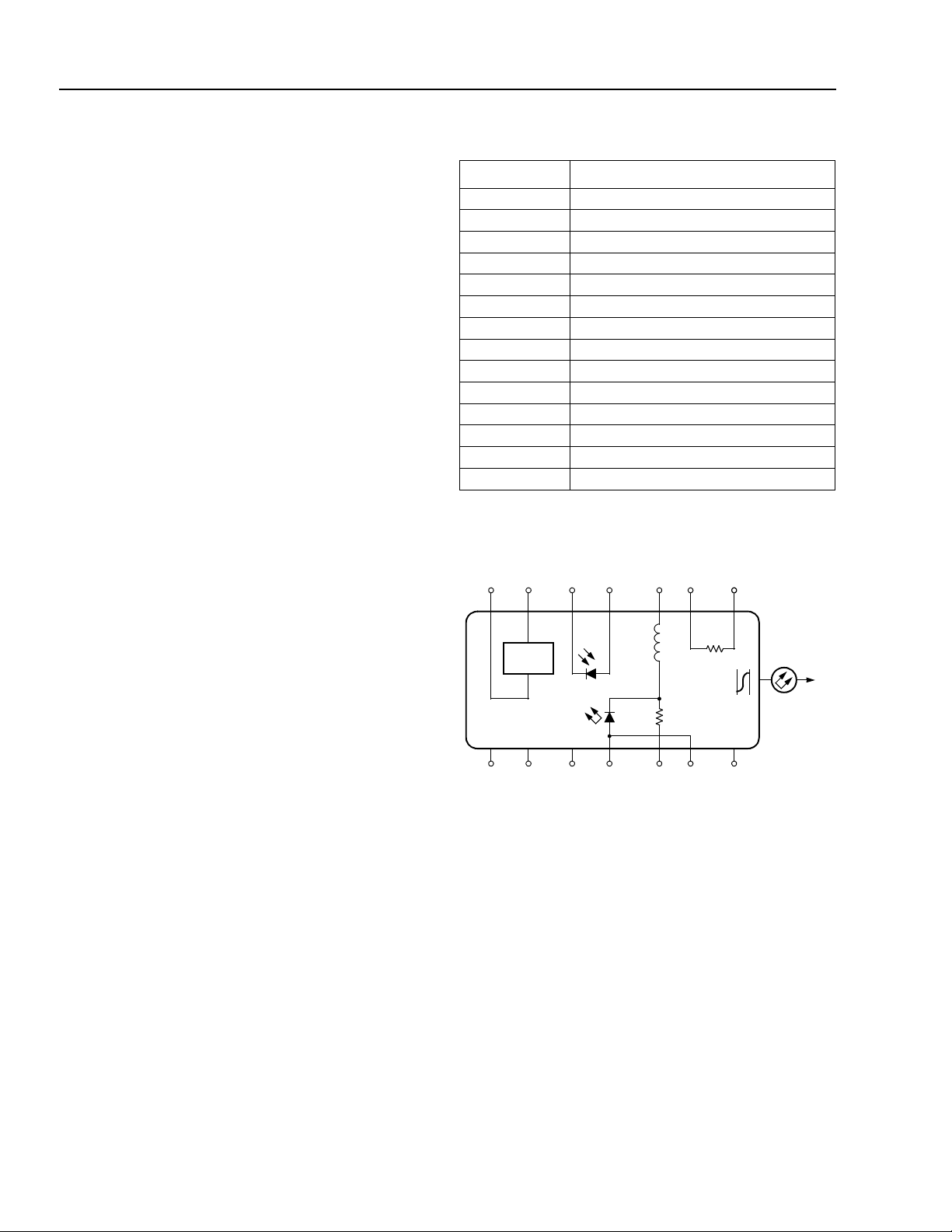

Standard Package

The laser module is fabricated in a 14-pin, hermetic,

metal/ceramic butterfly package that incorporates a

bias tee, which separates the dc-bias path from the RF

input. The RF input has a nominal 25 Ω impedance.

The laser module is equipped with

SMF-28

The fiber has a 900 µm tight buffer jacket. Var ious connectors and pigtail lengths are available.

*

type fiber .

Pin Information

Pin Name

1 Thermistor

2 Thermistor

3 Laser dc Bias (Cathode) (–)

4 Back-facet Monitor Anode (–)

5 Back-facet Monitor Cathode (+)

6 Thermoelectric Cooler (+)*

7 Thermoelectric Cooler (–)

8 Case Ground

9 Case Ground

10 Case Ground

11 Laser Anode (+)

12 RF Laser Input Cathode (–)

13 Laser Anode (+)

14 Case Ground

* A positive current through the thermoelectric heat pump cools the

laser.

† Both leads should be grounded for optim um performance.

76 54 32 1

++– –

–

TEC

PACKAGE

GROUNDS

8 9 10 11 12 13

Top view.

160 nH

+–+

L1

R1

20

Ω

TH

10 k

Ω

ISOLATOR

NC

14

Figure 1. Circuit Schematic

†

†

†

1-567F.b

Agere Systems’ optoelectronic components are being

qualified to rigorous internal standards that are consistent with

design and manufacturing operations are

Telcordia Technologies

TR-NWT-000468. All

ISO

* 9001

certified. The module is being fully qualified for central

office applications.

*

ISO

is a registered trademark of The International Organization f or

Standardization.

†

SMF-28

is a trademark of Corning Inc.

2 Agere Systems Inc.

Page 3

Data Sheet, Rev . 3 D2570, D2526G, D2555 Wavelength-Selected

1-532

Note: Dimensions are in inches and (millimeters).

0.118

(3.00)

0.062 (1.58)

0.140

(3.56)

0.031 (0.79)

0.129 (3.28) R

0.086

(2.18)

0.041 (1.04)

July 2001 Direct Modulated Isolated DFB Laser Module

Absolute Maximum Rat ings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratings only. Functional operation of the device is not implied at these or any other conditions in excess

of those given in the performance characteristics of the data sheet. Exposure to absolute maximum ratings for

extended periods can adversely affect device reliability.

Parameter Symbol Min Max Unit

Laser Reverse Voltage V

dc Forward Current I

Operating Case Temperature Range T

Storage Case Temperature Range* T

Photodiode Reverse Voltage V

Photodiode Forward Current I

* Does not apply to shipping container.

RLMAX

FLMAX

C

stg

RPDMAX

FPDMAX

—2V

—150mA

–40 70 °C

–40 85 °C

—10V

—2mA

Handling Precautions

Power Sequencing

To avoid the possibility of damage to the laser module

from power supply switching transients, follow this turnon sequence:

1. All ground connections

2. Most negative supply

3. Most positive supply

4. All remaining connections

Reverse the order for the proper turn-off sequence.

Electrostatic Discharge

CAUTION: This device is susceptible to damage

as a result of electrostatic discharge.

Take proper precautions during both

handling and testing. Follow guidelines such as JEDEC Publication No.

108-A (Dec. 1988).

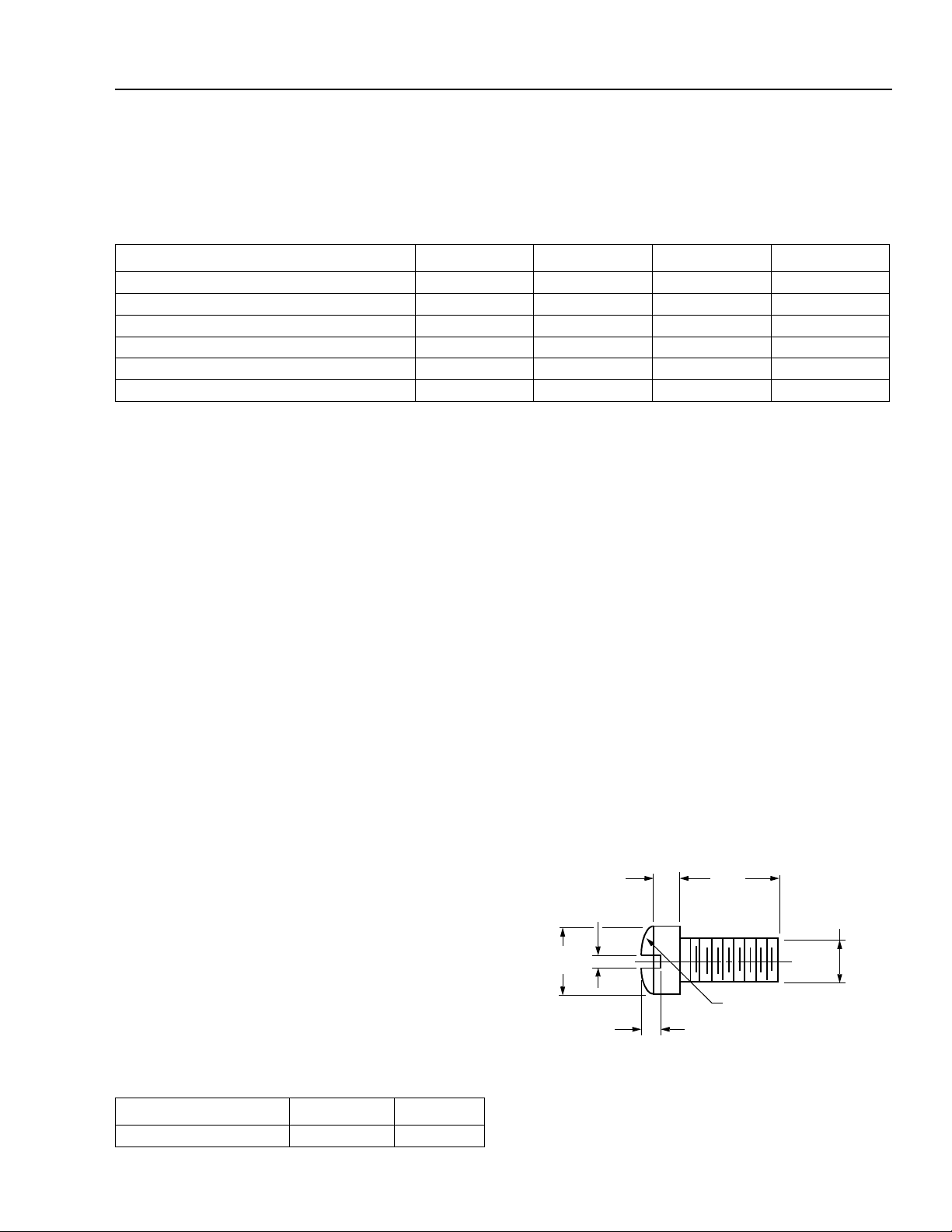

Mounting Instructions

The minimum fiber bend radius is 1.23 in (31.25 mm).

To avoid degradation in performance, mount the mod-

ule on the board as follows:

1. Place the bottom flange of the module on a flat heat

sink at least 0.5 in. x 1.180 in. (12.7 mm x 30 mm) in

size. The surface finish of the heat sink should be

better than 32 µin. (0.8 µm), and the surf ace flatness

must be better than 0.001 in. (25.4 µm). Using thermal conductive grease is optional ; how ever, thermal

performance can be improved by up to 5% if conductive grease is app lied betwe en the bottom flange

and the heat sink.

2. Mount four #2-56 screws with Fillister heads

(M2-3 mm) at the four screw hole locations (see

Outline Diagram). The Fillister head diameter must

not exceed 0.140 in. (3.55 mm). Do not apply more

than 1 in./lb. of torque to the screws.

Agere Systems employs a human-body model (HBM)

for ESD-susceptibility testing and protection-design

evaluation. ESD voltage thresholds are dependent on

the critical parameters used to define the model. A

standard HBM (resistance = 1.5 k¾, capacitance =

100 pF) is widely used and, therefore, can be used for

comparison purposes. The HBM ESD threshold presented here was obtained using these circuit parameters:

Parameter Value Unit

Human-body Model >400 V

Agere Systems Inc. 3

Figure 2. Fillister Head Screw

Page 4

D2570, D2526G, D2555 Wavelength-Selected Data Sheet, Rev. 3

Direct Modulated Isolated DFB Laser Module July 2001

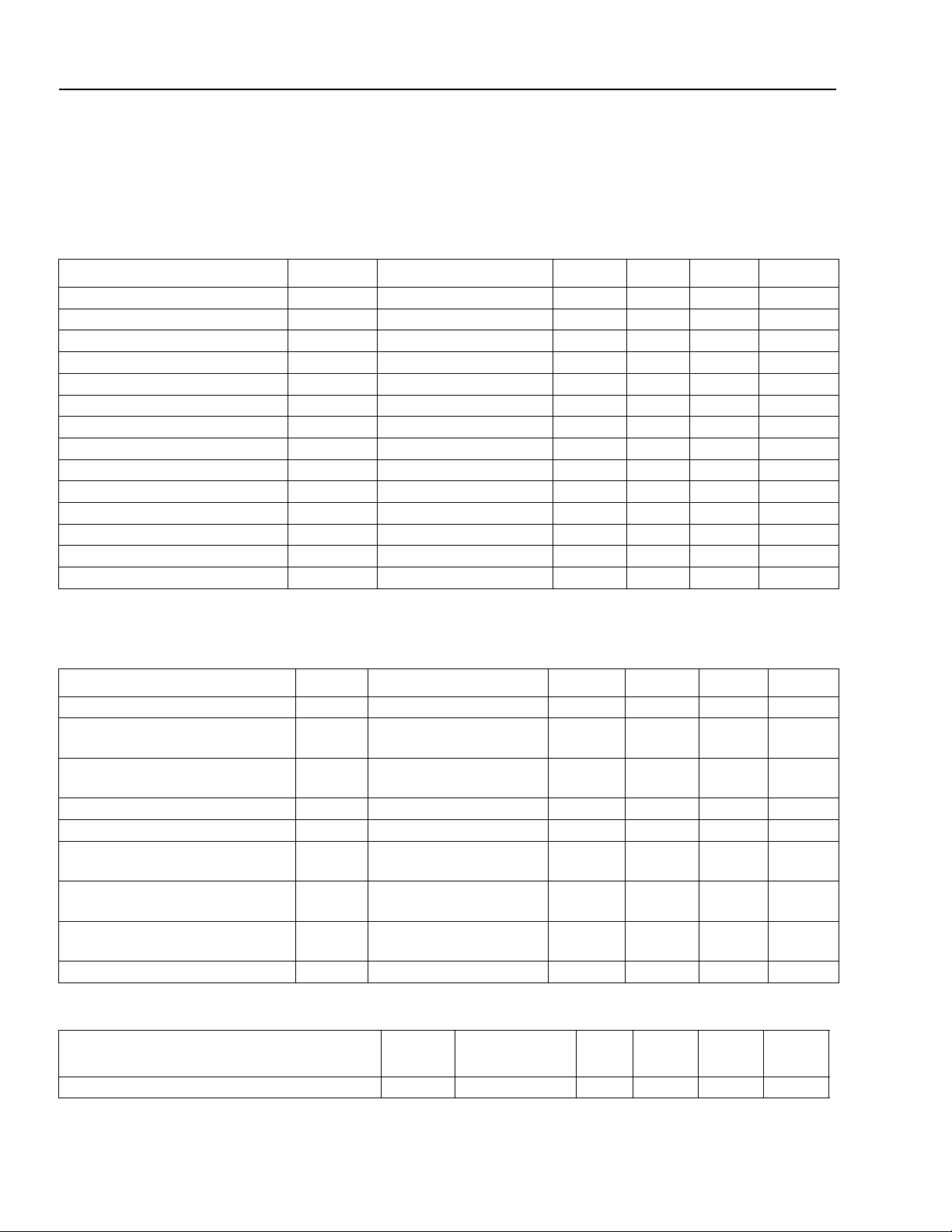

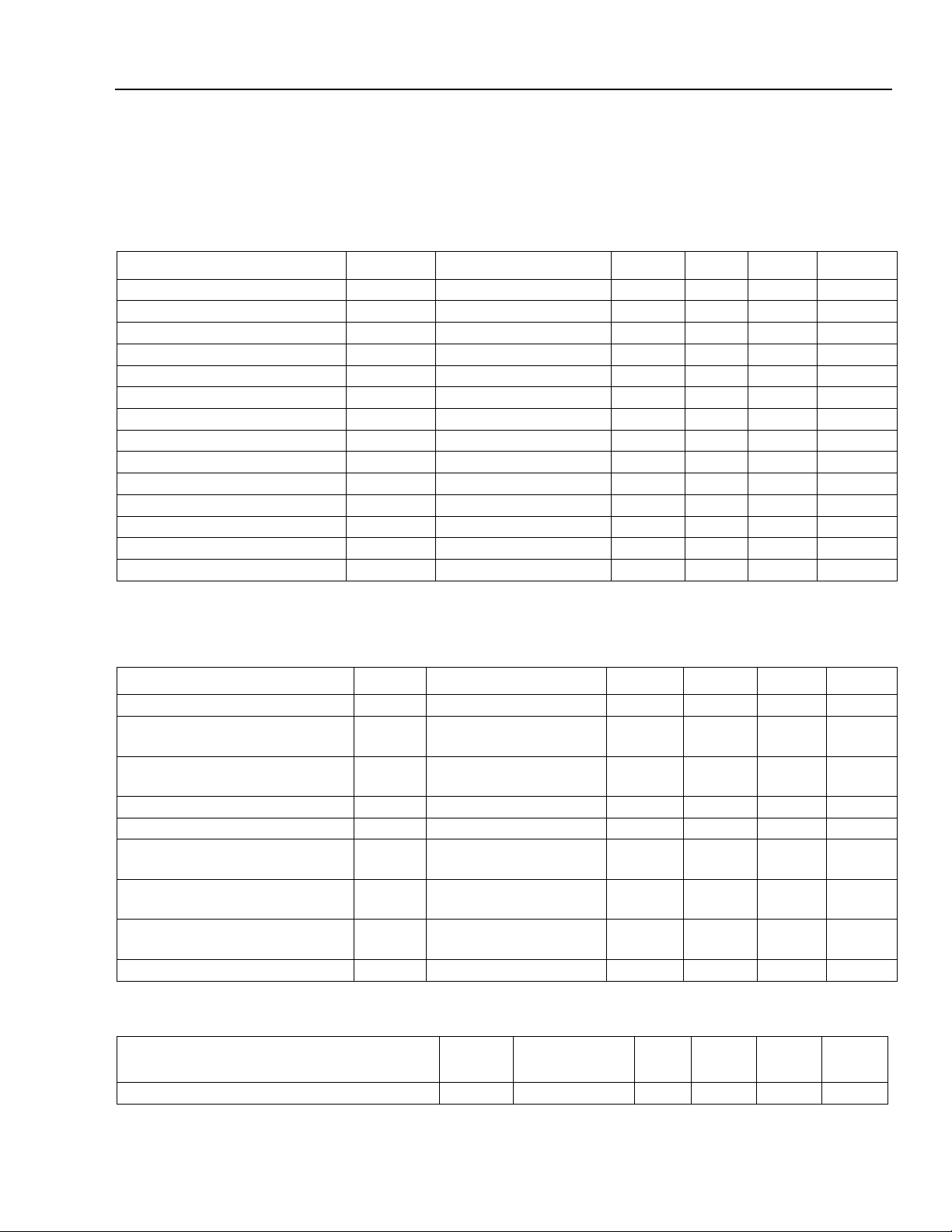

D2526 Characteristics

Minimum and maximum values are testing requirements. Typical values are characteristics of the device and are

the result of engineering e v aluations . Typical values are for inf ormation purposes only and are not part of the testing

requirements.

Table 1. Electrical Characteristics (at 25 °C laser temperature)

Parameter Symbol Test Conditions Min Typ Max Unit

Slope Efficiency η L

Threshold Current I

Laser Forward Voltage V

Laser Submount Temperature T

Monitor Reverse-bias Voltage* V

Monitor Current I

Monitor Dark Current I

Input Impedance Z

Thermistor Current I

Resistance Ratio

†

Thermistor Resistance R

TEC Current I

TEC Voltage V

TH

LF

LASER

RMON

RMON

D

IN

TC

— — 9.1 — 9.6 —

TH

TEC

TEC

TEC Capacity ∆TT

* Standard operating condition is 5.0 V reverse bias.

† Ratio of thermistor resistance at 0 °C to thermistor resistance at 50 °C.

F

= 2 mW (CW) 0.06 0.09 0.13 mW/mA

——1430mA

LF = 2 mW (CW) — 1.3 1.8 V

—20—30°C

—3510V

POL = 1 mW (CW) 0.1 0.3 1.5 mA

IF = 0, V

RMON

= 5 V — 0.01 0.1 µA

——25—Ω

— 10 — 100 µA

TL = 25 °C 9.5 — 10.5 kΩ

TL = 25 °C, TC = 70 °C — 0.6 1.0 A

TL = 25 °C, TC = 70°C — 1.3 2.0 V

C

= 70 °C — — 50 °C

Table 2. Optical Characteristics (at 25 °C laser temperature)

Parameter Symbol Test Conditions Min Typ Max Unit

Peak Optical Output Power P

Center Wavelength

(See Table 10.)

Line Width (3 dB full width) ∆λ Modulated at 2.5 Gbits/s

PEAK

λcT

—2.0——mW

L

= 25 °C

CW wavelength

1528.77 — 1610.06 nm

—210MHz

at rated power

Side-mode Suppression Ratio SMSR CW 30 — — dB

C

Optical Isolation — T

Wavelength Drift (EOL) ∆λ Tested over

= 0 °C to 70 °C 30 — — dB

——±0.1nm

25-year lifetime

Center Wavelength Drift with

C

/∆T

0 °C ≤ TC ≤ 70 °C — — 1 pm/°C

C

∆λ

Case Temperature

Wavelength Temperature Tuning

— — — 0.095 — nm/°C

Coefficient

C

Tracking Error — T

= –20 °C/25 °C/70 °C — — 1 dB

Table 3. Dispersion Performance

Parameter Symbol

Test

Conditions

Min Typ Max Unit

Dispersion Penalty for Extended Reach DP 1800 ps/nm — — 2.0 dB

4 Agere Systems Inc.

Page 5

Data Sheet, Rev . 3 D2570, D2526G, D2555 Wavelength-Selected

July 2001 Direct Modulated Isolated DFB Laser Module

D2555 Characteristics

Minimum and maximum values are testing requirements. Typical values are characteristics of the device and are

the result of engineering evaluations. Typical values are for information purposes only and are not part of the testing requirements.

Table 4. Electrical Characteristics (at 25 °C laser temperature)

Parameter Symbol Test Conditions Min Typ Max Unit

Slope Efficiency η L

Threshold Current I

Laser Forward Voltage V

Laser Submount Temperature T

Monitor Reverse-bias Voltage* V

Monitor Current I

Monitor Dark Curren t I

Input Impedance Z

Thermistor Current I

Resistance Ratio

†

Thermistor Resistance R

TEC Current I

TEC Voltage V

TH

LF

LASER

RMON

RMON

D

IN

TC

——9.1—9.6—

TH

TEC

TEC

TEC Capacity ∆TT

* Standard opera ti ng condition is 5.0 V reverse bias.

† Ratio of thermistor resistance at 0 °C to thermistor resistance at 50 °C.

F

= 2 mW (CW) 0.05 0.08 0.10 mW/mA

— — 12 35 mA

LF = 2 mW (CW) — 1.3 1.8 V

—20—30°C

—3510V

POL = 1 mW (CW) 0.1 0.3 1.9 mA

IF = 0, V

RMON

= 5 V — 0.01 0.1 µA

——25—Ω

— 10 — 100 µA

TL = 25 °C 9.5 — 10.5 kΩ

TL = 25 °C, TC = 70 °C — 0.6 1.0 A

TL = 25 °C, TC = 70°C — 1.3 2.0 V

C

= 70 °C — — 50 °C

Table 5. Optical Characteristics (at 25 °C laser temperature)

Parameter Symbol Test Conditions Min Typ Max Unit

Peak Optical Output Power P

Center Wavelength

PEAK

λcT

(See Table 11.)

Line Width (3 dB full width) ∆λ Modulated at 2.5 Gbits/s

—2.0——mW

L

= 25 °C

1528.77 — 1563.86 nm

CW wavelength

—210MHz

at rated power

Side-mode Suppression Ratio SMSR CW 30 — — dB

C

Optical Isolation — T

Wavelength Drift (EOL) ∆λ Tested over

= 0 °C to 75 °C 30 — — dB

——±0.1nm

25-year lifetime

Center Wavelength Drift with

C

/∆T

0 °C ≤ TC ≤ 75 °C — — 1 pm/°C

C

∆λ

Case Temperature

Wavelength Temperature Tuning

— — — 0.095 — nm/°C

Coefficient

C

Tracking Error — T

= –20 °C/25 °C/70 °C — — 1 dB

Table 6. Dispersion Performance

Parameter Symbol

Test

Conditions

Min Typ Max Unit

Dispersion Penalty for Extended Reach DP 3000 ps/nm — — 2.0 dB

Agere Systems Inc. 5

Page 6

D2570, D2526G, D2555 Wavelength-Selected Data Sheet, Rev. 3

Direct Modulated Isolated DFB Laser Module July 2001

D2570 Characteristics

Minimum and maximum values are testing requirements. Typical values are characteristics of the device and are

the result of engineering evaluations. Typical values are for information purposes only and are not part of the testing requirements.

Table 7. Electrical Characteristics (at 25 °C laser temperature)

Parameter Symbol Test Conditions Min Typ Max Unit

Slope Efficiency η L

Threshold Current I

Laser Forward Voltage V

Laser Submount Temperature T

Monitor Reverse-bias Voltage* V

Monitor Current I

Monitor Dark Current I

Input Impedance Z

Thermistor Current I

Resistance Ratio

†

Thermistor Resistance R

TEC Current I

TEC Voltage V

TH

LF

LASER

RMON

RMON

D

IN

TC

— — 9.1 — 9.6 —

TH

TEC

TEC

TEC Capacity ∆TT

* Standard operating condition is 5.0 V reverse bias.

† Ratio of thermistor resistance at 0 °C to thermistor resistance at 50 °C.

F

= 10 mW (CW) 0.12 0.15 0.2 mW/mA

——1425mA

LF = 10 mW (CW) — 1.3 1.8 V

—20—30°C

—3510V

POL = 5 mW (CW) 0.25 0.7 1.25 mA

IF = 0, V

RMON

= 5 V — 0.01 0.1 µA

——25—Ω

—10—100µA

TL = 25 °C 9.5 — 10.5 kΩ

TL = 25 °C, TC = 70 °C — 0.6 1.0 A

TL = 25 °C, TC = 70°C — 1.3 2.0 V

C

= 70 °C — — 50 °C

Table 8. Optical Characteristics (at 25 °C laser temperature)

Parameter Symbol Test Conditions Min Typ Max Unit

Peak Optical Output Power P

Center Wavelength

PEAK

λcT

(See Table 12.)

Line Width (3 dB full width) ∆λ Modulated at 2.5 Gbits/s

—10——mW

L

= 25 °C

1528.77 — 1610.06 nm

CW wavelength

—210MHz

at rated power

Side-mode Suppression Ratio SMSR CW 30 — — dB

C

Optical Isolation — T

Wavelength Drift (EOL) ∆λ Te sted over

= 0 °C to 70 °C 30 — — dB

——±0.1nm

25-year lifetime

Center Wavelength Drift with

C

/∆T

0 °C ≤ TC ≤ 70 °C — — 1 pm/°C

C

∆λ

Case Temperature

Wavelength Temperature Tuning

— — — 0.095 — nm/°C

Coefficient

C

Tracking Error — T

= –20 °C/25 °C/70 °C — — 1 dB

Table 9. Dispersion Performance

Parameter Symbol

Test

Conditions

Min Typ Max Unit

Dispersion Penalty for Extended Reach DP 1800 ps/nm — — 2.5 dB

6

6 Agere Systems Inc.

Page 7

Data Sheet, Rev . 3 D2570, D2526G, D2555 Wavelength-Selected

)

July 2001 Direct Modulated Isolated DFB Laser Module

Outline Drawings

Dimensions are in inches and (millimeters).

0.605

(15.37)

MAX

0.365

(9.27)

MAX

0.500 (12.70)

MIN

0.500

(12.70)

0.350

(8.89)

0.105 (2.67) DIA

TYP (4) PLACES

0.180 (4.56)

0.056 (1.42)

1.025 (26.04)

0.020 (0.51) TYP

0.100 (2.54) TYP

0.820 (20.83)

0.700 (17.78)

PIN 1

TRADEMARK, CODE, LASER SERIAL NUMBER,

AND DATE CODE IN APPROX. AREA SHOWN

STRAIN

RELIEF

~

0.078 (1.98)

PIN 14

0.213 (5.40) TYP

39.37 (1000.00)

2.03 (51.6)

0.863 (21.91)

0.575 (14.61)

MIN

0.10

(2.5)

0.10 ± 0.002

(2.54 ± 0.051)

0.036

(0.91)

0.260 (6.60)

0.200

(5.08

0.215

(5.47)

REF

0.215 (5.45)

1.180 (29.97)

HEAT SINK

0.030 (0.75)

1-520.g

Agere Systems Inc. 7

Page 8

D2570, D2526G, D2555 Wavelength-Selected Data Sheet, Rev. 3

Direct Modulated Isolated DFB Laser Module July 2001

Ordering Information

Table 10. Ordering Information D2526G (FC-PC Connector)

Device

Code

ITU Freq.

(THz)

Center

Wavelength

(nm)

Comcode

D2526G61 196.1 1528.77 108221599

D2526G60 196.0 1529.55 108221581

D2526G59 195.9 1530.33 108221573

D2526G58 195.8 1531.12 108221565

D2526G57 195.7 1531.90 108221557

D2526G56 195.6 1532.68 108003658

D2526G55 195.5 1533.47 108003641

D2526G54 195.4 1534.25 108003633

D2526G53 195.3 1535.04 108003625

D2526G52 195.2 1535.82 108003617

D2526G51 195.1 1536.61 108003609

D2526G50 195.0 1537.40 108003591

D2526G49 194.9 1538.19 108003583

D2526G48 194.8 1538.98 108003575

D2526G47 194.7 1539.77 108003567

D2526G46 194.6 1540.56 108003559

D2526G45 194.5 1541.35 108003542

D2526G44 194.4 1542.14 108003534

D2526G43 194.3 1542.94 108003526

D2526G42 194.2 1543.73 108003518

D2526G41 194.1 1544.53 108003500

D2526G40 194.0 1545.32 108003492

D2526G39 193.9 1546.12 108003484

D2526G38 193.8 1546.92 108003476

D2526G37 193.7 1547.72 108003468

D2526G36 193.6 1548.51 108003450

D2526G35 193.5 1549.32 108003443

D2526G34 193.4 1550.12 108003435

D2526G33 193.3 1550.92 108003427

D2526G32 193.2 1551.72 108003419

D2526G31 193.1 1552.52 108003385

D2526G30 193.0 1553.33 108003377

D2526G29 192.9 1554.13 108003369

D2526G28 192.8 1554.94 108003351

D2526G27 192.7 1555.75 108003344

D2526G26 192.6 1556.55 108003336

D2526G25 192.5 1557.36 108003328

D2526G24 192.4 1558.17 108003310

D2526G23 192.3 1558.98 108003302

D2526G22 192.2 1559.79 108003294

D2526G21 192.1 1560.61 108003286

Device

D2526G19 191.9 1562.23 108003260

D2526G18 191.8 1563.05 108221540

D2526G17 191.7 1563.86 108221532

D2526G916 191.6 1564.68 108512526

D2526G915 191.5 1565.50 108512518

D2526G914 191.4 1566.31 108479858

D2526G913 191.3 1567.13 108479841

D2526G912 191.2 1567.95 108479833

D2526G911 191.1 1568.77 108479825

D2526G910 191.0 1569.59 108479817

D2526G909 190.9 1570.42 108479809

D2526G908 190.8 1571.24 108480369

D2526G907 190.7 1572.06 108480351

D2526G906 190.6 1572.89 108480344

D2526G905 190.5 1573.71 108479791

D2526G904 190.4 1574.54 108479783

D2526G903 190.3 1575.37 108479775

D2526G902 190.2 1576.20 108479767

D2526G901 190.1 1577.02 108479759

D2526G900 190.0 1577.85 108479742

D2526G899 189.9 1578.69 108480336

D2526G898 189.8 1579.52 108479734

D2526G897 189.7 1580.35 108479700

D2526G896 189.6 1581.18 108479692

D2526G895 189.5 1582.02 108479684

D2526G894 189.4 1582.85 108479676

D2526G893 189.3 1583.69 108479668

D2526G892 189.2 1584.53 108479650

D2526G891 189.1 1585.36 108479643

D2526G890 189.0 1586.20 108479635

D2526G889 188.9 1587.04 108479627

D2526G888 188.8 1587.88 108479619

D2526G887 188.7 1588.72 108479601

D2526G886 188.6 1589.57 108479585

D2526G885 188.5 1590.41 108479577

D2526G884 188.4 1591.25 108479569

D2526G883 188.3 1592.10 108479551

D2526G882 188.2 1592.95 108479544

D2526G881 188.1 1593.79 108479536

D2526G880 188.0 1594.64 108479528

D2526G879 187.9 1595.49 108479510

Code

ITU Freq.

(THz)

Center

Wavelength

(nm)

Comcode

8 Agere Systems Inc.

Page 9

Data Sheet, Rev . 3 D2570, D2526G, D2555 Wavelength-Selected

July 2001 Direct Modulated Isolated DFB Laser Module

Ordering Information

Table 10. Ordering Information D2526G (FC-PC Connector)

Device

Code

D2526G20 192.0 1561.42 108003278

D2526G877 187.7 1597.19 108479494 D2526G869 186.9 1604.33 108578220

D2526G876 187.6 1598.04 108479486 D2526G868 186.8 1604.88 108578204

D2526G875 187.5 1598.89 108479478 D2526G867 186.7 1605.74 108578196

D2526G874 187.4 1599.75 108479460 D2526G866 186.6 1606.60 108578188

D2526G873 187.3 1600.60 108479452 D2526G865 186.5 1607.47 108578162

D2526G872 187.2 1601.45 108479445 D2526G864 186.4 1608.33 108578154

D2526G871 187.1 1602.31 108479437 D2526G863 186.3 1609.19 108578105

D2526G870 187.0 1603.17 108578246 D2526G862 186.2 1610.06 108578097

Table 11. Ordering Information D2555G (FC-PC Connector)

Device

Code

D2555G61 196.1 1528.77 108309113 D2555G38 193.8 1546.92 108167008

D2555G60 196.0 1529.55 108309105 D2555G37 193.7 1547.72 108166992

D2555G59 195.9 1530.33 108309089 D2555G36 193.6 1548.51 108166984

D2555G58 195.8 1531.12 108309071 D2555G35 193.5 1549.32 108166976

D2555G57 195.7 1531.90 108309063 D2555G34 193.4 1550.12 108166968

D2555G56 195.6 1532.68 108167180 D2555G33 193.3 1550.92 108166950

D2555G55 195.5 1533.47 108167172 D2555G32 193.2 1551.72 108166943

D2555G54 195.4 1534.25 108167164 D2555G31 193.1 1552.52 108166935

D2555G53 195.3 1535.04 108167156 D2555G30 193.0 1553.33 108166927

D2555G52 195.2 1535.82 108167149 D2555G29 192.9 1554.13 108166877

D2555G51 195.1 1536.61 108167131 D2555G28 192.8 1554.94 108166851

D2555G50 195.0 1537.40 108167123 D2555G27 192.7 1555.75 108166836

D2555G49 194.9 1538.19 108167115 D2555G26 192.6 1556.55 108166810

D2555G48 194.8 1538.98 108167107 D2555G25 192.5 1557.36 108166794

D2555G47 194.7 1539.77 108167099 D2555G24 192.4 1558.17 108166786

D2555G46 194.6 1540.56 108167081 D2555G23 192.3 1558.98 108166760

D2555G45 194.5 1541.35 108167073 D2555G22 192.2 1559.79 108166745

D2555G44 194.4 1542.14 108167065 D2555G21 192.1 1560.61 108166737

D2555G43 194.3 1542.94 108167057 D2555G20 192.0 1561.42 108166695

D2555G42 194.2 1543.73 108167040 D2555G19 191.9 1562.23 108166687

D2555G41 194.1 1544.53 108167032 D2555G18 191.8 1563.05 108309972

D2555G40 194.0 1545.32 108167024 D2555G17 191.7 1563.86 108309964

D2555G39 193.9 1546.12 108167016

ITU Freq.

(THz)

ITU Freq.

(THz)

(continued)

Center

Wavelength

(nm)

Center

Wavelength

(nm)

Comcode

Comcode

(continued)

Device

Code

ITU Freq.

(THz)

Center

Wavelength

Comcode

(nm)

D2526G878 187.8 1596.34 108479502

Device

Code

ITU Freq.

(THz)

Center

Wavelength

(nm)

Comcode

Agere Systems Inc. 9

Page 10

D2570, D2526G, D2555 Wavelength-Selected Data Sheet, Rev. 3

Direct Modulated Isolated DFB Laser Module July 2001

Orderin g Information

Table 12. Ordering Information D2570H

Device

Code

D2570H61 196.1 1528.77 108278425 D2570H18 191.8 1563.05 108277369

D2570H60 196.0 1529.55 108278417 D2570H17 191.7 1563.86 108277351

D2570H59 195.9 1530.33 108278409 D2570H916 191.6 1564.68 108512500

D2570H58 195.8 1531.12 108278391 D2570H915 191.5 1565.50 108512492

D2570H57 195.7 1531.90 108278383 D2570H914 191.4 1566.31 108488149

D2570H56 195.6 1532.68 108277914 D2570H913 191.3 1567.13 108488131

D2570H55 195.5 1533.47 108277500 D2570H912 191.2 1567.95 108488123

D2570H54 195.4 1534.25 108277492 D2570H911 191.1 1568.77 108488115

D2570H53 195.3 1535.04 108277484 D2570H910 191.0 1569.59 108488107

D2570H52 195.2 1535.82 108277476 D2570H909 190.9 1570.42 108488099

D2570H51 195.1 1536.61 108277468 D2570H908 190.8 1571.24 108488081

D2570H50 195.0 1537.40 108277450 D2570H907 190.7 1572.06 108488073

D2570H49 194.9 1538.19 108277443 D2570H906 190.6 1572.89 108488065

D2570H48 194.8 1538.98 108277435 D2570H905 190.5 1573.71 108488057

D2570H47 194.7 1539.77 108277427 D2570H904 190.4 1574.54 108488040

D2570H46 194.6 1540.56 108277419 D2570H903 190.3 1575.37 108488032

D2570H45 194.5 1541.35 108277393 D2570H902 190.2 1576.20 108488024

D2570H44 194.4 1542.14 108177924 D2570H901 190.1 1577.02 108488016

D2570H43 194.3 1542.94 108177916 D2570H900 190.0 1577.85 108488008

D2570H42 194.2 1543.73 108177908 D2570H899 189.9 1578.69 108487992

D2570H41 194.1 1544.53 108177890 D2570H898 189.8 1579.52 108487984

D2570H40 194.0 1545.32 108177882 D2570H897 189.7 1580.35 108487976

D2570H39 193.9 1546.12 108177874 D2570H896 189.6 1581.18 108487968

D2570H38 193.8 1546.92 108177866 D2570H895 189.5 1582.02 108487950

D2570H37 193.7 1547.72 108177858 D2570H894 189.4 1582.85 108487943

D2570H36 193.6 1548.51 108177841 D2570H893 189.3 1583.69 108487935

D2570H35 193.5 1549.32 108177833 D2570H892 189.2 1584.53 108487927

D2570H34 193.4 1550.12 108177153 D2570H891 189.1 1585.36 108487919

D2570H33 193.3 1550.92 108177825 D2570H890 189.0 1586.20 108487901

D2570H32 193.2 1551.72 108177809 D2570H889 188.9 1587.04 108487893

D2570H31 193.1 1552.52 108177791 D2570H888 188.8 1587.88 108487885

D2570H30 193.0 1553.33 108177783 D2570H887 188.7 1588.72 108487877

D2570H29 192.9 1554.13 108177767 D2570H886 188.6 1589.57 108487869

D2570H28 192.8 1554.94 108177759 D2570H885 188.5 1590.41 108487851

D2570H27 192.7 1555.75 108177742 D2570H884 188.4 1591.25 108487844

D2570H26 192.6 1556.55 108177734 D2570H883 188.3 1592.10 108487836

D2570H25 192.5 1557.36 108177726 D2570H882 188.2 1592.95 108487828

D2570H24 192.4 1558.17 108177718 D2570H881 188.1 1593.79 108487810

D2570H23 192.3 1558.98 108177700 D2570H880 188.0 1594.64 108487802

D2570H22 192.2 1559.79 108177692 D2570H879 187.9 1595.49 108487794

D2570H21 192.1 1560.61 108177684 D2570H878 187.8 1596.34 108487786

D2570H20 192.0 1561.42 108277385 D2570H877 187.7 1597.19 108487778

D2570H19 191.9 1562.23 108277377 D2570H876 187.6 1598.04 108487760

ITU Freq.

(THz)

(

continued)

Center

Wavelength

(nm)

®

(

Ferrule)

ST

Comcode Device

Code

ITU Freq.

(THz)

Center

Wavelength

(nm)

Comcode

10 Agere Systems Inc.

Page 11

Data Sheet, Rev . 3 D2570, D2526G, D2555 Wavelength-Selected

July 2001 Direct Modulated Isolated DFB Laser Module

Ordering Information

Table 12. Ordering Information D2570H

Device

Code

D2570H875 187.5 1598.89 108487752

D2570H874 187.4 1599.75 108487745

D2570H873 187.3 1600.60 108487737

D2570H872 187.2 1601.45 108487729

D2570H871 187.1 1602.31 108487711

D2570H870 187.0 1603.17 108578659 D2570H863 186.3 1609.19 108578402

D2570H869 186.9 1604.33 108578642 D2570H862 186.2 1610.06 108578394

ITU Freq.

(THz)

(continued)

Center

Wavelength

(nm)

Ferrule)

(

ST

Comcode Device

(continued)

Code

D2570H868 186.8 1604.88 108578634

D2570H867 186.7 1605.74 108578618

D2570H866 186.6 1606.60 108578469

D2570H865 186.5 1607.47 108578428

D2570H864 186.4 1608.33 108578410

ITU Freq.

(THz)

Center

Wavelength

(nm)

Comcode

Laser Safety Information

Class IIIb Laser Product

FDA/CDRH Class IIIb laser product. All versions are Class IIIb laser products per CDRH, 21 CFR 1040 Laser

Safety requirements. The device has been classified with the FDA under accession number 8720010.

This product complies with 21 CFR 1040.10 and 1040.11.

8.3 µm/125 µm single-mode fiber pigtail with 900 µm tight buffer jacket and connector

Wavelength = 1.5 µm

Maximum power = 40 mW

Because of size constraints, laser saf ety labeling (includi ng an FD A Class IIIb label) is not affix ed to the module b ut

attached to the outside of the shipping carton.

Product is not shipped with power supply.

Caution: Use of controls, adjustments, and procedures other than those specified herein may result in

hazardous laser radiation exposure .

DANGER

INVISIBLE LASER RADIATION

IS EMITTED FROM THE END

OF FIBER OR CONNECTOR

Avoid direct exposure to beam

Do not view beam directly with

optical instruments

INVISIBLE LASER RADIATION EMITTED FROM END OF FIBER OR CONNECTOR

Avoid exposure to beam

Class IIIb Laser Product FDA/CDRH, 21 CFR 1040 Max. Output: 40 mW Wavelength: 1.5 µm

Agere Systems Inc. 11

Page 12

D2570, D2526G, D2555 Wavelength-Selected Data Sheet, Rev. 3

Direct Modulated Isolated DFB Laser Module July 2001

For additional information, cont ac t your Agere S y s tems A cc ount M anager or the following:

INTERNET:

E-MAIL:

N. AMERICA: Agere Systems Inc., 555 Union Boulevard, Room 30L-15P-BA, Allentown, PA 1810 9-3286

ASIA PACIFIC: Agere Systems Singapore Pte. Ltd., 77 Science Park Drive, #03-18 Cintech III, Singapore 118256

CHINA: Agere Systems (Shanghai) Co., Ltd., 33/F Jin Mao Tower, 88 Century Boulevard Pudong, Shanghai 200121 PRC

JAPAN: Agere Systems Japan Ltd., 7-18, Higashi-Gotanda 2-chome, Shinagawa-ku, Tokyo 141, Japan

EUROPE: Data Requests: DATALINE:

Agere Systems Inc. reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of their use or application.

is a registered trademark of Agere Systems Inc.

ST

Copyright © 2001 Agere Systems Inc.

All Rights Reserved

July 2001

DS00-165OPTO-3 (Replaces DS00-165OPTO-2)

http://www.agere.com

docmaster@agere.com

1-800-372-2447

Tel. (65) 778 8833

Tel. (86) 21 50471212

Tel. (81) 3 5421 1600

Tec hni c al Inquiries: OPTOELECTRONICS MARKETING:

, FAX 610-712-4106 (In CANADA:

, FAX (65) 777 7495

, FAX (86) 21 50472266

, FAX (81) 3 5421 1700

Tel. (44) 7000 582 368

1-800-553-2448

, FAX (44) 1189 328 148

, FAX 610-712-4106)

(44) 1344 865 900

(Ascot UK)

Loading...

Loading...