Page 1

查询1241CADC供应商

1241/1243/1245-Type Uncooled Laser Transmitter

Data Sheet

September 1999

Features

Backward compatible with 1227/1229/1238-Type

■

Laser Transmitters

Space-saving, self-contained, 20-pin DIP

■

Uses field-proven, reliable InGaAsP MQW laser

■

Requires single 5 V power supply

■

SONET/SDH compa tible

■

Uncooled laser with automatic optical power con-

■

trol for constant output power over case temperature range

Offering multiple output power o ptio ns an d SONE T/SDH compatib ility, the 12 41/1243-Type U ncooled La se r Transmi t ter is

manufactured in a 20-pin, plastic DIP with a single-mode fiber

pigtail.

No thermoel ec tric cooler required; reduces size

■

and power consumption

Uses low-power dissipation CMOS technology

■

Qualified to meet the intent of Bellcore reliability

■

practices

Operates over data rates to 1062.5 Mbits/s (NRZ)

■

Operation at 1.3 µm or 1.55 µm wavelength

■

Typical average output power options of –11 dBm,

■

–8 dBm, –5 dBm, –2 dBm, and 0 dBm

ECL compatible, differential inputs

■

Operating temperature range of –40 °C to +85 °C

■

Transmitter-disable option

■

Applications

Telecommunications

■

— Inter- and intraoffice SONET/ITU-T SDH

— Subscriber loop

— Metropolitan area networks

High-speed data communications

■

— Fibre channel (FC-0)

Page 2

Data Sheet

1241/1243/1245-Type Uncooled Laser Transmitter September 1999

Description

The 1241/1243/1245-type Laser Transmitters are

designed for use in transmission systems and highspeed data communication applications. Used in

intraoffice and intermediate-reach applications, the

transmitters are configured to operate at SONET rates

up to OC-12, as well as at ITU-T synchronous digital

hierarchy (SDH) rates up to STM-4. Specific versions

are also capable of operating up to 1062.5 Mbits/s.

The transmitter meets all present Bellcore GR-253CORE requirements, ANSI T1.117-1991 SONET single-mode, and the ITU-T G.957 and G.958 recommendations. (See Table 5 to select transmitters for the

various SONET/SDH segments.)

The transmitter requires a single power supply (+5 V or

–5 V) and operates over data rates of 1 Mbits/s to

622 Mbits/s (NRZ). Automatic power control circuitry

provides constant optical output power over the operating case temperature range. The automatic power control circuitry also compensates for laser aging. The

optical wavelength tolerance at 25 °C is 1310 nm. The

temperature coefficient of wavelength for 1.3 µm FabryPerot transmitters (1241-Type) is approximately

0.4 nm/°C. The temperature coefficient of wavelength

for 1.3 µm and 1.55 µm distributed-feedback (DFB)

transmitters (1243/1245-Type) is approximately

0.1 nm/°C.

Transmitters are available for operation over several dif-

ferent temperature ranges from –40 °C to +85 °C. Manufactured in a 20-pin DIP, the transmitter consists of a

hermetic, InGaAs laser and a single CMOS driver IC.

The low-power consumption circuit provides modulation, automatic optical output power control, and data

reference. The module can be driven by either ac- or

dc-coupled data in single-ended or differential configuration. (See Recommended User I nte rfaces section for

typical connection schemes.) The laser bias and backfacet monitor currents are electrically accessible for

transmitter performance monitoring. The transmitter

optical output may be disabled by a logic-level input.

Functional Overview

Transmitter Circuit Description and

Operation

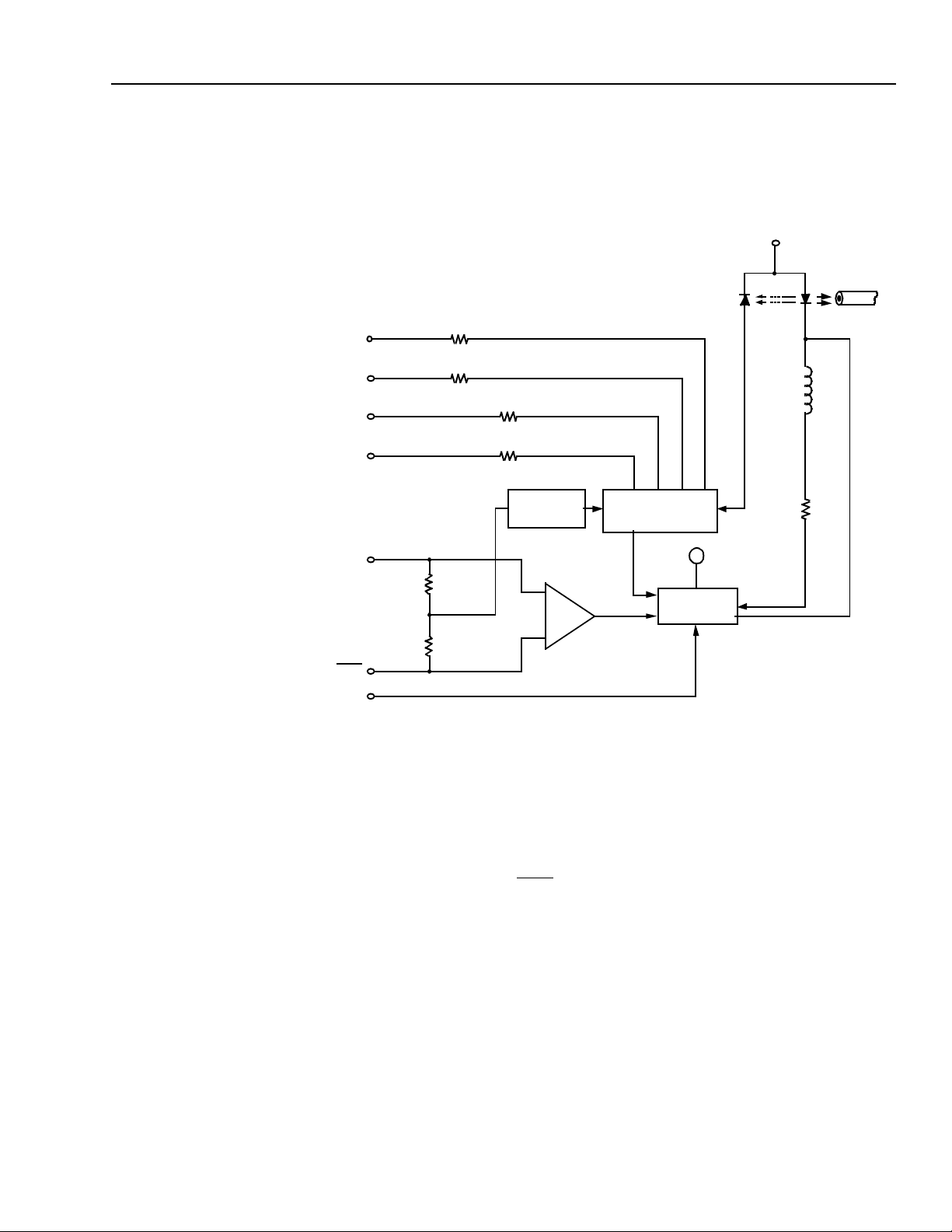

Figure 1 shows a simplified schematic of the transmitter; pin information is listed in Table 1. The laser within

the transmitter is driven by a single CMOS integrated

circuit, which provides the input data signal re ference

level with automatic, temperature-compensated laser

bias, and modulation-current control. A back-facet pho-

todetector diode within the laser module provides an

indication of the laser's average optical output power.

The back-facet diode current is accessible as a voltage

proportional to photocurrent through pins 17 and 19 on

the transmitter. The back-facet diode also forms part of

the feedback control circuit, which helps maintain constant output power.

The laser bias current is accessible as a dc-voltage by

measuring the voltage developed across pins 2 and 4

of the transmitter. Dividing this voltage by 10 Ω will

yield the value o f the laser bias current. This valu e will

change up or down in response t o operati ng temperature, power supply voltage, data pattern, and laser

aging characteristics.

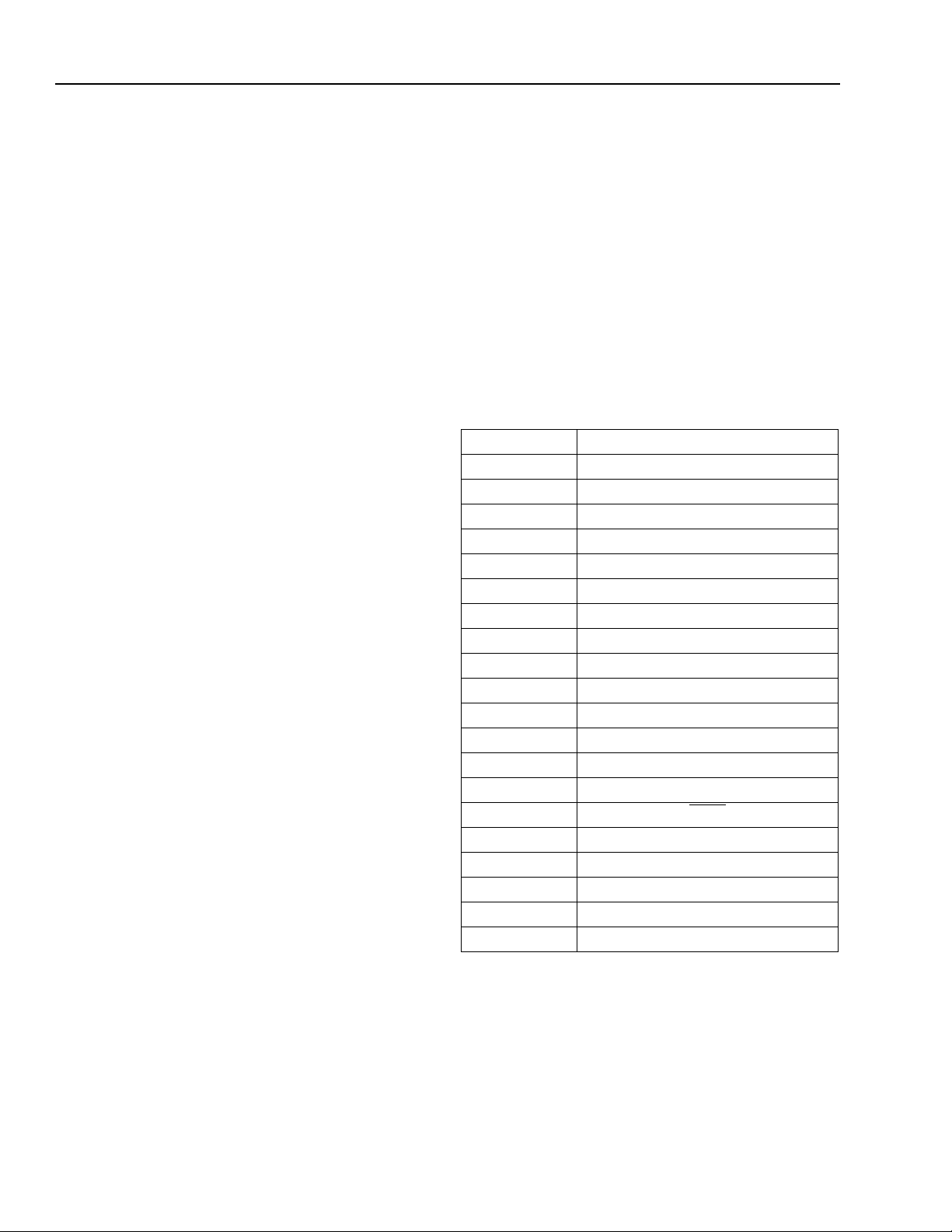

Table 1. Pin Descriptions

Pin Number Name

1 No user connection

2 Laser bias monitor (+)

3 No user connection

4 Laser bias monitor (–)

5V

6V

EE

CC

*

†

*

†

7 Transmitter disable

8V

9V

10 No user connection

CC

CC

†

11 Case ground (RF ground)

12 V

CC

13 Case ground (RF ground)

14 V

EE

15 DATA

16 DATA

17 Laser back-facet monitor (–)

18 V

CC

19 Laser back-facet monitor (+)

20 No user connection

* Pins d esignate d as no user co nnection should not be tie d to

ground or any other circuit potential.

† Lase r back-facet and bi as m on itor funct io ns a re cu stomer-use

optio ns that are not require d for normal operations of the transmitter. They are normally used during manufacture and for

diagnostics.

*

*

†

2 Agere Systems Inc.

Page 3

Data Sheet

September 1999

1241/1243/1245-Type Uncooled Laser

Functional Overview

TRANSMITTER

(continued)

(2)

(+)

(4)

(–)

(19)

(+)

(17)

(–)

(16)

DATA

(15)

DATA

(7)

DISABLE

15 k•

LASER BIAS MONITOR VOLTAGE

15 k•

15 k•

LASER BACK-FACET MONITOR VOLTAGE

15 k•

30 k•

V

– 1.3 V

CC

30 k•

BAND GAP

REFERENCE

INPUT DATA

COMPARATOR

BACK-FACET

DETECTOR

AUTOMATIC POWER

CONTROL CIRCUITRY

MODULATION

CIRCUITRY

I

BF

TEMPERATURE

t

SENSOR

I

BIAS

V

CC

LASER

FIBER PIGTAIL

10 •

I

MOD

1-868(C).h

Figure 1. Simplified Transmitter Schematic Input Data

Input Data

Data enter s the transmitt er through a comparator.

These inputs have internal pull-down resistors to a volt-

. Thi s conf igura-

age reference that is 1.3 V below V

CC

tion allows the transmitter to be dr iven from either a

input signal, the optical signal will be the complement

of the data input signal.

The differental inputs of the 1241 Gbit versions are terminated internally with 100 Ω between t he DATA and

DA TA

inputs.

single-ended or a differential input signal. Since the

input is a comparator instead of a gate, the absolute

input signal levels are not important when the inputs

are driven differentially. When driven sin gle-ended,

however, the input signal voltage should be centered

around V

– 1.3 V to eliminate pulse-width distortion.

CC

With a single-ended input, either input can be used and

the unused input can be left as an open circu i t due to

the internal reference shown in Figure 1. The optical

output signal will be in the same sense as the input

data—an input logic high turns the las er diode on and

Minimum Data Rate

Because the modulation and bias control circuitry are

influenced by the input data pattern, the standard

transmitter cannot be used in burst-mode type applications. For burst-mode applications, please contact your

Agere Account Man ager. The minimum data rate

(pseudorandom data, 50% average duty cycle) for the

1241/1243/1245-Type Transmitters is approximately

1 Mbit/s.

an input logic low turns the laser diode off. However, if

the nega tive input is used with a single-ended data

Agere Systems Inc. 3

Page 4

Data Sheet

1241/1243/1245-Type Uncooled Laser Transmitter September 1999

Functional Overview

Since most applications operate at very high data

rates, high-frequency design techniques need to be

used to ensure optimum performance from the transmitter and interfacing circuitry. Input signal paths

should be kept as short and as straight as possible; differential signal lines should be equal in length, and

controlled-impedance stripline or microstrip construction should always be used when laying out th e printedwiring board traces for the data lines. The Recommended User Inter faces section of this data sheet

shows several methods of interfacing to the transmitter.

(continued)

Power Supplies

The transmitter is configured for operation from either a

single +5 V power supply or a single –5 V power supply . F or positive power supply operation, connect Vcc to

the +5 V power supply and c onnect V

circuit common. For operation from a –5 V power supply, connect V

power supply. Whichever option is chosen, the V

V

connection to the transmitter should be well filtered

EE

to prevent power supply noise from interfering with

transmitter operation.

to ground and connect VEE to the –5 V

CC

to ground or

EE

CC

or

Transmitter Specifications

Connector Opti ons

The standard optical fiber pigtail is 8 µm core singlemode fiber having a 0.036 in. (914 µm) diameter tightbuffered outer-jacket. The standard length is 39 in. ±

4 in. (1 m ± 10 cm) and c an be te rm inated with either

an SC or FC-PC optical connector. Other connector

options may be available on special order . Contact your

Agere Account Manager for ordering information.

Handling Precautions

CAUTION: This device is susceptible to damage as

a result of electrostatic discharge (ESD).

Take proper precautions during b o th

handling and testing. Follow guidelines

such as JEDEC Publication No. 108-A

(Dec. 1988).

Although protection circuitry is designed into the

device, take proper precautions to avoid exposure to

ESD. Agere employs a human-body model (HBM) for

ESD-suscepti bility testing and protection-design evaluation. ESD voltage thresholds are dependent on the

critical parameters used to define the model. A stan dard HBM (resistance = 1.5 kΩ, capacitance = 100 pF)

is wi dely used and, there fore, can be used for comparison purposes. The HBM ESD withstand voltage established for the 1241-/1243- T yp e Transmitter is ±1000 V.

Optical Output Power

During manufacture, the optical output power of every

transmitter is tuned to the typical value specified in the

data sheet for that particular transmitter code. The tuning is performed at room ambient and a power supply

voltage of 5 V. The minimum and maximum values

listed in the data sheet for each code group reflect the

worst-case limits that the transmitter is expected to

operate within over its lifetime and over the allowed

power supply and the operating temperature range.

Every transmitter shipped receives a final test, which

includes a SONET eye-mask test at either the OC-3

(STM-1) data rate of 155.52 Mbits/s, the OC-12 (STM4)

data rate of 622.08 Mbits/s, or the fibre channel FC-0

data rate of 1062.5 Mbits/s. The eye-mask test is

meant to examine the performance of the transmitter's

output optical waveform relative to a minimum data pattern eye opening.

Transmitter Processing

The transmitter can withstand normal wave-soldering

processes. The complete transmitter module is not hermetically sealed; therefore, it should not be immersed

in or sprayed with any cleaning so lutio n or solvents.

The process cap and fiber pigtail jacket deformation

temperature is 85 °C. Transmitter pins can be wavesoldered at maximum temperature of 250 °C for

10 seconds.

Installation Considerations

Although the transmitter features a robust design, care

should be used during handling. The optical connector

should be kept free from dust, and the process cap

should be kept in place as a dust cover when the

device is not connected to a cable. If contamination is

present on the optical connector, canned air with an

exten sion tube can be used to remove any debris.

Other cleaning procedures are identified in the technical note, Cleaning Fiber-Optic As se mblies (TN95010LWP).

4 Agere Systems Inc.

Page 5

Data Sheet

September 1999

1241/1243/1245-Type Uncooled Laser

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratin gs onl y. Functional operation o f the device is not implied at thes e or any other conditions in excess

of those given in the operations sections of the data sheet. Exposure to absolute maximum ratings for extended

periods can adversely affect device reliability.

Parameter Symbol Min Max Unit

Supply Voltage

Operating Case Temperat ure Range

*

†

Storage Case Temperature Range T

Lead Soldering Temperature/Time — — 250/10 °C/s

Relative Humidity (noncondensing) RH — 85 %

Minimum Fiber Bend Radius — 1.00 (25.4) — in. (mm)

*With VEE connected to –5 V, VCC must be at 0 V; with VCC connected to +5 V, V

†

Specification depends upon the code ordered. The de vice is capable of a cold start at –40 °C; specifications are me t

after a warm-up time determined by the system thermal design.

——5.5V

T

C

stg

–40 85 °C

–40 85 °C

EE

must be at 0 V.

Characteristics

Minimum and maximum values specified over operating case temperature range at 50% duty cycle data signal and

end of life (EOL). Typical values ar e measured at beginning-of-life (BOL) room temperature unless otherwise noted.

Table 2. Electrical Characteristics

Parameter Symbol Min Typ Max Unit

Power Supply Voltage

Power Supply Current Drain I

Input Data Voltage:

Low

High

Input Transition Time

Transmitter Disable Voltage

Transmitter Enable Voltage V

Output Disable Time

Output Enable Time

Laser Bias Voltage

Laser M on it o r Voltage (50% duty cycle )

1. With V

2. Input measured from V

3. Between 10% and 90% (50% duty cycle) where t is the bit period in ns.

4. The tran smitter is normally enabled and only requires an external voltage to disable.

5. Time measured from rising edge of disable signal until optical output (laser diode) has turned off.

6. Time measured from falling edge of enable signal until optical output has stabilized at nominal output power level.

7. The laser bias current is obtained by dividing the bias voltage by the 10 Ω current-sensing resist ors. (See Figure 1.) W hen measuring these

8. The laser back-f acet monitor voltage is a scaled output that trac ks the trans m itter optical output power.

EE

connected to –5 V, VCC must be at 0 V; with VCC connecte d to +5 V, V

voltage s or using the m in conjunction with alarm circuits, use a high-inpu t impedance device.

1

2

3

4

5

6

7

8

CC

with 50 Ω load to (VCC – 2 V). 10K, 10K H, an d 100K ECL c o mp atible.

V 4.75 5.0 5.50 V

TOTAL

VIL

V

IH

t

I

V

D

EN

t

D

t

EN

V

B

V

BF

— 30 130 mA

–1.81

–1.16

—t/4—ns

VCC – 2.0 — V

V

EE

— — 0.20 µs

— — 2.00 µs

0.01 0.06 0.70 V

0.01 0.05 0.20 V

EE

must be at 0 V.

—

—

–1.47

–0.88

CC

V

V

V

—VEE + 0.8 V

Agere Systems Inc. 5

Page 6

1241/1243/12 45-Ty pe Unco ole d Las er Transmitter

Data Sheet

September 1999

Characteristics

(continued)

Table 3. Optic al Characteristics

Parameter Symbol Min Typ Max Unit

Average Power Output Options

Extinctio n Ratio

2

Optical Rise and Fall Times

OC-3/STM-1

OC-12/STM4

1062.5 Mbits/s

1

3

:

P

r

t

R

tR, t

tR, t

O

E

, t

F

F

F

See Ordering Information. dBm

10 — — dB

—

—

—

—

—

—

1.0

0.5

0.37

ns

ns

ns

Center Wavelength λ See Ordering Information. nm

RMS Spectral Width

Side-mode Suppression Ratio

1. Output power definitions and measurement per ITU-T Recommenda tion G.957 and G.958.

2. Ratio of logic 1 to logic 0 power levels.

3. Be t w ee n 10% and 90% ( 50 % duty cycle) .

4. Roo t- m ean-squa r e spectra l wi dth accoun ts for modes up to and inclu ding thos e 20 dB down from the central mode.

(Applies to 1241-Type only. )

5. Ap pl ie s to 1243/124 5-Type only.

4

5

∆λ ——4nm

SMSR 30 — — dB

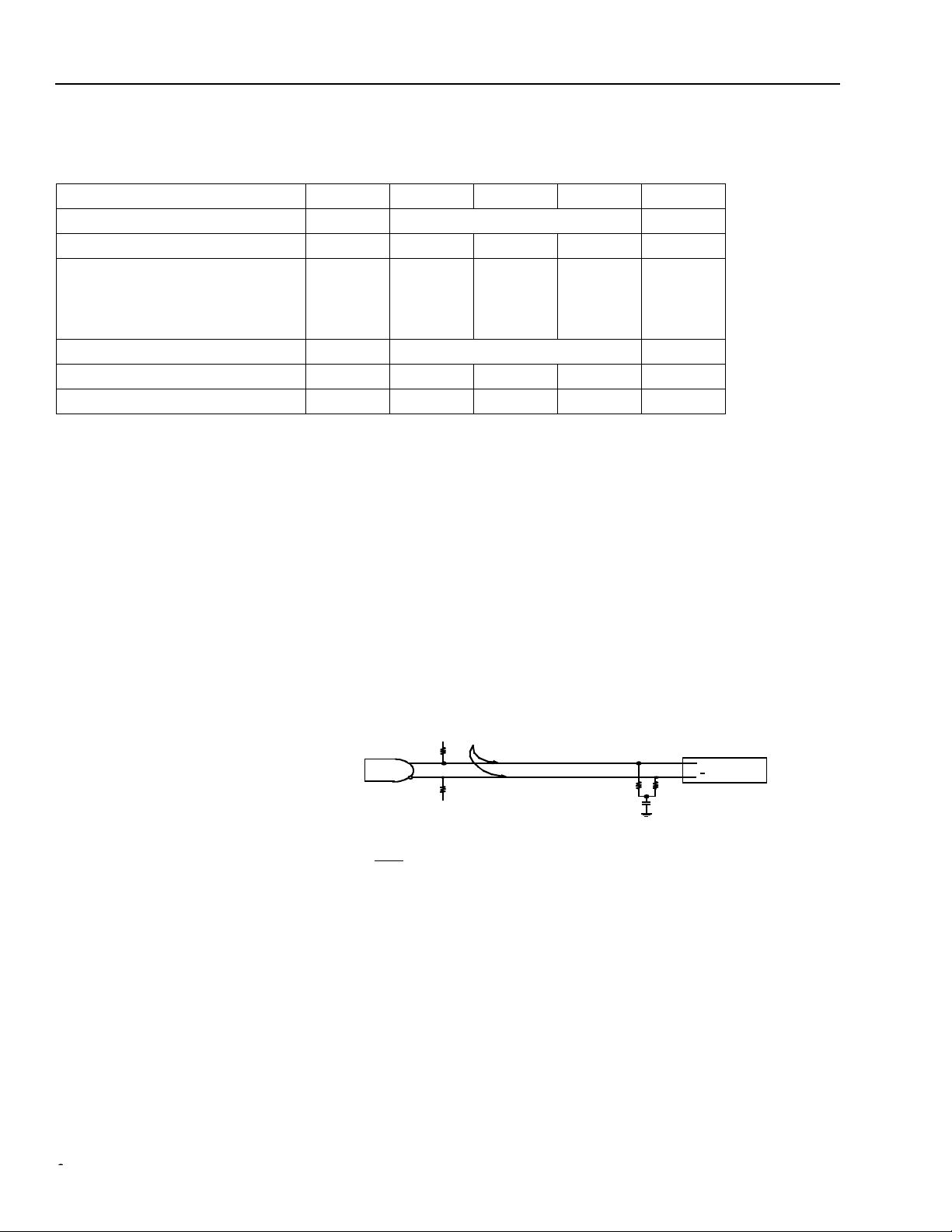

Recommended User Interfaces

V

EE

50 • MICROSTRIP OR STRIPLINE-

360 •

ECL

DRIVER

360 •

* Locate these comp o ne nt s a s cl os e to DATA/DATA inputs as possible.

CONTROLLED IMPEDANCE TRACES

V

EE

50 •*

0.1 µF

50 •*

16

D

TRANSMITTER

15

D

1-496(C).c

Note: The 1241 gigab it version does not requ i r e the external 50 Ω termi nations since this terminatio n is included inside t he module.

Figure 2. dc-Coupled, Differential Input

66 Agere Systems Inc.

Page 7

Data Sheet

September 1999

1241/1243/1245-Type Uncooled Laser

Recommended User Interfaces

Note: Input ca n als o be c on ne c ted to DATA; unuse d input pin remains unconnected.

(622 M bits/s a nd below only.)

Figure 3. dc -coupled, Single-End e d Input

(continued)

50 • COAX

OR 50 •

STRIPLINE

VCC – 2 V

(CUSTOMER

SUPPLIED)

1.0 µF

50 •

15

16

D

TRANSMITTER

D

1-497(C)

V

CC

*

50 • COAX

OR 50 •

STRIPLINE

1.0 µF

1.0 µF

* This network introduces a slight offset between DATA and DATA, which tur ns the laser

619 •

15

D

TRANSMITTER

16

D

1960 •

*

27 •

*

EE

V

50 •

1-498(C)

transmitter off wh en t h er e is no data present at t he inputs. ( 62 2 Mb its/s and bel ow o nly.)

Figure 4. ac-Coupled, Single-Ended Input

Qualification and Reliability

To help ensure high product reliability and customer satisfaction, Agere Systems is committed to an intensive quality program that starts in the design phase and proceeds through the manufacturing proc ess. Optoelectronics modules are qualified to Agere Systems internal standards using MIL-STD-883 test methods and procedures and using

sampling techniques consistent with Bellcore requirements. The 1241/1243/1245 series of transmitters have

undergone an extensive and rigorous set of qualification tests. This qualification program fully meets the intent of

Bellcore reliability practices TR-NWT-000468 and TA-NWT-00 0983. In addition, the desi gn, development, and manufacturing facility of the Op toel ectronics unit at Agere Systems has been ce rtified to be in full complia nce with the

latest ISO-9001 Quality System Standards.

Agere Systems Inc. 7

Page 8

Data Sheet

1241/1243/12 45-Type Uncooled Las er Transmitter

September 1999

Outline Diagram

Dimensions are in inches and (millimeters). Unless ot herwise noted, tolerances are ±0.005 in (±0.127 mm).

0.635

(16.14)

0.350 (8.89)

0.125

(3.18)

0.110

(2.80)

(34.01)

0.100

(2.54)

0.900

(22.86)

1.339

TOP VIEW

PIN 20PIN 11

0.950

(24.13)

PIN 1 INDICATOR

0.144

(3.66)

0.018

(0.46)

0.400

(10.16)

PIN 1PIN 10

BOTTOM VIEW

1-987C).a

88 Agere Systems Inc.

Page 9

Data Sheet

September 1999

1241/1243/1245-Type Uncooled Laser

Laser Safety Information

Class I Las e r Product

All versions of the 1241/1243/1245-Type transmitters are Class I laser products per CDRH, 21 CFR 1040 Laser

Safety requirements. The 1241/1243/1245-Type transmitters have been classified with the FDA under accession

number 8720009. All versions are Class I laser products per IEC 825-1:1993.

CAUTION: Use of controls, adjustments, and procedures other than those specified herein may result in

hazardous laser radiation exp osure.

This product complies with 21 CFR 1040.10 and 1040.11.

8.8 µm single-mode pigtail with connector

Wa v el ength = 1.3 µm

Maximum power = 1.6 mW

Notice

Unterminated optical connectors may emit laser radiation.

Do not view with optical instruments.

Table 4. A gere Transmitters for SONET/SDH Ap pl ications

1.3 µm Transmitter Type

Connector

Type

FC-PC 1241FAUC 1241FBUC 1243FAFD 1243FBDC 1245FAFC 1245FBDC

SC 1241CAUC 1241CBUC 1243CAFD 1243CBD C 1245CAFC 1245CBDC

* Full SONE T/ S DH co mpliance, –4 0 °C to +85 °C.

† Full SON ET / S DH co mp liance, –2 0 °C t o +70 °C.

Short and Intermed iate Reach

(<2 km and ~15 km)

OC-3/

STM-1

OC-12/

STM-4

OC-3/

STM-1

*

Long Reach

~40 km

OC-12/

STM-4

1.55 µm Transmitter Type

Long Reach

~80 km

OC-3/

STM-1

OC-12/

STM-4

†

Agere Systems Inc. 9

Page 10

Data Sheet

1241/1243/12 45-Type Uncooled Las er Transmitter

September 1999

Ordering Information

Table 5. 1241/1243/1245- Type Transmitter Ordering Information

OC-3/STM-1 Transmitter Codes

Operating

Case Temp.

Range (°C)

Min Max Min Typ Max Min Max

0 65 –3 0 2 1290 1330 FC-PC 1227AE 1241FADC 108123449

0 65 –3 0 2 1290 1330 SC 1227AF 1241CADC 108123480

0 65 –5 –2 0 1280 1335 FC-PC 1227YA 1241FAFC 108123357

0 65 –5 –2 0 1280 1335 SC 1227YB 1241CAFC 108123373

0 65 –8 –5 –2 1260 1360 SC 1227CA 1241CALC 108123324

0 65 –8 –5 –2 1260 1360 FC-PC 1227C 1241FALC 108123563

–20 70 –5 –2 0 1480 1580 SC 1229CB5 1245CAFC 108400409

–20 70 –5 –2 0 1480 1580 FC-P C 1229FB5 1245FAFC 108400417

–40 85 –5 –2 0 1280 1335 SC 1227Y D 1243CAFD 108123423

–40 85 –5 –2 0 1280 1335 FC-P C 1227YE 1243FAFD 108123415

–40 85 –12 –8 –5 1260 1360 SC 1227FB 1241CAPC 108123282

–40 85 –12 –8 –5 1260 1360 FC-PC 1227F 1241FAPC 108123266

–40 85 –15 –11 –8 1260 1360 SC 1227HA 1241CAUC

–40 85 –15 –11 –8 1260 1360 FC-PC 1227H 1241FAUC

0 65 –3 0 2 1290 1330 FC-PC 1227AK 1241FBDC 108123456

0 65 –3 0 2 1290 1330 SC 1227AN 1241CBDC 108123498

0 65 –8 –5 –2 1260 1360 FC-PC 1227D 1241FBLC 108123316

–20 70 –3 0 2 1480 1580 SC 1229CA5 1245CBDC 108400391

–20 70 –3 0 2 1480 1580 FC-PC 1229FA5 1245FBDC 108400425

–40 85 –3 0 2 1280 1335 FC-PC 1229FA 1243FBDC 108123506

–40 85 –3 0 2 1280 1335 SC 1229CA 1243CBDC 108123522

–40 85 –12 –8 –5 1260 1360 FC-PC 1227G 1241FBPC 108123274

–40 85 –15 –11 –8 1260 1360 FC-PC 1227AC 1241FBUC

–40 85 –15 –11 –8 1274 1356 SC 1227PG 1241CBU

10 65 –11 –8 –5 1260 1360 FC-P C 1238A 1241FCPC 108309287

10 65 –11 –8 –5 1260 1360 FC-P C 1238B 1241FCPD 108309295

10 65 –3 0 2 1290 1330 FC-PC 1238C 1241FCDC 108309279

Average Output

Power

(dBM)

Center

Connector 122x

Wavelength

(nm)

OC-12/STM-4 Transmitter Codes

Fibre Channel—1062.5 Mbits/s

Equivalent

Product

Order

Code

Comcode

*

108123209

*

108123159

*

108123167

*

108123217

* ∆λ for these codes is 2.5 nm maximum. All other 1241-type codes are 4 nm maximum.

1010 Agere Systems Inc.

Page 11

Data Sheet

September 1999

1241/1243/1245-Type Uncooled Laser

Part Numbering for the 1241/1243/1245-Type Transmitter

1 2 4 X XXX X Field D escription

Laser Type:

1 = 1.3 µm Fabry-Perot laser, 3 = 1.3 µm DFB laser, 5 = 1.55 µm DFB laser

Optical Connector:

C = SC, F = FC/PC

Data Rate:

A = 155 Mbits/s, B = 622 Mbits/s, C = 1062.5 Mbits/s

Typical Power :

D = 0 dBm, F = –2 dBm, L = –5 dBm, P = –8 dBm, U = –11 dBm

Customer Options:

A—F

Table 6. Related Produc ts

Description Device Number Document Number

155 Mbits/s and 622 Mbits/s for SONET/

SDH Applications

155 Mbits/s and 622 Mbits/s Receivers

with Clock and Data Recovery for

SONET/SDH Applications

1340-Type Pin Rece iver DS99-072LWP

1345-Type Pin Rece iver with Clock and

Data Recovery

DS99-071LWP

Agere Systems Inc. 11

Page 12

For additional information, contact your Agere Systems Account Manager or the following:

INTERNET: http://www.agere.com

E-MAIL: docmaster@agere.com

N. AMERICA: Agere Systems Inc ., 555 Uni on Boulevard, Room 30L-15P-BA, A llentown, PA 18109-3286

1-800-372-2447, FAX 610-712-4106 (In CANADA: 1-800-553-2448, FAX 610-712-4106)

ASIA: Agere Systems Hong Kong Ltd., Suites 3201 & 3210-12, 32/F, Tower 2, The Gateway, Harbour City, Kowloon

Tel. (852) 3129-2000, FAX (852) 3129-2020

CHINA: (86) 21-5047-1212 (Shanghai), (86) 10-6522-5566 (Beijing), (86) 755-695-7224 (Shenzhen)

JAPAN: (81) 3-5421-1600 (Tokyo), KOREA: (82) 2-767-1850 (Seoul), SINGAPORE: (65) 778-8833, TAIWAN: (886) 2-2725-5858 (Taipei)

EUROPE: Tel. (44) 7000 624624, FAX (44) 1344 488 045

Agere Systems Inc. reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of their use or application.

Copyright © 2001 Agere Systems Inc.

All Right s Reserv ed

September 1999

DS99-228LWP (Replaces DS99-073LWP)

Loading...

Loading...