AGERE OR2C04A-4T100I, OR2C06A-4J160I, OR2C06A-4M84, OR2C04A-4J160, OR2C04A-4J160I Datasheet

...

ORCA

®

Series 2

Field-Programmable Gate Arrays

Data Sheet

June 1999

Features

■

High-performance, cost-effective, low-power

0.35 µm CMOS technology (OR2CxxA), 0.3 µm CMOS

technology (OR2TxxA), and 0.25 µm CMOS technology

(OR2TxxB), (four-input look-up table (LUT) delay less

than 1.0 ns with -8 speed grade)

■

High density (up to 43,200 usable, logic-only gates; or

99,400 gates including RAM )

■

Up to 480 user I/Os (OR2TxxA and OR2TxxB I/Os are

5 V tolerant to allow interconnection to both 3.3 V and

5 V devices, selectable on a per-pin basis)

■

Four 16-bit look-up tables and four latches/flip-flops per

PFU, nib ble-oriented f or im ple menti ng 4-, 8-, 16-, and/or

32-bit (or wider) bus structures

■

Eight 3-state buffers per PFU for on-chip bus structures

■

Fast, on-chip user SRAM has features to simplify RAM

design and increase RAM speed:

— Asynchronous single port: 64 bits/PFU

— Synchronous single port: 64 bits/PFU

— Synchronous dual port: 32 bits/PFU

■

Improved ability to combine PFUs to create larger RAM

structures using write-port enable and 3-state buffers

■

Fas t, den se m u ltipliers can be cre ated w it h th e multiplier

mode (4 x 1 multiplier/PFU):

— 8 x 8 multiplier requires only 16 PFUs

— 30% increase in speed

■

Flip-flop/latch opti ons to allow programmable priority of

synchronous set/reset vs. clock enable

■

Enhanced cascadable nibble-wide data path

capabilities for adders, su btr acto rs, counte rs , m ulti pliers ,

and comparators inc lu din g internal fast-carry operation

■

Innovative, abundant, and hierarchical nibbleoriented routing resources that allow automatic use of

internal gates for all device densities without sacrificing

performance

■

Upward bit stream compatible with the

ORCA

ATT2Cxx/

ATT2Txx series of devices

■

Pinout-compatible with new

ORCA

Series 3 FPGAs

■

TTL or CMOS input levels programmable per pin for the

OR2CxxA (5 V) devices

■

Individually programmable drive capability:

12 mA sink/6 mA source or 6 mA sink/3 mA source

■

Built-in boundary scan (

IEEE

*1149.1 JTAG) and

3-state all I/O pins, (TS_ALL) testability functions

■

Multiple configuration options, including simple, low pincount serial ROMs , an d pe ripheral or JTAG modes for insystem programming (ISP)

■

Full PCI bus compliance for all devices

■

Supported by industry-standard CAE tools for design

entry, synthesis, and simulation with

ORCA

Foundry

Development System support (for back-end implementation)

■

New, added features (OR2TxxB) have:

— More I/O per package than the OR2TxxA family

— No dedicated 5 V supply (V

DD

5)

— Faster configuration speed (40 MHz)

— Pin selectab le I /O clampi ng diod es pr ovide 5V or 3 .3V

PCI compliance and 5V tolerance

— Full PCI bus complianc e in both 5V and 3.3V PCI sys-

tems

*

IEEE

is a registered trademark of The Institute of Electrical and

Electronics Engineers, Inc.

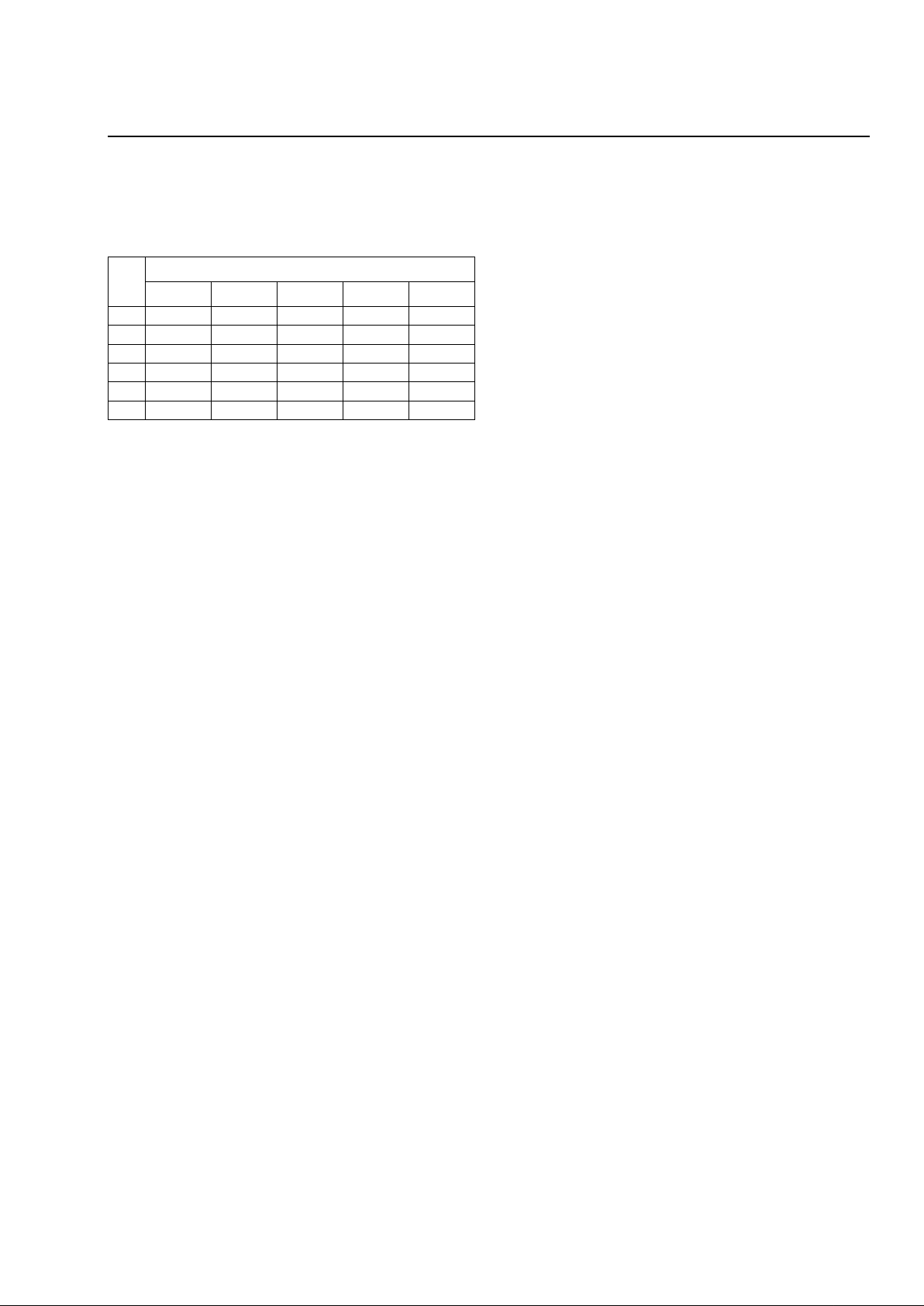

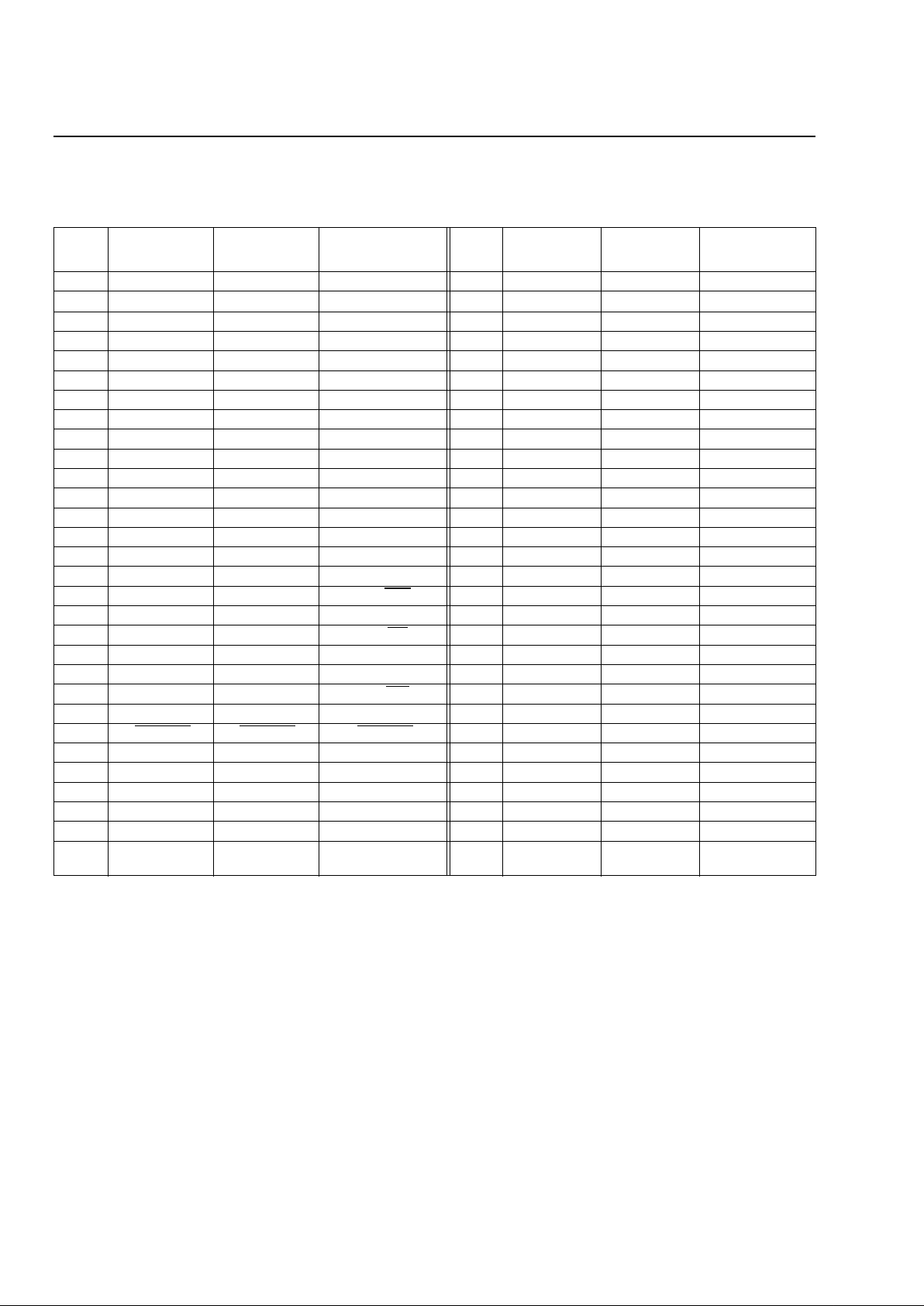

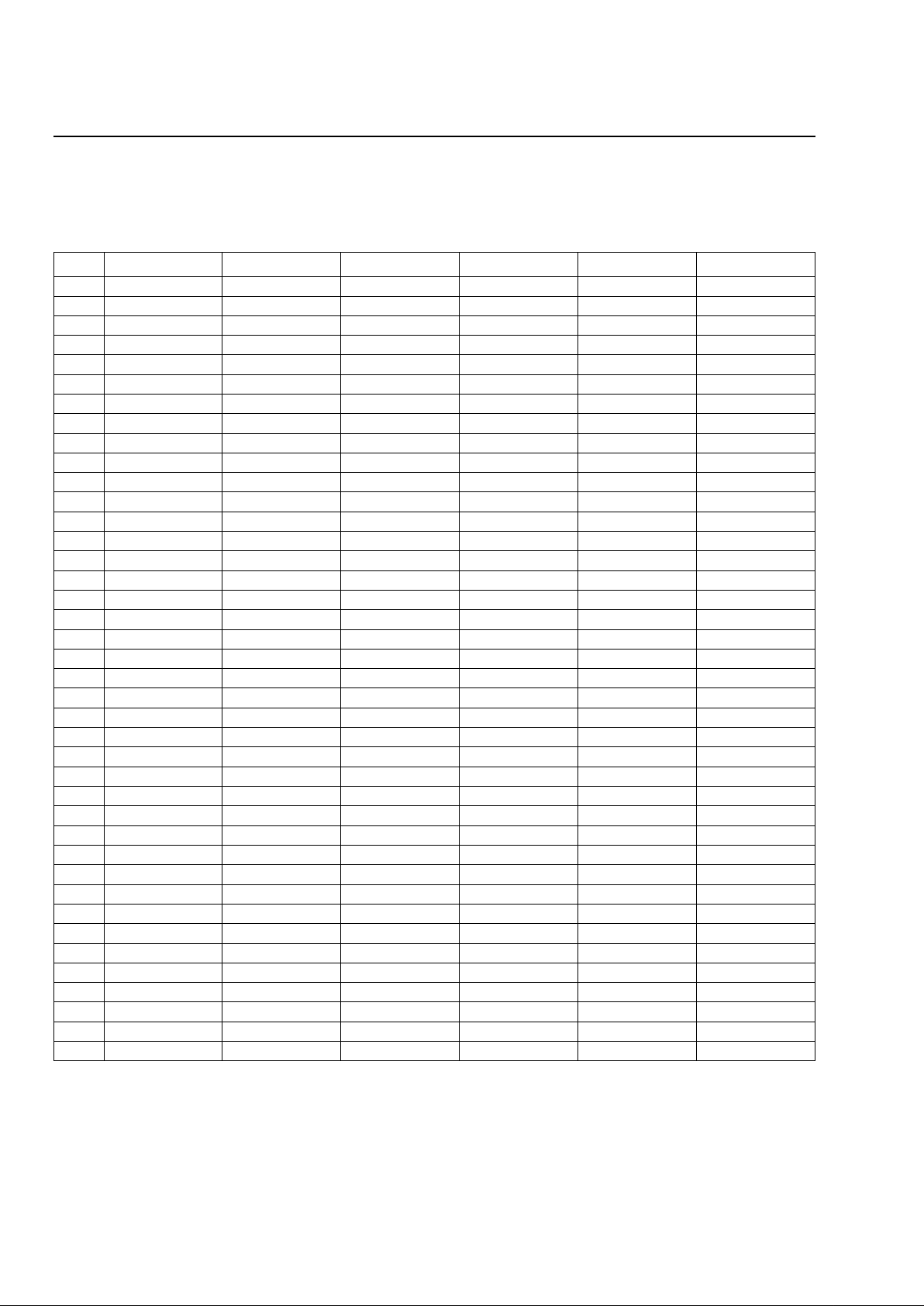

Table 1

. ORCA

Series 2 FPGAs

* The first number in the usable gates column assumes 48 gates per PFU (12 gates per four-input LUT/FF pair) for logic-only designs . The

second number assumes 30% of a design is RAM. PFUs used as RAM are counted at four gates per bit, with each PFU capable of

implementing a 16 x 4 RAM (or 256 gates) per PFU.

Device

Usable

Gates*

# LUTs Registers

Max User

RAM Bits

User

I/Os

Array Size

OR2C04A/OR2T04A 4,800—11,000 400 400 6,400 160 10 x 10

OR2C06A/OR2T06A 6,900—15,900 576 576 9,216 192 12 x 12

OR2C08A/OR2T08A 9,400—21,600 784 724 12,544 224 14 x 14

OR2C10A/OR2T10A 12,300—28,300 1024 1024 16,384 256 16 x 16

OR2C12A/OR2T12A 15,600—35,800 1296 1296 20,736 288 18 x 18

OR2C15A/OR2T15A/OR2T15B 19,200—44,200 1600 1600 25,600 320 20 x 20

OR2C26A/OR2T26A 27,600—63,600 2304 2304 36,864 384 24 x 24

OR2C40A/OR2T40A/OR2T40B 43,200—99,400 3600 3600 57,600 480 30 x 30

Data Sheet

ORCA

Series 2 FPGAs June 1999

2 Lucent Technologies Inc.

Table of Contents

Contents Page Contents Page

Features ......................................................................1

Description...................................................................3

ORCA

Foundry Development System Overview.........5

Architecture .................................................................5

Programmable Logic Cells ..........................................5

Programmable Function Unit...................................5

Look-Up Table Operating Modes ............................7

Latches/Flip-Flops .................................................15

PLC Routing Resources ........................................17

PLC Architectural Description................................22

Programmable Input/Output Cells.............................25

Inputs.....................................................................25

Outputs..................................................................26

5 V Tolerant I/O (OR2TxxB) ..................................27

PCI Compliant I/O..................................................27

PIC Routing Resources .........................................28

PIC Architectural Description.................................29

PLC-PIC Routing Resources.................................30

Interquad Routing......................................................32

Subquad Routing (OR2C40A/OR2T40A Only)......34

PIC Interquad (MID) Routing .................................36

Programmable Corner Cells......................................37

Programmable Routing..........................................37

Special-Purpose Functions....................................37

Clock Distribution Network ........................................37

Primary Clock ........................................................37

Secondary Clock ...................................................38

Selecting Clock Input Pins.....................................39

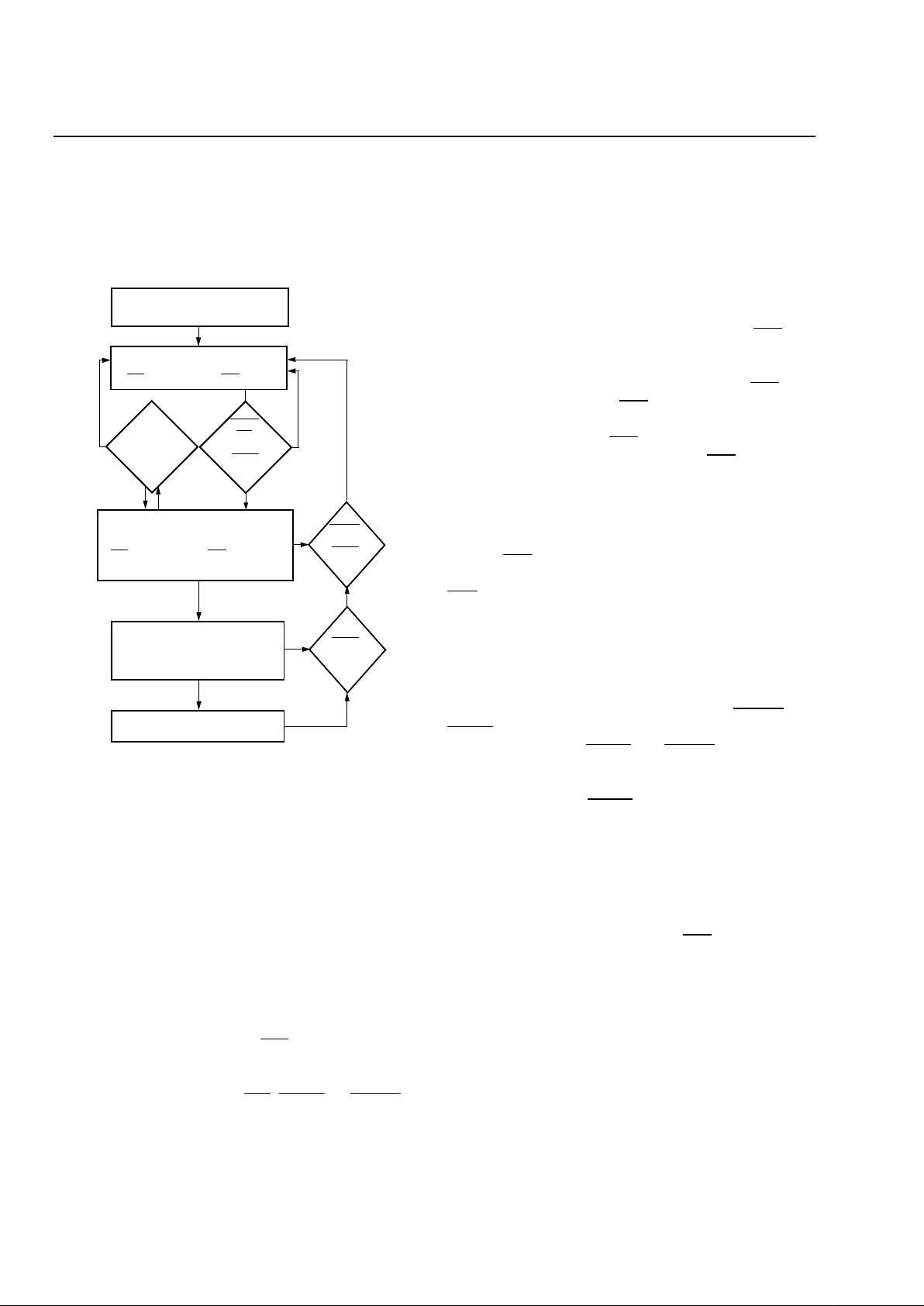

FPGA States of Operation.........................................40

Initialization............................................................40

Configuration .........................................................41

Start-Up .................................................................42

Reconfiguration .....................................................42

Partial Reconfiguration ..........................................43

Other Configuration Options..................................43

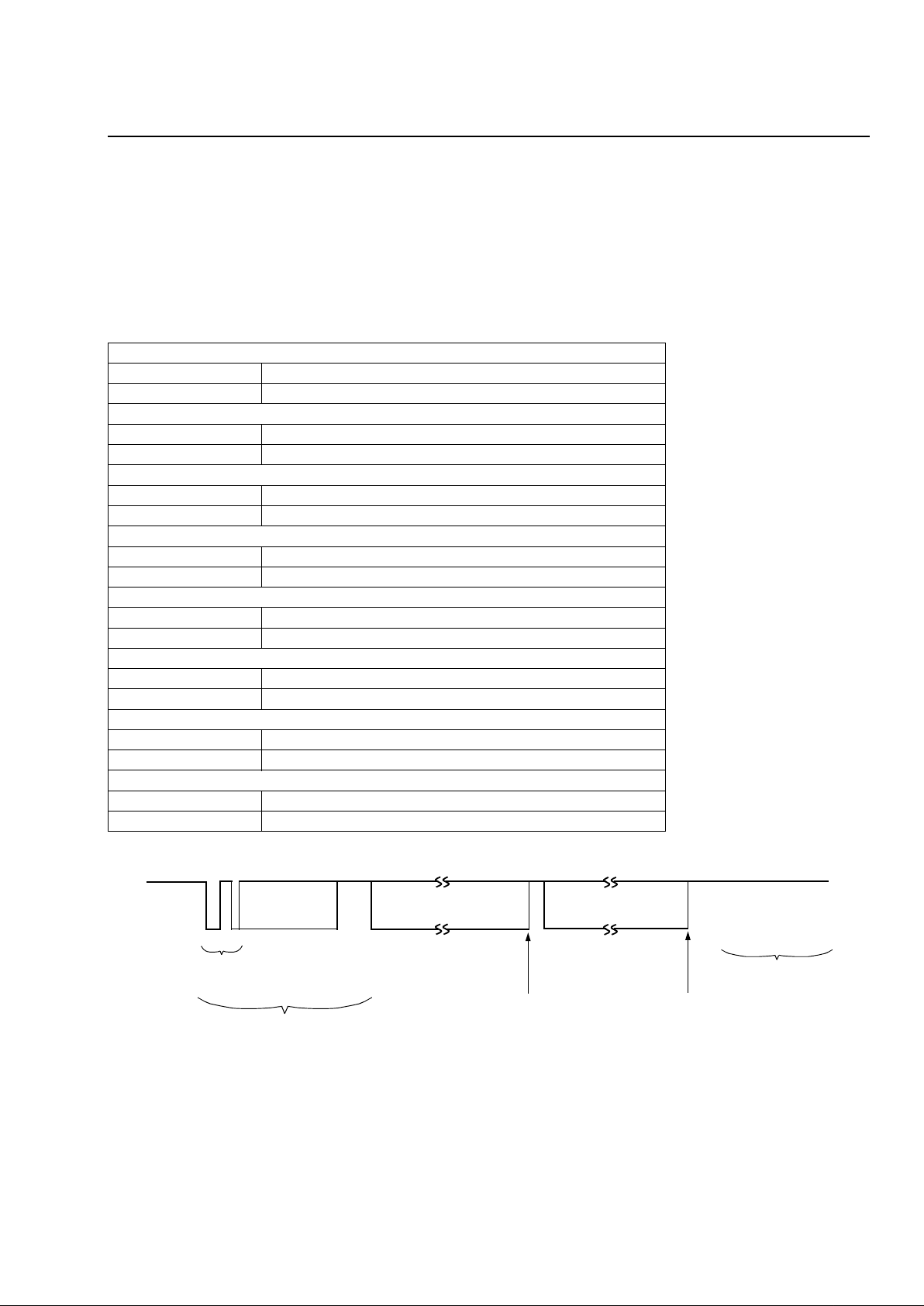

Configuration Data Format ........................................43

Using

ORCA

Foundry to Generate

Configuration RAM Data.....................................44

Configuration Data Frame .....................................44

Bit Stream Error Checking.........................................47

FPGA Configuration Modes.......................................47

Master Parallel Mode.............................................47

Master Serial Mode ...............................................48

Asynchronous Periphera l Mode ..................... .......49

Synchronous Peripheral Mode..............................49

Slave Serial Mode .................................................50

Slave Parallel Mode...............................................50

Daisy Chain ...........................................................51

Special Function Blocks ............................................52

Single Function Blocks ..........................................52

Boundary Scan......................................................54

Boundary-Scan Instructions...................................55

ORCA

Boundary-Scan Circuitry ............................56

ORCA

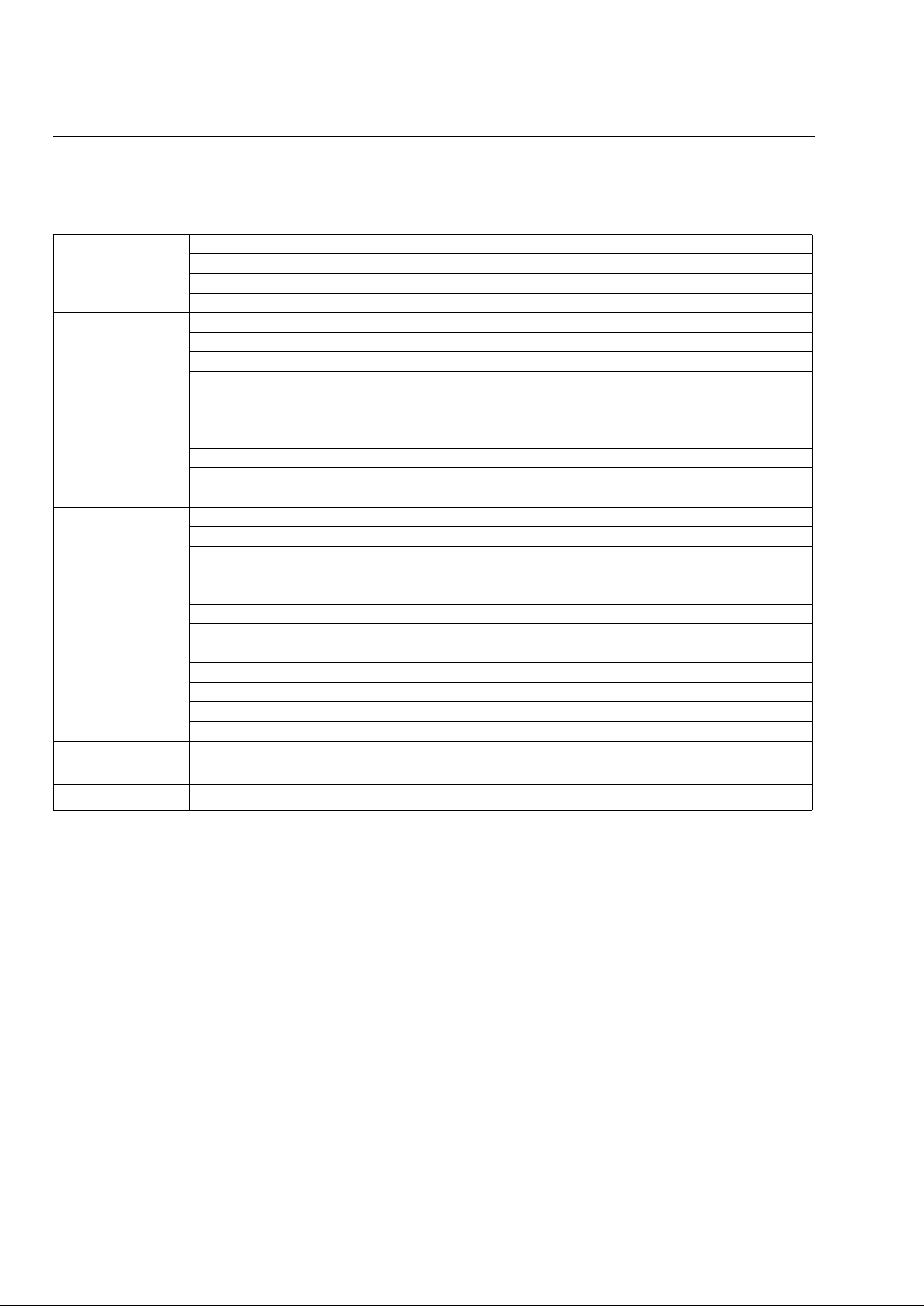

Timing Characteristics....................................60

Estimating Power Dissipation....................................61

OR2CxxA...............................................................61

OR2TxxA ...............................................................63

OR2T15B and OR2T40B................ ...... .................65

Pin Information ..........................................................66

Pin Descriptions................. ...... ....... ...... .................66

Package Compatibility ...........................................68

Compatibility with Series 3 FPGAs........................70

Package Thermal Characteristics............................126

QJA......................................................................126

yJC.......................................................................126

QJC......................................................................126

QJB......................................................................126

Package Coplanarity ...............................................127

Package Parasitics..................................................127

Absolute Maximum Ratings.....................................129

Recommended Operating Conditions......................129

Electrical Characteristics .........................................130

Timing Characteristics .............................................132

Series 2................................................................160

Measurement Conditions.........................................169

Output Buffer Characteristics...................................170

OR2CxxA.............................................................170

OR2TxxA .............................................................171

OR2TxxB .............................................................172

Package Outline Drawings ......................................173

Terms and Definitions..........................................173

84-Pin PLCC........................................................174

100-Pin TQFP......................................................175

144-Pin TQFP......................................................176

160-Pin QFP........................................................177

208-Pin SQFP......................................................178

208-Pin SQFP2....................................................179

240-Pin SQFP......................................................180

240-Pin SQFP2....................................................181

256-Pin PBGA .....................................................182

304-Pin SQFP......................................................183

304-Pin SQFP2....................................................184

352-Pin PBGA .....................................................185

432-Pin EBGA .....................................................186

Ordering Information................................................187

Index........................................................................189

Data Sheet

June 1999

ORCA

Series 2 FPGAs

Lucent Technologies Inc. 3

Description

The

ORCA

Series 2 series of SRAM -bas ed FPGAs are

an enhanced version of the ATT2C/2T architecture.

The latest

ORCA

series includes patented architectural

enhancements that make functions faster and easier to

design while conserving the use of PLCs and routing

resources.

The Series 2 devices can be used as drop-in replacements for the ATT2Cxx/ATT2Txx series, respectively,

and they are also bit stream compatible with each

other. The usable gate counts associated with each

series are provided in Table 1. Both series are offered

in a variety of packages, speed grades, and temperature ranges.

The

ORCA

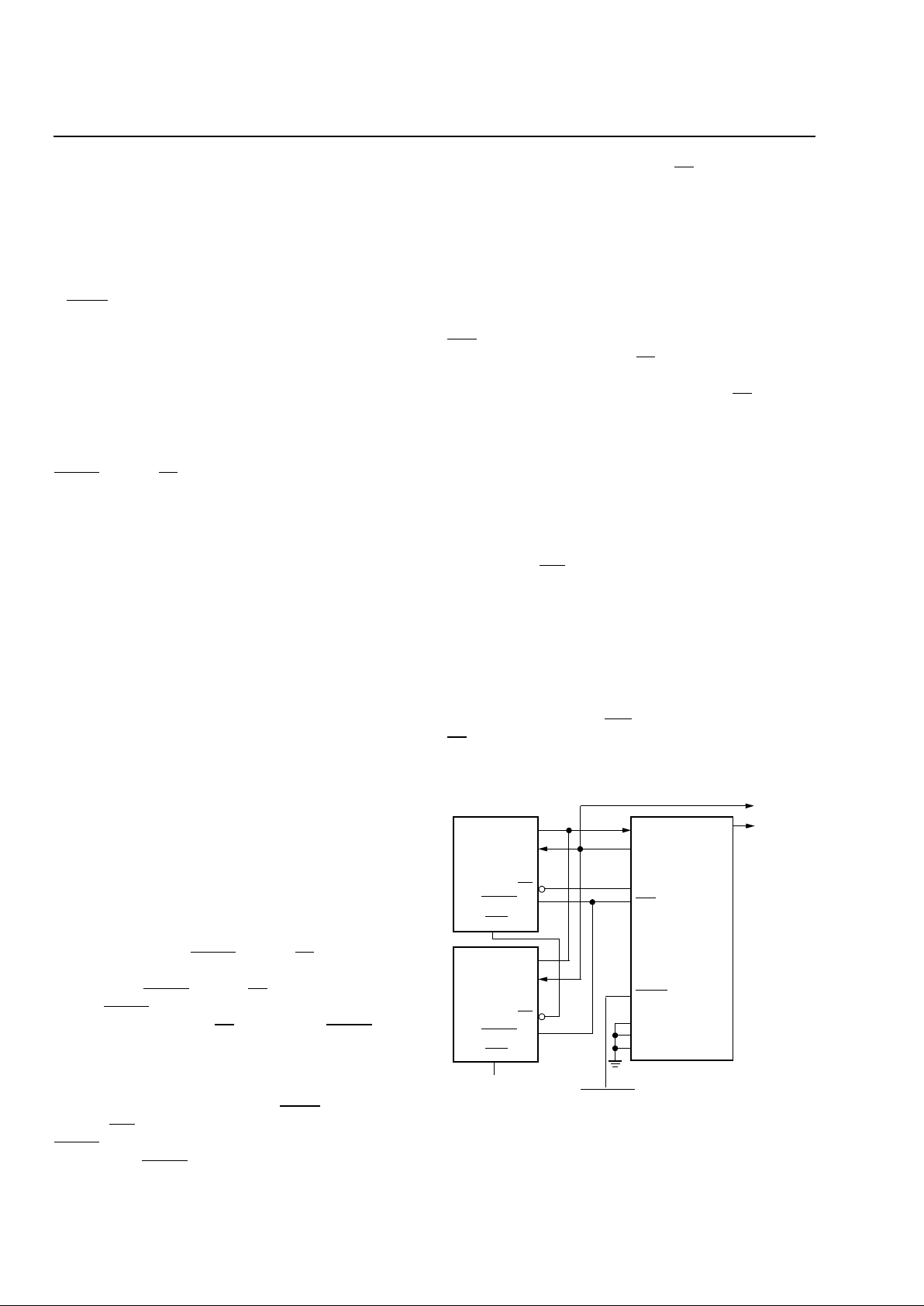

series FPGA consists of two basic ele-

ments: programmable logic cells (PLCs) and program-

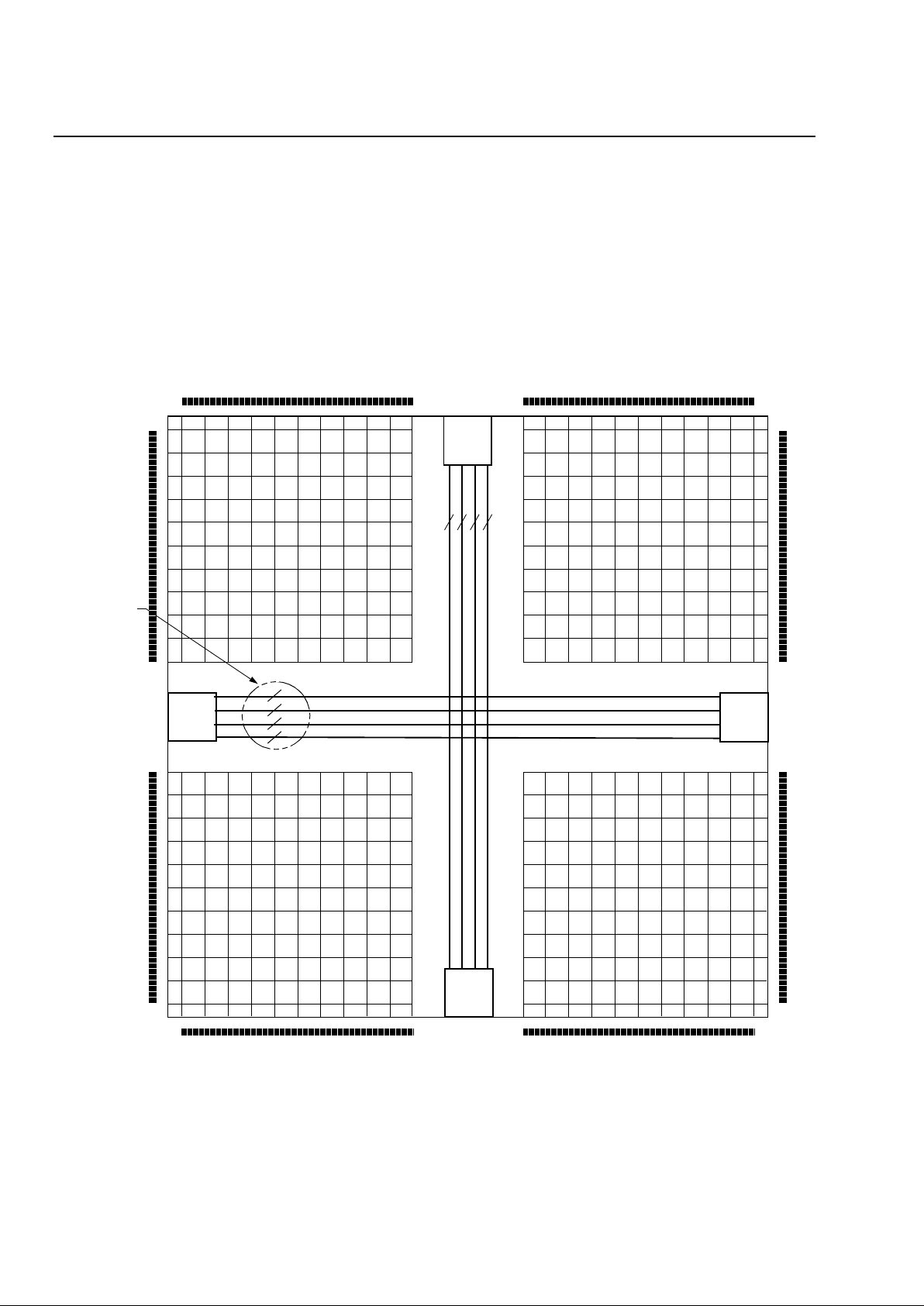

mable input/output cells (PICs). An array of PLCs is

surrounded by PICs as shown in Figure 1. Each PLC

contains a programmable function unit (PFU). The

PLCs and PICs also contain routing resources and

configuration RAM. All logic is done in the PFU. Each

PFU contains four 16-bit look-up tables (LUTs) and four

latches/flip-flops (FFs).

The PLC architecture provides a balanced mix of logic

and routing that allows a higher utilized gate/PFU than

alternative architectures. The routing resources carry

logic signals between PFUs and I/O pads. The routing

in the PLC is symmetrical about the horizontal and vertical axes. This improves routability by allowing a bus of

signals to be routed into the PLC from any direction.

Some examples of the resources required and the performance t hat can be ach ie v ed us ing th ese devices are

represented in Table 2.

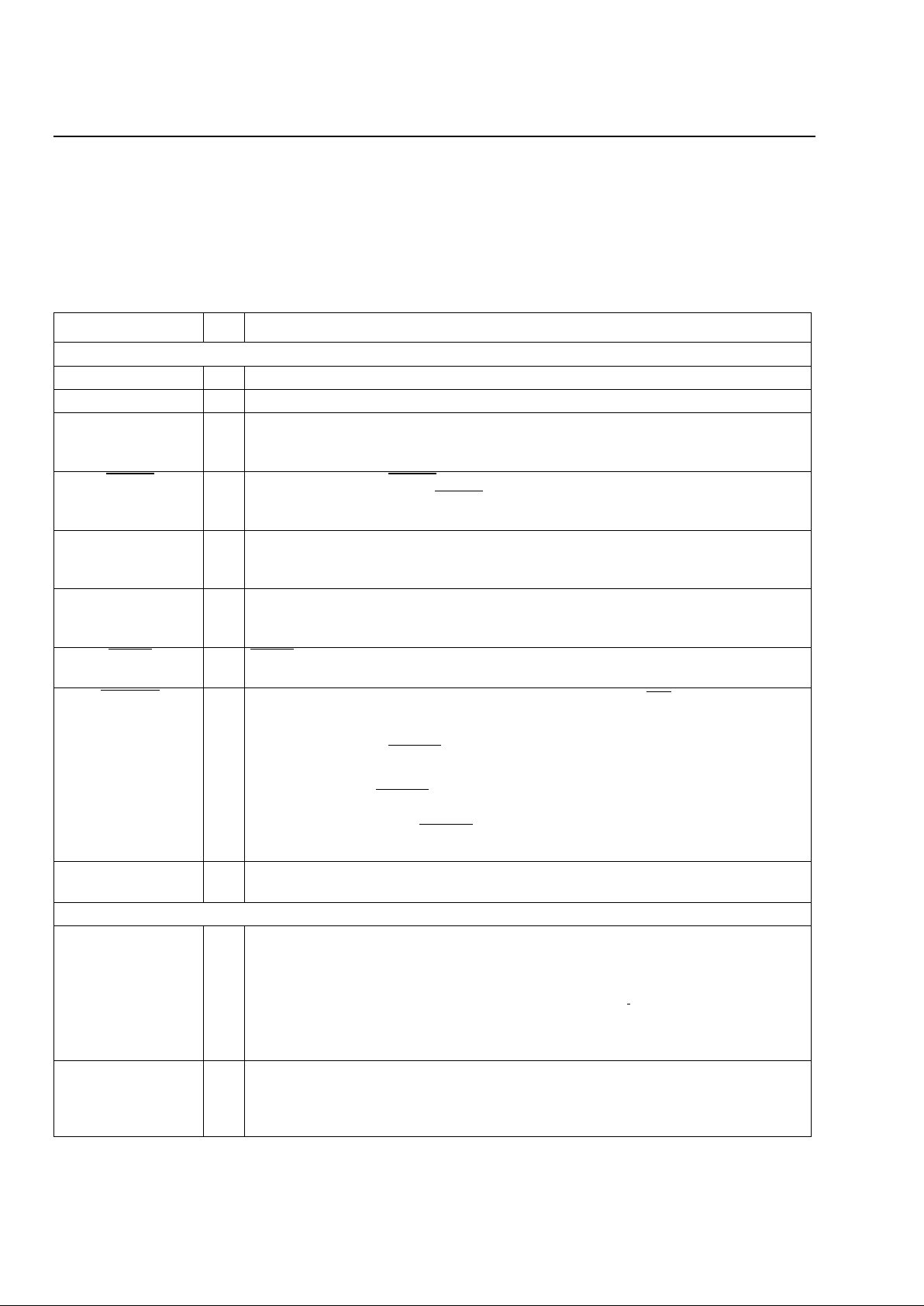

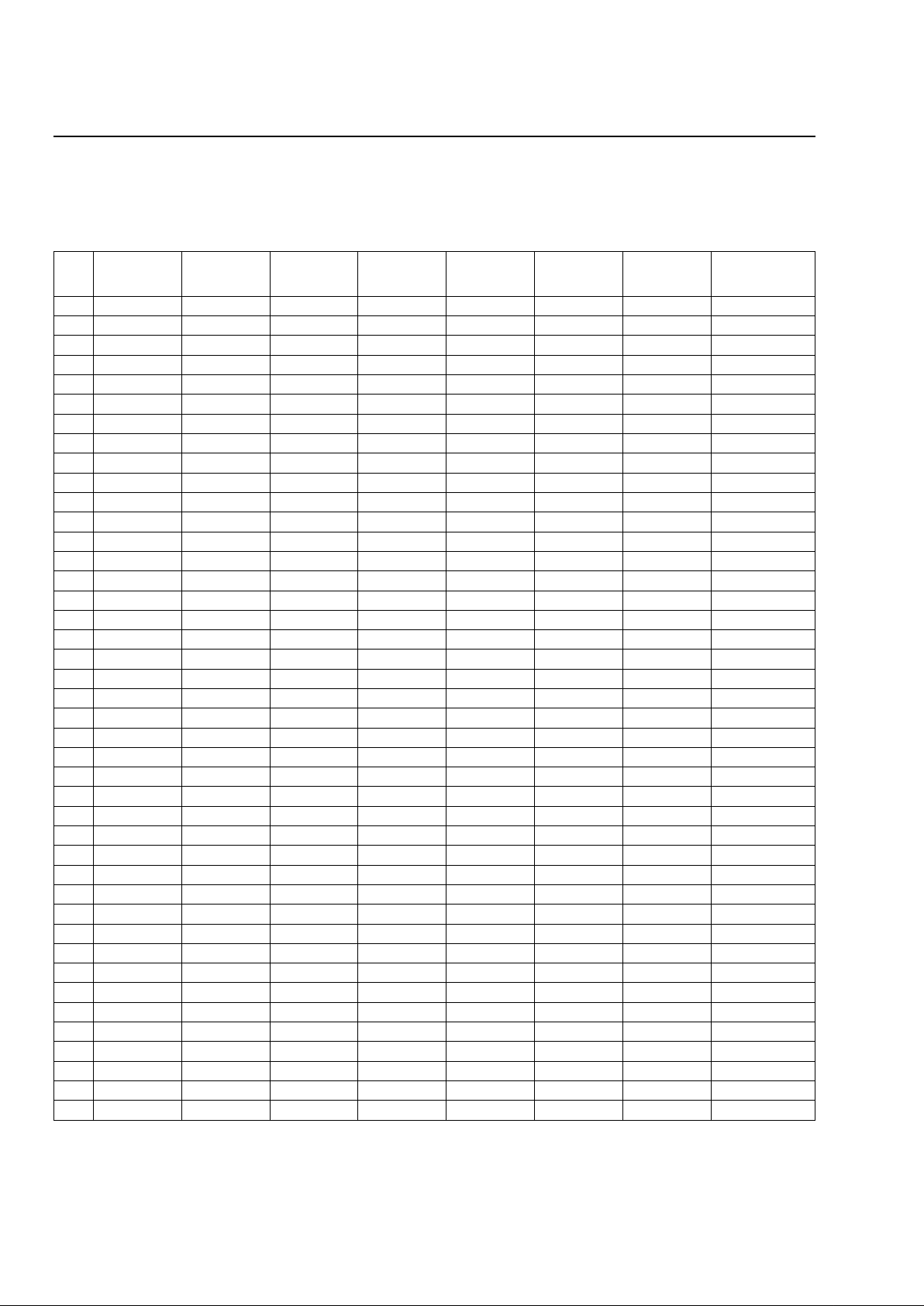

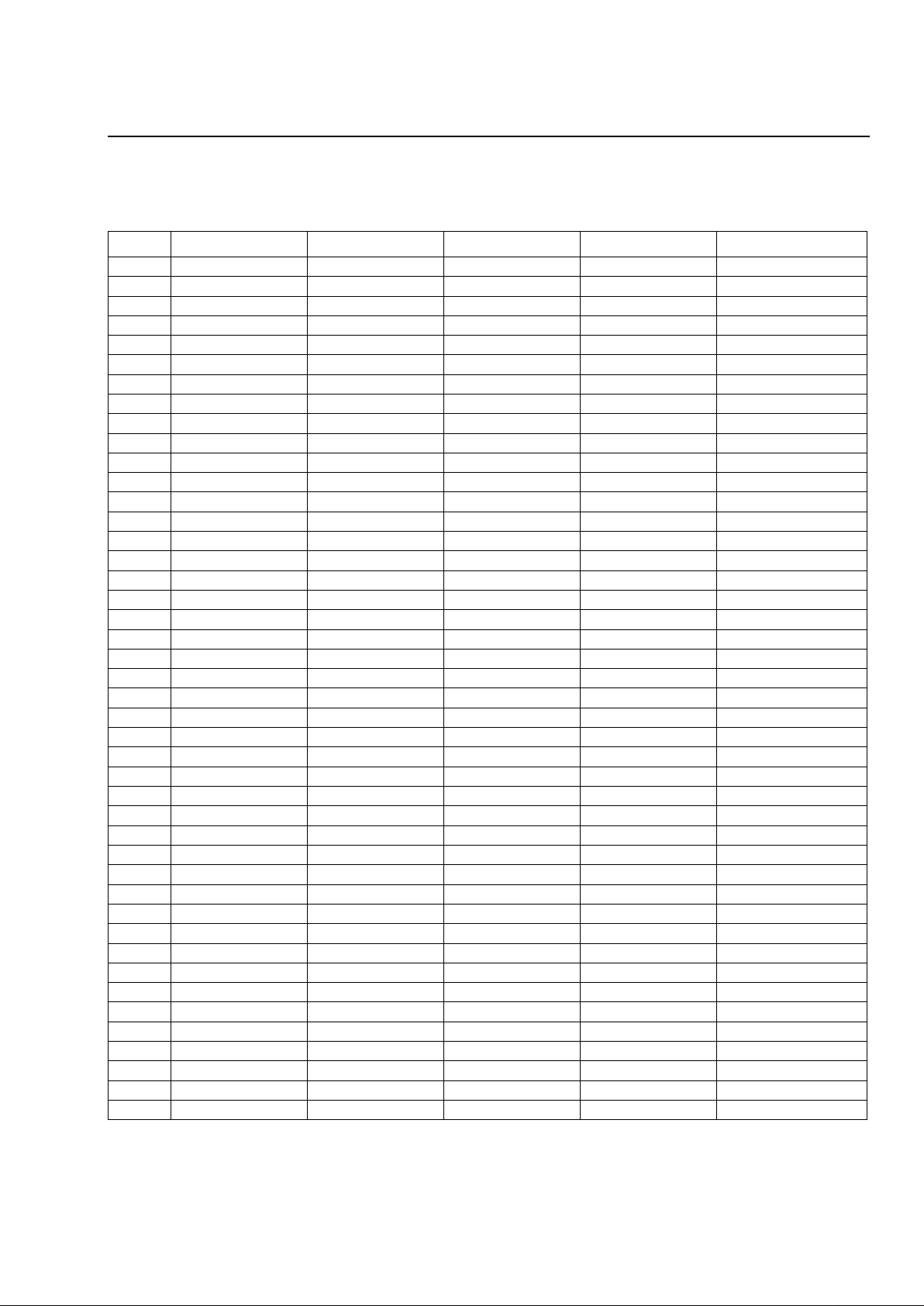

Table 2

. ORCA

Series 2 System Performance

1. Implemented using 4 x 1 multiplier mode (unpipelined), register-to-register, two 8-bit inputs, one 16-bit output.

2. Implemented using two 16 x 12 ROMs and one 12-bit adder, one 8-bit input, one fixed operand, one 16-bit output.

3. Implemented using 4 x 1 multiplier mode (fully pipelined), two 8-bit inputs, one 16-bit output (28 of 44 PFUs contain only pipelining registers).

4. Implemented using 16 x 4 synchronous single-port RAM mode allowing both read and write per clock cycle, including write/read address

multiplexer.

5. Implemented using 16 x 4 synchronous single-port RAM mode allowing either read or write per clock cycle, including write/read address mul-

tiplex er.

6. Implemented using 16 x 2 synchronous dual-port RAM mode.

7. OR2TxxB available only in -7 and -8 speeds only.

8. Speed grades of -5, -6, and -7 are for OR2TxxA devices only.

Function

#

PFUs

Speed Grade

Unit

-2A -3A -4A -5A -6A -7A -7B -8B

16-bit loadable up/down

counter

4 51.0 66.7 87.0 104.2

129.9 144.9 131.6 149.3

MHz

16-bit accumulator 4 51.0 66.7 87.0 104.2

129.9 144.9 131.6 149.3

MHz

8 x 8 parallel multiplier:

— Multiplier mode, unpipelined

1

— ROM mode, unpipelined

2

— Multiplier mode, pipelined

3

22

9

44

14.2

41.5

50.5

19.3

55.6

69.0

25.1

71.9

82.0

31.0

87.7

103.1

36.0

107.5

125.0

40.3

122.0

142.9

37.7

103.1

123.5

44.8

120.5

142.9

MHz

MHz

MHz

32 x 16 RAM:

— Single port (read and write/

cycle)

4

— Single port

5

— Dual port

6

9

9

16

21.8

38.2

38.2

28.6

52.6

52.6

36.2

69.0

83.3

53.8

92.6

92.6

53.8

92.6

92.6

62.5

96.2

96.2

57.5

97.7

97.7

69.4

112.4

112.4

MHz

MHz

MHz

36-bit parity check (internal) 4 13.9 11.0 9.1 7.4

5.6 5.2 6.1 5.1

ns

32-bit address decode

(internal)

3.25 12.3 9.5 7.5 6.1

4.6 4.3 4.8 4.0

ns

Data Sheet

ORCA

Series 2 FPGAs June 1999

4 Lucent Technologies Inc.

Description

(continued)

The FPGA’s functionality is determined by internal configuration RAM. The FPGA’s internal initialization/configuration circuitry loads the configuration data at powerup or under system control. The RAM is loaded by using one of

several configuration modes. The configuration data resides externally in an EEPROM, EPROM, or ROM on the

circuit board, or any other storage media. Serial ROMs provide a simple, low pin count method for configuring

FPGAs, while the peripheral and JTAG configuration modes allow for easy, in-system programming (ISP).

5-6779(F)

Figure 1. Series 2 Array

PL9 PL8 PL7 PL6 PL5 PL4 PL3 PL2 PL1PL13 PL12 PL11

PR12PR11PR9PR8PR7PR6PR5PR4PR3PR2PR1 PR13 PR18PR17PR16PR15PR14RMIDPR10

PT1 PT2 PT3 PT4 PT5 PT6 PT7 PT8 PT9 PT11 PT12

R1C1 R1C2 R1C3 R1C4 R1C5 R1C6 R1C7 R1C8 R1C9 R1C10

R1C18R1C17R1C16R1C15R1C14R1C13R1C12R1C11

PT13 PT14 PT15 PT16 PT17 PT18

PB1 PB2 PB3 PB4 PB5 PB6 PB7 PB8 PB9 PB10 PB11 PB12

PL18 PL17 PL16 PL15 PL14

PB13 PB14 PB15 PB16 PB17 PB18

PL10

BMID

PT10

vIQ

R2C1 R2C2 R2C3 R2C4 R2C5 R2C6 R2C7 R2C8 R2C9 R2C10

R3C1 R3C2 R3C3 R3C4 R3C5 R3C6 R3C7 R3C8 R3C9 R3C10

R4C1 R4C2 R4C3 R4C4 R4C5 R4C6 R4C7 R4C8 R4C9 R4C10

R5C1 R5C2 R5C3 R5C4 R5C5 R5C6 R5C7 R5C8 R5C9 R5C10

R6C1 R6C2 R6C3 R6C4 R6C5 R6C6 R6C7 R6C8 R6C9 R6C10

R7C1 R7C2 R7C3 R7C4 R7C5 R7C6 R7C7 R7C8 R7C9 R7C10

R8C1 R8C2 R8C3 R8C4 R8C5 R8C6 R8C7 R8C8 R8C9 R8C10

R9C1 R9C2 R9C3 R9C4 R9C5 R9C6 R9C7 R9C8 R9C9 R9C10

R10C1 R10C2 R10C3 R10C4 R10C5 R10C6 R10C7 R10C8 R10C9 R10C10

R2C18R2C17R2C16R2C15R2C14R2C13R2C12R2C11

R3C18R3C17R13C16R3C15R3C14R3C13R3C12R3C11

R4C18R4C17R4C16R4C15R4C14R4C13R4C12R4C11

R5C18R5C17R5C16R5C15R5C14R5C13R5C12R5C11

R6C18R6C17R6C16R6C15R6C14R6C13R6C12R6C11

R7C18R7C17R7C16R7C15R7C14R7C13R7C12R7C11

R8C18R8C17R8C16R8C15R8C14R8C13R8C12R8C11

R9C18R9C17R9C16R9C15R9C14R9C13R9C12R9C11

R10C18R10C17R10C16R10C15R10C14R10C13R10C12R10C11

R18C18R18C17R18C16R18C15R18C14R18C13R18C12R18C11

R17C18R17C17R17C16R17C15R17C14R17C13R17C12R17C11

R16C18R16C17R16C16R16C15R16C14R16C13R16C12R16C11

R15C18R15C17R15C16R15C15R15C14R15C13R15C12R15C11

R14C18R14C17R14C16R14C15R14C14R14C13R14C12R14C11

R13C18R13C17R13C16R13C15R13C14R13C13R13C12R13C11

R12C18R12C17R12C16R12C15R12C14R12C13R12C12R12C11

R11C18R11C17R11C16R11C15R11C14R11C13R11C12R11C11

R18C10R18C9R18C8R18C7R18C6R18C5R18C4R18C3R18C2R18C1

R17C10R17C9R17C8R17C7R17C6R17C5R17C4R17C3R17C2R17C1

R16C10R16C9R16C8R16C7R16C6R16C5R16C4R16C3R16C2R16C1

R15C10R15C9R15C8R15C7R15C6R15C5R15C4R15C3R15C2R15C1

R14C10R14C9R14C8R14C7R14C6R14C5R14C4R14C3R14C2R14C1

R13C10R13C9R13C8R13C7R13C6R13C5R13C4R13C3R13C2R13C1

R12C10R12C9R12C8R12C7R12C6R12C5R12C4R12C3R12C2R12C1

R11C10R11C9R11C8R11C7R11C6R11C5R11C4R11C3R11C2R11C1

hIQ

TMID

LMID

Lucent Technologies Inc. 5

Data Sheet

June 1999

ORCA

Series 2 FPGAs

ORCA

Foundry

Development System

Overview

The

ORCA

Foundry Development System interfaces to

front-end design entry tools and provides the tools to

produce a configured FPGA. In the design flow, the

user defines the functionality of the FPGA at two

points: at design entry and at the bit stream generation

stage.

Following design entry, the dev elopment system’s map ,

place, and route tools translate the netlist into a routed

FPGA. Its bit stream generator is then used to generate

the configuration data which is loaded into the FPGA’s

internal configuration RAM. When using the bit stream

generator, the user selects options that affect the functionality of the FPGA. Combined with the front-end

tools,

ORCA

Foundry produces configuration data that

implements the various logic and routing options discussed in this data sheet.

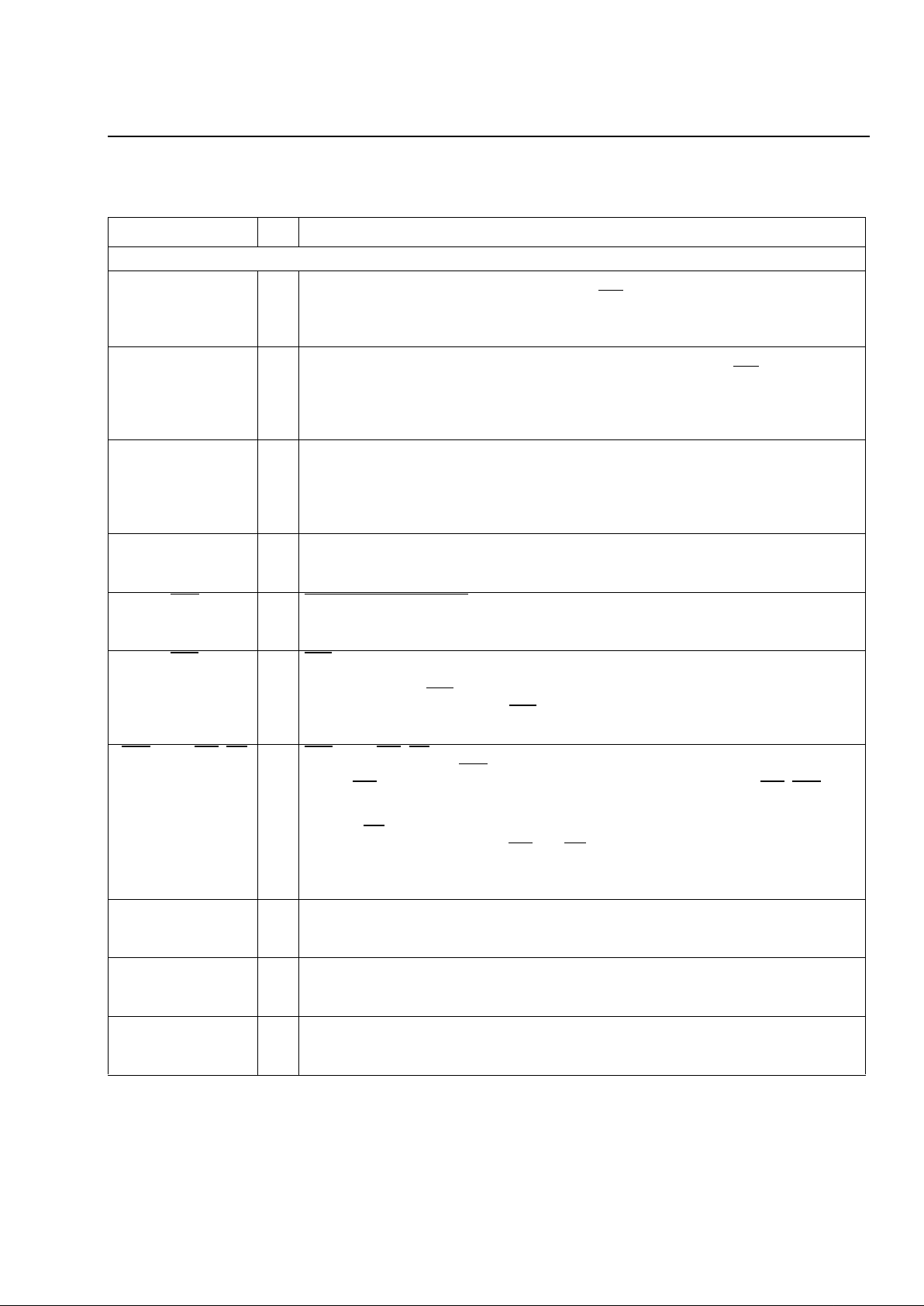

Architecture

The

ORCA

Series FPGA is comprised of two basic

elements: PLCs and PICs. Figure 1 shows an array of

programmable logic cells (PLCs) surrounded by programmable input/output cells (PICs). The Series 2 has

PLCs arranged in an array of 20 rows and 20 columns.

PICs are located on all four sides of the FPGA between

the PLCs and the IC edge.

The location of a PLC is indicated by its row and column so that a PLC in the second row and third column

is R2C3. PICs are indicated similarly, with PT (top) and

PB (bottom) designating rows and PL (left) and PR

(right) designating columns, followed by a number. The

routing resources and configuration RAM are not

shown, but the interquad routing blocks (hIQ, vIQ)

present in the Series 2 series are shown.

Each PIC contains the necessary I/O buffers to interface to bond pads. The PICs also contain the routing

resources needed to connect signals from the bond

pads to/from PLCs. The PICs do not contain any useraccessible logic elements, such as flip-flops.

Combinatorial logic is done in look-up tables (LUTs)

located in the PFU. The PFU can be used in different

modes to meet different logic requirements. The LUT’s

configurable medium-/large-grain architecture can be

used to implement from one to four combinatorial logic

functions. The flexibility of the LUT to handle wide input

functions, as well as multiple smaller input functions,

maximizes the gate count/PFU.

The LUTs can be programmed to operate in one of

three modes: combinatorial, ripple, or memory. In com-

binatorial mode, the LUTs can realize any four-, five-,

or six-input logic functions. In ripple mode, the highspeed carry logic is used for arithmetic functions, the

new multiplier function, or the enhanced data path

functions. In memory mode, the LUTs can be used as a

16 x 4 read/write or read-only memory (asynchronous

mode or the new synchronous mode) or a new 16 x 2

dual-por t mem ory.

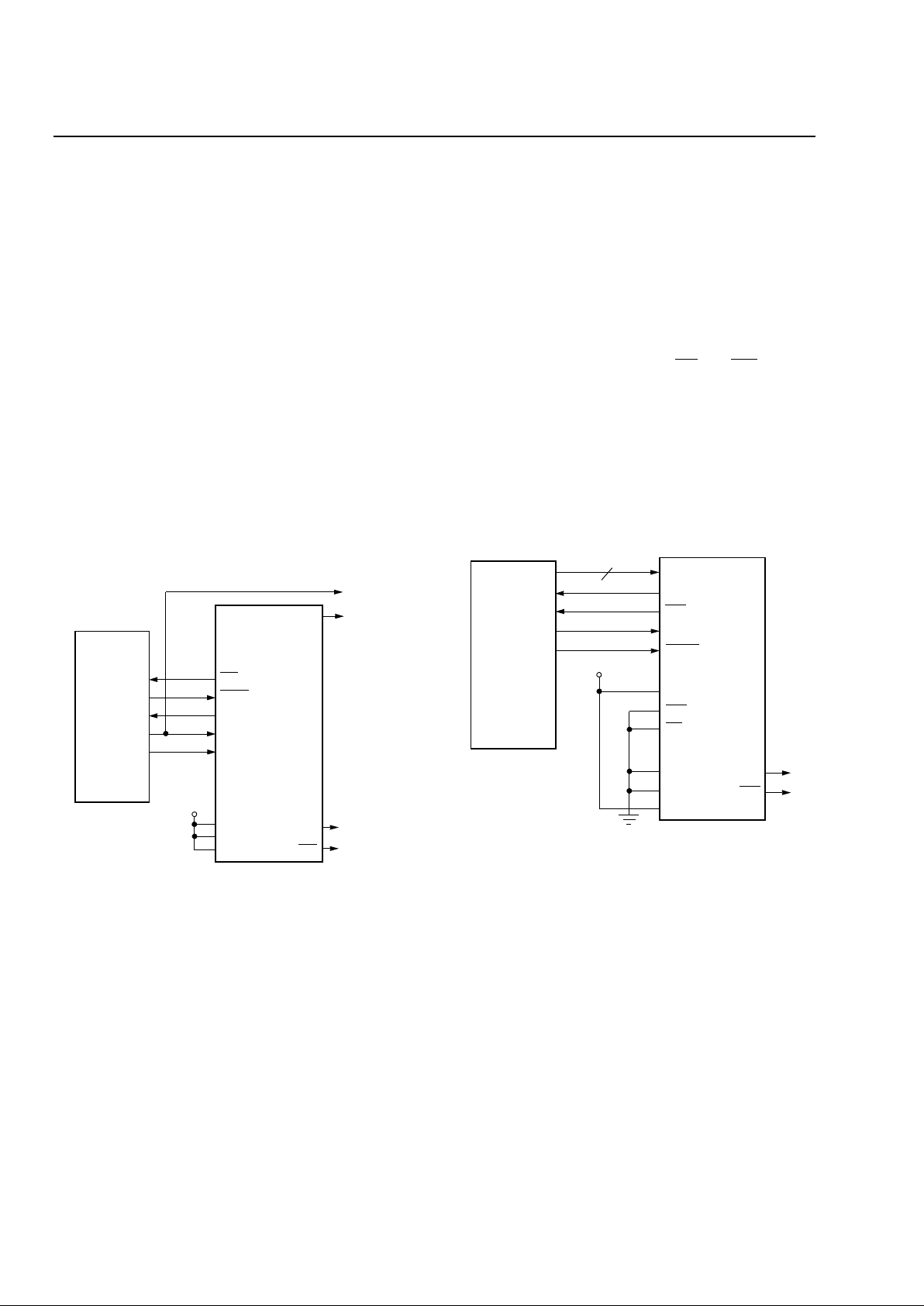

Programmable Logic Cells

The programmable logic cell (PLC) consists of a programmable function unit (PFU) and routing resources.

All PLCs in the array are identical. The PFU, which contains four LUTs and four latches/FFs for logic implementation, is discussed in the next section.

Programmable Functio n Unit

The PFUs are used for logic. Each PFU has 19 external inputs and six outputs and can operate in several

modes. The functionality of the inputs and outputs

depends on the operating mode.

The PFU uses three input data buses (A[4:0], B[4:0],

WD[3:0]), four control inputs (C0, CK, CE, LSR), and a

carry input (CIN); the last is used for fast arithmetic

functions. There is a 5-bit output bus (O[4:0]) and a

carry-out (COUT).

5-2750(F).r3

Figure 2. PFU Ports

PROGRAMMABLE LOGIC CELL (PLC)

WD3

WD2

WD1

WD0

A4

A3

A2

A1

A0

B4

B3

B2

B1

B0

O4

O3

O2

O1

O0

PROGRAMMABLE

FUNCTION UNIT

CE LSRC0 CK

(ROUTING RESOURCES, CONFIGURATION RAM)

CIN

(PFU)

COUT

Data Sheet

ORCA

Series 2 FPGAs June 1999

6 Lucent Technologies Inc.

Programmable Logic Cells

(continued))

Key: C = controlled by configuration RAM.

Figure 3. Simplified PFU Diagram

5-4573(F)

A4

A3

A2

A1

A4

A3

A2

A1

QLUT3

A0

CARRY

CARRY

A3

A2

A1

A0

QLUT2

B4

B3

B2

B1

B4

B3

B2

B1

QLUT1

B0

CARRY

CARRY

B3

B2

B1

B0

QLUT0

CIN

C0

LSR

GSR

WD[3:0]

CK

CKEN

TRI

PFU_XOR

B4

A4

PFU_NAND

PFU_MUX

C

C

C C

WD3

WD2

WD1

WD0

C

C

C

T

T

T

T

REG3

SR EN

REG2

SR EN

REG1

SR EN

REG0

SR EN

O4

O3

O2

O1

O0

F3

C

C

COUT

F2

F1

F0

D0

D1

D2

D3

Q0

Q1

Q2

Q3

C

T

T

T

T

C

Figure 2 and Figure 3 show high-level and detailed

views of the ports in the PFU, respectively. The ports

are referenced with a two- to four-character suffix to a

PFU’s location. As mentioned, there are two 5-bit input

data buses (A[4:0] and B[4:0]) to the LUT, one 4-bit

input data bus (WD[3:0]) to the latches/FFs, and an

output data bus (O[4:0]).

Figure 3 shows the four latches/FFs (REG[3:0]) and the

64-bit look-up table (QLUT[3:0]) in the PFU. The PFU

does combinatorial logic in the LUT and sequential

logic in the latches/FFs. The LUT is static random

access memory (SRAM) and can be used for read/

write or read-only memory. The eight 3-state buffers

found in each PLC are also shown, although they actually reside external to the PFU.

Each latch/FF can accept data from the LUT. Alternatively, the latches/FFs can accept direct data from

WD[3:0], eliminating the LUT delay if no combinatorial

function is needed. The LUT outputs can bypass the

latches/FFs, which reduces the delay out of the PFU. It

is possible to use the LUT and latches/FFs more or

less independently. For example, the latches/FFs can

be used as a 4-bit shift register, and the LUT can be

used to detect when a register has a particular pattern

in it.

Lucent Technologies Inc. 7

Data Sheet

June 1999

ORCA

Series 2 FPGAs

Programmable Logic Cells

(continued)

Table 3 lists the basic operating modes of the LUT. The

operating mode affects the functionality of the PFU

input and output ports and internal PFU routing. For

example, in some operating modes, the WD[3:0] inputs

are direct data inputs to the PFU latches/FFs. In the

dual 16 x 2 memory mode, the same WD[3:0] inputs

are used as a 4-bit data input bus into LUT memory.

The PFU is used in a variety of modes, as illustrated in

Figures 4 through 11, and it is these specific modes

that are most relevant to PFU functionality.

PFU Control Inputs

The four control inputs to the PFU are clock (CK), local

set/reset (LSR), clock enable (CE), and C0. The CK,

CE, and LSR inputs control the operation of all four

latches in the PFU. An active-low global set/reset

(GSRN) signal is also available to the latches/FFs in

every PFU. Their operation is discussed briefly here,

and in more detail in the Latches/Flip-Flops section.

The polarity of the control inputs can be inverted.

The CK input is distributed to each PFU from a vertical

or horizontal net. The CE input inhibits the latches/FFs

from responding to data inputs. The CE input can be

disabled, always enabling the clock. Each latch/FF can

be independently programmed to be set or reset by the

LSR and the global set/reset (GSRN) signals. Each

PFU’s LSR input can be configured as synchronous or

asynchronous. The GSRN signal is always asynchronous. The LSR signal applies to all four latches/FFs in

a PFU. The LSR input can be disabled (the default).

The asynchronous set/reset is dominant over clocked

inputs.

The C0 input is used as an input into the special PFU

gates for wide functions in combinatorial logic mode.

In the memory modes, this input is also used as the

write-port enable input. The C0 input can be disabled

(the default).

Look-Up Table Operating Modes

The look-up table (LUT) can be configured to operate

in one of three general modes:

■

Combinatorial logic mode

■

Ripple mode

■

Memory mode

The combinatorial logic mode uses a 64-bit look-up

table to implement Boolean functions. The two 5-bit

logic inputs, A[4:0] and B[4:0], and the C0 input are

used as LUT inputs. The use of these ports changes

based on the PFU operating mode.

The functionality of the LUT is determined by its operating mode. The entries in Tab le 3 show the basic modes

of operation for combinatorial logic, ripple, and memory

functions in the LUT. Depending on the operating

mode, the LUT can be divided into sub-LUTs. The LUT

is comprised of two 32-bit half look-up tables, HLUTA

and HLUTB. Each half look-up table (HLUT) is comprised of two quarter look-up tables (QLUTs). HLUTA

consists of QLUT2 and QLUT3, while HLUTB consists

of QLUT0 and QLUT1. The outputs of QLUT0, QLUT1,

QLUT2, and QLUT3 are F0, F1, F2, and F3, respectively.

Table 3. Look-Up Table Operating Modes

For combinatorial logic, the LUT can be used to do any

single function of six inputs, any two functions of five

inputs, or four functions of four inputs (with some inputs

shared), and three special functions based on the two

five-input functions and C0.

Mode Function

F4A Two functions of four inputs, some inputs

shared (QLUT2/QLUT3)

F4B Two functions of four inputs, some inputs

shared (QLUT0/QLUT1)

F5A One function of five inputs (HLUTA)

F5B One function of five inputs (HLUTB)

R 4-bit ripple (LUT)

MA 16 x 2 asynchronous memory (HLUTA)

MB 16 x 2 asynchronous memory (HLUTB)

SSPM 16 x 4 synchronous single-port memory

SDPM 16 x 2 synchronous dual-port memory

8 Lucent Technologies Inc.

Data Sheet

ORCA

Series 2 FPGAs June 1999

Programmable Logic Cells

(continued)

The LUT ripple mode operation offers standard arithmetic functions, such as 4-bit adders, subtractors,

adder/subtractors, and counters. In the

ORCA

Series 2, there are two new ripple modes available.

The first new mode is a 4 x 1 multiplier, and the second

is a 4-bit comparator. These new modes offer the

advantages of faster speeds as well as denser logic

capabilities.

When the LUT is configured to operate in the memory

mode, a 16 x 2 asynchronous memory fits into an

HLUT. Both the MA and MB modes were available in

previous

ORCA

architectures, and each mode can be

configured in an HLUT separately. In the Series 2,

there are two new memory modes available. The first is

a 16 x 4 synchronous single-port memory (SSPM), and

the second is a 16 x 2 synchronous dual-port memory

(SDPM). These new modes offer easier implementation, faster speeds, denser RAMs, and a dual-port

capability that wasn’t previously offered as an option in

the ATT2Cxx/ATT2Txx families.

If the LUT is configured to operate in the ripple mode, it

cannot be used for basic combinatorial logic or memory

functions. In modes other than the ripple, SSPM, and

SDPM modes, combinations of operating modes are

possible. For example, the LUT can be configured as a

16 x 2 RAM in one HLUT and a five-input combinatorial

logic function in the second HLUT. This can be done by

configuring HLUTA in the MA mode and HLUTB in the

F5B mode (or vice versa).

F4A/F4B Mode—Two Four-Input Functions

Each HLUT can be used to implement two four-input

combinatorial functions, but the total number of inputs

into each HLUT cannot exceed five. The two QLUTs

within each HLUT share three inputs. In HLUTA, the

A1, A2, and A3 inputs are shared by QLUT2 and

QLUT3. Similarly, in HLUTB, the B1, B2, and B3 inputs

are shared by QLUT0 and QLUT1. The four outputs

are F0, F1, F2, and F3. The results can be routed to

the D0, D1, D2, and D3 latch/FF inputs or as an output

of the PFU. The use of the LUT for four functions of up

to four inputs each is given in Figure 4.

F5A/F5B Mode—One Five-Input Variable Function

Each HLUT can be used to implement any five-input

combinatorial function. The input ports are A[4:0] and

B[4:0], and the output ports are F0 and F3. One five or

less input function is input into A[4:0], and the second

five or less input function is input into B[4:0]. The

results are routed to the latch/FF D0 and latch/FF D3

inputs, or as a PFU output. The use of the LUT for two

independent functions of up to five inputs is shown in

Figure 5. In this case, the LUT is configured in the F5A

and F5B modes. As a variation, the LUT can do one

function of up to five input variables and two four-input

functions using F5A and F4B modes or F4A and F5B

modes.

5-2753(F).r2

Figure 4. F4 Mode—Four Functions of Four-

Input Variables

5-2845(F).r2

Figure 5. F5 Mode—Two Functions of Five-Input

Variables

QLUT2

A3

A3

A2

A1

A0

A2

A1

A0

F2

QLUT3

A4

A4

A3

A2

A1

A3

A2

A1

F3

HLUTA

QLUT0

B3

B3

B2

B1

B0

B2

B1

B0

F0

QLUT1

B4

B4

B3

B2

B1

B3

B2

B1

F1

HLUTB

QLUT3

QLUT2

F3

QLUT1

QLUT0

B4

B3

B2

B1

B0

F0

WEA

A3

A2

A1

A0

B4

B3

B2

B1

B0

A4

A3

A2

A1

A0

HLUTA

HLUTB

c0

WPE

WD3

WD2

WD3

WD2

F2

Lucent Technologies Inc. 9

Data Sheet

June 1999

ORCA

Series 2 FPGAs

Programmable Logic Cells

(continued)

F5M and F5X Modes—Special Function Modes

The PFU contains logic to implement two special function modes which are variations on the F5 mode. As

with the F5 mode, the LUT implements two independent five-input functions. Figure 6 and Figure 7 show

the schematics for F5M and F5X modes, respectively.

The F5X and F5M functions differ from the basic F5A/

F5B functions in that there are three logic gates which

have inputs from the two 5-input LUT outputs. In some

cases, this can be used for faster and/or wider logic

functions.

As can be seen, two of the three inputs into the NAND,

XOR, and MUX gates, F0 and F3, are from the LUT.

The third input is from the C0 input into PFU. Since the

C0 input bypasses the LUTs, it has a much smaller

delay through the PFU than for all other inputs into the

special PFU gates. This allows multiple PFUs to be

cascaded together while reducing the delay of the critical path through the PFUs. The output of the first special function (either XOR or MUX) is F1. Since the XOR

and MUX share the F1 output, the F5X and F5M

modes are mutually exclusive. The output of the NAND

PFU gate is F2 and is always available in either mode.

To use either the F5M or F5X functions, the LUT must

be in the F5A/F5B mode; i.e., only 5-input LUTs

allowed. In both the F5X and F5M functions, the outputs of the five-input combinatorial functions, F0 and

F3, are also usable simultaneously with the special

PFU gate outputs.

The output of the MUX is:

F1 = (HLUTA & C0) + (HLUTB &

C0

)

F1 = (F3 & C0) + (F0 &

C0

)

The output of the exclusive OR is:

F1 = HLUTA ⊕ HLUTB ⊕ C0

F1 = F3 ⊕ F0 ⊕ C0

The output of the NAND is:

F2 =

HLUTA & HLUTB & C0

F2 = F3 & F0 & C0

5-2754(F).r3

Figure 6. F5M Mode—Multiplexed Function of T w o

Independent Five-Input Variable

Functions

5-2755(F).r2

Figure 7. F5X Mode—Exclusive OR Function of T wo

Independent Five-Input Variable

Functions

QLUT3

QLUT2

A4

A4

A3

A2

A1

A0

A3

A2

A1

A0

QLUT1

QLUT0

B4

B4

B3

B2

B1

B0

B3

B2

B1

B0

C0

F3

F0

F1

F0

F2

F3

A4 A4

A3

A2

A1

A0

A3

A2

A1

A0

B4 B4

B3

B2

B1

B0

B3

B2

B1

B0

C0

F3

F0

F1

F0

F2

F3

HLUTA

HLUTB

10 Lucent Technologies Inc.

Data Sheet

ORCA

Series 2 FPGAs June 1999

Programmable Logic Cells

(continued)

5-2751(F).r3

Figure 8. F5M Mode—One Six-Input Variable

Function

F5M Mode—One Six-Input Variable Function

The LUT can be used to implement any function of sixinput variables. As shown in Figure 8, five input signals

(A[4:0]) are routed into both the A[4:0] and B[4:0] ports,

and the C0 port is used for the sixth input. The output

port is F1.

Ripple Mode

The LUT can do nibble-wide ripple functions with highspeed carry logic. Each QLUT has a dedicated carryout net to route the carry to/from the adjacent QLUT.

Using the internal carry circuits, fast arithmetic and

counter functions can be implemented in one PFU.

Similarly, each PFU has carry-in (CIN) and carry-out

(COUT) ports for fast-carry routing between adjacent

PFUs.

The ripple mode is generally used in operations on two

4-bit buses. Each QLUT has two operands and a ripple

(generally carry) input, and provides a result and ripple

(generally carry) output. A single bit is rippled from the

previous QLUT and is used as input into the current

QLUT. For QLUT0, the ripple input is from the PFU CIN

port. The CIN data can come from either the fast-carry

routing or the PFU input B4, or it can be tied to logic 1

or logic 0.

The resulting output and ripple output are calculated by

using generate/propagate circuitry. In ripple mode, the

two operands are input into A[3:0] and B[3:0]. The four

result bits, one per QLUT, are F[3:0] (see Figure 9).

The ripple output from QLUT3 can be routed to dedicated carry-out circuitry into any of four adjacent PLCs,

or it can be placed on the O4 PFU output, or both. This

allows the PLCs to be cascaded in the ripple mode so

that nibble-wide ripple functions can be expanded easily to any length.

5-2756(F).r32

Figure 9. Ripple Mode

The ripple mode can be used in one of four submodes.

The first of these is

adder/subtractor mode

. In this

mode, each QLUT generates two separate outputs.

One of the two outputs selects whether the carry-in is

to be propagated to the carry-out of the current QLUT

or if the carry-out needs to be generated. The result of

this selection is placed on the carry-out signal, which is

connected to the next QLUT or the COUT signal, if it is

the last QLUT (QLUT3).

The other QLUT output creates the result bit for each

QLUT that is connected to F[3:0]. If an adder/subtractor

is needed, the control signal to select addition or subtraction is input on A4. The result bit is created in onehalf of the QLUT from a single bit from each input bus,

along with the ripple input bit. These inputs are also

used to create the programmable propagate.

QLUT3

QLUT2

A4

A4

A3

A2

A1

A0

A3

A2

A1

A0

QLUT1

QLUT0

B4

B4

B3

B2

B1

B0

B3

B2

B1

B0

C0

F3

F0

F1

QLUT3

B3

B3

A3

A3

F3

QLUT2

B2

B2

A2

A2

F2

QLUT1

B1

B1

A1

A1

F1

QLUT0

B0

B0

A0

A0

F0

CIN

CIN

COUT

COUT

Lucent Technologies Inc. 11

Data Sheet

June 1999

ORCA

Series 2 FPGAs

Programmable Logic Cells

(continued)

The second submode is the

counter submode

(see

Figure 10). The present count is supplied to input

A[3:0], and then output F[3:0] will either be incremented by one for an up counter or decremented by

one for a down counter. If an up counter or down

counter is needed, the control signal to select the direction (up or down) is input on A4. Generally, the latches/

FFs in the same PFU are used to hold the present

count value.

5-4643(F).r1

Figure 10. Counter Submode with Flip-Flops

In the third submode,

multiplier submode

, a single

PFU can affect a 4 x 1-bit multiply and sum with a partial product (see Figure 11). The multiplier bit is input at

A4, and the multiplicand bits are input at B[3:0], where

B3 is the most sign ifi cant bi t (M SB) . A[ 3:0 ] c ontai ns the

partial product (or other input to be summed) from a

previous stage. If A4 is logical 1, the multiplicand is

added to the partial product. If A4 is logical zero, zero is

added to the partial product, which is the same as

passing the partial product. CIN can hold the carry-in

from the less significant PFUs if the multiplicand is

wider than 4 bits, and COUT holds any carry-out from

the addition, which may then be used as part of the

product or routed to another PFU in multiplier mode for

multiplicand width expansion.

Figure 11. Multiplier Submode

Ripple mode’s fourth submode features

equality

comparators

, where one 4-bit bus is input on B[3:0],

another 4-bit bus is input on B[3:0], and the carry-in is

tied to 0 inside the PFU. The carry-out (¦) signal will be

0 if A = B or will be 1 if A ¦ B. If larger than 4 bits, the

carry-out (¦) signal can be cascaded using fast-carry

logic to the carry-in of any adjacent PFU. Comparators

for greater than or equal or less than (>, =, <) continue

to be supported using the ripple mode subtractor. The

use of this submode could be shown using Figure 9

with CIN tied to 0.

DQ

COUT

LUT

A3

QLUT3

F3

Q3

COUT

DQ

A2

QLUT2

F2

Q2

DQ

A1

QLUT1

F1

Q1

DQ

A0

QLUT0

F0

Q0

CIN

CIN

+

10

A3 B3

0

A4

COUT

F3

+

A2 B2

F2

+

A1 B1

F1

+

A0 B0

F0

CIN

10

0

10

0

10

0

5-4620(F)

12 Lucent Technologies Inc.

Data Sheet

ORCA

Series 2 FPGAs June 1999

Programmable Logic Cells

(continued)

Asynchronous Memory Modes—MA and MB

The LUT in the PFU can be configured as either read/

write or read-only memory. A read/write address

(A[3:0], B[3:0]), write data (WD[1:0], WD[3:2]), and two

write-enable (WE) ports are used for memory. In asynchronous memory mode, each HLUT can be used as a

16 x 2 memory. Each HLUT is configured independently, allowing functions such as a 16 x 2 memory in

one HLUT and a logic function of five input variables or

less in the other HLUT.

Figure 12 illustrates the use of the LUT for a 16 x 4

memory. When the LUTs are used as memory, there

are independent address, input data, and output data

buses. If the LUT is used as a 16 x 4 read/write memory, the A[3:0] and B[3:0] ports are address inputs

(A[3:0]). The A4 and B4 ports are write-enable (WE)

signals. The WD[3:0] inputs are the data inputs. The

F[3:0] data outputs can be routed out on the O[4:0]

PFU outputs or to the latch/FF D[3:0] inputs.

5-2757(F).r3

Figure 12. MA/MB Mode—16 x 4 RAM

To increase memory word depth above 16 (e.g., 32 x

4), two or more PLCs can be used. The address and

write data inputs for the two or more PLCs are tied

together (bit by bit), and the data outputs are routed

through the four 3-statable BIDIs available in each PFU

and are then tied together (bit by bit).

The control signal of the 3-statable BIDIs, called a RAM

bank-enable, is created from a decode of upper

address bits. The RAM bank-enable is then used to

enable 4 bits of data from a PLC onto the read data

bus.

The

ORCA

Series 2 series also has a new AND function available for each PFU in RAM mode. The inputs to

this function are the write-enable (WE) signal and the

write-port enable (WPE) signal. The write-enable signal is A4 for HLUTA and B4 for HLUTB, while the other

input into the AND gates for both HLUTs is the writeport enable, input on C0 or CIN. Generally, the WPE

input is driven by the same RAM bank-enable signal

that controls the BIDIs in each PFU.

The selection of which RAM bank to write data into

does not require the use of LUTs from other PFUs, as

in previ ous

ORCA

architectures. This reduces the number of PFUs required for RAMs larger than 16 words in

depth. Note that if either HLUT is in MA/MB mode, then

the same WPE is active for both HLUTs.

To increase the memory’s word size (e.g., 16 x 8), two

or more PLCs are used again. The address, writeenable, and write-port enable of the PLCs are tied

together (bit by bit), and the data is different for each

PLC. Increasing both the address locations and word

size is done by using a combination of these two techniques.

The LUT can be used simultaneously for both memory

and a combinatorial logic function. Figure 13 shows the

use of a LUT implementing a 16 x 2 RAM (HLUTA) and

any function of up to five input variables (HLUTB).

5-2845(F).a.r1

Figure 13. MA/F5 Mode—16 x 2 Memory and One

Function of Five Input Variab les

A3 A3

A2

A1

A0

WD3

A2

A1

A0

WD3

F3

F2

WD2WD2

WD1

WD0

B3

B2

B1

WD0

B3

B2

B1

F1

F0

B0B0

WD1

A4

B4

WEA

WEB

HLUTA

HLUTB

WPE

C0

C0

QLUT3

QLUT2

F3

QLUT1

QLUT0

B4

B3

B2

B1

B0

F0

WEA

A3

A2

A1

A0

B4

B3

B2

B1

B0

A4

A3

A2

A1

A0

HLUTA

HLUTB

F2

WD3

WPE

WD3

C0

Lucent Technologies Inc. 13

Data Sheet

June 1999

ORCA

Series 2 FPGAs

Programmable Logic Cells

(continued)

Synchronous Memory Modes—SSPM and SDPM

The MA/MB asynchronous memory modes described

previously allow the PFU to perform as a 16 x 4

(64 bits) single-port RAM. Synchronously writing to this

RAM requires the write-enable control signal to be

gated with the clock in another PFU to create a write

pulse. To simplify this functionality, the Series 2 devices

contain a

synchronous single-port memory

(SSPM)

mode, where the generation of the write pulse is done

in each PFU.

With SSPM mode, the entire LUT becomes a 16 x 4

RAM, as shown in Figure 14. In this mode, the input

ports are write enable (WE), write-port enable (WPE),

read/write address (A[3:0]), and write data (WD[3:0]).

To synchronously write the RAM, WE (input into a4)

and WPE (input into either C0 or CIN) are latched and

ANDed together. The result of this AND function is sent

to a pulse generator in the LUT, which writes the RAM

synchronous to the RAM clock. This RAM clock is the

same one sent to the PFU latches/FFs; however , if necessary, it can be programmably inverted.

5-4642(F).r1

Figure 14. SSPM Mode—16 x 4 Synchronous

Single-Port Memory

The write address (WA[3:0]) and write data (WD[3:0])

are also latched by the RAM clock in order to simplify

the timing. Reading data from the RAM is done asynchronously; thus, the read address (RA[3:0]) is not

latched. The result from the read operation is placed on

the LUT outputs (F[3:0]). The F[3:0] data outputs can

be routed out of the PFU or sent to the latch/FF D[3:0]

inputs.

There are two ways to use the latches/FFs in conjunction with the SSPM. If the phase of the latch/FF clock

and the RAM clock are the same, only a read address

or write address can be supplied to the RAM that

meets the synchronous timing requirements of both

the RAM clock and latch/FF clock. Therefore, either a

write to the RAM or a read from the RAM can be done

in each clock cycle, but not both. If the RAM clock is

inverted from the latch/FF clock, then both a write to

the RAM and a read from the RAM can occur in each

clock cycle. This is done by adding an external write

address/read address multiplexer as shown in

Figure 15.

The write address is supplied on the phase of the clock

that allows for setup to the RAM clock, and the read

address is supplied on the phase of the clock that

allows the read data to be set up to the latch/FF clock.

If a higher-speed RAM is required that allows both a

read and write in each clock cycle, the synchronous

dual-port memory mode (SDPM) can be used, since it

does not require the use of an external multiplexer.

5-4644(F).r1

Figure 15. SSPM with Read/Write per Clock Cycle

WE

WPE

A4

DQ

DQ

CIN, C0

A[3:0]

WD[3:0]

WR

WA[3:0]

RA[3:0]

WD[3:2]

HLUTA

F3

F2

DQ

DQ

WR

WA[3:0]

RA[3:0]

WD[1:0]

HLUTB

F1

F0

WRITE PULSE

GENERATOR

A[3:0], B[3:0]

WD[3:0]

WE

A

WD

RAM CLK

WRITE ADDRESS

READ ADDRESS

0

1

WPE

SSPM

CLOCK

DQ

PFU

Data Sheet

ORCA

Series 2 FPGAs June 1999

14 Lucent Technologies Inc.

Programmable Logic Cells

(continued)

Note: The lower address bits are not shown.

Figure 16. Synchronous RAM with Write-Port Enable (WPE)

UPPER

ADDRESS

BITS

ADDRESS

DECODE

LUT1

BANK_EN1

UPPER

ADDRESS

BITS

ADDRESS

DECODE

LUT2

BANK_EN2

WR

DI

WPE

DO

16 x 4 RAM +

4 BUFFERS/PFU

BIDI

DOUT

4

WR

DI

WPE

DO

16 x 4 RAM +

4 BUFFERS/PFU

DIN

WR

CLK

4

BIDI

4

4

5-4640(F)

To increase memory word depth above 16 (e.g., 32 x

4), two or more PLCs can be used. The address and

write data inputs for the two or more PLCs are tied

together (bit by bit), and the data outputs are routed

through the four 3-statable BIDIs available in each

PFU. The BIDI outputs are then tied together (bit by

bit), as seen in Figure 16.

The control signals of the 3-statable BIDIs, called RAM

bank-enable (BANK_EN1 and BANK_EN2), are created from a decode of upper address bits. The RAM

bank-enable is then used to enable 4 bits of data from

a PLC onto the read data (DOUT) bus.

The Series 2 series now has a new AND function available for each PFU in RAM mode. The inputs to this

function are the write-enable (WE) signal and the writeport enable (WPE) signal. The write-enable signal is

input on A4, while the write-port enable is input on C0

or CIN. Generally, the WPE input is driven by the same

RAM bank-enable signal that controls the BIDIs in each

PFU.

The selection as to which RAM bank to write data into

does not require the use of LUTs from other PFUs, as

in previ ous

ORCA

architectures. This reduces the number of PFUs required for RAMs larger than 16 words in

depth.

A special use of this method can be to increase word

depth to 32 words. Since both the WPE input into the

RAM and the 3-state input into the BIDI can be

inverted, a decode of the one upper address bit is not

required. Instead, the bank-enable signal for both

banks is tied to the upper address bit, with the WPE

and 3-state inputs active-high for one bank and activelow for the other.

To increase the memory’s word size (e.g., 16 x 8), two

or more PLCs are used again. The address, writeenable, and write-port enable of the PLCs are tied

together (bit by bit), and the data is different for each

PLC. Increasing both the address locations and word

size is accomplished by using a combination of these

two techniques.

Lucent Technologies Inc. 15

Data Sheet

June 1999

ORCA

Series 2 FPGAs

Programmable Logic Cells

(continued)

5-4641(F).r1

Figure 17. SDPM Mode—16 x 2 Synchronous

Dual-Port Memory

The Series 2 devices have added a second synchronous memory mode known as the

synchronous dual-

port memory

(SDPM) mode. This mode writes data

into the memory synchronously in the same manner

described previously for SSPM mode. The SDPM

mode differs in that two separate 16 x 2 memories are

created in each PFU that have the same WE, WPE,

write data (WD[1:0]), and write address (WA[3:0])

inputs, as shown in Figure 17.

The outputs of HLUTA (F[3:2]) operate the same way

they do in SSPM mode—the read address comes

directly from the A[3:0] inputs used to create the

latched write address. The outputs of HLUTB (F[1:0])

operate in a dual-port mode where the write address

comes from the latched version of A[3:0], and the read

address comes directly from RA[3:0], which is input on

B[3:0].

Since external multiplexing of the write address and

read address is not required, extremely fast RAMs can

be created. New system applications that require an

interface between two different asynchronous clocks

can also be implemented using the SDPM mode. An

example of this is accomplished by creating FIFOs

where one clock controls the synchronous write of data

into the FIFO, and the other clock controls the read

address to allow reading of data at any time from the

FIFO.

Latches/Flip-Flops

The four latches/FFs in the PFU can be used in a variety of configurations. In some cases, the configuration

options apply to all four latches/FFs in the PFU. For

other options, each latch/FF is independently programmable.

Table 4 summarizes these latch/FF options. The

latches/FFs can be configured as either positive or

negative level-sensitive latches, or positive or negative

edge-triggered flip-flops. All latches/FFs in a given PFU

share the same clock, and the clock to these latches/

FFs can be inverted. The input into each latch/FF is

from either the corresponding QLUT output (F[3:0]) or

the direct data input (WD[3:0]). For latches/FFs located

in the two outer rings of PLCs, additional inputs are

possible. These additional inputs are fast paths from

I/O pads located in PICs in the same row or column as

the PLCs. If the latch/FF is not located in the two outer

rings of the PLCs, the latch/FF input can also be tied to

logic 0, which is the default. The four latch/FF outputs,

Q[3:0], can be placed on the five PFU outputs, O[4:0].

Table 4. Configuration RAM Controlled Latch/

Flip-Flop Operation

The four latches/FFs in a PFU share the clock (CK),

clock enable (CE), and local set/reset (LSR) inputs.

When CE is disabled, each latch/FF retains its previous

value when clocked. Both the clock enable and LSR

inputs can be inverted to be active-low.

WE

WPE

A4

DQ

DQ

CIN, C0

WA[3:0]

WD[1:0]

WR

WA[3:0]

RA[3:0]

WD[1:0]

HLUTA

F3

F2

DQ

DQ

WR

WA[3:0]

RA[3:0]

WD[1:0]

HLUTB

F1

F0

WRITE PULSE

GENERATOR

A[3:0]

WD[1:0]

RA[3:0]

B[3:0]

SSPM OUTPUT SDPM OUTPUT

Function Options

Functionality Common to All Latch/FFs in PFU

LSR Operation Asynch ronous or synchronous

Clock Polarity Noninverted or inverted

Front-End Select Direct (WD[3:0]) or from LU T

(F[3:0])

LSR Priorit y Either LSR or CE has prio rity

Functionality Set Individually in Each Latch/FF in PFU

Latch/FF Mode Latch or flip-flop

Set/Reset Mode Set or Reset

Data Sheet

ORCA

Series 2 FPGAs June 1999

16 Lucent Technologies Inc.

Programmable Logic Cells

(continued)

The set/reset operation of the latch/FF is controlled by

two parameters: reset mode and set/reset value. When

the global set/reset (GSRN) or local set/reset (LSR) are

inactive, the storage element operates normally as a

latch or FF. The reset mode is used to select a synchronous or asynchronous LSR operation. If synchronous,

LSR is enabled only if clock enable (CE) is active. For

the Series 2 series, a new option called the LSR priority allows the synchronous LSR to have priority over the

CE input, thereby setting or resetting the FF independent of the state of CE. The clock enable is supported

on FFs, not latches. The clock enable function is implemented by using a two-input multiplexer on the FF

input, with one input being the previous state of the FF

and the other input being the new data applied to the

FF. The select of this two-input multiplexer is clock

enable (CE), which selects either the new data or the

previous state. When CE is inactive, the FF output

does not change when the clock edge arrives.

The GSRN signal is only asynchronous, and it sets/

resets all latches/FFs in the FPGA based upon the set/

reset configuration bit for each latch/FF. The set/reset

value determines whether GSRN and LSR are set or

reset inputs. The set/reset value is independent for

each latch/FF.

If the local set/reset is not needed, the latch/FF can be

configured to have a data front-end select. Two data

inputs are possible in the front-end select mode, with

the LSR signal used to select which data input is used.

The data input into each latch/FF is from the output of

its associated QLUT F[3:0] or direct from WD[3:0],

bypassing the LUT. In the front-end data select mode,

both signals are available to the latches/FFs.

For PLCs that are in the two outside rows or columns of

the array, the latch/FFs can have two inputs in addition

to the F and WD inputs mentioned above. One input is

from an I/O pad located at the PIC closest to either the

left or right of the given PLC (if the PLC is in the left two

columns or right two columns of the array). The other

input is from an I/O pad located at the closest PIC

either above or below the given PLC (if the PLC is in

the top or the bottom two rows). It should be noted that

both inputs are available for a 2 x 2 array of PLCs in

each corner of the array. For the entire array of PLCs, if

either or both of these inputs is unavailable, the latch/

FF data input can be tied to a logic 0 instead (the

default).

To speed up the interface between signals external to

the FPGA and the latches/FFs, there are direct paths

from latch/FF outputs to the I/O pads. This is done for

each PLC that is adjacent to a PIC.

The latches/FFs can be configured in three modes:

1. Local synchronous set/reset: the input into the PFU’s

LSR port is used to synchronously set or reset each

latch/FF.

2. Local asynchronous set/reset: the input into LSR

asynchronously sets or resets each latch/FF.

3. Latch/FF with front-end select: the data select signal

(actually LSR) selects the input into the latches/FFs

between the LUT output and direct data in.

For all three modes, each latch/FF can be independently programmed as either set or reset. Each latch/

FF in the PFU is independently configured to operate

as either a latch or flip-flop. Figure 18 provides the logic

functionality of the front-end select, global set/reset,

and local set/reset operations.

Note: CD = configuration data.

5-2839(F).a

Figure 18. Latch/FF Set/Reset Configurations

CE

D

S_SET

S_RESET

CLK

SET RESET

Q

LSR

GSRN

CD

CE

D

CLK

SET RESET

LSR

CD

CE

CE

D

CLK

SET RESET

CD

CE

CE

WD

LSR

GSRN

PDINLR

LOGIC 0

WD

F

LOGIC 0

WD

GSRN

Q Q

PDINTB

F

PDINLR

PDINTB

F

LOGIC 0

WD

PDINLR

PDINTB

Lucent Technologies Inc. 17

Data Sheet

June 1999

ORCA

Series 2 FPGAs

Programmable Logic Cells

(continued)

PLC Routing Resources

Generally, the

ORCA

Foundry Development System is

used to automatically route interconnections. Interactive routing with the

ORCA

Foundry design editor

(EPIC) is also available for design optimization. To use

EPIC for interactive layout, an understanding of the

routing resources is needed and is provided in this section.

The routing resources consist of switching circuitry and

metal interconnect segments. Generally , the metal lines

which carry the signals are designated as routing

nodes (lines). The switching circuitry connects the routing nodes, providing one or more of three basic functions: signal switching, amplification, and isolation. A

net running from a PFU or PIC output (source) to a

PLC or PIC input (destination) consists of one or more

lines, connected by switching circuitry designated as

configurable interconnect points (CIPs).

The following sections discuss PLC, PIC, and interquad

routing resources. This section dis c us ses the PLC

switching circuitry, intra-PLC routing, inter-PLC routing,

and clock distribution.

Configurable Interconnect Points

The process of connecting lines uses three basic types

of switching circuits: two types of configurable interconnect points (CIPs) and bidirectional buffers (BIDIs). The

basic element in CIPs is one or more pass transistors,

each controlled by a configuration RAM bit. The two

types of CIPs are the mutually exclusive (or multiplexed) CIP and the independent CIP.

A mutually exclusive set of CIPs contains two or more

CIPs, only one of which can be on at a time. An independent CIP has no such restrictions and can be on

independent of the state of other CIPs. Figure 19

shows an example of both types of CIPs.

f.13(F)

Figure 19. Configurable Interconnect Point

3-Statable Bidirectional Buffers

Bidirectional buffers provide isolation as well as amplification for signals routed a long distance. Bidirectional

buffers are also used to drive signals directly onto

either vertical or horizontal XL and XH lines (to be

described later in the inter-PLC routing section). BIDIs

are also used to indirectly route signals through the

switching lines. Any number from zero to eight BIDIs

can be used in a given PLC.

The BIDIs in a PLC are divided into two nibble-wide

sets of four (BIDI and BIDIH). Each of these sets has a

separate BIDI controller that can have an application

net connected to its TRI input, which is used to 3-state

enable the BIDIs. Although only one application net can

be connected to both BIDI controllers, the sense of this

signal (active-high, active-low, or ignored) can be configured independently. Therefore, one set can be used

for driving signals, the other set can be used to create

3-state buses, both sets can be used for 3-state buses,

and so forth.

2

INDEPENDENT CIP

CD

A

B

AB

=

MULTIPLEXED CIP

A

B

C

A

B

C

O

O

CD

18 Lucent Technologies Inc.

Data Sheet

ORCA

Series 2 FPGAs June 1999

Programmable Logic Cells

(continued)

5-4479p2(F)

Figure 20. 3-Statable Bidirectional Buffers

Intra-PLC Routing

The function of the intra-PLC routing resources is to

connect the PFU’s input and output ports to the routing

resources used for entry to and exit from the PLC.

These are nets for providing PFU feedback, turning

corners, or switching from one type of routing resource

to another.

PFU Input and Output P orts.

There are 19 input ports

to each PFU. The PFU input ports are lab eled A[4:0],

B[4:0], WD[3:0], C0, CK, LSR, CIN, and CE. The six

output ports are O[4:0] and COUT. These ports correspond to those described in the PFU section.

Switchin g Lin es.

There are four sets of switching lines

in each PLC, one in each corner. Each set consists of

five switching elements, labeled SUL[4:0], SUR[4:0],

SLL[4:0], and SLR[4:0], for the upper-left, upper-right,

lower-left, and lower-right sections of the PFUs,

respectively. The switching lines connect to the PFU

inputs and outputs as well as the BIDI and BIDIH lines,

to be described later. They also connect to both the

horizontal and vertical X1 and X4 lines (inter-PLC routing resources, described below) in their specific corner.

One of the four sets of switching lines can be connected to a set of switching lines in each of the four

adjacent PLCs or PICs. This allows direct routing of up

to five signals without using inter-PLC routing.

BIDI/BIDIH Lines.

There are two sets of bidirectional

lines in the PLC, each set consisting of four bidirectional buffers. They are designated BIDI and BIDIH and

have similar functionality. The BIDI lines are used in

conjunction with the XL lines, and the BIDIH lines are

used in conjunction with the XH lines. Each side of the

four BIDIs in the PLC is connected to a BIDI line on the

left (BL[3:0]) and on the right (BR[3:0]). These lines can

be connected to the XL lines through CIPs, with BL[3:0]

connected to the vertical XL lines and BR[3:0] connected to the horizontal XL lines. Both BL[3:0] and

BR[3:0] have CIPs which connect to the switching lines.

Similarly , each side of the four BIDIHs is connected to a

BIDIH line: BLH[3:0] on the left and BRH[3:0] on the

right. These lines can also be connected to the XH

lines through CIPs, with BLH[3:0] connected to the vertical XH lines and BRH[3:0] connected to the horizontal

XH lines. Both BLH[3:0] and BRH[3:0] have CIPs which

connect to the switching lines.

CIPs are also provided to connect the BIDIH and BIDIL

lines together on each side of the BIDIs. For example,

BLH3 can connect to BL3, while BRH3 can connect to

BR3.

RIGHT-LEFT BIDI

LEFT-RIGHT BIDI

UNUSED BIDI

LEFT-RIGHT BIDI

BIDI

CONTROLLER

TRI

RIGHT-LEFT BIDIH

LEFT-RIGHT BIDIH

UNUSED BIDIH

LEFT-RIGHT BIDIH

BIDIH

CONTROLLER

Lucent Technologies Inc. 19

Data Sheet

June 1999

ORCA

Series 2 FPGAs

Programmable Logic Cells

(continued)

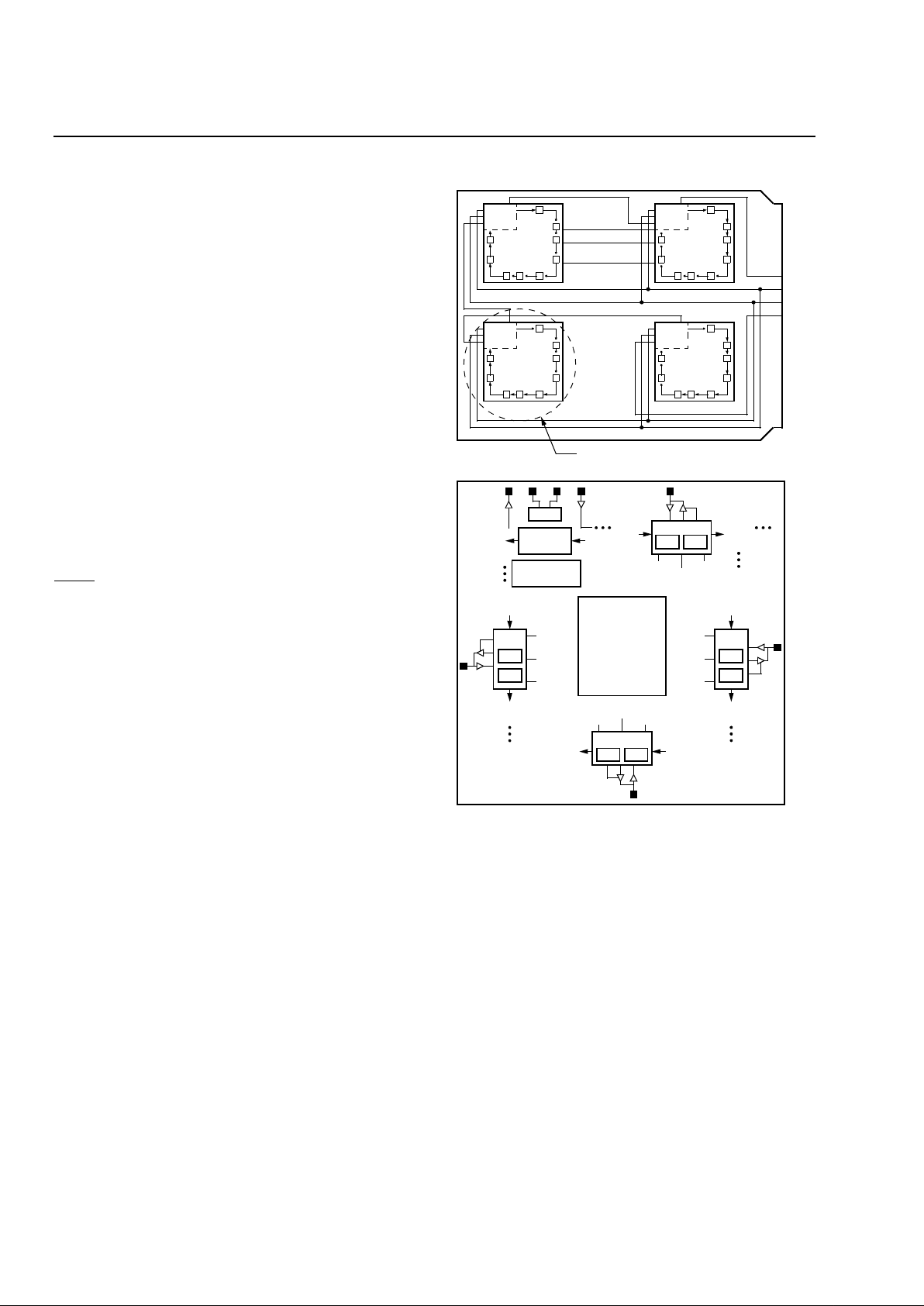

Inter-PLC Routing Resources

The inter-PLC routing is used to route signals between

PLCs. The lines occur in groups of four, and differ in the

numbers of PLCs spanned. The X1 lines span one

PLC, the X4 lines span four PLCs, the XH lines span

one-half the width (height) of the PLC array, and the XL

lines span the width (height) of the PLC array. All types

of lines run in both horizontal and vertical directions.

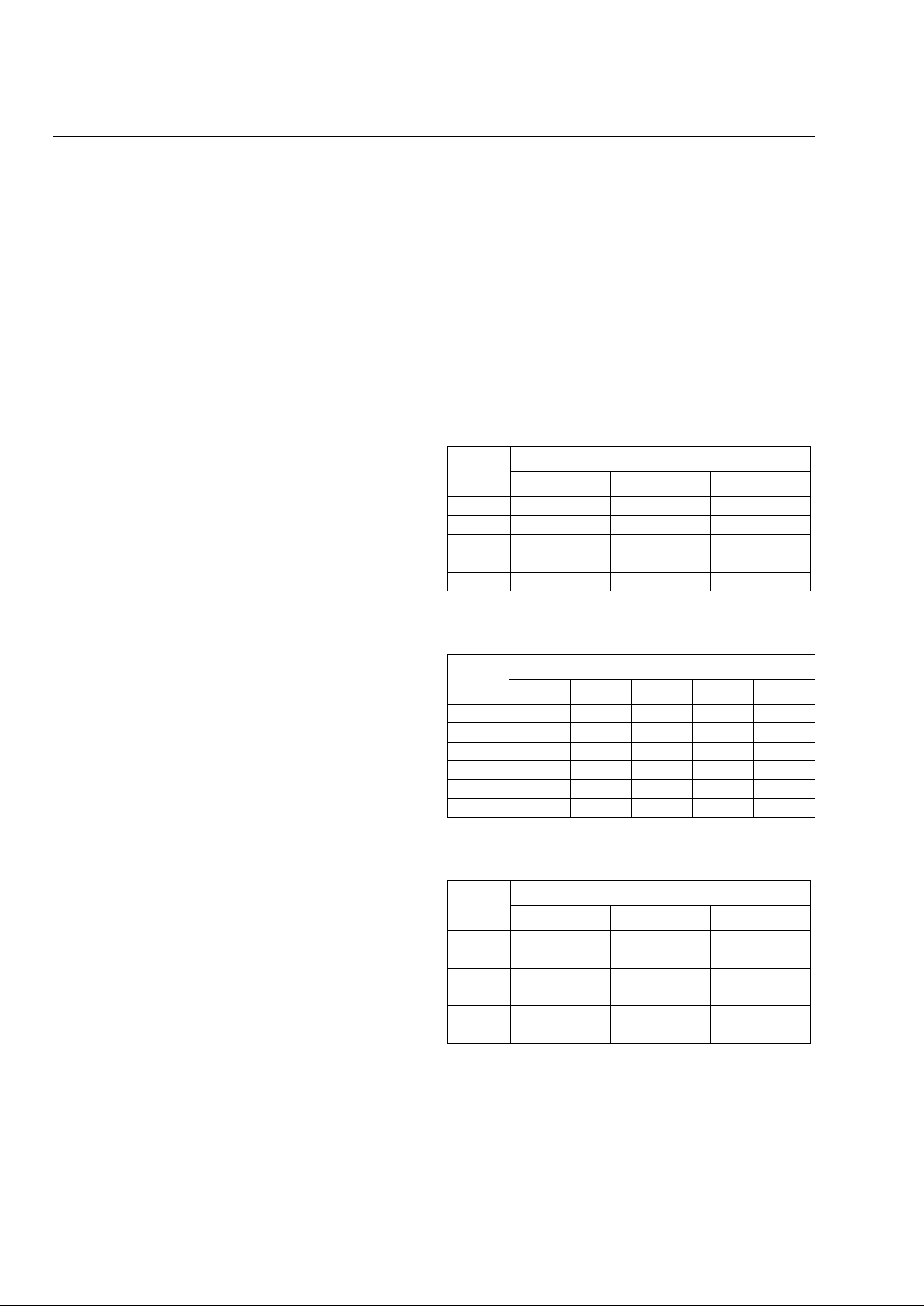

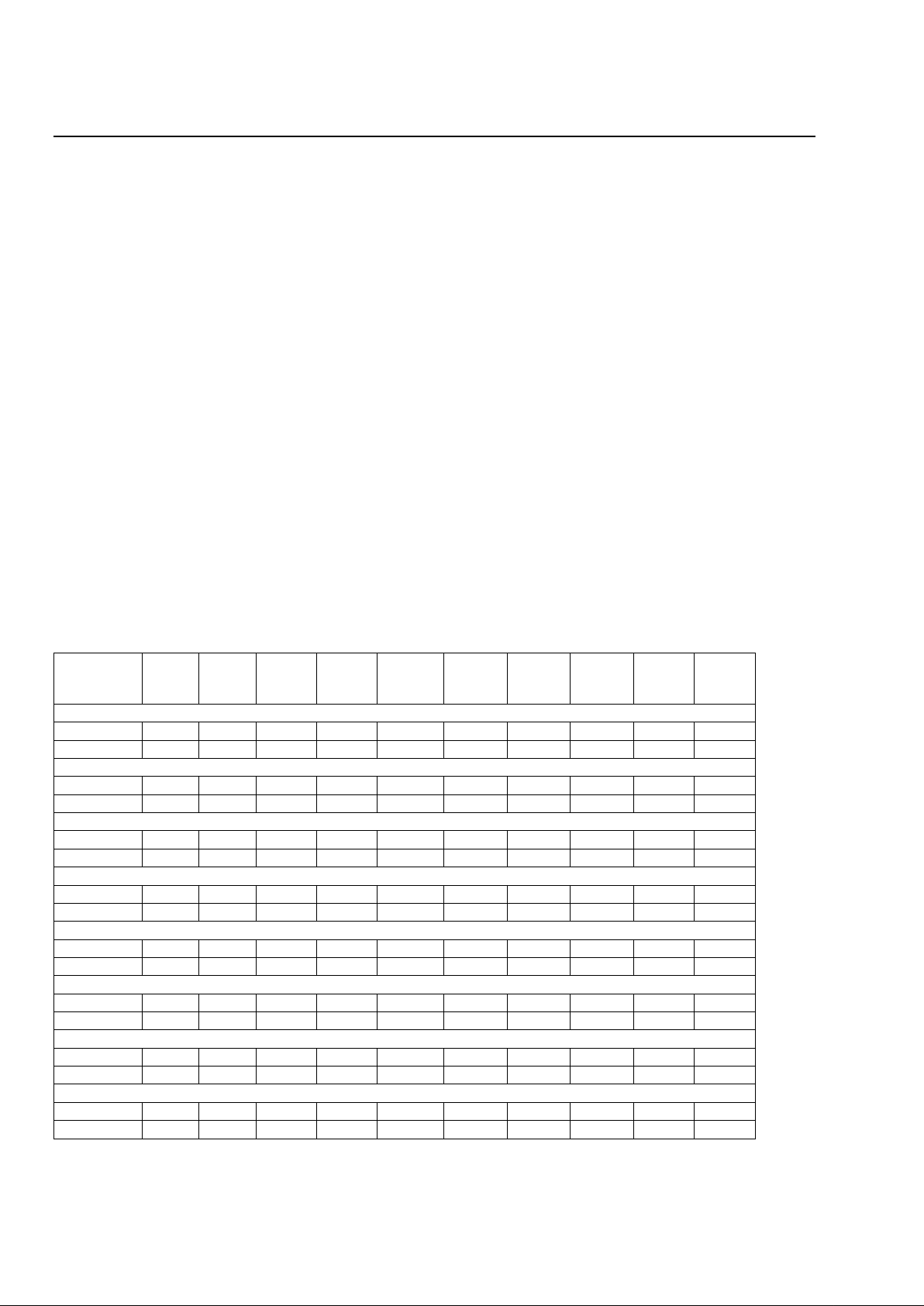

Table 5 shows the groups of inter-PLC lines in each

PLC. In the table, there are two rows/columns each for

X1 and X4 lines. In the design editor, the horizontal X1

and X4 lines are located above and below the PFU.

Similarly, the vertical segments are located on each

side. The XL and XH lines only run below and to the left

of the PFU. The indexes specify individual lines within a

group. For example, the VX4[2] line runs vertically to

the left of the PFU, spans four PLCs, and is the third

line in the 4-bit wide bus.

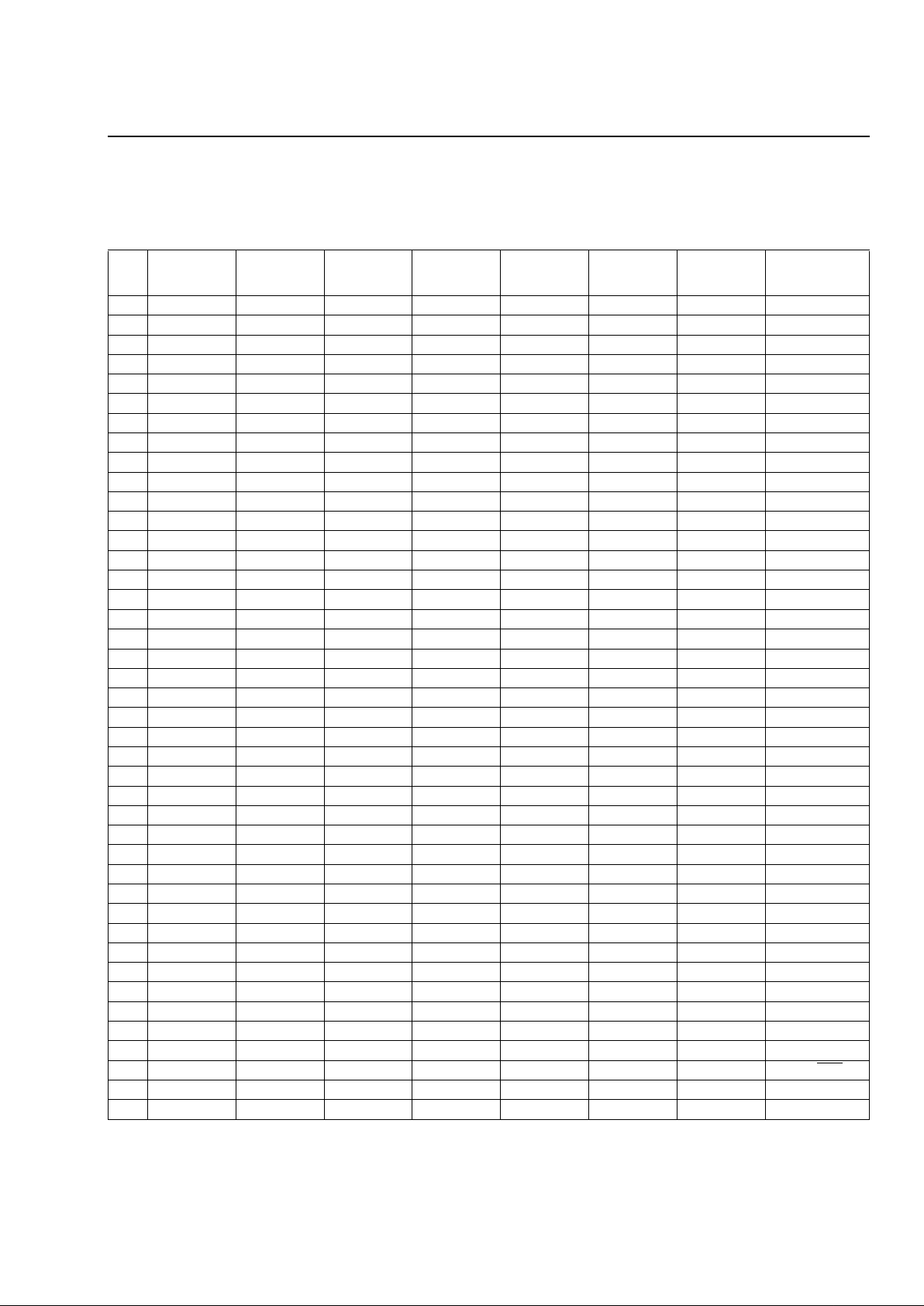

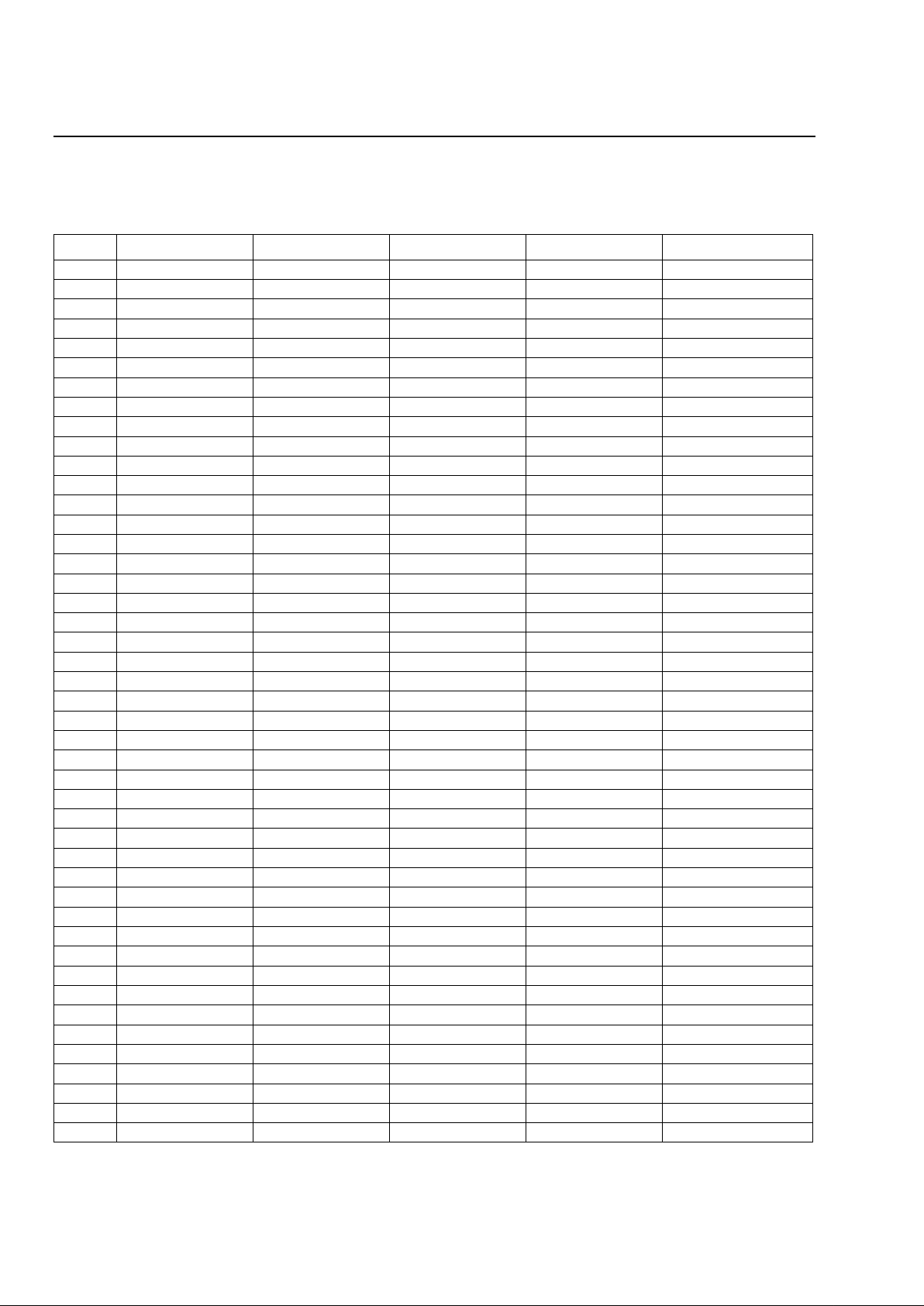

Table 5. Inter-PLC Routing Resources

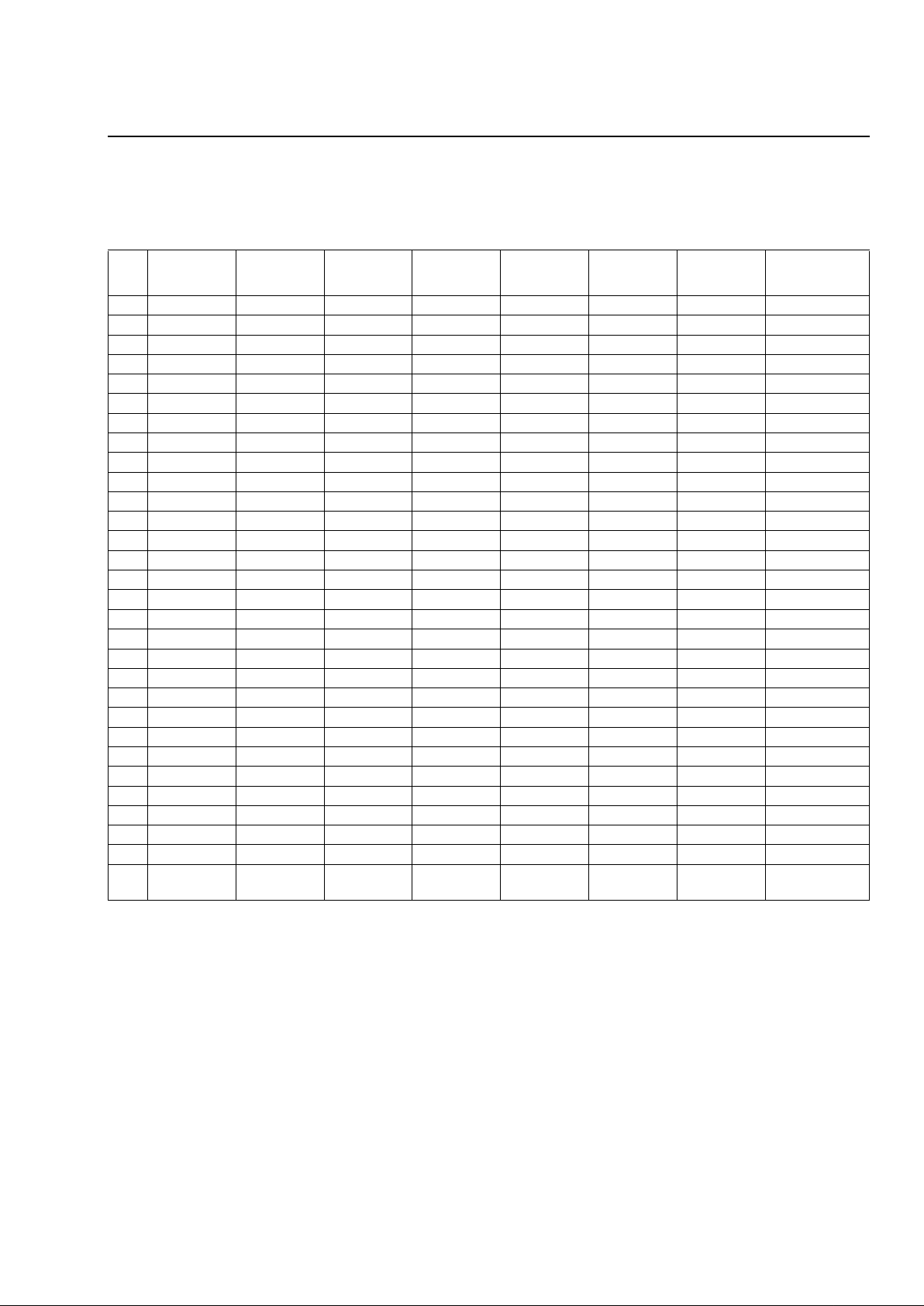

Figure 21 shows the inter-PLC routing within one PLC.

Figure 22 provides a global view of inter-PLC routing

resources across multiple PLCs.

5-4528(F)

Figure 21. Single PLC View of Inter-PLC Lines

X1 Lines.

There are a total of 16 X1 lines per PLC:

eight vertical and eight horizontal. Each of these is subdivided into nibble-wide buses: HX1[3:0], HX1[7:4],

VX1[3:0], and VX1[7:4]. An X1 line is one PLC long.

If a net is longer than one PLC, an X1 line can be

lengthened to n times its length by turning on n – 1

CIPs. A signal is routed onto an X1 line via the switching lines.

X4 Lines.

There are four sets of four X4 lines, for a

total of 16 X4 lines per PLC. They are HX4[3:0],

HX4[7:4], VX4[3:0], and VX4[7:4]. Each set of X4 lines

is twisted each time it passes through a PLC, and one

of the four is broken with a CIP. This allows a signal to

be routed for a length of four cells in any direction on a

single line without additional CIPs. The X4 lines can be

used to route any nets that require minimum delay. A

longer net is routed by connecting two X4 lines

together by a CIP. The X4 lines are accessed via the

switching lines.

Horizontal

Lines

Vertical

Lines

Distance

Spanned

HX1[3:0] VX1[3:0] One PLC

HX1[7:4] VX1[7:4] One PLC

HX4[3:0] VX4[3:0] Four PLCs

HX4[7:4] VX4[7:4] Four PLCs

HXL[3:0] VXL[3:0] PLC Array

HXH[3:0] VXH[3:0] 1/2 PLC Array

CKL, CKR CKT, CKB PLC Array

PROGRAMMABLE

FUNCTION UNIT

DIRECT[4:0]

HX4[7:4]

HX1[7:4]

DIRECT[4:0]

HXH[3:0]

HX1[3:0]

DIRECT[4:0]

DIRECT[4:0]

HX4[3:0]

VX4[7:4]

VX1[7:4]

VXL[3:0]

VX1[3:0]

VX4[3:0]

VXH[3:0]

CKB, CKT

HXL[3:0]

CKL, CKR

20 Lucent Technologies Inc.

Data Sheet

ORCA

Series 2 FPGAs June 1999

Programmable Logic Cells

(continued)

XL Lines.

The long XL lines run ve rtically and horizontally the height and width of the array, respectively.

There are a total of eight XL lines per PLC: four horizontal (HXL[3:0]) and four vertical (VXL[3:0]). Each

PLC column has four XL lines, and each PLC row has

four XL lines. Each of the XL lines connects to the two

PICs at either end. The Series 2, which consists of a

18 x 18 array of PLCs, contains 72 VXL and 72 HXL

lines. They are intended primarily for global signals

which must travel long distances and require minimum

delay and/or skew, such as clocks.

There are three methods for routing signals onto the XL

lines. In each PLC, there are two long-line drivers: one

for a horizontal XL line, and one for a vertical XL line.

Using the long-line drivers produces the least delay.

The XL lines can also be driven directly by PFU outputs

using the BIDI lines. In the third method, the XL lines

are accessed by the bidirectional buffers, again using

the BIDI lines.

XH Lines

. Four by half (XH) lines run horizontally and

four XH lines run vertically in each row and column in

the array. These lines travel a distance of one-half the

PLC array before being broken in the middle of the

array, where they connect to the interquad block (discussed later). They also connect at the periphery of the

FPGA to the PICs, like the XL lines. The XH lines do

not twist like XL lines, allowing nibble-wide buses to be

routed easily.

Two of the three methods of routing signals onto the

XL lines can also be used for the XH lines. A special

XH line driver is not supplied for the XH lines.

Clock Lines.

For a very fast and low-skew clock (or

other global signal tree), clock lines run the entire

height and width of the PLC array. There are two horizontal clock lines per PLC row (CKL, CKR) and two

vertical clock lines per PLC column (CKT, CKB). The

source for these clock lines can be any of the four I/O

buffers in the PIC. The horizontal clock lines in a row

(CKL, CKR) are driven by the left and right PICs,

respectively. The vertical clock lines in a column (CKT,

CKB) are driven by the top and bottom PICs, respectively.

The clock lines are designed to be a clock spine. In

each PLC, there is a fast connection available from the

clock line to the long-line driver (described earlier).

With this connection, one of the clock lines in each PLC

can be used to drive one of the four XL lines perpendicular to it, which, in turn, creates a clock tree.

This feature is discussed in detail in the Clock Distribution Network section.

Minimizing Routing Delay

The CIP is an active element used to connect two lines.

As an active element, it adds significantly to the resistance and capacitance of a net, thus increasing the

net’s delay. The advantage of the X1 line over a X4 line

is routing fl e x ibil ity. A net f rom PLC db to PL C cb is eas ily routed by using X1 lines. As more CIPs are added to

a net, the delay increases. To increase speed, routes

that are greater than two PLCs away are routed on the

X4 lines because a CIP is located only in every fourth

PLC. A net that spans eight PLCs requires seven X1

lines and six CIPs. Using X4 lines, the same net uses

two lines and one CIP.

All routing resources in the PLC can carry 4-bit buses.

In order for data to be used at a destination PLC that is

in data path mode, the data must arrive unscrambled.

For example, in data path operation, the least significant bit 0 must arrive at either A[0] or B[0]. If the bus is

to be routed by using either X4 or XL lines (both of

which twist as they propagate), the bus must be placed

on the appropriate lines at the source PLC so that the

data arrives at the destination unscrambled. The

switching lines provide the most efficient means of connecting adjacent PLCs. Signals routed with these lines

have minimum propagation delay.

Data Sheet

June 1999

ORCA

Series 2 FPGAs

Lucent Technologies Inc. 21

Programmable Logic Cells

(continued)

5-2841(F)2C.r9

Figure 22. Multiple PLC View of Inter-PLC Routing

PFU

PFU

PFU PFU

PFUPFU

PFUPFU

PFU

SHOWS PLCs

CKR

CKL

CKR

CKL

HX4[4]

HX4[5]

HX4[6]

HX4[7]

HX1[7:4]

HX4[5]

HX4[6]

HX4[7]

HX4[4]

HXL[0]

HXL[1]

HXL[2]

HXL[3]

HX1[3:0]

HX4[0]

HX4[1]

HX4[2]

HX4[3]

HXL[3]

HXL[0]

HXL[1]

HXL[2]

HX4[1]

HX4[2]

HX4[3]

HX4[0]

HX4[4]

HX4[5]

HX4[6]

HX4[7]

HX1[7:4]

HX4[5]

HX4[6]

HX4[7]

HX4[4]

HX1[7:4]

HX4[4]

HX4[5]

HX4[6]

HX4[7]

HX4[5]

HX4[6]

HX4[7]

HX4[4]

HXL[0]

HXL[1]

HXL[2]

HXL[3]

HX4[0]

HX4[1]

HX4[2]

HX4[3]

HXL[3]

HXL[0]

HXL[1]

HXL[2]

HX4[1]

HX4[2]

HX4[3]

HX4[0]

CKR

CKL

HXH[3:0]

HX1[7:4]

HX1[3:0]

CKR

CKL

HXH[3:0]

HX1[7:4]

HX1[3:0]

CKR

CKL

HXH[3:0]

HX1[7:4]

HX1[3:0]

CKR

CKL

HXH[3:0]

VX1[3:0]

CKT

CKB

VX4[0]

VX4[1]

VX4[2]

VX4[3]

VX4[4]

VX4[5]

VX4[6]

VX4[7]

VXH[3:0]

VX1[7:4]

VXL[0]

VXL[1]

VXL[2]

VXL[3]

VX4[1]

VX4[2]

VX4[3]

VX4[0]

VX4[5]

VX4[6]

VX4[7]

VX4[4]

VXL[1]

VXL[2]

VXL[3]

VXL[0]

VX4[0]

VX4[1]

VX4[2]

VX4[3]

VX1[3:0]

CKT

CKB

VX4[1]

VX4[2]

VX4[3]

VX4[0]

VX4[0]

VX4[1]

VX4[2]

VX4[3]

VX4[4]

VX4[5]

VX4[6]

VX4[7]

VXL[0]

VXL[1]

VXL[2]

VXL[3]

VX4[1]

VX4[2]

VX4[3]

VX4[0]

VX4[5]

VX4[6]

VX4[7]

VX4[4]

VXL[3]

VXL[0]

VXL[1]

VXL[2]

VX1[3:0]

CKT

CKB

VX1[3:0]

CKT

CKB