AGERE 980X Datasheet

Preliminary Data Sheet

April 1999

980-Type Ultrahigh-

Reliability Pump Laser Module

The 980-Type Ultrahigh-Reli ability Pump Laser Module is ideally suited for fiber amplifier-based optical transmission systems that require a long-term life expectancy.

Features

■

Extremely high reliability

— Laser-welded packaging technology used to

attain ultrastable long-term operation

— 29-year life

■

Planar InGaAs PIN photodiode monitor for laser

back-facet output

■

Wide range of stable CW optical output power

■

Individually certified for ultrahigh reliability

■

InGaAs ridge waveguide 980 nm single-mode

laser diode

■

Standard low-profile, laser-welded, metal, hermetic, 14-pin butterfly package

■

Single-mode fiber with Bragg Grating (FBG) for

stable operation

■

Stable single spatial mode kink-free operation over

a wide range of temperatures and currents

Applications

■

Undersea optical transmission systems

■

Ultrahigh reliability optical communications for military systems

Description

The 980-Type Pump Laser Module is a precision,

high-performance, ultrahigh-reliability lightwave component that provides high output power light, in the

980 nm range. The 980-Type Pump Laser Module is

comprised of a single-mode laser diode, PIN backfacet monitor, microlensed single-mode fiber, and a

Fiber Bragg Grating (FBG) for improved stability, all

encased in a specially designed 14-pin, oxygen free,

butterfly package.

The 980-Type Pump Laser Module is capable of

providing a wide range of output power in the

974 nm to 984 nm wavelength range for erbiumdoped amplifier (EDFA) system application. The

pump laser module is designed and individually certified for high-reliability operation and long-term life

expectancy. The 980 nm InGaAs laser chip utilizes a

ridge guide design for high performance and reliability. Chip and facet parameters are optimized for stabilized optical coupling and efficient pumping of the

EDFA. The laser package design also includes a

microlensed single-mode fiber and a planar InGaAs

PIN back-facet photomonitor assembled in a modular

organic-free hermetic package. Laser welding technology is used for critical joints to achieve long-term

stability. Data is archived for at least ten years. Each

module is fully characterized and traceable. Long-life

performance and reliability are ensured through

extensive steps of burn-in, overstress, and power

aging. The 980-T ype Pump Laser Module is available

with a typical power output range of 20 mW to

70 mW.

980-Type Ultrahigh Preliminary D ata Sheet

Reliability Pump Laser Module April 1999

22

Lucent Technologies Inc.

Description

(continued)

The 980-Type Pump Laser Module has been specifically designed for undersea optical amplified very high

capacity transmission systems that require long-term

life expectancy. The extremely stringent reliability

requirements imposed on the 980-Type (necessary to

achieve long-term system life) are accomplished

through careful design, exacting manufacture, and thorough testing. The 980-Type qualification plan consists

of a basic set of electro-optic and mechanical tests

designed to confirm the performance and reliability of

the module over its projected service life under

assumed operating conditions. Custom designed,

extended qualification test programs can be developed

to focus on customer system requirements.

Based on the results of qualification testing, a certification program has been developed to ensure the highreliability performance of the devices. Each 980-Type

device undergoes this certification process where the

perf orman c e pa r a me t e rs ar e me a su re d be fore, during ,

and after environmental stresses. The certification

results for each 980-T ype Pump Laser Module are then

examined to ensure that only the pump laser modules

that exhibit performance consistent with long-term system operation are selected for product.

Each 980-Type is individually serialized for full traceability and is shipped with the appropriate test data.

The 980-Type assembly, test, and certification facilities

have all passed the rigorous qualification process

required for all facilities that manufacture devices

employed in undersea applications. Also, on an ongoing basis, small quantities of product from each manufacturing lot are retained and tested as part of a

surveillance program for undersea devices. Each surveillance group is subjected to the complete spectrum

of environmental/mechanical stresses required during

the qualification process. The surveillance results are

reviewed and compiled so that long-term trends can be

studied. The reliability performance of the 980-Type

Pump Laser Module is a result of a rigorous qualification process combined with an extensive and ongoing

surveillance program.

Pinout Information

Top View.

1-675(F).e

Figure 1. Pinout Schematic

7654321

8 9 10 11 12 13

14

Preliminary Data Sheet 980-Type Ultrahigh

April 1999 Reliability Pump Laser Module

3

Lucent Technologies Inc.

Pinout Information

(continued)

Table 1. Pinout Descriptions

Handling Precautions

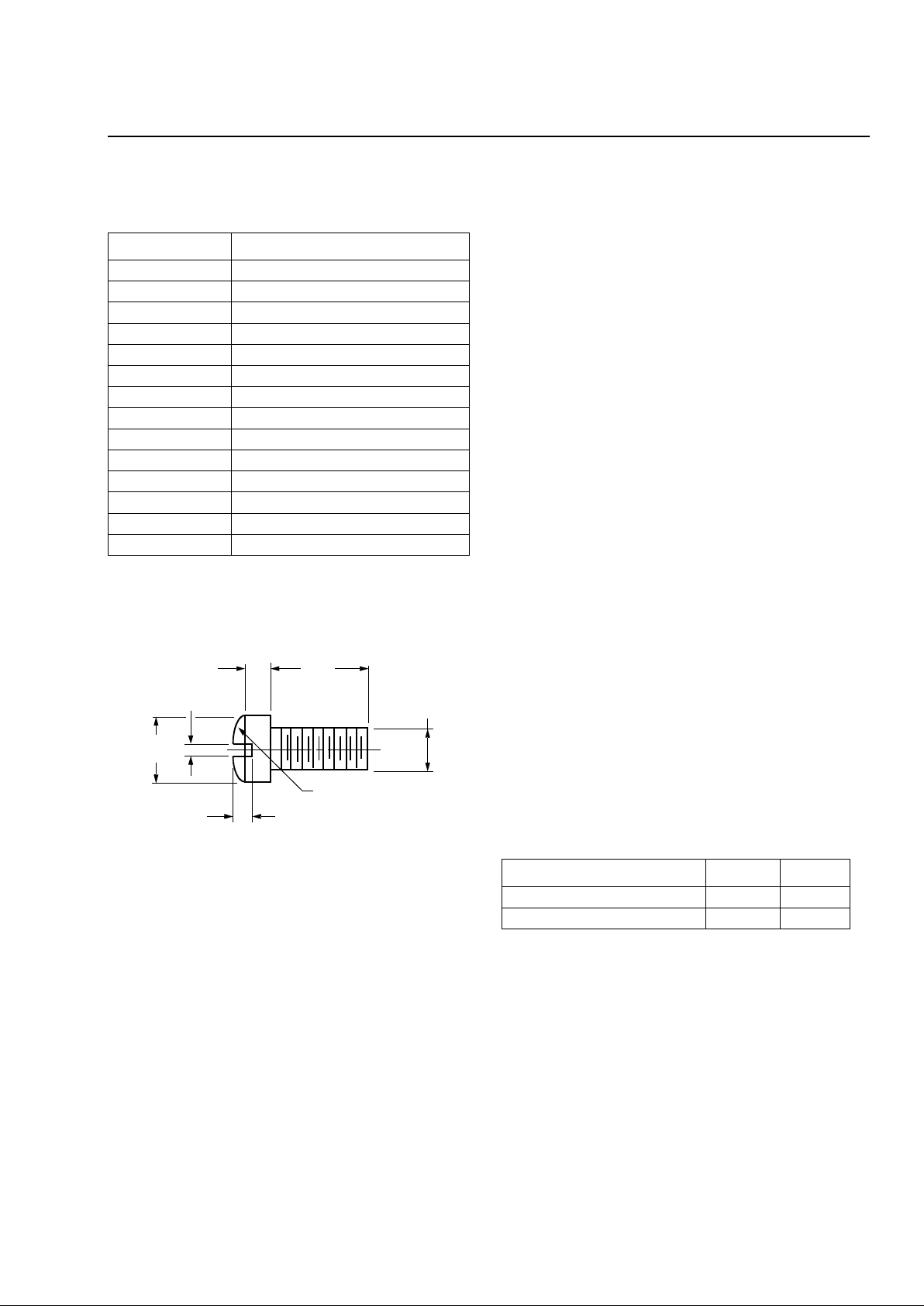

Note: Dimensions are inches and (millimeters).

1-532(F)

Figure 2. Fillister Head Screw

Power Sequencing

Adopt the following sequence for turn-on as a matter of

good practice to avoid the possibility of damage to the

pump laser module from power supply switching transients:

1. All ground connections

2. Most negative supply

3. Most positive supply

4. All remaining connections

Reverse the order for the proper turn-off sequence.

Mounting Instructions

The minimum fiber-bend radius is 25 mm.

To avoid degradation in performance, mount the mod-

ule on the board as follows (see Figure 2):

1. Place the bottom flange of the module on a flat heat

sink at least 0.5 in. x 1.180 in. (12.7 mm x 30 mm) in

size. The surface finish of the heat sink should be

better than 32 µin. (0.8 µm), and the surface flatness

must be better than 0.001 in. (25.4 µm).

Mount four #2-56 screws with Fillister heads (M23 mm) at the four screw hole locations (see Outline

Diagram). The Fillister head diameter must not exceed

0.140 in. (3.55 mm). Do not apply more than 2 in./lb. of

torque to the screws. To minimize package distortion, it

is recommended that a washer is used above and

beneath each mounting foot.

Electrostatic Discharge

Caution: This is a Class 0 ESD device which is

susceptible to damage as a result of

electrostatic discharge (ESD). Take

proper precautions during both handling

and testing. Follow JEDEC Publication

No. 108-A (Dec. 1998).

Lucent employs a human-body model (HBM) and the

field-induced charged-device model (CDM) for ESDsusceptibility testing and protection design evaluation.

ESD voltage thresholds are dependent on the critical

parameters used to define the model. A standard HBM

(resistance = 1.5 kΩ, capacitance = 100 pF) is widely

used and, therefore, can be used for comparison purposes. The HBM ESD threshhold presented here was

obtained using these circuit parameters:

Pin Connection

1 Chassis Ground

2 Chassis Ground

3 Photodetector Anode

4 Photodetector Cathode

5 Chassis Ground

6 Chassis Ground

7 Chassis Ground

8 Chassis Ground

9 Chassis Ground

10 Pump Laser Anode

11 Pump Laser Cathode

12 Chassis Ground

13 Chassis Ground

14 Chassis Ground

0.118

(3.00)

0.062 (1.58)

0.140

(3.56)

0.031 (0.79)

0.129 (3.28)

0.086

(2.18)

0.041 (1.04)

Parameter Value Unit

Charged-device Model ≥200 V

Human-body Model ≥400 V

Loading...

Loading...