AGERE 1345TNPD, 1345TNPC, 1345TMPD, 1345TMPC, 1345TBPD Datasheet

...

1345-Type Receiver with

Clock Recovery and Data Retiming

Data Sheet

January 2000

Operating at 1.3 µm or 1.55 µm wavelengths and at

155 Mbits/s or 622 Mbits/s, the versatile 1345-T ype Receiver is

manufactured in a 20-pin, plastic DIP with a multimode fiber

pigtail.

Features

■

Backward compatible with 1330 family

■

Space-saving, self-contained, 20-pin plastic DIP

■

Silicon based ICs

■

Single 5 V power supply operation including

photocurrent monitor capability

■

Exceeds all SONET (GR-253-CORE) and ITU-T

G.958 jitter requirements

■

Clocked decision circuit

■

Regenerated differential clock signal

■

Wide dynamic range

■

Qualified to meet the intent of

Telcordia Technolo-

gies

™ reliability practices

■

Operates at data rates of 155 Mbits/s or

622 Mbits/s

■

Positive ECL (PECL) data outputs

■

CMOS (TTL) link-status flag output

■

Operation at 1.3 µm or 1.55 µm wavelengths

■

Operating temperature range of –40 °C to +85 °C

Applications

■

Telecommunications:

— Inter- and intraoffice SONET/ITU-T SDH

— Subscriber loop

— Metropolitan area networks

■

High-speed data communications

Description

The 1345-Type fiber-optic receiver is designed for

use in transmission systems or medium- to highspeed data communication applications. Used in

intermediate- and long-reach applications, the

receiver operates at the SONET OC-3 or OC-12 data

rate as well as the ITU-T synchronous digital hierarchy (SDH) rate of STM-1 or STM-4, depending on

the receiver model chosen. The receiver meets all

present

Telcordia Technologies

GR-253-CORE

requirements, the current ANSI T1X1.5 intraoffice

specifications, and the ITU-T G.957 and G.958 recommendations. Compact packaging, a high level of

integration, and a wide dynamic range make these

receivers ideal for data communications.

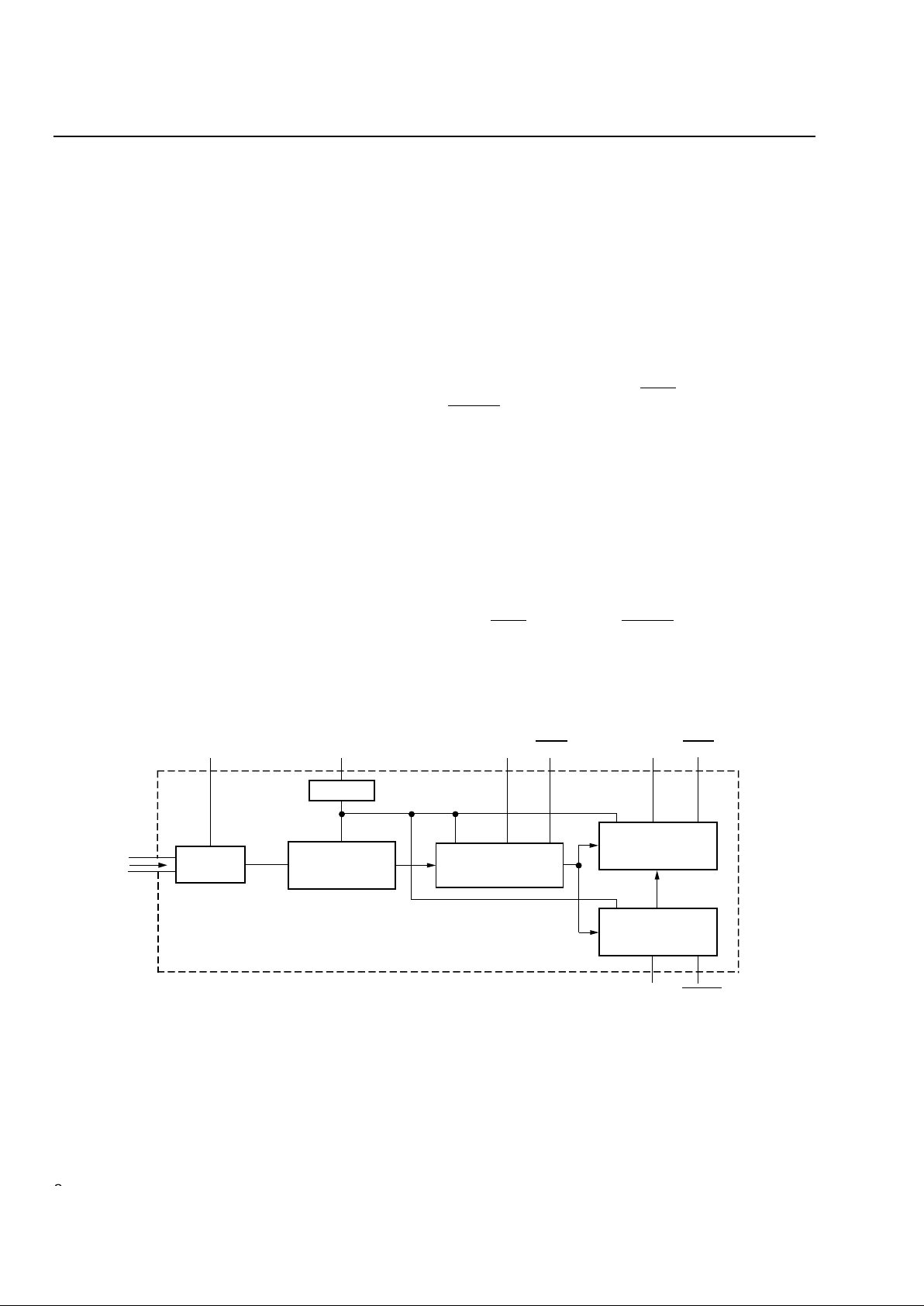

Manufactured in a 20-pin DIP, the receiver consists of

a planar InGaAs PIN photodetector, a silicon preamplifier, a silicon bipolar limiting amplifier that converts

the small signal to ECL levels, a timing recovery unit

to recover the clock, and a silicon bipolar decision circuit.

2

2

Agere Systems Inc.

1345-Type Receiver with Data Sheet

Clock Recovery and Data Retiming January 2000

Description

(continued)

The receiver converts optical signals in the range of

1.1 µm to 1.6 µm into retimed clock and data signals.

The clock and data outputs are raised-ECL (PECL)

logic levels. A CMOS-level flag output indicates when

there is a loss of optical signal.

The receiver requires a 5 V power supply for the amplifier, logic, and PLL CRC circuits. The operating case

temperature range is –40 °C to +85 °C.

Pin 10

Pin 10 on the 1345-Type receiver is not an internally

connected (NIC) pin. This definition allows the 1345 to

be used in most customer 20-pin receiver module

applications. Customer’s printed-wiring boards that are

designed with ground, +5 V, –5 V, or no connection to

this pin are all acceptable options. For those applications that require monitoring the photocurrent of the

PIN photodetector for power monitoring purposes,

there are versions of the 1345 that require +5 V or –5 V

applied to Pin 10. Check Tables 3 and 4 for ordering

information.

Flag Output

When the optical input falls below the link status flag

switching threshold, the link status flag is deactivated

and its output logic level changes from a CMOS logic

HIGH to a CMOS logic LOW.

Squelched Data and Clock Outputs

In some versions of the 1345 receiver (see Table 4),

when the link status flag is deactivated, the data and

clock outputs are squelched (stop outputting a signal).

When this occurs, the DATA, DATA

, CLOCK, and

CLOCK

outputs switch to a constant dc output voltage

level of 1.3 V.

Nonsquelched Data and Clock Outputs

Agere Systems also manufactures nonsquelching versions of the 1345 receiver for those applications that

require the data and clock outputs to continue to function after the link status flag is deactivated. In those

versions of the receiver, when the link status flag is

deactivated, a signal will continue to appear at the

DA TA, DAT A

, CLOCK, and CLOCK outputs. See T ab le 4

for nonsquelching codes.

1-724(C)

Figure 1. Block Diagram

FILTER

Si

PREAMPLIFIER

InGaAs

PIN

SILICON BIPOLAR

LIMITING AMPLIFIER

5 V DATADATA

SILICON BIPOLAR

DECISION CIRCUIT

FLAG

PLL TIMING

RECOVERY UNIT

CLOCKCLOCK

FLAG

OPTIONAL VPIN

3

Agere Systems Inc.

Data Sheet 1345-Type Receiver with

January 2000 Clock Recovery and Data Retiming

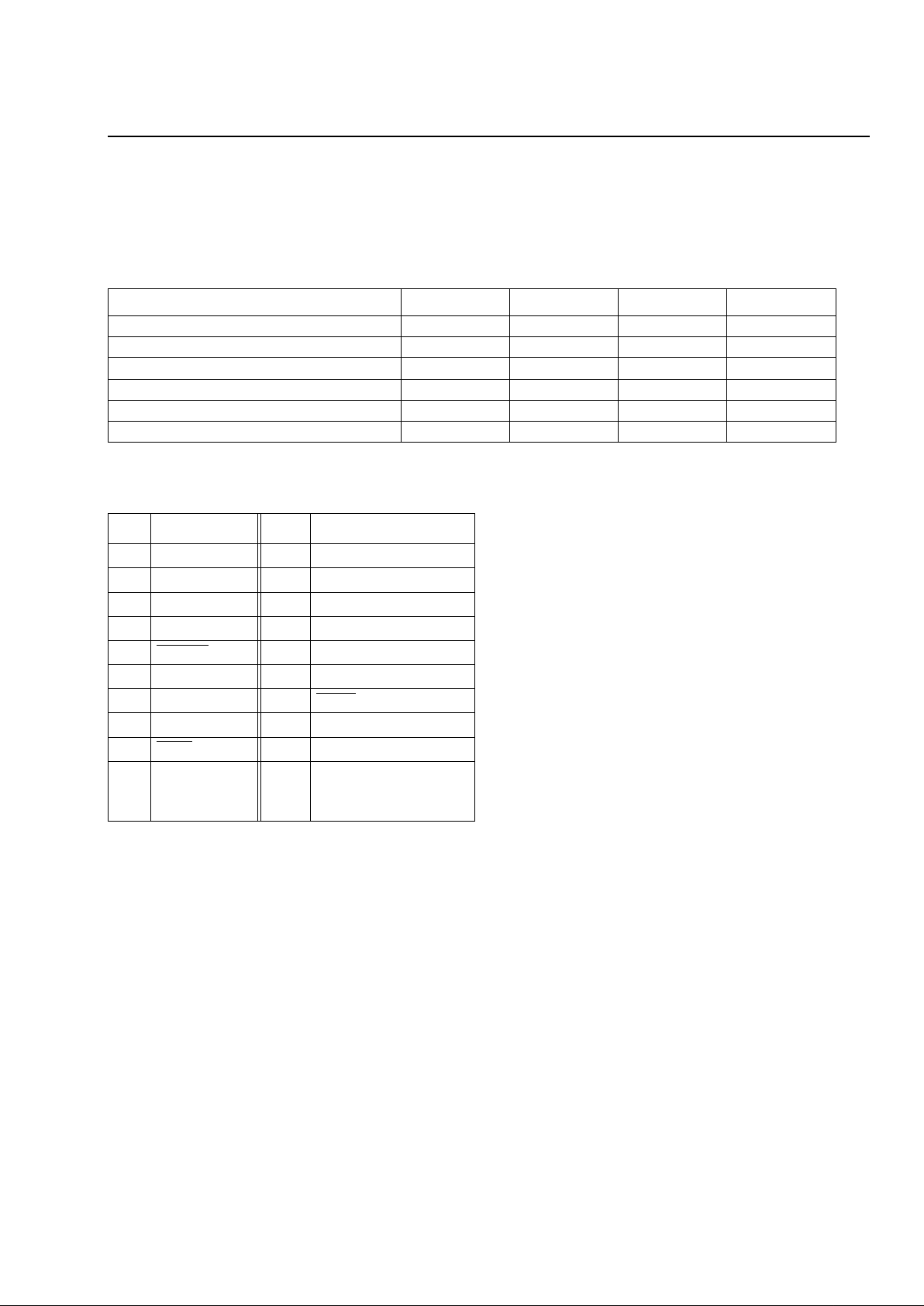

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratings only. Functional operation of the device is not implied at these or any other conditions in excess

of those given in the operational sections of the data sheet. Exposure to absolute maximum ratings for extended

periods can adversely affect device reliability.

Parameter Symbol Min Max Unit

Supply Voltage V

CC

05.5V

Operating Case Temperature Range T

C

–40 85 °C

Storage Case Temperature Range T

stg

–40 85 °C

Lead Soldering Temperature/Time — — 250/10 °C/s

Operating Wavelength Range λ 1.1 1.6 µm

Minimum Fiber Bend Radius — 1.0 (25.4) — in. (mm)

Pin Information

* Pins designated as no user connection are not connected inter-

nally. However, to allow for future functional upgrades, it is recommended that the user not make any connections to these pins.

†

The link status flag is a logic flag that indicates the presence or

absence of a minimum acceptable level of optical input. A logic

high on the FLAG output indicates the presence of a valid optical

signal.

Mounting and Connections

The pigtail consists of a 39 in. ± 4 in. (1 m ± 10 cm),

62.5 µm core/125 µm cladding multimode fiber. The

standard fiber has a 0.036 in. (914 µm) diameter tightbuffered outer-jacket. The minimum fiber bending

radius during operation is 1.0 in. (25.4 mm).

Electrostatic Discharge

CAUTION: This device is susceptible to damage

as a result of electrostatic discharge

(ESD). Take proper precautions during

both handling and testing. Follow guidelines such as

EIA

®

Standard

EIA

-625.

Although protection circuitry is designed into the

device, take proper precautions to avoid exposure to

ESD.

Agere Systems Inc. employs a human-body model

(HBM) for ESD susceptibility testing and protectiondesign evaluation. ESD voltage thresholds are dependent on the critical parameters used to define the

model. A standard HBM (resistance = 1.5 kΩ capacitance = 100 pF) is widely used and, therefore, can be

used for comparison purposes. The HBM ESD threshold established for the 1345 receiver is ±1000 V.

Receiver Processing

The 1345-Type receiver devices can withstand normal

wave-soldering processes. The complete receiver

module is not hermetically sealed; therefore, it should

not be immersed in or sprayed with any cleaning solution or solvents. The process cap and fiber pigtail jacket

can deform at temperatures greater than 85 °C. The

receiver pins can be wave-soldered at maximum temperature of 250 °C for 10 seconds.

Pin Name Pin Name

1 Ground 20 No User Connection*

2 Ground 19 No User Connection*

3 Ground 18 No User Connection*

4 CLOCK 17 No User Connection*

5CLOCK

16 Ground

6 Ground 15 Ground

7DATA 14FLAG

†

8 Ground 13 Ground

9DATA

12 FLAG

†

10 No Internal

Connection or

Optional V

PIN

11 V

CC

4

4

Agere Systems Inc.

1345-Type Receiver with Data Sheet

Clock Recovery and Data Retiming January 2000

Application Information

The 1345 receiver is a highly sensitive fiber-optic

receiver. Although the data outputs are digital logic levels (PECL), the device should be thought of as an analog component. When laying out the printed-wiring

board (PWB), the 1345 receiver should be given the

same type of consideration one would give to a sensitive analog component.

At a minimum, a double-sided printed-wiring board with

a large component-side ground plane beneath the

receiver must be used. In applications that include

many other high-speed devices, a multilayer PWB is

highly recommended. This permits the placement of

power and ground connections on separate layers,

which helps minimize the coupling of unwanted signal

noise into the power supplies of the receiver.

Layout Considerations

A fiber-optic receiver employs a very high-gain, widebandwidth transimpedance amplifier. The amplifier

detects and amplifies signals that are only tens of nA in

amplitude. Any unwanted signal currents that couple

into the receiver circuitry cause a decrease in the

receiver's sensitivity and can also degrade the performance of the receiver's loss of signal (FLAG) circuit. To

minimize the coupling of unwanted noise into the

receiver, route high-level, high-speed signals such as

transmitter inputs and clock lines as far away as possible from the receiver pins. If this is not possible, then

the PWB layout engineer should consider interleaving

the receiver signal and flag traces with ground traces in

order to provide the required isolation.

Noise that couples into the receiver through the power

supply pins can also degrade device performance. The

application schematics, Figures 2—3, show recommended power supply filtering that helps minimize

noise coupling into the receiver. The bypass capacitors

should be high-quality ceramic devices rated for RF

applications. They should be surface-mount components placed as close as possible to the receiver power

supply pins. The ferrite bead should have as high an

impedance as possible in the frequency range that is

most likely to cause problems. This will vary for each

application and is dependent on the signaling frequencies present on the application circuit card. Surfacemount, high-impedance beads are available from several manufacturers.

Data and Flag Outputs

The data and clock outputs of the 1345 receiver are

driven by open-emitter NPN transistors which have an

output impedance of approximately 7 Ω. Each output

can provide approximately 50 mA maximum output current. Due to the high switching speeds of ECL outputs,

transmission line design must be used to interconnect

components. To ensure optimum signal fidelity, both

data outputs (DATA and DATA

) and clock outputs

(CLOCK and CLOCK

) should be terminated identically.

The signal lines connecting the data and clock outputs

to the next device should be equal in length and should

have matched impedances.

Controlled impedance stripline or microstrip construction must be used in order not to degrade the quality of

the signal into the next component and to minimize

reflections back into the receiver. Excessive ringing due

to reflections caused by improperly terminated signal

lines makes it difficult for the component receiving

these signals to decipher the proper logic levels and

may cause transitions to occur where none were

intended. Also, by minimizing high frequency ringing

due to reflections caused by improperly designed and

terminated signal lines, possible EMI problems can be

avoided. The applications sections in the Signetics™

ECL 10K/100K Data Manual

or the National Semicon-

ductor

®

ECL Logic Databook and Design Guide

pro-

vide excellent design information on ECL interfacing.

The FLAG and FLAG

outputs of the OC-3/STM-1

155 Mbits/s receiver and the OC-12/STM-4 622 Mbits/s

receiver are 5 V TTL logic-level compatible. The FLAG

output is provided directly by the comparator IC. However, the FLAG output is derived from the FLAG

output

through an inverter. Excessive loading of the FLAG

out-

put can cause the FLAG output to malfunction.

Recommended User Interface

The 1345 receiver is designed to be operated from a

5 V power supply and provides raised or pseudo-ECL

(PECL) data outputs. Figures 2 and 3 show two possible application circuits for the 1345 receiver. Figure 2

represents an application for a PECL compatible interface while Figure 3 shows a possible application for an

ac-coupled, ECL-compatible interface. In both

instances, the DATA outputs are terminated with a

Thévenin equivalent circuit, which provides the equivalent of a 50 Ω load terminated to (V

CC

– 2 V). A single

50 Ω resistor terminated to (V

CC

– 2 V) could also be

used, but this requires a second power supply. Other

methods of terminating ECL-type outputs are discussed in the references previously mentioned.

Loading...

Loading...