Agatec G.C.P.V., L.P.G. G.E.P.V. User Manual

ErNs 511502

4/01

Gas Fired

\@'9,-4

Cookers

(.e]

NOTE:

TO RETAIN

The Gas fired

.uiLuirlty

or in the

THESE INSTALLATION

FUTURE

FOR

ranges

by i"

absence

arc delivered

Aifllorised

of local codes

lnstallation

Aga

Models:

Gas

G.C.

For U.S.

INSTRUCTIONS

REFERENCE.

unassembled

Distributor

Aga

with:

Power

P.V.

G.E.

P.V.

and

SHOULD

Before

and corrected

installation

whefe necessary

lnstructions

Vent

(2

Oven)

(4

Candian

LEFT

BE

Fired

N.G. and

Oven)

Markets

VMTH THE

be made,

can

conform

to

APPLIANCE

for

Range

the site

is inspected

local installation

wiih

L.P'G.

AND THE

USER

fof

codes

ln Canada:

The CANiCGA-B149

ln U.S.:

The National

Assembly

essential that

It is

weight of

Approximate

top face of

The

co'nply

The location

Fuel Gas

is undertaken

the range-

weights:

l\4odels

G.E. - 585k9

with tl-e cunent

must also

installation

the base

-

406k9

G.C.

(12901b)

the heanh

codes

ANSI 2223

Code

site by

on

or hearth

must

Building Regula

pfovide

the same

on

(900|b)

be of non-combustible

adequate

1-latest

edition

Aga Distributorto

INSTALLATION

which the

oas and

space

range stands

material

Na onal

for servicing

Flre

and aif

ensure

should

minimum

for a

Laws

circulation

correct

be level

performance and

and strong

thickness

around

enough

of 12mm

the range

safety'

to support

(1/2) and

the

WALL

TILING

lfthe cooker

overlap

NOTE:

Eiienrni

APPLIANCE.

ALL GAS

Maximum

The maximum

L. P. Gas. TFe

for

wg. L.P.

appliance and

The

anv o;essure

isoijtea

t;ating of

on completion

according

is to stand

the range

A [4ANUAL

io rne nppLrANcE

CONTROLS

Heat

gas

Gas to enable

testinq ofihat

from tne

gas-suppli

the

to manufactureis

in a fecess

plate.

top

VALVE lllUST

MUST

lnput 4.4kW

pressure

inlet

minimum

its individual

ga1

test the

gas

the correct

svstem

supply

pi6lng

gas

installation

or against a

GAS SUPPLY

BE INSTALLED

THE PURPoSE

FoR

BE U.S. PIPE

(15,000

piping

instuctions.

Btu/h)

at the appliance

pressrlrc

inlet

manifold

shut-offvalve

at test

system

syiteh

THREADS.

at the

Pressure

must

pressures

by closing

at te.t

for soundness

prcsstre

wallwhich

-

lN AN

must

be disconnected

is to be tiled,

U.S. PIPE

ACCESSIBLE

TURNING

oF

not exceed

appliance

be obtained

to

in excess

its Individual

equal to or

purge.

and

in no circLlmstances

THREADS

oN oR SHUTTING

1o inches

must be 5

from

psig (3.skPa).

1/2

of

manual

less than

testing

Leak

LOCATION

w.g. for Natural

inches w

gas

the

shut-offvalve

1/2

ofthe appliance

lN

g

NaturalGasand11

supply

The

psi (3

should the

THE GAS

oF GAS To

Gas,

piping

appliance

duing

skPa)

shall

tiles

PIPE

rHE

14 inches

inches

system

any

during

must be

pressure

be conducted

w-g

NOTE:

Kitchen

ii'" ipptilncacan

room must

In the event

to satisfy

Use soapy

or Intemal

have a

of an extractor

the demands

gas

new

water solution

Ai. SUPPIY

onty be

permanent vent of minimum

ofthe

on

initilled

fan being

in a room

fan wit-hout

fltted in

connections

which meets

the vacinity

influencing

SUPPLY

AIR

free air

combustion

to ensure

ventilaiion

area 36cm

ofthe range,

efficiency

there are

regulations

(5

2

2

sin

)

compensatory

and

no

leaks

in force

flue conditions

but in any

ventllation

event the

will be requircd

gas

ELECTRICAL

1'10/l2oV6oHz,loAN4PFLEX|BLEcoRDANDPLUGPAMLLELTYPE.Theapp|iancewheninsta||ed,mustbe

ete;11ically

Codes

etectrical socket

An

user to disconnect.

grounded

ANSI/NFPA

in accordance

70.

must

Do

be

position

not

with local

provided

within 6

socket above

codes or, in

feet ofthe

Eleciiical

the appliance.

Grounding

the absence

LH side ofthe

WARNING

Instiuctions

of local

appliance

codes,

w1h the Na6onal Electrical

and easily

accessible

to the

Thisapp|ianceisequippedwitha(three-prong)groundingp|ugforyourprotectionagainstashockhazardand

snould

plugged

be

dirbitly

into a

proper

receptaale

Do not

cut or

remove the

grounding

prong

from

this

plug

VENT SYSTEM

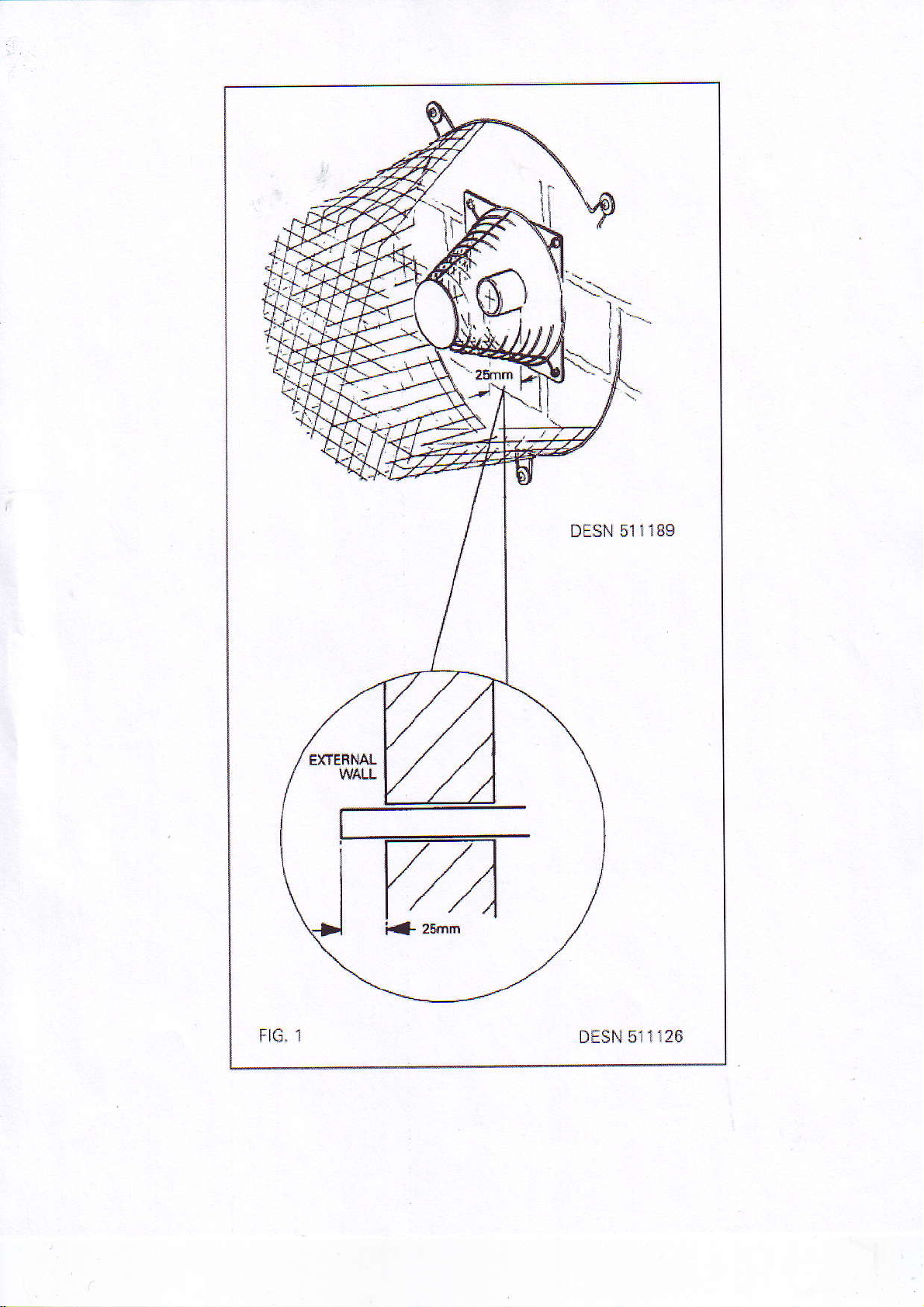

Products of combustion

metres

appliance can be

The vent

(19.5fr)

in length through a

pipe

should

discharge is by a fan

from rear L.H. or-R.H. sides, from the

exit through the outsrde

powered

Faximum

of 6 x 90' bends

wall fixing

pipe

vent

rear centre or

plate

50mm

or I metres

by 25mm

(2in)

diameter which can

(29ft)

with one

from the under side

(

1in) Fig. 1

bend Exits from the

(Figs.

2 & 3).

reach up to 6

DESN 511189

1

FIG,

DESN 511

126

rtt

el ffic{lrhl

S|l'E

EL

i f,ffi

gx

al'lr: ml

||!$ru

ffi.TD

tHtt^tsl

]

!t \rrfir ntr{N

o

off

xtE

||n/rdr*l

I L,'1: lSilr$d€l,M

I nE|,|n&

!3r

t'

Carejts|* t &€l rU rids

vArft !*hr&fig donlr6b. Wdng r.rq$ {3i

]rrpr.fllr

rawF

\is|ly

frsrnl

qrd

d!ng4|qf

{rr'ldrrt als $dr6s.

& *xs{ra$hn

ldar

cp!|q!rj

Loading...

Loading...