Page 1

With specific exceptions, the installing of any type of Aga

Cooker is subject to the respective directions contained in

current issue of The Building Regulations. In addition,

Planning Permission may need to be obtained, which

should be applied for separately. The complete range of

Aga cookers are suitable for Natural or Propane gases

only and cannot be used on any other gas.

The complete cooker is floor-mounted and the space in

which the appliance is to be fitted must have the following

minimum dimensions:-

A minimum clearance of 60mm is required above the

raised insulating cover handle.

Side Clearances: A 3mm gap is required each side

between the cooker top plate and adjoining work surfaces

that maybe fitted, this is to allow for the safe removal of

the top plate should this be required at a later date.

Where cookers are fitted against side walls a 116mm

clearance is required at the right hand side for oven doors

access. (A further 116mm is necessary if a left hand side

gas connection is required.

If the Aga is to be installed in a brick recess, then the

minimum clearances should be increased by at least

10mm on either side, to allow for the walls not being

square and also for the natural dimensional variations

found in the castings.

In addition a minimum clearance of 1000mm must be

available at the front of the cooker to enable the cooker to

be serviced.

NOTE: AGA GAS FIRED COOKERS ARE DELIVERED

EX-WORKS UNASSEMBLED. ASSEMBLY IS

UNDERTAKEN ON SITE BY THE AUTHORISED AGA

DISTRIBUTOR.

Cooker Base or Hearth

It is essential that the base or hearth on which the cooker

stands should be level and be capable of supporting the

total weight of the respective cooker.

Models GC and GCB 406Kg, GE and GEB - 584Kg.

The top of the hearth must be of non-combustible material

thickness of 12mm.

The wall behind the cooker must be of non-combustible

material for a minimum thickness of 25mm.

Tiling

When the cooker is to stand in a recess, or against a wall

which is to be tiled, in no circumstances should the tiles

overlap the cooker top plate.

Installation Requirements

The installation of the cooker must be in accordance with

the relevant requirements of the Gas Safety Regulations,

Building Regulations and the bylaws of the local Water

Undertaking.

It should be in accordance also with any relevant

requirements of the Gas Region and Local Authority.

In you own interest, and that of safety to comply with the

law, all gas appliances should be inst alled by a competent

person, in accordance with the relative regulations.

Failure to install appliances correctly could lead to

prosecution.

On completion, test the gas installation for soundness.

REMEMBER, when replacing a part on this appliance,

use only spare parts that you can be assured conform to

the safety and performance specification that we require.

Do not use reconditioned or copy parts that have not been

clearly authorised by AGA.

Installation Instructions for

Aga BF Gas Fired Cooker Models

GC, GCB, GE and GEB

Consumer Protection

As responsible manufacturers we take care to make sure that our

products are designed and constructed to meet the required safety

standards when properly installed and used.

IMPORTANT NOTICE: PLEASE READ THE ACCOMPANYING

WARRANTY. Any alteration that is not approved by Aga could

invalidate the approval of the appliance, operation of the warranty

and could affect your statutory rights.

Important

This appliance may contain some of the materials that are indicated.

It is the Users/Installers responsibility to ensure that the necessary

personal protective clothing is worn when handling, where

applicable, the pertinent parts that contain any of the listed materials

that could be interpreted as being injurious to health and safety, see

below for information.

Firebricks, Fuel beds, Artificial Fuels - when handling use disposable

gloves.

Fire Cement - when handling use disposable gloves.

Glues and Sealants - exercise caution - if these are still in liquid form

use face mask and disposable gloves.

Glass Yarn, Mineral W ool, Insulation Pads, Ceramic Fibre, Kerosene

Oil - may be harmful if inhaled, may be irritating to skin, eyes, nose

and throat. When handling avoid inhaling and contact with skin or

eyes. Use disposable gloves, face-masks and eye protection. After

handling wash hands and other exposed parts. When disposing of

the product, reduce dust with water spray, ensure that parts are

securely wrapped.

FOR USE IN GB & IE

Gas Fired Cookers

PLEASE READ THESE INSTRUCTIONS BEFORE INSTALLING YOUR AGA

1 03/07 EINS 511056

INSTALLATION

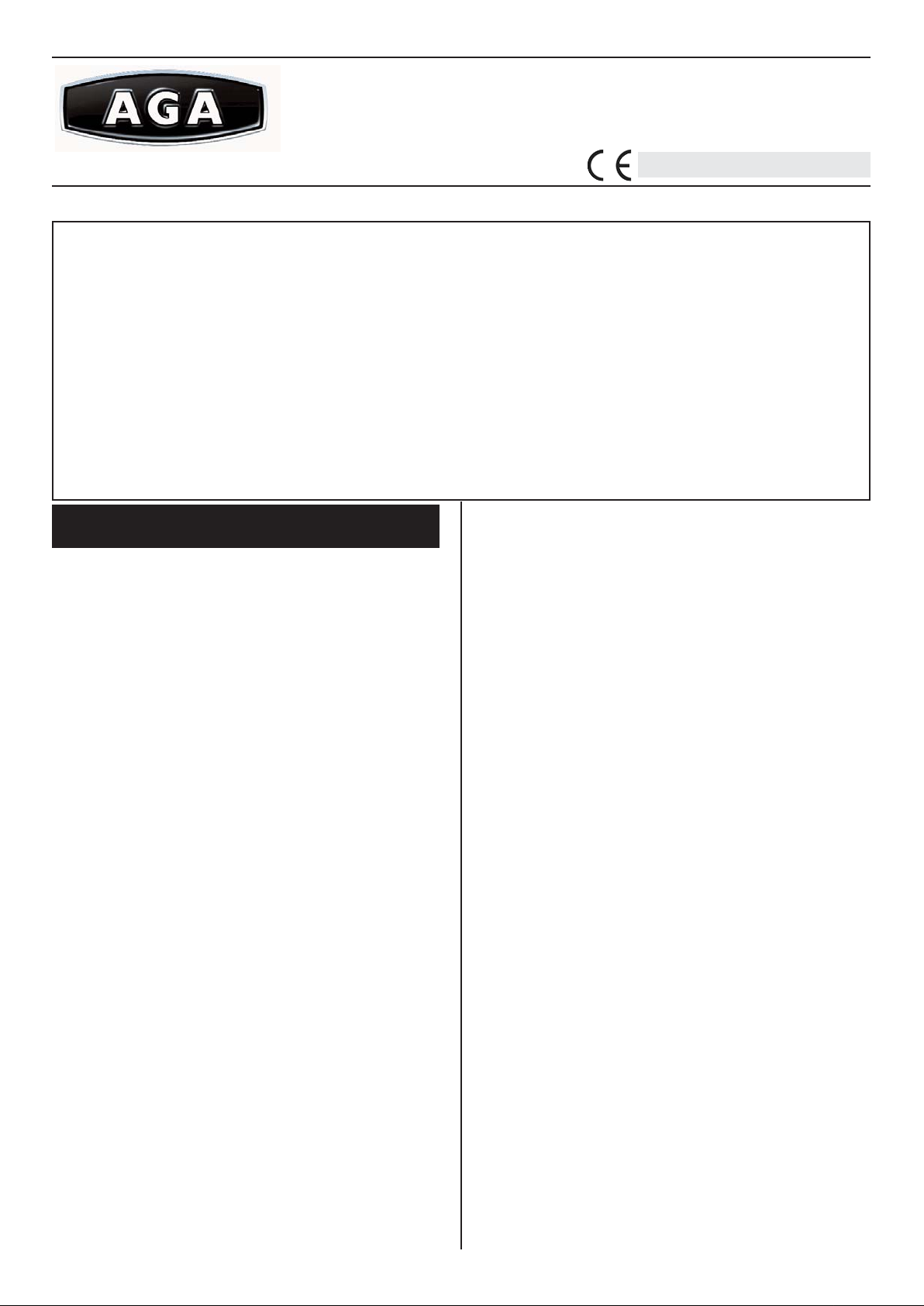

Page 2

2

ABCDEFGHJKLMNPQ STUV

mm

987 889 851 679 41

1330

756

1125

39

3

698 499 127 41 530R116 770 484 328 828

NATURAL G20

MAXIMUM HEAT INPUT 5kW 5kW

Thermostat Bypass 100 or 120 120 or 140

Main Burner Injector 285 285

Pilot Injector N35 N35

Inlet Pressure G20 20mbar 20mbar

PROPANE G31

MAXIMUM HEAT INPUT

5kW (357g/h) 5kW (357g/h)

Thermostat Bypass 60 or 80 80 or 100

Main Burner Injector 180 180

Pilot Injector L23 L23

Inlet Pressure 37mbar 37mbar

Burner Pressure 28mbar 28mbar

Models GC and GCB Balanced flue GC GCB

For Natural Gas the gas valve outlet pressure is non-adjustable, BUT for reference purposes only . A pressure

drop of 1-2mbar can be observed between inlet and outlet pressures on a cold appliance.

V = VENT PIPE

S = FLUE PIPE

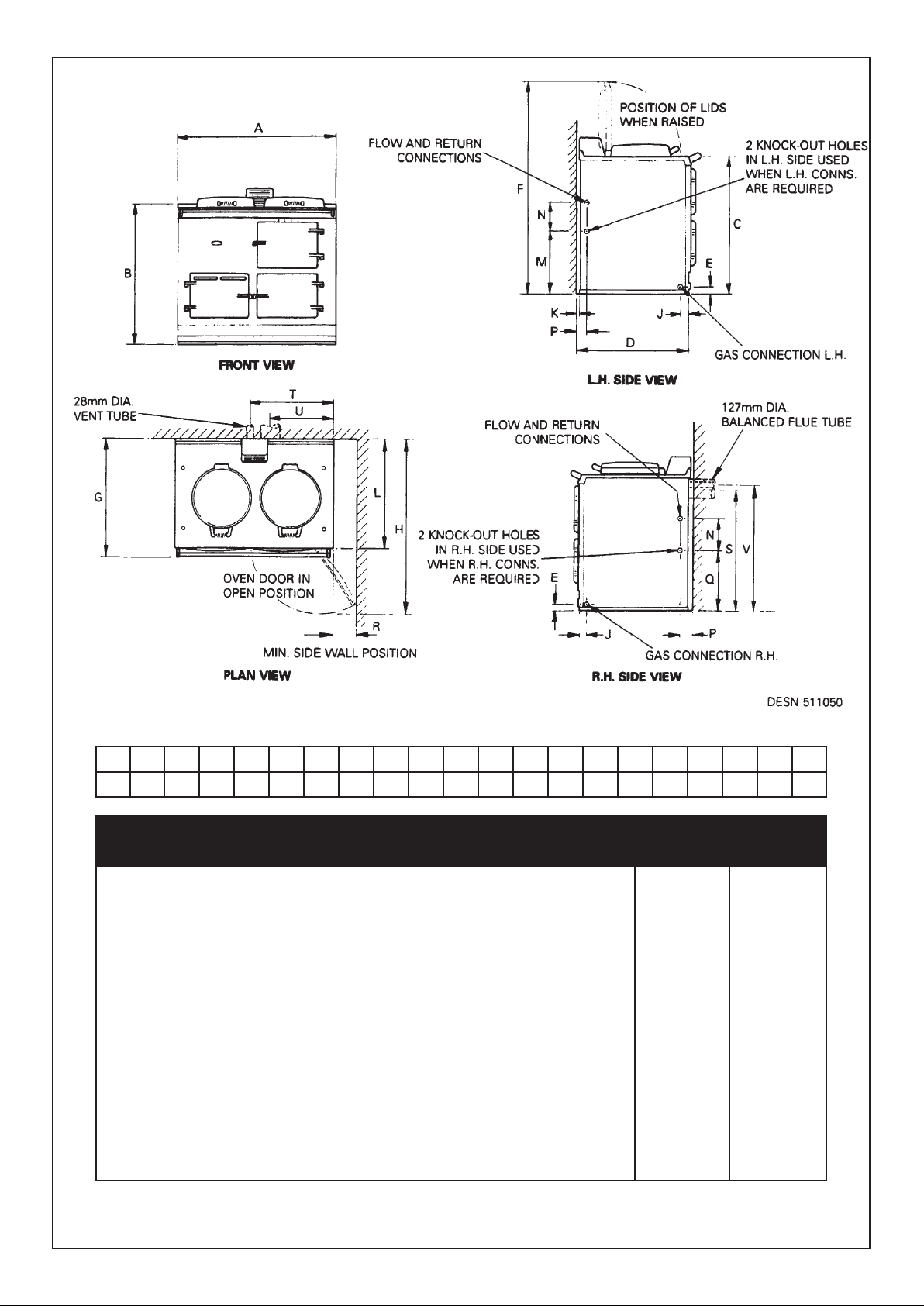

Page 3

3

NATURAL G20

MAXIMUM HEAT INPUT 5kW 5.8kW

Thermostat Bypass 100 or 120 120 or 140

Main Burner Injector 285 330

Pilot Injector N35 N35

Inlet Pressure G20 20mbar 20mbar

PROPANE G31

MAXIMUM HEAT INPUT

5kW (357g/h)

5.8kW (414g/h)

Thermostat Bypass 60 or 80 80 or 100

Main Burner Injector 180 200

Pilot Injector L23 L23

Inlet Pressure 37mbar 37mbar

Burner Pressure 28mbar 32mbar

Models GE and GEB Balanced flue GE GEB

ABCDEFGHJKLMNPQ STUV

mm

1487

889 851 679 41

1330

756

1125

39

3

698 632 591 51 67R116 770 484 328 828

For Natural Gas the gas valve outlet pressure is non-adjustable, BUT for reference purposes only . A pressure

drop of 1-2mbar can be observed between inlet and outlet pressures on a cold appliance.

V = VENT PIPE

S = FLUE PIPE

Page 4

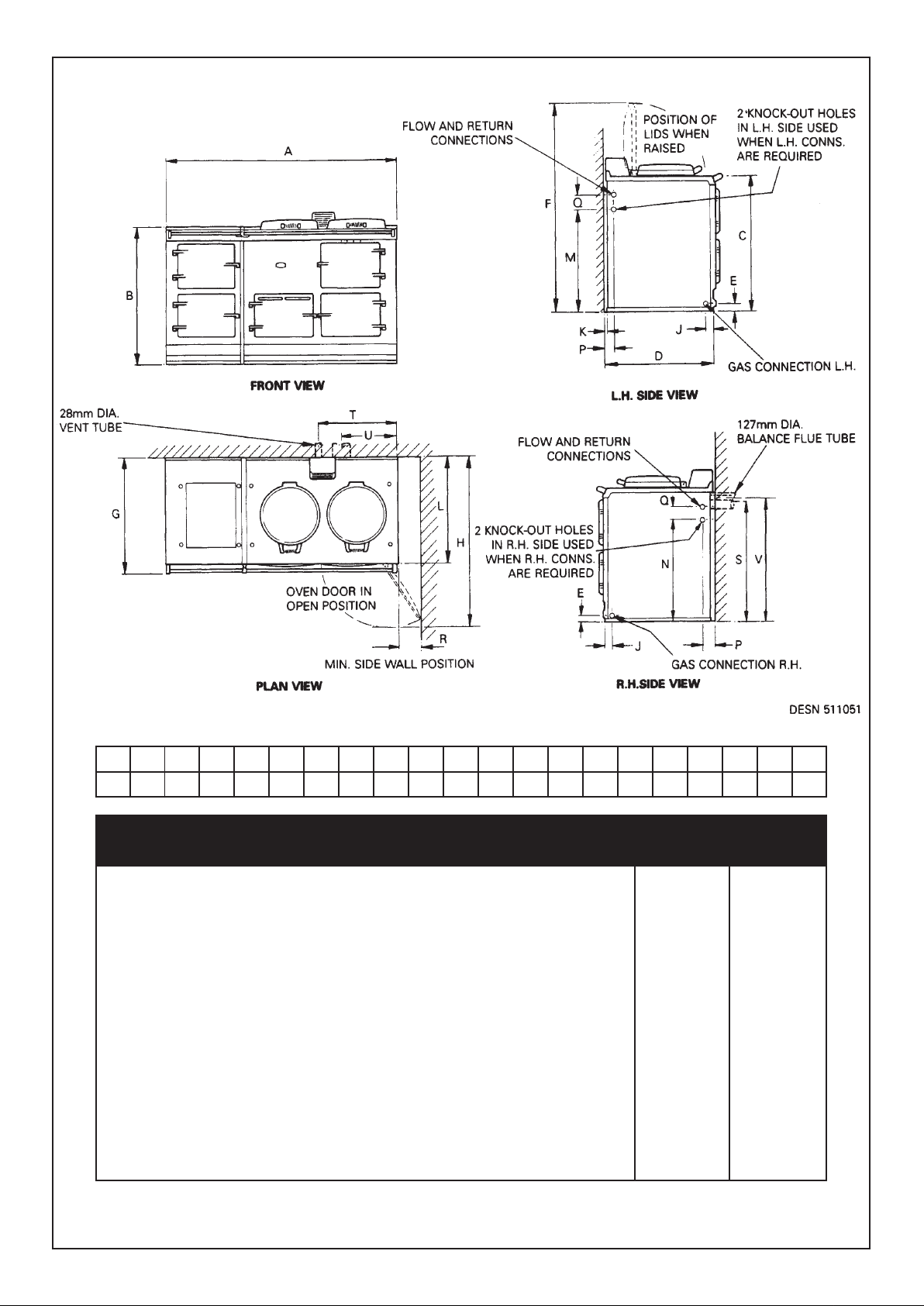

The terminal is suitable for wall thicknesses from 228mm

to 600mm cut size

Should the installation of the appliance be in an unusual

location or restricted space, special procedures may be

necessary.

Terminal Position

The minimum acceptable spacings from the terminal to

obstructions and ventilation openings are as shown in the

diagram.

Where the terminal is fitted within 600mm below plastic

guttering an aluminium shield 1500mm long should be

fitted to the underside and immediately beneath the

guttering or eaves.

Where the terminal is fitted within 450mm below eaves or

painted guttering an aluminium shield 750mm long should

be fitted to the underside and immediately beneath the

guttering or eaves.

Minimum siting dimensions for Balanced Flue terminals

Position Minimum Spacing

mm

A Directly below an openable window,

air vent, or an other ventilation opening 300

B Below gutter, drain/soil pipe 300

C Below eaves 300

D Below a balcony or car port roof 600

E From vertical drain pipes and soil pipes 300

F From internal or external corners 600

G Above adjacent ground or balcony level 300

H From surface facing the terminal 600

I Facing terminals 600

J From opening (door/window)

in car port into dwelling 1200

K Vertical from a terminal 1500

L Horizontally from a terminal 300

Terminal Protection

A terminal guard is supplied with the cooker and must be

fitted if flue termination is less than 2 metres above

ground level, or subject to damage.

When fitted, it must be positioned to provide a minimum

of 50mm clearance from any part of the terminal and be

central over the terminal.

4

FLUE SYSTEM

AROUND THE HOUSE

DESN 511052

UNDER CAR PORT, ETC.

DESN 511053

Page 5

Kitchen or Internal Space Air Supply

Where the appliance is to be installed in a kitchen or

internal space, it does not require the kitchen or internal

space containing it to have a permanent air vent.

Installation pipes should be fitted in accordance with

current Gas Regulations. Pipework from the meter/tank to

the cooker must be of adequate size, cooker connection

size of 15mm Dia. On completion test the gas installation

for soundness and purge in accordance with current Gas

Regulations.

A 3Amp 230V~50Hz fused electrical supply is required

adjacent to the appliance. External wiring to the fan unit

must be installed using a 3 core heat resisting 85°C PVC

sheathed cable and in accordance with the current Wiring

Regulations and any local regulations which apply. The

wiring should be completed as indicated:

The method of connection to the mains electricity supply

must facilitate complete electrical isolation of the

appliance, preferably by the use of an unswitched

shuttered socket outlet in conjunction with a fused three

pin plug. Alternatively, a fused double pole switch, having

a contact separation of at least 3mm in both poles, serving

only the appliance may be used.

(Models GCB and GEB Only)

In a domestic hot water system, the hot water storage

vessel must be of the indirect cylinder of calorifier type.

The hot water storage vessel should be insulated,

preferably, with not less than 75mm thick mineral fibre, or

its equivalent.

Pipework not forming part of the useful heating surface

should be insulated to help prevent heat loss and possible

freezing, particularly where pipes are run through roof

spaces and ventilated under floor spaces. Cisterns

situated in areas which may be exposed to freezing

conditions should also be insulated.

Draining taps must be located in accessible positions

which permit the draining of the whole system, including

the boiler and hot water storage vessel.

Draining taps should be at least 15mm nominal size. The

use of horizontal pipe runs should be avoided wherever

possible in order to prevent the collection of air in the

system. If horizontal runs are unavoidable, the pipes

should rise upwards in the direction away from the boiler.

Hot water systems should be in accordance with the

relevant recommendations.

Water Circulation System

(Models GCB and GEB only)

The cooker boiler should be connected to a cistern water

supply and subject to a maximum head of 18.25m and

minimum 1m.

The 28mm minimum diameter primary flow pipe must rise

continuously from the cooker boiler to the cylinder to

ensure good gravity circulation and have an open vent.

The 28mm diameter primary flow and return pipes must

not exceed 5.5m in length and be well insulated.

Water Connections

(Models GCB and GEB only)

The two 28mm copper flow and return pipes from the

boiler can be obtained for right or left hand connections.

Hot Water Storage Vessel

It is recommended that an indirect 190 litre (40 gallon) hot

water storage cylinder of the double feed type should be

lagged and fixed vertically as near as possible to the

cooker.

The water draw-off pipes to the taps must be dead leg

connection from the vent/expansion pipe.

A drain tap must be fitted at the lowest point of the

system.

Cooker Boiler Heat Exchanger

The heat exchanger must be connected to a 190 litre (40

gallon) copper double feed indirect cylinder.

THE HOT WATER SYSTEM

5

INSTALLATION PIPES

ELECTRICAL

AIR SUPPLY

Page 6

LIGHTING THE BURNER - Fig. 2

CAUTION: NO SMOKING OR NAKED LIGHTS

Open the outer burner door to expose the gas control

combination valve.

CAUTION: BEFORE LIGHTING: ENSURE THAT THE

GAS VALVE CONTROL KNOB 2 IS SET IN THE OFF

POSITION (SEE FIG. A) AND COMBUSTION

DISCHARGE SAFETY DEVICE BUTTON IS

DEPRESSED.

1. Turn off union gas cock 1. Test the gas installation

from the meter cock for soundness and purge.

2. Turn on gas supply to cooker and open gas cock 1.

3. Turn the gas valve control knob 2 anti-clockwise to

the position (see Fig. B.). Press down and hold the

knob in the position while depressing the piezo ignitor

3 several times until the pilot has lit. This can be

observed through the viewing window 4.

4. When the pilot has lit continue to hold the gas valve

control knob for approximately 30 seconds. If it goes

out, wait 3 minutes and repeat the procedure holding

for a little longer.

5. With the pilot flame established, release the gas valve

control knob 2 gradually and rotate anti-clockwise to

its low fire position. Where upon the main burner will

automatically light. Leave in the low fire position for at

least 30 minutes.

NOTE: ANY ATTEMPT TO ROTATE THE CONTROL

KNOB BEFORE RELEASE MAY RESULT IN

DAMAGE.

6. After 30 minutes rotate the control knob further anti-

clockwise to the mid-position of the green band for

normal running (see Fig. D).

6

COMMISSIONING

OFF ON

DESN 510252 ‘A’

FIG A

OFF

IGNITION

WHITE BLOCK

LOW FIRE

GREEN BAND

NORMAL RUNNING

FIG B

FIG C

FIG D

6

5

Page 7

NOTE: AFTER SEVERAL HOURS THE HEAT

INDICATOR SHOULD BE ON OR ABOUT THE BLACK

LINE IN THE SILVER SECTION.

IT MAY BE NECESSARY TO ADJUST THE CONTROL

KNOB SLIGHTLY IN THE GREEN BAND TO ACHIEVE

THIS.

IF THE FLAME HAS EXTINGUISHED FOR WHATEVER

REASON, WAIT THREE MINUTES (MINIMUM) BEFORE

RE-LIGHTING.

7. On the first lighting or if the cooker has been cold for

a long time. moisture from the insulation may run

down the enamelled front of the cooker. This should

be wiped off to prevent staining.

8. Check the inlet gas pressure is as indicated in the data

plate as follows:

(i) Turn the gas valve control knob 2 to OFF position (see

Fig. A). Remove the inlet pressure test nipple plug 5

and fit pressure gauge. Turn gas valve control knob 2

to the mid position of green band.

(ii) Check inlet pressure correctly corresponds to the

data plate.

(iii) Check that the gas pressure is unaffected when other

gas appliances are used.

(iv)Turn gas valve control knob 2 to ignition position (see

Fig. B). Remove the pressure gauge and replace gas

nipple plug. Turn gas valve control knob 2 to the

mid-position of the green band for normal running.

NOTE FOR L.P. COOKERS ONLY

Repeat instruction 8 on completely cold cooker with the

pressure gauge fitted to the burner pressure test point 6.

Check that the burner pressure correctly corresponds to

the table on pages 2 or 3.

NOTE: IF FOR ANY REASON A GAS RATE CHECK IS

REQUIRED, TURN OFF ALL OTHER APPLIANCES

USING GAS AND USING THE GAS METER TEST DIAL

AND STOP WATCH, CHECK THAT THE MAXIMUM GAS

INPUT IS AS INDICATED ON THE DATA PLATE.

Once the correct setting has been confirmed, the heat

control will operate automatically to maintain the

cooker at full temperature.

NOTE: REMEMBER TO NOTE THE SETTING

POSITION IF TURNING OFF THE COOKER.

Hand these and the Operating Instructions to the User for

retention and instruct in the safe operation of the

appliance.

Advise the User of the precautions necessary to prevent

damage to the Domestic Hot Water System and to be

building in the event of the Domestic Hot Water System

remaining inoperative during frost conditions.

Finally advise the User that, for continued efficient and

safe operation of the appliance it is important the

adequate servicing is carried out at regular intervals

recommended by the Aga Distributor or local Gas Region.

7

INSTRUCTIONS

Page 8

8

With Aga's policy of continuous product improvement, the

Company reserves the right to change specifications and make

modifications to the appliance described and illustrated at any time.

Aga

For further advice or information contact your

Station Road local distributor/stockist.

Ketley Telford

Shropshire TF1 5AQ

www.aga-web.co.uk www.agalinks.com

England www.agacookshop.co.uk

Loading...

Loading...