Page 1

AGA SIX-FOUR SERIES - DC6 (FFD)

OWNERS MANUAL

(L.P.G.)

05/07 EINS 512453

PLEASE READ THESE INSTRUCTIONS BEFORE USING THIS APPLIANCE

Remember, when replacing a part on this appliance, use only spare parts that you can be

assured conform to the safety and performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised by Aga.

For use in GB and IE

Comprising

Servicing, Installation & Users

Instructions

&

Cooking Guide

DESN 512387 A

Page 2

SECTION PAGE

INSTALLATION SECTION 3

INSTALLATION 4

TECHNICAL DATA 5

FITTING AND PRODUCT DIMENSIONS 6

ELECTRICAL CONNECTION 7-8

CONNECTING TO GAS 9-11

PRESSURE TESTING 11

LEVELLING AND MOBILITY WHEELS 12

FITTING OF HOTPLATE CASTINGS AND PAN 13-17

SUPPORTS

SPLASHBACK 17

USERS GUIDE 18

GENERAL INFORMATION 19

HEAL TH AND SAFETY 20

PRODUCT VIEW 21

CONTROL PANEL 22

GAS HOTPLATE 23-24

FITTING OF PAN SUPPORTS 25

SETTING UP THE COOKER FOR USE 26

SIMMERING OVEN 27

SIMMERING OVEN RECIPES 28-31

THE GRILL 32

THE OVENS 33

OVEN COOKING GUIDE 34-38

THE MINUTE TIMER 39

AUTOMATIC COOKING CONTROL 40-41

CLEANING AND CARING FOR YOUR COOKER 42-47

SERVICING SECTION 48

SERVICING 49-57

WIRING DIAGRAM 58

2

CONTENTS

Page 3

Installation

Section

3

Remember, when replacing a part on this appliance, use only spare parts that you can be

assured conform to the safety and performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised by Aga.

Page 4

INSTALLATION

WARNING: THIS APPLIANCE SHALL BE INSTALLED IN ACCORDANCE WITH THE

REGULATIONS IN FORCE AND ONLY USED IN A WELL VENTILATED SPACE, READ THE

INSTRUCTIONS BEFORE INSTALLING OR USING THIS APPLIANCE.

PRIOR TO INSTALLATION, ENSURE THAT THE LOCAL DISTRIBUTION CONDITIONS

(TYPE OF GAS AND GAS PRESSURE) AND THE ADJUSTMENTS OF THE APPLIANCE ARE

COMPATIBLE.

THE ADJUSTMENT CONDITIONS FOR THIS APPLIANCE ARE STATED ON THE DATA

PLATE WHICH IS SITUATED IN THE RIGHT HAND VENT SLOT AT THE BASE OF THE

APPLIANCE.

This appliance is not connected to a combustion products evacuation device. It must be installed

and connected in accordance with current installation regulations. Particular attention shall be

given to the relevant requirements regarding ventilation. (B.S. 5440 Part 2). It should be in

accordance also with any relevant requirements of the Gas Region and Local Authority.

In your own interest, and that of safety to comply with the law, all gas appliances must be

installed by a competent person. Failure to install appliances correctly could lead to prosecution.

On completion, test the gas installation for soundness.

WARNING: THIS APPLIANCE MUST BE EARTHED.

The appliance is designed for the voltage stated on the data plate.

The DC6 is supplied from the manufacturers as a fully tested chassis construction. Hot plate,

doors, splashback, pan supports and handrail are assembled during installation.

4

Page 5

HOTPLATE

PROPANE G30/G31 - (APPLIANCE CATEGORY I

3+

)

L.H.F. R.H.F. R.H.R. L.H.R. CENTRE CENTRE

WOK FRONT REAR

BURNER TYPE UL TRA-RAPID RAPID RAPID SEMI-RAPID SEMI-RAPID UL TRA-RAPID

MAXIMUM HEAT 4.0 kW 3.0 kW 3.0 kW 1.75 kW 1.75 kW 5.0 kW

INPUT (287g/h) (215g/h) (215g/h) (125g/h) (125g/h) (360g/h)

INJECTOR MARKING

MAIN 0.46 85 85 65 65 110

SECONDARY 0.66 - - - - -

PRESSURE POINT POSITION:REAR RH SIDE OF HOTPLATE

PRESSURE SETTING: G30 = 28 mbar G31: 37mbar

BURNER IGNITION: H.T. SPARK

ELECTRIC GRILL AND OVENS

TOP OVEN POWER RATING - 1.45 kW

GRILL ELEMENT - POWER RATING 2.25kW

SLOW COOKING OVEN - POWER RATING 0.9kW

LOWER OVEN (FAN) - 2.0kW

230V 30 AMP POWER SUPPLY

This is a CLASS 1, type X appliance.

The data plaque is located on a pull out plate - lower front of appliance (See Fig. 10, Page 21).

TECHNICAL DATA

5

Page 6

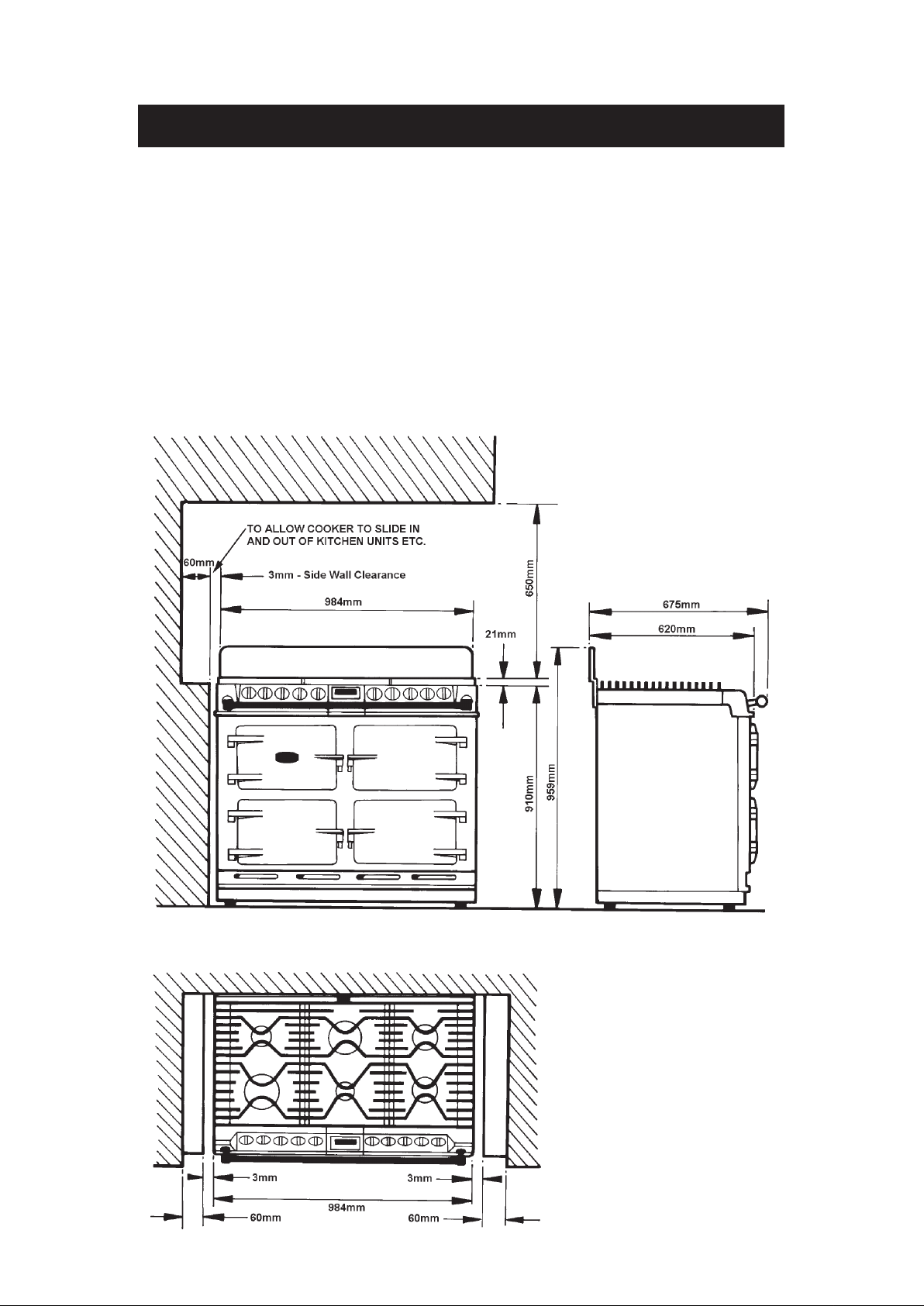

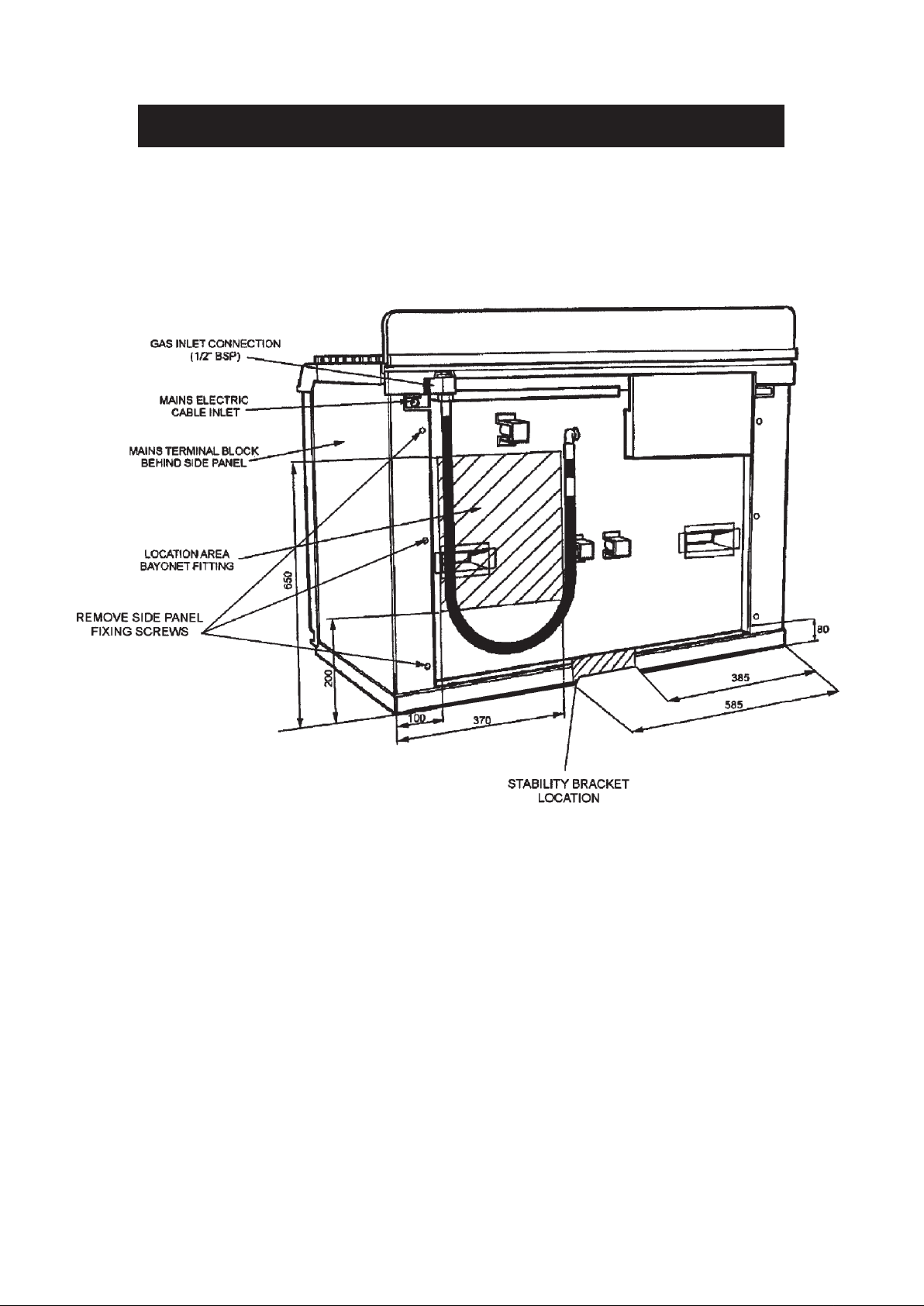

FITTING AND PRODUCT DIMENSIONS

6

Fig. 1

DESN 512388 C

Any side wall above the cooker on either side shall be not less than 60mm horizontally from the

cooker (Fig. 1).

Surfaces over the top of the cooker must not be closer than 650mm.

A minimum clearance of 1000mm must be available at the front of the cooker to enable it to be

serviced.

The vent slots in the back of the top plate must not be obstructed.

The cooker must stand on a firm and level surface and we recommend that any soft material

such as linoleum is removed.

PLEASE NOTE: WHEN FITTING A COOKER HOOD

If a cooker hood is to be fitted, we only recommend the 6-4 Series CH900 cooker hood. It must

be installed at a height of at least 800mm above the hotplate.

Page 7

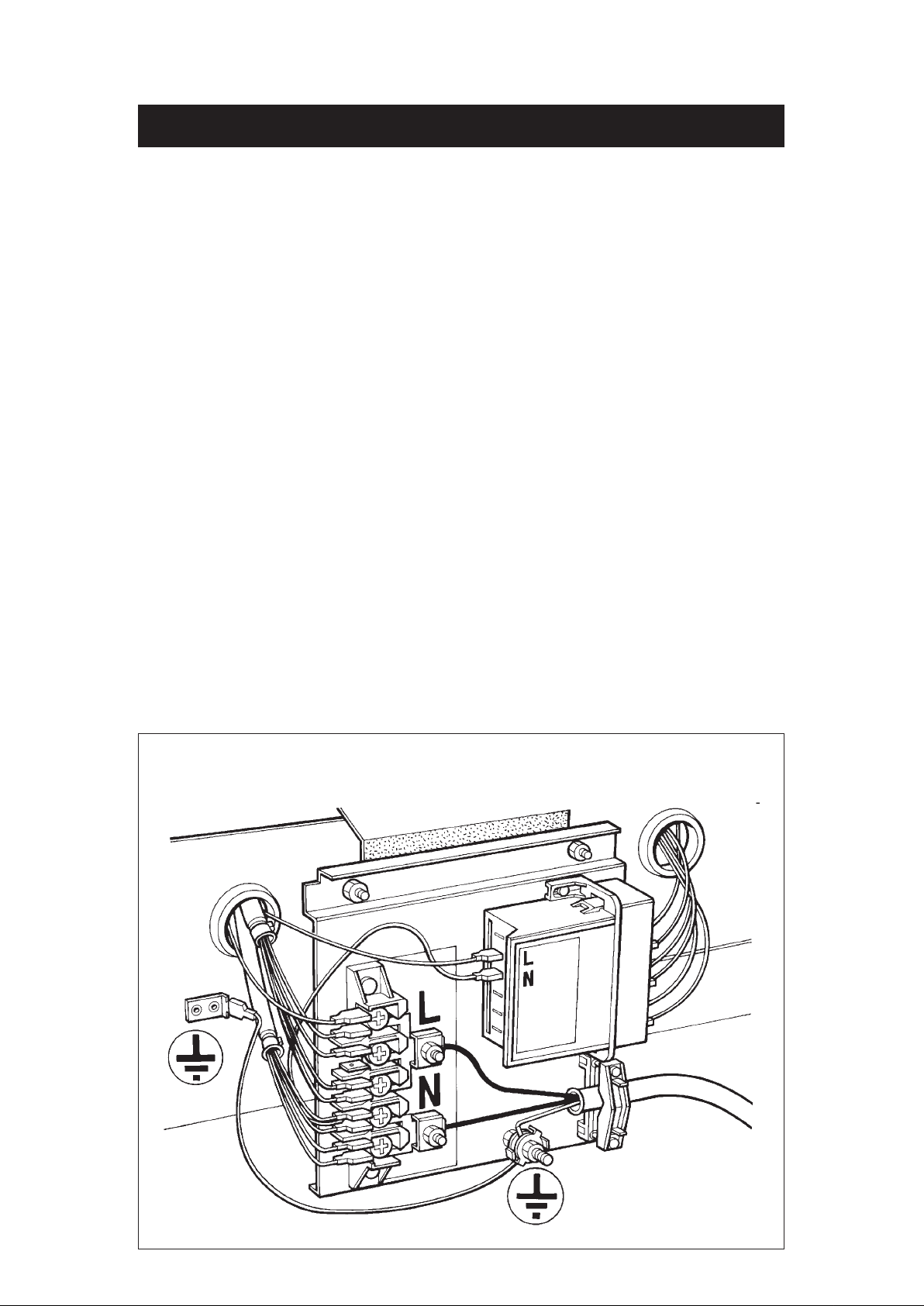

ELECTRICAL CONNECTION IS LOCATED AT THE TOP RIGHT HAND SIDE OF THE

APPLIANCE, BEHIND SIDE PANEL. DURING INSTALLATION REMOVE THE RIGHT HAND

SIDE PANEL TO CONNECT ELECTRICAL SUPPLY.

Remove 6 screws securing side panel to gain access to mains terminal. See Fig. 3 for location

of cover.

Remember that the mains electrical cable must be routed through the grommet at the rear right

hand side of the cooker near the top, before connecting to the mains terminal connection.

REFER TO FIG. 2 for wire connection to appliance.

Remember that an excess of cable length is required inside the cooker to allow for possible

servicing of the spark generator.

Remember that an excess of cable length is required behind the cooker for the withdrawal of the

cooker from between the kitchen units etc.

SINGLE PHASE CONNECTION - The cooker requires a 30amp power supply fitted in

conjunction with a Double Pole Isolator with a minimum contact clearance of 3mm and be

connected to the mains with a minimum 6mm

2

cable to comply with the latest editions of the

Local and National Wiring Regulations.

THE ISOLATOR MUST NOT BE POSITIONED IMMEDIATELY ABOVE THE COOKER, BUT

MUST BE SITED WITHIN 2 METRES OF THE APPLIANCE.

Replace the right hand side panel once electrical connection has been made and replace fixing

screws.

NOTE: Ensure that the insulation card covering the mains terminal is in place, between the side

panel and mains terminal.

7

ELECTRICAL CONNECTION

Fig. 2a DESN 513312

SINGLE PHASE CONNECTION - MINIMUM 6mm

2

CABLE AND MUST COMPLY WITH THE

LATEST EDITIONS OF LOCAL AND NATIONAL WIRING REGULATIONS.

Page 8

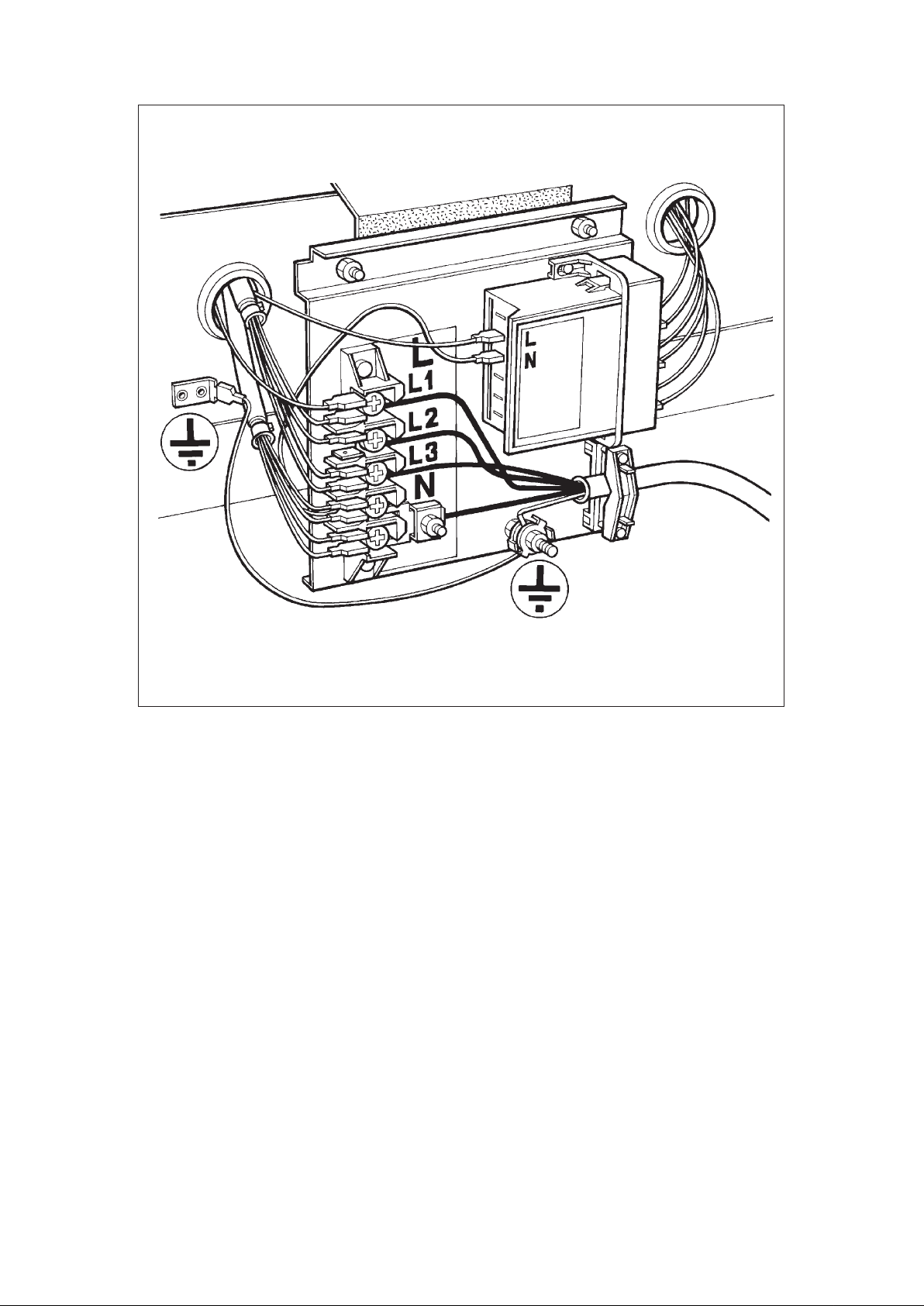

Fig. 2b DESN 513313 A

THREE PHASE CONNECTION - MINIMUM 2.5mm

2

AND MUST COMPLY WITH THE

LATEST EDITIONS OF THE LOCAL AND NATIONAL WIRING REGULATIONS.

8

Page 9

To allow ease of servicing and cooker mobility, an approved flexible 4ft hose should be fitted.

Supply piping should not be less than R 1/2 (1/2” BSP). Connection is made to the R 1/2 (1/2”

BSP) female threaded entry in the inlet block located just below the hotplate level on the rear

right hand side of the cooker.

The gas bayonet connector must be fitted to the wall in the shaded area dimensioned in Fig. 4.

Take into account that it must be possible to pull the cooker forward sufficiently for servicing.

Ensure flexible hose is not trapped between cooker back panel and rear wall. Ensure hose is

routed within the shaded area and away from shielded oven vent. The flexible hose must be in

accordance with the relevant standards.

IMPORTANT: THE GAS SUPPLY CONNECTION AT THE WALL MUST NOT PROJECT OUT

FROM THE WALL BY MORE THAN 45MM, SO THAT IT DOES NOT FOUL WITH THE BACK

OF THE COOKER.

Check for gas soundness after connecting the appliance.

FLEXIBLE HOSE

The flexible hose must be suitable for use with Propane gas, capable of 70ÞC temperature rise,

and carry a red stripe, band or label. If in doubt contact your supplier.

9

CONNECTING TO GAS

Fig. 3 DESN 512389

Page 10

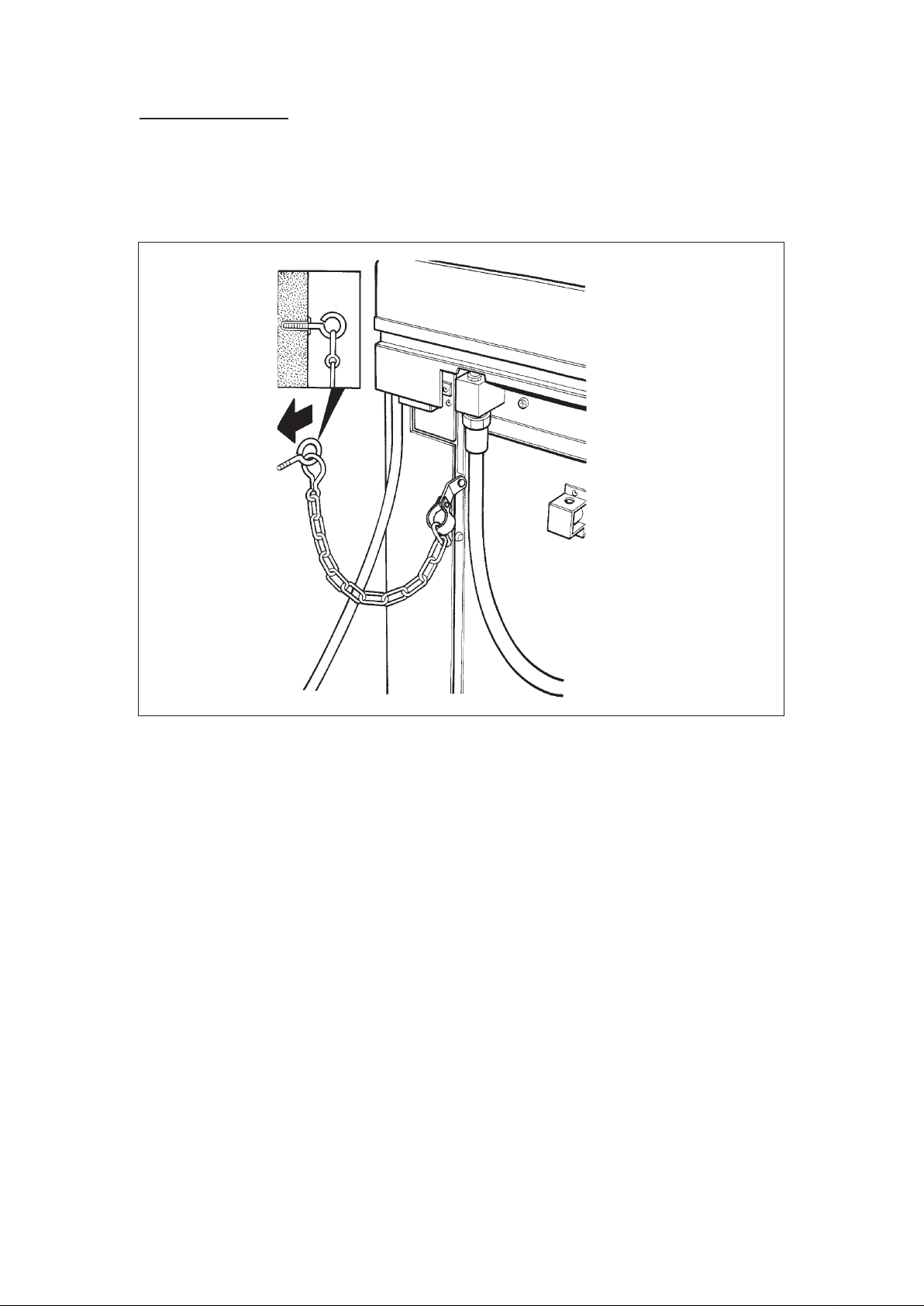

COOKER ST

ABILITY

A stability bracket shall be secured firmly to the fabric of the building, when the appliance is

connected to the gas supply by a flexible hose. For positioning of bracket (See Fig. 3). Asafety

chain must also be anchored firmly to the wall and cooker to prevent the flexible hose from

straining, when the cooker is withdrawn for servicing. When fitting a stability bracket and chain

refer to dimensions in Fig. 3 and Fig. 3A.

Fig. 3A DESN 512384

10

Page 11

The pressure test point is situated at the rear right hand side of the hotplate.

Place the wok burner head, burner cap and ring into position on the hotplate. Light the burner by

pushing in the appropriate control knob, and turning it anti-clockwise IGNITION position, until gas

ignites, then continue to turn to the FULL ON position.

For LPG appliance (propane), the pressure should be 37mbar (14.8 inches water gauge).

Turn off the tap, disconnect the pressure gauge and refit test point blanking screw.

11

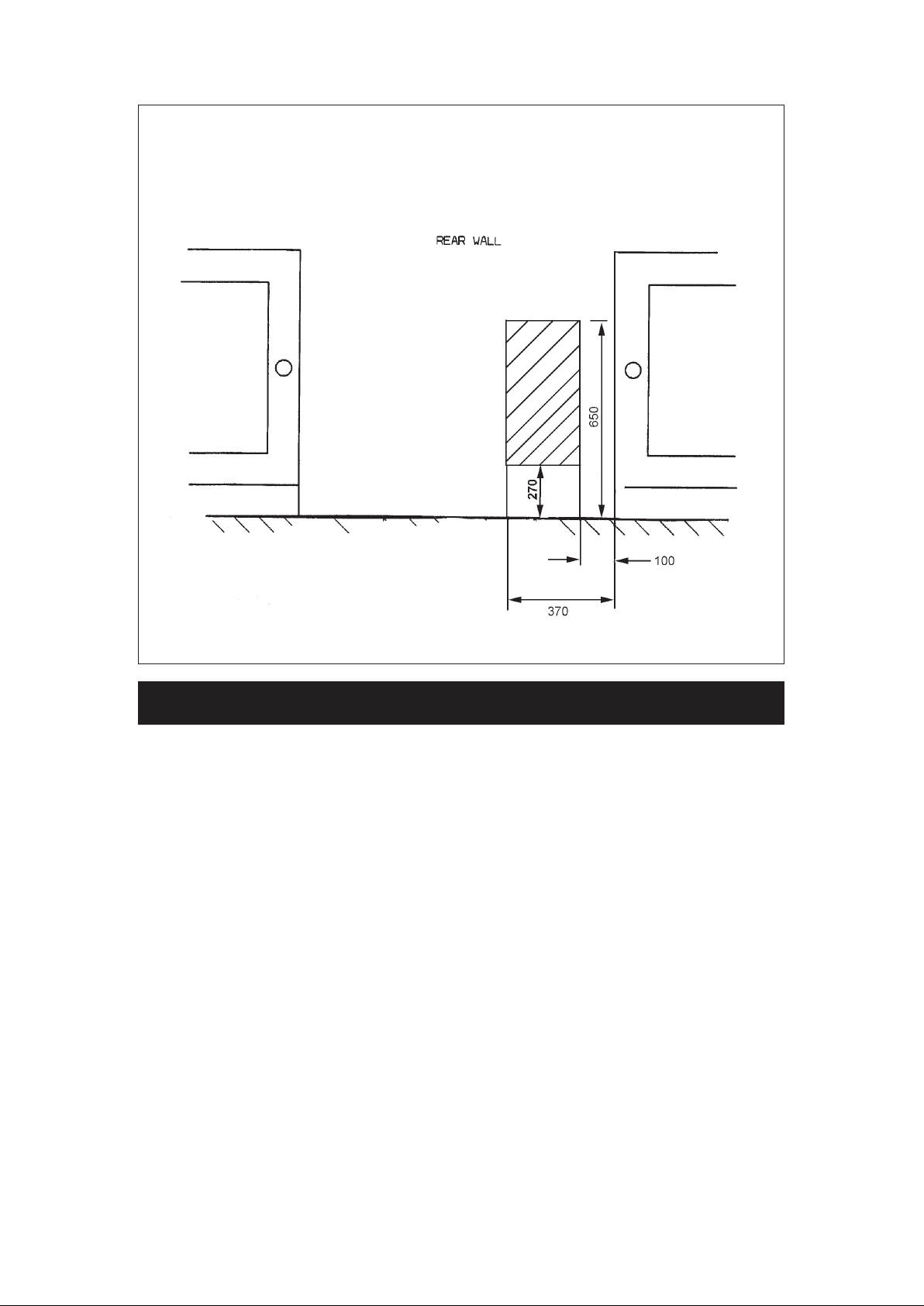

PRESSURE TESTING

POSITION OF GAS BAYONET ON WALL (locate in shaded areas)

IMPORTANT: THE GAS SUPPLY CONNECTION AT THE WALL MUST NOT PROJECT

OUT FROM THE WALLBY MORE THAN 45MM, SO THAT IT DOES NOT FOUL WITH THE

BACK OF THE COOKER.

Fig. 4 DESN 512390 A

Page 12

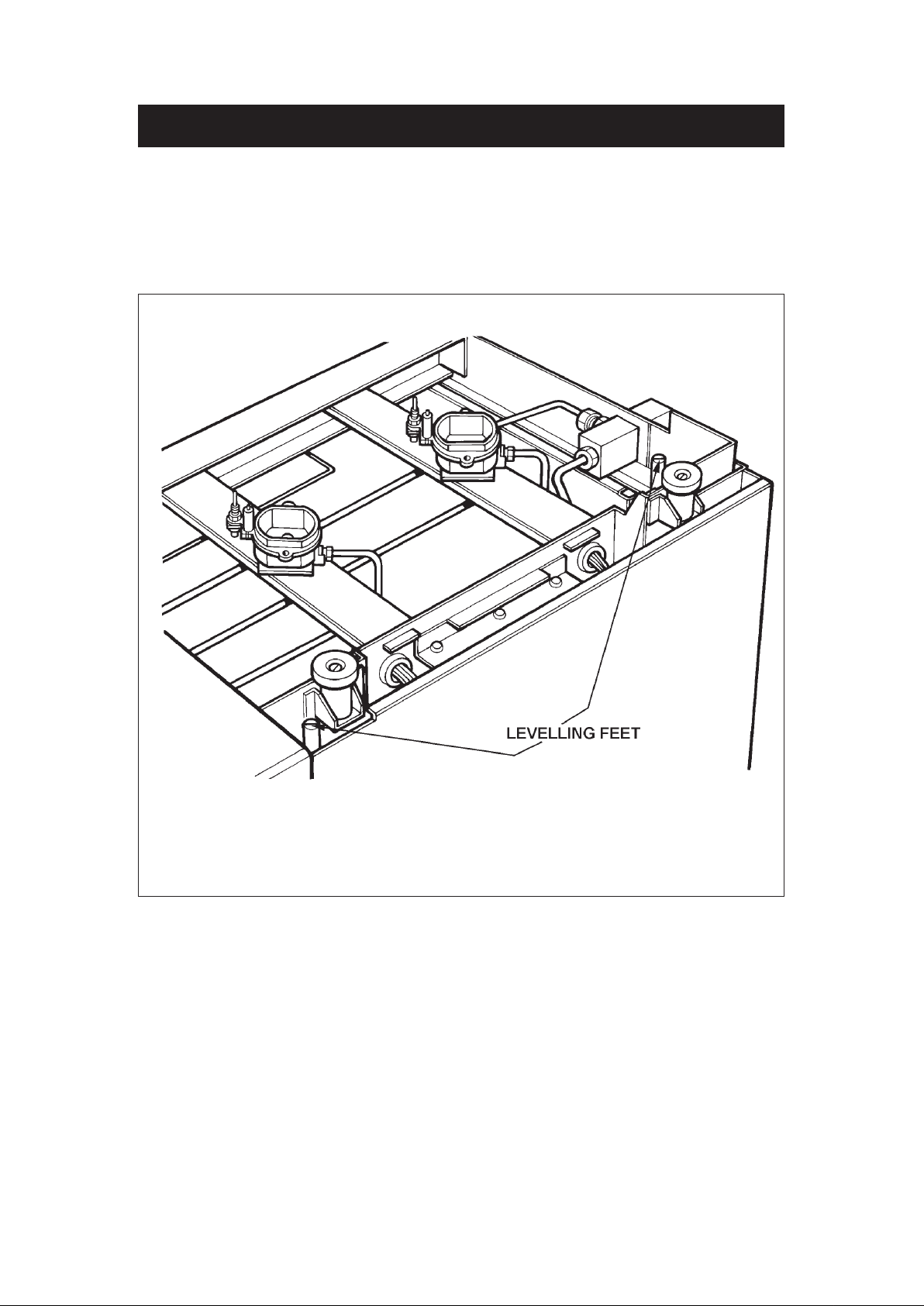

INSTALLATION/LEVELLING

The DC6 is designed to stand on a flat and level surface, however, any unevenness may be

overcome by adjusting the four levelling feet, one at each corner of the base plate. The adjusting

screws are accessed by removing left and right hand hotplate castings (See section ‘To Remove

Hotplate Castings - Servicing Section Page 50). To raise the cooker turn screw clockwise, to

lower turn screw anti-clockwise.

There are rollers on the base of the cooker to allow for positioning.

When the cooker is in the correct position the four levelling feet can be adjusted to level the

cooker. THE FEET MUST BE LOWERED ENOUGH TO PREVENT THE COOKER ROLLING

OUT OF POSITION. (See Fig. 5)

12

DESN 512391 BFig. 5

LEVELLING AND MOBILITY WHEELS

Page 13

HOTPLATE CASTINGS

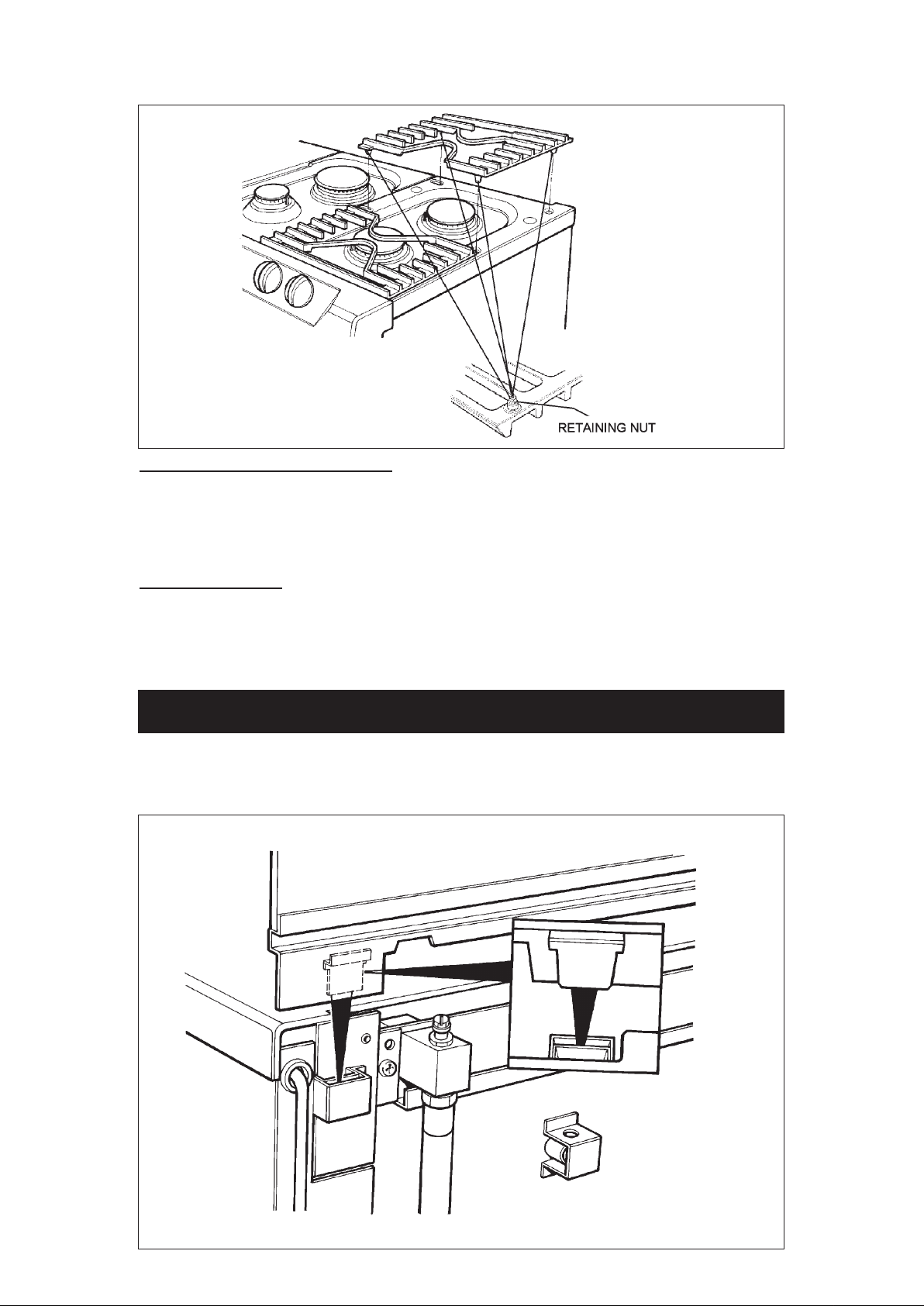

1. Attach earth cable from centre casting to cooker chassis and locate over burner bodies.

Repeat for LH and RH castings and that the gaskets are fitted where the outer castings

overlap centre castings. Ensure that earth cables are attached. (See Fig. 6A)

2. Secure castings using 8 profiled fixing nuts. DO NOT OVERTIGHTEN. (See Fig. 6B).

FITTING OF HOTPLATE CASTING AND PAN SUPPORTS

13

Fig. 6B

Fig. 6A

DESN 512393 C

DESN 512400 A

Page 14

Fig. 7A DESN 513714

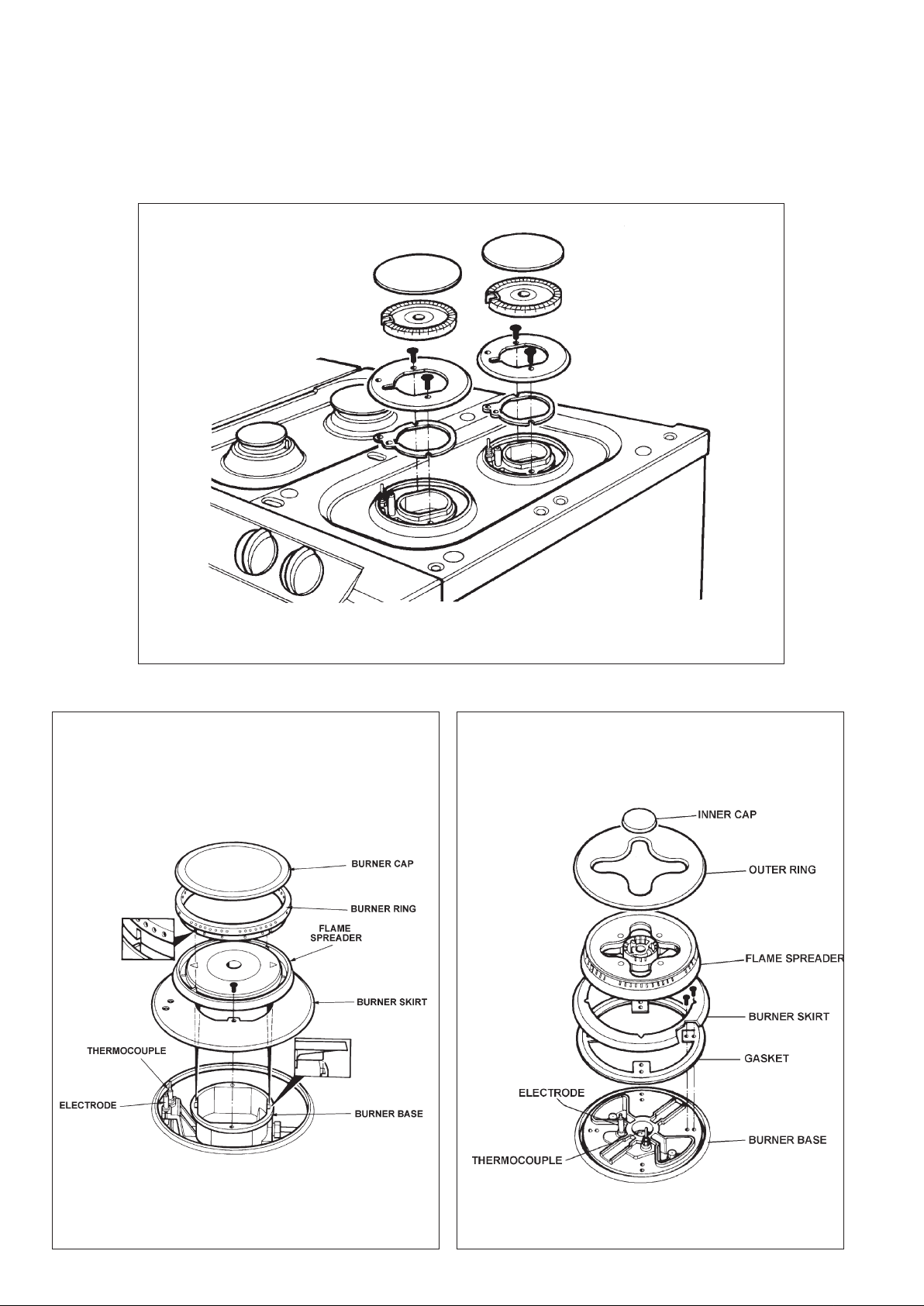

4. Position burner caps onto burner bodies. (See Figs. 7A, 7B, & 7C).

14

ULTRA RAPID BURNER

Fig. 6C DESN 512419 A

3. Fit and secure six burner rings using M4 screws on rear left hand, front centre, front right

hand and rear right hand burners. Use No.6 3/8 screw on front left hand and centre rear

burners. (See Fig. 6C).

NOTE: The fitting of LH and centre burners are the same as shown in Fig. 6B.

DESN 513512

WOK BURNER

Page 15

Fig. 7C DESN 511617

FITTING BURNER CAP - RAPID AND SEMI-RAPID

BURNERS

BURNER CAP

RETAINING LUGS

15

Fig. 7B DESN 511618

BURNER CAP

ASSEMBLY OF RAPID AND SEMI-RAPID BURNERS

BURNER HEAD

ELECTRODE

Page 16

16

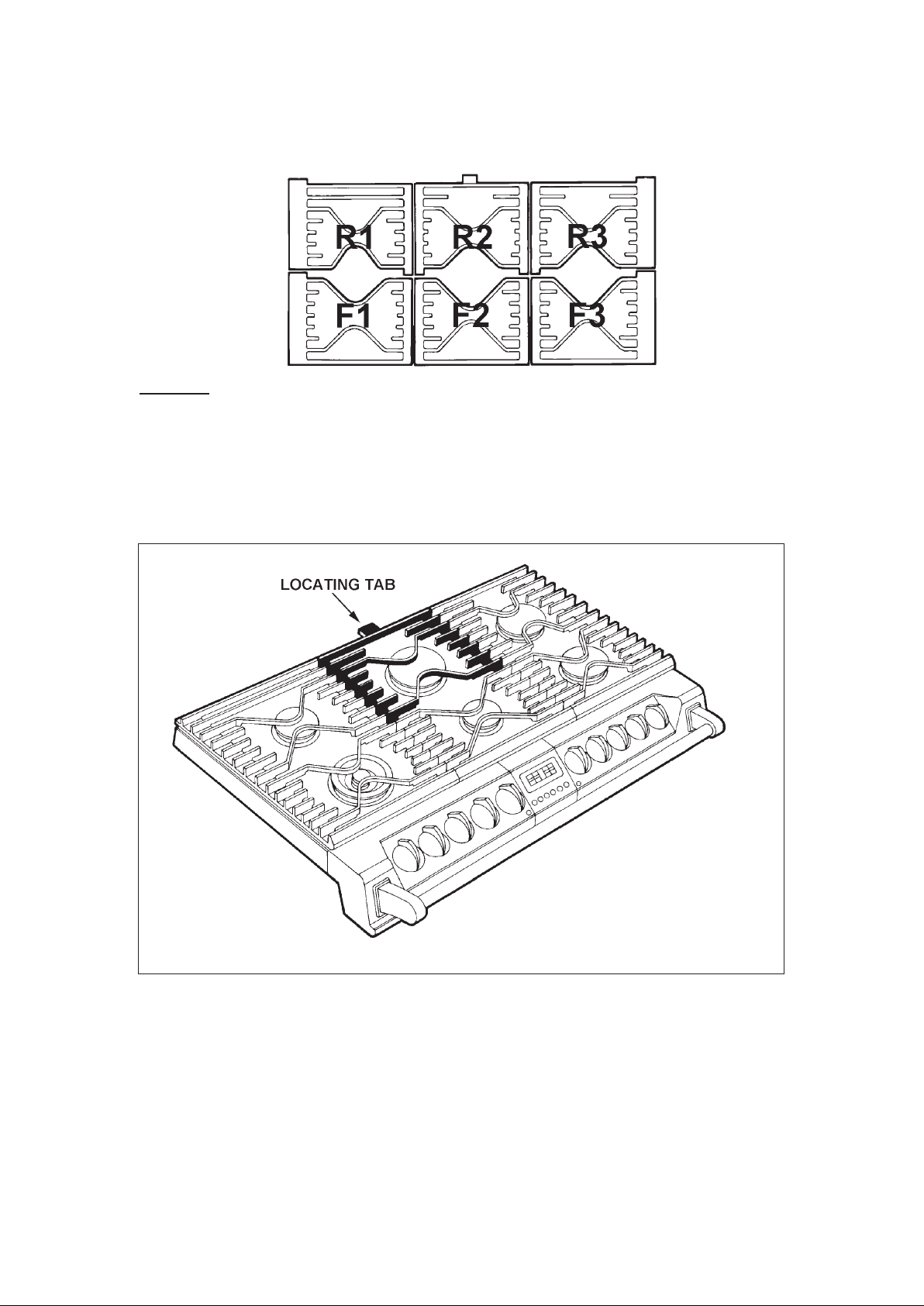

5. Fit the pan supports in the following order The pan supports are marked on the underside to

correspond to the markings below. The pan supports must locate in the recesses in the

hotplate casting. (See Fig. 8A & 8B)

Important

It is very important for the performance and reliability of the hob that the pan supports are fitted

in accordance with the AGASIX-FOUR SERIES - DC6 OWNERS MANUAL.

To help identify the correct location of the pan supports, the centre rear pan support has been

uniquely designed with a tag, as shown. This pan support must be fitted in the rear centre

position with the tag pointing towards the back of the appliance.

Fig. 8A

Fig. 8B

DESN 513712 A

DESN 512995 A

Page 17

1. Locate tabs on rear of splashback assembly, into the brackets on the upper rear of the

cooker. (See Fig. 9).

Push fully into place.

Fig. 9

DESN 512394

17

SPLASHBACK

Fig. 8C DESN 513716

TO ADJUST PAN SUPPORT LEVEL

1. Loosen retaining nut using 8mm spanner. (See Fig. 8C).

2. To prevent rocking adjust the pan support foot using 2.5mm allen key.

3. Check pan support is level with opposing pan supports.

4. Retighten retaining nut.

HANDRAIL

FITTING

1. Position handrail assembly onto locating studs at each end of facia. Ensure the grub screw

at each end of the hand rail is facing downwards.

2. Push handrail assembly fully against facia and lock in place by tightening 2 grub screws

(2

1

/2 mm). (See Fig. 6A).

Page 18

Users

Guide

18

Page 19

19

GENERAL INFORMATION

As responsible manufacturers we take care to make sure that our products are designed and

constructed to meet the required safety standards when properly installed and used.

IMPORTANT NOTICE: PLEASE READ THE ACCOMPANYING WARRANTY.

Any alteration that is not approved by Aga could invalidate the approval of the appliance,

operation of the warranty and could affect your statutory rights.

In the interests of safety and effective use, please read the following before using your new Aga

appliance.

The use of gas on a cooking appliance results in the production of heat and moisture in the room

in which it is installed. Ensure that the kitchen is well ventilated, keep the natural ventilation holes

open or install a mechanical ventilation device (mechanical extractor hood).

Prolonged intensive use of the appliance may call for additional and/or more effective ventilation,

for example, opening of a window, or, increasing the level of mechanical ventilation where

present.

Installation must be to local and National IEE Wiring Regulations and carried out by a qualified

CORGI engineer, from an Authorised Distributor.

A little smoke and some odour may be emitted when first switched on. This is normal and

harmless (from oven lagging and starch binder on the element insulation) and will cease after a

short period of use.

Your appliance has a gas hob, three electric ovens; the lower right hand oven is a slow cooking

oven, the upper right hand oven is a conventional oven.

The lower left hand oven is an electric fan oven. The fan behind the rear panel ensures an even

distribution of heat within the oven during cooking, ie. the temperature at the lowest shelf position

is the same as the temperature at the highest shelf position.

The electric grill is situated in the roof of the top left hand compartment.

Refer to the diagram (See Fig. 10) to familiarise yourself with the cooker and refer to the relevant

section for the simmering oven, fan oven, conventional oven, grill and gas hotplate etc.

Your cooker is supplied with the following accessories:

5 oven shelves

1 large roasting tin

1 grill shelf

1 grill pan

1 grill grid

1 baking tray

1 cast iron frying pan

The following loose parts are also packed with:

6 pan supports (cast)

3 spillage wells (cast)

6 burner caps

6 burner heads

1 burner ring

1 handrail assembly

1 splashback assembly

1 fitting kit

6 burner skirts

2 spacer rings

6 gaskets

Page 20

APPLIANCE

YOUNG CHILDREN SHOULD BE KEPTAW AY FROM THE APPLIANCE AS SOME SURF ACES

CAN BECOME HOT TO TOUCH.

z During use the appliance can become hot. Care should be taken to avoid touching heating

elements inside the oven.

Deep Fat Frying

z Use a deep pan, large enough to completely cover the appropriate heating area.

z Never fill the pan more than one-third full of fat or oil.

z Never leave fat or oil unattended during the heating or cooking period.

z Never use a lid on the pan.

z IMPORTANT: Oil is a fire risk, do not leave pans containing oil unattended.

z In the event of fire cover with a lid and turn OFF the appliance.

Do not attempt to extinguish the fire using water.

Smother the flames on the hob, rather than attempting to remove the pan to the outside.

Burns and injuries are caused almost invariably by picking up the burning pan to carry

outside.

20

HEALTH & SAFETY

Page 21

21

Fig. 10 DESN 513710

Page 22

z The GAS HOTPLATE CONTROL KNOBS can only be rotated anti-clockwise from the OFF

position.

Symbol - Ignition Setting

Large Flame Symbol - High Setting

Small Flame Symbol - Low Setting

(See ‘HOTPLATE’ section).

z The GRILL ELEMENT CONTROL KNOB can be rotated in either direction.

Clockwise Full on, with both elements on

Anti-clockwise Economy grill, centre element only

z The OVEN CONTROL KNOBS can only be rotated clockwise from the OFF position.

z The OVEN NEONS illuminate when ovens are switched on. When the required

temperature is reached the neon will extinguish.

22

CONTROL PANEL

Fig. 11 DESN 513715

Page 23

z The hotplate has six gas burners:

front left - ultra rapid (wok) burner - rated at 4.0 kW

rear left and front centre - semi-rapid burners - each rated at 1.75 kW

rear right and front right - rapid burner - each rated at 3.0 kW

centre rear - ultra rapid burner - rated at 5.0 kW

z The semi rapid burners are especially suited for use with small pans and gentle simmering

or poaching.

z All burners have a set simmer position and are easily adjustable.

z WARNING: The LPG Six-Four Series is not approved for use with a flat griddle plate.

The flat griddle plate MUST NOT be used, only use the round ribbed pan provided.

Performance and technical problems can occur when a large flat griddle plate is fitted over

LPG burners, delayed ignition of unburnt gas can occur on LPG products, especially on a

hotplate fitted with high rated burners.

TO USE THE HOTPLATE

z To light a hotplate burner, push in and turn the control knob anti-clockwise to the large

flame symbol ( ), and hold in for 3 seconds until the burner lights, then turn the knob to

the required setting.

z If the burner flame should accidentally go out, turn off the burner control and do not

attempt to re-light the burner for at least one minute.

z The control may be set towards a lower position, simply by turning the control knob

towards the small flame symbol.

z IMPORTANT: The cast iron supports on the appliance are much heavier than those on

most gas hotplate cookers, therefore care must be taken when removing or refitting them

to the hob. It is important that they are lifted from the appliance and not dragged across

adjacent enamelled components which would result in damaging the enamel.

.

GAS HOTPLATE

23

Page 24

SOME SAFETY POINTS

z Simmering aids such as asbestos or mesh mats are not recommended. They can impede

burner performance, damage the pan supports and waste fuel.

z Commercially available foil spillage aids are unnecessary on this cooker and could effect

the combustion.

z Some ‘Wok’ cooking pans are unstable. Check with the ‘Wok’manufacturer before

purchasing.

z Do not use unstable and misshapen pans (e.g. with convex bases) that tilt easily.

z Pans and kettles with concave bases should not be used.

z The minimum pan diameter recommended is 120mm.

z Place all pans centrally over the burners. The flames must be on the base of the pan. Do

not allow the flames to go up the sides of the pan. (See Fig. 12).

z Always position pan handles away from the front of the cooker - out of reach of small

children.

z NEVER leave a chip pan unattended.

NOTE

Aluminium pans may cause a metallic marking on the pan supports. This will not affect the

durability of the enamel. The appliance warranty does not cover mis-use of the pan supports.

24

Fig. 12 DESN 512396

Page 25

25

TO FIT PAN SUPPORTS

Fit the pan supports in the following order. The pan supports are marked on the underside to

correspond to the markings below. The pan supports must locate in the recesses in the hotplate

casting.

Import

ant

It is very important for the performance and reliability of the hob that the pan supports are fitted

in accordance with the AGASIX-FOUR SERIES - DC6 OWNERS MANUAL.

To help identify the correct location of the pan supports, the centre rear pan support has been

uniquely designed with tag, as shown. This pan support must be fitted in the rear centre position

with the tag pointing towards the back of the appliance.

Fig. 13A DESN 513712 A

Fig. 13B DESN 512995 A

Page 26

SETTING UP THE COOKER FOR USE

Before you can use the lower left hand oven of the appliance it will be necessary to set the ‘time

of day’ clock.

This is a 24 hour clock, and when the power supply is initially switched on, or after an interruption

in supply, the clock will show AUTO and 0.00 alternately.

SETTING THE TIME OF DA

Y

1. Press and hold the MINUTE TIMER and COOK TIME buttons at the same time,

(the word AUTO flashes and the 0.00 is displayed steadily) press the plus + or minus buttons until the required time of day is displayed. The time will increase/decrease from

12.00 hours in minute intervals, slowly and then gaining speed. .

The cooker is now ready for manual use.

26

Fig. 14

Page 27

THE SIMMERING OVEN

This is used for long, slow cooking over 6-8 hours, keeping food warm and warming plates for

short periods.

EXTRA CARE MUST BE TAKEN WHEN WARMING BONE CHINA - USE THE LOWEST

SETTING.

The slow cooking setting is the area marked between 110ºC - 120ºC on the oven control knob.

USING THE SLOW COOKING SETTING

Points to bear in mind when preparing food.

z Do not place dishes directly on to the oven base. Always place onto shelf supplied. See

Fig. 17B.

z Push dishes well back in the oven to ensure that they are positioned over the element

beneath the base plate.

z Make sure all dishes will fit into the oven before preparing the food.

z All dishes cooked by the slow cooking method should be cooked for a minimum of 6

hours. They will ‘hold’ at this setting for a further 1-2 hours but marked deterioration in

appearance will be noticed in some cases.

z Joints of meat and poultry should be cooked at 180ºC for 30 minutes before transferring

to the slow cooking oven.

z Meat over 2.7kg (6lbs) and poultry over 2kg (4lbs 8ozs) are unsuitable for the slow cooking

method.

z Always stand covered joints on a rack over a meat tin, to allow good air circulation.

z Make sure that pork and poultry reach an internal temperature of at least 90ºC.

z This method is unsuitable for stuffed meat and poultry.

z Always bring soups, casseroles and liquids to the boil before putting in the oven.

z When casseroles are used, cover the food first with foil and then the lid to prevent loss of

moisture.

z Always thaw frozen food completely before cooking.

z Root vegetables will cook better if cut into small pieces.

z Adjust seasonings and thickenings at the end of the cooking time.

z Egg and fish dishes need only 1-5 hours cooking and should be included in day cooking

sessions, where they can be observed from time to time.

z Dried red kidney beans must be boiled for a minimum of ten minutes, after soaking, and

before inclusion in any dish.

STORAGE AND RE-HEATING OF FOOD

z If food is to be frozen or not served immediately, cool it in a clean container as quickly as

possible.

z Thaw frozen food completely in the refrigerator before re-heating.

z Re-heat food thoroughly and quickly either on the hotplate or in a hot oven 180ºC, and

then serve immediately.

z Only re-heat food once.

SIMMERING OVEN

27

Page 28

IDEAS FOR THE SIMMERING OVEN

Many favourite recipes can be adapted for this type of cooking. Check that chosen ovenware will fit into the oven.

Meal 1

6 - 8 hours cooking

Ragout of Beef in Ale

Baked Potatoes

Recipes

Ragout of Beef in Ale

30ml (2tbsps) oil 1. Sauté the meat in hot oil in a flame proof casserole dish until

675g (11/2

lbs) chuck steak, cubed brown.

1 clove of garlic, crushed 2. Sauté the garlic, onions, carrots and mushrooms until brown.

2 carrots, sliced 3. Stir in flour and mix well.

100g (4oz) mushrooms, quartered 4. Add mustard, sugar and tomato purée.

2 medium onions, sliced 5. Stir in the ale and seasoning. Return meat.

40g (1

1/2 ozs) plain flour 6. Bring to the boil and cover. Transfer to oven.

5ml (1 tsp) coarse-grained mustard

10ml (1dsp) demerara sugar

30ml (2tbsps) tomato purée

450ml (3/4 pt) brown ale

salt and freshly ground pepper

Baked Pot

atoes

4 medium sized potatoes 1. Wash and prick well all over.

2. Wrap in one layer of foil.

3. Place directly on the shelf.

28

Simmering Oven

Simmering Oven • Simmering Oven • Simmering Oven • Simmering Oven • Simmering Oven •

Page 29

Meal 2 6 - 8 hours cooking

Roast Fillet of Lamb

Dauphinoise Potatoes

Bread and Butter Pudding

Recipes

Roast fillet of Lamb

900g - 1.25 kg (2-2 1/2 lbs) lamb 1. Season and wrap the lamb in foil.

2. Stand meat on a rack (if possible) over a small shallow tin.

Dauphinoise Pot

atoes

450g (1lb) potatoes, thinly sliced 1. Grease a shallow oval or rectangular dish.

1-2 cloves of garlic, crushed 2. Arrange layers of potatoes, seasoning and garlic in the dish, ending

125ml (1/4 pt) double cream with potatoes.

salt and freshly ground black pepper 3. Pour over the cream and cover well with foil.

Bread and Butter Pudding

6-8 medium slices of wholemeal bread 1. Grease a shallow oval or rectangular dish.

Approx 50g (2ozs) butter, melted 2. Cut the crusts off the bread and divide into rectangles/triangles.

Grated rind of one orange (optional) 3. Dip enough pieces of bread in the butter on one side to cover the

25g (1oz) desiccated coconut base of the dish, butter side up.

50 - 100g (2 - 4oz) luxury/tropical mixed fruit 4. Sprinkle with half of the fruit, coconut, sugar and orange rind.

50g (2oz) soft brown sugar 5. Cover with a second layer of bread dipped in the butter and then

450ml (3/4 pt) milk the remaining rind, fruit, coconut and sugar.

2 eggs 6. Whisk the eggs and milk together and pour over the bread. Stand

for 1/2 hour before baking. Leave uncovered in the oven.

Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven •

29

Page 30

Meal 3 6 - 8 hours cooking

Gammon and Apricot Pie

Braised Red Cabbage

St. Clements Pudding

Recipes

Gammon and Apricot Pie

2 gammon rashers approx 15mm (1/2”) thick 1. Remove the rind from the gammon. Nick the edges and lay them

100g (4oz) no-soak dried apricots in a shallow dish.

25g (1oz) sultanas 2. Sprinkle with apricots, sultanas and pepper.

3 large potatoes, thinly sliced 3. Overlap the sliced potatoes on top of the gammon. Pour over

300ml (

1/2

pt) chicken stock stock.

50g (2oz) butter, melted 4. Brush with melted butter place in the oven.

Braised Red Cabbage

350g (3/4 lb) red cabbage 1. Slice the red cabbage finely

25g (1oz) butter 2. Melt the butter in a large saucepan and sauté the onion and apple

1 medium onion, sliced until starting to soften.

1 medium cooking apple, sliced 3. Add the cabbage and cook for a further 2 minutes

30ml (2 tbsps) cider vinegar 4. Mix in the vinegar, honey and seasoning.

45ml (3 tbsps) honey 5. Transfer to an ovenproof dish, and cover tightly with foil. Place in

salt and pepper the oven.

S

t Clements Pudding

2 rounds of thick sliced wholemeal bread 1. Grease a shallow oven-proof dish and line the base with fingers of

a little milk bread.

50g (2oz) butter or margarine 2. Pour over sufficient milk to be absorbed by the bread.

50g (2oz) soft brown sugar 3. Cream the fat and sugar.

grated rind and juice of 1 lemon 4. Add the yolks, lemon and orange rind and juice. Beat.

grated rind and juice of 1 orange 5. Whisk the egg whites stiffly and fold most of them into the

3 eggs, separated creamed mixture.

caster sugar for sprinkling 6. Spread this mixture over the bread.

7. Finish with a layer of the remaining egg white, thickly dredged with

sugar. Leave uncovered. Place in the oven.

Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven •

30

Page 31

Meal 4

Chilli Con Carne

Frangipane and Apple Pudding

Recipes

Chilli Con Carne

450g (1lb) minced beef 1. Brown the minced beef in a flame proof casserole dish.

1 x 400g (14oz) tin tomatoes 2. Stir in the spice mix.

1 x 400g (14oz) tin kidney beans 3. Add beans drained, tomatoes and water.

1 packet Chilli con carne spice mix 4. Mix well together. Bring to boil, cover well and place in oven.

100ml (4 fl oz) water

Frangip

ane and

Apple Pudding

450g (1lb) cooking apples, grated 1. Grease a shallow oven dish.

50g (2oz) vanilla fudge, chopped 2. Mix the apples and fudge together and place into the dish.

50g (2oz) softened butter 3. Cream the rest of the ingredients and add a few drops of almond

50g (2oz) soft brown sugar essence.

50g (2oz) ground almonds 4. Carefully spread over the apple. Leave uncovered and place in

12g (1/2 oz) plain flour oven.

1 egg

almond essence

Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven • Slow Cooking Oven •

31

Page 32

THE GRILL

z THE GRILL COMPARTMENT DOOR MUST BE KEPT OPEN WHEN THE GRILL IS ON.

z CAUTION: Accessible parts may be hot when the grill is in use. Young children

should be kept away.

z The very high speed instant grill is divided into two areas to save energy and to suit

individual grilling requirements.

z Turn the grill control clockwise and the whole of the grilling area can be used for large

amounts of food. Turn the control anti-clockwise and the middle area only can be used for

small amounts e.g. 2 slices of bread, one or two chops etc.

z Most food is cooked at a high setting but for thicker pieces of meat/poultry and for food

such as well done steak the heat can be reduced by turning the control down to a lower

setting.

z For best results pre-heat at a high setting for approximately 2 minutes.

z The grill pan fits on the shelf supplied. The shelf is designed to lock in place, but is

removable for cleaning. See Fig. 17B .

z Food should be cooked on the grid or in the base of the grill pan. Some dishes can be

placed straight onto the shelf or floor of the compartment. This is useful when browning

the top of food such as cauliflower cheese.

z The oven side panels are self cleaning.

z The grill pan can be stored in the base of the grill compartment, when the grill is off.

The following information is for guidance only as shape, thickness, size of food and personal

taste can vary.

FOOD SUGGESTED HEAT SETTING

Toast HIGH

Pikelet/Crumpet/Muffins HIGH

Bacon HIGH

Sausage HIGH TO MED.

Beefburger MED. as per packet instructions

Steak med./rare HIGH TO MED.

Chops HIGH TO MED.

Fish - whole HIGH TO MED.

- steaks HIGH TO MED.

- fillets HIGH

Chicken portions HIGH TO MED.

Toppings i.e. meringue, HIGH

potato, cheese etc.

32

Page 33

General

z The ovens and grill compartment are fitted with side and back self cleaning panels. The

roof of the oven is also self-cleaning enamel.

z The shelves are designed to be non-tilt.

z To remove a shelf, lift clear of the side notches and slide forward. To replace a shelf, insert

into the oven with the short prongs at the rear, facing upwards. Slide into position above

the side notches then allow to drop down on the runner.

z Do not place the grid shelf or food on the bases of the ovens.

z Pre-heat the ovens at the appropriate settings until the neon light goes out.

z For effective heat distribution, leave a gap of no less than 12mm between the dishes and

the sides of the oven.

z Do not use a tray or tin greater than 30cm x 24cm (12 hole bun tin or swiss roll tray).

Condensation

Condensation may form on the cooker. This is quite normal and nothing to worry about. The

condensation forms when heat and moisture are present, for example during cooking. Whenever

possible try to make sure that the food which contains a lot of moisture for example casseroles

are covered. If you do notice any condensation, wipe it up straight away.

THE OVENS

33

Page 34

Cooking Hints

z Shelf positions are counted from the bottom.

z Put dishes in the centre of the shelf.

z When using the fan oven, reduce conventional oven settings by 10ºC - 20ºC and in some

cases, cooking time by up to 10 minutes for every hour.

z It is important to check that food is piping hot before serving.

z You can change the setting and cooking times to suit your tastes.

Deep Fat Frying

z Do not try to fry too much food at a time, especially frozen food.

This only lowers the temperature of the oil or fat too much, resulting in greasy food.

z Always dry food thoroughly before frying and lower it slowly into the hot oil or fat. Frozen

foods in particular, will cause frothing and spitting, if added too quickly.

z Never heat fat, or fry with a lid on the pan.

z Keep the outside of the pan, clean and free from streaks of oil or fat.

z The following chart gives a guide to cooking a number of every day items.

34

OVEN COOKING GUIDE

Page 35

z The right hand upper oven is a conventional oven which means that the heating elements are in the top and under

the base of the oven compartment.

z The cooking charts are a general guide but times and temperatures may vary according to individual recipes.

z The meat sections should be used as a general guide but may vary according to the size, shape of joint on or off the

bone.

z Thaw frozen joints before cooking them.

z The times are for open roasting. If covered allow for extra time.

z The turkey/chicken is cooked when the juices run clear when pierced with a skewer. If the juices are still pink

continue to cook, checking every 15 minutes.

z Shelves are numbered from the bottom upwards.

35

APPROXIMATE COOKING TIME & COMMENTS

FOOD SETTING °C

SHELF

POSITION

Conventional Oven

Fish

190 25 - 30 mins depending on size

Steaks

Whole Fish e.g. trout, mackerel

190 20 - 25 mins depending on thickness

Oven-fried fish 210 - 220 25 mins depending on packet instructions

Salmon (2.7kg) 160 - 170 15 - 18 mins per 450g

180 - 190 30 mins per 450g + 30 mins over (medium rare)

Meat & Poultry

Beef

180 - 190

180 - 190

190 - 200

180 - 190

25 mins per 450g + 25 mins over

30 - 35 mins per 450g + 35 mins over

Lamb

Chicken

Pork

Turkey

25 mins per lb + 25 mins over

1

1

/2 - 3 hours depending on recipe

2 hours

35 mins

45 mins - 1 hour using raw fruit

45 mins - 1 hour

Duck & Goose

Casserole

Puddings

Milk Puddings

Baked Custard

Baked Sponge Pudding

Fruit Crumble

190 - 200

150 - 160

160

150

190

190 - 200

20 - 25 mins per 450g + 20 mins over

15 - 18 mins per 450g + 15 mins over

Conventional Oven • Conventional Oven • Conventional Oven • Conventional Oven

2 or 3

2 or 3

3 or 4

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1

1

1 or 2

1 or 2

1 or 2

2 or 3

2 or 3

Page 36

36

APPROXIMATE COOKING TIME

FOOD SETTING °C

SHELF

POSITION

45 mins

140 - 150 1 or 2

2

1

2 or 3

1 or 2

3

3

2 or 3

3

3

1 or 2

1

1

1 or 2

2 or 3

2 or 3

2 or 3

2 or 3

2 or 3

2 or 3

2 or 3

2 or 3

2 or 3

2

100 - 110

3 - 4 hours - Turn meringues over as soon as they are set

Meringues

Yeast Mixture

30 - 45 mins

Bread - loaves 220 - 230

15 - 20 mins

Bread - rolls 220 - 230

25 - 35 mins

Chelsea Buns etc 190

Cakes, Pastries, Biscuits &

Scones

20 - 25 mins

Small Cakes 190

25 - 30 mins

Victoria Sandwich 180

7 - 10 mins

Swiss Roll 190

20 mins

Fatless Sponge (180mm) 190

10 - 15 mins

Scones 220

1 hour - Place on a piece of citron peel after 20 mins

Maderia Cake 180

2 - 2

1

/2hours

Med. Rich Fruit Cake 150

4 - 4

1

/2hours

Christmas Cake 140 - 150

1 - 1

1

/2hours

Gingerbread 150 - 160

1

1

/4- 1 1/2hours

Shortbread 150

15 - 25 mins depending on recipe

Biscuits 170 - 180

30 mins - 1

1

/2hours depending on recipe

Tray Bakes & Tea Breads

180 - 190

Small Tarts 20 - 25 mins depending on recipe, Pies 45 - 50 mins depending on recipe

Shortcrust Pastry

200

25 mins

Rich Shortcrust 190

8 - 10 mins depending on recipe

Flaky/Puff Pastry

220 - 230

25 - 35 mins

Choux Pastry 200

Miscellaneous

45 mins

Yorkshire Pudding - Large 220

20 - 25 mins

Yorkshire Pudding - Individual 220

45 mins

Soufflés 190

Meringue Toppings

• Conventional Oven • Conventional Oven • Conventional Oven • Conventional Oven • Conventional Oven • Conventional Oven •

Page 37

Whole Fish e.g. trout, mackerel

Steaks

Oven-fried fish

Salmon (2.7kg)

Meat & Poultry

Beef

Lamb

Pork

Chicken

Turkey

Duck & Goose

Casserole

Puddings

Milk Puddings

Baked Custard

Baked Sponge Pudding

Fruit Crumble

Fan Oven

• Fan Oven • Fan Oven • Fan Oven • Fan Oven • Fan Oven • Fan Oven • Fan Oven •

z The left hand lower oven is a fan oven, which means that the air is circulated to create an even temperature

throughout. In most cases food requires a lower oven temperature when cooked in ovens by approximately 10ºÞC 20ºC.

z The cooking charts are a general guide but times and temperatures may vary according to individual recipes.

z The meat sections should be used as a guide but may vary according to the size, shape of joint on or off the bone.

z Thaw frozen joints thoroughly before cooking them.

z The times are for open roasting. If covered with foil allow for extra time..

z The turkey/chicken is cooked when the juices run clear when pierced with a skewer. If the juices are still pink

continue to cook checking every 15 minutes until juices run clear.

FOOD

SETTING °C

APPROXIMATE COOKING TIME

Fish

170

170

170

140 - 150

170 - 180

170 - 180

170 - 180

170 - 180

150 - 160

170 - 180

130 - 140

140

140

160

170 - 180

25 - 30 mins depending on size

20 - 25 mins depending on thickness

25 mins depending on packet instructions

15 - 18 mins per 450g

30 mins per 450g + 30 mins over (medium rare)

25 mins per 450g + 25 mins over

30 - 35 mins per 450g + 35 mins over

20 - 25 mins per 450g + 20 mins over

15 - 18 mins per 450g + 15 mins over

25 mins per lb + 25 mins over

1 1/2 - 3 hours depending on recipe

2 hours

35 mins

45 mins - 1 hour using raw fruit

45 mins - 1 hour

37

Page 38

Fan Oven • Fan Oven • Fan Oven • Fan Oven • Fan Oven • Fan Oven • Fan Oven • Fan Oven • Fan Oven • Fan Oven •

FOOD SETTING °C

APPROXIMATE COOKING TIME

Meringue Toppings 130 45 mins

3 - 4 hours - Turn meringues over as soon as they are set

30 - 45 mins

15 - 20 mins

25 - 35 mins

20 - 25 mins

25 - 30 mins

7 - 10 mins

20 mins

10 - 15 mins

1 hour - Place on a piece of citron peel after 20 mins

2 - 2

1

/2 hours

4 - 4

1

/2

hours

1 - 1

1

/2 hours

1

1

/4

- 1

1

/2

hours

15 - 25 mins depending on recipe

30 mins - 1

1

/

2

hours depending on recipe

Small Tarts 20 - 25 mins depending on recipe, Pies 45 - 50 mins depending on recipe

25 mins

8 - 10 mins depending on recipe

25 - 35 mins

45 mins

20 - 25 mins

45 mins

80 - 90

200 - 210

200 - 210

180

170 - 180

160 - 170

200 - 210

170

200 - 210

160

130

130

130 - 140

140 - 150

130 - 180

160 - 170

190

180

210

190 - 200

200

200

170 - 180

Meringues

Yeast Mixtures

Bread - loaves

Bread - rolls

Chelsea Buns etc.

Cakes, Pastries, Biscuits &

Scones

Small Cakes

Victoria Sandwich

Swiss Roll

Fatless Sponge (180mm)

Scones

Maderia Cake

Med. Rich Fruit Cake

Christmas Cake (205mm)

Gingerbread

Shortbread

Biscuits

Tray Bakes & Tea Breads

Shortcrust Pastry

Rich Shortcrust

Flaky/Puff Pastry

Choux Pastry

Miscellaneous

Yorkshire Pudding - large

Yorkshire Pudding - individual

Soufflès

38

Page 39

The minute timer works separately from the time of day clock and can be set to time periods from

1 minute to 23:59 hours. Only a one handed operation is required.

SETTING THE MINUTE TIMER

1. Press the MINUTE TIMER button the bell symbol and 0.00 will be displayed. Set the

required time by using the plus + and minus - buttons.

2. After 5 seconds the display will go back to showing the time of day, the bell symbol will

remain steady and the set time will immediately start to count down, by pressing the

minute timer button, the display will show the time remaining.

3. At the end of the set time, a beep will sound, the bell symbol will flash and continue for 2

minutes unless cancelled by pressing the MINUTE TIMER button or MANUAL

button.

4. The setting can be cancelled by pressing the MINUTE TIMER and minus - buttons and

running the time back to 0.00.

39

THE MINUTE TIMER

DESN 512657FIG. 15

Page 40

This can be used to set an automatic cooking programme in the bottom lef

t fan oven only

. It

switches the electricity on or off at the pre-set times.

The maximum length of cooking programme which can be set is 23 hours and 59 minutes e.g.

delay time + cooking time = maximum 23 hours and 59 minutes.

Before setting a programme check that the clock is telling the correct time of day, and have the

following information to hand:

z The length of time the food needs to cook.

z The time that the food is to finish cooking.

z The oven control setting required.

SETTING THE

AUTOMATIC COOKING PROGRAMME

Either the STOP TIME or the COOK TIME buttons can be pressed first.

Each setting will remain displayed for 5 seconds before changing back to display the time of day .

An example of setting a programme using the cook time button first.

The food needs 2 hours and 30 minutes at 140ºC and is required to be ready by 18.00 hours.

1. Place the food on the correct shelves in the oven.

2. Check that the clock is telling the correct time of day.

3. Press the COOK TIME button and then the plus + or minus - buttons until 2 hours 30

minutes is displayed.

4. Press the STOP button and then the plus + or minus - buttons until 18.00 hours is

displayed.

5. Set the oven temperature control to 140ºC.

6. 5 seconds after setting, the clock will display the time of day and AUTO.

7. When cooking starts the COOK TIME symbol illuminates and remains throughout

cooking.

8. When the cooking has finished, a beep will sound and continue for 2 minutes, unless

cancelled manually.

The AUTO symbol will flash. To cancel these and return to manual press MANUAL COOK

button twice.

SETTING

AN END TIME ONLY , AUTOMATICALLY

1. Place the food on the correct shelves in the oven.

2. Press the STOP button until the time at which cooking is to end, appears on the display.

3. Set the oven temperature control.

Cooking will start immediately and the COOK TIME symbol will illuminates and remain

throughout cooking.

4. When the cooking is finished, a bleep will sound and continue for 2 minutes unless cancelled

manually.

The AUTO symbol will flash.

5. To cancel and return to manual mode, press the MANUAL COOK TIME twice.

Programmes can be adjusted at any time by pressing the appropriate buttons and the plus + and

minus - buttons as described previously.

CANCELLING

A

PROGRAMME

The cooking programme can be cancelled by pressing the COOK TIME button and the minus

- buttons until 0.00 appears in the display.

Press the MANUAL COOK TIME button to return the oven to manual mode.

NOTE

: When an automatic cooking programme has been set, the time of day clock cannot be

adjusted.

40

AUTOMATIC COOKING CONTROL

Page 41

KEY LOCK - If this mode is activated, a program can be set but it will not be activated, i.e. ON

and OFF times can be set, but timer will not switch the ovens on.

T

O ACTIV

ATE KEY LOCK FUNCTION

1. Ensure the timer is in manual mode (no active programs).

2. Hold the MINUTE TIMER button and COOK TIME button simultaneously for

approximately 8 seconds. The display will read ON.

3. Press the + plus button. The display reads OFF and the key symbol appears. After

approximately 5 seconds the time of day reappears next to the key symbol. The key lock

is now activated.

T

O DEACTIVATE KEY LOCK FUNCTION

1. Ensure the timer is in manual mode.

2. Hold the MINUTE TIMER button and COOK TIME button simultaneously for

approximately 8 seconds, the display will read OFF.

3. Press the + plus button. The display reads ON, the key symbol disappears. After

approximately 5 seconds the time reappears and the key lock is now deactivated.

41

Page 42

General

z Always switch OFF at the mains before cleaning.

z Use as little water as possible.

z Do not use CAUSTIC CLEANING SOLUTIONS

z Do not use a steam cleaner to clean this cooker.

z Wipe up any spills as they occur and transfer pans to other burners to continue cooking.

z TAKE CARE NOT TO DAMAGE THE OVEN THERMOSTAT PHIAL OR THE HOTPLATE

IGNITION ELECTRODES DURING CLEANING.

z After cleaning, ensure all parts are thoroughly dry before replacing.

z When re-fitting the burner caps and burner heads make sure that they are properly located.

z THE FOLLOWING PARTS ARE NOT DISHWASHER SAFE:

Aluminium burner heads (LHR, CF, RHR, RHF).

IMPORTANT: Aga recommend Vitreous Enamel Association approved cleaners for

cleaning the vitreous enamelled surfaces of this product.

But they are unsuitable for use on: chrome and stainless steel component s, handrails and

their brackets.

THE COOKER CANNOT BE MOVED ONCE INSTALLED.

DO NOT ATTEMPT TO MOVE THE COOKER BY PULLING THE HANDRAIL OR DOORS.

42

CLEANING & CARING FOR YOUR COOKER

Page 43

COOKER PART AND FINISH

Vitreous Enamel

Grill - base only

Hotplate

Control panel

Pan supports

Roasting tin

Grill pan

Conventional, fan and simmering oven base only

Door liners

Front of cooker

Doors

High T

emperature Protective Coating

Hand rail bracket

Burner caps

Burner heads

Plinth

Glass

Grill element cover

Splashback

S

tainless Steel

Door catches

Handrail

Chromium Plated

Oven and grill shelves

Shelf supports

Grill pan handle

Grill pan grid

Plastic

Grill pan handle

Control knobs

Timer facia & controls

Neons

CLEANING METHOD

Clean with a damp cloth and hot soapy

water. Stubborn stains can be removed with

mild cream, paste or liquid cleaners, or by

gently rubbing with a well moistened,

liberally soaped very fine steel wool pads

e.g. Brillo.

The pan supports, roasting tin and baking

tray may OCCASIONALL

Y be cleaned in a

dishwasher.

z Check that the cleaning agent is

approved by the (VEA) Vitreous Enamel

Association.

Clean with a damp cloth and hot soapy

water.

IMPORT

ANT:

DO NOT USE ABRASIVES

As for enamel cleaning above. Polish with a

clean dry cloth or kitchen roll.

Use warm soapy water or a proprietary

stainless steel or chrome cleaner.

Wipe with a damp cloth and soapy water.

A well moistened liberally soaped very fine

steel wool pad e.g. Brillo, or stainless steel

cleaner may be used.

Wipe with a damp cloth and hot soapy water.

Stubborn stains may be removed with a

cream cleaner carefully applied.

CLEANING & CARING FOR YOUR COOKER

43

Page 44

COOKER P

ART AND FINISH

Self-Clean Enamel

Fan Oven, Conventional Oven, Simmering

Oven: sides, top and back

Grill Compartment: sides and back

Aluminium

Right & left rear outer burner caps

Right front outer burner cap

Centre front outer burner cap

Non-S

tick Coating

Griddle plate

CLEANING METHOD

This special enamel has a continuous

cleaning action, which works best if a pattern

of low and high temperature cooking is

followed. By using low temperature roasting,

excessive fat splashes can be avoided.

Should any excessive staining occur,

immediately clean the area with hot water

containing detergent, and a nylon washingup brush. Resistant stains require the oven

to be run at 210°C for 2 hours.

DO NOT USE ANY CLEANING

MATERIALS WHICH MAY CLOG THE

PORES OF THE SPECIAL COATING e.g.

PASTES AND POWDERS, SOAP-FILLED

PADS, WIRE WOOL, SPRAY CLEANERS,

BRUSH-ON OVEN CLEANERS, CAUSTIC

SOLUTIONS, METAL SCRAPERS/KNIVES,

AND PREVENT THE CONTINUOUS

CLEANING ACTION.

As for enamel cleaning. Do not place in a

dishwasher

NOTE: Care must be taken to prevent

cleaning materials, water or dirt, from

entering and blocking the burner head, ports

and especially the gasway. Remove any

blockage with a fine needle or nylon brush.

Soak and wash in hot soapy water.

DO NOT USE ABRASIVES OR PLACE IN A

DISHWASHER.

44

DESN 512935 AFIG. 16

Page 45

Oven Shelves - These shelves are designed to slide out

Grill Shelf - operates as oven shelves

STOP ON SHELF

MUST PROJECT

UPWARDS

SHELF STOP AND

ANTI TILT BRACKET

Refit as follows:

Locate in guide as above.

Please Note: Shelf slides out to stop position.

Fig. 17A

Fig. 17B

DESN 511867

DESN 512411

DESN 511866

45

Page 46

46

ASSEMBLY OF RAPID AND SEMI-RAPID BURNER

FITTING BURNER CAP - RAPID AND SEMI-RAPID

BURNER

BURNER CAP

BURNER HEAD

ELECTRODE

BURNER CAP

RETAINING LUGS

DESN 511618

DESN 511617

Fig. 18

Fig. 19

Page 47

47

DESN 513512Fig. 20A

WOK BURNER

DESN 513714Fig. 20B

ULTRA RAPID BURNER

Page 48

Servicing

Section

Remember, when replacing a part on this appliance, use only spare parts that you can be

assured conform to the safety and performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised by Aga.

48

Page 49

z In the event of your appliance requiring maintenance, please call Aga Service or contact

your authorised distributor/stockist.

z Your cooker must only be serviced by a Qualified CORGI Engineer from an Authorised

Distributor or Stockist.

z Do not alter or modify the cooker.

z Only the spares specified by the manufacturer are to be fitted.

49

SERVICING

Page 50

WARNING: WHEN SERVICING OR REPLACING GAS CARRYING COMPONENTS,

DISCONNECT GAS SUPPLY TO APPLIANCE AND AFTER COMPLETION CHECK

APPLIANCE FOR GAS SOUNDNESS.

WARNING: WHEN SERVICING OR REPLACING COMPONENTS, ISOLATE THE

APPLIANCE FROM THE ELECTRIC SUPPLY AND BEFORE RECONNECTING, CHECK FOR

ELECTRICAL SUPPLY.

A. TO REMOVE HOTPLATE

1. Isolate from electric supply.

2. Remove pans supports and burner caps. (See Fig. 21).

3. Remove burner fixing screws (14) and hotplate fixing nuts (8).

4. Lift off burner fixing rings (6).

5. Lift off hotplate castings in the following order: left hand, right hand and centre. (See Fig.

22).

NOTE: Each hotplate casting has an earth lead. Each lead must be disconnected before

completely removing hotplate casting. (See Fig. 23).

6. Re-assemble in reverse order.

50

Fig. 21

Fig. 22

DESN 512935 A

DESN 512393 C

Page 51

B. TO REMOVE SIDE PANELS

1. Isolate from electric supply.

2. Lower the cooker onto the rollers by turning the adjusting feet fully anti-clockwise.

NOTE: It may be necessary to disconnect the flexible gas connection to allow the cooker

to be withdrawn from between the kitchen units.

3. Roll the cooker slightly forward, unhook the safety chain and disconnect the flexible hose.

4. Remove rear fixing screws (3) and slide side panel back and out.

5. Re-assemble in reverse order.

C. TO REMOVE FACIA CASTINGS

1. Isolate from electric supply.

2. Proceed as ‘TO REMOVE HOTPLATE CASTINGS’.

3. Pull off control knobs.

4. Remove control panel fixing screws (4 per casting) (See Fig. 24). When removing the

screws support the casting.

NOTE: When removing the castings, the oven indicator neons require disconnecting from

the facia, hold the cables at their entry into the neon twist and pull, this will disengage the

neon assembly. Be careful when refitting facia castings to position neon and wires

correctly,

51

Fig. 24

Fig. 23

DESN 512400 A

DESN 512407 B

Page 52

D. TO REMOVE HANDRAIL (SEE FIG. 24)

1. Loosen 2 grub screws, one at each end of hand rail (see fig. 24) using 2

1

/2 mm socket key.

2. Slide handrail forwards, off locating studs.

E. TO REMOVE TIMER

1. Isolate from electric supply.

2. Proceed as ‘TO REMOVE HOTPLATE CASTINGS’.

3. Remove fixing screws (4). Two top rear and two lower front of timer housing.

4. The timer assembly can now be lifted upwards sufficiently to disconnect electric cables at

rear of timer. (See Fig. 25).

NOTE: Take care to identify cable connections.

5. Slacken timer fixing screw sufficiently to allow timer securing strip to slide out of facia

panel. (See Fig. 25).

6. Remove timer clamping screw, withdraw clamp and lift out timer. (See Fig. 26).

7. Re-assemble in reverse order.

52

Fig. 25

Fig. 26

DESN 512401

DESN 512402

Page 53

E. TO REMOVE GAS TAPS/IGNITION SWITCHES

1. Isolate from electric and gas supply.

2. Proceed as ‘TO REMOVE HOTPLATE’.

3. Proceed as ‘TO REMOVE FACIA’.

4. Disconnect gas rail feed pipe (19mm nut). (See Fig. 27).

5. Disconnect all gas connections to taps (5 nuts - 13mm, 14mm and 19mm).

6. Remove (4) screws fixing gas rail.

7. Disconnect ignition switch.

8. Lift complete gas rail assembly clear of appliance.

9. Remove bolt (1) and clamp fixing to gas rail and withdraw tap from gas rail.

10. Re-assemble in reverse order.

53

Fig. 27 DESN 513527

Fig. 27A DESN 513711

Page 54

F. TO REMOVE GRILL REGULATOR

1. Isolate from electric supply.

2. Proceed as ‘TO REMOVE FACIA CASTINGS’.

3. Remove two screws securing control to control mounting panel.

4. Withdraw control and cables taking care not to strain the cables.

5. Disconnect cables from the control.

NOTE: Take care to identify terminations.

6. Re-assemble in reverse order.

G. TO REMOVE OVEN THERMOSTATS

1. Isolate from electric supply.

2. Proceed as ‘TO REMOVE GRILL REGULATOR’.

3. Remove (7) back panel screws.

4. Remove thermostat phial and capillary through back of cooker , note correct capillary route.

5. Re-assemble in reverse order.

H. TO REMOVE SPARK GENERATOR

1. Isolate from electric supply.

2. Proceed as ‘TO REMOVE HOTPLATE CASTINGS’. Remove right hand casting only.

3. Slacken electric panel fixing screws (2). (See Fig. 28).

4. Lift panel off screws via keyhole slots.

5. Lift panel clear of appliance.

6. Disconnect electric cables to generator.

7. Disconnect electrode cables.

8. Slacken two screws securing generator to electrics panel to cooker frame and carefully

withdraw generator.

9. Re-assemble in reverse order.

Fig. 28 DESN 513311 A

54

Page 55

I. TO REMOVE ELECTRODES (LHR, CF, CR, RHR, RHF BURNERS)

1. Isolate from electric supply.

2. Proceed as ‘TO REMOVE THE HOTPLATE’.

3. Proceed as ‘TO REMOVE SPARK GENERATOR’ disconnect the appropriate electrode

lead.

4. Withdraw clip securing electrode to burner and withdraw lead and electrode (See Fig. 29).

5. Re-assemble in reverse order.

J. TO REMOVE ELECTRODES (LHF BURNER)

1. Isolate from electrical supply.

2. Proceed as ‘TO REMOVE HOTPLATE’.

3. Proceed as ‘TO REMOVE SPARK GENERATOR’.

4. Disconnect the left hand burner pipe (13mm) and the inner burner pipe (13mm) using the

special spanner.

5. Remove the burner and burner fixing plate, by unscrewing the (4) screws holding the

burner mounting plate in place.

6. Turn burner over and remove electrode fixing clip. Withdraw electrode through top of

burner checking on route of lead.

7. Re-assemble in reverse order, re-routing lead along the same path.

55

DESN 513541

DESN 513713

Fig. 29

Fig. 29A

Page 56

56

Fig. 31

DESN 513532

DESN 513530Fig. 30

K. TO REMOVE THERMOCOUPLE (LHF BURNER)

1. Isolate from electric supply.

2. Proceed as ‘TO REMOVE HOTPLATE’.

3. Undo the nut fixing the thermocouple in place.

4. Push the thermocouple down and pull out from under the burner.

5. Disconnect the other end of the thermocouple cable from the gas valve. This is a push on

jack connector.

6. Re-assemble in reverse order.

Page 57

L. TO REMOVE THERMOCOUPLE (LHR, RHR AND RHF BURNERS)

1. Isolate from electric supply.

2. Proceed as ‘TO REMOVE THE HOTPLATE’.

3. Undo the nut fixing the thermocouple in place.

4. Push the thermocouple down and slide to the side to remove from the burner.

5. Disconnect the other end of the thermcouple cable from the gas valve, this is a push on

electrical terminal.

6. Re-assemble in reverse order.

M. TO REMOVE OVEN AND GRILL LINERS - SEE FIG. 33

1. Remove LH and RH runners (4 screws per runner).

2. Remove runners and liners.

57

Fig. 33 DESN 512415

Fig. 32 DESN 513531

Page 58

N. TO REMOVE ELEMENTS (RH OVENS)

1. Isolate from electrical supply.

2. Proceed as ‘TO REMOVE OVEN AND GRILL LINERS’.

3. Remove oven base panel (1) screw at the rear of the oven.

4. Lift out base panel.

5. Remove oven element fixing screws (2) at the rear of the oven and flex elements to

remove from location bracket, pull forwards to expose terminal connections.

6. Remove connection, make sure they do not fall down the back of the appliance.

NOTE: RH TOP OVEN has an element above the roof liner, remove in same way as for

base elements.

7. Re-assemble in reverse order.

O. TO REMOVE FAN OVEN ELEMENT

1. Isolate from electric supply.

2. Proceed as ‘TO REMOVE OVEN LINERS’.

NOTE: You will only need to remove one side.

3. Remove (4) fan cover fixing screws and withdraw panel.

4. Remove 3 screws securing element to frame and carefully withdraw element until access

can be made to the electrical terminals.

5. Disconnect terminals taking care not to allow the cable to fall down the rear of the

appliance.

6. Re-assemble in reverse order.

P. TO REMOVE OVEN FAN

1. Isolate from electric supply.

2. Proceed as ‘TO REMOVE OVEN ELEMENT’.

3. Remove 4 fixing screws securing fan assembly to frame.

4. Withdraw fan assembly sufficiently to gain access to motor electrical terminals and

disconnect cables.

5. Remove fan blade.

NOTE: Fan blade fixing nuts is LH thread.

6. Remove motor from mounting plate screws.

7. Re-assemble in reverse order.

58

Page 59

WIRING DIAGRAM - AGA DC6

59

Page 60

60

For further advice or information please

contact your local distributor/stockist

With Aga’s policy of continuous product

improvement, the Company reserves the right to

change specifications and make modifications to

the appliance described at any time.

Manufactured by

Aga

Station Road

Ketley Telford

Shropshire TF1 5AQ

England

www.aga-web.co.uk

www.agacookshop.co.uk

www.agalinks.com

Loading...

Loading...