Page 1

NOTE: THESE INSTRUCTIONS SHOULD BE LEFT

WITH THE APPLIANCE AND THE USER TO RETAIN

FOR FUTURE REFERENCE.

Aga Gas Fired ranges are delivered unassembled.

Before installation can be made the site is inspected for

suitability by an Authorised Aga Distributor and corrected

where necessary to conform with local installation codes

or in the absence of local codes with:

In Canada:

The CAN/CGA-B149 installation codes.

In U.S.:

The National Fuel Gas Code ANSI Z223. 1-latest edition.

Assembly is undertaken on site by the same Aga

Distributor to ensure correct performance and safety.

It is essential that the base or hearth on which the range

stands should be level and strong enough to support the

weight of the range.

Approximate weights:-

Models GC (Open Flue) and GC (Direct Vent)

- 408kg (900lb)

Models GE (Open Flue) and GC (Direct Vent)

- 585kg (1290lb)

The top face of the hearth must be of non-combustible

material for a minimum thickness of 12mm (1/2in) and

comply with current Building Regulations and National

Fire Laws.

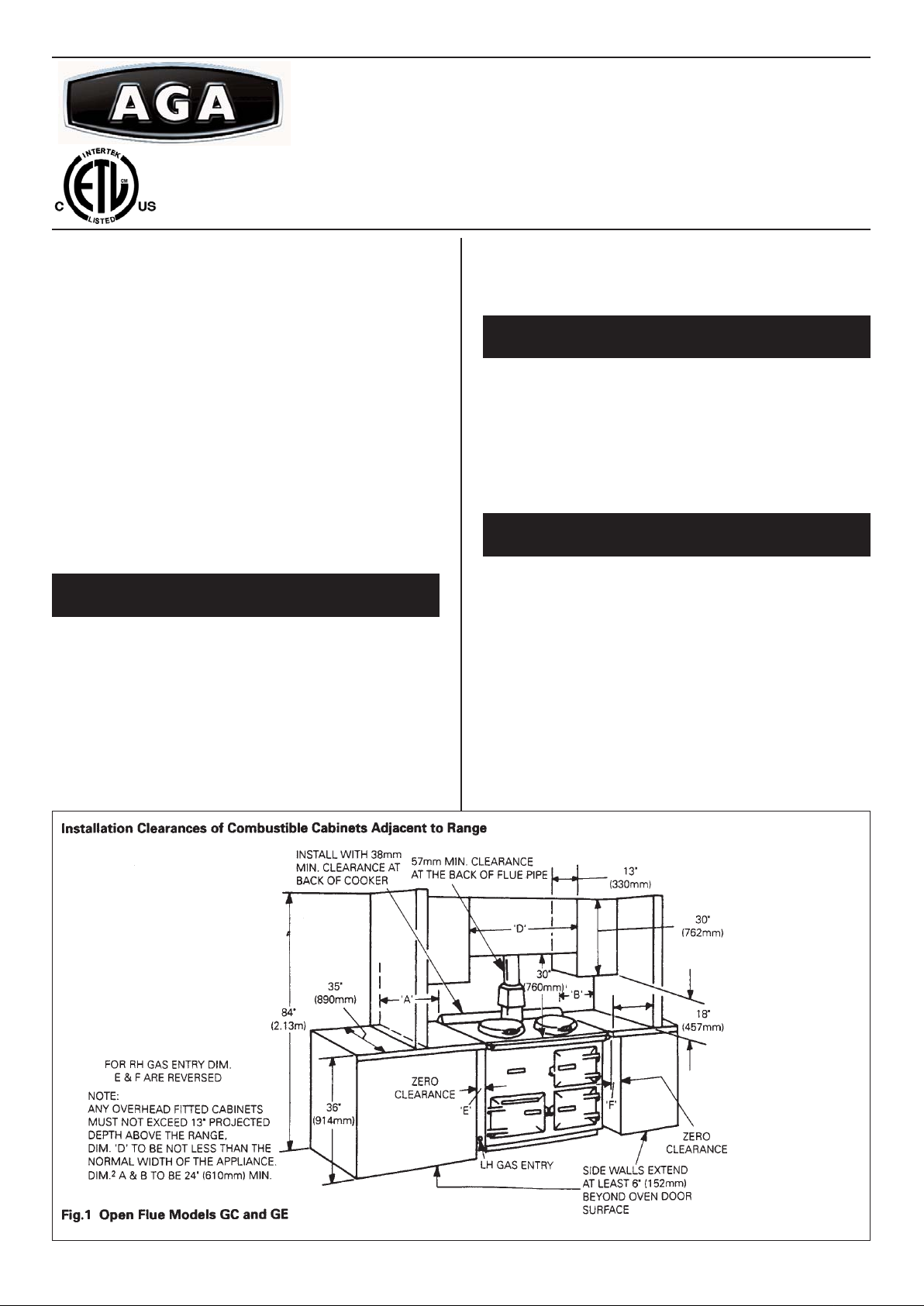

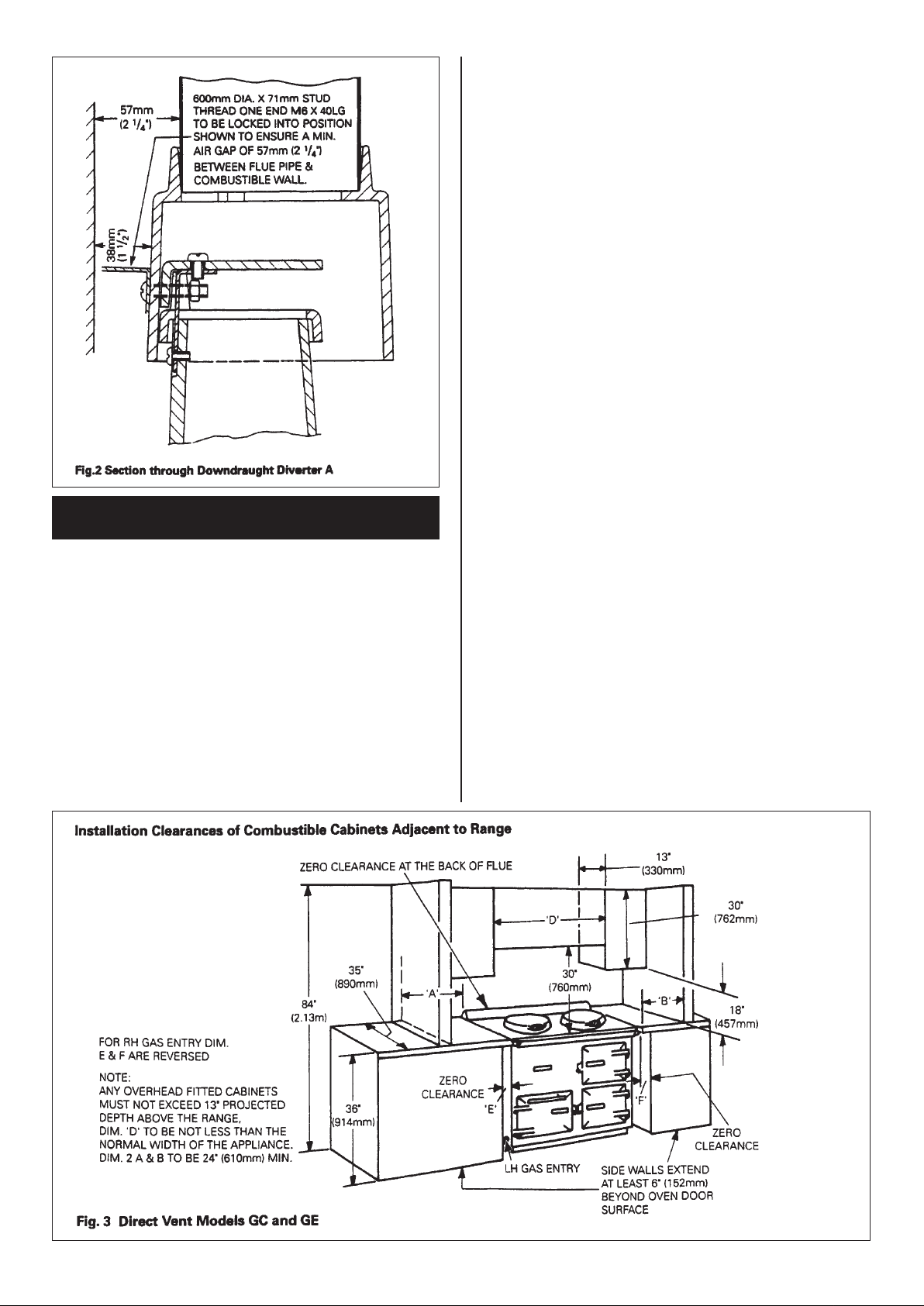

The wall behind the cooker draft hood and flue connector

must have a minimum air gap of 57mm (2 1/4”). Any

openings in the wall behind the range or in the floor under

the range must be sealed before appliance installation.

Ensure the draft hood is securely bolted to the support

spigot as shown in Fig. 2.

NOTE: THIS IS NORMALL Y FITTED AND SECURED BY

THE FACTORY BEFORE DESPATCH.

The wall behind the range must be the outside wall for

the venting of flue products. Wall thickness between

150mm (6 in) and 355mm (14 in) can be catered for at the

same time as site inspection.

Alternatively, special lengths can be offered to order up to

a maximum of 610mm (24 in) long.

Open Flue - Models GC and GE

Installation Instructions for Aga Gas Fired Range

Models: GC Open Flue Range (2 Oven)

GC Direct Vent Range (2 Oven)

GE Open Flue Range (4 Oven)

GE Direct Vent Range (4 Oven)

For U.S. and Canadian Markets

1 04/08 EINS 33644

BASE OR HEARTH

OPEN FLUE RANGE MODELS GC AND GE

DIRECT VENT RANGE-

MODELS GC AND GE

Page 2

2

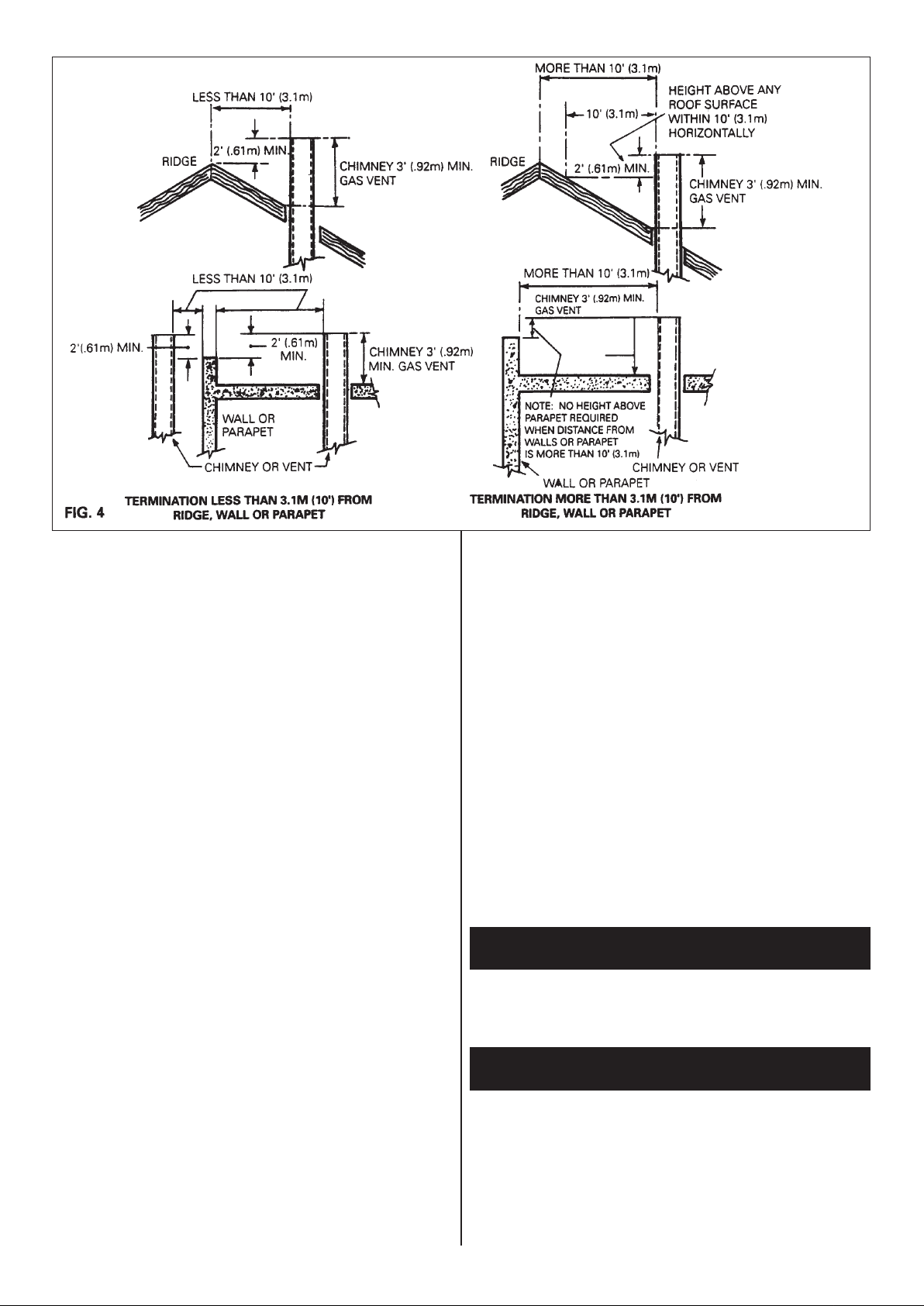

A 100mm (4in) Type B Gas Vent must be used and fastened

by screw to the draft hood flue collar.

U.S.

The gas vent must be connected to a chimney or

independently and in accordance with Chapter 26, chimney ,

Gas Vent and Fireplace Systems of the current issue of

Equipment and Volume of the ASHRAE Handbook. The gas

vent proximity to combustible materials must be installed as

recommended in ANSI/NFPA 211 and according to

manufacturers instructions. Chimneys and vents shall

terminate above roof level and in accordance with the

requirements of the current issue of ANSI/NFPA 211 (see

diagrams) and be at least 1.53m (5ft) above the flue collar

of the draft hood outlet.

Part 7, Venting of Equipment, outlined in the current

National Gas Code ANSI Z223 - latest edition gives detailed

guidelines on all these aspects.

Canada:

The gas vent must be connected to a chimney or

independently and in accordance with the CAN/CGA - B149

installation codes.

The air gap between vent and combustible materials must

be given for the following types of vent:

(i) Type B Vent - 25mm (1in) minimum.

(ii) Single wall vent connector - 150mm (6in) minimum.

Listed connectors passing through combustible walls and

partitions must be guarded by a ventilated metal thimble not

less than 200mm (8in) diameter.

Chimneys and vents shall terminate above roof level and in

accordance with the requirement of the current issue of the

CAN/CGA - B149 Installation Code (Code W) (see

diagrams) and be at least 1.53m (5ft) above the flue collar

of the draft outlet.

1. If suitable lined brick chimney is used it must be

swept before connection and not less than 150mm

(6in) internal diameter.

2. The top of the chimney should be fitted with an

approved Terminal.

3. The flue route to the chimney should be as direct as

possible. Resistance in the form of directional change

should be kept to a minimum. Right angle bends and

horizontal runs should be avoided.

4. The chimney terminal should terminate at the highest

possible point, preferably in a freely exposed position.

Termination at the roofs eaves is unacceptable.

5. The Aga Distributor or Local Gas Company should be

advised where any doubt arises as to the suitability of

the flue.

6. Approved factory made chimneys are acceptable with

VENT CONNECTION

Page 3

3

the appliance and should not be less than (4in) internal

diameter.

7. In the event of an extractor fan being fitted in the vicinity of

the range, compensatory ventilation will be required to

satisfy the demands of the fan without influencing

combustion efficiency or chimney flue condition.

Direct Vent - Models GC and GE

The location chosen for the appliance must permit the

provision of a satisfactory flue termination.

The location must also provide adequate space for servicing

and air circulation around the range.

Should the installation of the appliance be in an unusual

location or restricted space, special procedures may be

necessary and the following current codes give detailed guide

lines on this aspects:

U.S.: The National Fuel Gas Code ANSI Z223.

1-latest edition.

Canada: The CAN/CGA B -149 installation codes.

The following notes are intended to give general guidance.

1. The range must be installed so that the flue terminal is

exposed to the external air and terminal clearances comply

with:

In U.S.: The National Fuel Gas Codes ANSI Z223 1-latest

edition Section 7.7.

In Canada: CAN/CGA-B149 installation code.

2. Termination should be on a clear expanse of wall, the

terminal being preferably not less than 355mm (14in) away

from a corner, recess of projection.

3. A hole must be cut through an outside wall as indicated in

Fig. 6 with the hole rising from inside to outside face

of wall.

DO NOT install the terminal:-

(a) Within 300mm (12in) measured vertically, from the

bottom of an openable window, air vent or any other

ventilating opening.

(b) Within 300mm (12in) above adjacent ground level.

(c) Within 600mm (24in) of any surface facing the

terminal.

(d) Within 355mm (14in) (U.S.) or

300mm (12in) (Canada) below eaves or balcony.

The direct vent terminal must be protected by a terminal

protective guard installed over the terminal to prevent

unauthorised contact with hot terminal surfaces.

See Fig. 8.

4. All jointing faces providing primary air and flue exhaust

paths, must be sealed in an airtight fashion, with particular

emphasis on the following locations:

(a) Air intake tube joints to be sealed with silicone adhesive

provided.

(b) Combustion chamber top sealed with a fire-cemented

gasket to the outer barrel.

(c) Fire cement joints between underside contact faces of

hotplates and simmering plate with cement provided.

(d) Gasket between flue intake/exhaust manifold.

Gasket provided.

The air inlet/products outlet direct vent, and the terminal of the

appliance must not be less than 300mm (12in) to combustible

material. The terminal is suitable for walls of 150mm (6in) to

355mm (14in) overall thickness.

For special lengths up to 610mm (24in), consult your local Aga

Distributor.

If the cooker is to stand in a recess or against a wall which is

to be tiled, in no circumstances should the tiles overlap the

range top plate.

NOTE: A GAS CONTROL VALVE MUST BE INSTALLED.

IN THE GAS PIPELINE EXTERNALL Y OF THE RANGE (NOT

SUPPLIED).

9.5mm (3/8in) N.P.T. Male connection near the front of the

range on the L.H. or R.H. side - Optional.

ALL GAS CONTROLS MUST BE U.S. PIPE THREADS.

Maximum Heat Input: 4.4 kw (15,000 Btu/h)

WALL TILING

GAS SUPPLY - U.S. PIPE THREADS

Page 4

GC, GE Open Flue Models

Maximum Heat Input: 4.4kw (15,000 (Btu/h)

GC, GE Direct Vent Models

The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.5kPa). The appliance must be

isolated from the gas supply piping system by closing the

individual manual shut-off valve during any pressure

testing of the gas supply piping system at test pressures

equal to or less than 1/2 psig (3.5kPa).

The model and serial numbers for this appliance are

found on the name plate. These numbers must be used

when requesting advice from your Aga Distributor. The

name plate is located on the inside face of the outer

burner door. The maximum gas inlet pressure at the

appliance must not exceed 12 inches w.g. (2.98kPa) for

Natural Gas and 14 inches w.g. (3.48kPa) for L.P. Gas.

The minimum gas inlet pressure at the appliance must be

4 inches w.g. (1kPa) Natural Gas and 10 inched w.g.

(2.248kPa) L.P. Gas to enable the correct manifold

pressure to be obtained.

4

LOCATION OF NAME PLATE

Page 5

In a cold range, difficulty may be experienced in maintaining

the main burner alight on initial light-up only. Should this

occur, set the control knob to the position. Depress knob

and light pilot. With the pilot flame established, release the

control knob gradually and rotate anti-clockwise to its low fire

position, whereupon the main burner will light. Leave in the

low fire position for at least 30 minutes.

NOTE: Any attempt to rotate the control knob before

release may result in damage.

After 30 minutes rotate the control knob further anti-clockwise

to the mid position in the green band for normal running.

INITIAL LIGHTING OF RANGE

5

Page 6

NOTE: DO NOT ATTEMPT TO SERVICE THE RANGE

YOURSELF. CONTACT YOUR LOCAL AGA DISTRIBUTOR

ST ATING THE MODEL AND SERIAL NUMBER TOGETHER

WITH YOUR NAME AND ADDRESS

In the event of a component failure which requires

replacement, contact your local Aga Distributor who will

advise and supply the necessary replacement.

Expendable components that will require replacing at some

time or other are listed as follows:-

Description

1. Pilot Thermocouple

2. Main Burner

3a. Pilot Burner Assembly N.G.

3b. Pilot Burner Assembly L.P.G.

4. Combination Gas Valve

5a. Pressure Regulator N.G.

5b. Pressure Regulator L.P.G.

6. Combustion Chamber Door Seal

Models

GC and GE - Open Vent/GC and GE - Direct Vent

Gas Type Natural Gas L.P.G.

Range Model GC/GE GC/GE

Main Burner 400 180

Injector

Pilot Burner Injector

N35 L23

Combination 1.00mm 0.60mm

Gas Valve or or

Bypass Screw 1.20mm 0.80mm

Gas Burner 4.0 10.0

Pressure inch w.c. inch w.c.

Combination S.I.T. EUROSIT

Gas Valve

Pilot Assembly JOHNSONS

6

REPLACEMENT PARTS

TECHNICAL SPECIFICATION

Page 7

7

Fig. 12 Pilot/Thermocouple DESN 512827

Page 8

It is recommended that the range be serviced at regular annual

intervals.

Arrange with the householder that the range has been turned

OFF the night before to ensure it is cold upon arrival.

The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressure in excess of 1/2

psig (3.5kPa). The appliance must be isolated from the gas

supply piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply piping

system at test pressure equal to or less than 1/2 psig (3.5kPa).

1. Isolate the gas supply by turning off the service gas valve

beneath the combination gas valve. Break the hexagon

union connection nut.

2. Detach inner burner door fixing screws and draw

complete gas burner assembly clear of the combustion

chamber resting it on the floor in front of the range.

NOTE: THERE IS SUFFICIENT LENGTH OF

THERMOSTAT CAPILLARY TUBE WITHOUT DETACHING

THE SENSING END FROM THE TOP OF THE ROASTING

OVEN.

3. Remove the boiling plate, combustion chamber baffle

and simmering plate.

4. Check conditions of flueways and combustion

chamber and clean if necessary.

5. Lightly brush the perforated top of the gas burner and

check that the burner venturi is free of lint and fluff.

NOTE: IT MAY BE NECESSARY TO DETACH THE PILOT

ASSEMBLY AND REMOVE THE BURNER TO ENSURE IT

IS FREE.

6. Check the condition of the pilot thermocouple tip to ensure

it is clean and free of carbon. Heavy heat oxidised tips

should mean the removal of the thermocouple and a new

replacement. Examine and brush clean the pilot light parts

and examine the ignitor cable and connector strip to ensure

the PTFE insulation cable, remains intact and strip is

firmly connected to the spark electrode. Clean any carbon

away from the electrode.

7. Refit combustion chamber baffle.

8. DIRECT VENT MODEL ONLY - GC AND GE.

Using a wire brush, lightly remove the old sealing cement

on the contact under faces of the hotplate and simmering

plates to the cooker, and lighly smear another cement

sealing coat provided, before refitting of hotplates.

9. Refit gas burner assembly in reverse manner described in

2 and reconnect the gas supply at service gas valve union.

On completion test the gas installation for soundness and

purge. Leak testing of the appliance shall be conducted

according to manufacturer’s instructions.

NOTE: USE SOAPY WATER SOLUTION ON NEW GAS

CONNECTIONS TO ENSURE THERE ARE NO GAS

LEAKS.

10.Turn on the gas supply and follow the procedure for

lighting the burner.

11.Ensure that the pilot and main burner flames are

burning evenly, the thermocouple is enveloped by the

pilot flame.

12.Visually check main burner and pilot flame for correct

flame pattern. An established main burner at high fire will

be predominantly blue with yellow tippings on an even

height flame strip and be about 150mm (6in) high. See Fig.

11. Ensure all flameports have cross-lit and that the pilot

light flame is free from sooting.

13.The maximum depth of any cabinets installed above the

top cooking surface of the range must not exceed 330mm

(13in).

8

With Aga's policy of continuous product improvement, the

Company reserves the right to change specifications and make

modifications to the appliance described and illustrated at any time.

Aga-Ranges

110 Woodcrest Road

Cherry Hill

NJ 08003

800.633.9200

Installer Servicing Instructions for Aga Models

GC and GE Open Flue Ranges and

GC and GE Direct Vent Ranges

YEARLY SERVICE

www.aga-ranges.comFor further advice or information please contact

your local distributor/stockist

Loading...

Loading...