AGA DC3G Installation Manual

1

AGA DUAL CONTROL

Model No’s: DC3G

02/16 EINS 516911

For use in USA/Canada

Installation

Guide

PLEASE READ THESE INSTRUCTIONS BEFORE COMMENCING SITE SURVEY

OR INSTALLING THIS APPLIANCE.

IMPORTANT : SAVE INSTRUCTIONS FOR FUTURE REFERENCE

REMEMBER: when replacing a part on this appliance, use only replacement parts

that you can be assured conform to the safety and performance specification that

we require. Do not use reconditioned or copy parts that have not been clearly

authorized by AGA.

2

SECTION PAGE

PRODUCT SAFETY 3

GENERAL NOTES 4

DELIVERY REQUIREMENTS 4

GENERAL INSTALLATION REQUIREMENTS 4

APPLIANCE DIMENSIONS - AGA DC3G 5

TECHNICAL DATA 6

INSTALLATION 6 - 9

CONNECTION TO THE POWER SUPPLY - AGA DC3G 10

MAINS CABLE ROUTING - AGA DC3G 11

FLUE SYSTEM 12 - 15

WIRING DIAGRAM - AGA DC3G 16

GAS SUPPLY - U.S. PIPE THREADS 17

AIR SUPPLY 17

AGA DC3G P/F HANDRAIL CONNECTION 18 - 19

COMMISSIONING 20 - 21

YEARLY SERVICE 21 - 22

REPLACEMENT PARTS 22

INSTRUCTIONS 22

BURNER CONTROLS 23

CONTENTS LIST (LOOSE ITEMS) 24

CONTENTS

3

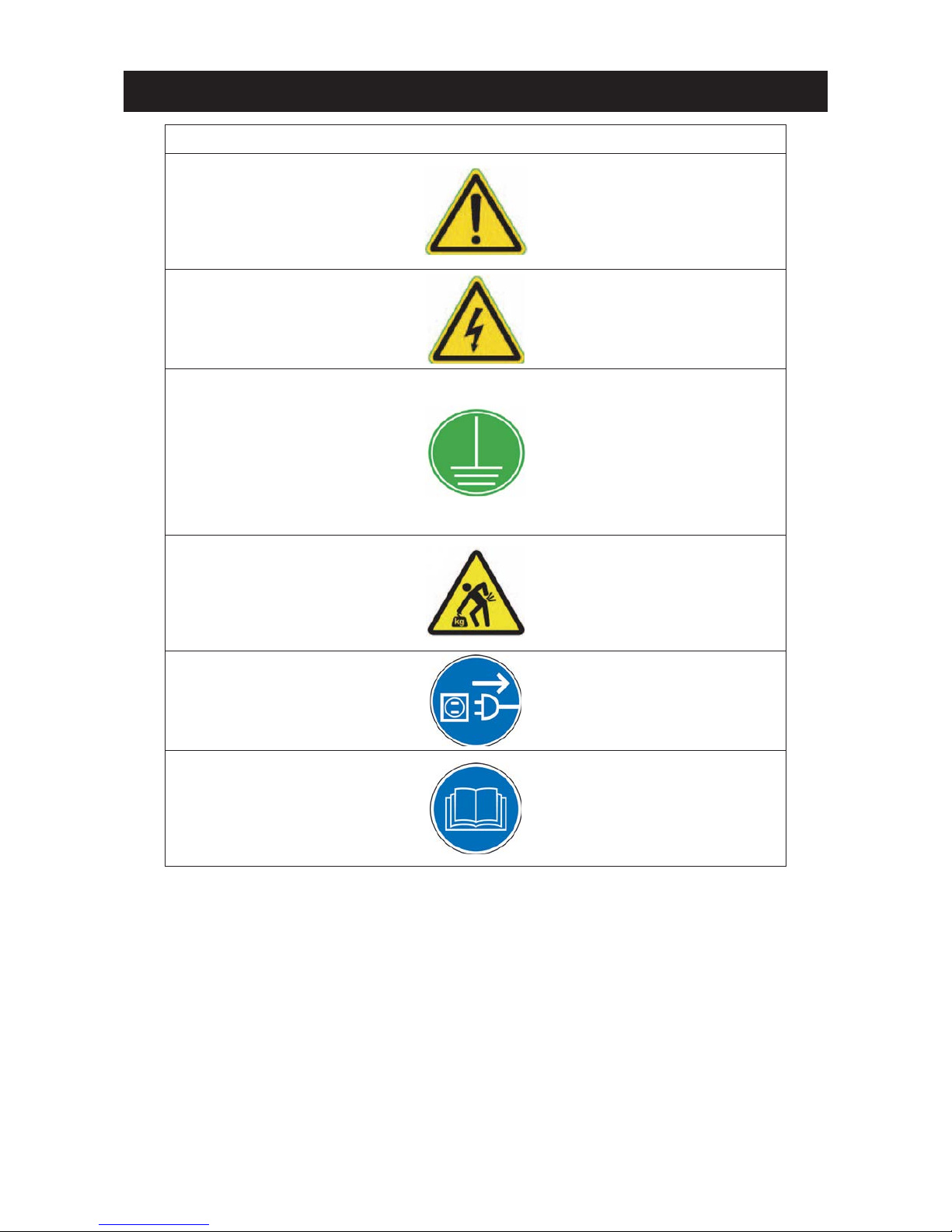

PRODUCT SAFETY

MEANING/DESCRIPTION SIGNIFICATION/DESCRIPTIONSYMBOL

WARNING/CAUTION

An appropriate safety instruction

should be followed or caution to a

potential hazard exists.

AVERTISSEMENT

Une consigne de sécurité

appropriée doivent être suivies ou

garde d’un danger potentiel

exists.

DANGEROUS VOLTAGE

To indicate hazards arising from

dangerous voltages.

TENSION DANGEREUSE

Pour indiquer les dangers

résultant des tensions

dangereuses.

PROTECTIVE EARTH (GROUND)

To identify any terminal which is

intended for connection to an

external conductor for protection

against electric shock in case of a

fault, or the terminal of a

protective earth (ground)

electrode.

TERRE DE PROTECTION

Pour marquer bornes destin

ées à

être raccordées à un conducteur

de protection extérieur contre les

chocs éclectiques en cas de

défaut d’isolement, ou pour

marquer la borne de la terre de

protection.

HEAVY

This product is heavy and

reference should be made to the

safety instructions for provisions

of lifting and moving.

LOURD

Ce produit est lourd et doit

être

fait référence auc consignes de

sécurité relatives aux dispositions

de soulever et déplacer.

DISCONNECT MAINS SUPPLY

Disconnect incoming supply

before inspection or maintenance.

APPAREIL À LASER DE

CLASSE 2

Alimentation d’entr

ée Débrancher

avant inspection ou d’entretien.

REFER TO MANUAL

Refer to relevant instructions

detailed within the product

manual.

ATTENTION, SURFACE TRÉS

CHAUDE

Reportez-vous aux instructions

applicables, indiquées dans le

manuel du produit.

4

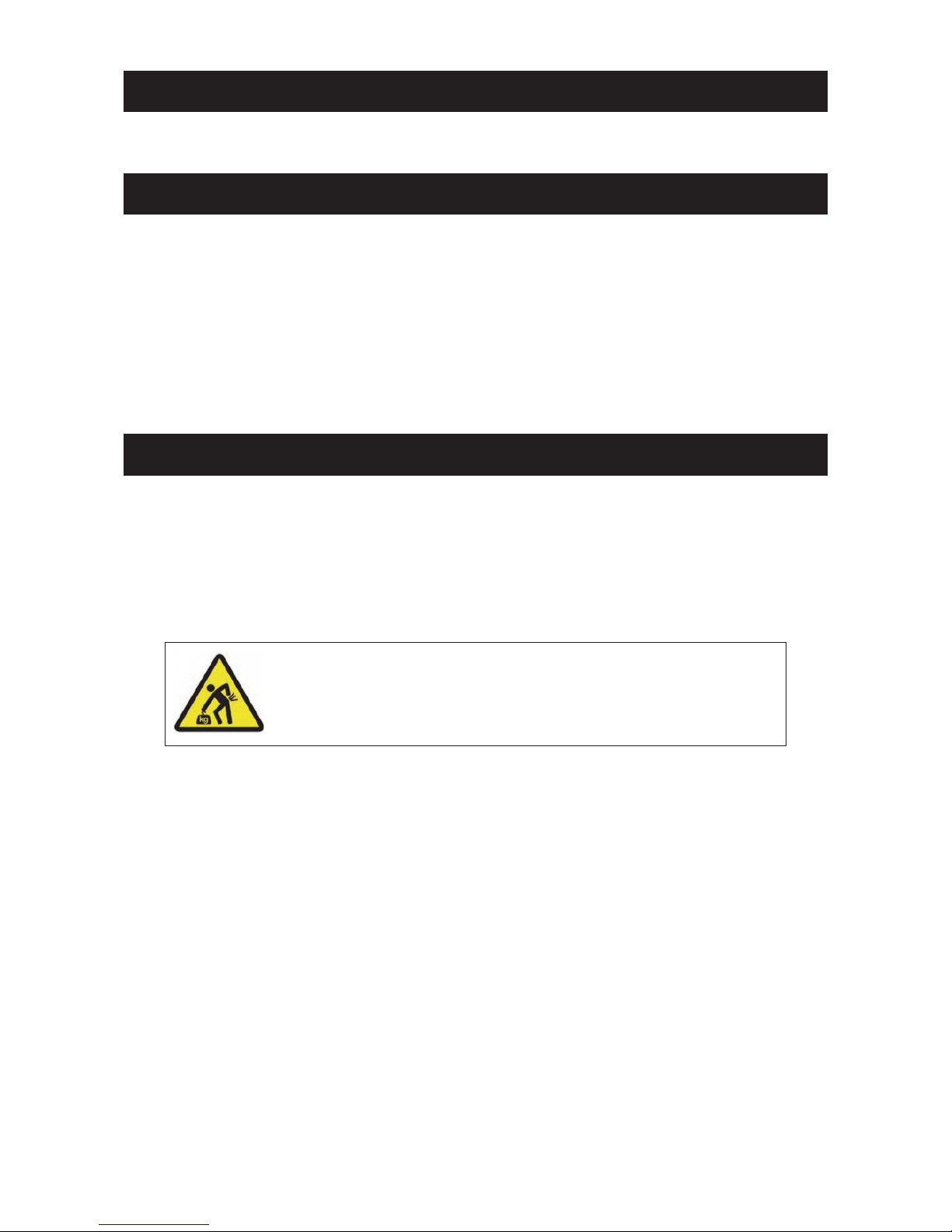

GENERAL NOTES

NOTE: THESE INSTALLATION INSTRUCTIONS SHOULD BE LEFT WITH THE RANGE AND THE USER TO

RETAIN FOR FUTURE REFERENCE.

DELIVERY REQUIREMENTS

The AGA DC3 arrives on 1 pallet.

Vent Pipe Installation kit (AG1M212542) arrives in a separate carton.

There must be access to the kitchen to manipulate a foot print of 39 9/16” (1005mm) x 29 1/8” (740mm). A

wooden template (skate with castor wheels) of dimensions 39 9/16” (1005mm) x 29 1/8” (740mm) could be

used to check if the AGA Dual Control fully built appliance is able to fit through the property grounds and

doors into its installation position in the kitchen. It must also be considered that the height of the appliance is

37 3/4” (960mm) off pallet and 43 1/4 ” (1100mm) on the pallet, so high level obstacles/restrictions must not be

overlooked.

GENERAL INSTALLATION REQUIREMENTS

The installation of the range must be in accordance with the relevant requirements of the local Wiring and

Building Regulations. It should be in accordance also with any relevant requirements of the local or state codes.

In your own interest and that of safety to comply with the law, all appliances should be installed by an authorized

AGA distributor in accordance with the relevant regulations.

CAUTION:

THIS UNIT IS HEAVY, PROPER EQUIPMENT AND ADEQUATE

MANPOWER MUST BE USED IN MOVING THE RANGE TO

AVOID DAMAGE TO THE UNIT OR THE FLOOR

5

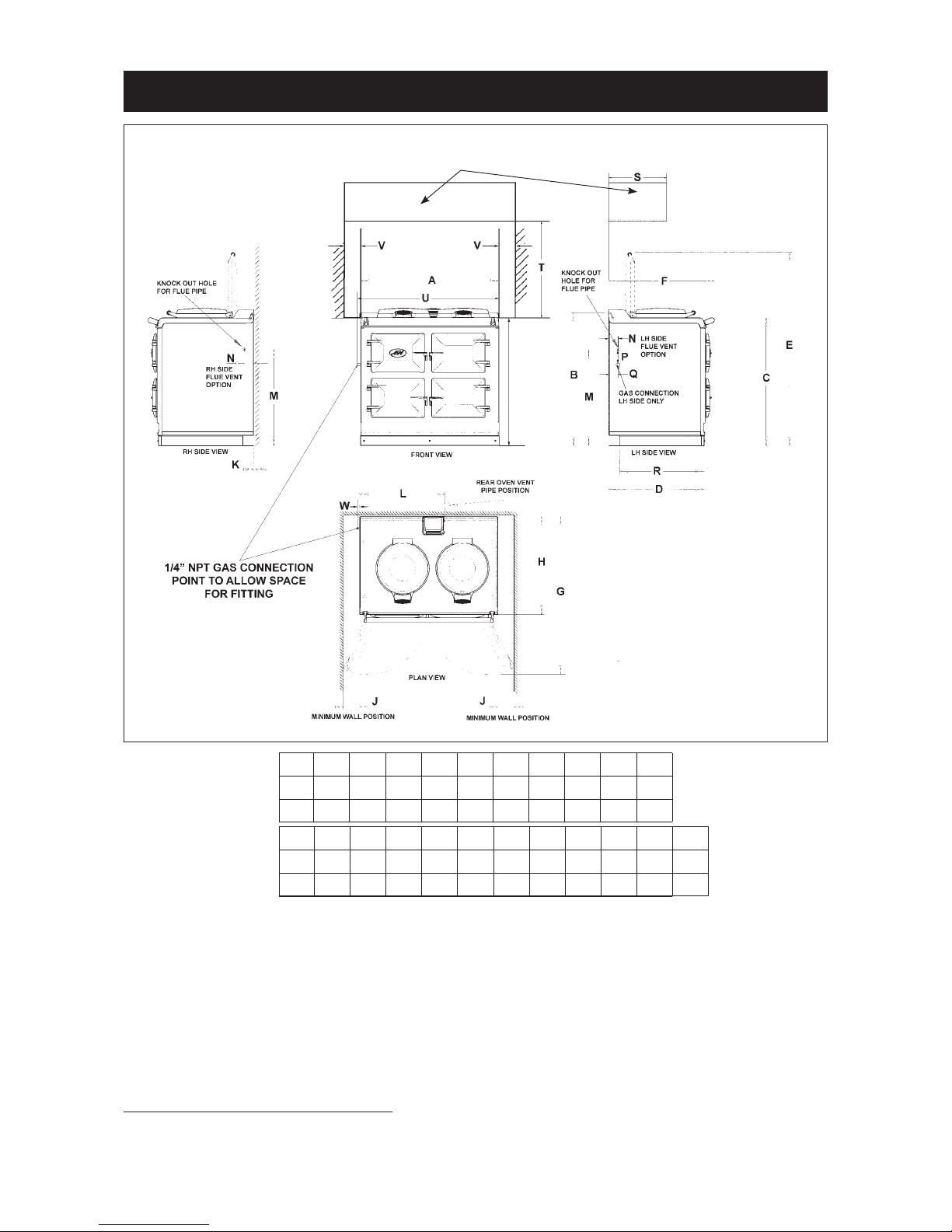

APPLIANCE DIMENSIONS - AGA DC3G

Fig. 1 DESN 516847 A

Range Dimensions

When surveying for a range installation the actual clearance required for the ‘body’ of the appliance should

be increased by 3/8” beyond the figures quoted above. This allows safe margin to take into account the

natural dimensional variations found in major castings. In particular the width across the appliance recess

could be critical.

APPLIANCE WEIGHT (Excludes Packaging)

Model: AGA Dual Control (DC3G) - 996lb (452kg)

GAS CONNECTION - AGA DC3G ONLY

1/4” NPT MALE AT LEFT REAR OF APPLIANCE

NOTE: GAS CONNECTION POINT PROTRUDES

A B C D E F G H J K

mm 987 951 913 680 1388 760 1145 698 116 10

inch

38

7/8 37

1/2 36 26 3/4 54

5/8 29 7/8 45

1/8 27

1/2 4

9/163/8

L M N P Q R S T U V W

mm 565 689 43 118 55 634 330 760 996 75 9

inch

22

1/4 27

1/8 1

3/4 4

5/8 2

1/8 25 13 30 39

3/16 33/8

OVERHEAD

CUPBOARDS

6

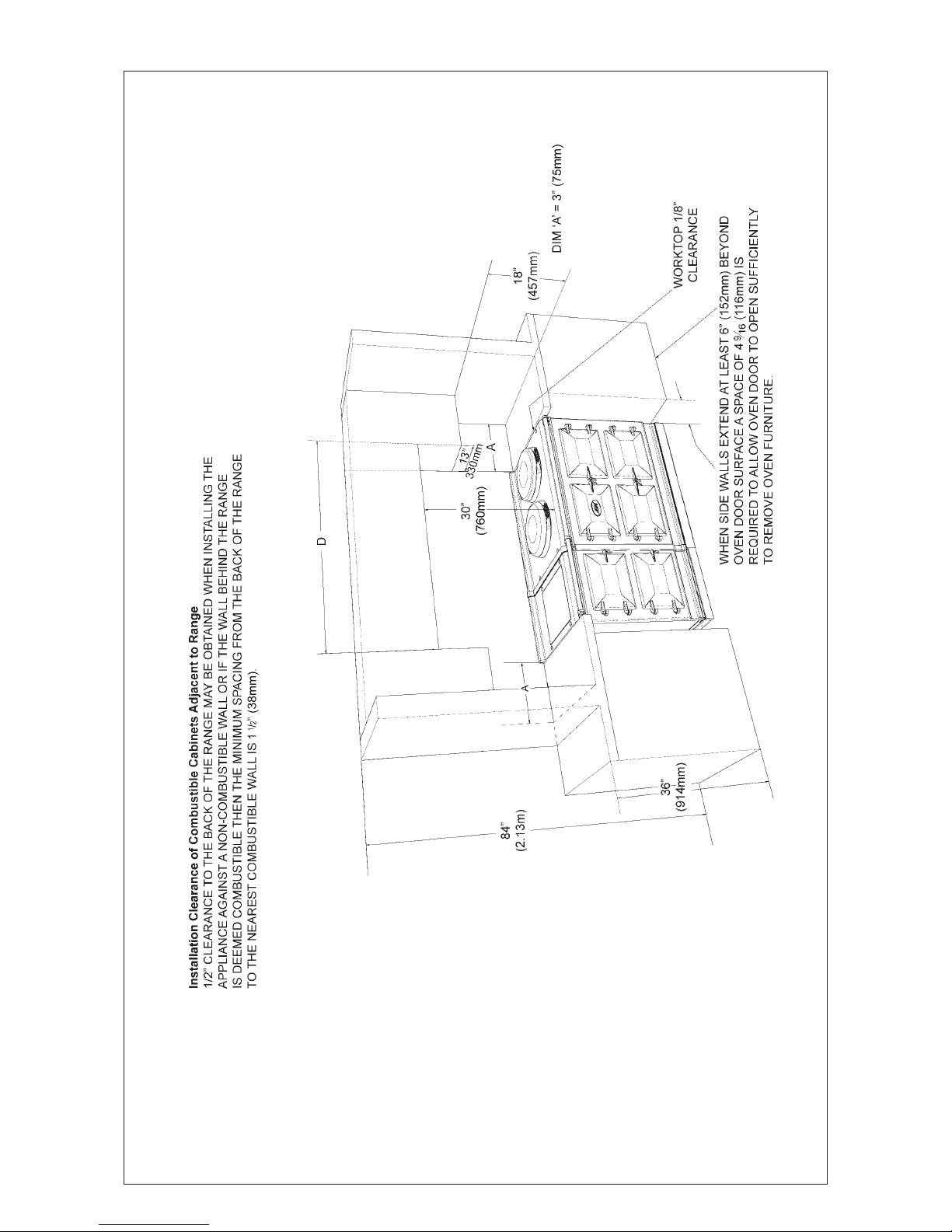

Side Clearances

A

1

/8” (3mm) gap is required each side between the range top plate and adjoining work surfaces that may be

fitted, this is to allow for the safe removal of the top plate should this be required at a later date.

Where ranges are to be fitted against a side wall a 4 9/16” (116mm) clearance is required on the right and left

hand side for oven door access.

If the AGA is to be installed in a brick recess, then the minimum clearance should be increased by at least

3

/8” (10mm), to allow for the walls not being square.

In addition a minimum clearance of 39 3/8” (1000mm) must be available at the front of the range to enable the

range to be serviced.

NATURAL GAS

MAXIMUM HEAT INPUT 6,800 Btu/hr

Thermostat Bypass 70

Main Burner Injector 112

Gas Supervision Injector 4212

Minimum Inlet Pressure 5” w.g.

Burner Pressure 4” w.g.

Models AGA DC3G and DC5G

TECHNICAL DATA

INSTALLATION

Range Base or Hearth

It is essential that the base or hearth on which the range stands should be level and be capable of supporting

the total weight of the range. The base of the built-in AGA plinth must be level and sit above the finished

height for service access.

Plinth

The front plinth cover is removable and must not be obstructed by flooring or tiles. If necessary the range

must be raised by the thickness of the tiles to ensure the plinth can be removed.

Rear Wall

Since this appliance runs continuously, please take note of these IMPORTANT instructions:

Combustible Walls

Houses constructed of combustible materials (such as all-timber or stud wall partitions and batoned

plasterboarded walls) require special wall heat protection features.

Non-combustible material behind a range must be of at least 1” (25mm) thick insulation board (Monolux or

equivalent), up to hotplate level.

SPECIAL NOTE: Ensure electric cabling or plastic services do not pass within or on the outside of the wall,

behind or directly above the range.

This type of material can age prematurely when exposed to continuous higher ambient temperature.

Alternatively the range can be spaced 1 1/2” (38mm) away from the wall to create an air gap.

The air gap must be left open and NOT blocked off across the top edge.

7

Tiling

When the range is to stand in a recess or against a wall which is to be tiled, under no circumstances should

the tiles overlap the range top plate, access to remove the hotplate must be allowed for servicing at a later

date.

A gap of at least

3

/8” (10mm) must be observed from the rear of the top plate and the wall behind the range.

Overhead Cabinets

To eliminate the risk of burns or fires by reaching over hot surface units, cabinet storage space located

above the surface units should be avoided.

8

NOTE: ANY OVERHEAD FITTED

CABINETS MUST NOT EXCEED 13”

PROJECTED DEPTH ABOVE THE

RANGE.

DIM ‘D’ TO BE NOT LESS THAN THE

NORMAL WIDTH OF THE RANGE.

Fig. 2 DESN 516668

9

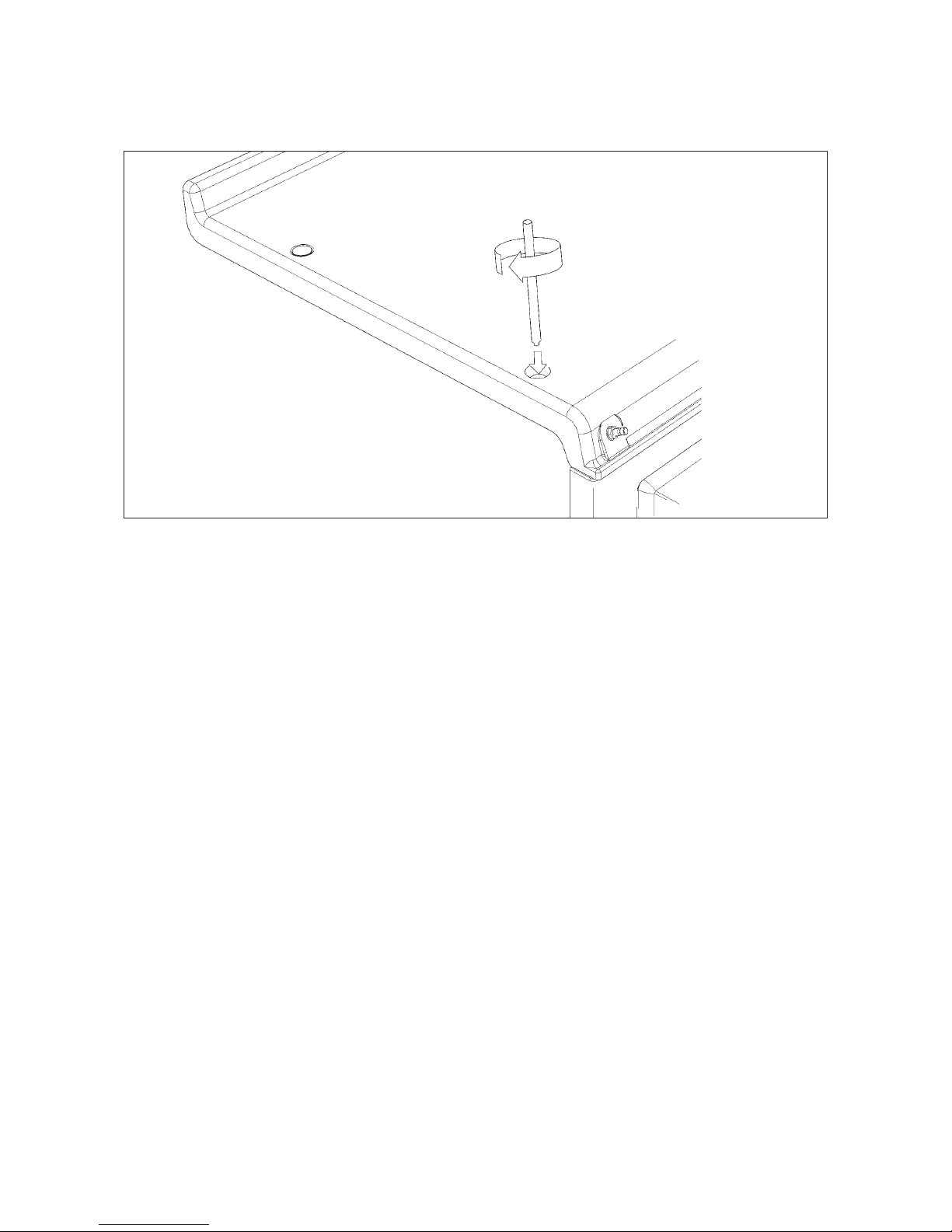

Top Plate Adjustment - AGA DC3 (See Fig. 4)

In general, adjustment of the top plate is to be avoided. However minimum use of the top plate adjusters can

be used to improve the alignment of the top plate.

Fig. 3

DESN 516751

Loading...

Loading...