Page 1

Installation

Guide

09/14 EINS 516899

PLEASE READ THESE INSTRUCTIONS BEFORE COMMENCING SITE SURVEY

OR INSTALLING THIS APPLIANCE.

IMPORTANT : SAVE INSTRUCTIONS FOR FUTURE REFERENCE

IMPORTANT : CONSERVER CES INSTRUCTIONS POUR REFERENCE FUTURE

For use in USA/Canada

AGA CITY24

Page 2

SECTION PAGE

PRODUCT SAFETY 3

GENERAL NOTES 4

HEALTH AND SAFETY 4

GENERAL INSTALLATION REQUIREMENTS 4

REMOVAL FROM PALLET AND RANGE INSTALLATION 5-6

RANGE DIMENSIONS 7

CLEARANCES 8

CONNECTION TO THE POWER SUPPLY 9

POWER CORD ROUTING 10

CONTROL KNOB AND HANDRAIL CONNECTION 11

WIRING DIAGRAM 12

AGA CITY24 CHECKLIST 13

2

CONTENTS

Page 3

PRODUCT SAFETY

MEANING/DESCRIPTION SIGNIFICATION/DESCRIPTIONSYMBOL

WARNING/CAUTION

An appropriate safety instruction

should be followed or caution to a

potential hazard exists.

AVERTISSEMENT

Une consigne de sécurité

appropriée doivent être suivies ou

garde d’un danger potentiel

exists.

DANGEROUS VOLTAGE

To indicate hazards arising from

dangerous voltages.

TENSION DANGEREUSE

Pour indiquer les dangers

résultant des tensions

dangereuses.

PROTECTIVE EARTH (GROUND)

To identify any terminal which is

intended for connection to an

external conductor for protection

against electric shock in case of a

fault, or the terminal of protective

earth (ground) electrode.

TERRE DE PROTECTION

Pour marquer bornes destin

ées à

être raccordées à un conducteur

de protection extérieur contre les

chocs éclectiques en cas de

défaut d’isolement, ou pour

marquer la borne de la terre de

protection.

HEAVY

This product is heavy and

reference should be made to the

safety instructions for provisions

of lifting and moving.

LOURD

Ce produit est lourd et doit

être

fait référence auc consignes de

sécurité relatives aux dispositions

de soulever et déplacer.

DISCONNECT MAINS SUPPLY

Disconnect incoming supply

before inspection or maintenance.

APPAREIL À LASER DE

CLASSE 2

Alimentation d’entr

ée Débrancher

avant inspection ou d’entretien.

REFER TO MANUAL

Refer to relevant instructions

detailed within the product

manual.

ATTENTION, SURFACE TRÉS

CHAUDE

Reportez-vous aux instructions

applicables, indiquées dans le

manuel du produit.

3

Page 4

HEALTH AND SAFETY

Consumer Protection

As responsible manufacturers we take care to make sure that our products are designed and constructed to meet the

required safety standards when properly installed and used.

PLEASE READ THE ACCOMPANYING WARRANTY

Any alteration that is not approved by AGA could invalidate the approval of the appliance, operation of the warranty and

could also affect your statutory rights.

4

GENERAL NOTES

NOTE: THESE INSTALLATION INSTRUCTIONS SHOULD BE LEFT WITH THE RANGE AND THE USER TO RETAIN

FOR FUTURE REFERENCE.

GENERAL INSTALLATION REQUIREMENTS

The installation of the range must be in accordance with the relevant requirements of the local Wiring and Building

Regulations. It should be in accordance also with any relevant requirements of the Local Authority.

In your own interest and that of safety to comply with the law, all appliances should be installed by an authorized AGA

distributor in accordance with the relevant regulations.

CAUTION:

THIS UNIT IS HEAVY, PROPER EQUIPMENT AND ADEQUATE

MANPOWER MUST BE USED IN MOVING THE RANGE TO

AVOID DAMAGE TO THE UNIT OR THE FLOOR

Page 5

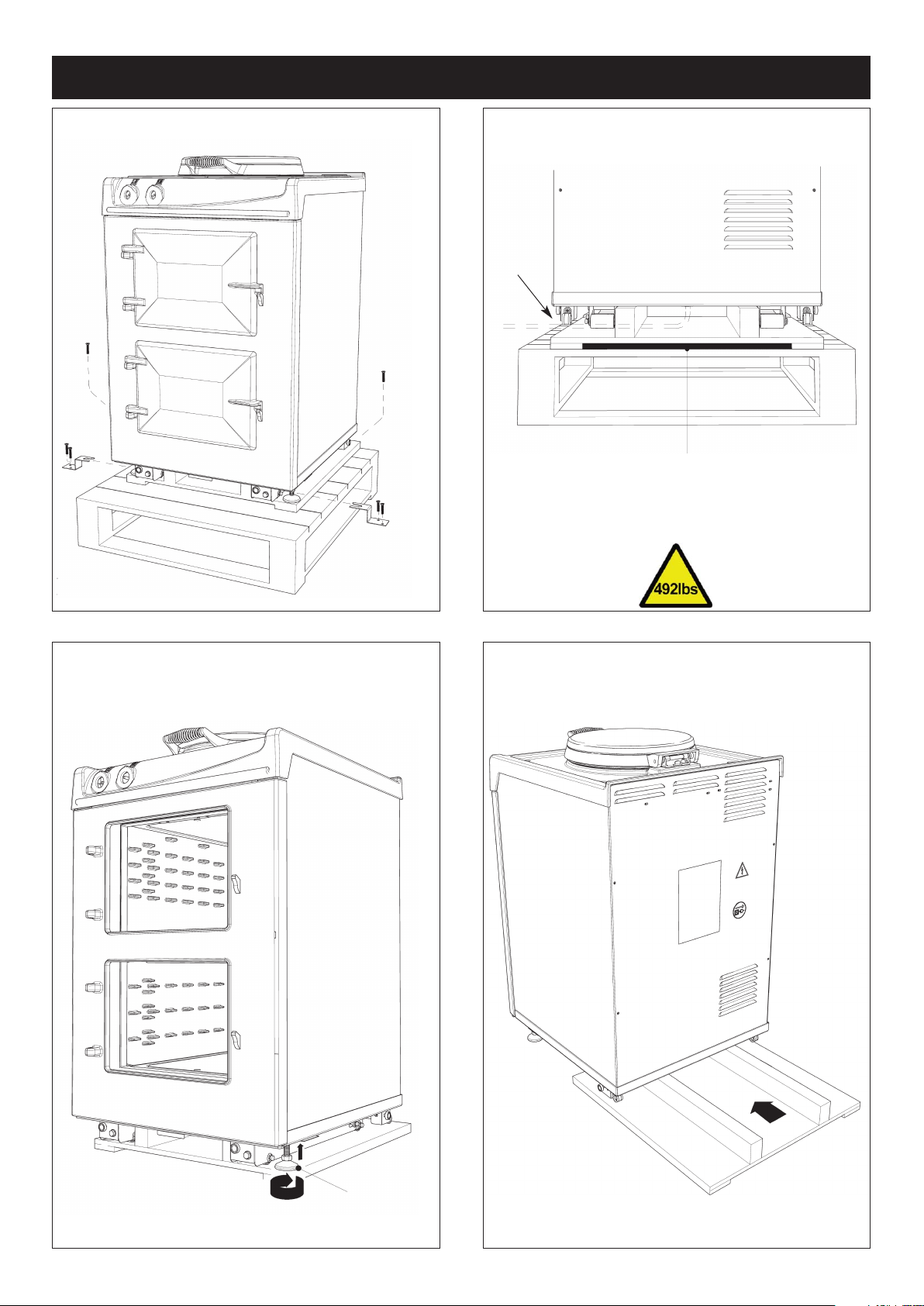

REMOVAL FROM PALLET AND RANGE INSTALLATION

Fig. 1 DESN 516905

Removing of transit brackets - Unscrew 4 screws and

remove brackets, from front and two screws from rear.

Fig. 2 DESN 516891

NOTE: Care must be taken not to trap power cord.

Range to be removed from rear of pallet only.

Recess provided for suitable appliance dolly.

Range to be secured to appliance dolly with

suitable straps (shaded area)

Fig. 3 DESN 516906

Once range is in position in kitchen, remove appliance

dolly and straps. The front stability feet can be raised

with a 12mm open end wrench to allow appliance to be

slid from transit pallet.

STABILITY FOOT

MAINS

CABLE

Fig. 4 DESN 516893

Slide range off transit pallet. Take care not to trap mains

cable.

5

Page 6

REMOVAL FROM PALLET AND RANGE INSTALLATION

Fig. 5 DESN 516907

Range can now be pushed back on its wheels into

desired position.

NOTE: Care must be taken not to trap mains cable.

Fig. 6 DESN 516895

Levelling of range - Use 13mm socket to adjust wheel

mechanism for FINE adjustment on both sides at rear

of the appliance.

Using a 12mm open end wrench, feet can be adjusted

at front to make FINE adjustments to the front of the

appliance and to provide a brake for the wheels.

Turning the bolt clockwise will lower the wheel thus

increasing height of the range.

Anti-clockwise lifts the wheels and lowers the range.

Fig. 7 DESN 516897

Fitting magnetic plinth

FRONT PLINTH

COVER FITS

OVER SIDE SKIRTS

MAKE SURE SIDE

PLINTH SKIRTS ARE

LOCATED IN FRONT

GUIDE BRACKET

Fig. 8 DESN 516888

Resting Plate Adjustment - Resting plates have

adjuster screw feet for setting of height and to improve

stability.

6

DESN 516917

Page 7

RANGE DIMENSIONS - AGA CITY24

Fig. 9 DESN 516904

Range Dimensions

When surveying for a range installation the actual clearance required for the ‘body’ of the range should be increased by

1/4” (6mm) beyond the figures quoted above. This allows safe margin to take into account the natural dimensional variations

found in major castings. In particular the width across the range recess could be critical.

APPLIANCE WEIGHT (Excludes Packaging)

Model: AGA CITY24 - 492lbs (223kg)

7

Page 8

CLEARANCES

The complete range is floor mounted and the space in which the appliance is to be fitted must have the following minimum

dimensions:-

A minimum clearance of 2

3

/8” (60mm) is required above the raised insulating cover handle.

Side Clearances

A 1/8” (3mm) gap is required each side between the range top plate and adjoining work surfaces that may be fitted, this is

to allow for the safe removal of the top plate should this be required at a later date.

Where ranges are fitted against side walls a 4

9

/16” (116mm) clearance is required on the left hand side for oven doors

access.

If the AGA is to be installed in a brick recess, then the minimum clearance should be increased by at least 1/8” (6mm), to

allow for the walls not being square.

In addition, a minimum clearance of 39

5

/8” (1000mm) must be available at the front of the ranges to enable the ranges to

be serviced.

Range Base or Hearth

It is essential that the base or hearth on which the range stands should be level and be capable of supporting the total

weight of the appliance.

The front plinth cover is removable and must not be obstructed by flooring or tiles. If necessary the range must be raised

by the thickness of the tiles to ensure the plinth can be removed, and the range can be rolled out for service.

Tiling

When the range is to stand in a recess or against a wall which is to be tiled, under no circumstances should the tiles overlap

the range top plate, access to remove the top plate must be allowed for servicing at a later date.

8

Since this appliance can be used continuously, please take note of these IMPORTANT instructions.

Combustible Walls

Houses constructed of combustible materials (such as all-timber or stud wall partitions and batoned plasterboarded

walls) require special wall heat protection features.

Non-combustible walls behind a range must be of at least 1/4” (25mm) thick insulation board (Monolux or equivalent), up

to hotplate level.

SPECIAL NOTE: Ensure electric cabling or plastic services do not pass within or on the outside of the wall, behind or

directly above the range. This type of material can age prematurely when exposed to continuous higher

ambient temperature.

Page 9

9

CONNECTION TO THE POWER SUPPLY

Electric Shock Hazard

Rating Plate is located behind removable plinth, see Fig. 4.

Electrical Grounding is required on this appliance.

DO NOT connect to the electrical supply until the appliance is permanently grounded.

This appliance must be connected to a grounded metallic permanent supply or a grounding

connector should be connected to the grounding terminal or wire lead on the appliance.

Failure to follow these instructions could result in death or serious injury.

This range must be supplied with a 240V, 60Hz power supply and connected to an individual, properly grounded branch

circuit protected by a circuit breaker. At 240V, it has a maximum load of 30 amps. Electric hook-up must be done by a

licensed electrician. This unit must be installed according to regional codes, or in the absence of codes, the National

Electrical Code.

l Product installation requires a separate (not shared) 240V/40 amp circuit protected by an appropriate branch circuit

supply.

l The power cord on your range is fitted with a standard four (4) conductor type 14-50P plug (matching receptacle

14-50R).

The method of connection to the mains electricity supply must facilitate complete electrical isolation of the appliance.

The mains connection and isolation should not be positioned above the range and must be positioned within the area

defined in Fig. 11, Page 10.

THIS RANGE MUST BE COMPLETELY ISOLATED FROM THE ELECTRICITY SUPPLY BEFORE SERVICING. THE

RANGE IS DESIGNED FOR THE VOLTAGE STATED ON THE RATING PLATE, WHICH IS SITUATED BEHIND THE

PLINTH COVER.

Page 10

MAINS CABLE ROUTING

Fig. 10 DESN 516918

Fig. 11 DESN 516874

THE MAINS SUPPLY MUST BE WITHIN THE ZONES SHOWN

10

SECURE MAINS CABLE USING ‘P’ CLIPS FOR LEFT HAND OR RIGHT HAND

CABLE MANAGEMENT

WORKTOP

3ft 11” (1.2 metres)

3ft 11” (1.2 metres)

RATING PLATE LOCATED BEHIND PLINTH

Fig. 10A DESN 516919

POWER CORD

50A/250V 12500W RATED FITTED WITH NEMA 14-50P RIGHT ANGLED PLUG

(MATCHING RECEPTACLE 14-50R)

UL OR CSA APPROVED

Page 11

CONTROL KNOB AND HANDRAIL CONNECTION

Fig. 12 DESN 516875

Control Knob Location

Ensure control knobs are located onto spindles correctly, as shown in Fig 12.

Handrail Location - AGA City24 (Traditional)

Locate handrail onto spindle, lock into position with grub screws (located on the inside of the bracket).

11

OVEN CONTROL

KNOB

HOTPLATE CONTROL

KNOB

Page 12

WIRING DIAGRAM

12

Fig. 13

Page 13

Tick Box

l Check hotplate lid and setting

l Check oven door seals, adjust door alignment if necessary.

Slow cook oven rope seals MUST have a gap between the door hinges. The roasting

oven is fitted with a continuous seal.

Ensure all plastic film is removed from the inside of the oven doors.

l Turn on roasting and slow cook oven, set hotplate to simmer. Raise hotplate lid to avoid staining.

l After 30 minutes, check hotplate temperatures (approx).

1. Simmerspot (200 - 250°C)

then hotplate to boiling, after 15 minutes check temperature

2. Hotspot (330 - 380°C)

l Guide customer through the Users Instructions of the range, offering best practices on oven

maintenance, energy usage, enamel cleaning (boiled vegetable water staining on enamel etc.)

Engineer’s Signature ........................................................ Date ...........................

AGA CITY24 CHECKLIST

SERIAL No.

131415

Page 14

Page 15

Page 16

16

www.agamarvel.com

Supplied by

AGA Marvel

1260 E. Van Deinse St.

Greenville, MI 48838

Business (616) 754-5601

Fax (616) 754-9690

Toll Free Telephone 800-223-3900

With AGA Marvel’s policy of continuous product im-

provement, the Company reserves the right to

change specifications and make modifications to

the appliance described and illustrated at any time.

For further advice or information contact

your local AGA Specialist

Loading...

Loading...