Page 1

03/08 EINS 511750

Remember, when replacing a p art on this appliance, use only spare p arts that you can be assured conform

to the safety and performance specification that we require. Do not use reconditioned or copy parts that

have not been clearly authorised by Aga-Ranges.

PLEASE READ THESE INSTRUCTIONS BEFORE USING THIS APPLIANCE

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE.

CUSTOMER: KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE

Comprising

Installation & Users

Instructions

&

Cooking

Guide

COMPANION/MODULE

(with Gas Hob)

OWNERS MANUAL

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage,personal injury or death.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT DO YOU DO IF YOU SMELL GAS

. Do not try to light any appliance.

. Do not touch any electrical switch

. Do not use any phone in your building.

. Immediately call your gas supplier from a neighbors phone.

Follow the gas suppliers instructions

. If you can not reach your gas supplier call the fire department.

Installation and service must be performed by a qualified installer, service agency

or the gas supplier.

FOR USE IN USA/CANADA

Page 2

2

CONTENTS

SECTION PAGE

INSTALLATION 3

LOCATION 4

PRODUCT DIMENSIONS - COMPANION 5

PRODUCT DIMENSIONS - MODULE 6

INSTALLATION CLEARANCE OF COMBUSTIBLE CABINETS 7

TECHNICAL DATA 8

INSTALLATION 9-15

INSTALLATION - MODULE ONLY 10

ELECTRICAL CONNECTIONS 16-17

CONNECTING TO GAS - COMPANION 18

PRESSURE TESTING 19

SERVICING - COMPANION & MODULE 20-27

USERS GUIDE 28

INTRODUCTION 29

SAFETY PRECAUTION AND HINTS 30

APPLIANCE VIEW 31

CONTROL PANEL 32

GAS HOTPLATE 33-34

THE GRILL & OVENS 35-36

OVEN COOKING GUIDE 37-41

CLEANING & CARING FOR YOUR COOKER 42-44

SERVICING 45

Page 3

Installation

Section

3

CAUTION:

THIS UNIT IS HEAVY, PROPER EQUIPMENT AND ADEQUATE

MANPOWER MUST BE USED IN MOVING THE RANGE TO

AVOID DAMAGE TO THE UNIT OR THE FLOOR

Remember, when replacing a part on this appliance, use only spare parts that you can be

assured conform to the safety and performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised by Aga-Ranges.

Page 4

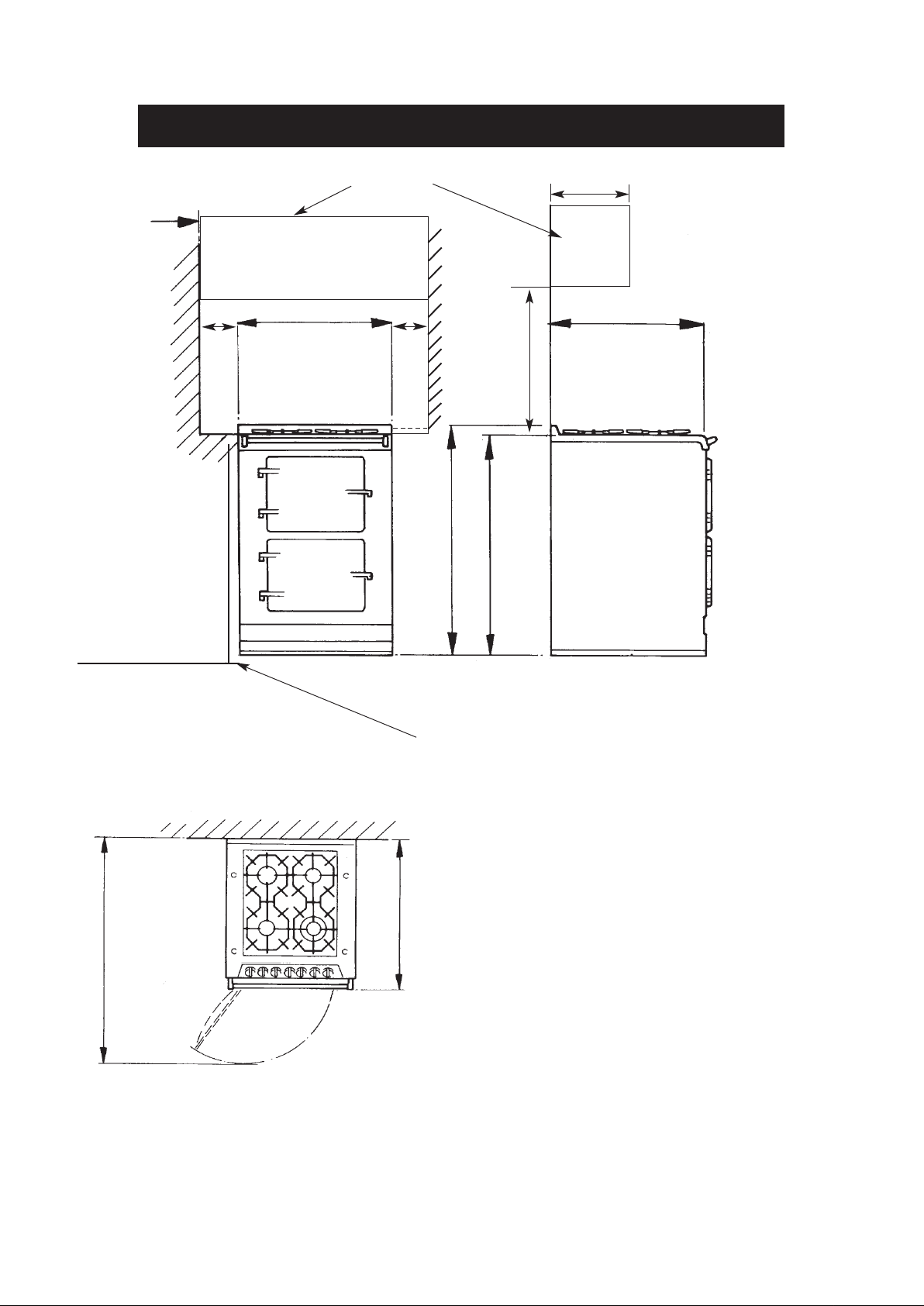

REFER TO FIG 1 & 2

The side wall clearance above the hob shall be greater than 3”.

Surfaces over the top of the range must not be closer than 28” and must not exceed 13” in depth.

The vent slots in the back of the top plate (or shroud) must not be obstructed.

Note: It is essential that the supply cable is routed away from any hot surfaces i.e. hot flue pipes.

In the interests of safety, due consideration must be given to the protection of the electric cable

to the Module/Companion.

The Module/Companion requires a 30 amp power supply and must be connected to the mains

with a cable which complies with the latest edition of the Local and National Wiring Regulations.

Remember that an excess of cable length is required for the possible withdrawal of the range.

A electrical socket type 14-30R must be provided within 5 feet of the left hand side of the range

and accessible for disconnection.

DO NOT position socket above or behind the range cooker.

An easily accessible manual shut off gas valve must be fitted before the metal flexi gas line

supply to the range. DO NOT fit valve behind the range cooker.

Any opening in the wall behind the appliance and in the floor under the appliance must be

sealed.

LEVELLING

The Aga Companion is designed to stand on a flat surface, however any unevenness may be

overcome by packing under the corners of the plinth with a suitable non-combustible material,

(up to 1/8”).

COMPANION ONLY

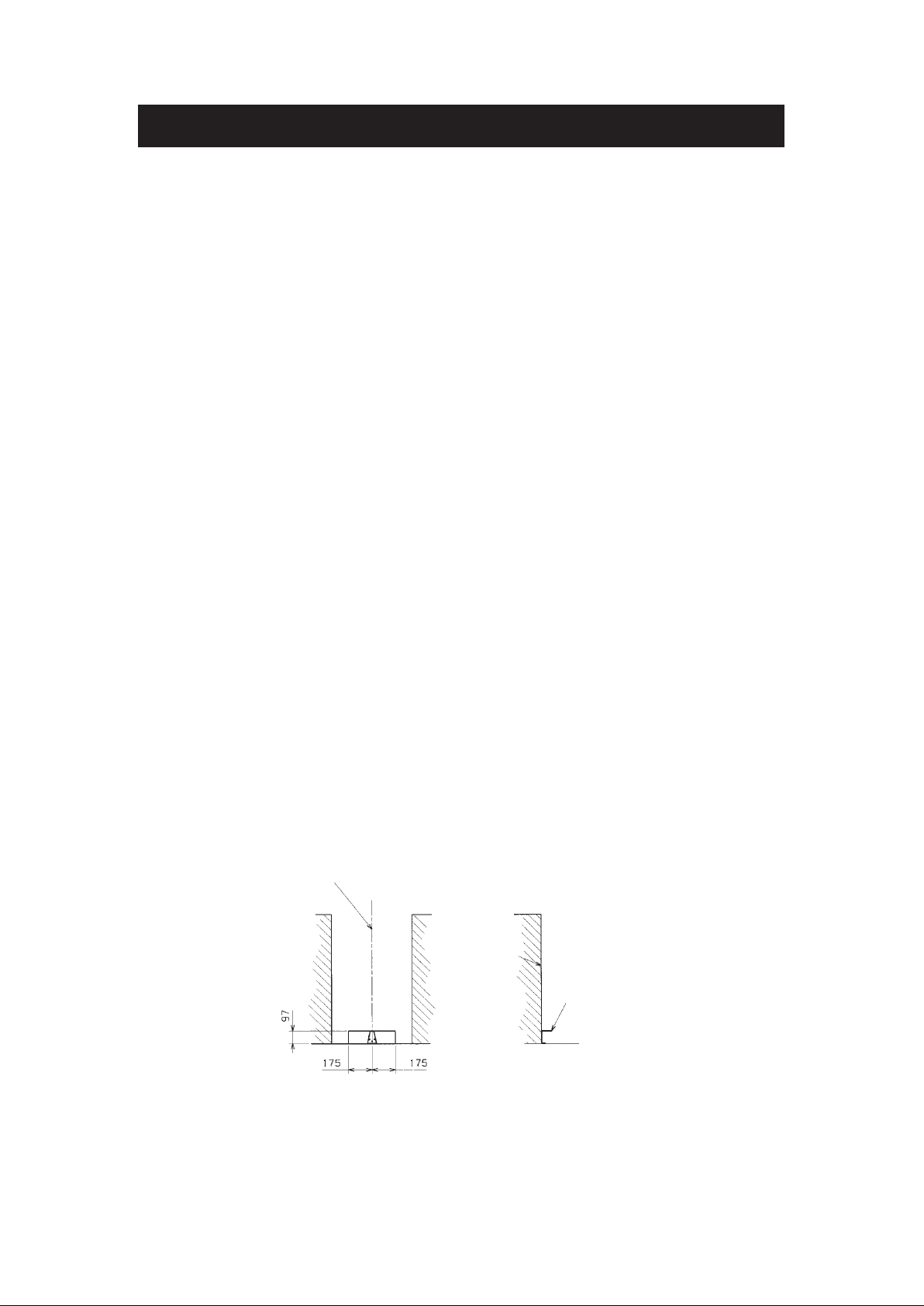

Ranges must have an anti-tip device correctly installed as per these instructions. If you pull the

range out from the wall for any reason, make sure that the device is properly engaged when you

push the range back against the wall. If it is not, there is a possible risk of the range tipping over

and causing injury if you or a child stand, sit or lean on an open door.

To reduce the risk of tipping, the range must be secured by a properly installed anti-tip bracket

supplied with the range. The bracket must be fitted within the shaded area shown in the diagram

using 2 x screws (No.10 x 1 1/4”) fixed in the wall or floor, longer screws may be required

depending on the wall or floor covering.

4

LOCATION

CENTRE LINE OF

COOKER

BRACKET

FLOOR

WALL

Page 5

5

PRODUCT DIMENSIONS - COMPANION

APPLIANCE CAN BE

CLOSE FITTED TO

KITCHEN UNITS UP TO

WORK TOP HEIGHT.

680mm

(26

3/4”)

595mm

75mm

75mm

600mm

(23

3/4”)

(421/2”)

(28”)

(231/2

”)

(3”)

(3”)

711mm MIN.

330mm MAX.

(13”).

910mm

(35 3/4”)

948mm

(37

3/8”)

1080mm

Fig 1

DESN 511616

OVERHEAD

CUPBOARD

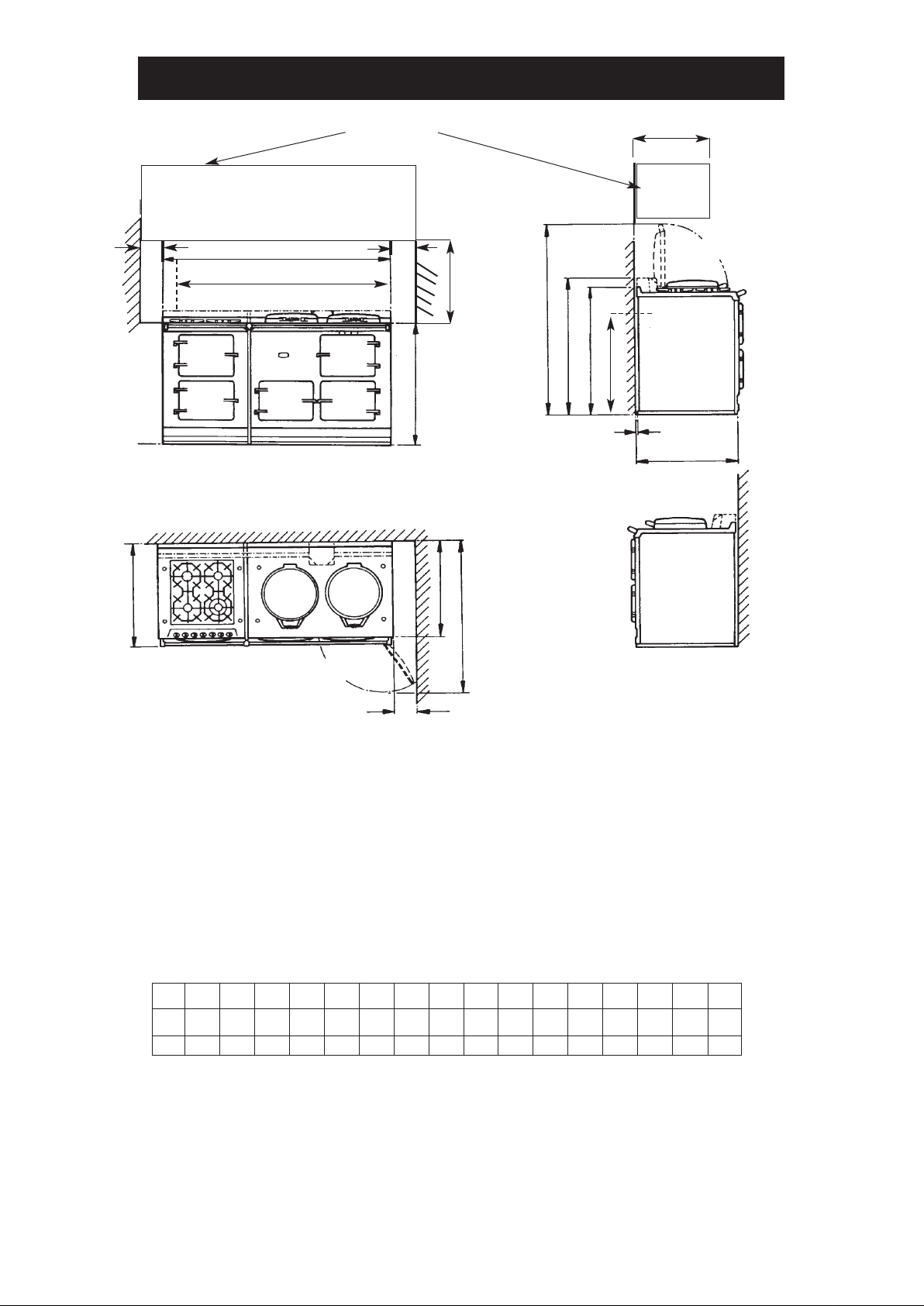

Page 6

MODULE ONLY:-

The extension channel section at the rear of each side plate may be removed, if required to clear

flue pipes with the following provisions:-

A 2” air gap should be provided on left hand side of the range (Power Vent models only)

COOKER DIMENSIONS

When surveying for a range cooker installation the actual clearance required for the ‘body’ of the

appliance should be increased overall by 1/2” beyond the figures quoted. This allows safe margin

to take into account the natural dimensional variations found in major castings. In particular the

width across an appliance recess could be critical.

PRODUCT DIMENSIONS - AGA GC (2-OVEN) WITH MODULE

A

N

C

E

Q

E

H

M

J

K

D

L

O

P

B

F

G

OVEN DOOR IN

OPEN POSITION

POSITION OF LIDS

WHEN RAISED

6

mm 1598

AB CDEF*GHJ K LM

330

28”

13”63” 35”

38”33

1/2”263/4”3” 513/4”293/4”441/4”41/2”

27

1/2”311/2”

60

5/8”

1/8”

ins

711

P

Q

N** O**

889 851 679 75 967 1330

756

1125 116 3 698 1533 800

DESN 511633

OVERHEAD

CUPBOARD

MAX

MIN

Fig 2

* ELECTRIC AND GAS POWER FLUE MODELS ONLY

**POSITION FOR GAS SUPPLY PIPE TO MODULE

NOTE: Dimensions for Aga GC3 (3 Oven) are identical to GC (2-Oven).

For gas supply connections to Aga GC3 (3 Oven) model - See Fig. 5A.

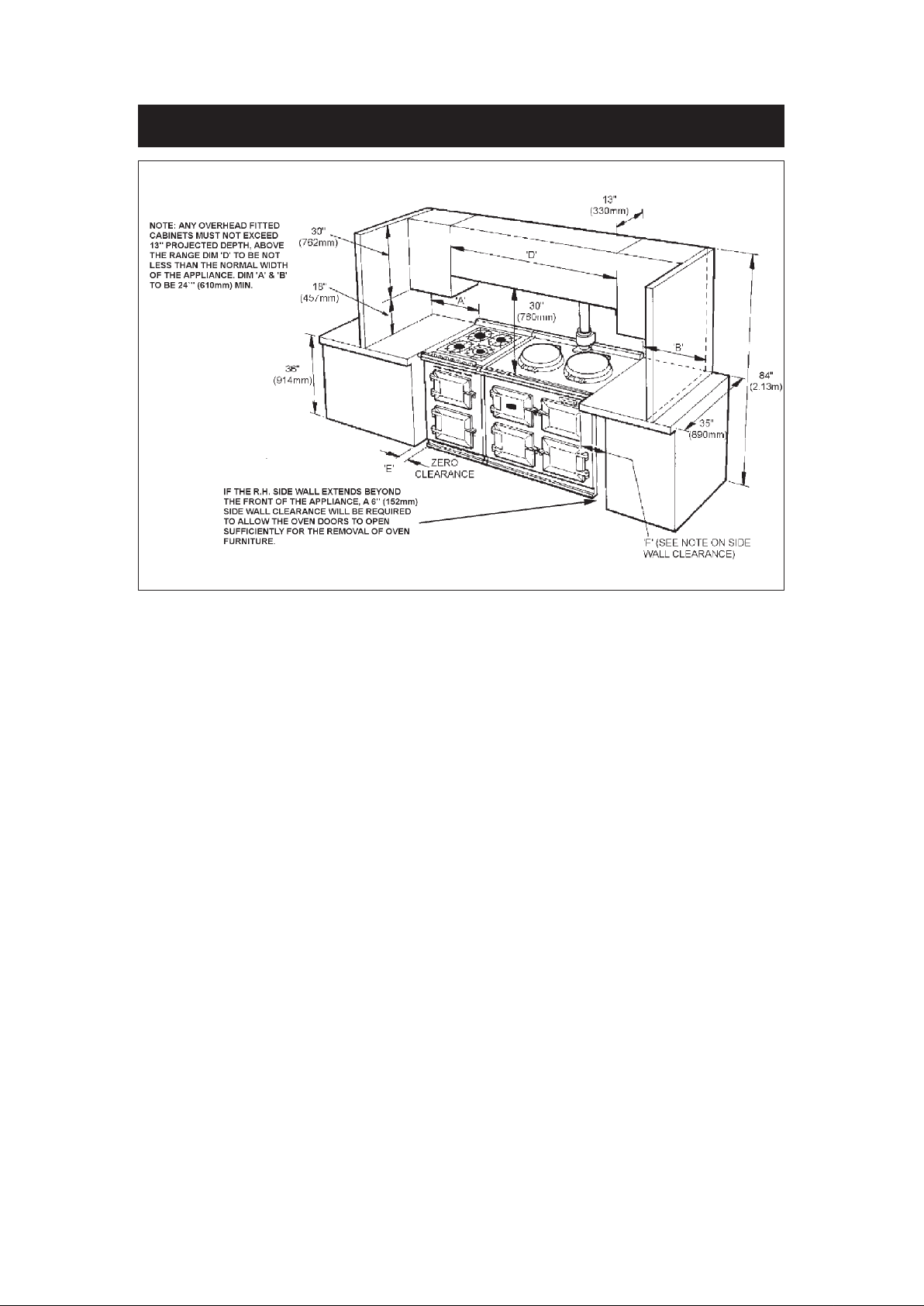

Page 7

7

INSTALLATION CLEARANCES OF COMBUSTIBLE CABINETS

ADJACENT TO RANGE (GC3 (3 OVEN) WITH MODULE SHOWN)

Fig 2A GC3 - Open Flue Model (with Module) DESN 512438

Page 8

HOTPLATE

NA

TURAL GAS

R.H.F. L.H.R. R.H.R. L.H.F.

BURNER TYPE ULTRA RAPID RAPID SEMI-RAPID SEMI-RAPID

(WOK)

MAXIMUM HEAT 3.5 kW 3.1 kW 1.8 kW 1.8 kW

INPUT 12,000 Btu/hr 10,600 Btu/hr 6,150 Btu/hr 6,150 Btu/hr

INJECTOR MARKING 170 155 118 120

PRESSURE POINT POSITION: FRONT LH HOTPLATE INJECTOR

PRESSURE SETTING: 4” wg

BURNER IGNITION: H.T. SPARK

PROP

ANE

R.H.F. L.H.R. R.H.R. L.H.F.

BURNER TYPE ULTRA-RAPID RAPID SEMI-RAPID SEMI-RAPID

(WOK)

MAXIMUM HEAT 12,000 Btu/hr 10,600 Btu/hr 6.150 Btu/hr 6.150 Btu/hr

INPUT 3.5 kW 3.1 kW 1.8 kW 1.8 kW

(250g/h) (221g/h) (128g/h) (128g/h)

(0.5l/h) (0.43l/h) (0.26l/h) (0.26l/h)

INJECTOR MARKING 105 94 72 75

PRESSURE POINT POSITION: FRONT LH HOTPLATE INJECTOR

PRESSURE SETTING: 10” wg

BURNER IGNITION: H.T. SPARK

ELECTRIC GRILL & OVENS 240 VOLT 60 Hz SINGLE PHASE 30 AMP

GRILL ELEMENT - POWER RATING 2 x 1.05 kW

TOP OVEN - POWER RATING 1.5 kW

LOWER OVEN (FANNED CONVECTION) - 1.9 kW

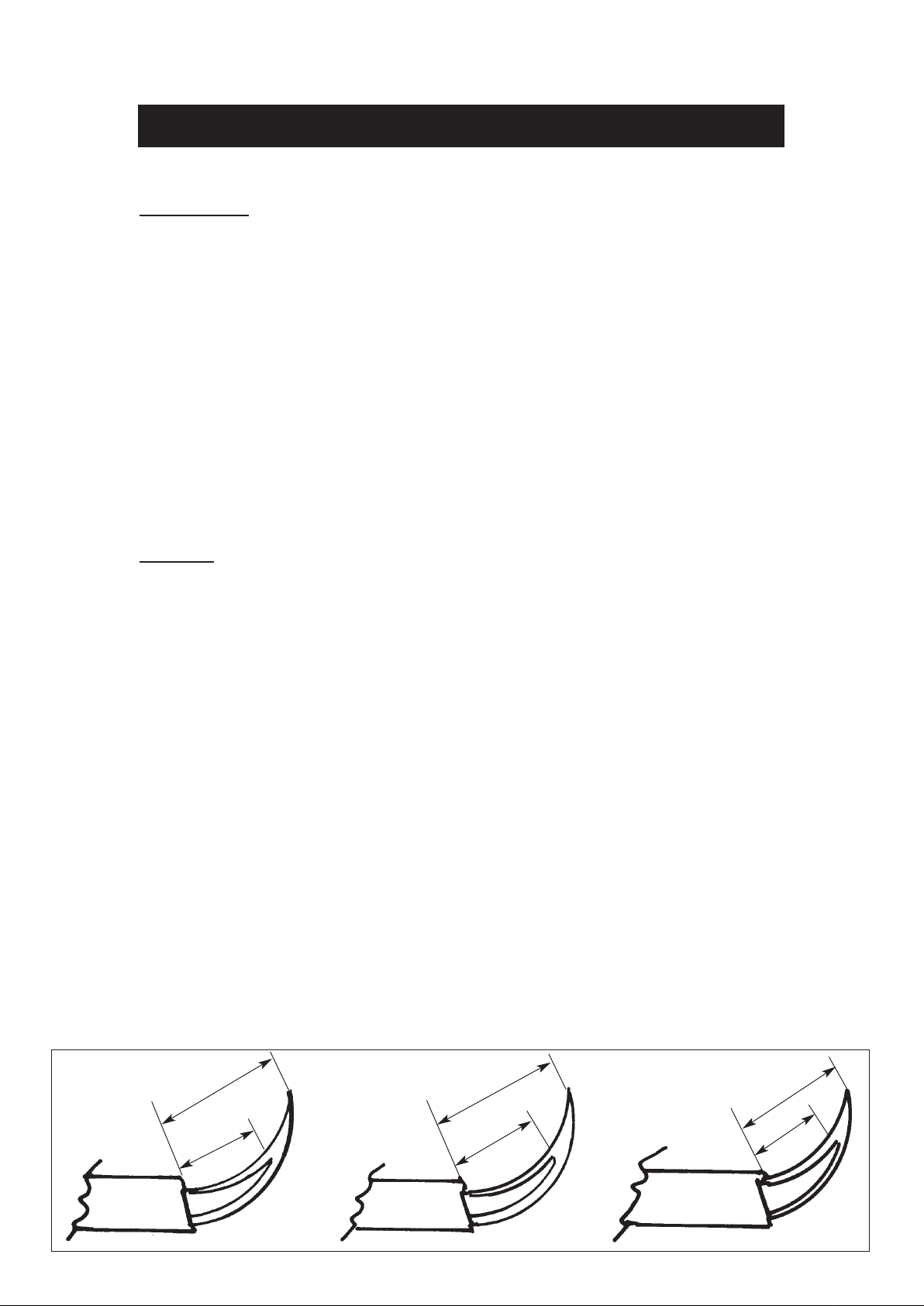

TYPICAL SECTION VIEW OF BURNER FLAMES

TECHNICAL DATA

8

11/16”

15/16”

9/16”

7/8”

1/2”

7/16”

11mm

17.5 mm

24 mm

14 mm

22 mm

12.5 mm

FRH HOTPLATE BURNER

RLH HOTPLATE BURNER

RLH & FRH HOTPLATE BURNER

Page 9

CAUTION: THIS INSTALLATION MUST CONFORM WITH LOCAL CODES OR, IN THE

ABSENCE OF LOCAL CODES WITH THE NATIONAL FUEL GAS CODE, ANSI Z223.I AND

NATIONAL ELECTRICAL CODE ANSI/NFPA 70 (IN CANADA CAN/CGA-B149) AND ONLY

USED IN A WELL VENTILATED SPACE, READ THESE INSTRUCTIONS BEFORE

INSTALLING OR USING THIS APPLIANCE.

PRIOR TO INSTALLATION, ENSURE THAT THE LOCAL DISTRIBUTION CONDITIONS

(NATURE OF GAS AND GAS PRESSURE) AND THE ADJUSTMENTS OF THE APPLIANCE

ARE COMPATIBLE.

THE GAS ADJUSTMENT CONDITIONS FOR THIS APPLIANCE ARE STATED ON THE DATA

PLATE WHICH IS SITUATED IN THE CENTRE VENT SLOT NEAR THE BASE OF THE

FRONT PLATE.

This appliance is not connected to a combustion products evacuation device. It shall be installed

and connected in accordance with current installation regulations. Particular attention shall be

given to the relevant requirements regarding ventilation.

It should be in accordance also with any relevant requirements of the Gas Region and Local

Authority.

The appliance and its individual gas shut off valve must be disconnected from the gas supply

piping system during any pressure testing of that system test pressure in excess of 1/2 psi (3.5

kPa).

The appliance must be isolated from the gas supply piping system by closing its individual

manual shut off valve during any pressure testing of the gas supply system at test pressures

equal to or less than 1/2 psi (3.5 kPa).

On completion test the gas installation for soundness and purge. Leak testing of the appliance

shall be conducted according to the manufacturers instructions.

NOTE: Use soapy water solution on new gas connections to ensure there are no gas leaks.

WARNING - ELECTRIC SHOCK HAZARD

It is the customers responsibility to contact a qualified electrical installer to make sure the

electrical installation is adequate and in conformance with National Electrical Code ANSI/FPA

70- latest edition, and all local codes and ordinances.

Take special care when cutting holes in walls or floor. Electrical wires may be behind the wall or

floor covering and could cause an electrical shock if you touch them.

Locate any electrical circuits that could be affected by the installation of this product and

disconnect power circuit.

Electrical ground is required on this appliance.

Do not have a fuse in the neutral or grounding circuit. A fuse in the neutral or grounding circuit

could result in electrical shock.

Do not use an extension lead with this appliance.

Check with a qualified electrician if you are not sure the appliance is properly grounded.

Failure to follow these instructions could result in death or serious injury.

INSTALLATION

9

Page 10

Having ensured all space requirements and regulations have been satisfied for the combined

arrangement (Aga Cooker and Module), the build and installation is to proceed as follows:-

1. It is essential that a base or hearth on which both cooker and module stands should be

level and capable of supporting the total weight of both units.

Module weight = 129kgs (284 lbs)

2. Unpack and remove the Module from the pallet.

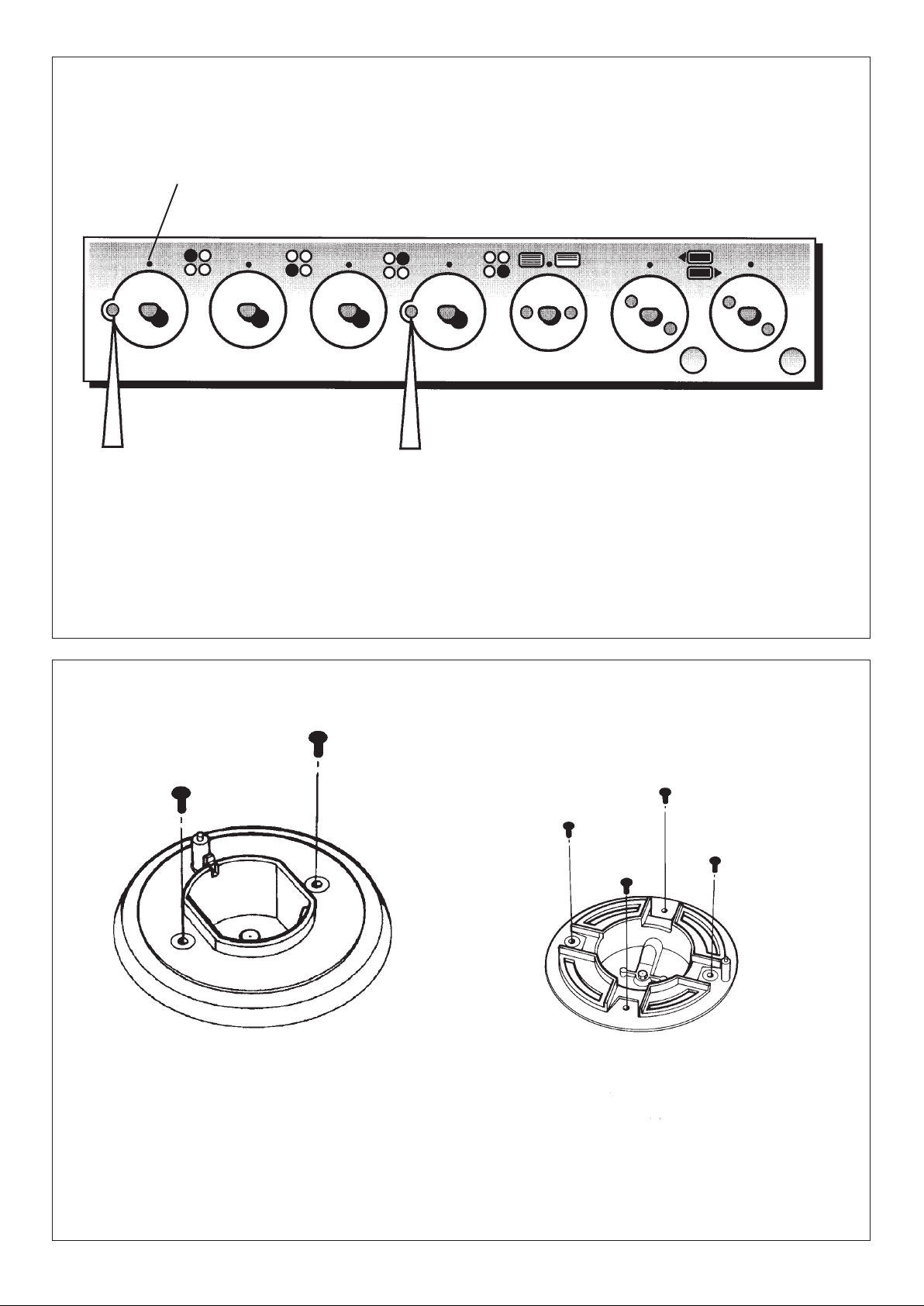

3. Remove top plate as follows:a) Remove pan supports and all control knobs.

b) Remove four chrome buttons and the four top plate retaining screws (2 each side).

c) Remove left hand and centre shrouds from the control panel to gain access to the

fixing screws. Remove two screws from control panel (one from left hand hole and

one from centre hole). (See Fig. 3).

d) Pull top plate forwards slightly and lift up at front. Support top plate and disconnect

wiring to the two neons. Remove top plate.

e) Lay the top plate on its top face, suitably protected.

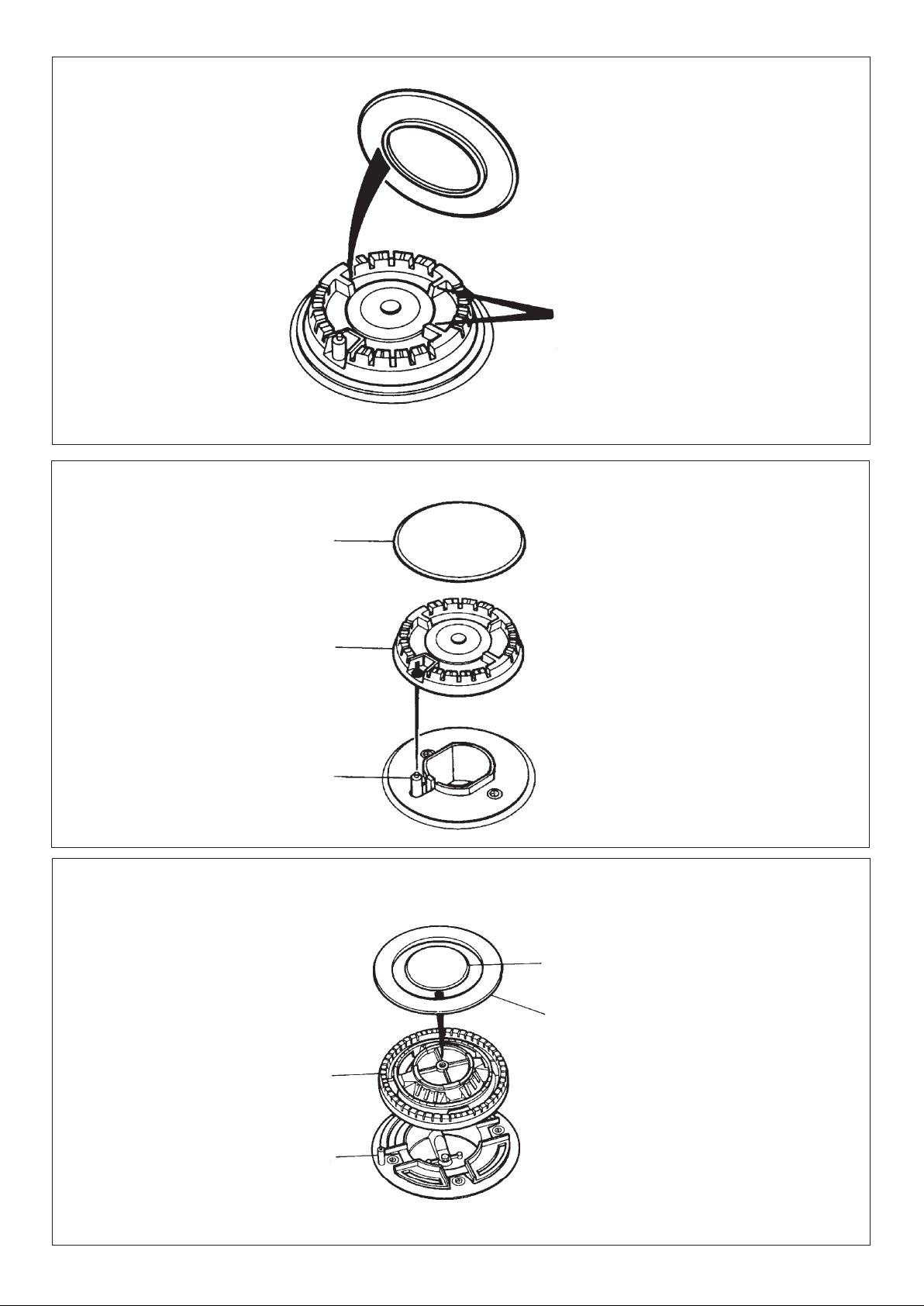

4. Remove hotplate as follows:a) Remove burner heads and burner caps.

b) Remove all of the screws retaining hotplate burner trims (4 from Wok burner, 2 each

from the other three burners). (See Fig. 4).

c) Carefully remove burner trims and gaskets, taking care not to damage gaskets or

burner electrodes.

d) Disconnect earth wire from left hand control panel mounting bracket.

e) Remove hotplate casting.

5. First check that the power cable being used to supply the appliance is isolated from the

power supply.

Connect power cable to the terminal block at the rear of the cooker (See Electrical

Connections).

Sufficient cable should be available to allow the cooker to be removed for servicing.

a) Mark off appropriate position on wall for gas supply to cooker (See Fig. 2).

Dimensions N and O, (see also Fig. 5).

b) Isolate the gas supply and connect pipework, as required up to the position marks.

NOTE: For connecting gas supply to Aga GC3 (Three Oven Model), see Fig. 5A.

Check for gas soundness after connecting gas supply.

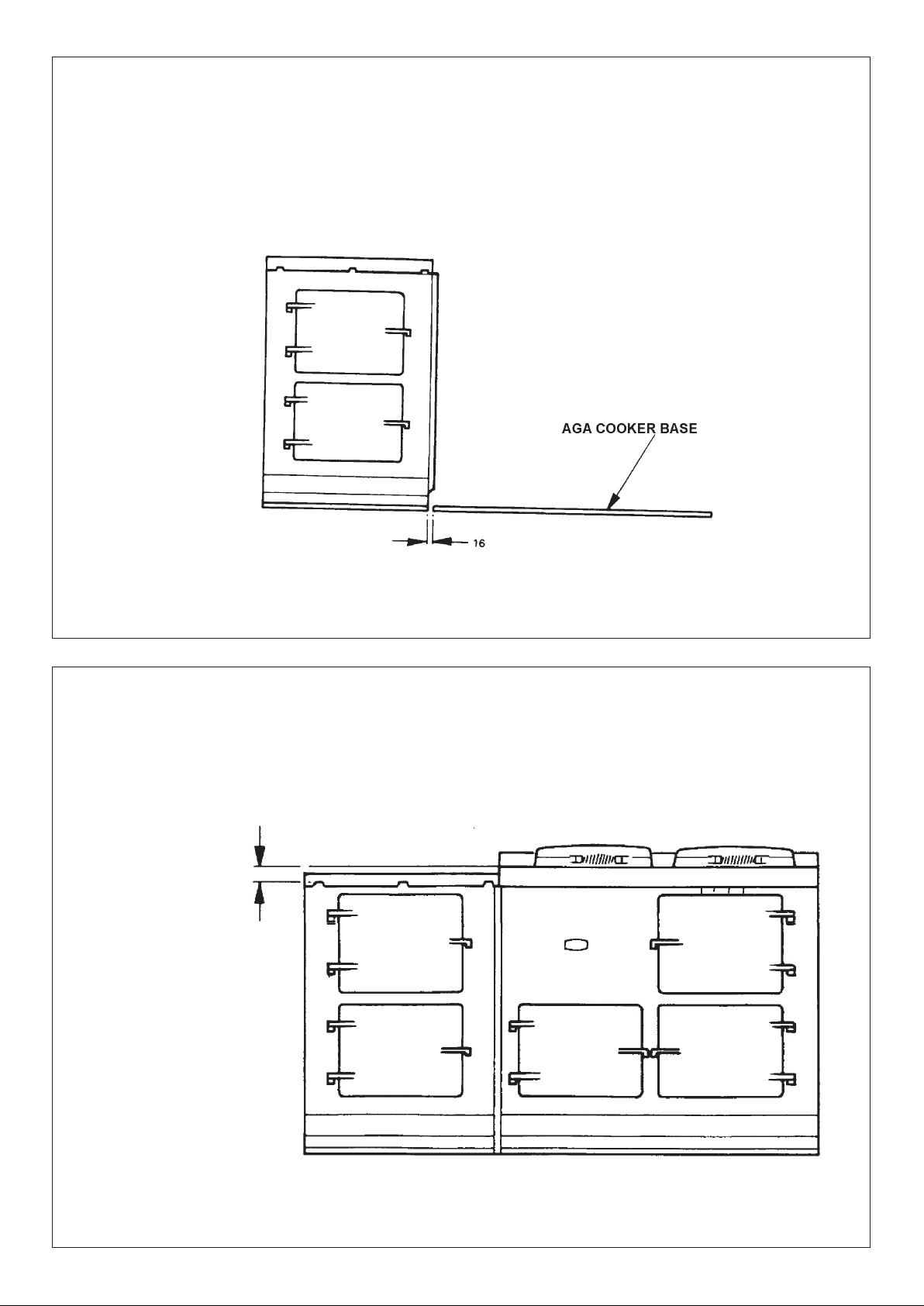

6. Position the cooker alongside the main Aga baseplate leaving 5/8” between the two

bases (See Fig. 6).

Check with a spirit level that the front plate is vertical and the ovens level. Shim under the

module base if necessary.

7. Check gas pressure and adjust regulators if required. (See Page 18).

NOTE: Use soapy water solution on new gas connections to ensure there are no gas

leaks.

8. Proceed with the main Aga build in accordance with normal practice until a check can be

made that the Module front plate and Aga front are the same height and that the distance

between the two units has been maintained. If not, adjustment should be made to the

Module position.

INSTALLATION - MODULE ONLY

10

Page 11

9. Levelling of the Simmering Plate on the main cooker can be carried out with its top plate

in position and verified across the Module (See Fig. 7).

10. Complete the main cooker build and loosely screw down the top plate.

11. Apply tape (provided) to the underside of the lap strip on the Module top plate.

12. Replace module hotplate. Reassemble in reverse order (See section 4). Ensure burner

heads and burner caps are correctly located (See Fig. 8A, 8B and 8C) and electrodes are

not damaged.

13. Replace Module top plate as follows:a) Support top plate at front and reconnect the wiring to the two neons.

b) Carefully lower the top plate into position taking care not to damage wires or neons.

c) Ensure holes for control spindles are aligned correctly, and replace 2 screws into

control panel.

d) Loosely screw the top plate down with 4 retaining screws.

14. Verify that the two top plates are level.

15. Secure handrails as shown on Instruction Sheet Page 26.

16. Finally tighten both top plates.

Commission the main Aga cooker, as stated in the relevant Installation Instructions and carry out

functional tests on each of the features on the Module (See Users Instructions).

11

Page 12

12

REMOVE 2 FIXING SCREWS

(WOK BURNER ONLY)

Fig 3

Fig 4

DESN 511645

DESN 511646

OFF

Page 13

13

Fig 5 - Gas Supply Connections

DESN 511647

(31

1/2”)

mm

mm

mm

mm

(2 3/8”)

(1”)

(22

1/4”)

Fig 5A - Aga GC3 (Three Oven Only) Gas Supply Connections (Approximate Positions)

NOTE: A special rubber grommet is

provided to fill-in the ‘knock-out’ hole

in the side panel. Pierce the centre of

the grommet and pass the 1/4” gas

supply pipe through it.

DESN 512449

Page 14

Fig 7

DESN 511255

14

64mm

FROM TOP SURFACE OF THE AGA TO LUGS ON

FRONT PLATE OF MODULE

TOP PLATE

OF MODULE

REMOVED

(2 1/2”)

mm

Fig 6

DESN 511254

mm

(5/8”)

Page 15

Fig 8A

DESN 511617

Fig. 8B

DESN 511618

Fig. 8C

DESN 511619

BURNER CAP

RETAINING LUGS

BURNER

CAP

BURNER

CAP

BURNER

RING

BURNER

HEAD

BURNER

HEAD

ELECTRODE

ELECTRODE

15

(WOK BURNER ONLY)

Page 16

Electric Shock Hazard

Electrical grounding is required on this range.

Do Not connect to the electrical supply until the range is permanently grounded.

Disconnect the power to the junction box before making the electrical connection.

This range must be connected to a grounded, metallic, permanent supply or a grounding

connector should be connected to the grounding terminal or wire lead on the range.

Do Not ground to gas pipe. Failure to follow these instructions could result in death or

serious injury.

z A four-wire single phase 240-volt, 60-Hz, AC-only electrical supply is required on a

separate, 30-amperes circuit, fused on both sides of the line.

z A time-delay fuse or circuit breaker is recommended.

z Local codes permit the use of a U.L.-listed, 250-volt, 30-amperes power cord (pigtail). This

cord contains four No. 10 copper wires and matches a four-wire receptacle of type 14-30R

shown in Fig. 9. Connectors on the appliance end must be provided at the point the power

supply enters the appliance.

Wire sizes (COPPER WIRE ONL Y) and connections must conform with the rating of range (30amperes).

z The wiring diagram is located on the back of the range.

16

ELECTRICAL CONNECTIONS

Page 17

6. Remove the terminal block cover screws located on the back of the range.

7. Make the four-wire connection following the “Power supply cord method”.

Power supply cord method

This range is manufactured to use a four-wire power supply cord rated at 250-volts, 30-amperes

(See “Four wire electrical connection”)

1. Assemble a U.L.-listed strain relief in the opening.

2. Insert the power supply cord through the strain relief, allowing enough slack to easily

attach the wiring to the terminal block.

3. Use only ring-type terminals to connect the power supply. To secure the power supply cord

use 6mm (1/4”) brass terminal nuts attached to the inside of the terminal block cover.

Be sure nuts are installed tight.

4. Complete electrical connection.

17

L1

WHITE

(NEUTRAL)

GREEN

(GROUND)

L2

Fig. 9

DESN 511752

Page 18

CAUTION: ENSURE THAT COOKER IS ISOLATED FROM ELECTRIC SUPPLY

The cooker can be installed with an approved flexible connection. Supply piping should not be

less than 3/8 I/D Flexiline. Connection is made to the 1/2” NPT female threaded elbow located

just below the hotplate level on the near left hand side of the cooker.

The gas flexiline connector must be fitted in the shaded area indicated in Fig. 10. Take into

account that it must be possible to pull the cooker forward sufficiently and that no strain occurs

on pipework. Ensure flexiline is not trapped between electrics cover and rear wall. Ensure

flexiline is routed within shaded area, and away from the shielded vent.

NOTE: AN EASILY ACCESSIBLE MANUAL SHUT GAS VALVE MUST BE FITTED BEFORE

THE METAL FLEX GAS LINE.

NOTE: Use soapy water solution on new gas connections to ensure there are no gas leaks.

18

CONNECTING TO GAS - COMPANION

Fig. 10

DESN 511751

480mm (18

7/8

”)

390mm (15

1/4

”)

200mm (7

7/8

”)

460mm (18”)

573mm (22

1/2

”)

558mm (22”)

279mm (11”)

TERMINAL

BLOCK

COVER

Page 19

The maximum gas inlet pressure to the appliance must not exceed 12” wg for N.G. and 14” for

L.P. Gas. The minimum gas inlet pressure at the appliance must not be less than 4” w.g. Natural

Gas and 10” wg L.P. Gas to enable the correct manifold pressure to be obtained.

NOTE: The regulator is pre-set for either N.G. or L.P. Gas.

Use the small hotplate burner injector as the pressure test point.

For Natural Gas manifold pressure is 4” w.g.

For L.P.G. (Propane Only) manifold pressure 10” w.g.

Access to the gas regulator is as follows:a) Remove pan supports and all control knobs.

b) Remove four chrome buttons and the four plate retaining screws (2 each side).

c) Remove left hand and centre shroud from the control panel to gain access to the fixing

screws. Remove two screws from control panel (one from left hand hole and one from

centre hole). (See Fig. 3).

d) Pull top plate forwards slightly and lift up at front. Support top plate and disconnect wiring

to the two neons. Remove top plate.

e) Lay the top plate on its top face, suitably protected.

PRESSURE TESTING

19

Page 20

AGA

COMPANION/MODULE (with Gas Hob Unit)

SER

VICING NOTES

DISCONNECT FROM ELECTRICITY SUPPLY BEFORE SERVICING.

WHEN REWIRING ANY ELECTRICITY COMPONENTS REFER TO CIRCUIT DIAGRAM AND

ELECTRICAL SCHEMATIC DIAGRAM ATTACHED BEFORE ELECTRICAL RECONNECTION.

CHECK THAT THE APPLIANCE IS ELECTRICALLY SAFE.

NOTE: TURN OFF GAS SUPPLY TO COOKER BEFORE SERVICING ANY GAS CARRYING

COMPONENTS. ALWAYS CHECK APPLIANCE FOR GAS SOUNDNESS AFTER

COMPLETION.

NOTE: USE SOAPY WATER SOLUTION TO ENSURE THERE ARE NO GAS LEAKS

A. REMOVAL OF TOP PLATE

1. Disconnect from electricity supply and remove pan supports and all control knobs.

2. (a) MODULE ONLY

Remove the handrail from the module top plate (See Page 25). Slacken grub screws

and remove socket screws from the jointing bracket to remove rail.

(b) MODULE ONLY

Remove shroud (if fitted) from rear of top plate.

MODULE AND COMPANION

(c) Remove four chrome buttons and the four top plate retaining screws (2 each side).

3. Remove left hand and centre shrouds from the control panel to gain access to the fixing

screws.

Remove two screws from control panel (one from left hand hole and one from centre hole)

(See Fig. 3).

4. Carefully pull top plate forwards slightly and lift up at the front. Support top plate and

disconnect the wiring to the neons.

Remove top plate.

5. Lay the top plate on its top face, suitably protected.

6. Re-assemble in reverse order.

B. REMOVAL OF HOTPLATE

1. Repeat operations 1 to 5 of section ‘A’.

2. Remove burner heads and burner caps.

3. Remove all of the screws retaining hotplate burner trims (4 from the Wok burner, 2 each

from the other three burners). (See Fig. 4).

4. Carefully remove burner trims and gaskets, taking care not to damage gaskets or burner

electrodes.

5. Disconnect earth wire from left hand control panel mounting bracket.

6. Remove Hotplate.

7. Re-assemble in reverse order, ensuring burner heads and burner caps are correctly

located and electrodes are not damaged. (See Figs. 8A, 8B and 8C).

C. TO CHANGE IGNITION GENERATOR

1. Turn off electricity supply.

2. Remove Top plate and Hotplate (See sections A and B).

3. Remove two screws retaining the generator fixing bracket to the burner mounting panel,

and remove generator (See Fig. 11).

4. Carefully remove all wiring from ignition generator (Fig. 11).

5. Re-assemble in reverse order and check operation of ignition to hotplate burners.

20

Page 21

D. TO CHANGE IGNITION ELECTRODE

1. Turn off electricity supply.

2. Remove Top Plate and Hotplate (See sections A and B).

3. Disconnect the electrode cable from the ignition generator.

4. Remove spring clip retaining electrode to burner body (See Fig. 13) and remove electrode

and cable.

5. Replace with new electrode ensuring spring clip is correctly located into burner body.

6. Re-assemble in reverse order and check operation of ignition to hotplate burners.

E. TO CHANGE HOTPLATE GAS TAP

1. Turn off gas supply and electricity supply.

2. Remove Top Plate and Hotplate (see sections A and B).

3. Remove controls mounting plate by removing the 6 screws (As shown in Fig. 14).

4. Disconnect supply pipes from rest of all 4 gas taps and pull wiring off tap switches.

5. Disconnect gas rail tube and remove 4 screws from gas rail support brackets. (See Fig. 15).

6. Remove gas rail/taps assembly and remove appropriate tap by removing 2 screws. (See

Fig. 16).

7. Re-assemble in reverse order ensuring that the sealing ring is correctly located between

the new tap and the gas rail. (Rewire as circuit diagram).

8. Check for gas soundness before fitting hotplate and top-plate.

9. When re-assembled, check for correct operation of tap/tap ignition switches.

F. TO CHANGE OVEN THERMOSTAT/GRILL CONTROL

1. Turn off electricity supply.

2. Remove hotplate and top plate (see sections Aand B).

3. Remove two screws retaining the thermostat/grill control to the controls panel.

4. Pull all of the wiring off the thermostat or grill control. The grill control can now be

removed.

5. From inside the oven, unclip thermostat phial.

(Top oven phial located at rear of oven; lower oven phial located at top right hand side).

6. Feed phial through hole in oven, then pull capillary up from side of cooker to remove

thermostat.

7. Re-assemble in reverse order, ensuring thermostat phial and capillary are not damaged

and phial is correctly located into retaining clips. (Rewire as circuit diagram).

8. Check operation of oven thermostat phial or grill control.

21

Page 22

22

Fig. 11

DESN 511792

SPARK

GENERATOR

TERMINAL

BLOCK

Page 23

23

Fig. 13

Fig. 14

DESN 511649

DESN 511650

Page 24

24

Fig. 15

Fig. 16

DESN 511651

DESN 511652

GAS RAIL

SUPPORT BRACKET

SCREWS

GAS RAIL

SUPPORT BRACKET

SCREWS

GAS TAP

TUBE NUT

GAS RAIL

TUBE NUT

Page 25

25

CAUTION: LABELALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS WIRING ERRORS CAN

CAUSE IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING

NOTE: 1. IGNITION SWITCHES AND THERMOSTATS ARE SHOWN

IN THE OFF POSITION WITH THE APPLIANCE COLD

AND FAN OVEN DOOR IS CLOSED.

2. THE COOKER IS COLD

(IE. CUT-IN & CUT-OUT NOT OPERATED)

Page 26

26

Page 27

27

HANDRAIL FITTING - MODULE ONL

Y

Prior to fitting the cooker top plate and hot cupboard/electric module top plate to the appliance:-

z Ensure the self adhesive silicone strip is fitted to the underside of the hot cupboard/electric module overlap to

protect the enamel and the jointing bracket fixing plate is fitted to the L.H. side of the cooker top plate.

z Fit all threads to the two end brackets.

z Fit one end bracket to the R.H. side of the cooker top plate, placing the fibre protection washer between the bracket

and the top plate lock in position with shakeproof washer and two hex. nuts.

z Fit the other end bracket to the L.H. side of the hot cupboard/electric module top plate as R.H.

The cooker and hot cupboard/electric module top plates can now be fitted to the appliance. (DO NOT SECURE COOKER

AND HOT CUPBOARD/ELECTRIC MODULE TOP PLATES AT THIS STAGE).

z Place one end cap on each handrail as shown.

z Hold handrail jointing bracket away from the cooker and locate the two handrails in the two end brackets and the

jointing bracket. Push towards the cooker.

z Position and fix the jointing bracket to the cooker and hot cupboard/electric module top plates with socket screws

and small fibre washers ensuring jointing bracket gasket is placed between the jointing bracket and top plates.

z Fit the two top plates securely to the appliance with corner stay nuts and buttons.

END BRACKET (2)

FIBRE

WASHERS (2)

SOCKET

SCREWS (2)

JOINTING BRACKET

FIXING PLATE

COOKER

HANDRAIL

JOINTING

BRACKET

SILICON

STRIP

JOINTING

BRACKET

GASKET

END CAP (4)

HOT CUPBOARD

HANDRAIL

FIBRE PROTECTION

WASHERS (2)

Page 28

Users

Guide

28

Page 29

INTRODUCTION

As responsible manufacturers we take care to make sure that our products are designed and

constructed to meet the required safety standards when properly installed and used.

IMPORTANT NOTICE: PLEASE READ THE ACCOMPANYING WARRANTY.

Any alteration that is not approved by Aga could invalidate the approval of the appliance,

operation of the warranty and could affect your statutory rights.

In the interests of safety and effective use, please read the following before using your new Aga

appliance.

The use of a gas cooking appliance results in the production of heat and moisture in the room in

which it is installed. Ensure that the kitchen is well ventilated, keep natural ventilation holes open

or install a mechanical ventilation device (mechanical extractor hood).

Prolonged intensive use of the appliance may call for additional ventilation, for example, opening

of a window or more effective ventilation, for example increasing the level of mechanical

ventilation where present. This appliance must not be used as a space heater.

Installation must be to Local and National Wiring Regulations and carried out by a Qualified

Engineer, from an authorised distributor.

A little smoke and some odour may be emitted when first switched on. This is normal and

harmless (from oven lagging and starch binder on the element insulation) and will cease after a

short period of use.

Your appliance has a gas hob, electric grill and two electric ovens. The upper oven is an electric

conventional oven with zoned heating, an electric grill is also incorporated in the roof of the oven.

The lower oven has an electric fan (convection). The fan behind the rear plate ensures an even

distribution of heat within the cavity during cooking i.e temperature at lowest shelf position is the

same as as the temperature at the highest shelf position.

Refer to the diagram, See Fig. 17 to familiarise yourself with the product and refer to the relevant

sections for upper oven, lower oven, grill and gas hotplate etc.

The appliance is fitted with a cooling fan, which functions during the use of the grill or top oven

(occasionally with the lower oven). The fan will continue to run after the grill/lower oven has been

turned off or until the unit has sufficiently cooled.

Your cooker is supplied with the following accessories:3 Grid shelves

1 Large grill pan and grid - (FOR USE IN THE UPPER OVEN ONLY)

1 Grill shelf

1 Roasting tin

1 Baking tray

The following loose parts are also packed with the appliance:-

2 twin pan supports

4 hotplate burner heads

4 hotplate burner caps

1 burner ring (wok burner)

29

Page 30

30

SAFETY PRECAUTION AND HINTS

1. Do not store combustible materials, gasoline or other inflammable vapors and liquids near

a range cooker.

2. Ensure and maintain the continual free passage of air to the burner housing. Do not stand

obstacles against burner outer door and loose hair from dogs or cats must not be allowed

to accumulate behind the outer burner door.

Child Safety

Children MUST be taught safe range practices to prevent possible injury . Listed below are some

basic practices we recommend you read and follow for safe use of this appliance when children

are present.

Children are more sensitive to heat than adults, therefore:-

1. Do not leave children alone or unsupervised near the range cooker and discourage them

from this area.

2. Children should not be allowed to mount on any part of the range cooker.

3. Children MUST be taught that the range cooker and its utensils can be hot.

4. Children should be taught that the range cooker is not a toy. They should be forbidden to

play with the range cooker gas controls behind burner door or any other range cooker

parts.

5. Let the heavy, hot utensils cool in a safe place but out of reach of small children.

CAUTION: AVOID STORING ITEMS OF INTEREST TO CHILDREN IN ANY CABINETS

INSTALLED ABOVE THE RANGE TO PREVENT THE RANGE BEING USED TO OBTAIN

CABINET ACCESS AND POSSIBLE SERIOUS INJURY.

Temperatures in cabinet storage spaces above the range may be unsafe for storage of some

types of materials such as volatile liquids or aerosol sprays which can explode.

Ensure spare storage cabinets are capable of supporting the heavy weight of cooking utensils of

the range.

The maximum depth of any cabinets installed above the top of the range must not exceed

330mm (13in).

In the event of prolonged power failure ensure grill and electric oven controls are turned off.

Always wear proper apparel - loose fitting or hanging garments should never be worn while using

the appliance.

Use only dry potholders - Moist or damp potholders on hot surfaces may result in burns from

steam. Do not let potholders touch hot heating elements. Do not use a towel or other bulky

clothes.

IMPORTANT:-

Do not use water on grease fires - smother fire or flame or use dry chemical or foam-type

extinguisher.

WARNING NEVER: Use this appliance as a space heater to heat or warm the

room. Doing so may result in carbon monoxide poisoning and overheating of

the room.

Page 31

31

DESN 511635

Fig 17

SEMI RAPID BURNER

SEMI RAPID BURNER

REMOVABLE

LINER

GRILL PAN

WITH GRID

GRID

SHELF

GRILL &

CONVENTIONA

L OVEN

ROASTING TIN

(BAKING TRAY NOT SHOWN)

FOR USE IN BOTH OVENS

FANNED

OVEN

CONTROL PANEL

GAS HOTPLATE

WOK BURNER

RAPID BURNER

Page 32

z The GAS HOTPLATE CONTROL KNOBS can only be rotated anti-clockwise from the OFF

position.

Large Flame Symbol - High Setting

Small Flame Symbol - Low Setting

(See ‘HOTPLATE’ section).

z The GRILL ELEMENT KNOB can be rotated in any direction.

Clockwise Full on with, both elements on (graduated in red)

Anti-clockwise Economy grill, front elements only

z The OVEN KNOBS can only be rotated clockwise from the OFF position.

z The OVEN NEONS illuminate when ovens are switched on. When the temperature

required is reached the neon will extinguish.

32

CONTROL PANEL

DESN 511620

Fig. 18

REAR

LEFT

FRONT

LEFT

REAR

RIGHT

FRONT

RIGHT

GRILL

TOP

OVEN

LOWER

OVEN

LOWER

OVEN

NEON

TOP

OVEN

NEON

GAS HOB BURNERS

OFF

Page 33

z The hotplate has four gas burners:-

rear left - rapid burner - rated at 3.25 kW/11,000 Btu/hr

front left and rear right - semi rapid burner - each rated at 1.8 kW/6,150 Btu/hr

front right - ultra rapid (wok) burner - rated at 3.5 kW/12,000 Btu/hr

z The semi rapid burners are especially suited for use with small pans and for gentle

simmering or poaching.

z All burners have a set simmer position and are easily adjustable.

TO USE THE HOTPLATE

z To light a hotplate burner, push in the appropriate control knob, hold in and turn anti-

clockwise to the large flame symbol.

z Press and hold the control knob in until the burner lights. If electricity is turned off, the

burner can be lit with a match.

z In the event of the burner flames being accidentally extinguished, turn off the burner

control and do not attempt to re-ignite the burner for at least one minute.

z The control may be set towards a lower position, simply by turning the control knob

towards the small flame symbol.

IMPORTANT SAFETY CONSIDERATION

z Simmering aids such as asbestos or mesh mats are not recommended. They may impede

burner performance, damage the pan supports and waste fuel.

z Commercially available foil spillage aids are unnecessary on this cooker.

z Some ‘Wok’ cooking pans are unstable. Check with the ‘Wok’ manufacturer before

purchasing.

z DO NOT USE unstable and mis-shapen pans (e.g. with convex bases) that tilt easily.

z The minimum pan diameter recommended is 5”.

z Place all pans centrally over the burners.

z Utensils handles should be turned inward and not extend over adjacent surface units - To

reduce the risk of burns, ignition of flammable materials, and spillage due to unintentional

contact with the utensil, the handle of a utensil should be positioned so that it is turned

inward, and does not extend over adjacent surface units.

z Pans and kettles with concave bases should not be used.

z Glazed cooking utensils - Only certain types of glass, glass/ceramic, ceramic, earthenware,

or other glazed utensils are suitable for range-top service without breaking due to the

sudden change in temperature.

z Ensure the correct size utensil is chosen to prevent food boil over.

z Hotplate burner flame size should be adjusted so that it does not extend beyond the edge

of the utensil, this instruction is based on safety considerations.

z Never leave surface units unattended at high heat settings - Boil over causes smoking and

greasy spillovers that may ignite.

33

GAS HOTPLATE

Page 34

Deep Fat Frying

z Use a deep pan large enough to completely cover the appropiate heating area.

z Never fill the pan more than one-third full of fat or oil.

z Never leave fat or oil unattended during the heating or cooking period.

z IMPORTANT: Oil is a fire risk, do not leave pans containing oil unattended.

z In the event of a fire cover with a lid and turn OFF the appliance.

Do not attempt to extinguish the fire using water.

Smother the flames on the hob preferably with a fire blanket, rather than attempting to

remove the pan to the outside or use dry chemical or foam type extinguisher.

Burns and injuries are caused almost invariably by picking up the burning pan to carry

outside.

34

Page 35

z THE TOP OVEN DOOR MUST BE KEPT OPEN WHEN THE GRILL IS ON.

z CAUTION: Accessible parts may be hot when the grill is in use. Young children should be

kept away.

z The grill has 5 heat settings on each of 2 elements (see control panel).

z For best results pre-heat at a high setting.

z The large grill pan and grid supplied will fit on any of the three shelf positions.

z Most foods should be cooked on the grill rack in the grill pan. You can turn the rack over

to suit different thicknesses of food. You can place some dishes straight onto the oven

shelf this is useful when browning the top of food such as cauliflower cheese and gratin

dishes.

z This cooker is supplied with one grid shelf for the top oven.

General

z Top and lower ovens are fitted with side and back self cleaning panels.

z The shelves are designed to be non-tilt.

z To remove a shelf lift clear of the side notches and slide forward. To replace a shelf insert

into the oven with the short prongs at the rear, facing upwards. Slide into position above

the side notches then allow to drop down on the runner.

z Do not place the grid shelf or food on the bases of the ovens.

z CAUTION: Placement of oven racks - Always place oven racks in desired location while

oven is cool. If rack must be moved while oven is hot, do not let potholder contact hot

heating element in oven.

z Pre-heat the ovens at the appropriate settings until the neon light goes out.

z When cooking in both ovens at the same time you may need to reduce the temperature

and cooking times (especially for baked foods).

z For effective heat distribution, leave a gap of no less than 1/2” between the dishes and

the sides of the oven.

z Do not use a tray greater than 111/2” x 91/2” (12 hole bun tin or swiss roll tray).

z The grill pan and grid supplied is not designed to fit the lower oven.

z Use care when opening door - let hot air or steam escape before removing or replacing

food.

z Do not heat unopened food containers - build up of pressure may cause container to burst

and result in injury.

z Keep oven vent ducts un-obstructed.

35

THE OVENS

THE BROILER (TOP OVEN)

Page 36

z DO NOT TOUCH HEATING ELEMENTS OR INTERIOR SURFACES OF OVEN - Heating

elements may be hot even though they are dark in colour. Interior surfaces of an oven

become hot enough to cause burns. During and after use, do not touch, or let clothing or

other flammable materials contact heating elements or interior surfaces of oven until they

have had sufficient time to cool. Other surfaces of the appliance may become hot enough

to cause burns - among these surfaces are (identification of surfaces - for example oven

vent openings and surfaces near these openings, oven doors and windows of oven doors).

z If you also have an Aga DO NOT use the small roasting tin provided with the Aga in the

Companion/Module. Please use utensils provided and place on the grid shelves.

Condensation

Condensation may form on the cooker. This is quite normal and nothing to worry about. The

condensation forms when heat and moisture are present, for example during cooking. Whenever

possible try to make sure that the food which contains a lot of moisture for example casseroles

are covered. If you do notice any condensation, wipe it up straight away.

36

Page 37

Cooking Hints

z Pre-heat selected oven until the neon light goes out.

z The guidelines are for cooking after the oven (s) have reached the desired temperature.

z Larger items may benefit from being turned.

z Shelf positions are counted from the top.

z Put dishes in the centre of the shelf.

z When using both ovens together reduce cooking times and settings.

z It is important to check that food is piping hot before serving.

z You can change the settings and cooking times to suit your tastes.

Deep Fat Frying

z Do not try to fry too much food at a time, especially frozen food.

This only lowers the temperature of the oil or fat too much, resulting in greasy food.

z Always dry food thoroughly before frying, and lower it slowly into the hot oil or fat. Frozen

foods in particular, will cause frothing or spitting, if added too quickly.

z Never heat fat, or fry with a lid on the pan.

z Keep the outside of the pan, clean and free from streaks of oil or fat.

z The following charts give a guide to cooking a number of every day items.

37

OVEN COOKING GUIDE

Page 38

z The cooking charts are a general guide but times and temperatures may vary according to individual recipes.

z The meat sections should be used as a guide but may vary according to the size, shape of meat on or off the bone.

z Thaw frozen pieces of meat thoroughly before cooking them.

z The times are for open roasting. If covered with foil allow extra time.

z The turkey/chicken is cooked when the juices run clear when pierced with a skewer. If the juices are still pink

continue to cook checking every 15 minutes until juices run clear or use a meat thermometer.

z Turkey Size - 16lbs Max.

z 1kg = 2.2Ib

38

APPROXIMATE COOKING TIME

FOOD SETTING °F

SHELF

POSITION

15 mins per lbs plus 20 mins

Roasting meat

350 3 Rare

20 mins per lbs plus 25 mins

Beef

350 3 Medium

30 mins per lbs plus 30 mins

350 3 Well Done

25 mins per lbs plus 25 mins

Lamb 350/375 3 Well Done

30 mins per lbs plus 20 mins

Pork 350/375 3 Well Done

Poultry

20 mins per lbs plus 20 mins

375/400 3Chicken

Top Oven (Conventional)

Top Oven (Conventional) • Top Oven (Conventional) • Top Oven (Conventional)

25 - 40 mins

Yorkshire Pudding

425 3

15 - 25 mins

Individual

Large

425 3

Page 39

39

300 2

45 mins- 1 hr

3- 4 hrs

Shortbread

Very Rich Fruit Cake 250/275

1- 2 hrs

Fruit Cake 300/325 3

15- 25 mins

Small Cakes 375 3

10- 20 mins

20- 35 mins

Scones 425 3

Victoria Sandwich 350 3

10 mins

Swiss Roll 410 2

10- 15 mins

Biscuits 350/375 2

30- 35 mins

Tray Bakes 350 3

Pastries

25- 35 mins

Plate Tarts 400 2

35- 45 mins

Fruit Pie 400 3

20- 25 mins

400 2

15- 20 mins

Vol-Au-Vents (frozen flaky) 425 3

20- 25 mins depending on size

Eclairs/Profiteroles 400/425 2

Puddings

2 hrs approx.

Milk Puddings 300/325 3

45- 55 mins

Baked Sponges 325/350 3

45- 55 mins

Baked Custards 300 3

1.5- 3 hrs depending on size

Meringues 200 3

30- 40 mins

Apple Crumble 350 3

Yeast Mixtures

30- 40 mins

Bread 425 3

10- 20 mins

Rolls and Buns 425 3

Cakes and Biscuits

APPROXIMATE COOKING TIME

FOOD SETTING °F

SHELF

POSITION

Top Oven (Conventional) • Top Oven (Conventional) • Top Oven (Conventional) • Top Oven (Conventional) • Top Oven (Conventional)

2

45 mins- 1 hr

3- 4 hrs

1- 2 hrs

Fruit Cake 3

3

15- 25 mins

Small Cakes 3

10- 20 mins

20- 35 mins

Scones 3

Victoria Sandwich 3

10 mins

Swiss Roll 2

10- 15 mins

Biscuits 2

30- 35 mins

Tray Bakes 3

Pastries

25- 35 mins

Plate Tarts 2

35- 45 mins

Fruit Pie 3

20- 25 mins

Mince Pies 2

15- 20 mins

Vol-Au-Vents (frozen flaky) 3

20- 25 mins depending on size

2

Puddings

2 hrs approx.

Milk Puddings 3

45- 55 mins

Baked Sponges 3

45- 55 mins

Baked Custards 3

1.5- 3 hrs depending on size

Meringues 3

30- 40 mins

Apple Crumble 3

Yeast Mixtures

30- 40 mins

Bread 3

10- 20 mins

Rolls and Buns 3

Cakes and Biscuits

Page 40

z The lower oven is fanned or a convection oven, which means the air is circulated to create an even temperature

throughout the oven. In most cases this means that food requires a lower temperature when cooked in this oven,

by approximately 10º (18ºF) - 20ºC (36ºF). Also some baked goods may require a slightly reduced cooking time by

a few minutes.

z The cooking charts are a general guide but times and temperatures may vary according to individual recipes.

z The meat sections should be used as a guide but may vary according to the size, shape of meat on or off the bone.

z Thaw frozen pieces of meat thoroughly before cooking them.

z The times are for open roasting. If covered with foil allow for extra time.

z The turkey/chicken is cooked when the juices run clear when pierced with a skewer. If the juices are still pink

continue to cook checking every 15 minutes until juices run clear or use a meat thermometer.

z Turkey size 16 lbs Max.

z 1kg = 2.2Ib

40

APPROXIMATE COOKING TIME

FOOD SETTING °F

SHELF

POSITION

Lower Oven (Fanned/Convection)

15 mins per lbs plus 15 mins

Roasting meat

325 2 or 3 Rare

20 mins per lbs plus 20 mins

Beef

325 2 or 3 Medium

30 mins per Ibs plus 30 mins

325 2 or 3 Well Done

25 mins per Ibs plus 20 mins

Lamb 325/250 2 or 3 Well Done

30 mins per Ibs plus 30 mins

Pork 325/350 2 or 3 Well Done

Poultry

20 mins per lbs plus 15 mins

350/375 2 or 3Chicken

20 mins per lbs plus 10 mins

Turkey 300 3 Up to 10lbs

15 mins per Ibs plus 20 mins

Over 10lbs

25 - 40 mins

Yorkshire Pudding

375/400 Any

15 - 25 mins

Individual

Large

375/400 Any

Lower Oven (Fanned) • Lower Oven (Fanned)

Page 41

41

APPROXIMATE COOKING TIME

FOOD SETTING °F

SHELF

POSITION

275 2 or 3

45 - 50 mins

3 - 4 hrs

Shortbread

Very Rich Fruit Cake 250/275 3

1 - 2 hrs

Fruit Cake 275/300 3

15 - 25 mins

Small Cakes 350 Any

8 - 12 mins

20 - 35 mins

Scones 400 Any

Victoria Sandwich 325 Any

10 mins

Swiss Roll 400 2

10 - 15 mins

Biscuits 325/350 Any

25 - 30 mins

Tray Bakes 325 3

Pastries

25- 35 mins

Plate Tart 375 2 or 3

25- 45 mins

Fruit Pie 375 2 or 3

20- 25 mins

Mince Pies 375 1 & 3

15- 20 mins

Vol-Au-Vents (frozen flaky) 380 1 & 3

20- 25 mins depending on size

Eclairs/Profiteroles 400 2

Puddings

2 hrs approx.

Milk Puddings 275 Any

45- 60 mins

Baked Sponges 320/325 2 or 3

45- 55 mins

Baked Custards 275 2 or 3

1.5- 3 hrs depending on size

Meringues 200 2 or 3

30- 40 mins

Apple Crumble 325 3

Yeast Mixtures

25- 35 mins

Bread 400 2 or 3

10- 20 mins

Rolls and Buns 400 2 or 3

Souffle

20- 25 mins

Cheese Souffle (Individual) 375 3

25- 35 mins

Cheese Souffle (Large) 375 3

Cakes and Biscuits

Lower Oven (Fanned) • Lower Oven (Fanned) Lower Oven (Fannned) • Lower Oven (Fanned) Lower Oven (Fanned)

Page 42

z Always switch OFF at mains before cleaning.

z When cleaning use as little water as possible.

z Do not use a steam cleaner to clean this range.

z Do not use abrasive pads, oven cleaner, or cleaners containing citric acid on

enamelled surfaces.

Surfaces that require cleaning are:

Enamelled Top and Front

z The easiest way to clean the Aga Comp anion/Module top and front plate is to mop up spills

as they happen.

z Baked on food is more difficult to clean but can usually be removed with proprietary

vitreous enamel cleaners or mild cream cleaners using a cloth, or if necessary, a nylon

scouring pad.

z If milk or fruit juice, or anything containing acid is spilt on the enamel wipe off

immediately.

z Clean off any condensation streaks on the front plate around the oven doors or the vitreous

enamel may be permanently discoloured.

z All that is usually needed to keep the vitreous enamelled surfaces of your cooker bright

and clean is a daily rub over with a damp cloth followed immediately with a clean, dry cloth

to avoid streaks.

Gas Hotplate

z If spillage does occur on a burner cap or pan support, move pan to another burner and

when cool, clean in hot soapy water.

z After cleaning, be sure all part s are dry. When fitting the burner cap and burner head, make

sure that the hole in the burner head is correctly located over the ignition electrode (See

Fig. 19A, 19B, 19C), and that the burner cap is sitting correctly on the burner head.

z The ignition electrode must not be displaced or damaged otherwise spark ignition will be

affected.

z The hotplate top is sealed. To clean, remove pan supports and wipe over visible surface.

z PLEASE NOTE: The following loose parts MUST NOT be cleaned in a dishwasher, as this

could damage or discolour the finish:- Pan Supports, Burner Caps, Burner Ring and Burner

Head.

z Aluminium pans may cause metallic marking on the pan supports. This will not affect the

durability of the enamel.

NOTE: The appliance guarantee does not cover the mis-use of the pan supports.

The Ovens

z The ovens are fitted with side and back panels which are of self cleaning enamel and

should not be scoured.

z The shelves can be removed and if necessary the shelf supports may also be removed by

taking out the screws.

z These items may be washed in the sink with normal oven cleaners, you may use a fine

wool soap pad for removing stubborn stains from the oven bases and shelf supports.

z NOTE: TAKE CARE NOT TO DAMAGE THE THERMOSTAT PHIALS IN THE OVENS

WHEN CLEANING.

42

CLEANING & CARING FOR YOUR COOKER

Page 43

Heat-Clean Enamel

z Fan Oven, Conventional Oven, Simmering Oven: sides, top and back

Grill Compartment: sides and back

This special enamel has a continuous cleaning action, which works best if a pattern of low

and high temperature cooking is followed. By using low temperature roasting, excessive fat

splashes can be avoided. Should any excessive staining occur , immediately clean the area

with hot water containing detergent, and a nylon washing-up brush. Resistant stains require

the oven to be run at 210°C for 2 hours.

DO NOT USE ANY CLEANING MATERIAL WHICH MAY CLOG THE PORES OF THE

SPECIAL COATING E.G. PASTES AND POWDERS, SOAP FILLED PADS, SPRAY

CLEANERS, BRUSH-ON OVEN CLEANERS, CAUSTIC SOLUTIONS, METALS

SCRAPERS/KNIVES, AND PREVENT THE CONTINUOUS CLEANING ACTION.

Door Liners

z May be cleaned with a cream cleaner or soap impregnated pad.

z DO NOT, however, immerse the doors in water as they are packed with insulating

material which will be damaged by excessive moisture.Door Liners

Controls

z The enamelled surfaces under the knobs can be treated as in the section ‘Door Liners’.

Avoid the use of excessive water.

z DO NOT use oven cleaners, scouring pads and abrasive powder for cleaning plastic

knobs. Awipe with a damp cloth should be sufficient.

43

Page 44

BURNER CAPS

RETAINING LUGS

BURNER

CAP

BURNER

CAP

BURNER

HEAD

BURNER

HEAD

BURNER

RING

ELECTRODE

ELECTRODE

Fig 19A

Fig 19B

Fig 19C- WOK BURNER ONLY

DESN 511617

DESN 511618

DESN 511619

44

Page 45

z In the event of your appliance requiring maintenance, please contact your authorised

distributor.

z Your cooker must only be serviced by a Qualified Engineer, from an authorised distributor

.

z Do not alter or modify the cooker.

z Only the spares specified by the manufacturer, are to be fitted.

SERVICING

454647

Page 46

Page 47

Page 48

48

For further advice or information contact

your local distributor/stockist

With Aga’s policy of continuous product

improvement, the Company reserves the right to

change specifications and make modifications to

the appliance described and illustrated at any time.

Aga-Ranges

110 Woodcrest Road

Cherry Hill, NJ 08003

USA

800.633.9200

www.aga-ranges.com

Loading...

Loading...