Page 1

AEL SERIES Aeon

Tools Required: Phillips Screwdriver, Adjustable Wrench & Pliers.

Hardware Required: Appropriate mounting hardware

8060146 R2

1 of 2

Models 232/432 Ceiling Mounted Fixture

Safety Precautions

Read all safety precautions and installation instructions carefully

before installing or servicing this fixture. Failure to comply with

these instructions could result in potentially fatal electric shock

and/or property damage.

It is recommended that a qualified electrician perform all wiring. This

fixture must be wired in accordance with all national and local

electrical codes.

Do not handle any energized fixture or attempt to energize any

fixture with wet hands or while standing on a wet or damp surface or

in water.

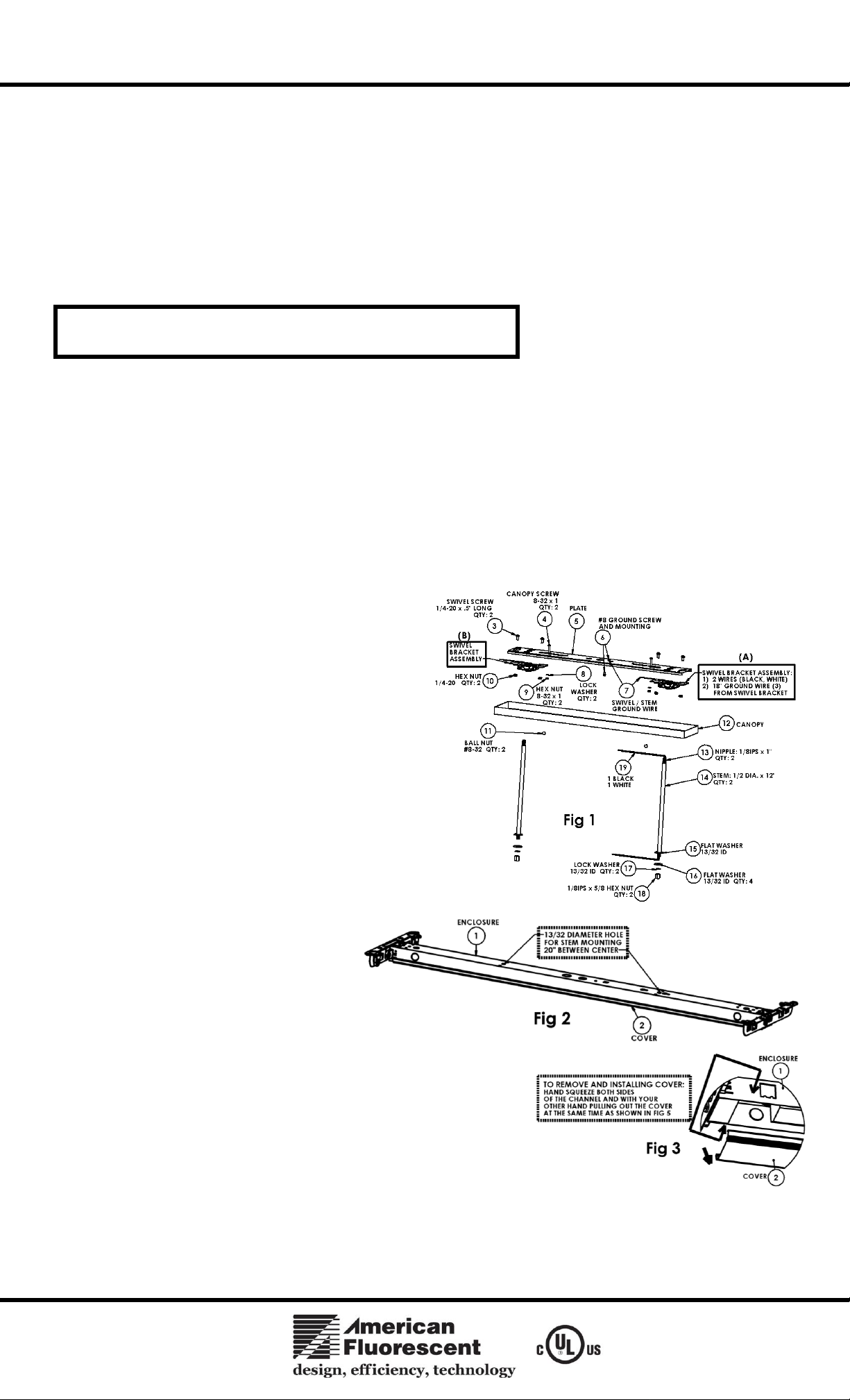

Parts Inventory (Items to be Assembled)

Packed inside the carton:

1) 1 Channel Sub-assembly with socket/bracket sub-assembly (Cut the plastic tie wraps on the flat carton)

Note: Same as Fig 2

2) Two swivel sub-assembly (See Fig 1)

a) 1 swivel sub-assembly with wires (A), assembled to plate (5)

b) 1 swivel sub-assembly without wires (B), assembled to plate (5)

3) Plate (5), Canopy (11), 2 stems (13) included, each stem has 2 Flat washer (14), (15), 1 lock washer, 1 hex nut

4) Parts bag: Small wire connectors, 2 #8-32 x 1inch long (4), 2 #8 lock washer (8), 2 #8-32 hex nut (9)

5) One 4ft metal frame with diffuser (25) (See Fig 5)

Model numbers ending in MV are designed for use in a 120277VAC, 60Hz fused circuit; otherwise the fixture is designed for

use in a 110-120VAC, 60Hz fused circuit. Do not use on a dimming

circuit unless unit is provided with appropriate dimming ballast.

To reduce the risk of electrical shock, and to assure proper operation,

this fixture must be adequately grounded. To accomplish proper

grounding, there must be a separate ground wire (green) or bare metal

contact (metal conduit) between this fixture and the ground

connection of your main power supply panel. The green ground

screw location is clearly marked on the fixture housing.

This fixture is intended to be used for dry, indoor lighting locations.

Assembly Instructions

1. Preparing for installation

A. Consult a local licensed electrician or electrical

contractor about installing the fixture if you are not sure

about installation.

2. Select a suitable dry location (use for indoors only). Make

sure mounting surface is capable of supporting the 19lbs

weight of the fixture.

3. Installing Fixture Mounting Plate (Fig 1) (Fixture

Total Load Weight: 19 lbs)

A. Before installing the mounting plate (5) that is shown in

Fig 1, make sure the two #8 screws (4), two lock

washers (8) and two hex nuts are installed to the

plate (5), and also make sure that the wires (19) and

ground wire (7) are placed under the plate (5) and

the end wires are able to reach the wiring location

area. Install the plate on the outlet box. Note: To rigidly

secure the plate, it is recommended to use an outlet box

and extra support hardware ¼ trade size screws (not

included) or ¼ toggle bolts (not included) at the four ¼

diameter hole located at both ends of the plate (5).

4. To Install Canopy / Stem to Plate Assembly (Fig 1)

A. Align the 2 holes on the canopy to the plate

two #8-32x1inch (4) and use the ball nut

(11) to secure the canopy temporarily.

B. Feed through the wires (19) to the stem (14)

and thread the end of the stem to the nipple

that is attached on the swivel bracket

assembly (A). Repeat these procedures to

connect the other stem (without wires) to the

swivel bracket assembly (B). Note: When

tightening the stem to the threads of the nipple from swivel bracket

assembly (a) and (b) make sure that the swivel ball groove is locked in

place to the bracket tab.

5. Assembling Channel Fixture (Use Fig 1 to Fig 4)

A. First remove hardware flat washers (15), (16), lock washers (17), hex nuts

(18) on both of the stems and also remove the channel cover (2) by using

the procedure in Fig 3.

Note: When mounting channel assembly, make sure that the ballast is near

the stem that has the wires.

B. Install the channel assembly: first make sure that you have the flat washers (15) installed on both of the stems (will be on top

of the channel after installation). Feed the wires through the channel hole (near ballast side) and align the other stem with the

other hole on the channel as they are shown in Fig 1 and Fig 2. Now re-install the hardware that you took off temporarily,

while holding the channel with one hand, fasten the flat washer (16), lock washer (17) and mechanically secure the channel

with the hex nut (18).

Page 2

AEL SERIES Aeon

Limited Factory Warranty

American Fluorescent Corporation hereby warranty that this fixture is free from defects in materials and workmanship when installed and used under

normal operating conditions for a period of 2 years from date of purchase from factory. This warranty covers all component parts and extends only to

replacement of defective fixture or components; it does not cover failure due to improper installation, misuse, mishandling or damage incurred in transit.

2 of 2

8060146 R2

Models 232/432 Ceiling Mounted Fixture

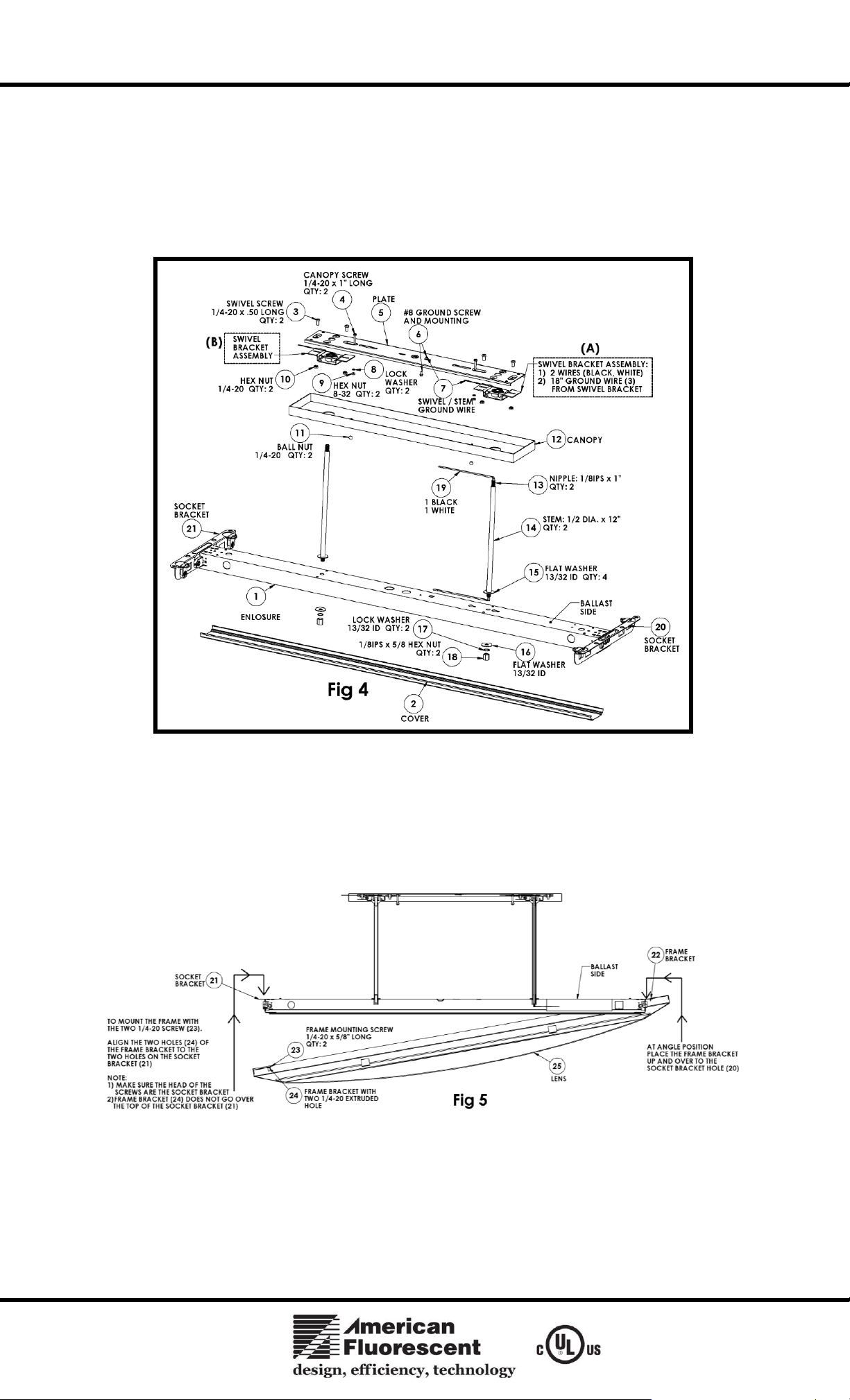

6. Wiring the Fixture (Use Fig 1 to Fig 4)

A. First, connect the ballast black wire with the wire nut (provided) to the black wire of the stem/swivel (A), now, connect the

ballast white wire with the wire nut (provided) to the white wire of the stem/swivel (A) (Fig 4). Note – for models with

luminaire disconnect pre-wired to ballast, reference the included instruction insert.

B. Re-install the channel cover (2) as it is shown in Fig 2.

C. Connect the power service in-line wires: First, remove the canopy (12) and unscrew the two #8-32 ball nut (11), with the wire

nut provided, connect the power service in-line black wire to the black wire from the swivel bracket assembly (A), with the

use of the wire connector provided, connect the power service in-line white wire to the white wire of the stem bracket

assembly (A) and the last wires to connect are the swivel ground wire and the power service in-line ground wire to the plate

(5) ground screw (6).

D. Now, re-install the canopy (12) and the two #8-32 ball nuts (11), which you removed for the purpose of wiring the fixture.

7. Installing the 4FT Metal Frame with the Two ¼-20 screws (Use Fig 5).

A. Tip the 4ft metal frame as it shown in Fig 5 and make sure the frame bracket bent tab (22) is on the hole of the socket bracket

(20), then swing the other end of the frame Up and against the socket bracket (21), now align the holes of the frame bracket

(24) to the socket bracket (21) two holes. Now, you can install and tighten the two ¼-20 x 5/8 screws. To install the screws,

you have to start from the top of the socket bracket (21) and screwed on to the two threaded holes of the frame bracket (24).

Note hold on one hand and use the other hand to fasten the two screws.

Loading...

Loading...