Page 1

A133/A217

SERVICE MANUAL

RICOH GROUP COMPANIES

PN: RCFM0400

Page 2

Page 3

®

®

SERVICE MANUAL

A133/A217

RICOH GROUP COMPANIES

Page 4

Page 5

A133

A217

FIELD SERVICE

MANUAL

PN: RCFM0400

Page 6

Page 7

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2000 RICOH Corporation. All rights reserved.

Page 8

Page 9

LEGEND

PRODUCT CODE COMPANY

RICOH SAVIN GESTETNER

A133 Aficio 400 9940DP 2640E

A217 Aficio 500 9950DP 2850E

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

* 6/96 Original Printing

1 11/97 A217 Addition

2 7/98 A612 Addition

Page 10

Page 11

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the cop ier po w er cor d is un plu gg ed .

2. The wall outlet should be ne ar th e cop i er an d ea sil y accessi b le.

3. Note that some compone nt s of th e cop i er an d th e pa pe r tr ay un i t are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mech anically driven comp on en ts.

5. If the start key is pressed before the copier completes the warm-up

period (Start key starts blinking red and green alternatively), keep hands

away from the mechanical and the electrical components as the copier

starts making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing uni t be com e extr e m ely ho t

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specifie d ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush wit h w at er as fir st aid. If unsuccessful, get

medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

CAUTION

+

2. The RAM board on the system control board has a lithium battery

which can explode if replaced incorrectly. Replace the battery

only with an identical one. The manufacturer recommends

replacing the entire RAM board. Do not recharge or burn this

battery. Used batteries must be handled in accord ance with local

regulations.

FSM a A133/A217

Page 12

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner bottle or the used toner. Toner dust may

ignite suddenly when exposed to open flame.

2. Dispose of used toner, de vel o pe r , an d or g an i c pho to con ductor according

to local regulations. (These are non-to xic supp lies. )

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lith ium batteries in order to dispose of them later, do

not put more than 100 batteries per sealed bo x. St or i n g lar g er nu m be rs

or not sealing them ap ar t ma y lead to che m i cal rea c tions and heat

build-up.

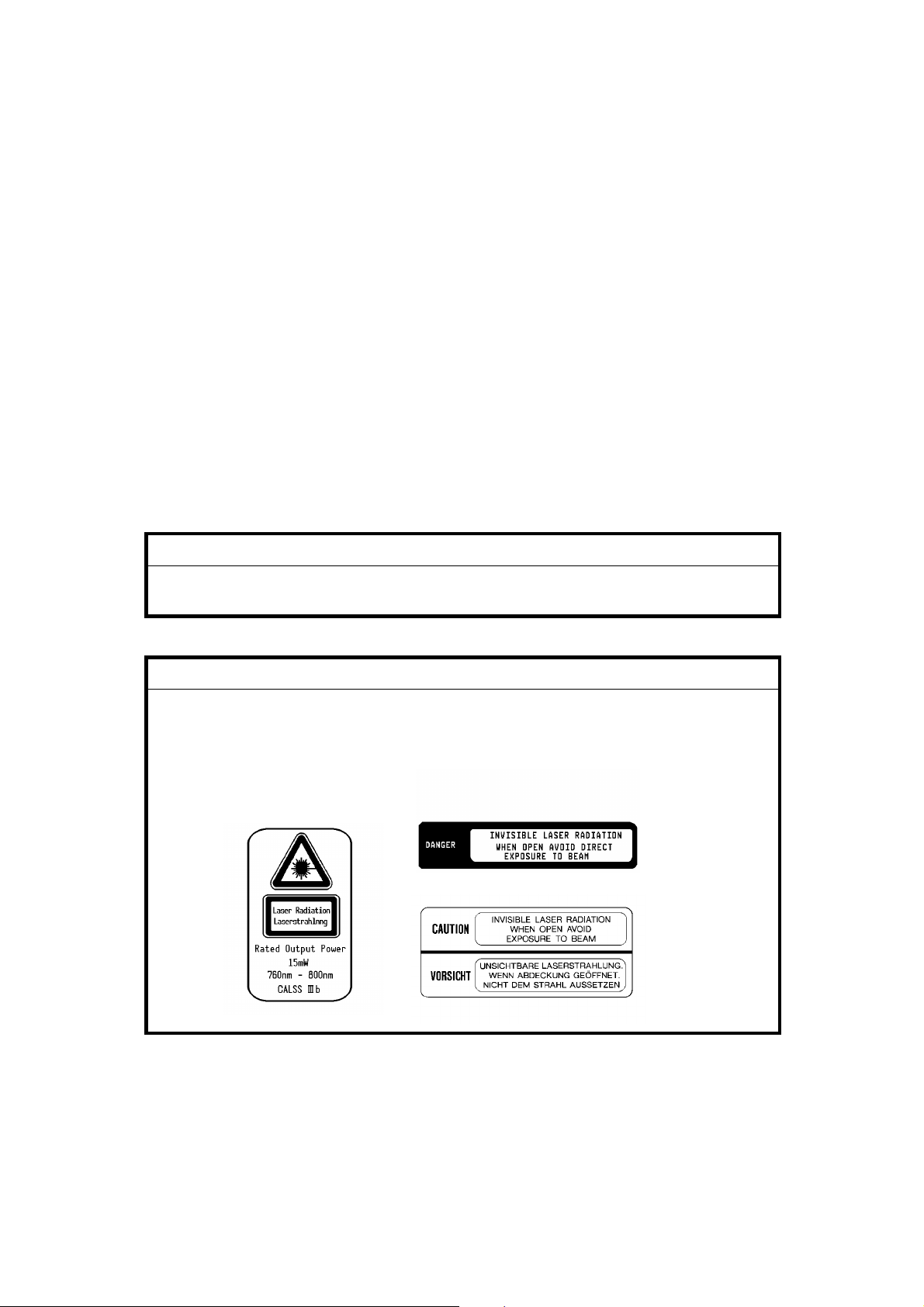

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair

of laser-based optical units in the field . The optical housing unit can only be

repaired in a factory or at a location with the requisite equipment. The laser

subsystem is replaceable in the field by a qualified Customer Engineer. The

laser chassis is not repairable in the field. Customer engineers are therefore

directed to return all chassis and laser subsystems to the factory or service

depot when replacement of the optical subsystem is required.

WARNING

+

Use of controls, or adju stm e nt, or performanc e of pr oce du res other than

those specified in th is manual may result in hazardous radiation exposure.

WARNING FOR LASER UNIT

+

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams

can seriously damage your eyes.

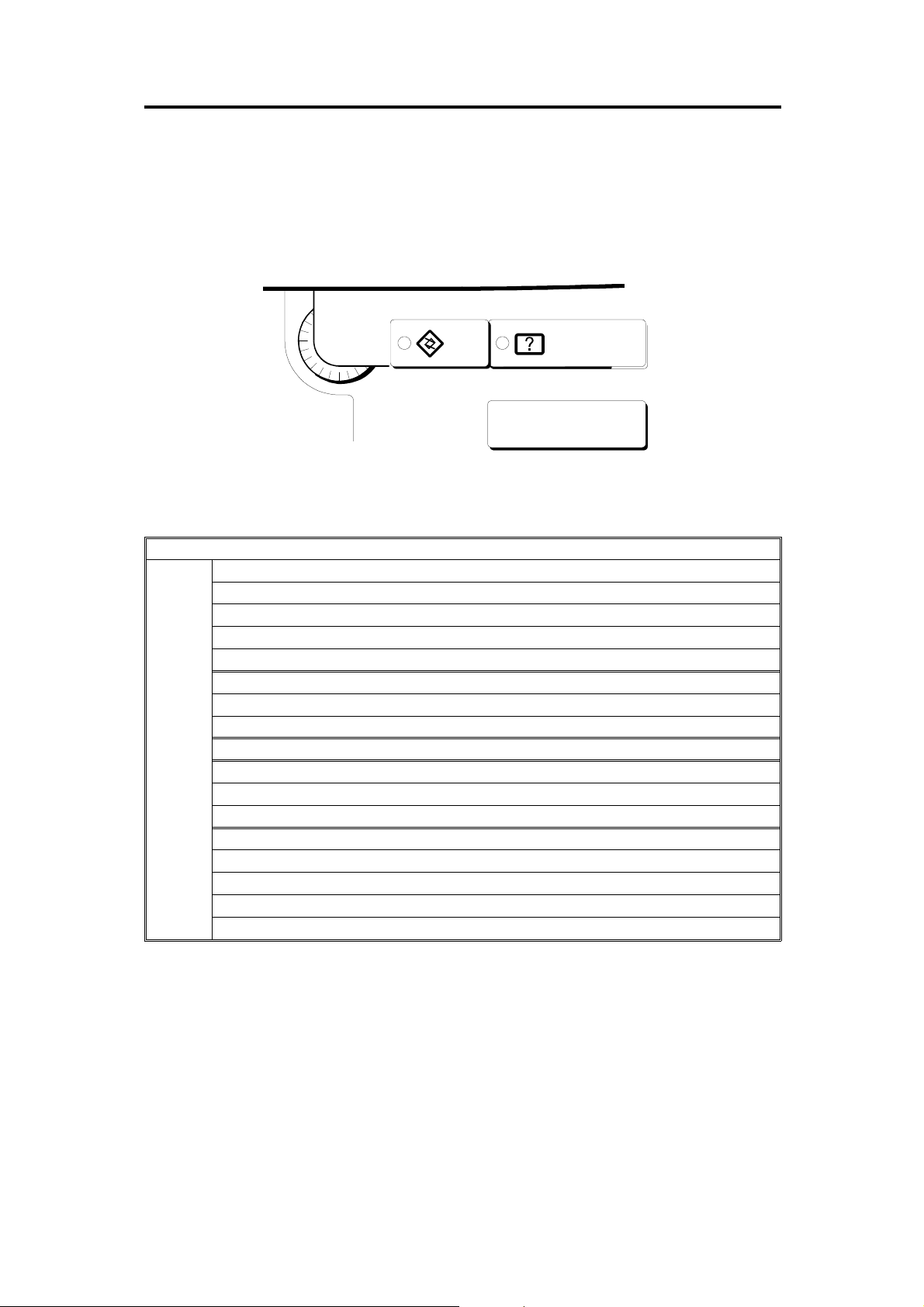

CAUTION MARKING:

For 115V version

For 230V version

A133/A217 b FSM

Page 13

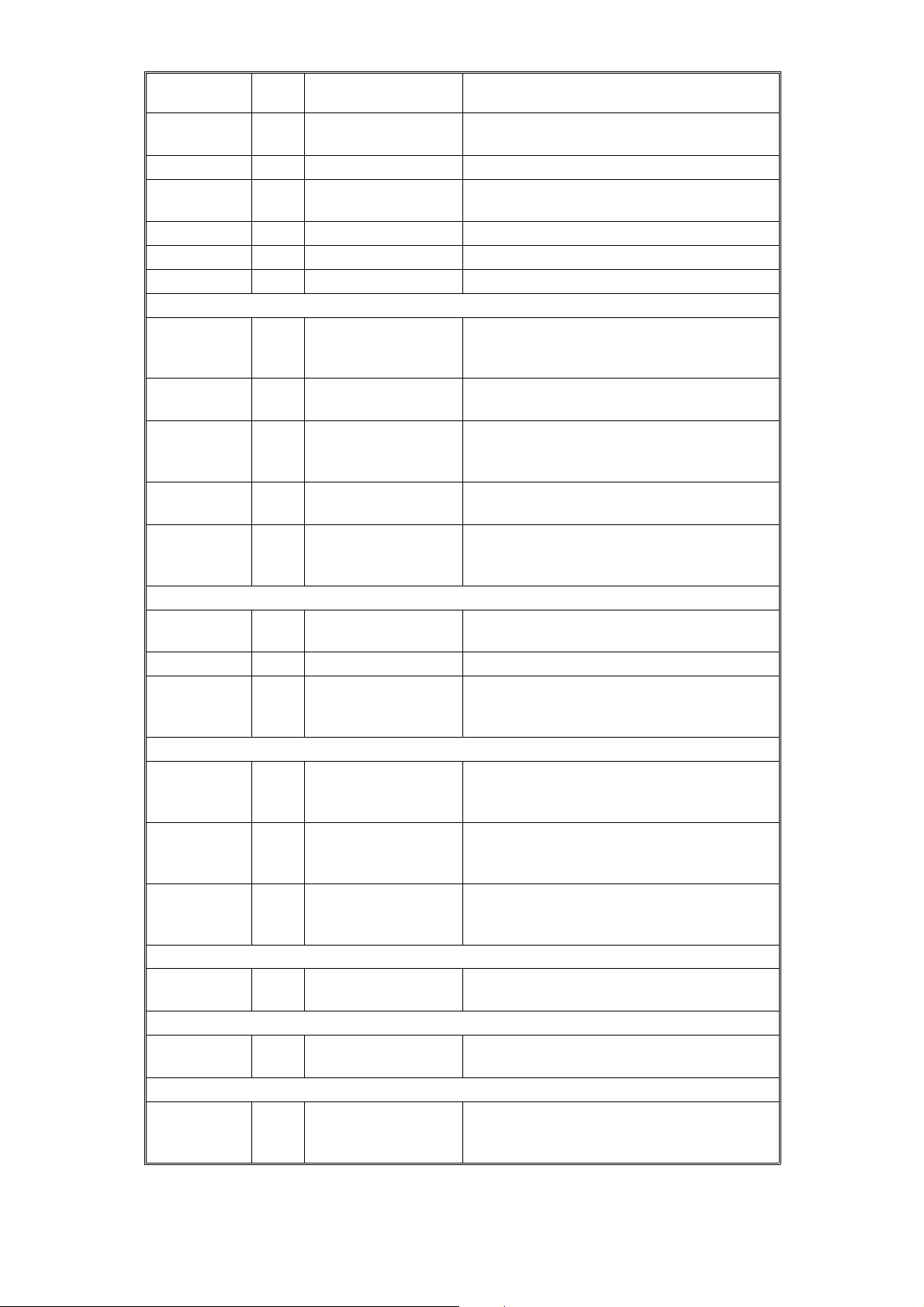

Table of Contents

OVERALL MACHINE INFORMATION

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

COMPONENT LAYOUT AND DESCRIPTIONS

1. MACHINE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1 NORMAL COPYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 DUPLEX COPYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

3. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . 2-3

4. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . . . 2-5

5. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

INSTALLATION PROCEDURE

1. INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 MACHINE LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.3 MINIMUM SPACE REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.4 POWER REQUIRMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

2. COPIER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

2.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

2.2 KEY COUNTER (OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

2.3 TRAY HEATER (OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

2.4 DRUM HEATER (OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

2.5 OPTICS ANTI-CONDENSATION HEATER (OPTION) . . . . . . . . . . . . . . . . . 3-14

3. PAPER SIZE SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.1 OPTIONAL PAPER FEED UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.2 1ST TRAY - NON-STANDARD PAPER SIZE SELECTION . . . . . . . . . . . . . 3-16

3.3 1ST TRAY - F/F4 SIZE PAPER SELECTION . . . . . . . . . . . . . . . . . . . . . . . . 3-17

FSM i A133/A217

Page 14

SERVICE TABLES

1. SERVICE REMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1 GENERAL CAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.2 DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.3 TRANSFER BELT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.4 SCANNER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.5 LASER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1.6 CHARGE CORONA UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1.7 DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1.8 DRUM CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

1.9 FUSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

1.10 PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

1.11 USED TONER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

1.12 OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

2. SERVICE PROGRAM MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2.1 SERVICE PROGRAM MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2.1.1 Service Program Access Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2.1.2 Accessing Copy Mode from within an SP Mode . . . . . . . . . . . . . . . . . . . 4-7

2.1.3 To Input a Value or Setting for an SP Mode . . . . . . . . . . . . . . . . . . . . . . . 4-7

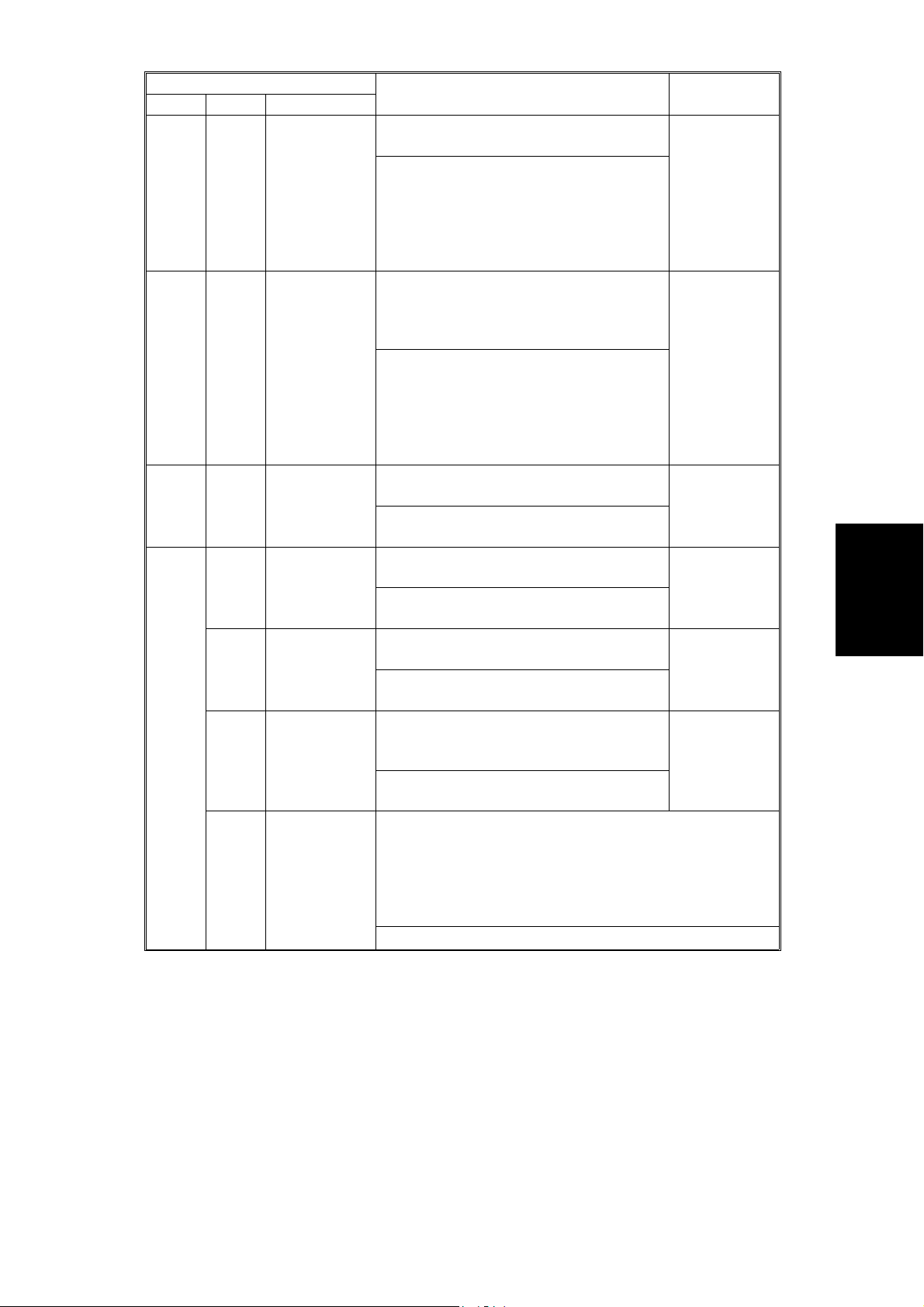

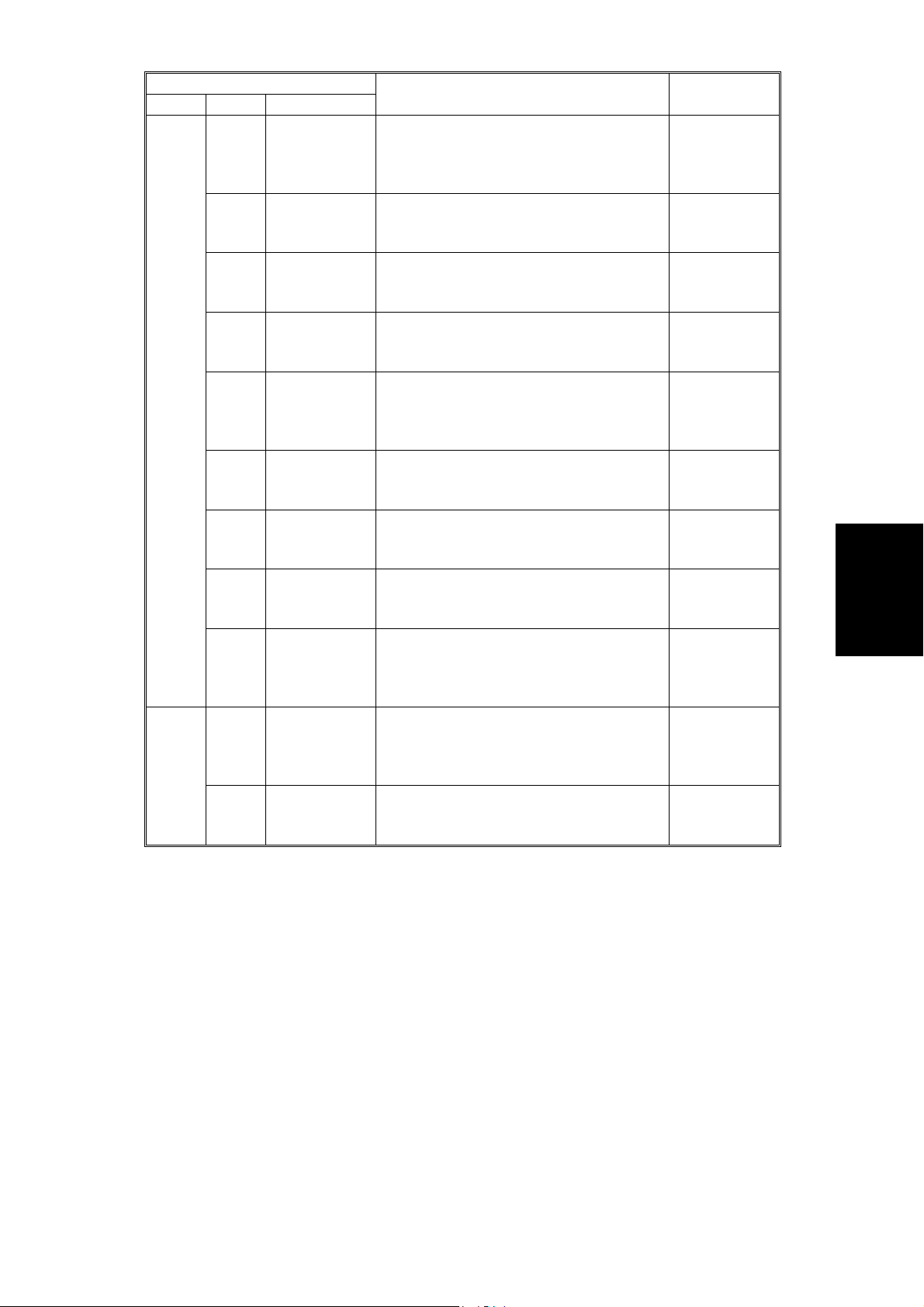

2.2 SERVICE PROGRAM MODE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

2.2.1 MAIN SP MODE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

2.2.2 TEST PATTERN PRINTING (SP 2902) . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

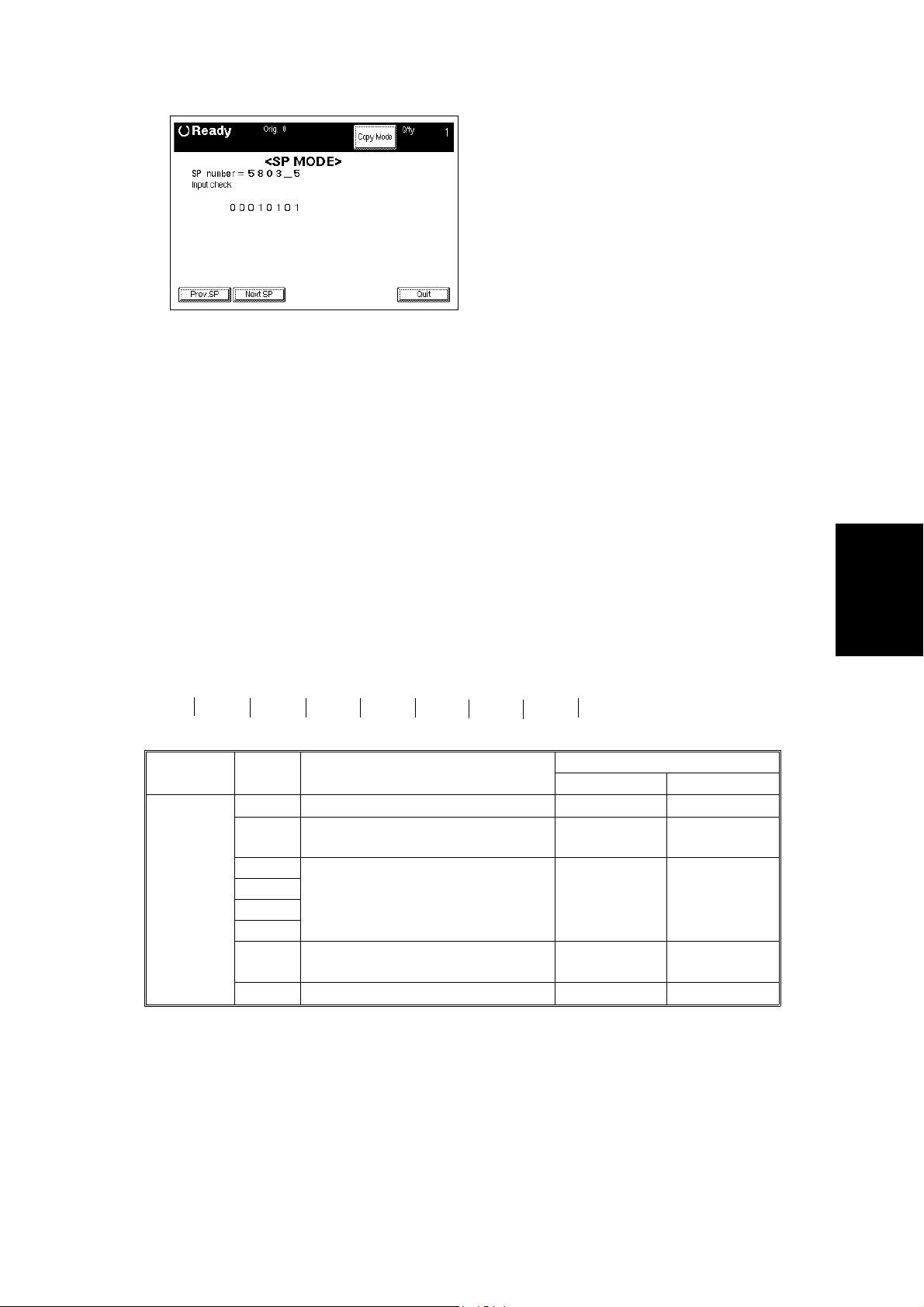

2.2.3 INPUT CHECK (SP5803) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

2.2.4 OUTPUT CHECK (SP5804) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

2.2.5 SYSTEM PARAMETER AND DATA LISTS (SP5990) . . . . . . . . . . . . . . 4-33

2.3 SP MODE AFTER REPLACEMENT AND CLEANING. . . . . . . . . . . . . . . . . . 4-34

2.4 MEMORY ALL CLEAR (SP5801) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

2.5 USER CODE FEATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

3. USER PROGRAM MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

3.1 How to Enter and Leave UP Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

3.2

UP Mode Table

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

4. TEST POINTS/DIP SWITCHES/LEDS . . . . . . . . . . . . . . . . . . . . . 4-38

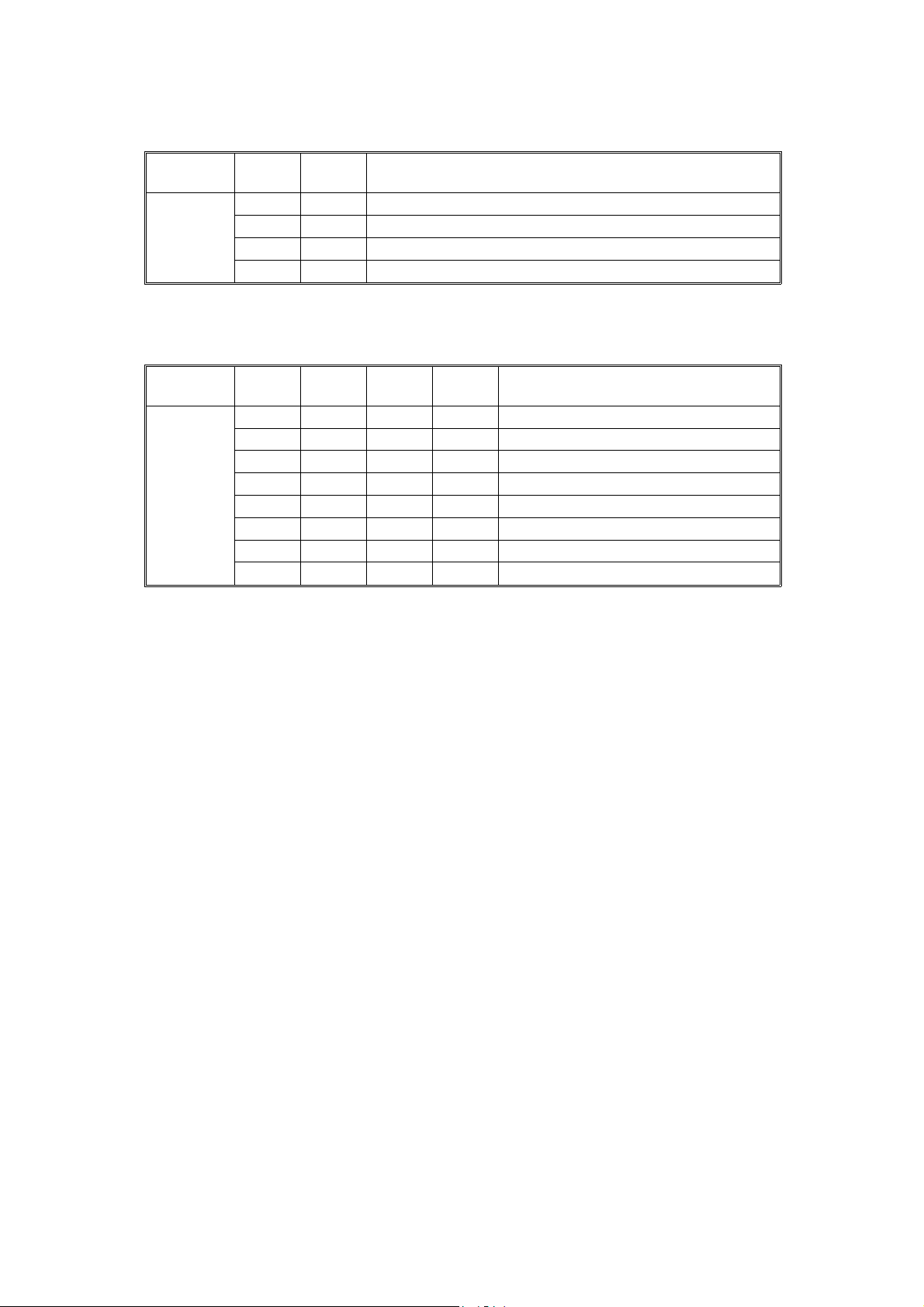

4.1 DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

4.2 TEST POINTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

A133/A217 ii FSM

Page 15

4.3 LEDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

4.4 VARIABLE RESISTORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

5. PREVENTIVE MAINTENANCE SCHEDULE . . . . . . . . . . . . . . . . 4-40

5.1 PM TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

5.2 REGULAR PM PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

6. SPECIAL TOOLS AND LUBRICANTS. . . . . . . . . . . . . . . . . . . . . 4-47

6.1 SPECIAL TOOLS AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

6.2 SPECIAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

REPLACEMENT AND ADJUSTMENT

1. INNER AND OUTER COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1 OUTER COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1.1 Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1.2 Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1.3 Left Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1.4 Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1.5 Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.1.6 Right Upper Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.1.7 Front Upper Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.1.8 Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

1.2 INNER COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

1.2.1 Right Inner Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

1.2.2 Middle Inner Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

1.2.3 Left Inner Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

2. SCANNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

2.1 EXPOSURE GLASS REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

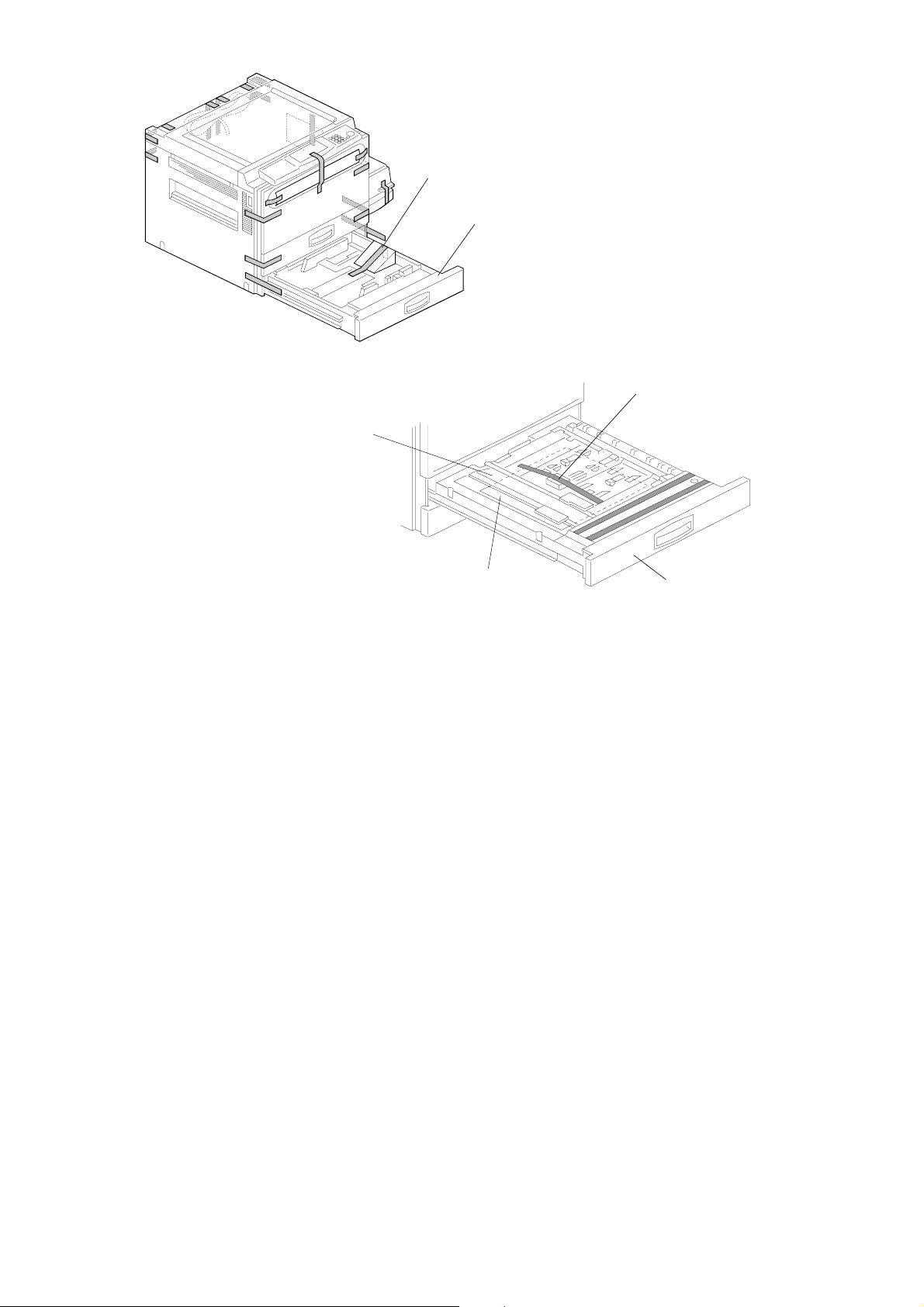

2.2 EXPOSURE LAMP REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

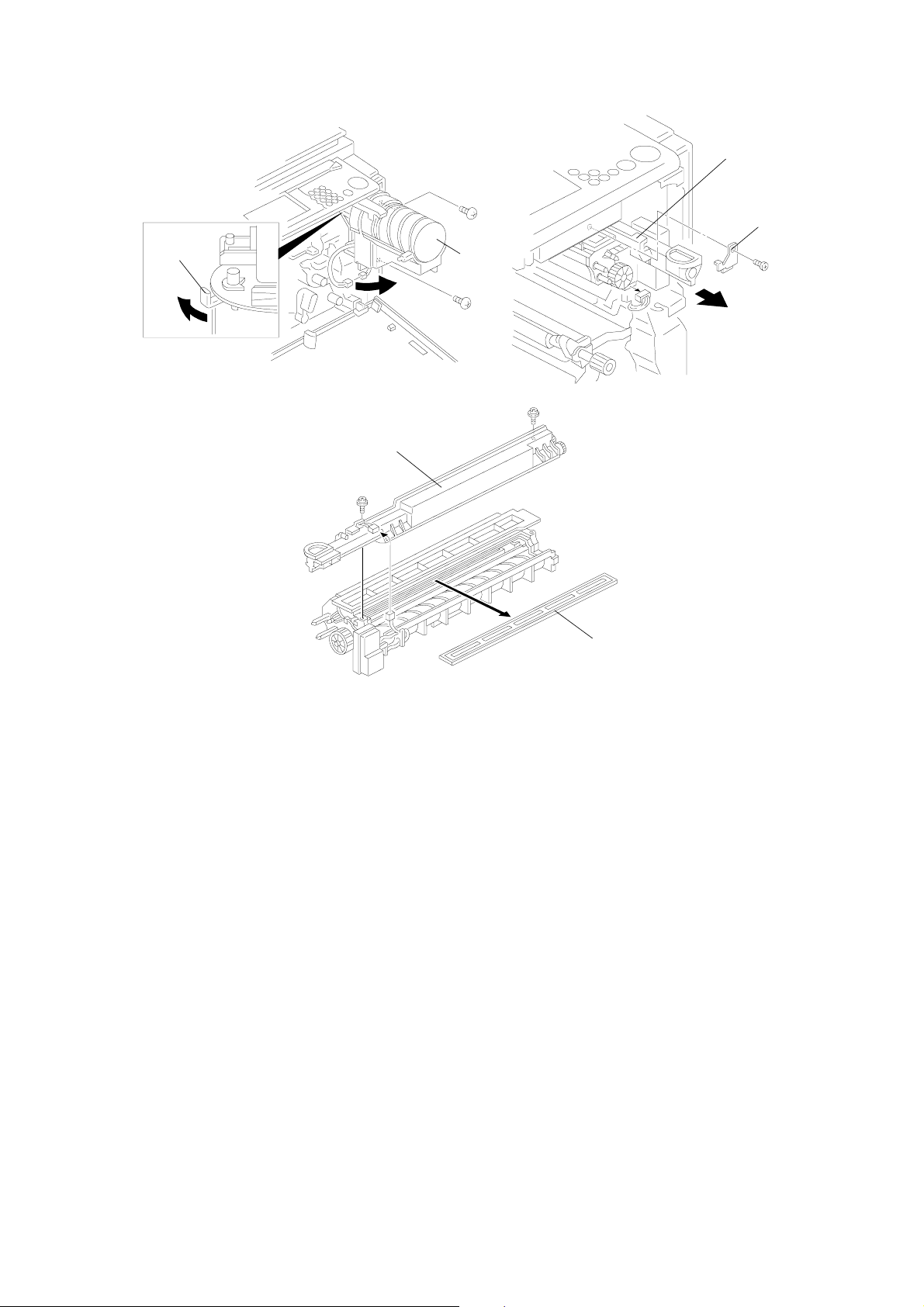

2.3 SCANNER WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

2.3.1 Front Scanner Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

2.3.2 Rear Scanner Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

2.3.3 Scanner Position Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

2.4 SCANNER HOME POSITION SENSOR REPLACEMENT . . . . . . . . . . . . . . 5-15

2.5 SCANNER DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

3. LASER EXPOSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

FSM iii A133/A217

Page 16

3.1 POLYGON MIRROR MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . 5-17

3.2 LD UNIT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

3.3 MAIN SCAN SYNCHRONIZATION DETECTOR BOARD REPLACEMENT . 5-19

4. DEVELOPMENT AND TONER SUPPLY . . . . . . . . . . . . . . . . . . 5-20

4.1 DEVELOPMENT UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

4.2 DEVELOPER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

4.3 TONER SUPPLY MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . 5-23

4.4 DEVELOPMENT DRIVE CLUTCH AND TONER SUPPLY CLUTCH

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

4.5 TD SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5. AROUND THE DRUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.1 DRUM UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.2 DRUM REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.3 PICK-OFF PAWL REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.4 ID SENSOR BOARD REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

5.5 DRUM CLEANING BLADE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

5.6 CLEANING BRUSH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

5.7 CHARGE CORONA GRID PLATE REPLACEMENT . . . . . . . . . . . . . . . . . . . 5-31

5.8 CORONA WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

5.9 QUENCHING LAMP REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

6. TRANSFER BELT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

6.1 TRANSFER BELT UNIT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

6.2 TRANSFER BELT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

6.3 TRANSFER BELT CLEANING BLADE REPLACEMENT . . . . . . . . . . . . . . . 5-35

6.4 TRANSFER BELT LIFT CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

7. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

7.1 LCT PICK-UP, SEPARATION, AND FEED

ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

7.2 TRAY PI CK-UP, SEPARATION, AND FEED

ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

7.3 PAPER FEED TRAY REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

7.4 BYPASS PAPER FEED UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

7.5 TRAY PAPER FEED UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

7.6 REGISTRATION SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-42

7.7 BY-PASS FEED AND BY-PASS RELAY CLUTCH REPLACEMENT . . . . . . 5-43

7.8 PAPER FEED CLUTCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

A133/A217 iv FSM

Page 17

7.9 RELAY CLUTCH REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

7.10 REGISTRATION CLUTCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . 5-45

8. LCT UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

8.1 LCT UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

8.2 LCT DRIVE BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

8.3 LCT MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

9. FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

9.1 FUSING UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

9.2 FUSING LAMP REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

9.3 HOT ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

9.4 PRESSURE ROLLER AND CLEANING ROLLER REPLACEMENT . . . . . . . 5-52

9.5 THERMISTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

9.6 THERMOFUSE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

9.7 HOT ROLLER STRIPPER PAWL REPLACEMENT . . . . . . . . . . . . . . . . . . . 5-55

10. DUPLEX UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

10.1 DUPLEX UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

10.2 FRICTION ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-57

10.3 DUPLEX FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

10.4 DUPLEX FEED MOTOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

11. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

11.1 FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

11.1.1 Optics Dust Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

11.1.2 Fusing Exhaust Fan Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

11.1.3 Ozone Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

11.2 PCB REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

11.2.1 SBU Assembly/EX-IPU Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

11.2.2 HDD Unit Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

11.2.3 SCU Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

11.2.4 BCU Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

11.2.5 AC Drive Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-65

11.2.6 DC Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

11.2.7 High Voltage Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

11.2.8 Lamp Stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

11.2.9 Scanner Drive Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

FSM v A133/A217

Page 18

Rev.10/97

11.2.10 Charge High Voltage Supply Board. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

11.2.11 Main Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

11.2.12 Development Bias Power Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

11.2.13 Transfer High Voltage Supply Board . . . . . . . . . . . . . . . . . . . . . . . . . 5-71

12. COPY IMAGE ADJUSTMENT- PRINTING/SCANNING . . . . . . 5-72

12.1 Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

12.1.1 Registration - Leading Edge/Side-to-Side . . . . . . . . . . . . . . . . . . . . . . 5-72

12.1.2 Blank Margins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

12.1.3 Double Copy Side-to-side Registration . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

12.2 Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-74

12.2.1 Registration: Platen Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-74

12.2.2 Registration: ADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75

12.3 Magnification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

12.3.1 Main Scan Magnification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

12.3.2 Sub Scan Magnification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

13. TOUCH SCREEN ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . 5-77

TROUBLESHOOTING

1. SERVICE CALL CONDITIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1 SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. SC CODE DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

3. ELECTRICAL COMPONENT DEFECTS . . . . . . . . . . . . . . . . . . . 6-17

3.1 SENSORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

3.2 SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

4. BLOWN FUSE CONDITIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

5. BCU Board History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

AUTO REVERSE DOCUMENT FEEDER (A548)

1. SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2.1 MECHANICAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2.2 ELECTRICAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

A133/A217 vi FSM

Page 19

3. ELECTRICAL COMPONENT DESCRIPTION . . . . . . . . . . . . . . . . 7-4

4. INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

4.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

4.2 INSTALLATION PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

5. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

5.1 DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

5.2 VARIABLE RESISTORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

5.3 LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

5.4 FUSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

6. REPLACEMENT AND ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . 7-9

6.1 TRANSPORT BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

6.2 FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

6.3 FRICTION BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

6.4 ORIGINAL SET AND ORIGINAL WIDTH SENSOR REPLACEMENT . . . . . . 7-12

6.5 VERTICAL REGISTRATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

6.5.1 One-sided Thin Original Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

6.5.2 Two-sided Original Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

6.6 SIDE-TO-SIDE REGISTRATION (DF POSITIONING) ADJUSTMENT . . . . . 7-15

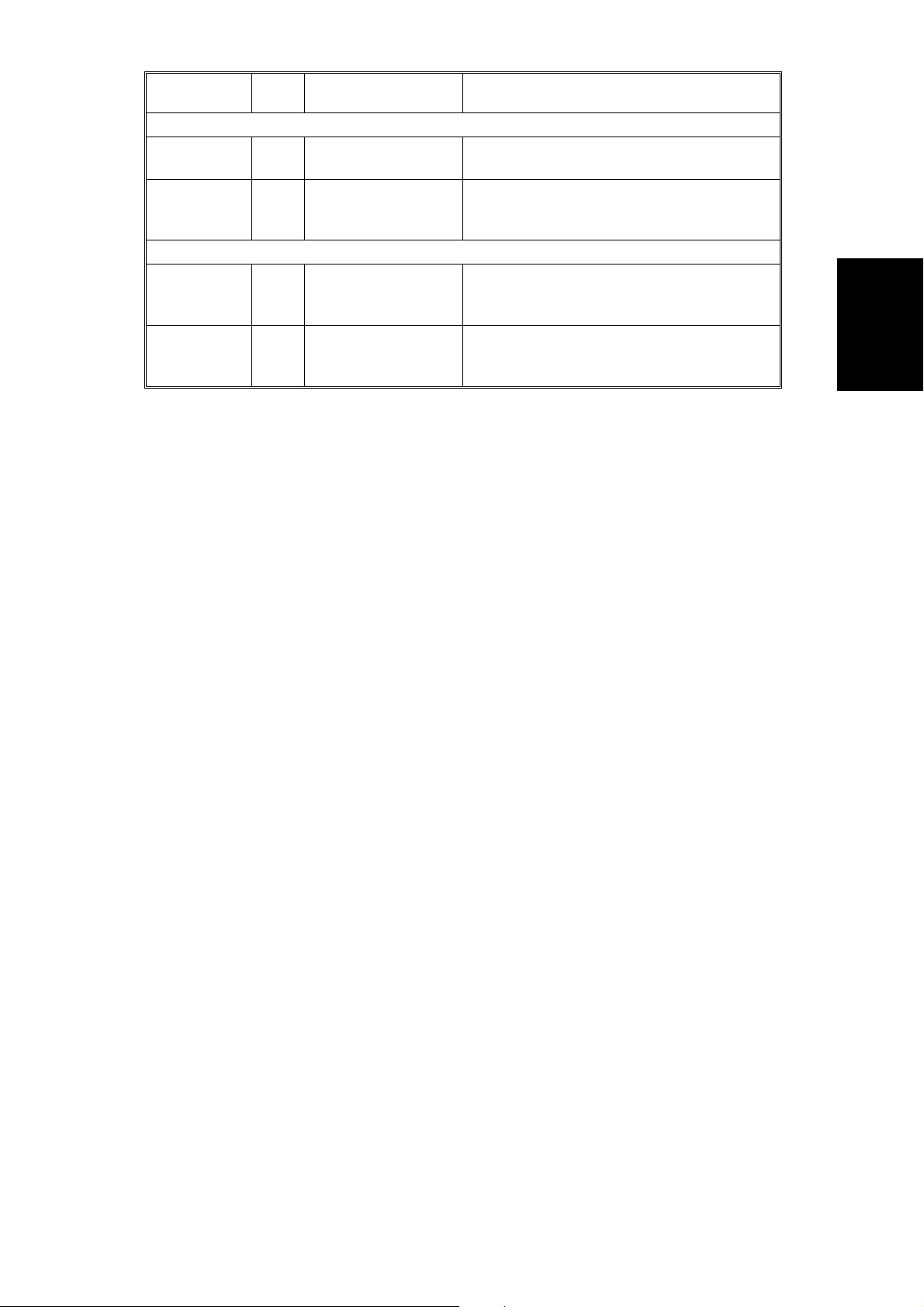

PAPER TRAY UNIT (A549/A550)

1. SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2.1 MECHANICAL COMPONENT LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2.2 DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

2.3 ELECTRICAL COMPONENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

3. INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

3.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

3.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

3.3 TRAY HEATER (OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

4. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

4.1 DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

4.2 TEST POINTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

5. REPLACEMENT AND ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . 8-12

FSM vii A133/A217

Page 20

Rev. 10/97

5.1 EXTERIOR COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

5.2 PAPER FEED CLUTCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

5.3 PAPER FEED UNIT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

5.4 FEED ROLLER, PICK-UP ROLLER, AND REVERSE

ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

5.5 RELAY SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

FINISHER (A612)

1. OVERALL MACHINE INFORMATION . . . . . . . . . . . . . . . . . . . . . . 9-1

1.1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

1.2 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

1.3 ELECTRICAL COMPONENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

1.4 DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

2. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

3. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

3.1 TEST POINT TABLE (MAIN BOARD). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

3.2 FUSE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

3.3 LED TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

3.4 DIP SW TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

3.4.1 Factory Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

3.4.2 Motor Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

3.4.3 Free Run Test Mode Without Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

4. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 9-14

4.1 EXTERIOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

4.2 ALIGNMENT BRUSH ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . 9-15

4.3 STACK HEIGHT SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 9-16

4.4 POSITIONING ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

4.5 BELT TENSION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

4.6 STAPLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

A217 COPIER

1. OVERALL MACHINE INFORMATION . . . . . . . . . . . . . . . . . . . . . 10-1

1.1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

1.2 MACHINE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

A133/A217 viii FSM

Page 21

Rev. 10/97

1.3 ELECTRICAL COMPONENT DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . . . 10-5

1.4 DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

2. DIFFERENCES FROM THE A133 MACHINE. . . . . . . . . . . . . . . 10-11

3. IMAGE PROCESSING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

3.1 EX-IPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

3.1.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

3.1.2 ANALOG PROCESSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

3.1.3 AUTO IMAGE DENSITY (ADS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

4. DEVELOPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

4.1 DEVELOPMENT DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

5. IMAGE FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

5.1 FUSING TEMPERATURE CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

5.1.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

5.1.2 ON/OFF CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

6. ENERGY SAVER AND ENERGY STAR . . . . . . . . . . . . . . . . . . . 10-17

7. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

8. SERVICE TABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

8.1 SP MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

8.2 OUTPUT CHECK TABLE (SP5804) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-39

8.3 TEST POINTS/DIP SWITCHES/LEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

8.3.1 DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

8.3.2 TEST POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

8.3.3 LEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

8.3.4 VARIABLE RESISTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

9. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 10-41

9.1 HDD UNIT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-41

9.2 DEVELOPMENT MOTOR & TONER SUPPLY

CLUTCH REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-42

9.3 FUSING UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-44

9.4 CLEANING ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-45

9.5 HOT ROLLER STRIPPER PAWL REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . 10-45

9.6 THERMISTOR AND THERMOFUSE REPLACEMENT. . . . . . . . . . . . . . . . . 10-46

9.7 FUSING LAMP REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-47

FSM ix A133/A217

Page 22

Rev. 7/98

9.8 HOT ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-48

9.9 PRESSURE ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-49

10. SERVICE CALL CONDITION . . . . . . . . . . . . . . . . . . . . . . . . . . 10-50

10.1 SC CODE DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-50

AUTO REVERSE DOCUMENT FEEDER A663

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

2. DIFFERENCES FROM THE A548 ARDF . . . . . . . . . . . . . . . . . . . 11-2

A195 Section 12 ( Only available through A195 training)

FINISHER A612

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

1.1 DIFFERENCES FROM THE A612 FINISHER. . . . . . . . . . . . . . . . . . . . . . . . . 13-3

2. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

A133/A217 x FSM

Page 23

A133 TAB INDEX

OVERALL MACHINE INFORMA T ION

REV.7/98

A612 FINISHER

COMPONENT LAYOUT AND DESCRIPTIONS

A217 COPIER

INSTALLATION PROCEDURE

A663 ARDF

SERVICE TABLES

A612 FINISHER

(SR710)

TAB

POSITION 1

T AB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

REPLACEMENT AND ADJUSTMENT

TROUBLESHOOTING

AUTO REVERSE DOCUMENT FEEDER A548

PAPER TRAY UNIT A550/A549

TAB

POSITION 5

T AB

POSITION 6

T AB

POSITION 7

TAB

POSITION 8

Page 24

Page 25

OVERALL MACHINE

INFORMATION

Page 26

Page 27

1. SPECIFICATIONS

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Copy Paper Size: Maximum

A3/11" x 17" (Paper tray)

Minimum

A5/8

A6/5

LCT

A4/11" x 8

Duplex Copying: Maximum

A3/11" x 17"

Minimum

A5/8

1/2

1/2

1/2

" x 5

" x 8

" x 5

" sideways (Paper tray)

1/2

" lengthwise (By-pass)

1/2

" sideways only

1/2

" sideways

1/2

Information

Overall Machine

Copy Paper Weigh t: Paper tray:

60 ~ 105 g/m2, 16 ~ 24 lb

By-pass:

60 ~ 157 g/m2, 16 ~ 42 lb

LCT:

60 ~ 128 g/m2, 16 ~ 34 lb

Duplex copying:

64 ~ 105 g/m2, 17 ~ 24 lb

Reproduction R at i os: 5 Enlargement an d 7 R ed uct i on

A4/A3 Version LT/DLT Version

400%

200%

Enlargement

Full size 100% 100%

Reduction

141%

122%

115%

93%

87%

82%

71%

65%

50%

25%

400%

200%

155%

129%

121%

93%

85%

77%

74%

65%

50%

25%

Zoom: 25% to 400% in 1% steps

Power Source: 120V/60Hz:

More than 12 A (for North America)

FSM 1-1 A133/A217

Page 28

220V ~ 240V/50Hz:

More than 7 A (for Europe)

220V ~ 240V/60Hz:

More than 7 A (for Asia)

Power Consumption:

Copier Only Full System

Maximum Less than 1.44 kW Less than 1.44 kW

Copying Less than 1.20 kW Less than 1.20 kW

Warm-up Less than 0.88 kW Less than 0.90 kW

Stand-by Less than 0.20 kW Less than 0.22 kW

NOTE:

1) Full System: Copier + ADF + Pap er Tr ay U nit + Fini sh er

Noise Emission:

Copier Only Full System

1. Sound Power Level

Copying 66.0 dB(A) 69.0 dB(A)

Stand-by 40.0 dB(A) 40.0 dB(A)

2. Sound Pressure Level at the Operator Position

Copying 54 dB(A) 59 dB(A)

Stand-by 25 dB(A) 25 dB(A)

NOTE:

The above measurements are to be made in accordance with ISO

7779.

Full System: Copier + ADF + Paper Tray U nit + Fini sh er .

Dimensions (W x D x H): 880 x 655 x 602 mm (34.7" x 25.8" x 23.8")

Measurement Conditions

1) With by-pass feed tab le cl ose d

2) With copy tray attached

3) With LCT cover closed

4) Without the 500-sheet copy tray

Weight: 95 kg (210 lb)

A133-A217 1-2 FSM

Page 29

Copying Speed (copies/minute):

A4 sideways/

11" x 8

"

1/2

40 18 26

Warm-Up Time

A3/11" x 17" B4/8

Less than 140 seconds (20°C, 68°F)

" x 14"

1/2

First Copy Time: Less than 5.2 s (from LCT)

Copy Number Input: Ten-key pad, 1 to 999 (count up or count down)

Manual Image Density

Selection: 7 steps

Automatic Reset: 30 s is the standard setting; it can be changed

with a UP mode.

Copy Paper Capacity:

Paper Tray By-pass Feed LCT

About 500 sheets x1 About 40 sheets About 1000 sheets

Hard Disk: 1 GB, Fast SCSI-2

Duplex Tray Capacity A4/11" x 8

": 50 sheets

1/2

A3/11" x 17": 50 sheets (80 g/m2, 20 lb paper)

30 sheets (81 ~ 105 g/m2,

21.5 ~ 27.9 lb paper)

Information

Overall Machine

Toner Replenishment: Cartridge exchange (700 g/cartridge)

Toner Yield: 20K copies (A4, 6% full black , ID Level 4*)

Developer Type 2 (850 grams), Yeild: 360K copies*

Optional Eq uipment:

Copy Tray Capacity B4/8

•

Platen cover

•

Document feeder

•

Paper tray unit wi th tw o pa pe r trays

•

Paper tray unit wi th thr e e pa pe r tr ays

•

Finisher

•

Key counter

•

Tray heater

•

Optical anti-condensation heater

•

Drum heater

•

500-sheet receivi ng tr ay

" x 14" ~ A4/8

1/2

" x 11" 500 sheets

1/2

A3\11" x 17" 200 sheets

Less than B5/5

1/2

" x 8

": 20 0 she et s

1/2

FSM 1-3 A133/A217

Page 30

Page 31

COMPONENT LAYOUT

AND DESCRIPTIONS

Page 32

Page 33

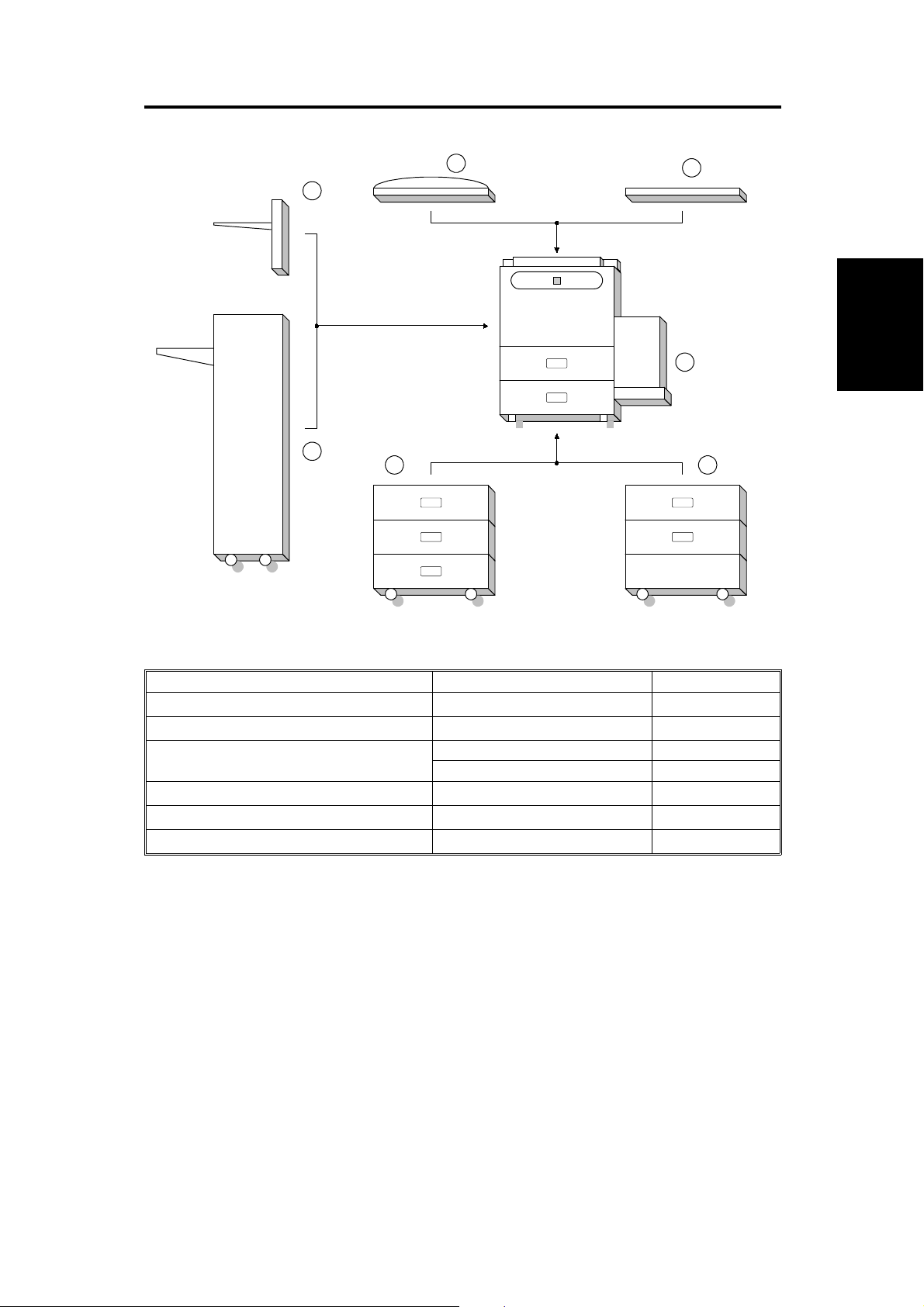

1. MACHINE CONFIGURATION

1

7

6

5 4

2

3

Component

Layout and

Descriptions

Item Machine Code No.

Copier

ADF (Option)

A133 3

A548 (DF61) 1

Paper Feed Unit (Option) A549 (PS290) 5

A550 (PS280) 4

Finisher (Option)

500-sheet Receiving Tray (Option)

Platen Cover (Option)

A612 (SR700) 6

A615(Type D) 7

A381 (Type 540) 2

FSM 2-1 A133/A217

Page 34

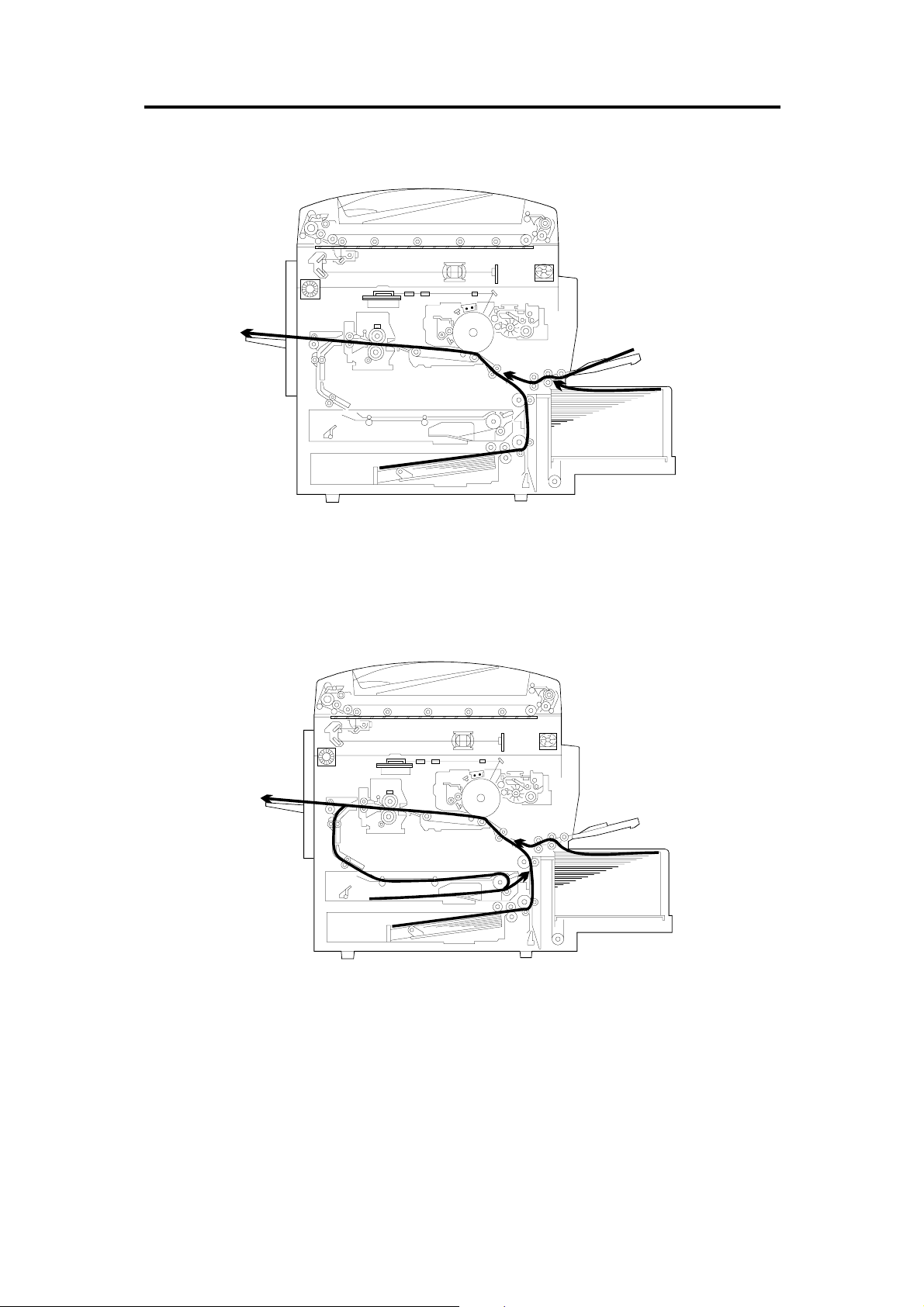

2. PAPER PATH

2.1 NORMAL COPYING

2.2 DUPLEX COPYING

A133/A217 2-2 FSM

Page 35

3. MECHANICAL COMPONENT LAYOUT

9

8

7

10

11

12

13

14

34

35

6

5

4

3

2

1

15

16

Component

Layout and

Descriptions

33

32

31

30

29

28

17

18

19

20

21

23

24252627

22

FSM 2-3 A133/A217

Page 36

1. 3rd. Mirror

22. Feed Roller

2. 2nd. Mirror

3. 1st. Mirror

4. Exposure Lamp

5. Polygonal Mirror Motor

6. Fθ Lenses

7. Cleaning Unit

8. Lens

9. Charge Corona Unit

10. Barrel Toroidal Lens (BTL)

11. CCD

12. Mirror

13. Drum

14. Development Unit

23. Separation Roller

24. Pick-up Roller

25. Duplex Feed Roller

26. Bottom Plate

27. Side Jogger Fen ce

28. Transfer Belt Unit

29. Entrance Rollers

30. End Jogger Fence

31. Pressure Roller

32. Fusing Exit Roller

33. Exit Rollers

34. Hot Roller

35. Optics Exhaust Fan Motor

15. Registration Rollers

16. By-pass Feed Relay Roller

17. By-pass Feed Roller

18. By-pass Pick-up Roller

19. By-pass Separation Roller

20. LCT

21. Relay Rollers

A133/A217 2-4 FSM

Page 37

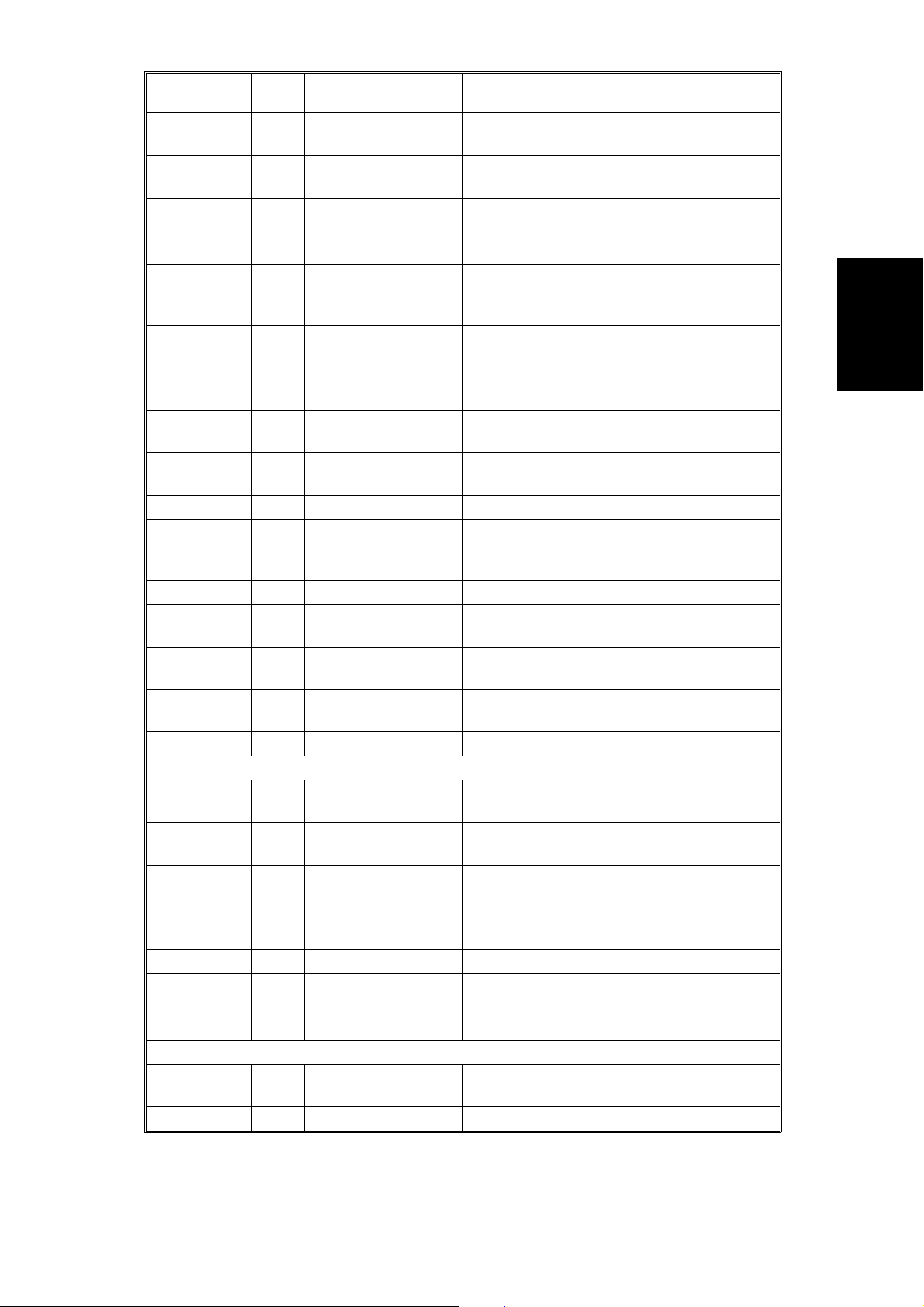

4. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on

the waterproof paper in the pocket for the locations of these components.

Symbol Index

No.

Printed Circuit Boards

PCB1 90

PCB2 89

PCB3 92

PCB4 93

PCB5 80

PCB6 85

PCB7 87

PCB8 79

PCB9 81

PCB10 84

PCB11 94

PCB12 86

PCB13 83

PCB14 31

PCB15 33

PCB16 40

PCB17 N/A

PCB18 51

PCB19 91

PCB20 7

Motors

M1 57

M2 66

Description Note

SCU (System Control

Unit)

AC Drive Provides ac power to the exposure lamp and

DC Power Supply Provides dc power.

BCU (Base-Engine

Control Unit)

Charge High Voltage

Supply

High Voltage Control Controls the high voltage boards and the

Operation Panel Controls the touch panel display and LED

Scanner Drive Drives the scanner motor.

EX-IPU (Extended

Image Processing

Unit)

SBU (Sensor Board

Unit)

Lamp Stabilizer Provides dc power for the exposure lamp.

Laser

Synchronization

Detector - 1

Laser

Synchronization

Detector - 2

Transfer High

Voltage

Development Bias

Power Pack

Duplex Control Controls the operation of the duplex tray.

Liquid Crystal Display Controls the guidance display and displays

LCT Interface Interfaces the LCT control signal between

Relay Board Switches ac power to either the dc drive

Laser Diode Drive Controls the laser diode.

Main Drives the main body components.

Toner Bottle Drive Rotates the toner bottle to supply toner to

Controls all copier functions, directly or

through other control boards.

fusing lamps.

Controls the mechanical parts of the printer.

Supplies high voltage to the charge corona

unit.

quenching lamp.

matrix, and monitors the key matrix.

Processes the video signal from the SBU

and sends the video signal to the LD unit.

Contains the CCD, and outputs a video

signal to the EX-IPU board.

Detects the laser beam at the start of the

main scan.

Detects the laser beam at the end of the

main scan.

Supplies high voltage to the transfer belt.

Supplies high voltage to the development

roller.

guidance for machine operation.

the main board and the LCT.

board (if the main switch is on) or to the

heaters (if the main switch is off).

the toner supply unit.

Component

Layout and

Descriptions

FSM 2-5 A133/A217

Page 38

Symbol Index

No.

M3 73

Description Note

Tray Lift Raises the bottom plate in the paper tray.

M4 56

M5 48

M6 74

M7 65

M8 78

M9 60

M10 55

M11 36

M12 39

M13 38

M14 75

M15 68

Sensors

S1 13

S2 15

S3 18

S4 46

S5 16

S6 47

S7 49

S8 50

S9 12

S10 19

S11 29

S12 30

Polygonal Mirror Turns the polygonal mirror.

LCT Lift Lifts up and lowers the LCT bottom plate.

Optics Exhaust Fan Removes heat from the optics unit.

IPU Fan Removes heat from the IPU board.

Exhaust Fan Removes heat from around the fusing unit.

Ozone Fan Removes ozone-laden air from inside the

machine.

Scanner Drive Drives the 1st and 2nd scanners (dc stepper

motor).

Duplex Feed Drives the feed roller and moves the bottom

plate up and down.

End Fence Jogger Drives the end fence jogger to square the

paper stack.

Side Fence Jogger Drives the side fence jogger to square the

paper stack.

DC Drive Board Fan Removes heat from around the DC drive

board.

Charge Inlet Fan Provides air flow around the charge corona

unit section.

By-pass Feed Paper

Width

By-pass Feed Paper

End

Tray Paper End Informs the CPU when the paper tray runs

Upper Relay Detects the leading edge of paper from the

Tray Upper Limit Detects the height of the paper stack in the

Lower Relay Detects misfeeds.

LCT Lower Limit Sends a signal to the CPU to stop lowering

LCT Paper End Informs the CPU when the LCT runs out of

LCT Upper Limit Signals the CPU to stop lifting the LCT

Registration Detects the leading edge of the copy paper

Image Density

(ID)

Toner Density

(TD)

Informs the CPU what width paper is in the

by-pass feed table.

Informs the CPU that there is no paper in the

by-pass tray.

out of paper.

paper tray and duplex unit to determine the

stop timing of the paper feed clutch and

duplex feed motor. Also detects misfeeds.

paper tray to stop the upper tray lift motor.

the LCT bottom plate.

paper.

bottom plate.

to determine the stop timing of the paper

feed clutch, and detects misfeeds.

Detects the density of various patterns on

the drum during process control.

Detects the amount of toner inside the

development unit.

A133/A217 2-6 FSM

Page 39

Symbol Index

No.

S13 1

S14 8

S15 9

S16 24

S17 6

S18 32

S19 28

S20 10

S21 2

S22 34

S23 35

S24 42

S25 37

S26 41

S27 23

S28 14

Switches

SW1 11

SW2 53

SW3 20

SW4 54

SW5 52

SW6 27

SW7 26

Magnetic Clutches

CL1 61

CL2 59

Description Note

Scanner HP Informs the CPU when the 1st and 2nd

scanners are at the home position.

Original Length-1 Detects the length of the original. This is one

of the APS (Auto Paper Select) sensors.

Original Length-2 Detects the length of the original. This is one

of the APS (Auto Paper Select) sensors.

Fusing Exit Detects misfeeds.

Platen Cover Informs the CPU whether the platen cover is

up or down (related to APS/ARE functions).

ARE: Auto Reduce and Enlarge

Toner End Instructs the CPU to add toner to the toner

supply unit, and detects toner end conditions.

Auto Response Returns the operation panel display and

exits from the energy saver mode.

Transfer Belt

Position

Original Width Detects the width of the original. This is one

Duplex Paper End Detects paper in the duplex tray.

Duplex Turn Detects the trailing edge of the copy paper

Duplex Entrance Detects misfeeds.

Side Fence Jogger

HP

End Fence Jogger

HP

Toner Overflow Detects when the used toner collection

By-pass Relay Detects misfeeds.

By-pass Feed Table Detects whether the by-pass feed table is

Tray Down Sends a signal to the CPU to lower the LCT

Tray Paper Size Determines what size of paper is in the

LCT Cuts the dc power line and detects whether

LCT Cover Cuts the dc power line of the LCT lift motor.

Main Supplies power to the copier.

Front Cover Safety Cuts the dc power line and detects whether

Toner Supply Turns the toner supply roller to supply toner

Development Drives the development roller.

Informs the CPU of the current position of

the transfer belt unit.

of the APS (Auto Paper Select) sensors.

to determine the jogging timing, and detects

misfeeds.

Detects the home position of the duplex side

fence jogger.

Detects the home position of the duplex end

fence jogger.

bottle is full.

open or closed.

bottom plate.

paper tray.

the LCT is open or not.

the front cover is open or not.

to the development unit.

Component

Layout and

Descriptions

FSM 2-7 A133/A217

Page 40

Symbol Index

CL3 76

CL4 58

CL5 63

CL6 71

CL7 72

CL8 62

Solenoids

SOL1 67

SOL2 77

SOL3 64

SOL4 69

SOL5 70

Lamps

L1 3

L2 43

L3 88

Description Note

No.

Transfer Belt Lift Controls the touch and release movement of

the transfer belt unit.

Registration Drives the registration rollers.

By-pass Feed Starts paper feed from the by-pass feed

table or LCT.

Relay Drives the relay rollers.

Paper Feed Starts paper feed from the paper tray.

By-pass Relay Drives the by-pass relay rollers.

By-pass Pick-up Drops the pick-up roller to the by-pass paper

feed position. When paper is fed from the

LCT, this solenoid assists SOL3.

Junction Gate Moves the junction gate to direct copies to

the duplex tray or to the paper exit.

LCT Pick-up Drops the pick-up roller all the way down to

the LCT paper feed position from the

by-pass paper feed position.

Pick-up Controls the up/down movement of the

pick-up roller in the paper tray.

Separation Controls the up/down movement of the

separation roller at the paper tray feed

station.

Exposure Applies high intensity light to the original for

exposure.

Fusing Provides heat to the hot roller.

Quenching Neutralizes any charge remaining on the

drum surface after cleaning.

Heaters

H1 21

H2 5

H3 22

Thermistors

TH1 45

Thermofuses

TF1 44

Thermoswitch

TS1 4

Drum (option) Turns on when the main switch is off to

prevent moisture from forming around the

drum.

Optics

Anti-condensation

(option)

Tray

(option)

Fusing Monitors the temperature at the central area

Fusing Provides back-up overheat protection in the

Exposure Lamp Opens the exposure lamp circuit if the 1st

Turns on when the main switch is off to

prevent moisture from forming on the optics.

Turns on when the main switch is off to keep

paper dry in the paper tray.

of the hot roller.

fusing unit.

scanner overheats.

A133/A217 2-8 FSM

Page 41

Symbol Index

Counters

CO1 25

CO2 N/A

Others

CB1 17

HDD 82

Description Note

No.

Total Keeps track of the total number of copies

made.

Key

(option)

Circuit Breaker

(220 ~ 240V

machines only)

Hard Disk Drive Scanned image data is compressed and

Used for control of authorized use. The

copier will not operate until it is installed,

when this option is enabled.

Provides back-up high current protection for

electrical components.

held here temporarily during copying; also

holds user stamp data.

Component

Layout and

Descriptions

FSM 2-9 A133/A217

Page 42

5. DRIVE LAYOUT

15

14

13

1

2

12

3

11

10

4

9

5

6

7

8

1. Toner Supply Clutch

2. Development Clutch

3. Drum Drive Pulley

4. Main Motor

5. Scanner Drive Motor

6. Fusing Drive Gear

7. Exit Drive Gear

8. Toner Collection Bottle Drive Gear

9. Transfer Belt Drive Gear

10. Cleaning Blade Drive Gear

11. Registration Clutch

12. Paper Feed Clutch

13. Relay Clutch

14. By-pass Feed Clutch

15. By-pass Relay Clutch

A133/A217 2-10 FSM

Page 43

INSTALLATION PROCEDURE

Page 44

Page 45

1. INSTALLATION REQUIREMENTS

1.1 ENVIRONMENT

1. Temperature Range: 50°F ~ 86°F (10°C ~ 30°C)

2. Humidity Range: 15% ~ 90%

3. Ambient Illumin at i on : Le ss tha n 1,500 lux (Do not expose to di r e ct

sunlight.)

4. Ventilation: 30 m3/hr/person

5. Ambient Dust: Less than 0.10 mg/m3 (2.7 x 10-6 oz/yd3)

6. If the place of instal lation is air-condi tio ne d or he ated, place the machi ne :

a) where it will not be subjected to sudden temperature changes.

b) where it will not be directly exposed to cool air from an air conditioner.

c) where it will not be directly exposed to heat from a heater.

7. Do not place the machine where it will be exposed to corrosive gases.

8. Do not install the machine at any location over 2,000 m (6,500 feet)

above sea level.

Installation

Procedure

9. Place the copier on a strong and level base.

10. Do not place the machine where it may be subjected to strong vibration.

1.2 MACHINE LEVEL

1. Front to back: Within 5 mm (0.2") of level

2. Right to Left: Within 5 mm (0.2") of level

FSM 3-1 A133/A217

Page 46

1.3 MINIMUM SPACE REQUIREMENTS

Place the copier near a po wer source, providing clearance as shown.

– Copier –

More than 10 cm or 3.9"

More than 50 cm or 19.7"More than 39 cm or

15.4"

– Copier with the optional finisher–

More than 70 cm ro

27.6"

More than 10 cm or 3.9"

More than 72 cm or 28.3"

More than 50 cm or

19.7"

More than 70 cm

1.4 POWER REQUIRMENTS

CAUTION

+

A. Be sure to ground the machine.

B. Make sure the plug is firmly inserted in the outlet.

C. Avoid multi-wiring.

1. Input voltage level:

120V, 60Hz: More than 12A

2. Permissible voltage fluctuation: ±10%

3. Do not set anything on the power cord.

A133/A217 3-2 FSM

Page 47

2. COPIER INSTALLATION

2.1 ACCESSORY CHECK

Check the quantity and condi tio n of the accessories in the box against the

following list:

Description Qt’y

1. Paper Size Decal ................................................... 1

2. Operating Instructions (except for -27 machines) .. 1

3. New Equipment Condition Report ..........................1

4. User Survey Card (-17 machines only) .................. 1

Installation

Procedure

FSM 3-3 A133/A217

Page 48

[F]

[E]

[B]

[C]

[D]

[A]

NOTE: 1) Keep the shipping retainers after installing the machine. They

will be reused if the machine is moved to another location in

the future.

2) Never lift the machine by holding the LCT, or the LCT will

break.

1. Remove the strips of tape.

2. Pull out the duplex tray [A] and remove the strips of tape.

3. Remove the guide rolle r stop pe r [B] .

4. Open the lower duplex guide plate [C] and remove the sheets of paper

[D]and the styrofoam.

5. Install the duplex tray i n th e m achi ne .

6. Pull out the paper tray [E], and remove the strips of tape and the bottom

plate stopper [F]. The n inst all th e pa pe r tray i n the m ach ine .

A133/A217 3-4 FSM

Page 49

[D]

[B]

[F]

[A]

[B]

[B]

[E]

[C]

[G]

[L]

[J]

[I]

[K]

[H]

7. Open the front cover and swing out the toner bottle holder [A].

8. Remove the strips of tape [B].

9. Remove transfer belt release pin [C] and cleaning blade release pin [D].

Installation

Procedure

NOTE: Put back pins [C] and [D] before transporting the machine to a

new location.

10. Turn the "A1" lever [E] counterclockwise to lower the transfer belt unit.

11. Remove the charge corona unit [F] (1 screw).

12. Remove the toner collection bottle [G] (1 connector).

13. Remove the drum knob (turn clockwise) [H] and drum bushing [I].

14. Disconnect the ID sensor harness [J] and carefully slide out the drum

unit [K] until t he front guide plate rele ase s fr om th e po si tioning pins.

15. Move the development unit [L] to the right - away from the drum, then

slide out the drum unit completely. Be careful not to scratch the Drum.

FSM 3-5 A133/A217

Page 50

[D]

[C]

[B]

[A]

[E]

[F]

16. Remove the toner bottle holder [A] (2 screws, 1 connector).

17. Turn the shutter lever [B] of the toner bottle holder as shown to prevent

toner from spilling.

18. Remove the development unit stopper [C] (1 screw).

19. Pull out the development unit [D] (1 connector). Be careful not to catch

the wire harness on the fram scr ew, on th e r igh t si de of the m ach ine .

Place the development unit on a clean sheet of paper.

20. Remove the toner supply unit [E] (2 screws, 1 connect or) If necessa ry,

remove the shipping tape from the front and back sides of the

development unit.

21. Remove the development filter [F].

A133/A217 3-6 FSM

Page 51

[A]

[B]

[C]

[D]

22. Pour about half a pack of developer [A] into the development unit. Then

rotate the knob [B] as shown to distribute the developer evenly. Then

pour in all the remaining developer and rotate the knob again.

NOTE: To prevent the developer from spilling, do not rotate the knob in

the other direction.

23. Replace the dev. filter. Attach the toner supply unit to the dev. unit.

24. Install the development unit in the copier and put back the stopper ([C]

that was removed in step 18).

NOTE: Be careful not to damage the bias wire on the frame screw.

25. Move the develo pme nt uni t to th e r igh t so th at the deve l op men t un i t is

away from the drum. Then install the drum un i t. Do no t scratch the drum.

26. Install the toner bottle holder, making sure that the toner bottle holder

[C] and bracket [D] are at right angles as shown above. If not, swing the

toner bottle holder out in the direction of the big arrow in the diagram.

27. Turn the "A1" lever clockwise to raise the transfer belt unit.

28. Install the charge cor ona un i t. Do not scratch the OPC drum.

Installation

Procedure

29. Install the toner collection bottle.

30. Install the toner bottle by following the instructions on the reverse side of

the front cover.

31. Swing the toner bottle holder into its original position and close the front

cover.

FSM 3-7 A133/A217

Page 52

[E]

[G]

[H]

[F]

[I]

[G]

[H]

[A]

[C]

[B]

32. Install the 500-sh ee t cop y tr ay i f req uir e d:

1) Remove caps [E] with wire cutters.

2) First, remove the screws [F], and fit the hooks [G] on the copy tray unit

into the openings. Then tighten the screws [H] that are built into the

copy tray unit.

3) Install the copy tray [I].

33. Install the optional platen cover [A] as shown if required :

1) Install two stud screws [B] on the top cover.

2) Position the platen cover bracket [C] on the stud screws and slide it to

the left.

A133/A217 3-8 FSM

Page 53

SCU

MSIS

IC 411

IC 412

COPY1

IC 413

COPY2

For USA models, proceed to step 37. Steps 34 through 36 are for the

220 ~ 240 V machine only.

34. Remove the rear cover.

35. Install the three ROMs which contain the language kit in the IC411,

IC412, and IC413 sockets on the SCU board (the lower left PCB as

viewed from the rear of the machine).

The "MSIS" ROM should be put in the IC411 socket.

The "COPY1" ROM should be put in the IC41 2 socke t.

The "COPY2" ROM should be put in the IC41 3 socke t.

NOTE: Do not bend the pins of the ROMs.

Do not install the ROMs the wrong way round.

36. Put the rear cover back on the machine.

37. Plug in the copier and turn on the main switch.

38. After the mach i ne reach es th e op er a ti o n con di t i on (t he star t but to n LED

is green), enter SP mode as follows:

1) Press the "Clear Modes" key.

2) Enter "107" usin g th e numeric keys.

3) Hold down the "Clear/Stop" key for more th an 3 secon ds.

Installation

Procedure

39. Perform the TD sensor initial setting as follows:

1) Enter "2801" and press the "Enter" key.

2) Touch "Start" on the LCD.

NOTE: The machine will automatically stop when TD sensor initial

setting is completed.

FSM 3-9 A133/A217

Page 54

[B]

On the paper tray

On the duplex tray

[A]

40. Perform the free run procedure as follows:

1) Enter "5802" and press the "Enter" key.

2) Touch "ON" on the LCD then touch "Copy Mode" on the LCD.

3) Set the number of cop i es at 50.

4) Close the platen cover or the ADF then press the "Start" key.

5) After finishing the free run, touch "SP Mode" on the LCD.

6) Touch "Quit" on the LCD to leave SP mode.

41. Pull out the paper tray and load paper into it (the paper size and

orientation should be as specified by the customer).

NOTE: The side and rear fences should be properly positioned.

42. Select the appropriate paper size for th e paper tray by sliding the paper

size slider [A] into the correct position.

NOTE: A non-standard pa pe r size can be select ed with a UP mode

(See the Paper Size Selection section).

43. When the optional Paper Feed Unit is installed: Ent er th e pr o pe r

paper size for each pape r tray using a UP mode. (See the Paper Size

Selection section.)

44. Attach the appropr iate paper size decals [B] to the pa pe r trays. Al so,

attach the duplex decal to the duplex tray.

NOTE: Paper size decals are also used for the optional paper feed unit.

Keep any remaining decals for use with the paper feed unit.

45. Check the copy quality and machine operation.

A133/A217 3-10 FSM

Page 55

2.2 KEY COUNTER (OPTION)

[F]

[D]

[E]

[G]

[C]

[A]

[B]

Installation

Procedure

CAUTION

+

Unplug the copier power cord before starting the following procedure.

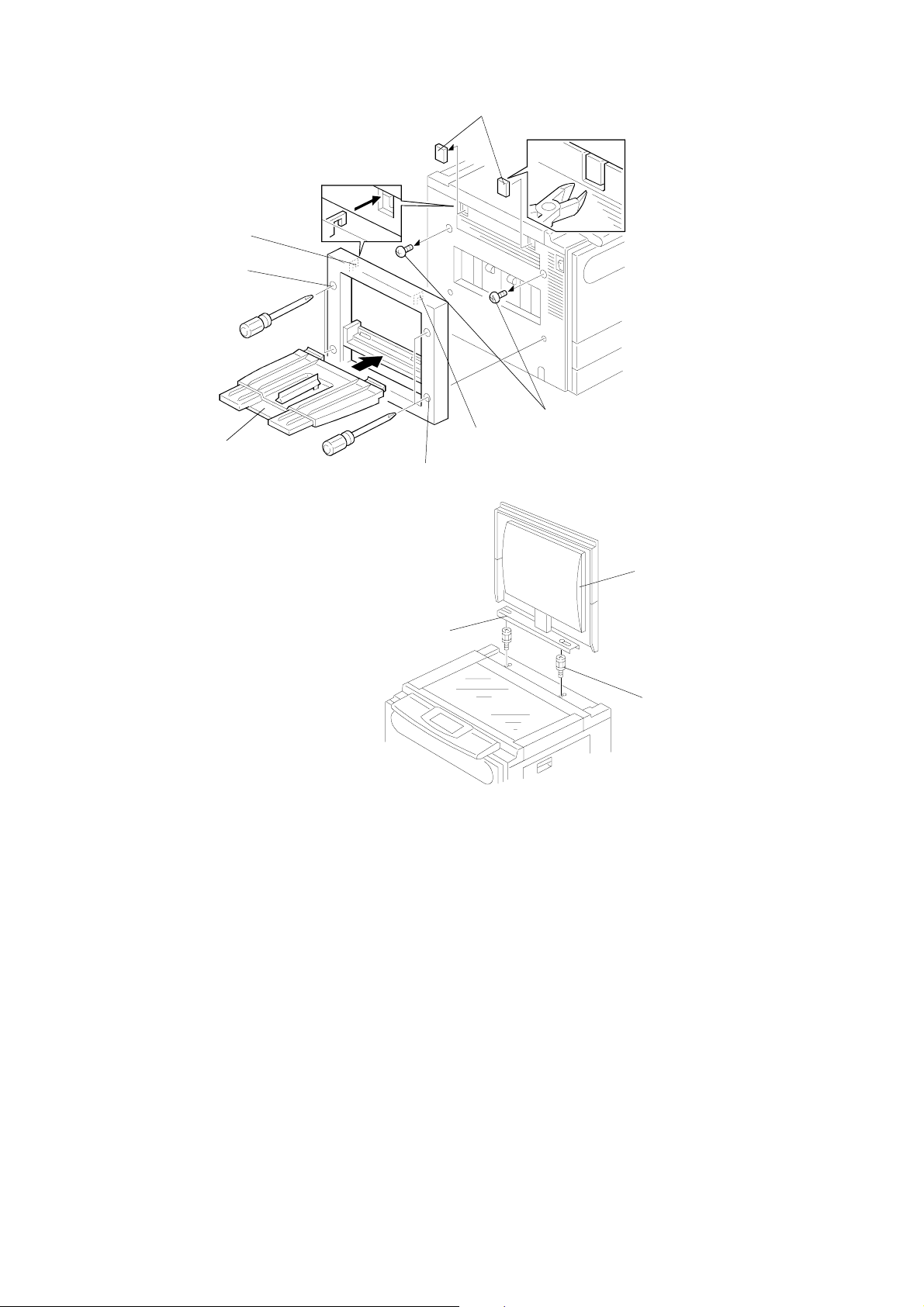

1. Remove the right cover [A]. (See "Replacement and Adjustment - Outer

Cover Removal".)

2. Remove the cap [B] with wire cutters.

3. Remove the key counter cover [C] (2 screws)

4. Pass the key counter holder conn ector [D] through th e op en ing [ E] .

5. Disconnect the connector [F] and connect the key counter holder

connector.

6. Mount the key counter holder [G] (2 screws).

7. Reassemble the machine and check the key counter’s operation.

FSM 3-11 A133/A217

Page 56

2.3 TRAY HEATER (OPTION)

[C]

[A]

CAUTION

+

Unplug the copier power cord before starting the following procedure.

1. Remove the duplex unit. (See "Replacemen t an d Ad j ust m en t - Dupl e x

Unit Removal".)

[B]

2. Remove the paper feed tray. (See "Replacement and Adjustment Paper Feed Tray Removal".)

3. Install the tray he ater [A] (2 screws).

4. Connect the connector of the hea te r to th e cop i er ’s con ne cto r [B] which

is mounted on the rear frame.

5. Fit the heater harness into the cable clamp.

6. Install the heater cover [C ] (1 scr ew) .

7. Reassemble the machine.

8. Check the printer side-to-side registration for the 1st paper feed station

(SP1002-2) and the duplex unit (SP1002-1).

NOTE:

Tell the customer that even when the copier’s main switch is

turned off, the copier power cord should be plugged in.

Otherwise, the tray heater will not function.

A133/A217 3-12 FSM

Page 57

2.4 DRUM HEATER (OPTION)

[B]

[C]

[D]

[A]

CAUTION

+

Unplug the copier power cord before starting the following procedure.

Installation

Procedure

1. Remove the transfer th e belt unit. (See "Replacement and Adjustment Transfer Belt Unit Removal".)

2. Move the "A1" lever clockwise.

3. Install the drum heater [A ] (2 screws).

4. Connect the connector of the hea te r to th e cop i er ’s con ne cto r [B] which

is mounted on the rear frame.

5. Fit the heater harness into the cable clamp.

NOTE:

6. Install the heater cover [D ] (1 scr ew) .

7. Reassemble the machine.

NOTE:

Route the heater ha rness under the hook [C].

Tell the customer that even when the copier’s main switch is

turned off, the copier power cord should be plugged in.

Otherwise, the drum heater will not function.

FSM 3-13 A133/A217

Page 58

2.5 OPTICS ANTI-CONDENSATION HEATER (OPTION)

[B]

[C]

CAUTION

+

Unplug the copier power cord before starting the following procedure.

1. Remove the exposure glass. (See "Replacement and Adjustment Exposure Glass Removal".)

[A]

2. Move the 1st scanner to the cent er of the scann er un i t.

3. Install the optics anti -condensation heater [A] (2 scwers).

4. Connect the connector of the hea te r to th e cop i er ’s con ne cto r [B] which

is mounted on the front frame of the scanner unit.

5. Fit the harness into the clamper [C].

6. Reassemble the machine.

NOTE:

Tell the customer that even when the copier’s main switch is

turned off, the copier power cord should be plugged in.

Otherwise, the optics anti-condensation heater will not function.

A133/A217 3-14 FSM

Page 59

3. PAPER SIZE SELECTION

3.1 OPTIONAL PAPER FEED UNIT

The paper size for the pa pe r fee d un i t can be selected with User Prog r am

mode.

You can select paper of the following sizes:

Metric version Inch version

, B4 , A4

A3

11" x 17" , 8

8" x 10", 8" x 13" , 8

" x 13"

8

1/4

1/2

, B5

" x 14" , 8

1/2

" x 13" ,

1/2

" x 11"

11" x 17" , 8

,

11" x 15" , 10" x 14" , 8" x 10

8" x 10" , A3 , B4 , A4

8" x 13" , 8

" x 13"

8

1/4

1/2

1/2

" x 14" , 8

" x 13" ,

" x 11"

1/2

1/2

,

" ,

,

User Tools

Guidance

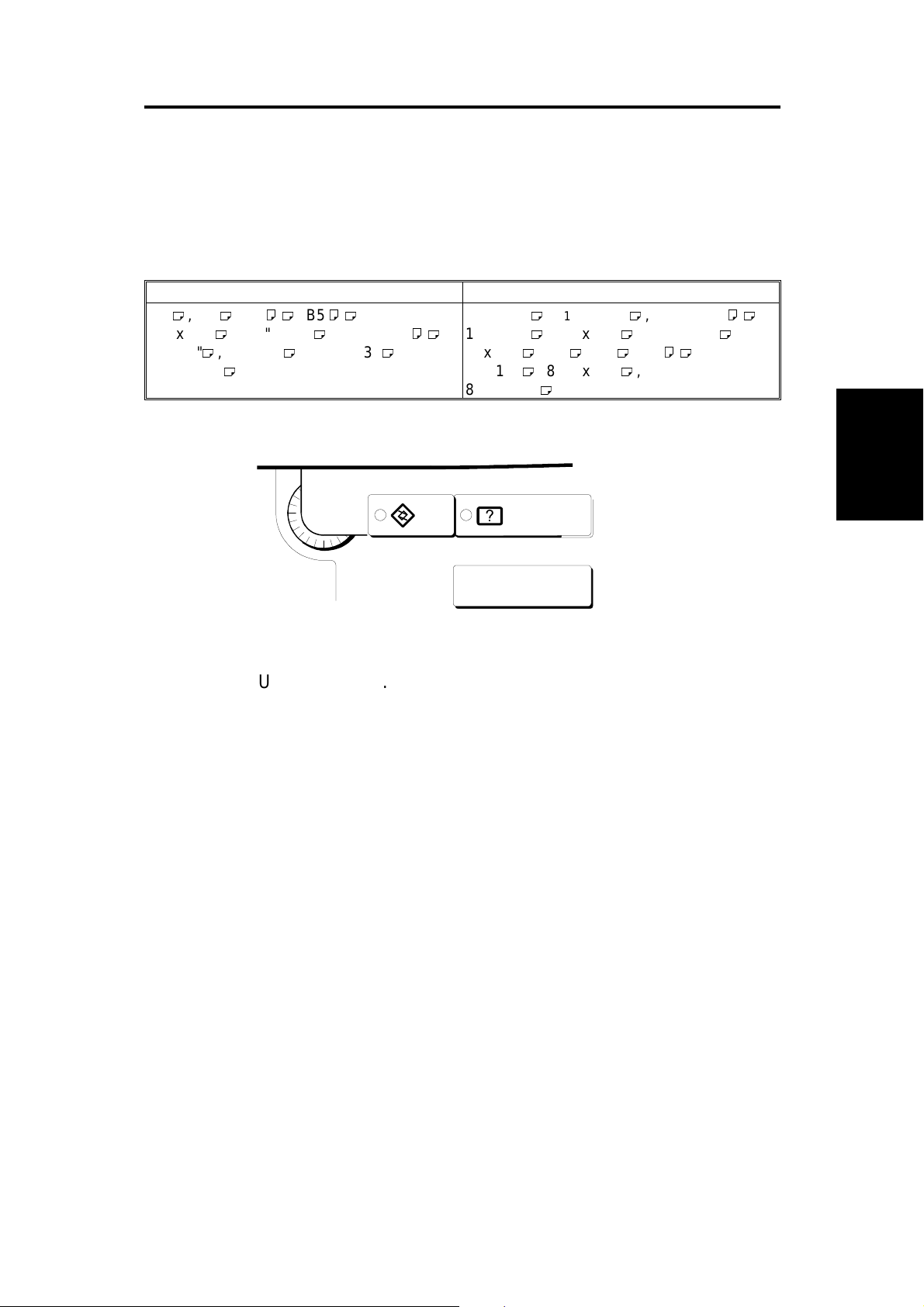

1. Press the User Tools key.

2. Touch the Basic Settings key.

3. Touch the Next key three times to reach the paper size setting menu.

4. Find the paper tray (2, 3, or 4) an d to uch the Ch an ge key. Se lect the new

paper size by touching a key. Then touch the Exit key.

5. Press the User Tools key.

Installation

Procedure

FSM 3-15 A133/A217

Page 60

3.2 1ST TRAY - NON-STANDARD PAPER SIZE SELECTION

For the 1st tray, a wider range of paper sizes can be selected with Us er

Program mode.

If a non-standard paper size is selected, the machin e ign ores the paper size

set with the paper size slider.

You can select paper of the following sizes:

Metric version Inch version

11" x 17" , 8

8" x 10"

" x 14" , 5

1/2

1/2

" x 8

1/2

" ,

11" x 15" , 10" x 14" , 8" x 10

1/2

"

User Tools

Guidance

[A]

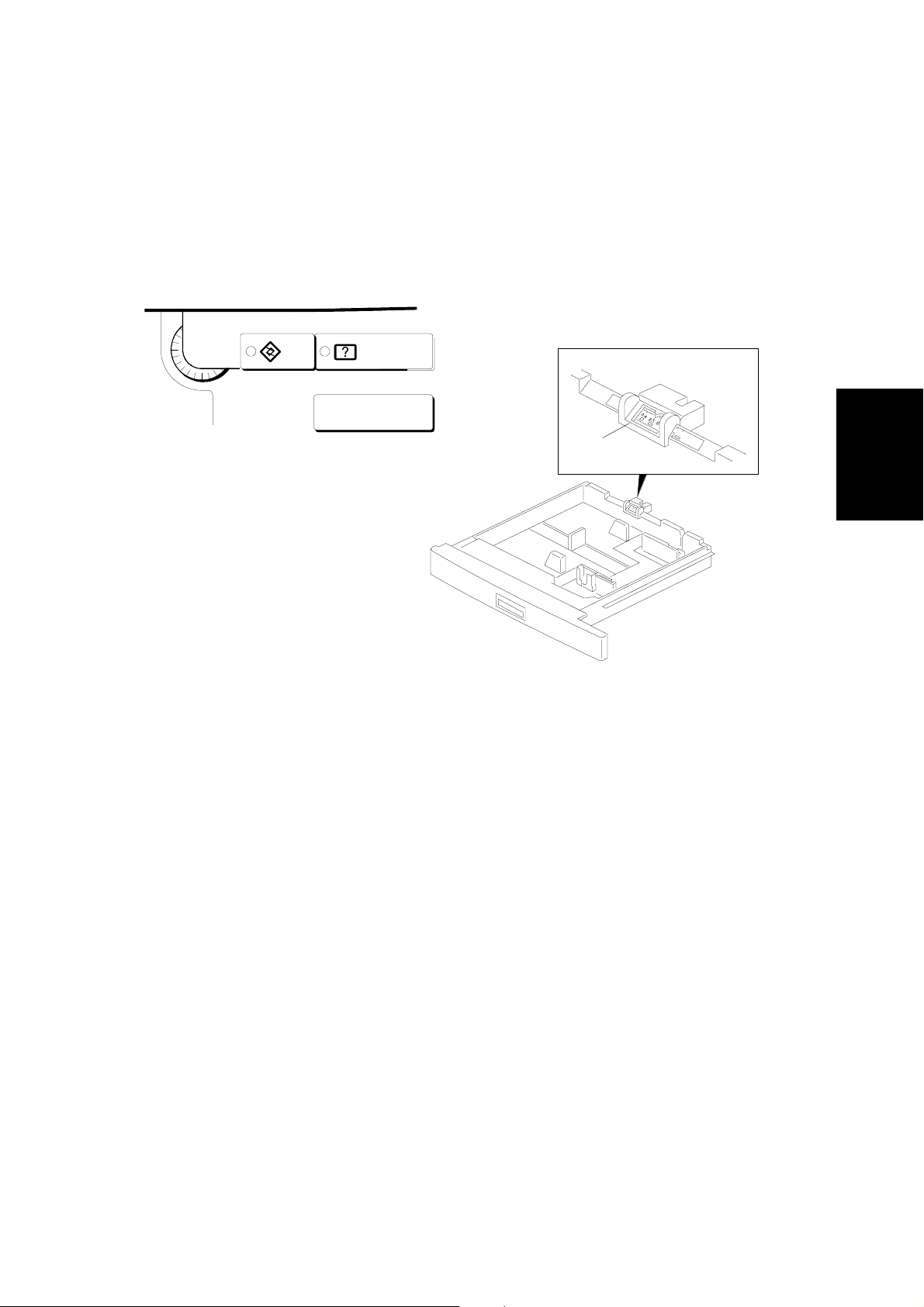

1. Slide the paper size slider [A] on the paper tray into the "*" position.

2. Press the User Tools key.

3. Touch the Basic Setting key.

4. Touch the Next key three times to reach the paper setting menu.

5. In the Tray <*> Paper Size Se tting menu, the pres en t size setting is

displayed. Touch the Change key. Select the new paper size by touching

a key. Then, touch the Exit key.

6. Press the User Tools key.

A133/A217 3-16 FSM

Page 61

3.3 1ST TRAY - F/F4 SIZE PAPER SELECTION

For the 1st tray, a wider range of F and F4 paper sizes can be selected with

User Program mode.

You can select paper of the following sizes:

8" x 13"

8

" x 13"

1/4

8

" x 13"

1/2

User Tools

Guidance

[A]

1. Slide the paper size slider [A] on the paper tray into the "F/F4" position.

2. Press the User Tools key.

3. Touch the Basic Setting key.

Installation

Procedure

4. Touch the Next key three times to reach the paper setting menu.

5. In the Tray <F/F4> Paper Size Se tting menu, the present s ize setting is

displayed. Touch the Change key. Select the new paper size by touching

a key. Then, touch the Exit key.

6. Press the User Tools key.

FSM 3-17 A133/A217

Page 62

Page 63

SERVICE TABLES

Page 64

Page 65

1. SERVICE REMARKS

1.1 GENERAL CAUTION

Do not turn off the main switch while any of the electrical compon ents are

active. Doing so might cause damage to units such as the transfer belt,

drum, and development unit when they are pulled out of or put back into the

copier.

1.2 DRUM

The organic photoconductor (OPC) drum is more sensitive to light and

ammonia gas than a sel e niu m drum . Fol low th e cau tio ns be l ow w he n

handling an OPC dr um.

1. Never expose the drum to direct sunlight.

2. Never expose the drum to direct light of more than 1,000 Lux for more

than a minute.

3. Never touch the drum surface with bare hand s. Whe n th e dr u m sur fa ce

is touched with a finger or beco mes di rty, wipe it with a dry cloth or cl ea n

it with wet cotton. Wipe with a dry cloth after cleaning with wet cotton.

4. Never use alcohol to clean the drum; alcohol diss olves the drum surface.

5. Store the drum in a cool, dry place away from heat.

6. Take care not to scratch the drum as the dr um l aye r is th in an d is easily

damaged.

7. Never expose the drum to corrosive gases such as ammonia gas.

8. Always keep the drum in the protective sheet when keeping the drum

unit, or the drum itsel f , ou t of the copie r . D oin g so avo ids exp osi n g it to

bright light or direct sunlight. This will protect the drum from light fatigue.

9. Before pulling out the drum unit, place a sheet of paper under the drum

to catch any spilt toner.

10. Dispose of used drums in accordance with local regulations.

Tables

Service

FSM 4-1 A133/A217

Page 66

Rev. 6/96

11. When installing a new drum in the drum unit, the following must be done.

a) Remove the protective sheet after securing the new drum to the drum

unit.

b) Do the ID Sensor Initial Setting procedure (SP Test Mode 3001).

12. When the drum unit is removed, push the development unit to the right

before re-installing the drum unit.

1.3 TRANSFER BELT UNIT

1. Replace the transfer belt every two PM cycles (240K copies) to avo id

bad effects on the drum.

2. Never touch the transfer belt surface with bare hands.

3. Take care not to scratch the transf er be lt as th e sur f ace is easi ly

damaged.

4. Before installing the new transfer belt, clean all the rollers with a dry cloth

to prevent the bel t fr o m slip pi n g.

1.4 SCANNER UNIT

1. When installing the exposure glass, make sure that the white reference

plate is facing dow n.

2. Clean the exposure glass with alcohol or glass cleaner to reduce the

amount of static electric ity on the glass surface.

3. Use a cotton pad with water or a blower brush to clean the mirrors and

lens.

4. Do not bend or crease the exposure l amp fl at cable .

5. Do not disassemble the lens unit. Doing so will throw the lens and the

copy image out of focus.

6. Do not turn any of the CCD positioning screws. Doing so will throw the

CCD out of position.

A133/A217 4-2 FSM

Page 67

1.5 LASER UNIT

1. Do not loosen the screws that secure the LD drive board to the laser

diode casing. Doing so would throw the LD unit out of adjustment.

2. Do not adjust the variable resistors on the LD unit, as they are adjusted

in the factory .

3. The polygon mirror and F-theta lenses are very sensitive to dust. Never

open the optical housing unit or remove the polygon mirror motor cover.

4. Do not touch the glass surface of the polygon mirror mot or unit with bare

hands.

1.6 CHARGE CORONA UNIT

1. Clean the charge corona wire with a dry cloth. Do not use sandpaper or

a solvent.

2. Clean the charge corona casing with wet cotton and a dry cloth.

3. Clean the end blocks with a blower brush first to remove toner and paper

dust. Then clean it with a dry cloth if any toner still remains on it.

4. Do not touch the corona wir e s with bare hands. Oil stai ns fr o m f ing er s

may cause uneven image density on copies.

5. Make sure that there is no foreign material (iron filings, etc.) on the

casing.

6. To avoid uneven charge, do not bend or scratch the wire surface when

installing new corona wires. Also be sure that the corona wires are

correctly positioned in the grooves of the end blocks.

7. Clean the charge grid pla te with a blower brush, water, then with a dry

cloth. When doing so, be careful not to damage the grids by letting fibers

attach to them.

8. Do not touch the charge gr id pl a te wit h bare hands. Also, do not ben d

the charge grid pl at e or make any de nt in it. Doing so may cause un eve n

charge.

1.7 DEVELOPMENT

1. Be careful not to nick or scratch the development ro ll er s.

Tables

Service

2. Place the development unit on a sheet of paper after removing it from the

copier.

3. Never disassemble the develo pm e nt rol ler asse mbl y. The po siti o n of the

doctor plate is set with spe c ial to ol s an d inst r ume nts at the factory to

ensure the proper gap between the doctor blade and the development

roller.

FSM 4-3 A133/A217

Page 68

4. Clean the drive gears after removing used developer.

5. Dispose of used developer in accordance with local regulations.

6. When removing or installing the development unit, be careful not to

damage the drum surface with the entrance seal on the development unit.

7. Never load different types of developer and toner into the development

unit. Doing so will cause poor copy quality and toner scattering.

8. Immediately after installing new developer, the TD sensor initial setting

procedure should be performed to avoid damage to the copier. Do not

perform the TD sensor initial setting with used developer. Do not make

any copies before doing the TD sensor initial setting.

9. When using a vacuum cleaner to clean the develo pment unit casing,

always ground the casing with your fingers to avoid damaging the toner

density sensor with static electricity.

10. After replacing th e TD senso r, do the TD sens or i nit i al set ti n g pro c ed ure

(SP 2801).