Rotary axis RA-40

Operating manual

1 Content

1 Content .................................................................................................................................. 2

2 Preface .................................................................................................................................. 4

3 Safety information ................................................................................................................. 4

General safety information .............................................................................................. 4

Please observe the information in the operating instructions! ......................................... 4

Protection against dangerous movements ...................................................................... 5

Explanation of symbols and signs ................................................................................... 5

3.4.1 Warnings .................................................................................................................. 5

3.4.2 Symbols ................................................................................................................... 5

4 Product description ................................................................................................................ 6

Intended use ................................................................................................................... 6

Warranty and liability ....................................................................................................... 6

5 Rotary axis RA-40 ................................................................................................................. 7

RA-40-2F ........................................................................................................................ 8

RA-40-4F ...................................................................................................................... 10

RA-40-2F-5E ................................................................................................................. 12

RA-40-4F-5E ................................................................................................................. 14

6 Installation ........................................................................................................................... 16

7 Connection .......................................................................................................................... 17

Power supplies ............................................................................................................. 17

Controller C11x0 ........................................................................................................... 18

Controller C12x0 ........................................................................................................... 20

Controller E12x0 ........................................................................................................... 22

Controller E11x0 ........................................................................................................... 24

Controller B1100 ........................................................................................................... 26

Motor connector ............................................................................................................ 28

Plug configuration encoder ........................................................................................... 29

7.8.1 Round connector on the module ............................................................................ 29

7.8.2 Encoder plug configuration on the controller .......................................................... 29

Electrical feed-through / Proximity switch cable-R11 .................................................... 30

Y-distributor plug R12 ................................................................................................... 30

Reference sensor.......................................................................................................... 30

8 6 Commissioning ................................................................................................................. 31

Setting speeds of the electric axes ............................................................................... 31

Overview electrical axes ............................................................................................... 31

Teaching of positions on electric axes .......................................................................... 32

1.1 Switching distance ........................................................................................................ 32

1.1.1 Reference sensor with electric axes ....................................................................... 32

9 Maintenance ........................................................................................................................ 33

10 Repairs ................................................................................................................................ 33

11 Component/replacement part lists ....................................................................................... 34

Overview motor cabel-designation-axes-controller-application ..................................... 34

Subject to change. 2 Ver s. 1.1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Motor cable ................................................................................................................... 35

Encoder ........................................................................................................................ 36

Controller ...................................................................................................................... 36

12 Disposal instructions............................................................................................................ 37

13 Installation manual in accordance with Appendix VI (EC-RL 2006/42/EC) .......................... 38

14 Installation declaration for partly completed machinery (EC-RL 2006/42/EC) ..................... 39

15 Risk assessment (EG-RL 2006/42/EG) ............................................................................... 40

16 Support ................................................................................................................................ 45

17 Notes ................................................................................................................................... 46

Subject to change. 3 Ver s. 1.1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

2 Preface

It is our aim to present all essential inform ation contained in these operating instruc tions as clearly

and concisely as possible. However, please do not hesitate to contact us should you have any queries.

We are always very grateful for your suggestions.

We wish you a successful integration of our devices into your machines or systems.

3 Safety information

General safety information

The pick and place EPS devices are constructed according to the state of the art and the

acknowledged safet y-related guidelines; they may only be used

for their intended purpose,

and only when in an operationally safe c ondition.

Please observe the information in the operati ng i nstructions!

The prerequisite for the safe handling and smooth operat ion of the pick and place EPS dev ices is

awareness of the fundam ental safety standards

Every person tasked with the installation, commissioning, maintenance and operation of the pick and

place EPS devices is required to have thoroughly read and understood the entire user manual,

particularly the "saf ety notes" chapter.

Furthermore, the rules and regulations on accident prevention applicable at the place of

installation/operation must also be observed. I m proper us e may result in dangers t o the life and limb

of the operator or third part ies and i n impairments to the machine or other assets.

In the event of faults that could impair safety, the machine must be switched off immediately and

secured to prevent restarting. The fault must then be remedied.

All work on the machines must be carried out with the m achines depressurised and disconnected

from the electrical power supply.

For the operation of t he machines, the user must provide prot ective covers, safety doors or other

safety precautions conf orming to the normal safety guidelines an d safety standards which prevent

people from entering or remaining in the working area of the machines during operation. The

machines may only be put into oper ation when the guards are securely closed.

Subject to change. 4 Ver s. 1.1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

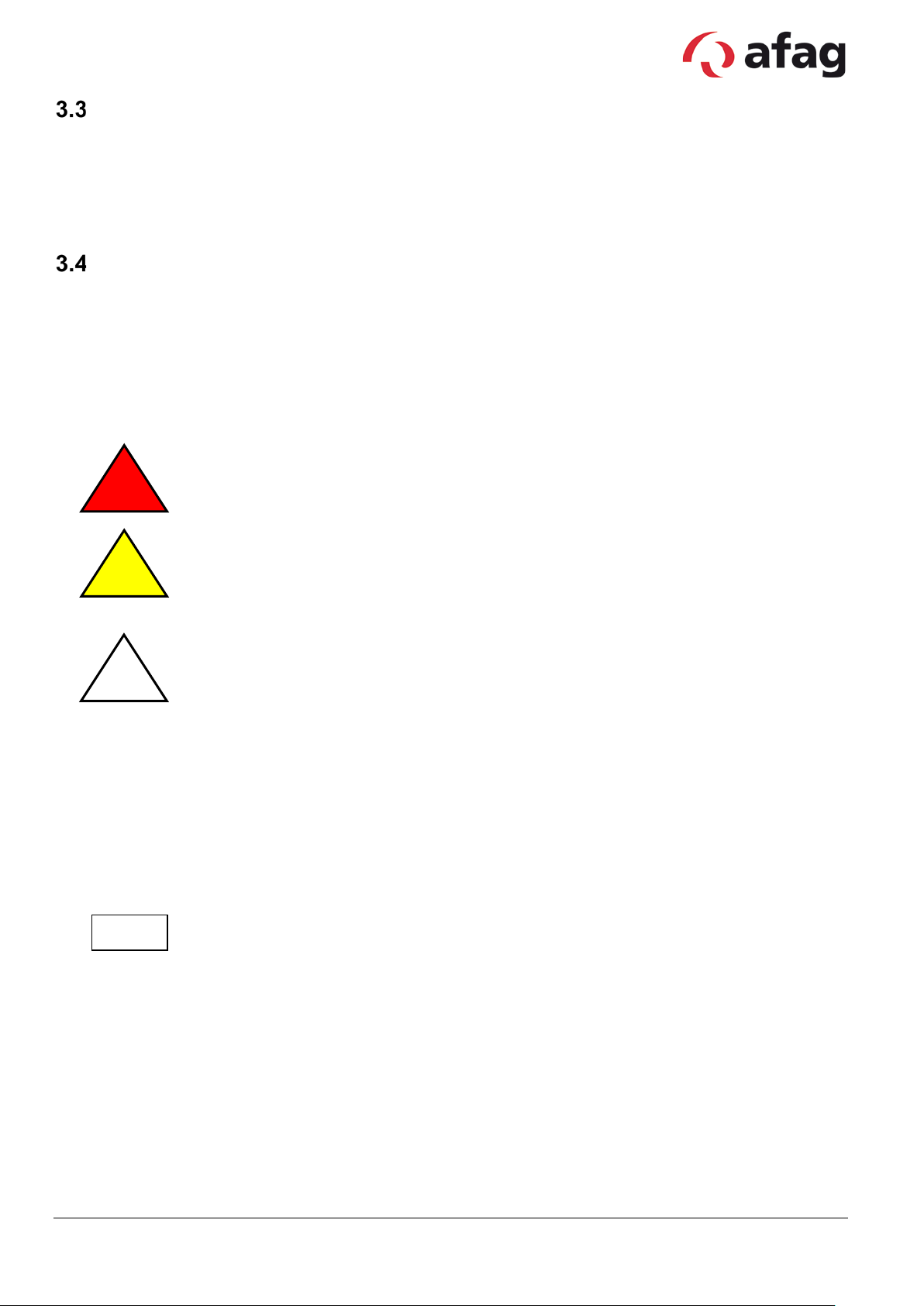

Danger

Warning

regulations are not

Caution

Information sign

! ! !

INFO

Protection against dangerous movements

Dangerous movements can occur if drives are actuated incorrectly. The drive components are

monitored so that a m alfunction c an be eff ectively ruled o ut. F or reasons of personal safet y, the risk

of injury and the risk of material damage, however, this must not be relied on exclusively. Faulty drive

movements must be anticipat ed until installed monitoring devices become go into effect.

Explanation of symbols and signs

The following warnings and symbols help readers understand

this manual quickly and ensur e that the EMD modules can be handled

safely.

3.4.1 Warnings

This symbol draws attention t o an imminently hazardous situati on t hat will r esult in

serious personal injur y or even death if the safety regulations ar e not observed.

This symbol draws attention to a pot entially hazardous situation that will result in

serious personal injury or property damage if the safety

observed.

This symbol draws attention to a pot entially hazardous situation that will result in

property damage if the safety regulations are not observed.

3.4.2 Symbols

This symbol indicates information that contributes to bet ter understanding.

Subject to change. 5 Ver s. 1.1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

4 Product description

Intended use

The pick and place EPS devices ar e used in automation systems and are intended exc lusively for

moving workpieces.

The pneumatic modules are intended exclusively for operation with compressed air (4-7 bar). Use for

any other purpose does not c onstitute an intended use.

The electric axes are intended exclusively for operation with original LinMot components (controllers,

cables...). Use for any other purpose does not constitute an int ended use.

The intended use also includes c om plianc e wit h t he prescr ibed i nstal lat ion and removal instructions,

the service and mainten anc e c onditions and observance of the specifications in the data sheets.

Warranty and liability

The "General Conditions of Sale and Delivery" of Afag GmbH shall apply in all cases.

The term of the warranty on Afag handling components and systems is:

24 months following commissioning, butnot exceeding 27 months following delivery.

Wear parts (e.g. shock absorbers) are excluded from the warranty. *

The guarantee covers the use or repair of defective Afag parts. No further claims will be

accepted.

The warranty will be voided in event of the following:

Use for other than the intended purpose

Failure to observe the information on installation, commissioning, operation and

maintenance in the operating manual

Improper installation, commissioning, operation and maintenance

Independent repairs and constructional changes without prior instruction by Afag

Automation AG/Afag Hardt GmbH

Removal of the serial number on the product

Using the module without shock absorbers, or with defective shock absorbers

Inadequate monitoring of wear parts

Failure to observe the EC Machinery Directive, accident prevention regulations, VDE

guidelines as well as the s afety/installation instr uc tions

Emergencies caused by external influence or force majeure.

*A customer has the right to a defect-free product. This is also applicable for accessories and

wear parts, if th ey are de fec ti ve.

Subject to change. 6 Ver s. 1.1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

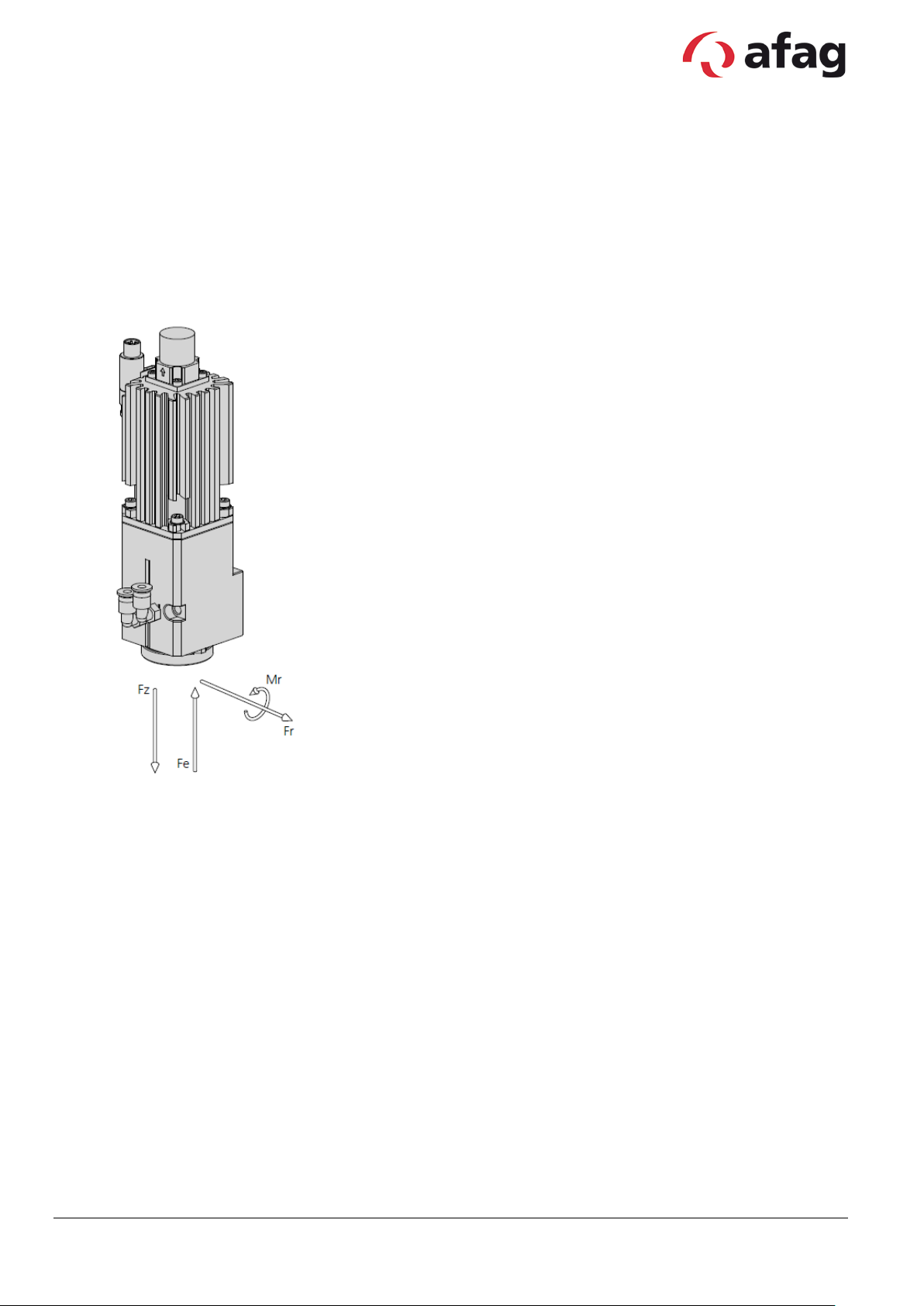

5 Rotary axis RA-40

Allgemein

Operating temperature: 0 - 50 °C

Bearing temperature: 0 - 50 °C

Humidity: < 90 %

Module stresses

Max. torque Mr: 10Nm

Max. press-in force Fe: 800N

Max. radial force: ±700N

Max. pulling force Fz: 350N

Subject to change. 7 Ver s. 1.1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Max. rotational speed

280 rpm

280 rpm

280 rpm

280 rpm

Fluid passages

2 2 2 2 Continuous torque

1.2 Nm

1.2 Nm

1.2 Nm

1.2 Nm

61440 Inc/U

61440 Inc/U

Mounting position

Angle of rotation

∞ ∞ ∞ ∞ Max. rotational speed

140 rpm

140 rpm

140 rpm

140 rpm

Fluid passages

2 2 2

2

102400 Inc/U

102400 Inc/U

Mounting position

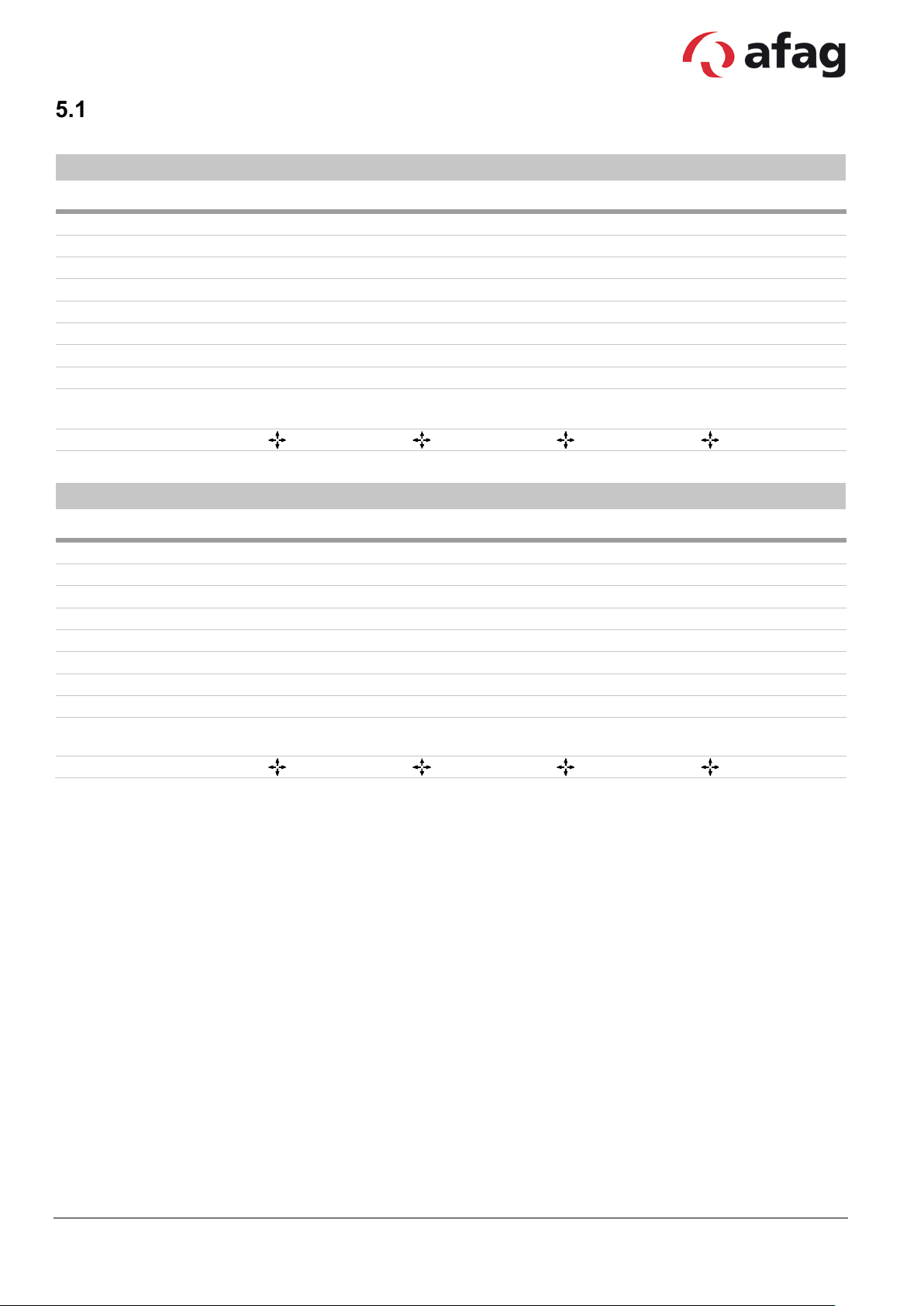

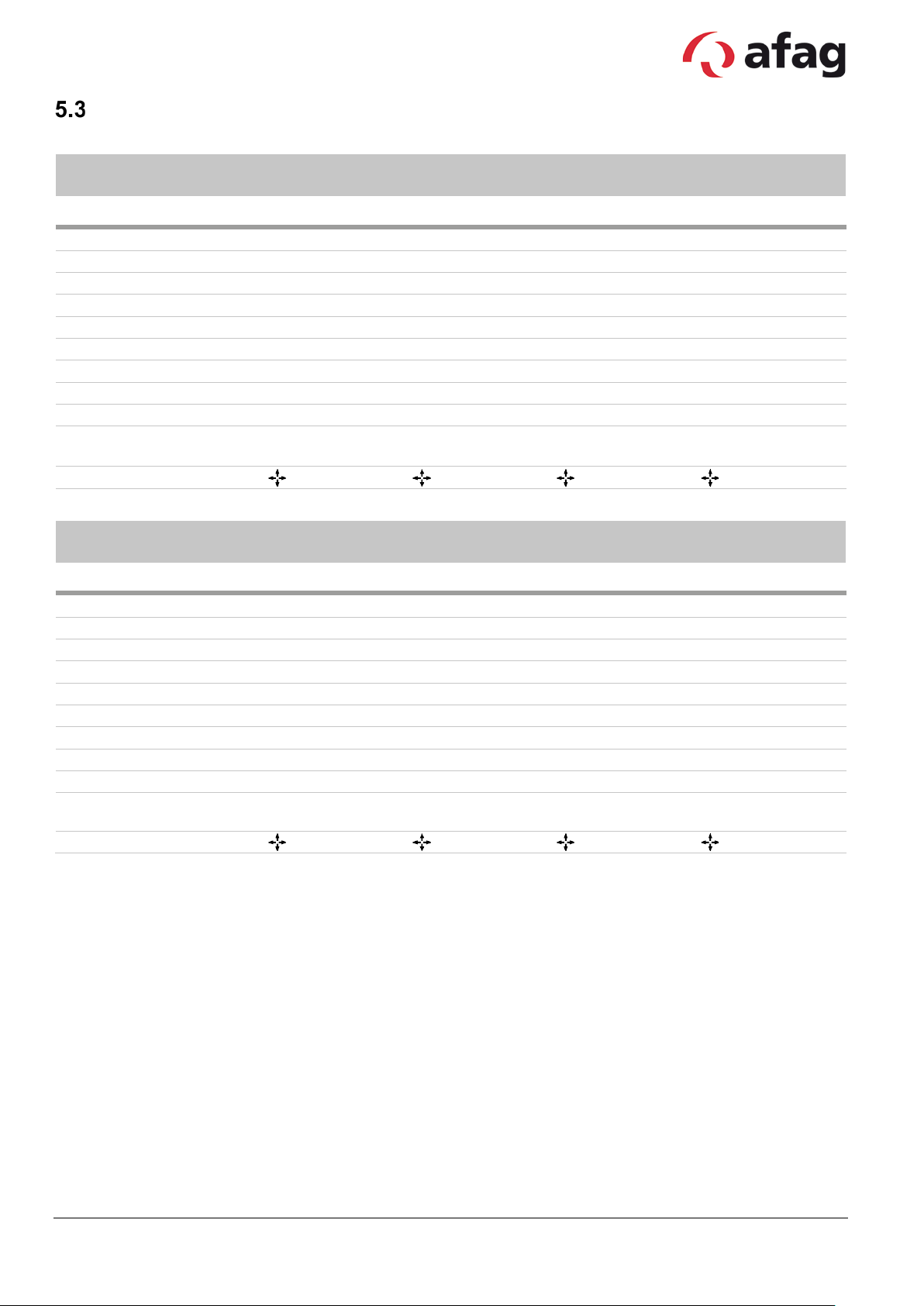

RA-40-2F

Type RA-40-2F-30-G RA-40-2F-30-W RA-40-2F-30-G-ZE RA-40-2F-30-W-ZE

Order number 50473180 50473182 50473183 50473184

Net weight 0.69 kg 0.69 kg 0.74 kg 0.74 kg

Angle of rotation ∞ ∞ ∞ ∞

Max. output torque 2.4 Nm 2.4 Nm 2.4 Nm 2.4 Nm

Ratio 30:1 30:1 30:1 30:1

Repeat accuracy +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 °

Encoder

SV-TLL ABZ,

SV-TLL ABZ,

Type RA-40-2F-50-G RA-40-2F-50-W RA-40-2F-50-G-ZE RA-40-2F-50-W-ZE

Order number 50473185 50473186 50473187 50473188

Net weight 0.69 kg 0.69 kg 0.74 kg 0.74 kg

Continuous torque 2 Nm 2 Nm 2 Nm 2 Nm

Max. output torque 4 Nm 4 Nm 4 Nm 4 Nm

Ratio 50:1 50:1 50:1 50:1

Repeat accuracy +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 °

Encoder

SV-TLL ABZ,

SV-TLL ABZ,

The technical data pertains to Afag standard test conditions. Air purity class 5 (ISO 14644-1)

Cleanroom class: 10 000 (Federal Standard 209E )

In the article description of a rotary axis the “F” stands for fluid passages and the “E” for electrical feed-through. There are two

version of motor plugs. A „G“ in the article description of the rotary axis stand for a straight and the „W“ for an angular plug. Also

see order key for RA-40.

Subject to change. 8 Ver s. 1.1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

A

141 mm

159 mm

Type RA-40-2F RA-40-2F (ZE)

Subject to change. 9 Ver s. 1.1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Max. rotational speed

280 rpm

280 rpm

280 rpm

280 rpm

Fluid passages

2 2 2 2 Continuous torque

1.2 Nm

1.2 Nm

1.2 Nm

1.2 Nm

61440 Inc/U

61440 Inc/U

Mounting position

Angle of rotation

∞ ∞ ∞ ∞ Max. rotational speed

140 rpm

140 rpm

140 rpm

140 rpm

Fluid passages

2 2 2

2

102400 Inc/U

102400 Inc/U

Mounting position

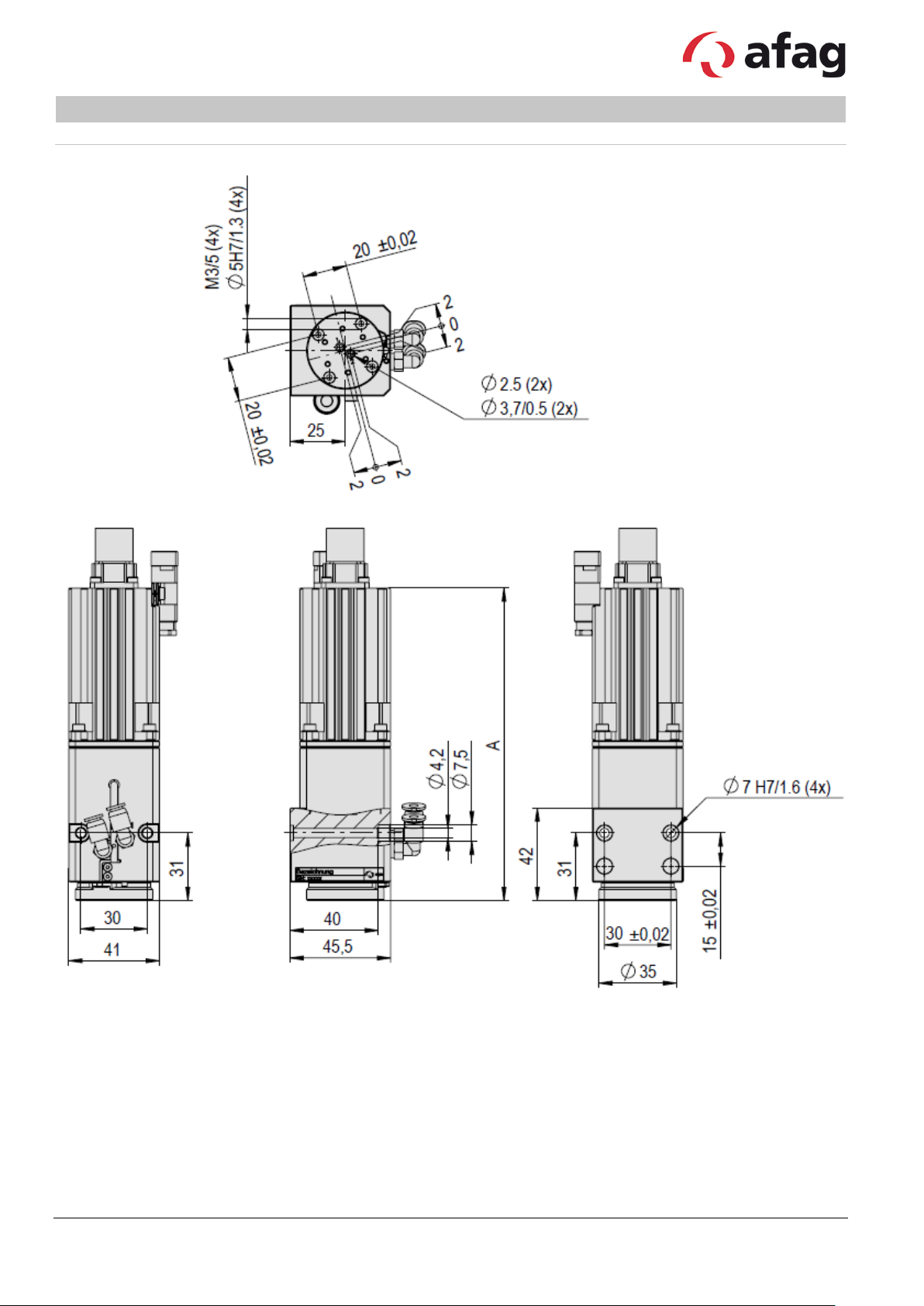

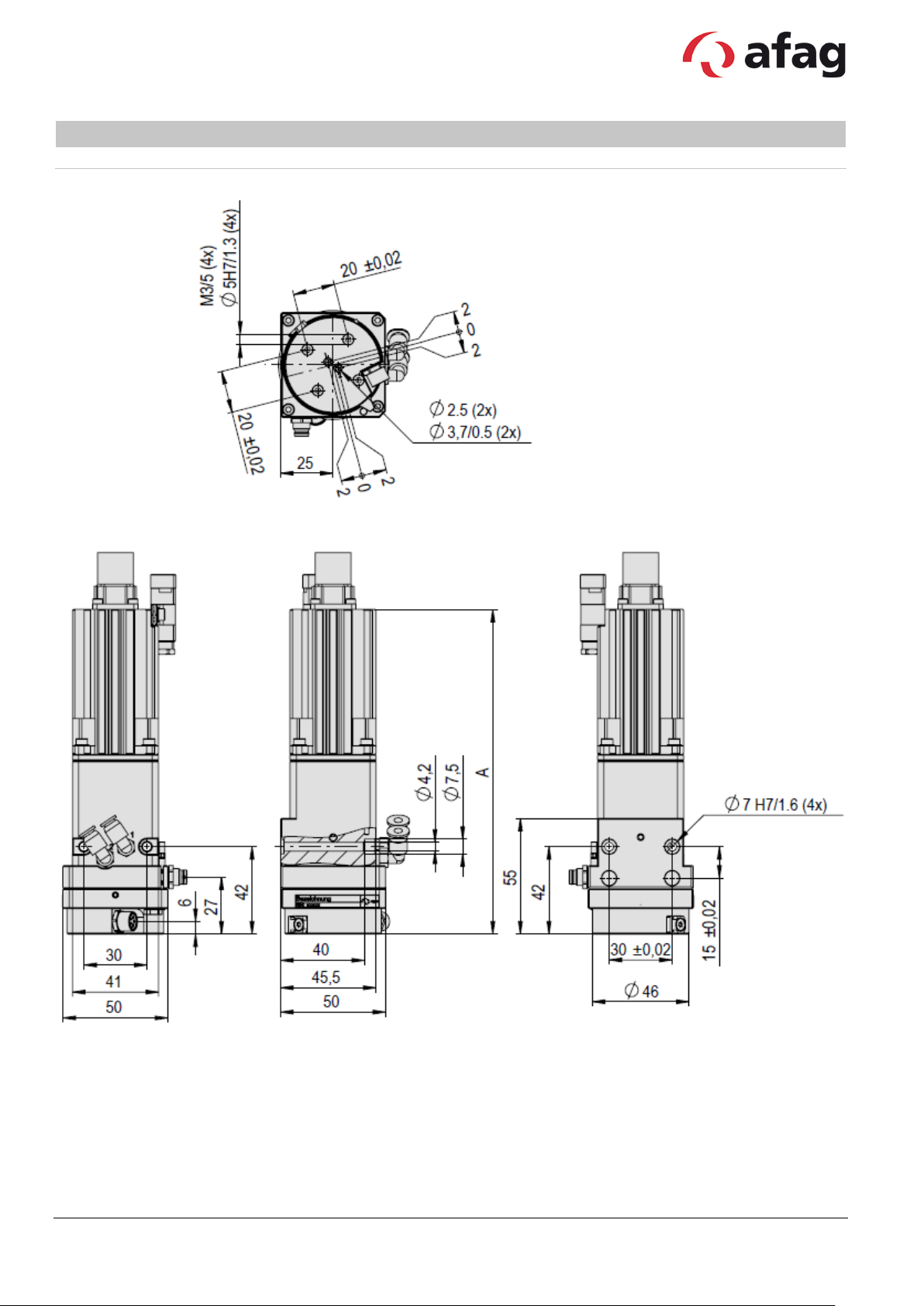

RA-40-4F

Type RA-40-4F-30-G RA-40-4F-30-W RA-40-4F-30-G-ZE RA-40-4F-30-W-ZE

Order number 50473189 50473190 50473191 50473192

Net weight 0.74 kg 0.74 kg 0.79 kg 0.79 kg

Angle of rotation ∞ ∞ ∞ ∞

Max. output torque 2.4 Nm 2.4 Nm 2.4 Nm 2.4 Nm

Ratio 30:1 30:1 30:1 30:1

Repeat accuracy +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 °

Encoder

SV-TLL ABZ,

SV-TLL ABZ,

Type RA-40-4F-50-G RA-40-4F-50-W RA-40-4F-50-G-ZE RA-40-4F-50-W-ZE

Order number 50473193 50473194 50473195 50473196

Net weight 0.74 kg 0.74 kg 0.79 kg 0.79 kg

Continuous torque 2 Nm 2 Nm 2 Nm 2 Nm

Max. output torque 4 Nm 4 Nm 4 Nm 4 Nm

Ratio 50:1 50:1 50:1 50:1

Repeat accuracy +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 °

Encoder

SV-TLL ABZ,

SV-TLL ABZ,

The technical data pertains to Afag standard test conditions. Air purity class 5 (ISO 14644-1)

Cleanroom class: 10 000 (Federal Standard 209E )

In the article description of a rotary axis the “F” stands for fluid passages and the “E” for electrical feed-through. There are two

version of motor plugs. A „G“ in the article description of the rotary axis stand for a straight and the „W“ for an angular plug. Also

see order key for RA-40.

Subject to change. 10 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

A

151 mm

169 mm

Type RA-40-4F RA-40-4F (ZE)

Subject to change. 11 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

30-G-ZE

30-W-ZE

Net weight

0.84 kg

0.84 kg

0.89 kg

0.89 kg

Angle of rotation

∞ ∞ ∞

∞

Max. rotational speed

280 rpm

280 rpm

280 rpm

280 rpm

Elektrische Durchführungen

5 x 2 A

5 x 2 A

5 x 2 A

5 x 2 A

Repeat accuracy

+/- 0.0017 °

+/- 0.0017 °

+/- 0.0017 °

+/- 0.0017 °

61440 Inc/U

61440 Inc/U

Mounting position

50-G-ZE

50-W-ZE

Net weight

0.84 kg

0.84 kg

0.89 kg

0.89 kg

Angle of rotation

∞ ∞ ∞

∞

Continuous torque

2 Nm

2 Nm

2 Nm

2 Nm

Max. output torque

4 Nm

4 Nm

4 Nm

4 Nm

Ratio

50:1

50:1

50:1

50:1

102400 Inc/U

102400 Inc/U

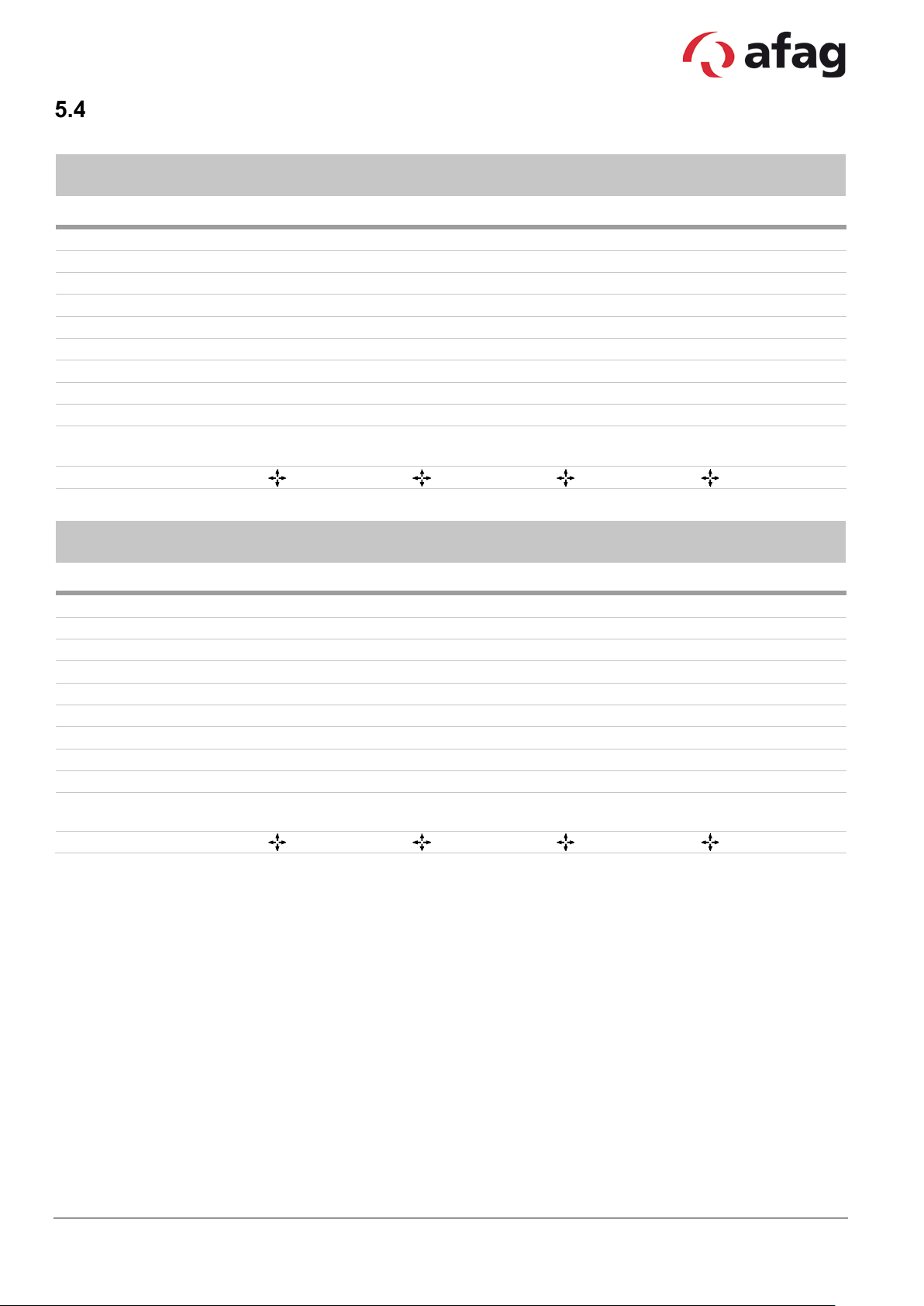

RA-40-2F-5E

Type RA-40-2F-5E-30-G RA-40-2F-5E-30-W RA-40-2F-5E-

Order number 50473197 50473198 50473200 50473201

Fluid passages 2 2 2 2

Continuous torque 1.2 Nm 1.2 Nm 1.2 Nm 1.2 Nm

Max. output torque 2.4 Nm 2.4 Nm 2.4 Nm 2.4 Nm

Ratio 30:1 30:1 30:1 30:1

RA-40-2F-5E-

Encoder

SV-TLL ABZ,

Type RA-40-2F-5E-50-G RA-40-2F-5E-50-W RA-40-2F-5E-

SV-TLL ABZ,

RA-40-2F-5E-

Order number 50473202 50473203 50473204 50473205

Max. rotational speed 140 rpm 140 rpm 140 rpm 140 rpm

Elektrische Durchführungen 5 x 2 A 5 x 2 A 5 x 2 A 5 x 2 A

Fluid passages 2 2 2 2

Repeat accuracy +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 °

Encoder

SV-TLL ABZ,

SV-TLL ABZ,

Mounting position

The technical data pertains to Afag standard test conditions. Air purity class 5 (ISO 14644-1)

Cleanroom class: 10 000 (Federal Standard 209E )

In the article description of a rotary axis the “F” stands for fluid passages and the “E” for electrical feed-through. There are two

version of motor plugs. A „G“ in the article description of the rotary axis stand for a straight and the „W“ for an angular plug. Also

see order key for RA-40.

Subject to change. 12 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

A

155 mm

173 mm

Type RA-40-2F-5E RA-40-2F-5E (ZE)

Subject to change. 13 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

30-G-ZE

30-W-ZE

Net weight

0.84 kg

0.84 kg

0.89 kg

0.89 kg

Angle of rotation

∞ ∞ ∞

∞

Max. rotational speed

280 rpm

280 rpm

280 rpm

280 rpm

Elektrische Durchführungen

5 x 2 A

5 x 2 A

5 x 2 A

5 x 2 A

Repeat accuracy

+/- 0.0017 °

+/- 0.0017 °

+/- 0.0017 °

+/- 0.0017 °

61440 Inc/U

61440 Inc/U

Mounting position

50-G-ZE

50-W-ZE

Net weight

0.84 kg

0.84 kg

0.89 kg

0.89 kg

Angle of rotation

∞ ∞ ∞

∞

Continuous torque

2 Nm

2 Nm

2 Nm

2 Nm

Max. output torque

4 Nm

4 Nm

4 Nm

4 Nm

Ratio

50:1

50:1

50:1

50:1

102400 Inc/U

102400 Inc/U

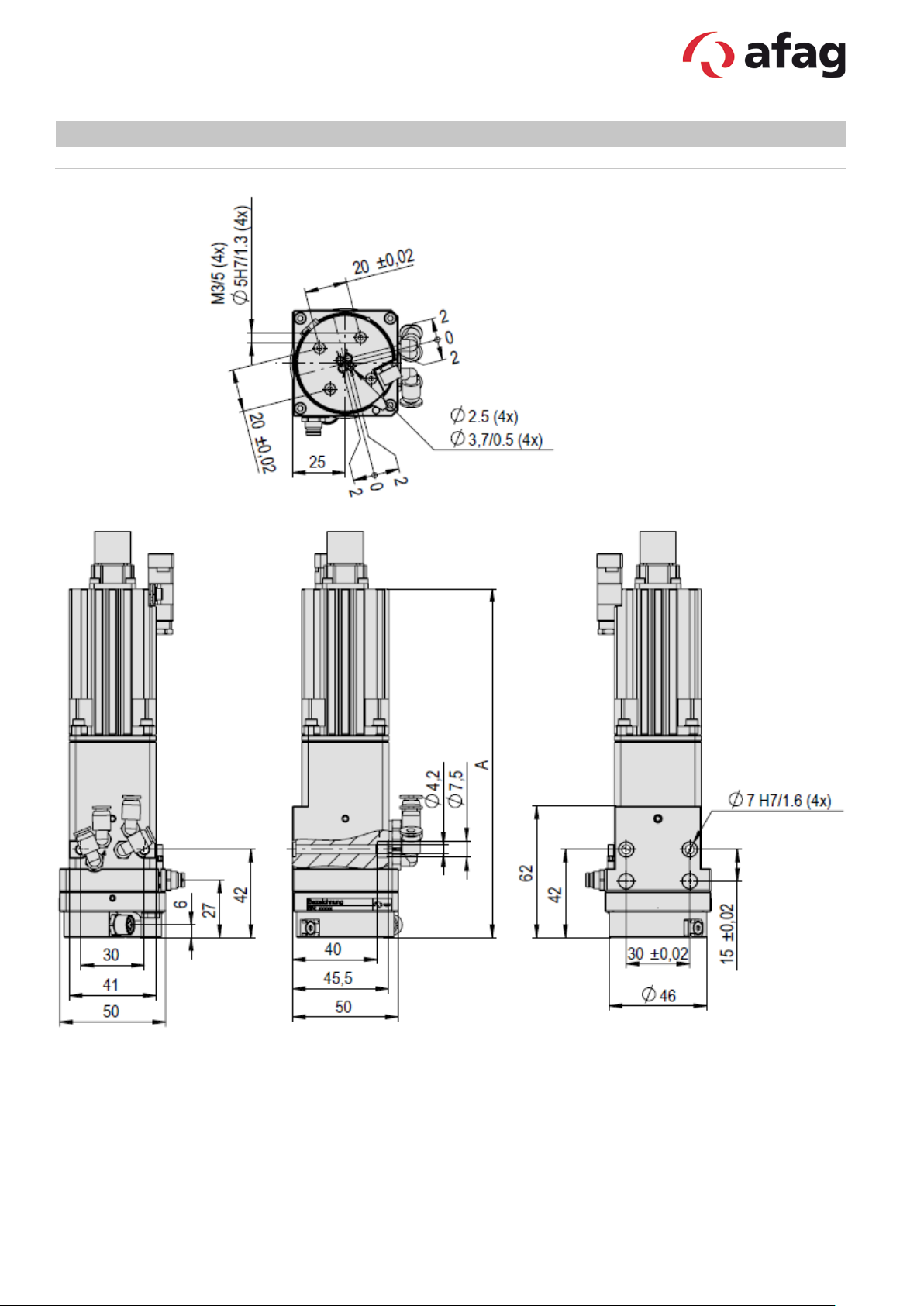

RA-40-4F-5E

Type RA-40-4F-5E-30-G RA-40-4F-5E-30-W RA-40-4F-5E-

Order number 50473206 50473207 50473208 50473209

Fluid passages 4 4 4 4

Continuous torque 1.2 Nm 1.2 Nm 1.2 Nm 1.2 Nm

Max. output torque 2.4 Nm 2.4 Nm 2.4 Nm 2.4 Nm

Ratio 30:1 30:1 30:1 30:1

RA-40-4F-5E-

Encoder

SV-TLL ABZ,

Type RA-40-4F-5E-50-G RA-40-4F-5E-50-W RA-40-4F-5E-

SV-TLL ABZ,

RA-40-4F-5E-

Order number 50473210 50473211 50473212 50473213

Max. rotational speed 140 rpm 140 rpm 140 rpm 140 rpm

Elektrische Durchführungen 5 x 2 A 5 x 2 A 5 x 2 A 5 x 2 A

Fluid passages 4 4 4 4

Repeat accuracy +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 ° +/- 0.0017 °

Encoder

SV-TLL ABZ,

SV-TLL ABZ,

Mounting position

The technical data pertains to Afag standard test conditions. Air purity class 5 (ISO 14644-1)

Cleanroom class: 10 000 (Federal Standard 209E)

In the article description of a rotary axis the “F” stands for fluid passages and the “E” for electrical feed-through. There are two

version of motor plugs. A „G“ in the article description of the rotary axis stand for a straight and the „W“ for an angular plug. Also

see order key for RA-40.

Subject to change. 14 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

A

165 mm

183 mm

Type RA-40-4F-5E RA-40-4F-5E (ZE)

Subject to change. 15 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Type

Recommended installation material

RA-40

• 2/4x O-ring 2.5x0.62 NBR70

2x centering bushings Ø5x2.5

!

!

6 Installation

Caution

The pick and place EPS device is a precision-mechanical unit. T her efore, you must

ensure the necessary care and c leanliness during transportation, installation and

adjustment.

Caution

Only original LinMot ca bl es may be used for the operation of the electric axes.

Otherwise, damage or faults may occur.

The installation material is dependent on the module utilised as well as the adaptors and weigh ts.

• 2x centering bushings Ø7x3

•

Subject to change. 16 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Technical data

SPH500-7207

SPH1013-7214

NT01-72/1500Multi

Type

Primary switched-mode power supply

Primary voltage

90-132 VAC, 50/60 Hz oder

(automatic switching)

3x340 – 550 VAC, 50/60 Hz

3x230/400/480 VAC, 50/60 Hz

Secondary voltage

54-80 VDC variable

54-80 VDC variable

72 VDC

Output power

480 W

960 W

1500 W

Power consumtion

600 W

1100 W

1500 W

Power loss max.

54 W

91 W

110 W

Peak output current (>0.5 s)

10 A

27 A

50 A

Nominal current

240 VAC = 4.5 A,

120 VAC = 9 A

3x230 VAC = 3.5 A, 400 VAC = 2 A,

480 VAC = 1.7 A

Efficiency

88%

91,5%

85% (at rated power)

Protection type

IP 20

IP 20

IP 20

Operating temperature

-25…70 °C

-25…70 °C

0…40 °C

Mass

1 kg

2 kg

17 kg

Dimension (HxWxD)

125x62x121 mm

230x66x177 mm

275x280x165 mm

External fuse

6 A (C,D,K Type)

16 - 32 A (C,D,K Type)

8 A (C,D,K Type)

7 Connection

Power supplies

Brief overview of the technical data of the power supplies. More detailed inf ormation can be found in

the operating manual of the power supply.

Subject to change. 17 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

180-264 VAC, 50/60 Hz

380 VAC = 3.1 A

Technical data

C1150-EC-XC

C1150-PN-XC

C1150-GP-XC

Logic power supply

24 VDC

24 VDC

24 VDC

Motor voltage supply

24 - 72 VDC

24 - 72 VDC

24 - 72 VDC

Max. output current motor (at 72 V)

25 A

25 A

25 A

Bus system int erfaces

EtherCat

Digitale I/Os

Profinet

Digitale I/Os

CANopen

Max. power consumption

30 W

30 W

30 W

Protection type

IP 20

IP 20

IP 20

Operating temperature

0 - 40 °C

0 - 40 °C

0 - 40 °C

Mass

1.5 kg

1.5 kg

1.5 kg

Distance between controllers

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

Fuse 72 V supply

16 AT

16 AT

16 AT

Fuse 24 V supply

3 AT

3 AT

3 AT

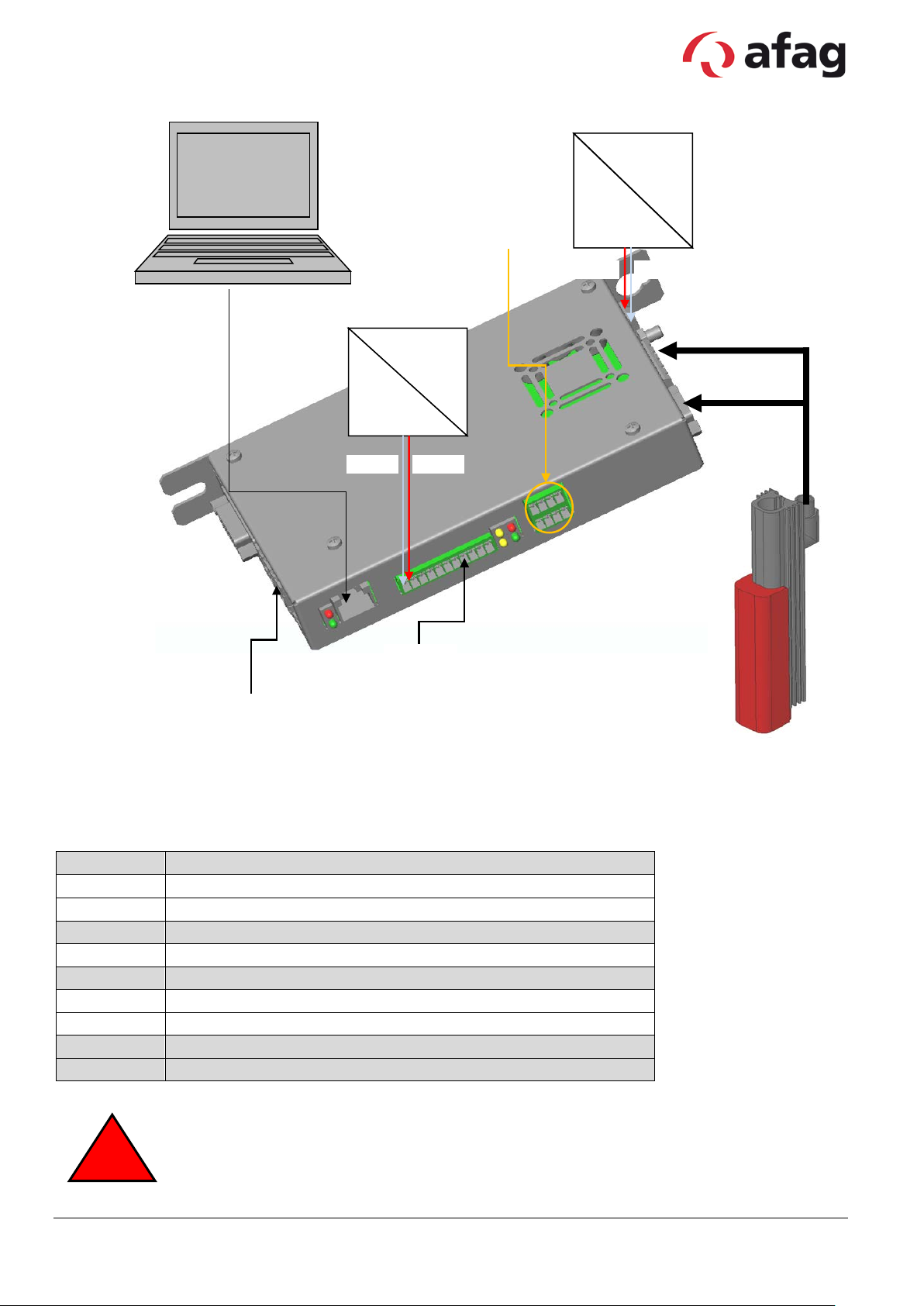

Controller C11x0

Brief overview of the interfaces of the controller C11x0. More detailed information can be found in the

operating instructions of the controller.

The controllers are preconfigured so that software modifications are generally not necessary.

modification is nec ess ary, the Li nMot-Talk 1100 so ftw are can be d ow nloaded free o f charge from

the website www.linmot.com.

If a

CANopen

DeviceNet

RS485/232

CANopen

DeviceNet

RS485/232

DeviceNet

RS485/232

Digitale I/Os

Subject to change. 18 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Connection

Description

X1 PWR+

Motor voltage supply +72 VDC

X1 PGND

Motor voltage supply GND

X2

Motorphasen

X3

Motor signals

X33

Safety relay (optional o n -S 1 vers ion)

X4.8

/Quickstop

X4.7

Reference sensor (optional)

X4.2

Logic power supply +24 VD C

X4.1

Logic power supply GND

!

2x RT Ethernet

safety relays

/Quickstop

mains

GND

+24VD

RS232

mains

PWR+

PGND

motor cable

external position

72 VDC

mains

24 VDC

mains

measuring system

(optional)

Danger when the safety door is open

The "safety relay" input (X33) on the controller C11xx must be deactivated or the power

pack (72 V) must be reliably disc onnected from the power supply on the primary side.

Subject to change. 19 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Technical data

C1250-EC-XC

C1250-IP-XC

C1250-PL-XC

C1250-PN-XC

Logic power supply

24 VDC

24 VDC

24 VDC

24 VDC

Motor voltage supply

24 - 72 VDC

24 - 72 VDC

24 - 72 VDC

24 - 72 VDC

Max. output current motor

(at 72 V)

25 A

25 A

25 A

25 A

Bus system int erfaces

EtherCat

Master Encoder

Ethernet IP

Master Encoder

PowerLink

Master Encoder

Profinet

Master Encoder

Max. power consumption

30 W

30 W

30 W

30 W

Protection type

IP 20

IP 20

IP 20

IP 20

Operating temperature

0 - 40 °C

0 - 40 °C

0 - 40 °C

0 - 40 °C

Mass

0.7 kg

0.7 kg

0.7 kg

0.7 kg

Distance between

controllers

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

Fuse 72 V supply

16 AT

16 AT

16 AT

16 AT

Fuse 24 V supply

3 AT

3 AT

3 AT

3 AT Technical data

C1250-SC-XC

C1250-SE-XC

Logic power supply

24 VDC

24 VDC

Motor voltage supply

24 - 72 VDC

24 - 72 VDC

Max. output current motor

(at 72 V)

25 A

25 A

Bus system int erfaces

Sercos III

Master Encoder

Sercos over EtherCAT

Master Encoder

Max.

30 W

30 W

Protection type

IP 20

IP 20

Operating temperature

0 - 40 °C

0 - 40 °C

Mass

0.7 kg

0.7 kg

Distance between

controllers

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

Fuse 72 V supply

16 AT

16 AT

Fuse 24 V supply

3 AT

3 AT

Controller C12x0

Brief overview of the interfaces of the controller C12x0. More detailed information can be found in the

operating manual of the controller.

The controllers are preconfigured so that software modifications are generally not necessary.

modification is nec ess ary, the Li nMot-Talk 1100 so ftw are can be d ow nloaded free o f charg e from

the website www.linmot.com.

If a

CANopen

DeviceNet

RS485/232

Digitale I/Os

CANopen

DeviceNet

RS485/232

Digitale I/Os

CANopen

DeviceNet

RS485/232

Digitale I/Os

CANopen

DeviceNet

RS485/232

Digitale I/Os

CANopen

DeviceNet

RS485/232

Digitale I/Os

CANopen

DeviceNet

RS485/232

Digitale I/Os

Subject to change. 20 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Connection

Description

X1 PWR+

Motor voltage supply +72 VDC

X1 PGND

Motor voltage supply GND

X2

Motor phases

X3

Motor signals

X33

Safety relay (optional on -S1 version)

X4.8

/Quickstop

X4.7

Reference sensor (optional)

X4.2

Logic power supply +24 VD C

X4.1

Logic power supply GND

!

mains

GND

+24VD

RS232

mains

PWR+

PGND

motor cable

RT Ethernet

RT Ethernet

safety relays

/Quickstop

72 VDC

mains

24 VDC

mains

Danger when the safety door is open

The "safety relay" input (X33) on the controller C12xx must be deactivated or the power

pack (72 V) must be reliably disc onnected from the power supply on the primary side.

Subject to change. 21 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Technical data

E1230-DP-UC

E1250-EC-UC

E1250-PL-UC

E1250-SE-UC

Logic power supply

24 VDC

24 VDC

24 VDC

24 VDC

Motor voltage supply

24 - 72 VDC

24 - 72 VDC

24 - 72 VDC

24 - 72 VDC

Max. output current motor

Standard-Ausführung:

Standard-Ausführung:

Standard-Ausführung:

Standard-Ausführung:

Bus system int erfaces

Profibus

Master Encoder

EtherCat

Master Encoder

PowerLink

Master Encoder

Sercos over Ethercat

Master Encoder

Max. power consumption

30 W

30 W

30 W

30 W

Protection type

IP 20

IP 20

IP 20

IP 20

Operating temperature

0 - 40 °C

0 - 40 °C

0 - 40 °C

0 - 40 °C

Mass

1 kg

1 kg

1 kg

1 kg

Distance between

controllers

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

Fuse 72 V supply

20 AT

20 AT

20 AT

20 AT

Fuse 24 V supply

2 AT

2 AT

2 AT

2 AT Technical data

E1250-IP-UC

E1250-PN-UC

E1250-SC-UC

Logic power supply

24 VDC

24 VDC

24 VDC

Motor voltage supply

24 - 72 VDC

24 - 72 VDC

24 - 72 VDC

Max. output current motor

(at 72 V)

Standard-Ausführung:

32 A

Standard-Ausführung:

32 A

Standard-Ausführung:

32 A

Bus system int erfaces

Ethernet IP

Master Encoder

Profinet

Master Encoder

Sercos III

Master Encoder

Max. power consumption

30 W

30 W

30 W

Protection type

IP 20

IP 20

IP 20

Operating temperature

0 - 40 °C

0 - 40 °C

0 - 40 °C

Mass

1 kg

1 kg

1 kg

Distance between

controllers

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

Fuse 72 V supply

20 AT

20 AT

20 AT

Fuse 24 V supply

2 AT

2 AT

2 AT

Controller E12x0

Brief overview of the interfaces of the controller E12xx. More detailed information can be found in the

operating manual of the controller.

The controllers are preconfigured so that software modifications are generally not necessary.

modification is nec ess ary, the Li nMot-Talk 1100 so ftw are can be d ow nloaded free o f charg e from

the website www.linmot.com.

If a

(at 72 V)

32 A

CANopen

DeviceNet

RS485/232

Digitale I/Os

CANopen

DeviceNet

RS485/232

Digitale I/Os

32 A

CANopen

DeviceNet

RS485/232

Digitale I/Os

CANopen

DeviceNet

RS485/232

Digitale I/Os

32 A

CANopen

DeviceNet

RS485/232

Digitale I/Os

CANopen

DeviceNet

RS485/232

Digitale I/Os

32 A

CANopen

DeviceNet

RS485/232

Digitale I/Os

Subject to change. 22 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Connection

Description

X1 PWR+

Motor voltage supply +72 VDC

X1 PGND

Motor voltage supply GND

X2

Motor phases

X3

Motor signals

X4.12

Safety Voltage Enable

X4.11

/Quickstop

X4.7

Reference sensor (optional)

X4.2

Logikspannungsversorgung +24 VDC

X4.1

Logic power supply GND

!

RS232

analogue

RT Ethernet Out

RT Ethernet In

mains

PWR+

PGND

mains

GND

+24VD

ID setting

of the controller

in hex

safety voltage

e

motor cable

/Quickstop

CANopen

RS485

Profibus DP

(nur E1130DP)

master

e

Ethernet

24 VDC

mains

72 VDC

mains

ncoder

nable

Danger when the safety door is open

For the controller E12xx, the power pack must be reliably disconnected from the power

supply on the primary side.

Subject to change. 23 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Technical data

E1100-GP

E1130-DP

Logic power supply

24 VDC

24 VDC

Motor voltage supply

24 - 72 VDC

24 - 72 VDC

Max. output current motor (at 72 V)

Standard- Ausführung: 8 A

XC-Ausführung: 25 A

Standard- Ausführung: 8 A

XC-Ausführung: 25 A

Bussystem Schnittstellen

CANopen

9 digitale Ein-/Ausgänge

Profibus

Master Encoder

Max. power consumption

30 W

30 W

Protection type

IP 20

IP 20

Operating temperature

0 - 40 °C

0 - 40 °C

Mass

1 kg

1 kg

Distance between controllers

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

Fuse 72 V supply

10 AT (bei Standard-

16 AT (bei HC/XC-controller)

10 AT (bei Standard-

16 AT (bei HC/XC-controller)

Fuse 24 V supply

2 AT

2 AT

Controller E11x0

Brief overview of the interfaces of the controller E11xx. More detailed information can be found in the

operating manual of the controller.

The controllers are preconfigured so that software modifications are generally not necessary.

modification is nec ess ary, the Li nMot-Talk 1100 so ftw are can be d ow nloaded free o f charge from

the website www.linmot.com.

If a

HC-Ausführung: 15 A

DeviceNet

RS485/232

16 digitale Eingänge

8 digitale Ausgänge

controller)

HC-Ausführung: 15 A

CANopen

DeviceNet

RS485/232

Digitale I/Os

controller)

Subject to change. 24 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Connection

Description

X1 PWR+

Motor voltage supply +72 VDC

X1 PGND

Motor voltage supply GND

X2

Motor phases (optional bei HC oder XC Reglern)

X3

Motor signals

X6

Digitale IO-Schnittst elle (nur E1100-GP, nicht im Bild)

X4.12

Safety Voltage Enable (! !! nicht bei E1100-GP !!!)

X4.11

/Quickstop

X4.7

Reference sensor (optional)

X4.2

Logic power supply +24 VD C

X4.1

Logic power supply GND

!

mains

PWR+

PGND

mains

GND

+24VD

RS232

ID setting

of the controller

Profibus DP

(nur E1130DP)

CANopen

RS485

master

e

motor cable

safety voltage

enable

(!!! not for

E1100

/Quickstop

72 VDC

mains

24 VDC

mains

in hex

ncoder

-GP !!!)

Gefahr bei geöffneter Schutztür

Beim Regler E11x0 muss das Leistungsnetzteil (72V) primärseitig sicher getrennt

werden.

Subject to change. 25 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Technical data

B1100-PP

B1100-GP

Logic power supply

24 VDC

24 VDC

Motor voltage supply

24 - 72 VDC

24 - 72 VDC

Max. output current motor (at 72 V)

Standard- Ausführung: 8 A

XC-Ausführung: 25 A

Standard- Ausführung: 8 A

XC-Ausführung: 25 A

Bussystem Schnittstellen

6 digitale Eingänge

CANopen

6 digitale Ausgänge

Max. power c onsumption

30 W

30 W

Protection type

IP 20

IP 20

Operating temperature

0 - 40 °C

0 - 40 °C

Mass

0.7 kg

0.7 kg

Distance between controllers

20 mm left/right

50 mm below/above

20 mm left/right

50 mm below/above

Fuse 72 V supply

10 AT (bei Standard-

10 AT (bei Standard-

Fuse 24 V supply

2 AT

2 AT

Controller B1100

Brief overview of the interfaces of the controller B1100. More detailed information can be found in the

operating manual of the controller.

The controllers are preconfigured so that software modifications are generally not necessary.

modification is nec ess ary, the Li nMot-Talk 1100 so ftw are can be d ow nloaded free o f charg e from

the website www.linmot.com.

If a

HC-Ausführung: 15 A

6 digitale Ausgänge

(bis zu 4 Positionen)

controller)

16 AT (bei HC/XC-controller)

HC-Ausführung: 15 A

DeviceNet

RS485/232

6 digitale Eingänge

controller)

16 AT (bei HC/XC-controller)

Subject to change. 26 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Connection

Description

X1 PWR+

Motor voltage supply +72 VDC

X1 PGND

Motor voltage supply GND

X2

Motor phases (optional bei HC oder XC Reglern)

X3

Motor signals

X14.14

/Quickstop

X14.2

Reference sensor (optional)

X14.25

Logic power supply +24 VDC

X14.13

Logic power supply GND

!

RS232

CANopen

RS485

24VD

+24VDC

GND

/Quickstop

motor cable

PWR+

PGND

mains

72 VDC

mains

24 VDC

mains

Danger when the safety door is open

For the controller B1100, the power pack (72V) must be reliably disconnected from the

power supply on the primary side.

Subject to change. 27 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Connector combinations

Connector on the axis

Connector on the controller

R connector:

D connector:

C connector:

W connector:

Motor conne c t or

Application:

Application:

- Electro slides ES20

- Portal axis PEL20

- Rotary axis SE20

- Electro slides ES30

- Portal axis PEL30

- Portal axis PDL30

- Portal axis PDL40

- Portal axis PDL40-HC

- Rotary axis SE30

Application:

- Controller B1100 standard

- Controller E11xx standard

Application:

- Controller B1100 standard, HC u nd XC

- Controller E11xx standard, HC und XC

- Controller E12xx UC

Y connector:

Application:

- Controller C11xx XC

- Controller C12xx XC

Subject to change. 28 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

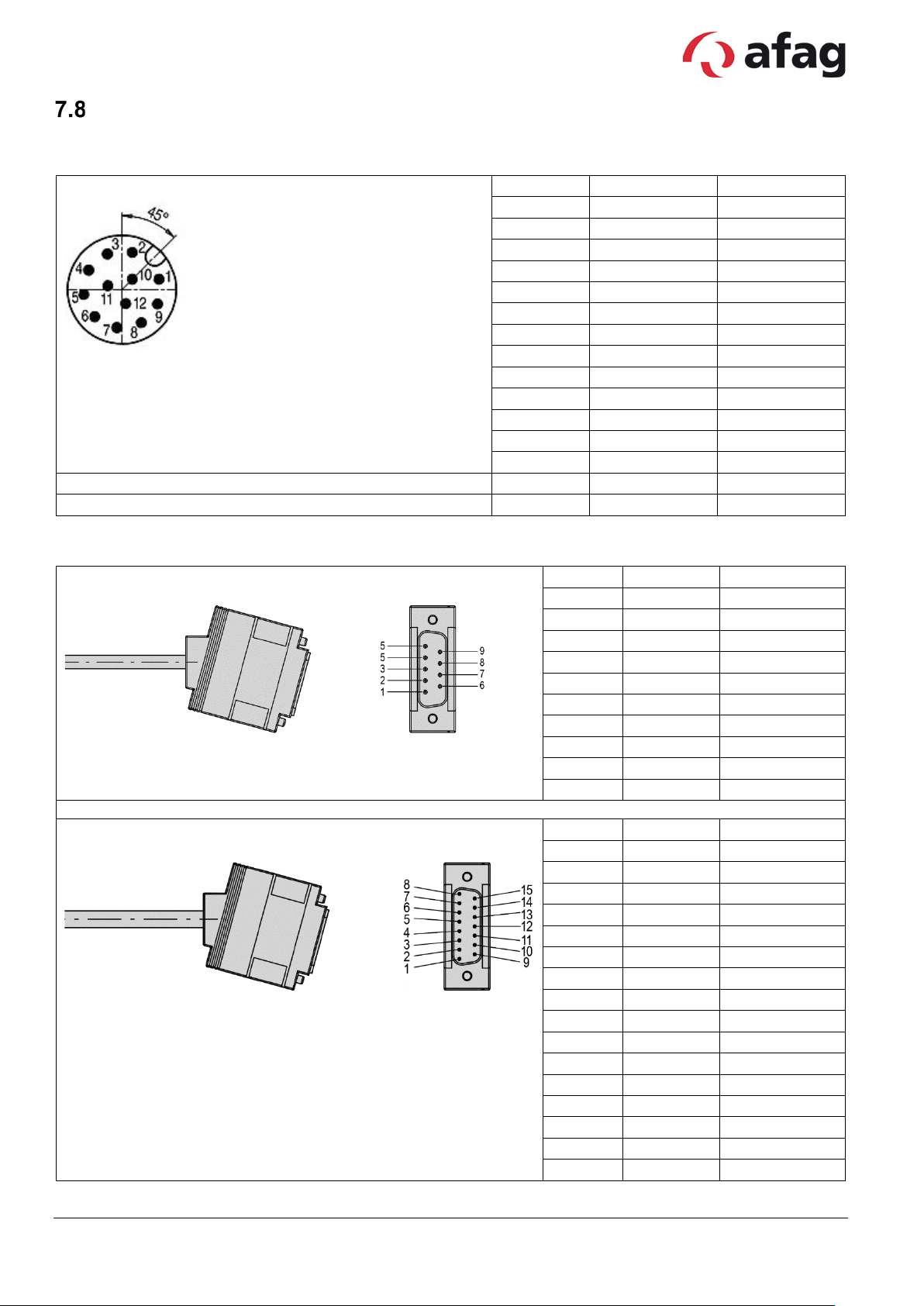

Cable connector S713 12pole M12x1

PIN

Function

Cable

1

open

-

2

Z+

grey 10

3

Z-

grey 9

4

open

-

5

+5V

grey 2

6

A-

grey 5

7

A+

grey 6

8

B-

grey 7

9

B+

grey 8

10

open

-

11

open

-

12

GND

grey 3

housing

screen

screen

NC

red 1

NC

grey4

Controller E11xx line

PIN

Function

Cable

1

+5 V

pink

2

A- / sin-

yellow

3

B- / cos-

grey

4

Z-

white

5

GND

red/blue

6

A+ / sin+

black

7

B+ / cos+

red

8

Z+

blue

9

open

-

housing

screen

screen

Controller C1xx0, B1100 und E12x0 line

PIN

Function

Cable

1

+5 V

pink

2

A- / sin-

yellow

3

B- / cos-

grey

4

Z- / Data -

white

5

GND

red/blue+purple

6

open

-

7

open

-

8

Clock-

green

9

A+ / sin+

black

10

B+ / cos+

red

11

Z+ / Data+

blue

12

open

-

13

open

-

14

open

-

15

Clock+

grey/pink

housing

screen

screen

Plug c onfi guration encoder

7.8.1 Round connector on the module

7.8.2 Encoder plug configuration on the controller

Subject to change. 29 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

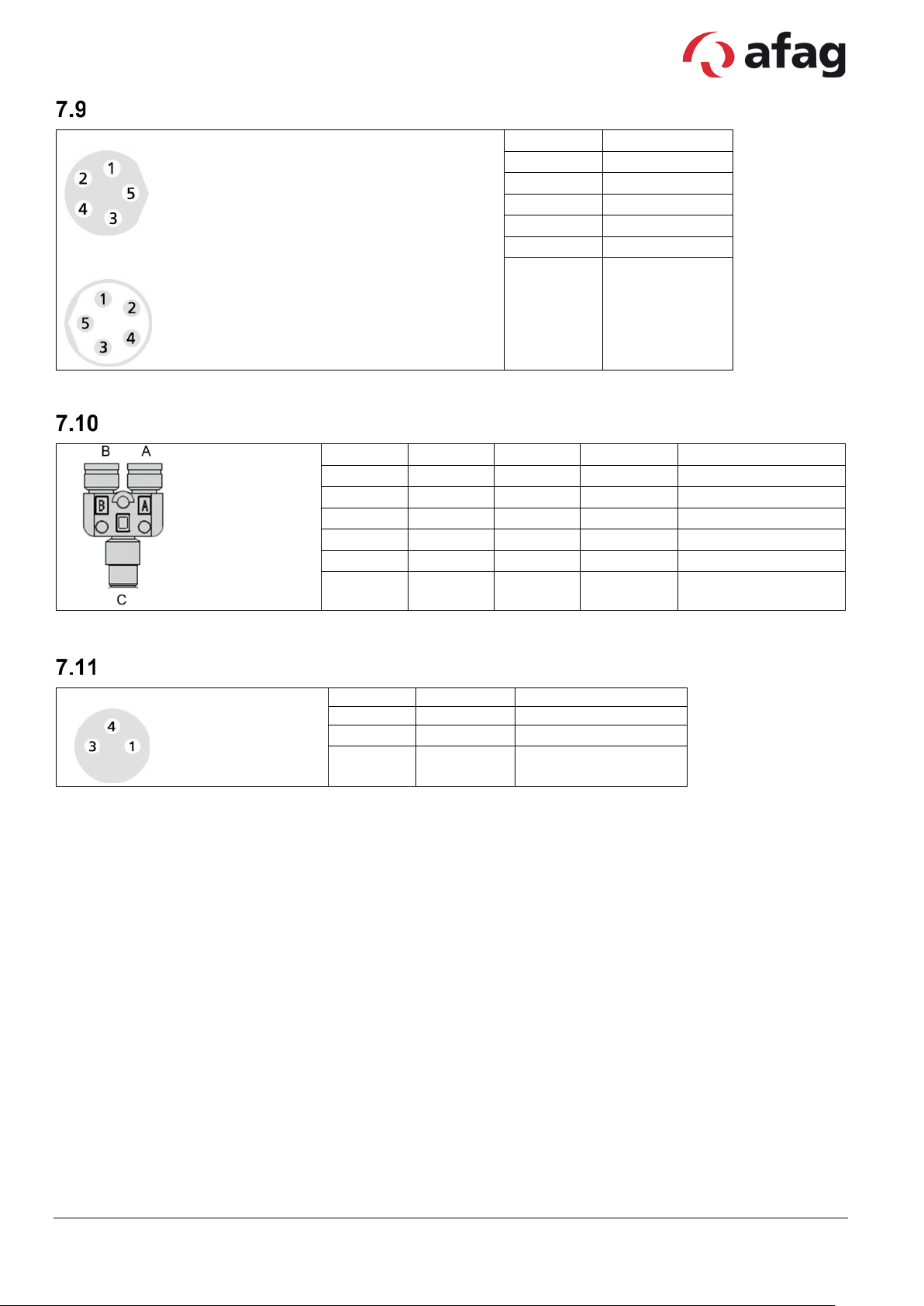

Socket 5pole M8x1

PIN

Cable

1

brown

2

white

3

blue

4

black

5

grey

housing

screen

PIN C

PIN A

PIN B

Function

Cable

1 1 1

24VDC

brown

2 4 -

Signal A

white

3 3 3

GND

blue

4 - 4

Signal B

black

5 - -

NC

grey

housing

screen

Connector 3pole M8x1

PIN A

Function

Cable

1

24VDC

brown

4

Signal

white

3

GND

blue

Electrical feed-through / Proximity sw itch cable-R11

Connector 5pole M8x1

Y-di s t ributor plug R12

Reference sensor

Subject to change. 30 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Max.

[m/s]

Max.

[m/s2]

Max.

[m/s2]

Std

[m/s]

Std

[m/s2]

Std

[m/s2]

Max.

[mm]

Max

[mm]

RA-40-x-50-x

0.84

30

30

0.84

20

20 ∞ ∞

RA-40-x-30-x

1.7

20

20

1.7

15

15 ∞ ∞

!

!

8 6 Commissioning

All information in the operating manuals of the individual modules must also be

observed.

Setting speeds of the electric axes

The speeds of the electric axes are generally set by the higher-ranking controller.

Example programs are availa bl e for a large number of comm on controllers. This allows the

maximum speed, accelerat ion and target position to be set.

CD provided upon delivery, or you can download them at

https://www.afag.com/de/service/support-tools/linmot.html.

These travel profiles ar e s tored in the controller when using the B1100-PP or E1100-GP controller

with EasyStep firm ware.

Caution

An excessively high speed or acceleration can cause damage to the device or the

periphery.

The following tables are intended as references for t he par ameters (speed, acceleration,

deceleration).

Please note that you do not have to adapt the standard parameters for your application.

They are heavily dependent on the load mass and the mechanical configuration.

These programs are available on the

Overview electrical axes

Type

Subject to change. 31 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

speed

accel.

decel.

speed

accel.

decel.

Pos.

Pos.

!

Teaching of pos itions on electric axes

The drive must be referenced first. Then you have the following possibilities:

Possibility 1 – move manually:

Move the axes into position by h and ( l ogic voltage ON, motor power OFF) and then read out values

from the controller for use in the Pick&Place movement.

Danger

For the controller B1100 or E1xxx, the power pack (72 V) must be reliably disconnected

from the power supply on the pr imary side.

With controller C1xx0 the "safety inputs" input (X33) must be deactivated or the

power pack (72 V) reliably disconnected on the primary side.

Possibility 2 – jog mode:

• Add value to or subtract value from current position

• Can be programmed with relat ive commands.

The existing module for absolute positioning can be convert ed i nto one for relative

positioning by changing one variable.

Possibility 3:

Set-up with safely reduced s peed. Please observe the manual on the safely reduced speed.

1.1 Switching distance

1.1.1 Reference sensor with electric axes

The sensor is installed parallel to the switching flag at a distance of 0.1 mm using a feeler

gauge.

Subject to change. 32 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

!

!

9 Maintenance

The EPS devices are high-performance devices with very short c ycle times. The service life of the

devices depends to a very great extent on the ambient conditions and the maintenance.

Therefore, the maintenance instructions for the individ ual modules must always be

followed.

The service and maintenance int ervals must be observed. The int er vals are based on a normal

environment. The approval of Afag Hardt GmbH must be obtained in advance if the devices are to

be operated in an environm ent with abrasive dusts or with corros ive or aggressive vapours, ga ses

or liquids.

10 Repairs

Repairs may only be carried out by Afag Hardt GmbH.

If you carry out the repair yourself, approval must be obtained in a dvance from eps GmbH.

Caution

Repairs may only be carried out by q ualified personnel.

Subject to change. 33 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Designation

Module/axis

Controller

Application

dynamic

roboter

Motor cableM21-8m-0-0-X

Motor cable-

Motor cable-

Motor cable-

Motor cable-

Motor cableM20-8m-0-2-2

Motor cableM16-8m-0-1-X

Motor cableM16-8m-0-1-1

Motor cableM16-8m-0-1-2

Motor cableM24-8m-0-2-X

Motor cableM22-8m-0-2-1

Motor cableM22-8m-0-2-2

Motor cable-

Motor cable-

Motor cable-

Motor cable

M16-8m-0-0-1

Motor cable

M16-8m-0-0-2

11 Component/replacement part lists

The replacement parts for the standard components are listed here. The ord er numb ers on our

delivery note are applicable to special components.

Overview motor cabel-designation-axes-controller-application

Designation

of producer

K05-D/R-8

KS05-D/R-8

KR05-D/R-8

K05-W/R-8

KS05-W/R-8

KR05-W/R-8

K05-Y/R-8

KS05-Y/R-8

KR05-Y/R-8

Designation

<->

<->

M21-8m-0-0-1

<->

M21-8m-0-0-2

<->

M20-8m-0-2-X

<->

M20-8m-0-2-1

<->

<->

<->

<->

of afag

ES20 SE20

ES30

RA-40

PEL20

SE30

PxL30

PxL40

C1xxx

B1100

PxL40-HP

E12xx

E11x0

installation

static installation

x x x x x X

x

x x x x x x x X

x x x x x x x x X

x x x x x x x X

x x x x x x x x X

x x x x x x x x x X

x x x x x X

x x x x x x X

x x x x x x x X

installation

K15-W/C-8

KS10-W/C-8

KR10-W/C-8

K15-Y/C-8

KS10-Y/C-8

KR10-Y/C-8

KS05-R/R-8

KR05-R/R-8

Note: X = preferred option; x = application possible

Subject to change. 34 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

<->

<->

<->

<->

M23-8m-0-1-X

<->

M17-8m-0-1-1

<->

M17-8m-0-1-2

<->

extension-

<->

extension-

x x x x x x x x X

x x x x x x x x x X

x x x x x x x x x x X

x x x x x x X

x x x x x x x X

x x x x x x x x X

x x x x x x x x X X

x x x x x x x x x x X

Designation

Module/axis

Controller

Application

dynamic

roboter

Motor cable

M23-8m-0-0-X

Motor cable

M17-8m-0-0-1

Motor cable

M17-8m-0-0-2

Designation

Art. no.

Motor cable-M16-4m-0-1-X

50463073

Motor cable-M16-6m-0-1-X

50463076

Motor cable-M16-8m-0-1-X

50463078

Motor cable-M16-4m-0-1-1

50437168

Motor cable-M16-6m-0-1-1

50437167

Motor cable-M16-8m-0-1-1

50427023

Extension-M16-2m-0-0-1

50450944

Extension-M16-4m-0-0-1

50427026

Extension-M16-6m-0-0-1

50463082

Extension-M16-2m-0-0-2

50463081

Motor cable-M17-4m-0-1-1

50437170

Motor cable-M17-6m-0-1-1

50437169

Motor cable-M17-8m-0-1-1

50427021

Extension-M17-2m-0-0-1

50463084

Extension-M17-4m-0-0-1

50427024

Extension-M17-6m-0-0-1

50463087

Extension-M17-2m-0-0-2

50463085

Extension-M17-4m-0-0-2

50463086

Motor cable-M20-4m-0-2-X

50463088

Motor cable-M20-6m-0-2-X

50463090

Motor cable-M20-8m-0-2-X

50463092

Motor cable-M20-4m-0-2-1

50463089

Motor cable-M20-6m-0-2-1

50463091

Motor cable-M20-8m-0-2-1

50463093

Designation

Art. no.

Motor cable-M21-4m-0-0-X

50463094

Motor cable-M21-6m-0-0-X

50463096

Motor cable-M21-8m-0-0-X

50463098

Motor cable-M21-4m-0-0-1

50463095

Motor cable-M21-6m-0-0-1

50463097

Motor cable-M21-8m-0-0-1

50463099

Motor cable-M22-4m-0-2-1

50463100

Motor cable-M22-6m-0-2-1

50463101

Motor cable-M22-8m-0-2-1

50463103

Motor cable-M23-4m-0-1-X

50463104

Motor cable-M23-6m-0-1-X

50463105

Motor cable-M23-8m-0-1-X

50463106

Motor cable-M24-4m-0-2-X

50463107

Motor cable-M24-6m-0-2-X

50463108

Motor cable-M24-8m-0-2-X

50463109

Designation

of producer

K15-C/C-8

KS10-C/C-8

KR10-C/C-8

Note: X = preferred opt ion; x = application possible

<->

<->

<->

extension-

extension-

extension-

Designation

of Afag

ES20 SE20

x x x x x x x x x X

x x x x x x x x x x X

x x x x x x x x x x x X

Motor c a ble

installation

ES30

RA-40

PEL20

SE30

PxL30

PxL40

C1xxx

PxL40-HP

E11xx

B1100

E12xx

static installation

installation

Subject to change. 35 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Bezeichnung

Art. Nr.

Encoder cable-G18-10m-0-0-1

50468310

Encoder cable-G18-10m-90-0-1

50468311

Extension-G18-2m-0-0-1

50468312

Extension-G18-5m-0-0-1

50468313

Encoder cable -G19-10m-0-0-1

50468314

Encoder cable -G19-10m-90-0-1

50468315

Designation

Art. no.

Controller B1100-GP

für CANopen, RS485, Digital IO

Controller B1100-GP-HC

für CANopen, RS485, Digital IO

16080027

Controller B1100-GP-XC

für CANopen, RS485, Digital IO

16080230

Controller B1100-PP

für Digital IO

16080231

Controller B1100-PP-HC

für Digital IO

16080232

Controller B1100-PP-XC

für Digital IO

16080233

Controller E1100-GP

für CANopen, RS 485, Digital IO

50465788

Controller E1100-GP-HC

für CANopen, RS 485, Digital IO

50465790

Controller E1100-GP-XC

für CANopen, RS 485, Digital IO

50465791

Controller E1100-RS

für RS485

16080016

Controller E1100-RS-HC

für RS485

16080014

Controller E1100-RS-XC

für RS485

16080234

Controller E1130-DP

für Profibus DP

50465761

Controller E1130-DP-HC

für Profibus DP

16080021

Controller E1130-DP-XC

für Profibus DP

Controller E1250-EC

für EtherCAT

16080243

Controller E1250-PL

für PowerLink

50465787

Controller C1250-SE-XC-1S

für Sercos over EtherCAT

Controller C1250-SC-XC-1S

für Sercos III

16080417

Controller C1250-PN-XC-1S

für Profinet

16080415

Controller C1250-PL-XC-1S

für PowerLink

Controller C1250-PD-XC-1S

für Profidrivet

16080763

Controller C1250-LU-XC-1S

für LinUDP

16080741

Controller C1250-IP-XC-1S

für Ethernet IP

16080411

Controller C1250-EC-XC-1S

für EtherCat

16080405

Controller C1200-GP-XC-1S

für General Purpose

16080407

Controller C1150-SE-XC-1S

für Sercos over EtherCAT

16080768

Controller C1150-PN-XC-1S

für Profinet

16080429

Controller C1150-EC-XC-1S

für EtherCat

16080434

Controller C1100-GP-XC-1S

für CANopen

16080432

Encoder

Controller

16080221

50465786

16080409

16080413

Subject to change. 36 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

12 Disposal instructions

Products

• Products that are predominantly made out of metal (axes, modules, adaptor plates etc.)

must be disposed of in accordance with the national laws of metal recycling.

• Electronic products (controllers, etc.) must be disposed of in accordance with the national

laws of electronic scrap.

Packaging

Cardboard, paper or PE film are predominantly used as packaging material.

These are materials that can be used in global recycling processes.

If the packaging is returned to us free domicile, Afag Hardt will take it back for free and dispose

of it accordingly.

Subject to change. 37 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Installation manual

the following conditions m ust be satisfied so that it can be assembled together with other parts to

Ins tallation may only be carried out by q ualified specialist personnel.

13 Installation manual in accordance with Appendix VI (EC-RL

2006/42/EC)

in accordance with Appendix VI

(EC-RL 2006/42/EC)

For the installation of the partly completed

machinery

form a complete machine cor rectly and without endangering the health and safety of persons:

Please observe the safety information in the risk assessment

Read, understand and observe the whole operating manual

RA-40

Subject to change. 38 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Installation declaration

meet the following basic r equi r ements of the machinery directi ve 2006/42/EC:

isions of the electrical equipment

The manufacturer commits to electronically submitting these special documents to individual state

14 Installation declaration for partly completed machinery (EC-RL

2006/42/EC)

for partly completed machinery

(EC-RL 2006/42/EC)

The manufacturer:

Afag Hardt GmbH

Gewerbestraße 11

D-78739 Hardt

hereby declares that the following products

RA-40

Appendix I, Article 1.1.2, 1.1.3, 1.1.5, 1.3.2, 1.3.4 and 1.5.1.

The partly completed machinery also corresponds to all prov

(2014/35/EU) and electromagnetic compatibility (2014/30/EU) directives.

The incomplete machine must only be put into operation when it has been f ound that the machine into

which the incomplete machine is to be installed corresponds to the provisions of the machinery directive

2006/42/EC.

offices upon request.

The technical document ation for this machine was dra wn up accor ding to Appendix VII, par t B

Name of the authorised representative: Walter Kunz

Address of the authorised representative: Gewerbest r aße 11 - 78739 Hardt

Subject to change. 39 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Procedures used

Angewan

15 Risk assessment (EG-RL 2006/42/EG)

for the risk assessment

Diagram utilised for general risk assessment in accordance with ISO/TR 1412-2:

Diagram utilised in accordance with EN 13849 for the determination of the required performance level

(PL):

Subject to change. 40 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Determination of the machine limitations

1.

Limits of use

Installation and equipping of various components, products

Application area of the machine

Yes

Industry

Yes

No

User groups

Function

Qualification/impairments

Maintenance,

Operation

trained

Operators

Operation

experienced/trained

2.

Spatial limits

Machine/system description

Energy supply interfaces

3.

Time limits

10 years

Recommended maintenance intervals

Maintenance

4.

Additional limits

0 – 50 °C

Required degree of cleanli ness

No special requirements

Materials and properties o f processed

Intended use

Business

Household

Qualified personnel

Apprentices

commissioning

Operation

Specialist training

Intended application duration

Highest/lowest ambient temperatures

materials

See system description

Electrical energy suppl y

Pneumatic energy supply

See

No special requirements

Subject to change. 41 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Identification of hazards

Risk

assessment

Persons who wear

Pos. Life phases Description of hazard

Hazard due to improper

1 Transport

transportation of

machine

Electrical hazard. Direct

2

Operation,

Maintenance

Repairs

or indirect contact with

energised parts when

errors occur on electrical

components.

S = S2

F = F1

O = O1

A = A1

Erg = 3

S = S2

F = F1

O = O1

A = A1

Erg = 3

Measures to reduce risk PL

Observe the total

weight and correct

transportation m ethods

--

in the operating manual.

1.

Electrical equipment

designed in accordance

with EN 60204.

2.

Installation and

maintenance of

electrical equipm ent

must only be carried out

by specialist personnel.

S = S2

F = F1

P = P1

PL = c

3.

Maintenance and repair

work must only be

carried out in a voltagefree and compressed

air-free state.

3

Maintenance

Repairs

Subject to change. 42 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

pacemakers must

maintain a safety

Pacemakers may be

affected by permanent

magnets.

S = S2

F = F1

O = O1

A = A1

Erg = 3

distance of a minimum

of 0.2 m from the

module.

The device is equipped

with corresponding

warning signs.

--

The personnel must be

instructed accordingly.

Risk

assessment

Risks of limb crushing,

Pos. Life phases Description of hazard

Pacemakers may be

4 Operation

affected by permanent

magnets.

bruising and broken

5 Operation

bones due to accessing

the travel range of the

moving device.

Burning of the skin due

to surface temperat ures

of up to 60°C.

6

Operation,

Maintenance

Repairs

S = S2

F = F1

O = O1

A = A1

Erg = 3

S = S2

F = F2

O = O2

A = A1

Erg = 4

S = S1

F = F1

O = O2

A = A1

Erg = 1

Measures to reduce risk PL

With the safeguard, a

safety distance of

0.2 m from the

--

pacemaker must be

guaranteed

Operation of the device

behind a

safeguard to ensure

that access to the

travel range is denied.

S = S2

F = F1

P = P1

PL = c

1.

Avoid direct contact

when the device is in

operation.

2.

Allow the device to cool

--

down before carrying

out maintenance work,

or protect the skin

accordingly (gloves,

long clothing...)

Subject to change. 43 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Risk

assessment

be reliably disconnected

Pos. Life phases Description of hazard

7

Maintenance,

commissioning

Risks of limb crushing,

bruising and broken

bones due to accessing

the travel range of the

device when the

protective door is open.

S = S2

F = F2

O = O2

A = A1

Erg = 4

Measures to reduce risk PL

1.

The pressurised air

supply must be reliably

disconnected.

2.

The "safety relay" input

(X33) on the controller

C1xxx must be

deactivated or the

power pack (72 V) must

from the power supply

on the primary side.

3.

The power pack (72 V)

must be reliably

disconnected from the

power on the primary

side when using the

B1100, E12xx or E1xxx

S = S2

F = F1

P = P1

PL = c

controllers.

4.

For linear motor axes

(excluding ES40, ES40HP, PDL40 and PDL40HP) through secure

monitoring of the

reduced speed!!!

Observe the special

documentation!!!

Furthermore, specialist

personnel must check

that all components

have been properly

installed and ensure

that there is no

manipulation.

Subject to change. 44 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

16 Support

Afag Hardt GmbH

Gewerbestraße 11

D-78739 Hardt

T +49 (0)7422/56003-20

E-Mail: support.hardt@afag.com

Internet: www.afag.com

Subject to change. 45 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

17 Notes

Subject to change. 46 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Afag Hardt GmbH

Gewerbestraße 11

D-78739 Hardt

T +49 (0)7422/56003-0

F +49 (0)7422/56003-29

E-Mail: sales@afag.com

Internet: www.afag.com

Subject to change. 47 Vers. 1. 1 en 01.01.2019

Afag Hardt GmbH – Gewerbestraße 11 - 78739 Hardt - Phone:07422/56003-0

Company headquarters: 78739 Hardt, Managing Director: Walter Kunz, HRB 480966 Stuttgart

Loading...

Loading...