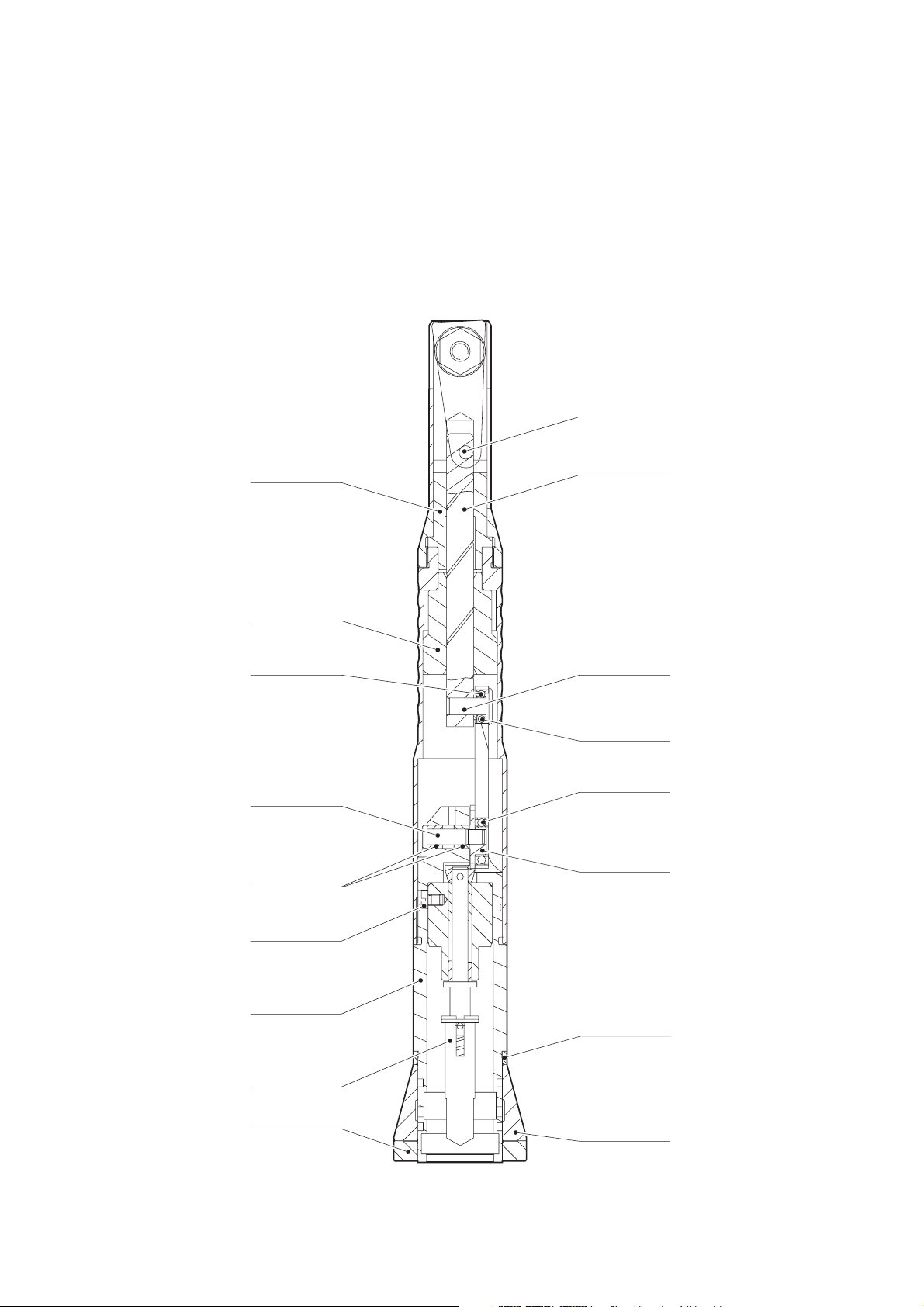

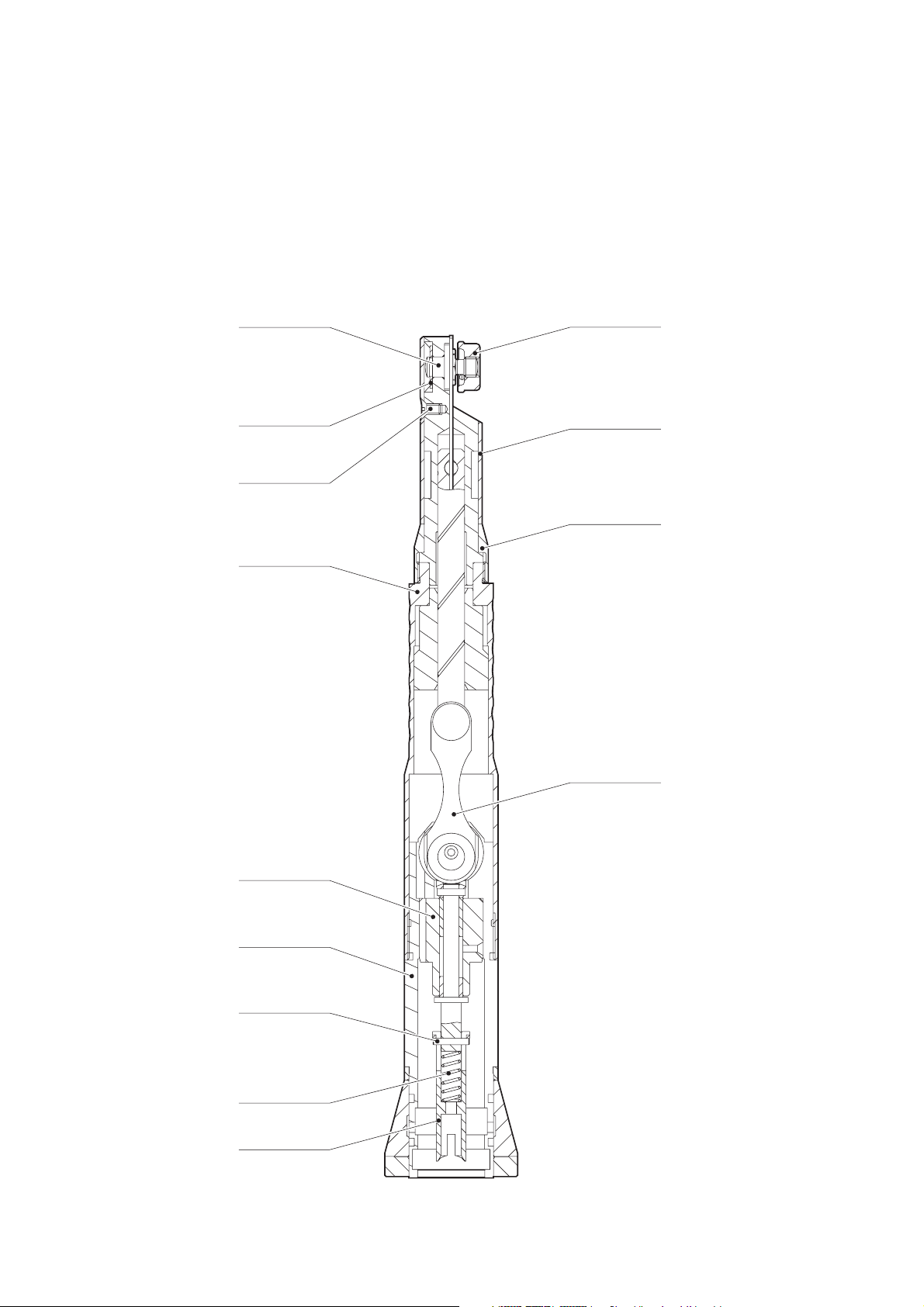

Aesculap Saw GD307 Service manual

Aesculap Power Systems

Service Manual

micro-Line saggital saw GD307

Service-Manual

micro-Line Sagittalsäge GD307

TA003323

GD307202

GD307204

GD307223

GD307224

GD307225

GD307200

GD307218

TA009542

TA009541

GD307219

GD307226

GD307227

GD307228

GD307229

GD307221

GD307222

GD307803

GD307207

TA007307

TA007306

GD307201

GD307205

GD307203

GD307210

GD307802

GD307227

GD307216

GD307217

GD307228

Aesculap Power Systems

micro-Line saggital saw GD307

Copyright information

Copyright© 2006

Aesculap AG & Co. KG®

All rights reserved 11/06

This service information is copyrighted. This service information must not

be copied or reproduced by any means either in whole or in part without

the express permission of Aesculap AG & CO. KG.

This manual is intended for informational purposes only. Ownership of this

manual alone does not constitute or imply authorization to service the

product.

The technical information, illustrations and dimensions contained in this

manual are non-binding. No claims may be made on the basis of the

information contained herein. We reserve the right to make improvements

without altering this documentation. We reserve the right to make

technical changes without prior notice.

Main address for servicing:

Aesculap Technischer Service (ATS)

Am Aesculap-Platz

78532 Tuttlingen / Germany

Phone: +49 7461 95-2700

Fax: +49 7461 16-2887

E-mail: ats@aesculap.de

Other service addresses can be obtained through the address indicated

above.

Manufacturer’s liability

We expressly point out that we can accept responsibility for any effects

on the safety, reliability, and performance of our medical products, if and

only if:

• any assembly, extensions, readjustments, modifications, or repairs are

performed by technically experienced, knowledgeable and trained

personnel and

• the medical products are used as set forth in the instructions for use.

It is possible to learn servicing the respective medical products through

appropriate courses of instruction offered by Aesculap. To arrange for such

a course, please contact Aesculap Technical Service (ATS).

To ensure that your Aesculap warranty remains valid, we recommend

using for repairs only Aesculap factory-tested spare parts. Spare parts, as

well as the relevant tools, can be ordered from Aesculap Technical Service

(ATS). Any unauthorized opening and/or alterations of the medical product

by third parties lead to the exclusion of our liability, as far as a fault is

attributable to such unauthorized opening and/or alteration of the

product. Aesculap cannot accept responsibility for the use of unsuitable

spare parts, tools or devices. After repairs, dropping, severe damage or

misuse, the product should be inspected by a qualified person.

This manual refers to the product as it was when the manual was

prepared. Technical changes, particularly of software, may be made at any

time.

General advisory

This service manual contains illustrations and explanations. Each

explanation covers the following: modes of operation, parts list, assembly,

disassembly, functionality test, and a tools/devices section (if applicable).

For further information about a specific product (e.g., troubleshooting list,

accessories) please refer to the relevant user instructions.

Documentation Art. no.

Instructions for use TA009539

It is crucial to maintain extreme cleanliness during repairs of the products

described below. All products must undergo thorough function tests after

any repairs. If, in the course of a repair, a labeled component is replaced,

the labeling must be transferred to the spare part. Either the original label

should be used or the spare part bearing the relevant label should be

ordered. Any such order should include the relevant information.

Unless otherwise indicated, all medical products should be inspected

annually.

General information about motors and handpieces

It is critically important that ball bearings be inspected annually. Even the

slightest defect or dirt can lead to overheating during use, which would

render the product unusable. If for the repair of e.g. a motor a ball bearing

has to be replaced, it is best in most cases to also replace all other ball

bearings.

If it is necessary to heat up adhesive joints during disassembly, a hot-air

heat gun is the appropriate tool. The smallest possible nozzle should be

used so as to avoid damaging other components. For glue joints, make

certain that the surfaces to be joined are absolutely clean and free of

grease. We recommend using Loctite Rapid Cleaner 7063 for this purpose

(WS. no. 520001750). Only use adhesives listed in this manual. Follow the

glue manufacturer’s recommendations.

Lubricate components with the recommended Aesculap product only.

Following disassembly, clean all components thoroughly and inspect them

for any damage. Do not install any component of uncertain condition.

Products must always be test-run for several minutes after any repair.

2

Contents

1. Safe handling .................................................................................................. 3

2. Tools, auxiliary materials, supplies ........................................................... 3

2.1 Tools .................................................................................................................. 3

2.2 Auxiliary materials ........................................................................................ 3

2.3 Supplies ............................................................................................................ 3

3. Expendable parts/Spare parts .................................................................... 3

4. Basic preparations and maintenance ...................................................... 4

4.1 Function tests ................................................................................................. 4

4.2 Maintenance ................................................................................................... 4

5. Troubleshooting list ...................................................................................... 5

6. Disassembling ................................................................................................. 6

6.1 Disassembling the handle part .................................................................. 6

6.2 Disassembling the rear housing ................................................................ 6

6.3 Disassembling the drive unit complete ................................................... 6

7. Assembling ...................................................................................................... 6

7.1 Preparations .................................................................................................... 6

7.2 Assembling the drive unit complete ........................................................ 6

7.3 Assembling the rear housing ...................................................................... 6

7.4 Assembling the handle part ........................................................................ 7

8. Postmaintenance ........................................................................................... 7

8.1 Function tests ................................................................................................. 7

8.2 Surface inspection ......................................................................................... 7

9. Parts list ........................................................................................................... 7

2. Tools, auxiliary materials, supplies

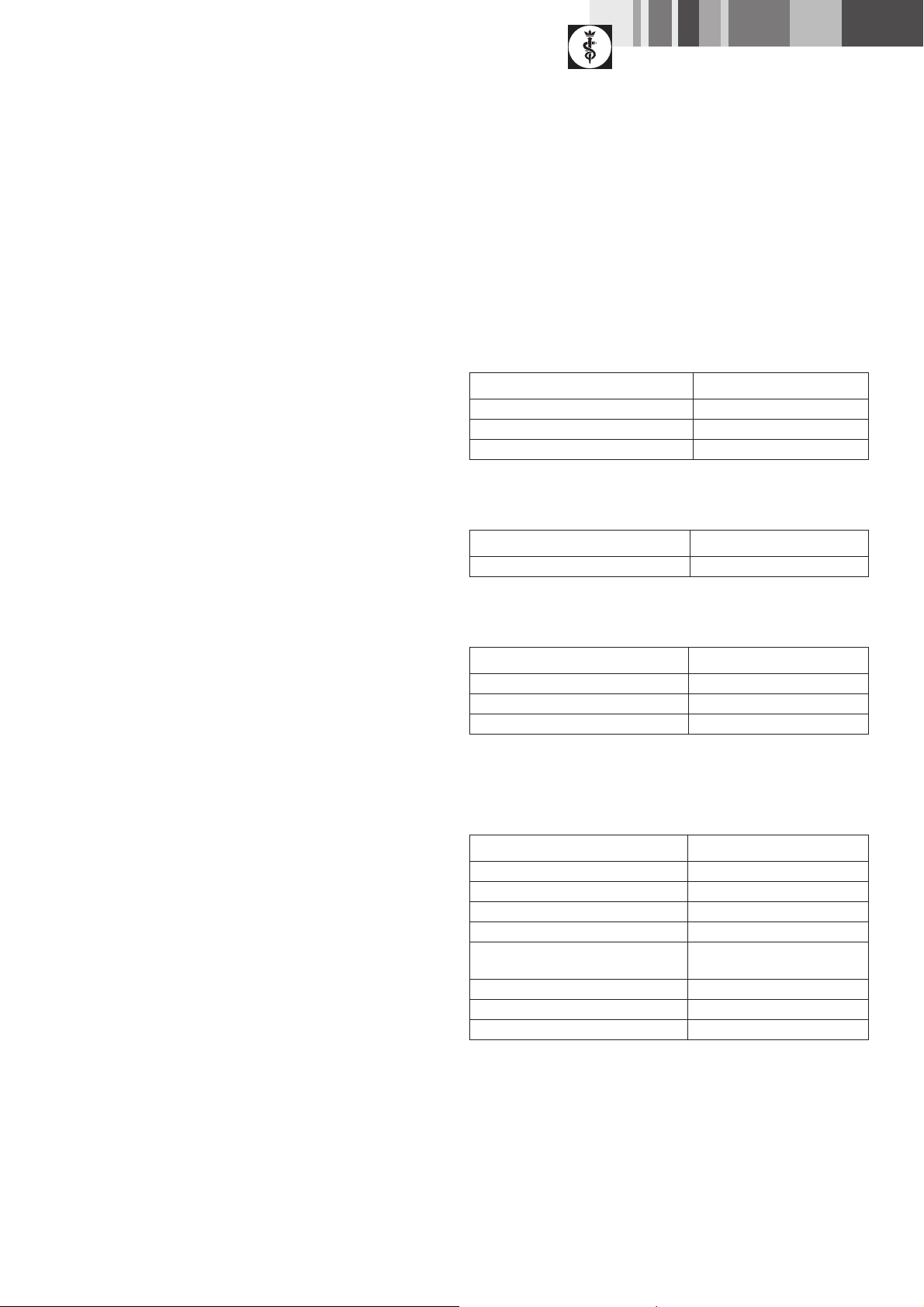

2.1 Tools

Designation Art. no.

Special device (disassembly) W-90000167

Special device (assembly) W-90000168

Special device (disassembly) W-90000169

2.2 Auxiliary materials

Designation Art. no.

Instructions for use TA009539

2.3 Supplies

Designation WS. no.

Loctite 572 560001817

Lubricant GB600

Uhu Plus “Schnellfest” 560001162-N

1. Safe handling

¾ Operate the micro-Line saggital saw GD307 only with authentic

Aesculap accessories.

3. Expendable parts/Spare parts

Designation Art. no.

Fastening nut GD307207

Connecting rod GD307210

Shim GD307223

Steel ball TA003323

Countersunk screw DIN 936

M 1.6 x 3.0

Retaining ring DIN 471 3.0 x 0.4 TA007307

Radial ball bearing 4 x 7 x 2 NR TA009541

Radial ball bearing 2.5 x 5 x 1.5 NR TA009542

TA007306

3

Loading...

Loading...