Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

BA-SINEDRIVE

USER’S MANUAL

P/N: EDU164 (V1.4)

AEROTECH, Inc. • 101 Zeta Drive • Pittsburgh, PA. 15238-2897 • USA

Phone (412) 963-7470 • Fax (412) 963-7459

Product Service: (412) 967-6440; (412) 967-6870 (Fax)

www.aerotech.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

If you should have any questions about the BA- SineDrive or comm ents regar ding the documentation, please re fer to

Aerotech online at:

http://www.aerotech.com.

For your convenience, a product registration form is available at our web site.

Our web site is continually updated with new product information, free downloadable softwa re, firmware upgrades,

and special pricing on selected products.

The BA-SineDrive and BAS software are products of Aerotech, Inc.

Windows 95/NT are products of Microsoft Corporation.

The BA-SineDrive Use r’s Manual Revision History:

Version 1.0 July 17, 1998

Version 1.1 October 22, 1998

Version 1.2 September 19, 2000

Version 1.3 October 6, 2000

Version 1.4 November 20, 2000

© Aerotech, Inc., 2001

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Table of Contents

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION............................................................................ 1-1

1.1. Product Overview............................................................................... 1-1

1.2. Velocity/Torque Amplifier.................................................................1-2

1.3. BAS DOS Software............................................................................ 1-3

1.4. BAS Windows Software Interface...................................................... 1-3

1.5. Hardware Overview and Function......................................................1-6

1.5.1. Motor and AC Power Connections....................................... 1-7

1.5.1.1. BAS 10/20/30..................................................... 1-7

1.5.1.2. BAS 50/75/100................................................... 1-8

1.5.2. Fusing and Inrush Limiting ..................................................1-9

1.5.2.1. BAS 10/20/30..................................................... 1-9

1.5.2.2. BAS 50/75/100................................................. 1-10

1.5.3. 20 - 80 Volt Option – BAS 10/20/30................................. 1-11

1.5.4. COM Port ........................................................................... 1-12

1.5.5. LED Status Indicators........................................................ 1-12

1.6. Safety Procedures and Warnings...................................................... 1-13

CHAPTER 2: CONFIGURATION AND COMMUNICATION........................... 2-1

2.1. Introduction........................................................................................ 2-1

2.2. BAS Control Board Jumper Selections.............................................. 2-1

2.3. BAS Communications Modes ............................................................ 2-2

2.4. Menu Commands................................................................................ 2-3

2.4.1. C-Change Parameter............................................................. 2-3

2.4.2. D-Display Tracking Information.......................................... 2-4

2.5. E - Display Error Message..................................................................2-6

2.5.1. BAS Faults........................................................................... 2-6

2.5.1.1. Invalid Hall Sequence ........................................2-6

2.5.1.2. RMS Current Error............................................. 2-6

2.5.1.3. Velocity Error..................................................... 2-6

2.5.1.4. Encoder Fault..................................................... 2-7

2.5.1.5. Thermistor Fault................................................. 2-7

2.5.1.6. RMS Current Error............................................. 2-7

2.5.2. F1- Abort Entry/Up One Menu Level ..................................2-7

2.5.3. F2/F3 - Previous/Next Menu................................................ 2-7

2.5.4. T - Transfer Parameters........................................................ 2-7

2.5.5. Space Bar ............................................................................. 2-7

2.5.6. CTRL-D............................................................................... 2-7

CHAPTER 3: PARAMETERS.................................................................................3-1

3.1. Introduction........................................................................................ 3-1

3.2. Parameters.......................................................................................... 3-1

3.2.1. PRM:1 Proportional Velocity Gain (KP)............................3-2

3.2.2. PRM:2 Integral Velocity Gain (KI).....................................3-2

3.2.3. PRM:3 Electronic Tach (VSCALE).................................... 3-2

3.2.4. PRM:4 Encoder Resolution (ENCODER).......................... 3-3

3.2.5. PRM:5 Electrical Cycles/Mechanical Revolution

(POLE PAIRS)..................................................................... 3-4

3.2.6. PRM:6 Hall Effects Available (HALLS) ............................ 3-4

Version 1.4 Aerotech, Inc. iii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents BA SineDrive User’s Manual

3.2.7. PRM:7 Initialization Current (INIT CURRENT)................ 3-5

3.2.8. PRM:8 Velocity Loop Update Rate (UPDATE)................ 3-6

3.2.9. PRM:9 Low Pass Filter Enable (FILTER).......................... 3-6

3.2.10. PRM:10 Filter Cutoff (CUT. FREQ.)..................................3-7

3.2.11. PRM:11 Commutation Phase Offset (PHASE OFF)...........3-7

3.2.12. PRM:12 Input Command Offset (CMD. OFF).................... 3-8

3.2.13. PRM:13,14 Current Offset Adjustment (IA OFFSET,

IB OFFSET).........................................................................3-8

3.2.14. PRM:15 Servo Peak Current Limit (CURR. LIMIT)..........3-9

3.2.15. PRM:16 Servo RMS Limit (RMS LIMIT)..........................3-9

3.2.16. PRM:17 Servo RMS Current Timeout (RMS TIME) .......3-10

3.2.17. PRM:18 Servo Velocity Trap (VEL ERR LMT).............. 3-10

3.2.18. PRM:19 Integral Clamp (INT CLAMP) ........................... 3-11

3.2.19. PRM:20 Operating Mode (MODE)................................... 3-11

3.2.20. PRM:21 Thermistor Polarity (THERM POL.)..................3-12

3.2.21. PRM:22 Enable Polarity (ENABLE POL.)....................... 3-13

3.2.22. PRM:23 Fault Output Polarity (FAULT POL.).................3-13

3.2.23. PRM:24 Encoder Polarity (Enc. Mult.)............................. 3-13

CHAPTER 4: MODE OF OPERATION AND TUNING.......................................4-1

4.1. Introduction........................................................................................ 4-1

4.2. Velocity and Current Mode................................................................4-1

4.2.1. Current Mode....................................................................... 4-1

4.2.2. Velocity Mode...................................................................... 4-2

4.3. Tuning.................................................................................................4-2

CHAPTER 5: TECHNICAL DETAILS...................................................................5-1

5.1. Introduction........................................................................................ 5-1

5.2. Hardware Overview and Function......................................................5-1

5.2.1. Motor and AC Power Connections....................................... 5-2

5.2.1.1. Wiring, Grounding, and Shielding

Techniques..........................................................5-2

5.2.1.2. Minimizing EMI Interference and CE

Compliance.........................................................5-2

5.2.1.3. Minimizing 50/60 HZ Line Interference.............5-3

5.2.2. COM Port.............................................................................5-4

5.2.3. LED Status Indicators ..........................................................5-5

5.3. The I/O Port........................................................................................5-6

5.3.1. SIN, SIN-N, COS, COS-N Signals.......................................5-6

5.3.2. Restore/Reset Signal.............................................................5-7

5.3.3. Input+/Input- Command INPUT .......................................... 5-7

5.3.4. Thermistor Input Signal........................................................ 5-7

5.3.5. External Enable Input........................................................... 5-8

5.3.6. Fault Output..........................................................................5-8

5.4. Encoder/Limits/Hall Effects Port........................................................ 5-9

5.4.1. Encoder Interface............................................................... 5-10

5.4.2. Hall Effect Interface...........................................................5-10

5.5. Servo Amplifier Specifications.........................................................5-14

5.6. BAS Amplifier Dimensions..............................................................5-15

5.6.1. Mounting Procedures for the BAS 10/20/30/50................. 5-17

5.6.2. Mounting Procedures for the BAS 75/100 .........................5-18

iv Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Table of Contents

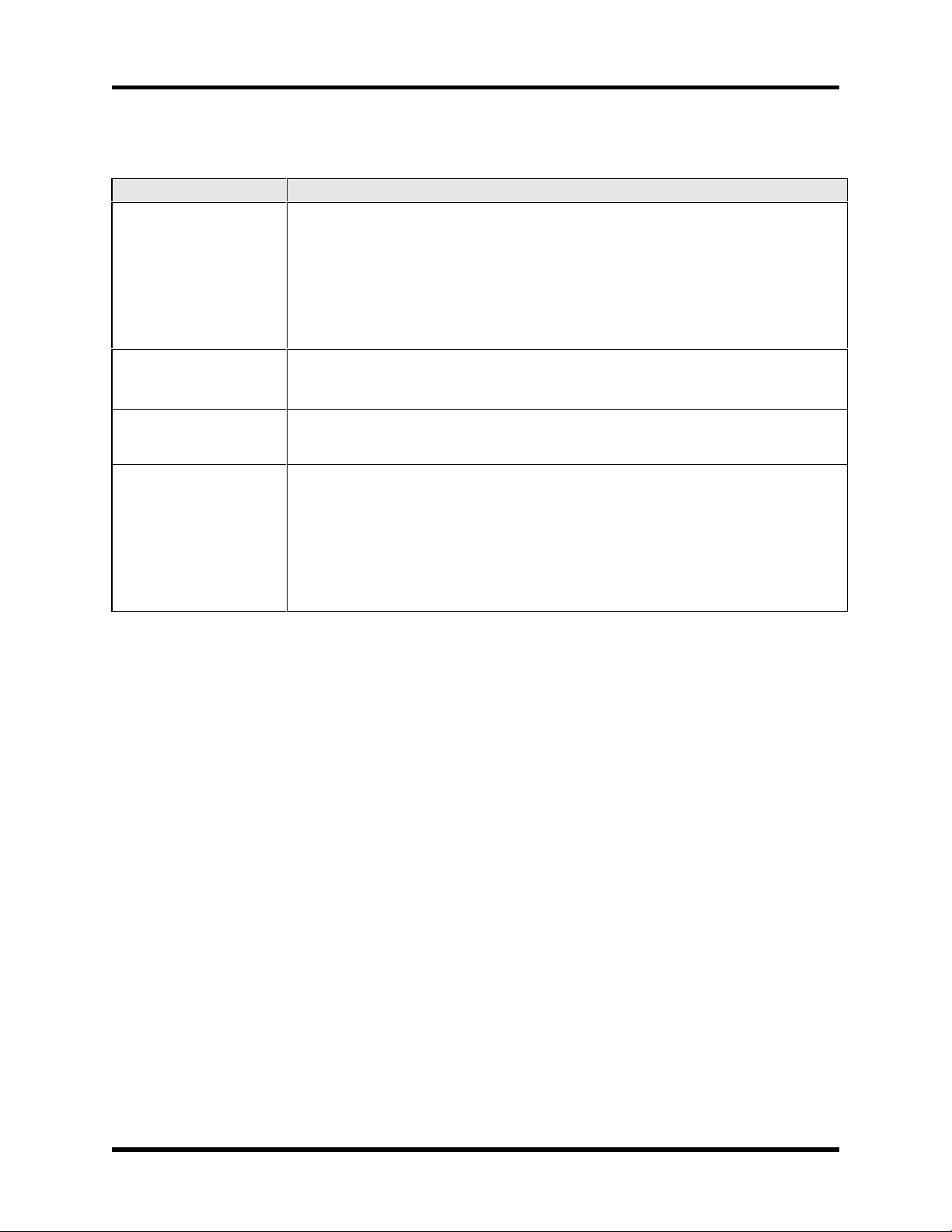

CHAPTER 6: TROUBLESHOOTING.................................................................... 6-1

6.1. Amplifier Related Problems ...............................................................6-1

APPENDIX A: WARRANTY AND FIELD SERVICE.......................................... A-1

APPENDIX A: WARRANTY AND FIELD SERVICE POLICY.......................... A-1

INDEX

∇ ∇ ∇

Version 1.4 Aerotech, Inc. v

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents BA SineDrive User’s Manual

vi Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual List of Figures

LIST OF FIGURES

Figure 1-1. BA-SineDrive Amplifiers (10/20/30/50/75/100)................................1-1

Figure 1-2. Illustration of Configuration............................................................... 1-2

Figure 1-3. BAS MMI Main Screen...................................................................... 1-4

Figure 1-4. Parameter Screen................................................................................1-4

Figure 1-5. Parameter Information........................................................................ 1-5

Figure 1-6. BA-SineDrive Hardware (10/20/30)...................................................1-6

Figure 1-7. BA-SineDrive Hardware (50/75/100)................................................. 1-6

Figure 1-8. Motor and AC Power Connections – 10/20/30 Models..................... 1-7

Figure 1-9. Motor and AC Power Connections – 50/75/100 Models................... 1-8

Figure 1-10. Fuse and Inrush Limiting – 10/20/30 Models.................................... 1-9

Figure 1-11. AC Input Fusing – 50/75/100 Models.............................................. 1-10

Figure 1-12. 20 –80V Option................................................................................1-11

Figure 2-1. Tracking Screen.................................................................................. 2-2

Figure 2-2. Parameter Screen................................................................................2-2

Figure 2-3. The Change Parameter Screen............................................................ 2-3

Figure 2-4. Changing a Parameter in the Change Parameter Screen.....................2-4

Figure 2-5. Display Tracking Screen ....................................................................2-4

Figure 2-6. Display Error Message Screen............................................................2-6

Figure 3-1. PI Control Loop.................................................................................. 3-1

Figure 5-1. BA-SineDrive Hardware.................................................................... 5-1

Figure 5-2. Wiring to Minimize EMI and Capacitive Coupling............................5-3

Figure 5-3. Back-Propagation Line Filter Connection..........................................5-3

Figure 5-4. Isolatio n Transformer Connection (eliminates torque

disturbance)........................................................................................ 5-4

Figure 5-5. Over-Temperature Circuitry...............................................................5-7

Figure 5-6. Electrical Characteristics of Opto-Isolated Input................................5-8

Figure 5-7. Electrical Characteristics of Opto-Isolated Output.............................5-8

Figure 5-8. CW Motor Rotation (Viewed from the Mounting Flange End)........ 5-10

Figure 5-9. Encoder Input Circuit....................................................................... 5-10

Figure 5-10. Hall Effect Input Circuit................................................................... 5-11

Figure 5-11. Hall Effect Motor Phasing................................................................ 5-11

Figure 5-12. Motor Rotation (From Mounting Flange End) .................................5-12

Figure 5-13. Motor Phase Voltage Observation Scheme ......................................5-13

Figure 5-14. Encoder Phase Voltage Observation Scheme................................... 5-13

Figure 5-15. BAS Amplifier Dimensions (10/20/30)............................................5-15

Figure 5-16. BAS Amplifier Dimensions (50/75/100).......................................... 5-16

Figure 5-17. BAS Amp Top View (Preferred Mounting, 10/20/30/50)................5-17

Figure 5-18. Preferred Mounting of BAS Amplifiers (10/20/30/50).....................5-18

Figure 5-19. Preferred Mounting of BAS Amplifiers (75/100)............................. 5-19

∇ ∇ ∇

Version 1.4 Aerotech, Inc. vii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

List of Figures BA SineDrive User’s Manual

viii Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual List of Tables

LIST OF TABLES

Table 1-1. COM Port Pinouts............................................................................ 1-12

Table 2-1. Power Board Jumper Selections.........................................................2-1

Table 2-2. Control Board Jumper Selections.......................................................2-1

Table 2-3. Bit Patterns......................................................................................... 2-5

Table 3-1. Settings for Proportional Velocity Gain PRM:1................................. 3-2

Table 3-2. Settings for Integral Velocity Gain PRM:2........................................ 3-2

Table 3-3. Settings for Electronic Tach PRM:3................................................... 3-2

Table 3-4. Settings for Encoder Resolution PRM:4............................................. 3-3

Table 3-5. Settings for Electrical Cycles/Mechanical Revolution PRM:5........... 3-4

Table 3-6. Settings for Hall Effects Available PRM:6......................................... 3-4

Table 3-7. Settings for Initialization Current PRM:7........................................... 3-5

Table 3-8. Settings for Velocity Update Rate PRM:8.......................................... 3-6

Table 3-9. Settings for Low Pass Filter PRM:9 ...................................................3-6

Table 3-10. Settings for Filter Cutoff PRM:10...................................................... 3-7

Table 3-11. Settings for Phase Offset PRM:11......................................................3-7

Table 3-12. Settings for Input Command Offset PRM:12...................................... 3-8

Table 3-13. Settings for Position Mode PRM:13, PRM:14 ...................................3-8

Table 3-14. Settings for Servo Peak Current Limit PRM:15................................. 3-9

Table 3-15. Settings for Servo RMS Limit PRM:16.............................................. 3-9

Table 3-16. Settings for Servo RMS Current Timeout PRM:17..........................3-10

Table 3-17. Settings for Servo Velocity Trap PRM:18........................................ 3-10

Table 3-18. Settings for Integral Clamp PRM:19................................................ 3-11

Table 3-19. Operating Modes PRM:20................................................................3-11

Table 3-20. Settings for Operating Mode PRM:20..............................................3-12

Table 3-21. Settings for Thermistor Polarity PRM:21.........................................3-12

Table 3-22. Settings for Enable Polarity PRM:22 ............................................... 3-13

Table 3-23. Settings for Fault Output Polarity PRM:23 ......................................3-13

Table 3-24. Settings for Encoder Polarity PRM:24 .............................................3-13

Table 5-1. COM Port Pinouts.............................................................................. 5-4

Table 5-2. I/O Connector Pinouts (P1)................................................................ 5-6

Table 5-3. Pinouts for the Encoder/Limits/Hall Effects Port............................... 5-9

Table 5-4. Electrical Specifications................................................................... 5-14

Table 6-1. Amplifier Faults, Causes, and Solutions............................................. 6-1

∇ ∇ ∇

Version 1.4 Aerotech, Inc. ix

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

List of Tables BA SineDrive User’s Manual

x Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Regulatory Information

DECLARATION OF CONFORMITY

Manufacturer’s Name and Address

Aerotech, Inc.

101 Zeta Drive

Pittsburgh, PA 15238-2897

Declares that the product:

Product Name: BA Intellidrive/BA Sinedrive

Conforms to the following product specifications:

EMC: EN 55011: Class B Emissions

EN 50082-1: Immunity

EN61000-4-2

EN61000-4-3

EN61000-4-4

EN61000-4-11

EN50141

LVD: IEC 204-1

and complies with EMC directive 89/336/EEC.

Pittsburgh, PA David F. Kincel_________________________

October 8, 1998 Quality Assurance Manager

Robert Novotnak__________________________

Engineer Verifying Compliance

General notes concerning the test setup.

This product was tested at Compliance Labs, Middlefield, OH on October 8, 1998.

The brushless amplifier was tested with a brushless servo motor. To ensure that the

product passes the conducted emissions tests, a line filter and common mode choke must

be connected to the main inputs. The filter is a Schaffner FN 2070-10-06 and the common

mode choke is a Renco Electronics RL-1329-1200. Ferrite must be added to each line of

the main inputs but not earth ground. In order for the product to conform to the radiated

emission standards, the motor cable must be shielded and the shield must be tied to the

earth ground. Ferrite must also be added (in common mode) to the motor cable but not

around the shield. Finally, a metal 25-pin connector with a metal backshell must be used

when making a connection to the 25-pin receptacle on the amplifier. The shield of the

feedback cable must be tied to the metal backshell. Failure to follow the described

procedures may cause the amplifier/motor to exceed emission limits.

∇ ∇ ∇

Version 1.4 Aerotech, Inc. xi

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Regulatory Information BA SineDrive User’s Manual

xii Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Preface

PREFACE

This section gives you an overview of topics covered in each of the sections of this

manual as well as conventions used in this manual. This manual contains information on

the following topics:

CHAPTER 1: INTRODUCTION

This chapter contains an introduction to the hardware and software architecture of the

BA-SineDrive.

CHAPTER 2: CONFIGURATION AND COMMUNICATION

This chapter covers the jumper configurations when used with a brush or brushless DC

motor. This chapter also covers the methods used to send commands to the BAS.

CHAPTER 3: PARAMETERS

This chapter describes the various parameters used on the BAS.

CHAPTER 4: MODE OF OPERATION

This chapter contains all information regarding the BAS’s modes of operation.

CHAPTER 5: TECHNICAL DETAILS

This chapter contains all detailed technical information regarding the BA-SineDrive.

CHAPTER 6: TROUBLESHOOTING

This chapter covers symptoms, probable causes, and solutions related to the BASineDrive.

APPENDIX A: WARRANTY AND FIELD SERVICE

Appendix A contains the warranty and field service policy for Aerotech products.

INDEX

The index contains a page number reference of topics discussed in this manual. Locator

page references in the index contain the chapter number (or appendix letter) followed by

the page number of the reference.

Version 1.4 Aerotech, Inc. xiii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Preface BA SineDrive User’s Manual

CUSTOMER SURVEY FORM

A customer survey form is included at the end of this manual for the reader’s comments

and suggestions about this manual. Readers are encouraged to critique the manual and

offer their feedback by completing the form and either mailing or faxing it to Aerotech.

Throughout this manual the following conventions are used:

é The terms BA-SineDrive and BAS are used interchangeably throughout this

manual

é The text <ENTER> is used to indicate that the Enter/Return key on the

keyboard is to be pressed.

é Hexadecimal numbers are listed using a preceding "0x" (for example, 0x300,

0x12F, 0x01EA, etc.,) to distinguish them from decimal numbers

é Graphic icons or keywords may appear in the outer margins to provide visual

references of key features, components, operations or notes.

é This manual uses the symbol "∇ ∇ ∇" to indicate the end of a chapter.

Although every effort has been made to ensure consistency, subtle differences may exist

between the illustrations in this manual and the component and/or software screens that

they represent.

∇ ∇ ∇

xiv Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Introduction

CHAPTER 1: INTRODUCTION

In This Section:

• Product Overview.....................................................1-1

• Velocity/Torque Amplifier ...................................... 1-2

• BAS DOS Software.................................................. 1-3

• Hardware Overview and Function............................ 1-6

• Safety Procedures and Warnings............................1-13

1.1. Product Overview

The BA-SineDrive (BAS) is a sine wave commutation amplifier (Figure 1-1). The BAS

incorporates a digital control board that allows velocity loop gains and parameters to be

set via PC RS-232. A simple DOS-based (or newer Windows-based) terminal program

supplied with the unit is used to communicate. The BAS10/20/30/50/75/100 are switching

Pulse Width Modulation (PWM) amplifiers. The amplifiers consist of an amplifier,

control board, and internal power supply.

Figure 1-1. BA-SineDrive Amplifiers (10/20/30/50/75/100)

Version 1.4 Aerotech, Inc. 1-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Introduction BA SineDrive User’s Manual

1.2. Velocity/Torque Amplifier

The BAS reads in a +/-10 volt signal and commutates a brushless motor with a sine wave

current command. Sine wave commutation is done via an encoder (quadrature input) and

provides the smoothest possible motion for a brushless motor. The input signal can be

either a velocity command or a torque (current) command. If the input signal is a current

command, a two-phase current command is sent directly to the amplifier. If the input

signal is a velocity command, the BAS closes the velocity loop digitally (using the

encoder, two controller gains and the velocity command). The output from the internal

control board is a two-phase current command to the amplifier.

The operating parameters are changed through the RS-232 interface. This interface is

menu driven and interfaces with either a hand held terminal or DOS emulation software.

All parameters are stored in flash memory. After the initial setup, the unit will boot in the

user-defined configuration. Figure 1-2 shows a typical configuration using the B AS.

Figure 1-2. Illustration of Configuration

1-2 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Introduction

1.3. BAS DOS Software

The BAS DOS software package is stored on a 1.44MB floppy disk, labeled “ BAS

Software Package.” The software includes a HT terminal emulator (com_bai.exe) and the

source files. The purpose of the com_bai.exe is to setup the BAS.

In order for the com_bai.exe to function correctly in DOS, the ansi.sys driver must be

added to the config.sys file.

DEVICE=c:\dos\ansi.sys

These programs can also run in a DOS shell under Windows 95/NT. Again, in order for

the com_bai.exe file to run correctly, the ansi.sys driver must be loaded. The following

examples illustrate how to load ansi.sys in Windows 95/NT.

For Windows 95, add the following line to the config.sys file.

device=c:\win95\command\ansi.sys

For Windows NT, add the following line to the config.nt file in the winnt\system32

directory.

device=%SystemRoot%\system32\ansi.sys

Restart the PC after making these changes.

The BAS must be in local mode to operate with the com_bai software. Pressing

CTRL-A will toggle between remote and local mode.

1.4. BAS Windows Software Interface

Included in the standard software package is the BAS Windows Software Interface. This

windows program is intended to take the place of the COM_BAI.EXE program for users

of Windows 95/98/NT.

To install the BAS Windows Software Interface:

1. Insert the BAS software CD into the CD-ROM drive of the PC.

2. From Windows 95/98/NT select the start button, then click Run, and type

“X:\Setup.exe” (where X is the drive letter corresponding to the CD-ROM

drive).

After the software has been installed, the program can be executed by double-clicking the

BASMMI icon.

In order for the MMI to communicate, the BAS be in remote mode. To enter remote

mode, run the com_bai.exe software in a DOS shell, and press CTRL-A.

Version 1.4 Aerotech, Inc. 1-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Introduction BA SineDrive User’s Manual

Figure 1-3. BAS MMI Main Screen

The BAS MMI interface is a graphical interface that allows the user to quickly view all

the parameters available on the SineDrive and make any adjustments that are required.

The parameters on the system are divided up by type. Select the button on the left for the

type of parameters that you wish to view/edit. Also available on this sub-menu is a

diagnostic utility and a setup utility for airing in configuring the unit. The Online Help

file (selectable from the Help menu) contains more information on these utilities.

To view the maximum and minimum value for any parameter, place , the mouse pointer

over the name of the parameter and the name will become highlighted. Click and hold the

left mouse button to see the parameter , range. Releasing the mouse button will hide the

range.

Figure 1-4. Parameter Screen

1-4 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Introduction

To view more information about a parameter (such as the purpose of a parameter or the

units associated with a parameter,), click on the right mouse button while the parameter

name is highlighted.

Figure 1-5. Parameter Information

Version 1.4 Aerotech, Inc. 1-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Introduction BA SineDrive User’s Manual

1.5. Hardware Overview and Function

The BA-SineDrive consists of two power connections (motor power and input power),

two LED indicator lamps, and three “D” style connectors. Refer to Figure 1-6 and

Figure 1-7 for locations.

AC Power

Motor

Connections

LED Status

Indicators

COM Port

P2

I/O Port

P1

Encoder/Limits/Hall

Effects Port

P3

Figure 1-6. BA-SineDrive Hardware (10/20/30)

AC Power

Motor

Connections

LED Status

Indicators

COM Port

P2

Encoder/Limits/Hall

Effects Port

P3

I/O Port

P1

Figure 1-7. BA-SineDrive Hardware (50/75/100)

1-6 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Introduction

1.5.1. Motor and AC Power Connections

1.5.1.1. BAS 10/20/30

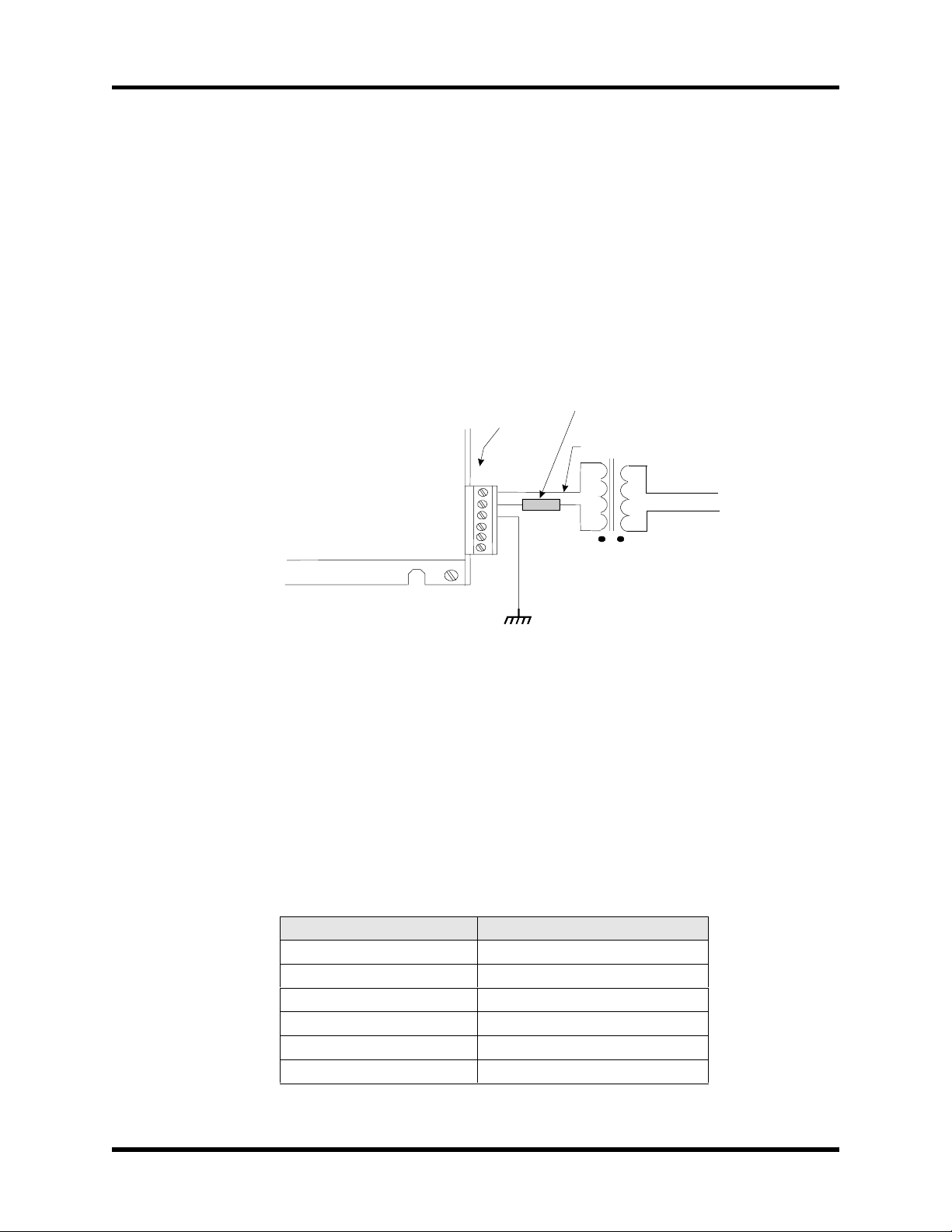

For the BAS10, 20 and 30, AC power is applied to the BAS through the AC receptacle

located on the front of the unit. The power cord is similar to the type used with personal

computers. The motor co nnection is made through the terminal strip located on the front

of the BAS. This connector contains the motor connections along with the earth ground

connection.

Motor Connection

AC Power

Motor

Cables

BM

Motor

110VAC or

220VAC

Figure 1-8. Motor and AC Power Connections – 10/20/30 Models

Version 1.4 Aerotech, Inc. 1-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Introduction BA SineDrive User’s Manual

1.5.1.2. BAS 50/75/100

AC power is applied to the B AS through the terminal strip on the front of the unit. T he

motor connections and e arth ground connectio ns are also made thr ough the terminal strip

located on the front of the BAS.

Auxiliary Power

Input

AC1

AC2

AC3

Ground

Motor Connector A

Motor Connector B

Motor Connector C

Ground

Figure 1-9. Motor and AC Power Connections – 50/75/100 Models

1-8 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Introduction

1.5.2. Fusing and Inrush Limiting

1.5.2.1. BAS 10/20/30

The BAS 10/20/30 do not contain a fuse or any inrush limiting internally. These can be

added externally to the AC input as shown in Figure 1-10.

RECOMMENDED MODELS:

BAS SERIES

THERMISTOR AND FUSING

RODAN SURGE GIARD SG100 (20A RMS)

KEYSTONE CL-10 (12A RMS)

AMETHERM #SL32IRO30 (30A RMS)

RECOMMENDED FUSE VALUE S:

BAS10 10 ASB

BAS20

BAS30

20 ASB

/2

+,

*<(/

%/8

%51

)86(

$&

,QSXW

DUE TO CAPACITIVE NATURE OF AMPLIFIER INPUT CIRCUIT,

CURRENT INRUSH LIMITING IS RECOMMENDED. NEGATIVE

TEMPERATURE COEFFICIENT THERMISTORS CAN BE USED

FOR THIS PURPOSE. THERMISTOR IS TO BE PLACED IN THE

AC HI LINE. ONLY ONE THERMISTOR NEEDED FOR ONE AMP.

ALTERNATELY, 2 THERMISTORS CAN BE USED IN AC HI & LO

FOR MULTIPLE AMPS IN PARALLEL.

Figure 1-10. Fuse and Inrush Limiting – 10/20/30 Models

Version 1.4 Aerotech, Inc. 1-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Introduction BA SineDrive User’s Manual

1.5.2.2. BAS 50/75/100

The BAS 50/75/100 contain inrush limiting internally. Fusing can be added if needed

externally (refer to Figure 1-11). The BAS 50 requires 2 phase input power while the

BAS 75/100 require 3 phase input power. Earth ground should be connected to the earth

ground connection on the unit. Motor connections are made through the A, B, and C

connections on the front of the unit.

BAS SERIES

FUSING

AC3

A.C.

Input

AC2

AC1

FUSES

Figure 1-11. AC Input Fusing – 50/75/100 Models

1-10 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Introduction

(L)

(H)

TB1

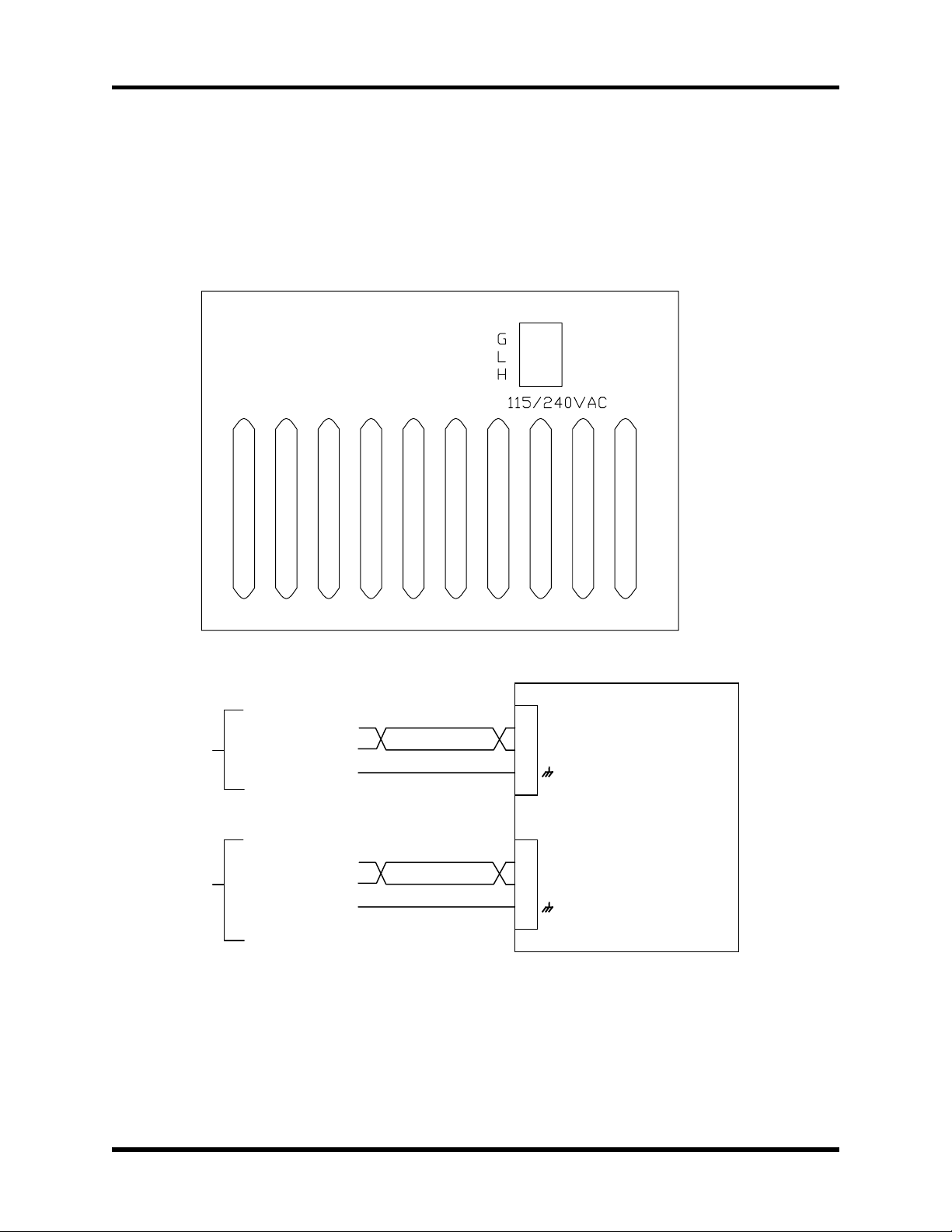

1.5.3. 20 - 80 Volt Option – BAS 10/20/30

If a BAS 10/20/30 - 80 amplifier was purchased, a separate AC input has been included

on the side of the amplifier. The internal power supply of the BAS amplifier requires a

minimum of 80VAC input to operate properly. Figure 1-12 shows the connection to the

separate AC power board. The connection is made to the AC input board with a three

terminal connector (Aerotech Part # ECK00213).

CONTROL

A.C.

BUS

A.C.

115VAC

OR

230VAC

14VAC

TO

56VAC

(DEPENDING

ON MODEL)

HI

LO

FRAME

HI

LO

FRAME

Figure 1-12. 20 –80V Option

J1

1

HI

2 3 LO

(G)

5

HI

6

LO

4

BAS

AMPLIFIER

Version 1.4 Aerotech, Inc. 1-11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Introduction BA SineDrive User’s Manual

1.5.4. COM Port

The COM port is a standard 9-pin “D” style connector located on the front of the BAS

(refer to Figure 1-6). It consists of two signal lines; transmit (TXD) and receive (RXD), a

ground, shield, and a 5V power supply line used to power the Aerotech Hand held

Terminal (HHT). Table 1-1 contains the connector pinouts. The BAS is configured as

Data Terminal Equipment (DTE); therefore, a NULL MODEM cable is required to

connect to the PC. This swaps pins 2 and 3 for proper communication.

Table 1-1. COM Port Pinouts

Pins Function

1Shield

2 Receive (RXD)

3 Transmit (TXD)

4,6,7,8 NC

5 Ground (GND)

9+5 V

The baud rate is 9600, with no parity (one stop bit).

The 5 Volt connection on COM port is for the hand held terminal and is a nonstandard connection.

1.5.5. LED Status Indicators

The BAS contains two LED’s located on the front of the unit that indicate the fault status

of the unit, refer to Figure 1-6. One of the LED’s indicates if power is applied to the unit,

the second indicates the status of the amplifier. A green light indicates the amplifier is in

the ready state and the motor is enabled, while a red light indicates a fault or the power

stage is disabled.

1-12 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Introduction

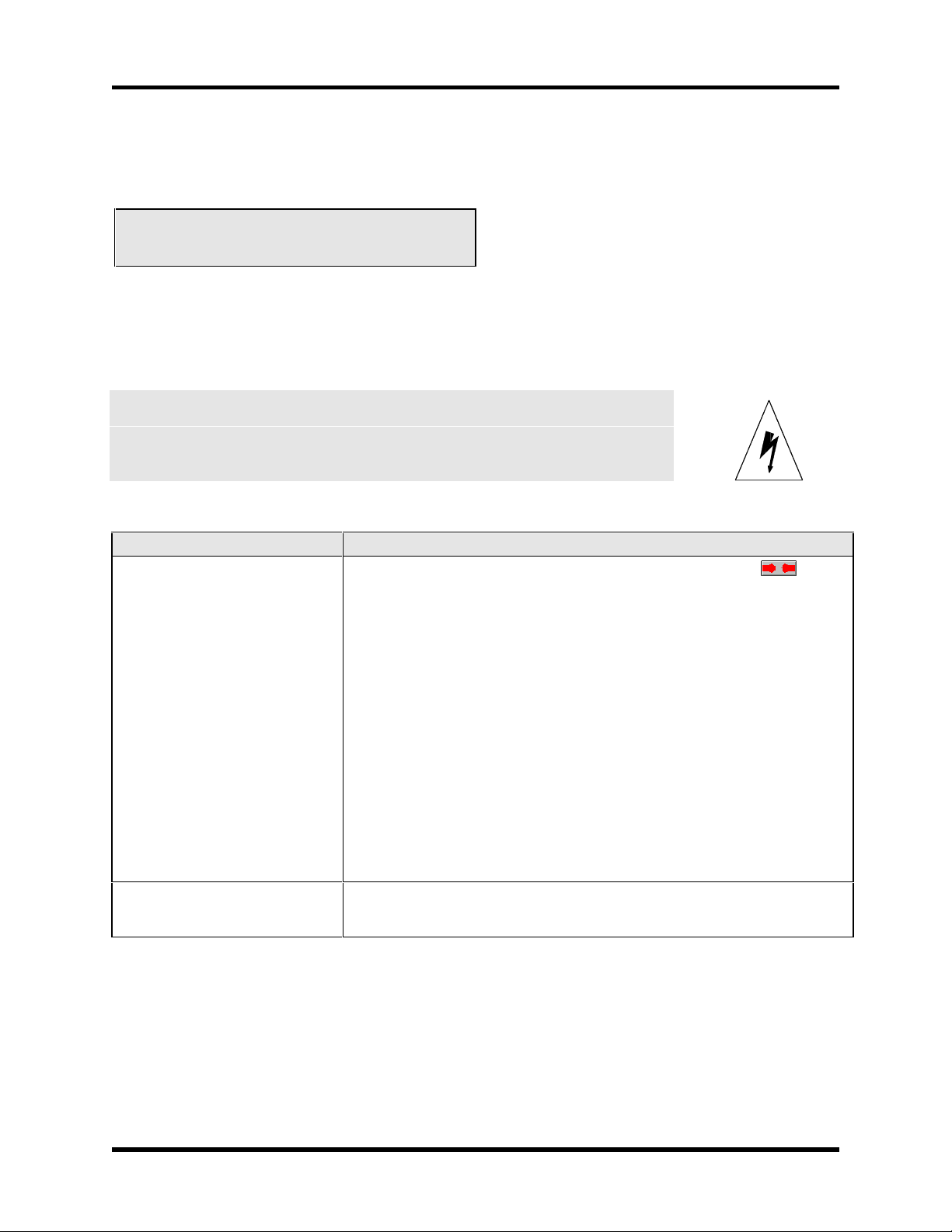

1.6. Safety Procedures and Warnings

The following statements apply wherever the Warning or Danger symbol appears within

this manual. Failure to observe these precautions could result in serious injury to those

performing the procedures and/or damage to the equipment.

To minimize the possibility of electrical shock and bodily injury, ensure that the

motor is decoupled from the mechanical system and no harm to personnel will result

if the motor begins to spin.

Before performing the following steps, ensure that the motor is completely

disconnected from the amplifier and the associated mechanical system.

To minimize the possibility of electrical shock and bodily injury when any electrical

circuit is in use, ensure that no person is exposed to the circuitry.

WARNING

WARNING

To minimize the possibility of bodily injury, make certain that all electrical power

switches (all switches external to the amplifier) are in the off position prior to making

any mechanical adjustments.

∇ ∇ ∇

Version 1.4 Aerotech, Inc. 1-13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Introduction BA SineDrive User’s Manual

1-14 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Configuration and Communication

CHAPTER 2: CONFIGURATION AND COMMUNICATION

In This Section:

• Introduction ........................................................................................ 2-1

• BAS Control Board Jumper Selections ...............................................2-1

• BAS Communications Modes .............................................................2-2

• Menu Commands.................................................................................2-3

2.1. Introduction

This chapter covers the jumper configurations when used with a brushless DC motor.

2.2. BAS Control Board Jumper Selections

The only user selectable jumper on the BAS Amplifier board is JP2. The jumper selects

between shunt and no shunt regulator.

Remove power from unit before changing the jumper.

The user selectable jumper on the power board is shown in Table 2-1.

Table 2-1. Power Board Jumper Selections

Jumper Position Mode

JP2

1-2 No shunt

2-3 Shunt board installed

The only user selectable jumper on the control board is JP2. It selects the input common

resistance. Refer to Table 2-2.

Table 2-2. Control Board Jumper Selections

Jumper Position Mode

JP2

1-2 5V Opto input

2-3 24V Opto input

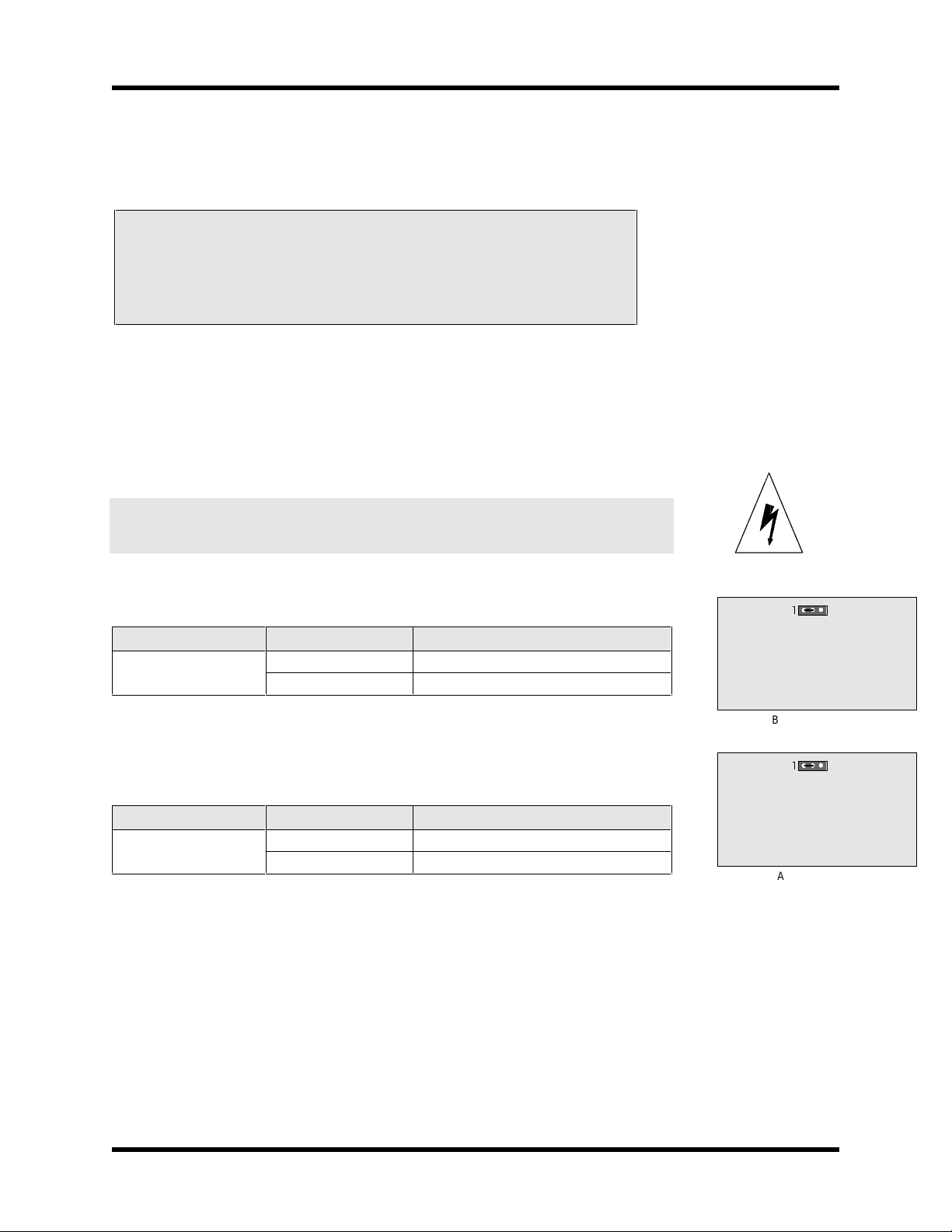

DANGER

JP2

BAS Power Board

JP2

BAS Control Board

Version 1.4 Aerotech, Inc. 2-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Configuration and Communication BA SineDrive User’s Manual

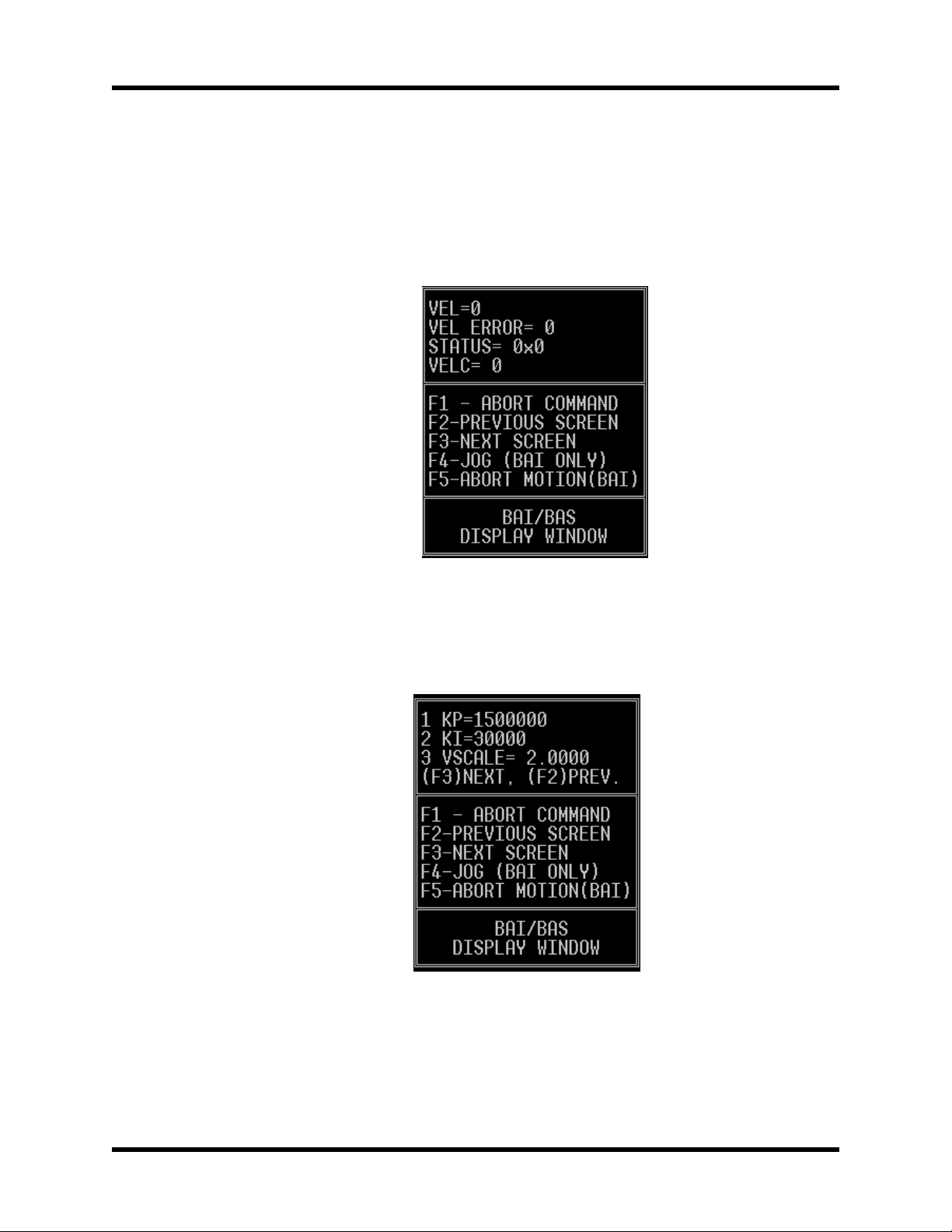

2.3. BAS Communications Modes

Using either the hand held terminal (HT) or the DOS emulation program, the first screen

the user will see is shown in Figure 2-1. This is the tracking screen (com_bai). This

program can be used with BA-Intellidrive (BAI) or BAS.

Figure 2-1. Tracking Screen

Pressing any key will take the user to the parameters screen. This screen is shown in

Figure 2-2.

Figure 2-2. Parameter Screen

2-2 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Configuration and Communication

2.4. Menu Commands

The BAS uses certain menu commands that allow the user to perform specific functions.

The first two parameters the user sees are the velocity loop gains. The fourth row shows

menu driven commands C, D, E, and T. The letter commands can be entered while in the

parameters screen. Pressing the letter immediately prompts the user for the next action.

These are described below.

1) C - Change a parameter.

2) D - Display tracking information.

3) E – Error Messages.

4) T - Transfer Parameters.

5) CTRL-D Reset the BAS.

F1 – Abort entry/return to previous menu.

F2/F3 – Previous or N ext menu.

<space> - cycles through menu commands.

2.4.1. C-Change Parameter

This command allows the user to change a parameter displayed on the screen, refer to

Figure 2-3. After pressing C, the user is prompted for the parameter they want to change.

To change the parameter, type in the number, press <ENTER> and the parameter is

changed and saved to the flash memory. Some parameters may not take effect until

issuing a reset. These parameters are discussed in Chapter 3: Parameters. Pressing the

F1 key aborts changing the pa rameter.

Figure 2-3. The Change Parameter Screen

Version 1.4 Aerotech, Inc. 2-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Configuration and Communication BA SineDrive User’s Manual

All parameters have upper and lower bounds. These bounds are provided in Chapter 3:

Parameters. If the user enters a number for a parameter which is out of the allowable

range, an error message appears. See the example in Figure 2-4, below.

Figure 2-4. Changing a Parameter in the Change Parameter Screen

2.4.2. D-Display Tracking Information

After pressing the D key, the user will see the following screen in Figure 2-5.

Figure 2-5. Display Tracking Screen

2-4 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Configuration and Communication

This screen shows the real time tracking display of the BAS. The velocity, velocity error,

status, and velocity command are shown. Status shows the current status of the BAS. The

bit patterns are shown in Table 2-3.

Table 2-3. Bit Patterns

Bit # Function

bit 0: Reserved

bit 1: Reserved

bit 2: Reserved

bit 3: Reserved

bit 4: Fault

bit 5: Reserved

bit 6: Reserved

bit 7: Reserved

See Section 2.5. for types of errors.

Version 1.4 Aerotech, Inc. 2-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Configuration and Communication BA SineDrive User’s Manual

2.5. E - Display Error Message

When an error occurs during operation, an error message will be generated. Errors can

occur from velocity error faults, amplifier faults or any other external fault. To display

these error messages, the error message selection should be chosen from the menu. Refer

to Figure 2-6.

Figure 2-6. Display Error Message Screen

2.5.1. BAS Faults

The BAS continually monitors different aspects of the amp/motor/encoder/control every

1ms for fault conditions. The possible fault conditions are listed below.

2.5.1.1. Invalid Hall Sequence

There are two invalid hall states that will cause the BAS to fault. They are the 000 and

111 states. The 111 state can occur if the encoder is not plugged into the BAS encoder

port. When initializing without halls, the BAS will ignore this fault.

2.5.1.2. RMS Current Error

PRM:16 and 17 will set the RMS fault threshold. The BAS uses averaging to monitor the

current command during operation. If the current command stays above the threshold too

long, the amplifier will fault.

2.5.1.3. Velocity Error

PRM:18 sets the max allowable velocity error before a fault occurs.

2-6 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Configuration and Communication

2.5.1.4. Encoder Fault

This fault will occur if an encoder is not present or if the BAS receives invalid signals

during operation.

2.5.1.5. Thermistor Fault

The thermistor can be used to monitor the motor. If the motor temperature is too high, the

BAS will detect this condition and generate a fault. Since many motors do not have

thermistors, PRM:21 can be used to disable this fault condition.

2.5.1.6. RMS Current Error

The above mentioned faults are all monitored by the software. In addition, there is

hardware on the BAS that also monitors the faults of the power stage. These faults are

listed below. Whenever the error message is AMP FAULT, one of the following has

occurred (note that the source of this fault cannot be easily determined):

• Over temperature

• Bias supply too low

• +5V too low

• RMS current (this is also monitored by the software and cannot be changed)

• Output short circuit

• DC bus over-voltage (if this occurs, a shunt board may be required).

2.5.2. F1- Abort Entry/Up One Menu Level

Pressing F1 aborts the current menu operation or moves up one level in the menu.

2.5.3. F2/F3 - Previous/Next Menu

This command allows the user to change the displayed parameters. The parameter

screens are circular, (i.e., if the user continually presses F3 or F2, they will eventually

return to the starting screen).

2.5.4. T - Transfer Parameters

Pressing "T" p ermits the user to upload or download parameters to their PC. The user is

queried to enter the file. File names follow the 8.3 convention and can co ntain numbers or

letters.

2.5.5. Space Bar

Pressing the space bar cycles through the available commands on the top level menu.

2.5.6. CTRL-D

Pressing "CTRL-D" issues a reset to the BAS. This is needed to clear any fault(s)

∇ ∇ ∇

Version 1.4 Aerotech, Inc. 2-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Configuration and Communication BA SineDrive User’s Manual

2-8 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Parameters

CHAPTER 3: PARAMETERS

In This Section:

• Introduction ...................................................................3-1

• Parameters ......................................................................3-1

3.1. Introduction

This chapter describes the various parameters used on the BAS. All parameters are

entered as numbers.

3.2. Parameters

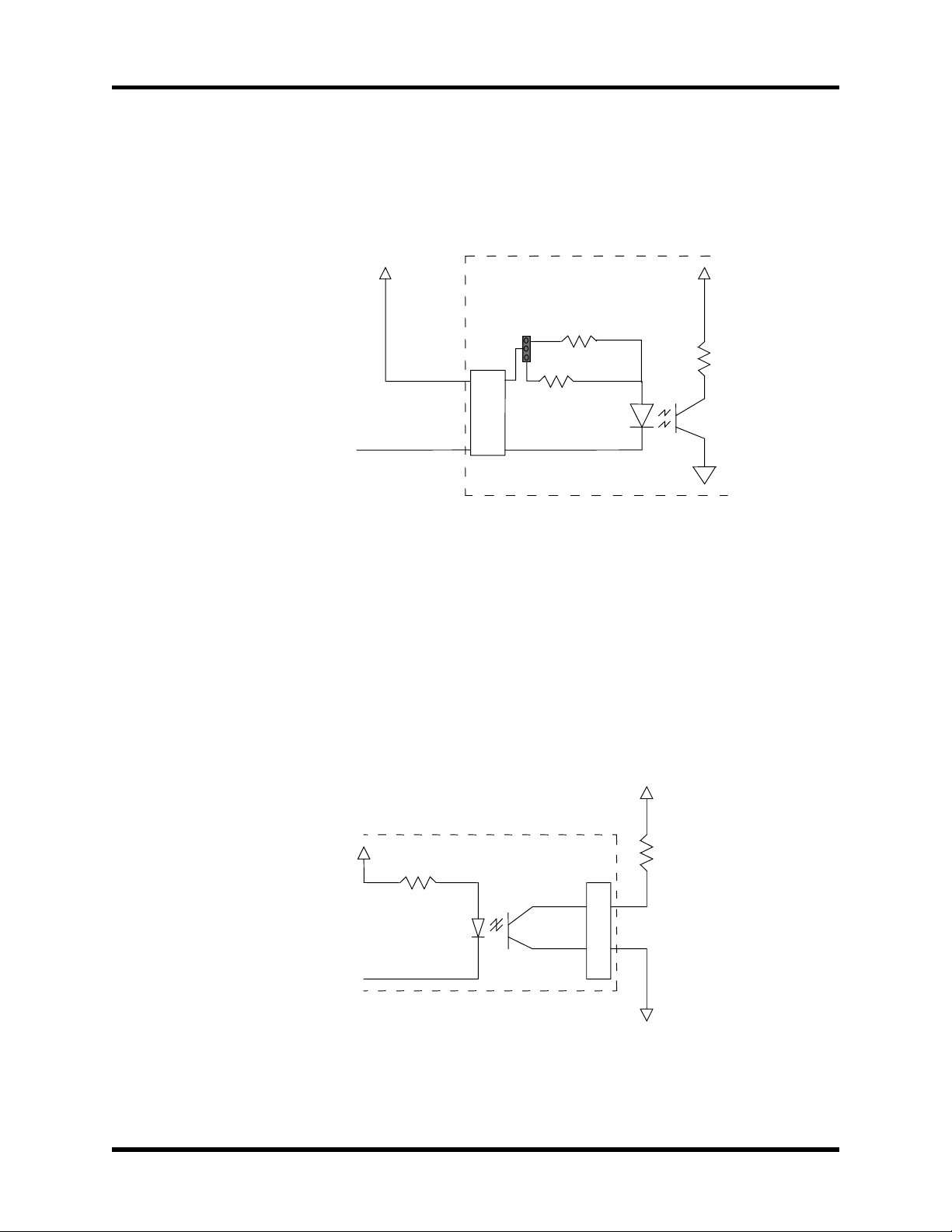

The servo loop parameters dictate the performance of the BAS’s operation. A block

diagram of the BAS’s velocity loop can been seen in Figure 3-1.

External Velocity

Command

PRM:20=2

Extern al Current

²

PRM:3

VSCALE

Velocity Feedback

from Encoder

KP

(PRM:1)

Kl/s

(PRM:2)

Command

Low Pass Filter

PRM:9, PRM:10

PRM:20=2

PRM:20=1, 2

Figure 3-1. PI Control Loop

The text in parentheses () following the parameter names in the section headings are

the abbreviation for that parameter as seen on the display.

To AMP

To AMP

Sine Wave

Commutation

(PRM:4, PRM:5)

Version 1.4 Aerotech, Inc. 3-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Parameters BA SineDrive User’s Manual

3.2.1. PRM:1 Proportional Velocity Gain (KP)

This parameter provides proportional gain adjustment to the velocity error mode of the PI

Control loop, refer to Table 3-1.

Table 3-1. Settings for Proportional Velocity Gain PRM:1

PRM:1 Settings

Default Value 750000

Maximum Value 2147483647

Minimum Value 0

Type Long (32 bit)

Units -

3.2.2. PRM:2 Integral Velocity Gain (KI)

This parameter provides integral gain adjustment to the velocity error mode of the PI

Control loop, refer to Table 3-2.

Table 3-2. Settings for Integral Velocity Gain PRM:2

PRM:2 Settings

Default Value 35000

Maximum Value 2147483647

Minimum Value 0

Type Long (32 bit)

Units -

3.2.3. PRM:3 Electronic Tach (VSCALE)

This parameter scales the velocity from the encoder. It is primarily used as a tach gain for

the velocity derived from the encoder. Refer to Table 3-3 for parameter settings.

Table 3-3. Settings for Electronic Tach PRM:3

PRM:3 Settings

Default Value 4

Maximum Value 1000

Minimum Value -1000

Units -

A negative value can be used to change the polarity of the velocity.

3-2 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Parameters

Vscale can be used to define the maximum speed the motor will move with a ± 10V input.

It can be calculated as follows:

90.40

Vscale

=

revX

=

z

sec

Where X rev/sec and counts/rev can be replaced by m/s for linear motors.

3.2.4. PRM:4 Encoder Resolution (ENCODER)

The encoder resolution is only needed for commutation. For rotary motors, this value

represents the line count of the encoder times 4. For example, if the resolution of the

encoder is 1000 (1000 lines/revolution), the user would enter 4000 for this parameter.

The multiplication by four is done in hardware on the controller.

z

Y

sec1

PRM

counts

8:/6000

rev

For linear motors, this number represents the number of counts for one electrical cycle.

For example, if a linear motor has an electrical cycle of 2.4 inches, and the encoder

resolution is 1µm, then the user would enter

Refer to Table 3-4 for parameter settings.

Requires a reset (CTRL-D) before taking effect.

Table 3-4. Settings for Encoder Resolution PRM:4

PRM:4 Settings

Default Value 4000

Maximum Value 2147483647

Minimum Value 300

Type Long (32 bit)

in

mmin

6

countsx

m

1000

11014.254.2

m

mm

60960

=

counts

Units Counts

Version 1.4 Aerotech, Inc. 3-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Parameters BA SineDrive User’s Manual

3.2.5. PRM:5 Electrical Cycles/Mechanical Revolution

(POLE PAIRS)

This parameter is the number of electrical cycles of the motor/mechanical revolution for

brushless motors. Also known as the number of pole-pairs. For linear motors, this PRM:5

should be one. Refer to Table 3-5 for parameter settings.

Requires a reset (CTRL-D) before taking effect.

Table 3-5. Settings for Electrical Cycles/Mechanical Revolution PRM:5

PRM:5 Settings

Default Value 4

Maximum Value 20

Minimum Value 1

Type Long (32 bit)

Units -

3.2.6. PRM:6 Hall Effects Available (HALLS)

If the motor has Hall effects available (PRM:6=1), the controller uses the halls to

initialize the commutation table. If the hall signals are not available or are not recognized

by the controller, the user should set this value to 0. If this value is 0, the controller

attempts to initialize the motor by energizing the phases to a known rotor position and

then commutate via the encoder from this known value. The peak current used to

energize the phases is given in PRM:7. Refer to Table 3-6 for parameter (PRM:6)

settings.

Requires a reset (CTRL-D) before taking effect.

If the user uses this method to initialize the motor on a linear stage, ensure that the stage

is not near a hardware limit.

Table 3-6. Settings for Hall Effects Available PRM:6

PRM:6 Settings

Default Value 1(Halls available)

Maximum Value 1

Minimum Value 0

Type Long (32 bit)

Units -

This method will not work on vertical stages.

3-4 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Parameters

3.2.7. PRM:7 Initialization Current (INIT CURRENT)

This parameter defines the peak current sent to the motor during an initialization. T his

only applies to brushless motors without hall signals (PRM:6=0). The value of this

parameter is in percent (%). Refer to Table 3-7 for parameter settings.

Care must be taken to ensure that the peak current applied to the motor does not

exceed the motor’s ratings.

IMPORTANT

Motor may jump during initialization. This is normal.

WARNING

Requires a reset (CTRL-D) before taking effect.

Table 3-7. Settings for Initialization Current PRM:7

PRM:7 Settings

Default Value 20

Maximum Value 100

Minimum Value 0

Type Long (32 bit)

Units % of Peak

The motor should not be in a limit.

Version 1.4 Aerotech, Inc. 3-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Parameters BA SineDrive User’s Manual

3.2.8. PRM:8 Velocity Loop Update Rate (UPDATE)

This parameter determines the velocity loop update time. The default value of 3

corresponds to a velocity loop update time of .5ms. Refer to Table 3-8 for parameter

settings. To compute the velocity loop update time, use the following formula:

Velocity loop update time = PRM:8/6000

Requires a reset (CTRL-D) before taking effect.

Table 3-8. Settings for Velocity Update Rate PRM:8

PRM:8 Settings

Default Value 3

Maximum Value 20

Minimum Value 1

Type Long (32 bit)

Units -

3.2.9. PRM:9 Low Pass Filter Enable (FILTER)

A low-pass filter can be inserted after sampling the torque/vel command by setting this

parameter to 1. The cutoff frequency is given in PRM:10. This can be used to smooth

out converter noise on the input command. Refer to Table 3-9 for parameter settings.

Requires a reset (CTRL-D) before taking effect.

Table 3-9. Settings for Low Pass Filter PRM:9

PRM:9 Settings

Default Value 0 (filter is not enabled)

Maximum Value 1

Minimum Value 0

Type Long (32 bit)

Units -

3-6 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Parameters

3.2.10. PRM:10 Filter Cutoff (CUT. FREQ.)

This parameter defines the cutoff frequency for the low-pass filter. The low pass filter

filters the current command from the PI loop. Refer to Table 3-10 for parameter settings.

Table 3-10. Settings for Filter Cutoff PRM:10

PRM:10 Settings

Default Value 500.0

Maximum Value 20000.0

Minimum Value 0

Type Float

Units Hz

3.2.11. PRM:11 Commutation Phase Offset (PHASE OFF)

This parameter allows the user to shift the commutation table by the value in PRM:11.

This parameter can be used if phase offsets occur in the current commands, (i.e., if the

current commands are out of phase with the back-emf of the motor). A phase shift can

occur if the hall signals are not aligned properly. Refer to Table 3-11 for parameter

settings.

This parameter can also be used to shift the commutation table for different Hall effect

schemes.

Requires a reset (CTRL-D) before taking effect.

Table 3-11. Settings for Phase Offset PRM:11

PRM:11 Settings

Default Value 0

Maximum Value 359

Minimum Value -359

Type Long (32 bit)

Units Degrees

Aerotech motors have a phase offset of 0°. Other vendors typically set it to 30°. Refer to

Section 5.4.2. for details on phasing

Version 1.4 Aerotech, Inc. 3-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Parameters BA SineDrive User’s Manual

3.2.12. PRM:12 Input Command Offset (CMD. OFF)

This parameter allows the user to correct for offsets in the external analog circuitry when

operating in velocity mode. Refer to Table 3-12 for parameter settings.

Table 3-12. Settings for Input Command Offset PRM:12

PRM:12 Settings

Default Value 0

Maximum Value 50000

Minimum Value -50000

Type Long (32 bit)

Units

3.2.13. PRM:13,14 Current Offset Adjustment (IA OFFSET, IB

OFFSET)

This parameter can be used to null out an offset in the current commands. PRM:13 is for

phase A and PRM:14 is for phase B. This value is added before the current commands

are sent to the DAC. Refer to Table 3-13 for parameter settings.

Table 3-13. Settings for Position Mode PRM:13, PRM:14

PRM:13, PRM:14 Settings

Default Value 0

Maximum Value 2048

Minimum Value -2048

Type Long (32 bit)

Units -

3-8 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Parameters

3.2.14. PRM:15 Servo Peak Current Limit (CURR. LIMIT)

This parameter controls the maximum allowable current that the PI loop can output. The

value is expressed in % of the amplifier’s peak current output. For example, if the

amplifier can output a peak current of 20 Amps, and PRM:15 is 50%, then the peak

current from the PI loop will be 10 Amps. Refer to Table 3-14 for parameter settings.

Table 3-14. Settings for Servo Peak Current Limit PRM:15

PRM:15 Settings

Default Value 100

Maximum Value 100

Minimum Value 0

Type Long (32 bit)

Units Percent (%)

Requires a reset (CTRL-D) before taking effect.

3.2.15. PRM:16 Servo RMS Limit (RMS LIMIT)

This parameter sets the RMS current limit that the PI loop can output before a fault

occurs. The value is expressed in % of the amplifier’s RMS current capability. For

example, if the amplifier has an RMS current rating of 10 Amps, and PRM:16 is 50%,

then the controller will generate a fault if the RMS current exceeds 5 Amps for longer

than the time given in PRM:17. Refer to Table 3-15 for parameter settings.

Table 3-15. Settings for Servo RMS Limit PRM:16

PRM:16 Settings

Default Value 20

Maximum Value 100

Minimum Value 0

Type Long (32 bit)

Units Percent (%)

Requires a reset (CTRL-D) before taking effect.

Version 1.4 Aerotech, Inc. 3-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Parameters BA SineDrive User’s Manual

3.2.16. PRM:17 Servo RMS Current Timeout (RMS TIME)

This parameter determines how long the current can remain above the RMS threshold

(given in PRM:16) before a fault is generated. Refer to Table 3-16 for p a rameter settings.

Table 3-16. Settings for Servo RMS Current Timeout PRM:17

PRM:17 Settings

Default Value 2

Maximum Value 10

Minimum Value 0

Type Long (32 bit)

Units Seconds

Requires a reset (CTRL-D) before taking effect.

3.2.17. PRM:18 Servo Velocity Trap (VEL ERR LMT)

This parameter defines the maximum allowable velocity error before a fault occurs. The

absolute value of the velocity error is compared against PRM:18. If it exceeds PRM:18, a

fault occurs. Setting this parameter to zero disables the velocity error check.

If the velocity error exceeds this value, the amplifier will be disabled and it issues a fault.

Refer Table 3-17 for parameter settings.

Table 3-17. Settings for Servo Velocity Trap PRM:18

PRM:18 Settings

Default Value 0

Maximum Value 65535

Minimum Value 0

Type Long (32 bit)

Units Counts/Samples

Requires a reset (CTRL-D) before taking effect.

3-10 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Parameters

3.2.18. PRM:19 Integral Clamp (INT CLAMP)

This parameter clamps the maximum value of the integrator term in the PI loop. This

prevents the PI controller from saturating in the presence of large velocity errors. Refer to

Table 3-18 for parameter settings.

Table 3-18. Settings for Integral Clamp PRM:19

PRM:19 Settings

Default Value 5000

Maximum Value 65535

Minimum Value 0

Type Long (32 bit)

Units Counts-Sam ples

Requires a reset (CTRL-D) before taking effect.

3.2.19. PRM:20 Operating Mode (MODE)

The BAS has two operating modes, refer to Table 3-19.

Table 3-19. Operating Modes PRM:20

Operating Mode PRM:20

Default value 1

Current command 1

Velocity command 2

The input is applied to pins 17 and 18 on connector P1.

Refer to Table 3-20 for parameter settings.

Requires a reset (CTRL-D) before taking effect.

Version 1.4 Aerotech, Inc. 3-11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Parameters BA SineDrive User’s Manual

Table 3-20. Settings for Operating Mode PRM:20

PRM:20 Settings

Default Value 1

Maximum Value 2

Minimum Value 1

Type Long (32 bit)

Units -

3.2.20. PRM:21 Thermistor Polarity (THERM POL.)

This parameter sets the polarity of the thermistor input. The thermistor input can be used

to detect an over temperature condition in a motor. A typical motor thermistor is a

positive temperature coefficient device, that is, as the temperature of the device increases,

so does the resistance of the device. The thermistor input on the BAS assumes this type

of device is used in the motor. Under normal operating conditions, the resistance of the

thermistor is low (i.e., 100 ohms). The BAS will see this as a low signal. As the

thermistor resistance increases, (i.e., 10K ohms), the internal pullup on the BAS will

dominate and the BAS will see this as a high signal. The BAS will then disable the po wer

stage. If the thermistor is not present (i.e., infinite resistance), the BAS will see this as an

over temperature condition and generate a fault. Consequently, this parameter should be

set to 1 if a thermistor is not present. Refer to Table 3-21 for parameter settings.

Table 3-21. Settings for Thermistor Polarity PRM:21

PRM:21 Settings

Default Value 1

Maximum Value 1

Minimum Value 0

Type Long (32 bit)

Units -

3-12 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Parameters

3.2.21. PRM:22 Enable Polarity (ENABLE POL.)

This parameter defines the logic value of the external enable signal for the power stage.

The external enable is found on the P1-5. Refer to Table 3-22 for p a rameter settings.

Table 3-22. Settings for Enable Polarity PRM:22

PRM:22 Settings

Default Value 0

Maximum Value 1

Minimum Value 0

Type Long (32 bit)

Units -

3.2.22. PRM:23 Fault Output Polarity (FAULT POL.)

This parameter defines the level of the fault output signal when a fault occurs. The

external fault output signal is found on the opto-isolated pin P1-10. Refer to Table 3-23

for settings.

Table 3-23. Settings for Fault Output Polarity PRM:23

PRM:23 Settings

Default Value 0 (active low)

Maximum Value 1 (active high)

Minimum Value 0 (active low)

Type Long (32 bit)

Units -

3.2.23. PRM:24 Encoder Polarity (Enc. Mult.)

This parameter allows the user to change the polarity of the encoder.

Table 3-24. Settings for Encoder Polarity PRM:24

PRM:24 Settings

Default Value 1

Maximum Value 1

Minimum Value -1

Type Long (32 bit)

Units -

∇ ∇ ∇

Version 1.4 Aerotech, Inc. 3-13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Parameters BA SineDrive User’s Manual

3-14 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Mode of Operation and Tuning

CHAPTER 4: MODE OF OPERATION AND TUNING

In This Section:

• Introduction ..................................................................4-1

• Velocity and Current Mode..........................................4-1

• Tuning ..........................................................................4-2

4.1. Introduction

This chapter contains all information regarding the BAS’s modes of operation.

4.2. Velocity and Current Mode

These two modes require an external command ±10 volt signal on P1-17 and P1-18. With

either mode, the BAS samples the external command and sinusoidally commutates a

brushless motor. If velocity mode is selected, the user can close the velocity loop

digitally on the BAS.

Commutation of a brushless motor requires the user to enter the encoder resolution

(PRM:4) and the number of pole-pairs (PRM:5). A commutation shift can also be added

by changing PRM:11.

A digital low pass filter can also be added to remove noise due to the PI controller or any

contamination during the A/D conversion. To enable the filter, change PRM:9 to a 1. The

filter cutoff can be found in PRM:10.

The user can also enable and disa ble the amplifier through the exter nal enable line P1-5 .

The polarity of this signal can be selected through PRM:22. A fault output is also

available on P1-10. Both the external enable and the fault output are opto-isolated.

When operating in current or velocity mode, the user typically needs to send the encoder

signals to the BAS and the external controller. To minimize the wiring, the encoder

signals on P3 are passed directly to P1-21, 22, 23, 24.

4.2.1. Current Mode

To operate the BAS in current mode, the user must first change the operating mode to

current command. This can be done by changing PRM:20 to 1. For this change to take

effect, a reset (CTRL-D) must be sent to the BAS.

When operating in current mode, the BAS relies on an external controller to close the

position and velocity loops. The BAS uses this command and with the encoder, will

sinusoidally commutate a brushless motor.

Version 1.4 Aerotech, Inc. 4-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Modes of Operation and Tuning BA SineDrive User’s Manual

4.2.2. Velocity Mode

To operate the BAS in velocity mode, the user must first change the operating mode to

velocity command. This can be done by changing PRM:20 to 2. For this change to take

effect, a reset (CTRL-D) must be sent to the BAS.

When operating in velocity mode, the BAS relies on an external controller to close the

position loop. The BAS, utilizing a proportional gain (PRM:1) and an integral gain

(PRM:2), closes the velocity loop digitally and sinusoidally commutates a brushless

motor. PRM:3 can be used as an electronic tach to scale the velocity.

Offsets in the velocity loop can be removed by modifying PRM:12.

4.3. Tuning

Starting with a zero input command signal (P1-17, P1-18 tied to sig. common), apply

power to the amplifier. If the motor spins uncontrollably, remove power and switch the

polarity of the input. If an encoder is being used, switch the sine and cosine input signals.

Verify complement signals (sin & sin-N, cos & cos-N) are of correct phasing.

Again, apply power to the amplifier. If the motor begins to oscillate, reduce Kp and KI

until oscillation stops. The Kp and Ks gains can be ad justed to provide maximum stiffness

on the motor shaft.

The PRM:12 is used to cancel any bias in the internal or external control circuit that

would cause the motor to rotate when the input command signal is zero.

∇ ∇ ∇

4-2 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Technical Details

CHAPTER 5: TECHNICAL DETAILS

In This Section:

• Introduction....................................................................5-1

• Hardware Overview and Function..................................5-1

• The I/O Port ...................................................................5-6

• Encoder/Limits/Hall Effects Port ...................................5-9

• BAS Amplifier Dimensions .........................................5-15

5.1. Introduction

This chapter contains detailed technical information regarding the inp uts and outputs of

the BA-SineDrive.

5.2. Hardware Overview and Function

The BA-SineDrive consists of two power connections (motor power and input power),

two LED indicator lamps, and three “D” style connectors. Refer to Figure 5-1 for

locations.

BAS 10/20/30

AC Power

Motor

Connections

LED S tatus

Indicators

COM Port

P2

I/O P ort

P1

Encoder/Lim its/Hall

Effects Port

P3

BAS 50/75/100 (BAS100 Show n)

Auxiliary

Power

I/O Po r t

P1

COM Port

P2

Figure 5-1. BA-SineDrive Hardware

AC Power

Mo to r

Connections

LED Status

Indicators

Encoder/Lim its/Hall

Effects Port

P3

Version 1.4 Aerotech, Inc. 5-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Technical Details BA SineDrive User’s Manual

5.2.1. Motor and AC Power Connections

For the BAS10, 20 and 30, AC power is applied to the BAS through the AC receptacle

located on the front of the unit. The power cord is similar to the type used with personal

computers. The motor co nnection is made through the terminal strip located on the front

of the BAS. This connector contains the motor connections along with the earth ground

connection.

5.2.1.1. Wiring, Grounding, and Shielding Techniques

To reduce electrical noise in the BAS Series amplifiers, the user should observe the motor

and input power wiring techniques explained in the following sections. This is suitable for

use on circuits capable of delivering not more than 5000A, 240V.

5.2.1.2. Minimizing EMI Interference and CE Compliance

The BAS amps are high efficiency PWM amplifiers operating at a 20 kHz switching rate.

The switching time between positive and negative rails on each of the motor leads is less

than 50 nano-seconds for a 320 VDC bus. This switching rate can generate

Electromagnetic Interference (EMI) into the MHz band. To minimize this EMI, it is

recommended that the motor leads be twisted together with the motor cable grounding

wire and surrounded with a foil shield. Refer to Figure 5-2.

In addition to the EMI effects, electrostatic (capacitive) coupling to the motor frame is

very high requiring the frame to be grounded in order to eliminate a shock hazard.

Additional electrostatic coupling exists between the three twisted motor leads and the foil

shield of the motor cable.

This coupling for ces high frequency currents to flow through the returning ear th ground

of the motor cable. To minimize this problem and maintain low levels of EMI radiation,

perform the following.

1. Use shielded cable to carry the motor current and tie the shield to earth ground. Refer

to Figure 5-2.

2. Place one toriod (ferrite) around the three motor leads (two leads for brush motors).

The toriod should have 10 turns for 16 AWG wire or 7 turns for 14 AWG wire. This

helps reduce the harmonics generated by the 20 KHz switching waveform. Use a

Ferroxcube 500T600-3C81 core or equal. Refer to Figure 5-2.

3. Use a cable with sufficient insulation. This will reduce the capacitive coupling

between the leads which, in turn, reduces the current generated in the shield wire.

4. Provide strong earth ground connections to the amplifier, additional heat sink, and

the motor. Offering electrical noise a low impedance path to earth ground not only

reduces radiated emissions, but also improves system performance.

5. If possible, do not route motor cables near cable carrying logic signals and use

shielded cable to carry logic signals.

In order to reduce conducted emissions, an external filter should be adde d to the BAS.

Aerotech can provide a filter box, PN# UFM, that will minimize line emissions for CE

(10A, 20A, and 30A models only).

5-2 Aerotech, Inc. Version 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

BA SineDrive User’s Manual Technical Details

One toroid (ferrite) around the three motor leads

(two for brush motors). There should be 10 turns

for 16 AWG wire and 7 turns for 14 AWG wire. Use

BAS

AMPLIFIER

LO

HI

A

B

C

a Ferroxcube 500T600-3C81 core or equal.

SHIELD

Twisted Together

MOTOR

Grounding

Screw

Earth Ground

This configuration is especially important if the BAS Amplifier is operating at DC bus voltages of 160 VDC or 320 VDC (e.g., 115 VAC or 230 VAC input power).

Case GND.

Figure 5-2. Wiring to Minimize EMI and Ca pacitive Coupling

5.2.1.3. Minimizing 50/60 HZ Line Interference

Operating the BAS series amplifiers from an off-line source of 115 VAC or 230 VAC

creates some additional problems.

First, there is a potential problem of EMI generated from the switching power stage of the

BAS amplifier propaga ting through the bridge rectifier and out through the HI and LO

input AC line connections. Back-propagation of noise into the AC lines can b e minimized

using a line filter. An example of such a filter and proper connection to the B AS amplifier

is shown in Figure 5-3.

10A slow blow -BAS10

BAS

AMPLIFIER

FRAME GND

A

C

LO

HI

B

Torque

to 5 - 7 in-lb

.

20A slow blow -BAS20

30A slow blow -BAS30

Use 60 degree C copper conductors only

Schaffner FN2070-10-06

includes common mode

choke and ferrite.

PN: UFM

115/230 VAC

50/60 Hz

Grounding Screw

Earth Ground

This configuration is especially important if the BAS Amplifier is operating at DC bus voltages of 160 VDC or 320 VDC (e.g., 115VAC or 230VAC input power).

Figure 5-3. Back-Propagation Line Filter Connection

Version 1.4 Aerotech, Inc. 5-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Technical Details BA SineDrive User’s Manual

Second, another problem that potentially exists with off line connections is 50/60 Hz