Aeromotive 17122 User Manual

AEROMOTIVE

Part # 17122

Street Rod Fuel Pump Kit

INSTALLATION INSTRUCTIONS

CAUTION:

Installation of this product requires detailed knowledge of automotive systems and

repair procedures. We recommend that this installation be carried out by a qualified

automotive technician.

Installation of this product requires handling of gasoline. Ensure you are working in a

well ventilated area with an approved fire extinguisher nearby. Extinguish all open flames,

prohibit smoking and eliminate all sources of ignition in the area of the vehicle before

proceeding with the installation.

When installing this product, wear eye goggles and other safety apparel as needed to

protect yourself from debris and sprayed gasoline.

WARNING!

The fuel system is under pressure. Do not open the fuel system until the pressure has

been relieved. Refer to the appropriate vehicle service manual for the procedure and

precautions for relieving the fuel system pressure.

Aeromotive system components are not legal for sale or use on emission controlled motor vehicles.

This kit contains the following parts

1 ea p/n 16301 fuel pump wiring kit

20 ft AN-08 stainless steel braided line

2 ea AN-08 straight hose end

2 ea AN-08 90-degree hose end

1 ea p/n 11203 Pump

2 ea p/n 12303 Filter

12 ea tie-wraps

2 ea 3/8-NPT Hex Nipple

2 ea p/n 15616 3/8-NPT to AN-08

If you are using a stock fuel tank, install a reservoir style sump in the bottom-rear of your fuel

tank. Exercise extreme caution and follow all manufacturer’s recommendations when

installing a reservoir style sump.

If you choose not to install a reservoir style sump, then you must install a high flow capacity

fuel tank pickup.(Installing a high flow pickup instead of a reservoir style sump may

shorten the fuel pump life and cause driveability problems. Stock fuel tanks have a small

inlet reservoir that is quickly emptied by a high flow fuel system, causing pump starvation

and cavitation. When using a pickup, you should maintain at least ½ tank of fuel in the

vehicle at all times, to avoid emptying the stock inlet reservoir.)

The following steps are typical of most installations:

Section 1 - Fuel pump installation

Section 2 – Fuel line hose end installation

Section 3 – Electrical Installation

Section 4 – Final checks and system start-up

:

Section 1 - Fuel pump installation:

DO NOT RUN THE PUMP DRY! Excessive wear will result if the pump runs dry.

DO NOT DISASSEMBLE THE PUMP! Disassembly will throw the pump out of calibration and void all warranties on this

product.

DO NOT ATTEMPT TO ADJUST THE OUTLET PRESSURE SCREW! The maximum outlet pressure has been preset at

the factory and locked in its current position. Adjusting it will void all warranties on this product.

1-1. Once the engine has been allowed to cool, disconnect the negative battery cable and relieve the fuel system

pressure.

1-2. Raise the vehicle and support it with jack stands.

1-3. Referring to the appropriate vehicle service manual for instructions, drain, disconnect any electrical and fuel

component connections, plug the open fuel line ends and remove the existing pump

1-4. Find a suitable place on the vehicle chassis to mount the Aeromotive fuel pump. Make sure the location will

accommodate the pump mounting bolts, will position the pump lower than the fuel tank, is clear of the exhaust, is

clear of any moving suspension or drivetrain components and will keep the pump clear of road obstructions or debris.

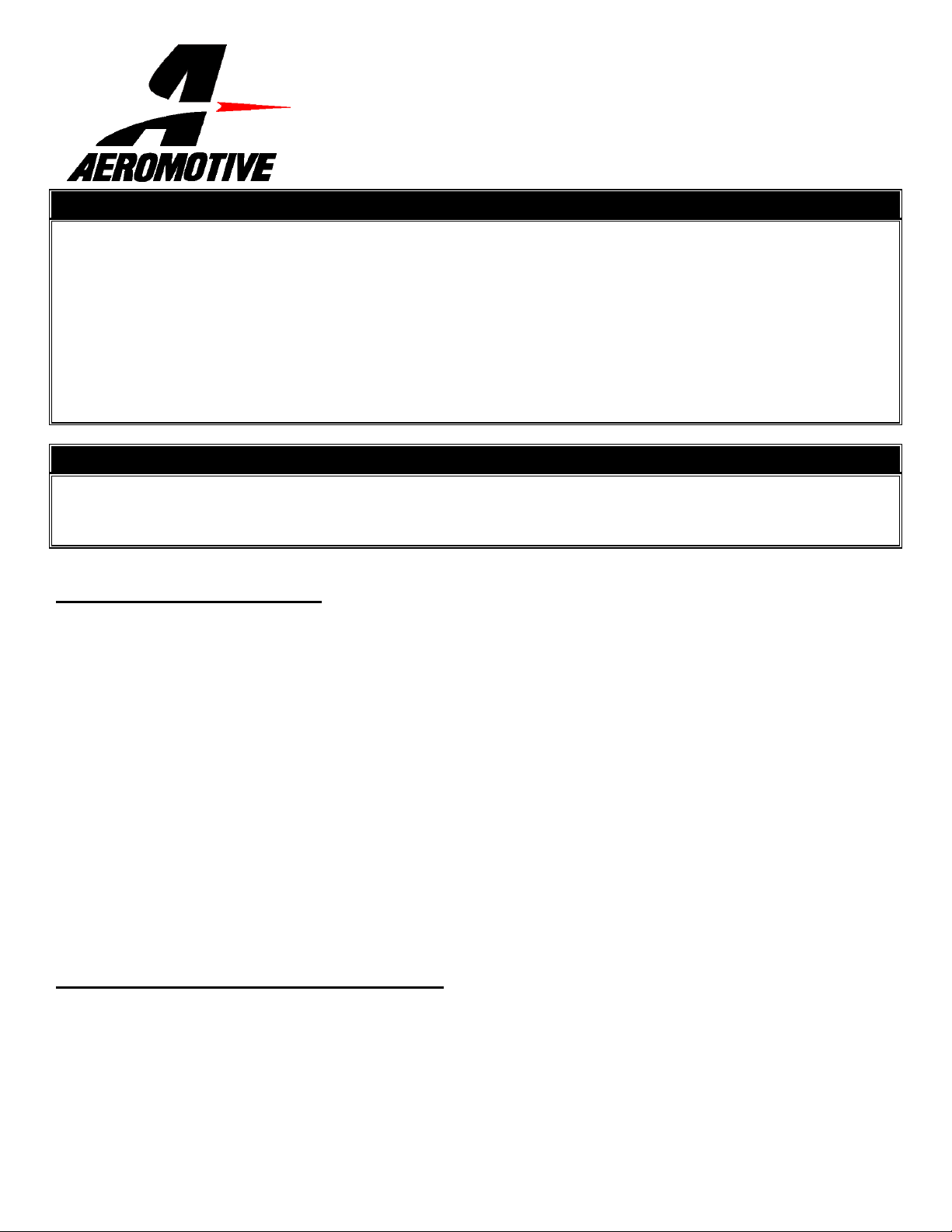

1-5. Apply pipe thread sealant to one end of each of the two 3/8-NPT hex nipples and thread into each side of the

Aeromotive fuel pump. (Figure 1-1)

Figure 1-1

1-6. Apply pipe thread sealant to remaining side of 3/8-NPT hex nipples and thread Aeromotive filters on both side of

Aeromotive fuel pump, paying close attention to pump and filter inlets and outlets. (Figure 1-2)

Inlet Side

Inlet Side

Figure 1-2

1-7. Apply pipe thread sealant to the pipe thread side of two 3/8-NPT to AN-08 Adapters and thread into the remaining

side of the fuel filters. (Figure 1-3)

Inlet Side

Figure 1-3

1-8. Making sure to mount the pump in the upright position and using the pump mounting bracket as a template, mark and

drill two mounting holes to accept ¼” bolts (not provided). Mount the pump bracket using two ¼” bolts, nuts and lock

washers (Not provided). Slide the pump into the bracket and tighten the clamping bolt. Do not over-tighten the

clamping bolt. Doing so can permanently damage the pump motor!

Note: Be sure to route all fuel lines clear of any moving suspension or drivetrain components, and any exhaust

components! Protect fuel lines from abrasion and road obstructions or debris.

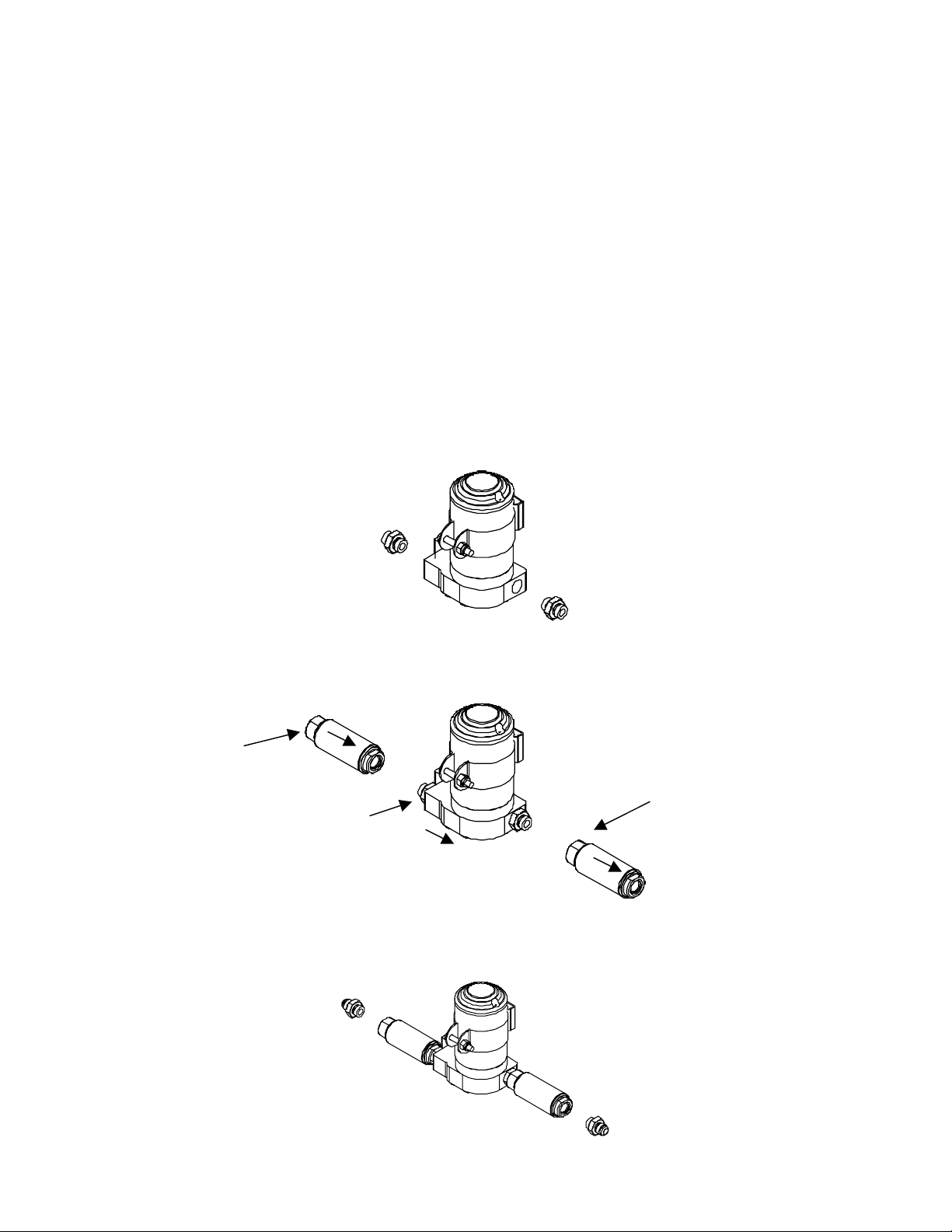

1-9. Using one of the supplied 90-degree AN-08 hose ends and one of the supplied straight AN-08 hose ends as a guide,

measure the length of AN-08 steel braided line needed to connect the fuel tank or fuel cell outlet to the fuel pump /

filter assembly inlet. This section of fuel line should be as short as possible to reduce the tendencies for vapor lock,

cavitation, and premature wear of your Aeromotive fuel pump.

1-10. Cut and assemble the steel braided hose and hose ends as shown in Section 2.

1-11. Using the above steel braided hose assembly, connect the 90-degree end to the outlet of the fuel tank / fuel cell

and the straight end to the fuel pump / filter assembly inlet and tighten. See figure 1-4

Figure 1-4

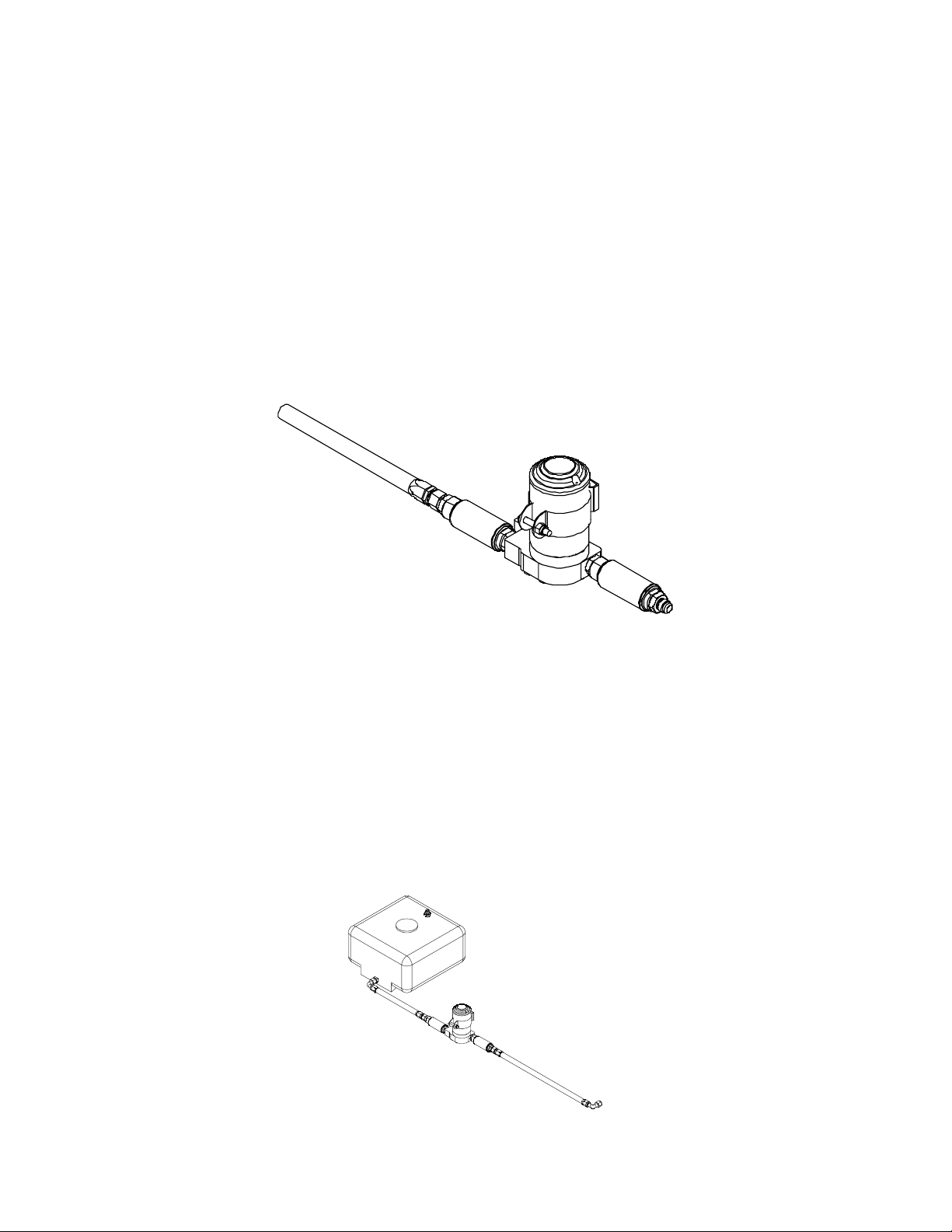

1-12. In the vehicles engine compartment determine where your fuel pressure regulator (Not supplied) is or will be

mounted. We recommend Aeromotive p/n 13201 for 2-port applications and Aeromotive p/n 13203 for 4-port

applications.

1-13. Using one of the supplied 90-degree AN-08 hose ends and one of the supplied straight AN-08 hose ends as a

guide, measure the length of AN-08 steel braided line needed to connect the fuel pump / filter assembly outlet to the

fuel pressure regulator (Not Supplied).

1-14. Cut and assemble the steel braided hose and hose ends as shown in Section 2.

1-15. Using the above steel braided hose assembly, connect the straight end to the outlet of the fuel pump / filter

assembly outlet and the 90-degree end to your fuel pressure regulator. See Figure 1-5

Figure 1-5

Loading...

Loading...