Aeromotive 11115 INSTALLATION INSTRUCTIONS

AEROMOTIVE Part # 11115

INSTALLATION INSTRUCTIONS

Not For Street Use!

CAUTION:

Installation of this product requires detailed knowledge of automotive systems and repair procedures. We

recommend that this installation be carried out by a qualified automotive technician.

Installation of this product requires handling of gasoline. Ensure you are working in a well ventilated area

with an approved fire extinguisher nearby. Extinguish all open flames, prohibit smoking and eliminate all sources

of ignition in the area of the vehicle before proceeding with the installation.

When installing this product, wear eye goggles and other safety apparel as needed to protect yourself

from debris and sprayed gasoline.

WARNING!

The fuel system is under pressure. Do not open the fuel system until the pressure has been relieved.

Refer to the appropriate vehicle service manual for the procedure and precautions for relieving the fuel system

pressure.

The enclosed Aeromotive fuel pump utilizes an o-ring sealed AN-12 style outlet ports; this port is NOT PIPE THREAD

and utilizes NO THREAD SEALANT.

To use this pump in your vehicle’s fuel system, we strongly recommend the following

Gravity feed the pump by mounting it lower than the fuel cell.

Utilize high pressure fuel lines, fittings and o-rings for all connections from the

fuel cell to the engine.

Failure to follow the above recommendations may result in fuel leakage, bursting of the fuel lines, poor vehicle

performance and/or decreased fuel pump life! Improper installation will void all warranties for this product!

Aeromotive system components are not legal for sale or use on emission controlled motor vehicles.

Performance Specifications: Model 11115

Fuel Compatibility Gasoline & Methyl Alcohol

Port Sizes 1 ¼” Inlet & AN-12 Outlet

Pump mounting:

Pump should be mounted as low as possible to ease priming.

Due to the large number of applications, no specific mounting instructions are provided.

Pump should turn at half the engine speed.

Recommend a 28-tooth pulley on the pump and a 14-tooth pulley on the crankshaft.

Call for details on Aeromotive mounting kits.

:

The following steps are typical of most installations:

1. Once the engine has been allowed to cool, relieve the fuel system pressure and disconnect the negative battery

cable.

2. Raise the vehicle and support it with jack stands.

3. Find a suitable place on the engine or chassis to mount the Aeromotive fuel pump. Make sure the location will

accommodate the pump mounting bracket, will position the pump as low as possible, is clear of the exhaust, is clear

of any moving suspension or drivetrain components and will keep the pump clear of track obstructions or debris.

Note: Be sure to route all fuel lines clear of any moving suspension or drivetrain components, and any exhaust

components! Protect fuel lines from abrasion and track obstructions or debris.

4. Acquire a 14-tooth, timing belt pulley for the crankshaft, a 28-tooth timing belt pulley for the pump and a ½” wide

timing belt of the desired length. Call Aeromotive for details on mounting kits.

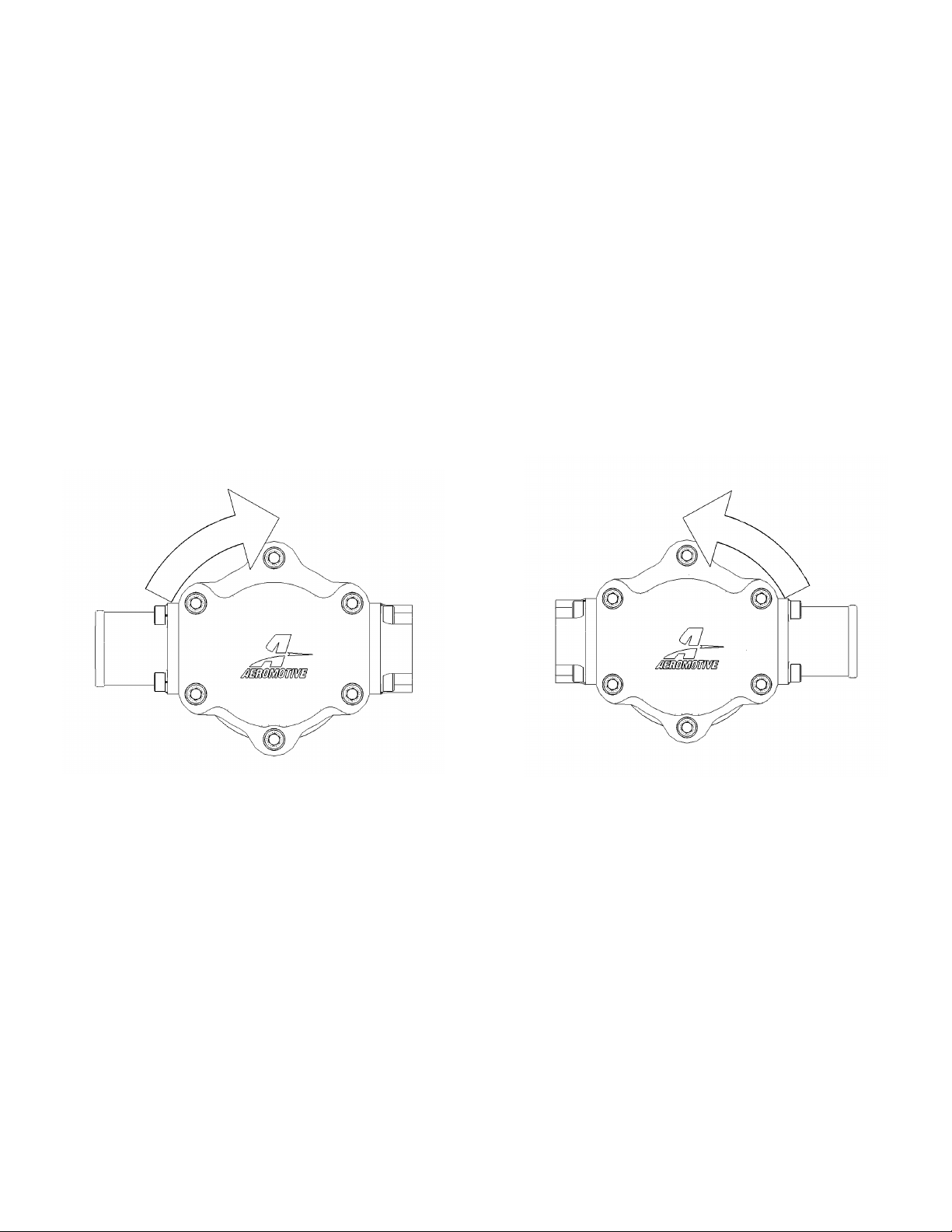

5. Determine which direction the fuel pump shaft will rotate. The direction the shaft is rotated will determine which port is

the inlet and which is the outlet. Using Figure 1a & 1b as a reference identify the fuel pump inlet and outlet ports. If the

fuel pump shaft is rotated in a clockwise direction as viewed from the front of the pump the inlet and outlet ports will

be as shown in Figure 1a. If the fuel pump shaft is rotated in a counter-clockwise direction the inlet as shown in figure

1a now becomes the outlet and the outlet in figure 1a is now the inlet, this is shown in figure 1b.

INLET INLETOUTLET

Figure 1a Figure 1b

6. Connect the fuel cell sump to the fuel filter inlet, utilizing a minimum of 1 ¼” fuel line. Next, connect the fuel filter outlet

to the fuel pump inlet utilizing a minimum of AN-10 steel braided fuel line, refer to Figure 1 for determining the fuel

pump inlet.

7. Connect the fuel pump outlet to the vehicle’s fuel system. Make sure you use high pressure (1000 psi minimum)

fuel line for this connection!

Note: Be sure to route all fuel lines clear of any moving suspension or drivetrain components, and any exhaust

components! Protect fuel lines from abrasion and track obstructions or debris.

OUTLET

Loading...

Loading...