Aeroflex UTMC UTR50, UTR75, UTR100, UTR25, UTR150 Datasheet

...

Semicustom Products

UTR 0.8µ Gate Array Family

Preliminary Data Sheet

Jan. 2000

FEATURES

q Up to 200,000 usable equivalent gates

q Clock rates up to 180 MHz

q Advanced 0.8µ radiation-hardened silicon gate CMOS

q Operating voltage of 5V

q QML Class Q & V compliant

q Designed specifically for high reliability applications

q Radiation-hardened to 1.0E6 rads(Si) total dose

(functional) and SEU-immune cells to less than 1.0E-10

errors/bit-day

q JTAG (IEEE 1149.1) boundary-scan registers built into

I/O cells

q Low noise package technology for high speed circuits

q Design support using Mentor Graphics®, SynopsysTM and

VHDL tools on HP® and Sun® workstations

q Standard Microcircuit Drawing pending

PRODUCT DESCRIPTION

The high-performance UTR 0.8µ gate array family

features densities of up to 200,000 equivalent gates and is available in MIL-PRF-38535 QML Q and V quality levels and

radiation-hardened.

For those designs requiring stringent radiation hardness,

UTR’s 0.8µ process employs a special processing module that

enhances the total dose radiation hardness of the field and gate

oxides while maintaining circuit density and reliability. In addition, for both greater transient radiation-hardness and latchup

immunity, the UTR 0.8µ process is built on epitaxial substrate

wafers.

Developed from UTMC’s patented architectures, the

UTR 0.8µ array family uses a highly efficient continuous transistor architecture for the internal cell construction. Combined

with state-of-the-art placement and routing tools, the

utilization of available transistors is maximized using three levels of metal interconnect.

The UTR 0.8µ family of gate arrays is supported by an extensive cell library that includes SSI, MSI, and 54XX equivalent

functions, as well as, configurable RAM and other megafunctions. UTMC’s megacell library includes the following

functions:

• Intel 80C31® equivalent

• MIL-STD-1553 functions (BRCTM, RTI, RTMP)

• MIL-STD-1750 microprocessor

• RISC microcontroller

• Configurable RAM

2

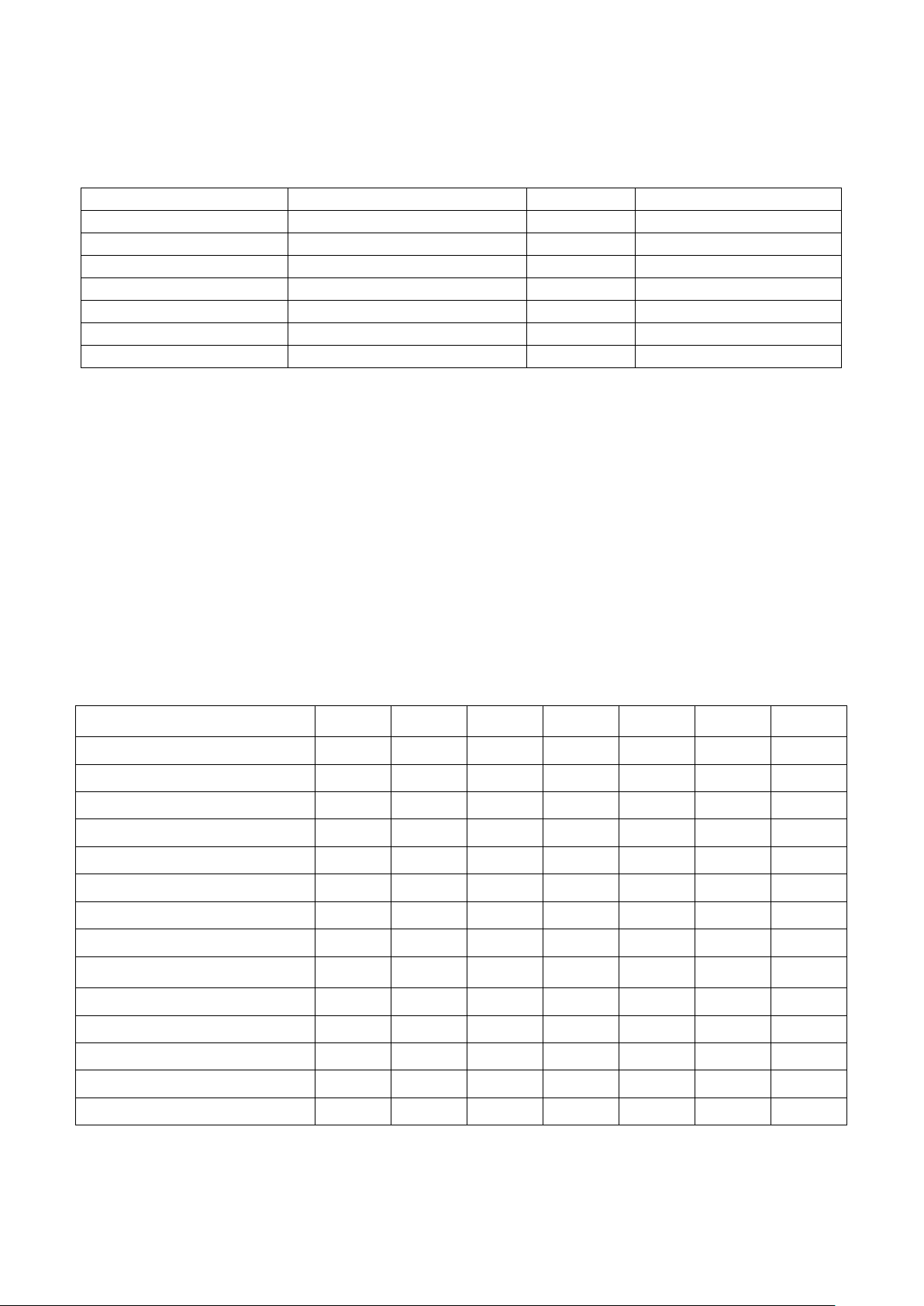

Table 1. Gate Densities

Notes:

1.The "R" denotes radiation-hardened.

2.Based on NAND2 equivalents. Actual usable gate count is design-dependent. Estimates reflect a mix of functions including RAM.

3.Includes five pins that may or may not be reserved for JTAG boundary-scan, depending on user requirements.

4.Reserved for dedicated VDD/VSS and V

DDQ/VSSQ

.

Low-noise Device and Package Solutions

The UTR 0.8µ output drivers feature programmable slew rate

control for minimizing noise and switching transients. This feature allows the user to optimize edge characteristics to match

system requirements. Separate on-chip power and ground buses

are provided for internal cells and output drivers which further

isolate internal design circuitry from switching noise.

In addition, UTMC offers advanced low-noise package technology with multi-layer, co-fired ceramic construction featuring

built-in isolated power and ground planes. These planes provide

lower overall resistance/inductance through power and ground

paths which minimize voltage drops during periods of heavy

switching. These isolated planes also help sustain supply voltage during dose rate events, thus preventing rail span collapse.

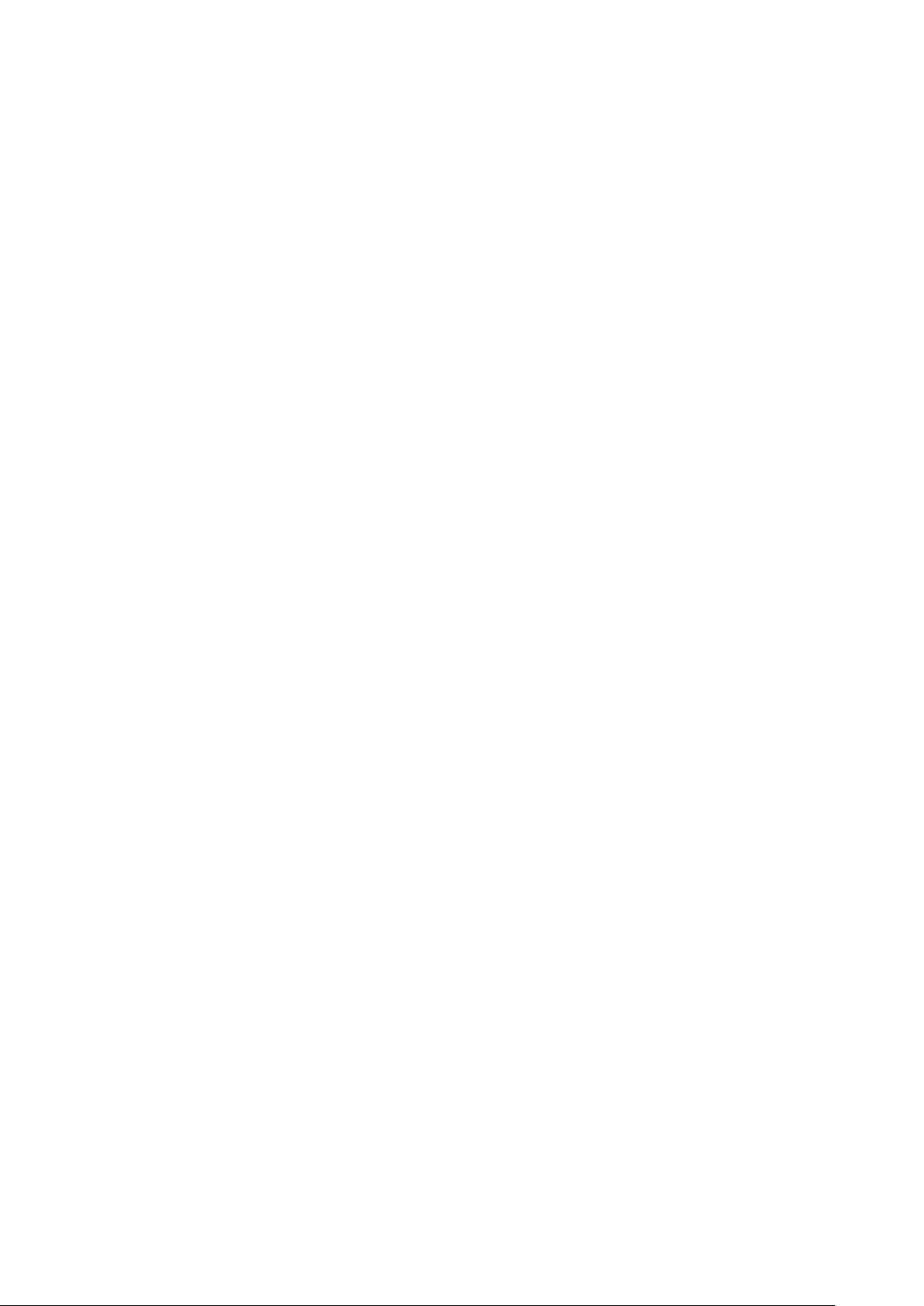

Flatpacks are available with up to 304 leads; PGAs are available

with up to 280 leads. UTMC’s flatpacks feature a non-conductive tie bar that helps maintain lead integrity through test and

handling operations. In addition to the packages listed in Table

2, UTMC offers custom package development and package tooling modification services for individual requirements.

Table 2. Packages

Notes:

1. The number of device I/O pads available may be restricted by the selected package.

2. PGA packages have one additional non-connected index pin (i.e., 144 + 1 index pin = 145 total package pins for the 144 PGA).

Contact UTMC for specific package drawings.

DEVICE PART NUMBERS1EQUIVALENT USABLE GATES2SIGNAL I/O3POWER & GROUND PADS

4

UTR25 5,000 - 25,000 175 40

UTR35 35,000 175 40

UTR50 50,000 175 40

UTR75 75,000 256 80

UTR100 125,000 256 80

UTR150 150,000 256 80

UTR200 200,000 256 80

PACKAGE TYPE/LEADCOUNT

1

UTR25 UTR35 UTR50 UTR75 UTR100 UTR150 UTR200

Flatpack

84 X X X

132 X X X

172 X X X X X X X

196 X X X X X X X

224 X X X X

256 X X X X

304 X X X X

PGA

2

84 X X X

120 X X X X

144 X X X

208 X X X X X X X

280 X X X X

3

Extensive Cell Library

The UTR 0.8µ family of gate arrays is supported by an extensive

cell library that includes SSI, MSI, and 54XX-equivalent functions, as well as, RAM and other megafunctions. User-

selectable options for cell configurations include scan for all

register elements, as well as output drive strength. UTMC’s

megacell library includes the following functions:

• Intel® 80C31 equivalent

• MIL-STD-1553 functions (BCRTM, RTI, RTMP)

• MIL-STD-1750 microprocessor

• Standard microprocessor peripheral functions

• Configurable RAM

Refer to UTMC’s UTR 0.8µ Design Manual for complete cell

listing and details.

I/O Buffers

The UTR 0.8µ gate array family offers up to 342 device pad

locations (note: device pad availability is affected by package

selection and pinout.) The I/O cells can be configured by the

user to serve as input, output, bidirectional, three-state, or additional power and ground pads. Output drive options range from

2 to 8mA. To drive larger off-chip loads, output drivers can be

combined in parallel to provide additional drive up to 12mA.

Other I/O buffer features and options include:

• Slew rate control

• Pull-up and pull-down resistors

• TTL, CMOS, and Schmitt levels

• Built-in boundary-scan

JTAG Boundary-Scan

The UTR 0.8µ arrays include a test access port and boundaryscan architecture that conforms to the IEEE Standard 1149.1

(JTAG). Some of the benefits this capability offers include the

following:

• Allows easy test of complex assembled printed circuit

boards

• Can be used to gain access to and control internal

scan paths

• Can be used to initiate Built-In Self Test

Clock Driver Distribution

UTMC design tools provide methods for balanced clock distribution that maximize drive capability and minimize relative

clock skew between clocked devices.

Speed and Performance

UTMC specializes in high-performance circuits designed to operate in harsh military and radiation environments. Table 3

presents a sampling of typical cell delays.

Note that the propagation delay for a CMOS device is a function

of its fanout loading, supply voltage, operating temperature, and

processing tolerance. In a radiation environment, additional performance variances must be considered. The UTR 0.8µ

simulation models account for all of these effects to accurately

determine circuit performance for its particular set of use

conditions.

Power Dissipation

Each internal gate or I/O driver has an average power consumption based on its switching frequency and capacitive loading.

The radiation-hardened processes exhibit power dissipation that

is typical of CMOS processes. For a rigorous power estimating

methodology, refer to the UTMC UTR 0.8µ Design Manual or

consult with a UTMC Applications Engineer.

Loading...

Loading...