Page 1

OWNER’S GUIDE

USE AND CARE MANUAL

DUCTED COOLER MODELS:

TD3800, TD4801, TD4812, TD6801, TD6812

TH3800, TH4801, TH4812, TH6801, TH6812,

TUP6801, TUP6812

For Customer Assistance

CALL 1-800-325-6952

DO NOT RETURN TO PLACE OF PURCHASE!

Congratulations: You have purchased a product of superior performance and design,

Safety

Installation

Start-up

Operation

Maintenance

Trouble Shooting

which will give the best service when properly installed, operated and maintained.

This guide will provide you with information needed to mount, operate, inspect, maintain,

and troubleshoot your evaporative air cooler.

The first section, Installation and Start-Up, gives details for installation. The second

section, Maintenance, contains operational and maintenance instructions , while

Troubleshooting includes information on commonly encountered problems.

INSTALLER: Please deliver this guide to owner.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING.

Read all instructions carefully before installation.

Use only the blower motor and circulating pump(s)

combinations marked on the Model Nameplate indicating

suitability for use in this model. Any other motors or pumps

cannot be substituted.

Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable codes

and standards, including fire rated construction.

When cutting or drilling into a wall or ceiling, do not

damage electrical wiring or other concealed utilities (water

or gas lines, sewer lines, etc.).

Cooler motor, pump, cabinet and junction box must be

grounded in accordance with all local and national codes.

A ground wire must be used between the power supply

and the cooler.

Be sure that the cooler is connected to proper line voltage

stamped on the pump and blower (fan) motor specification

plate. NOTE: Improper voltage will void the pump and/or

motor warranties and may cause serious personal injury

or property damage.

Do not operate this blower (fan) motor with any solid-state

speed control device.

Always disconnect electrical power to unit before working

on or servicing cooler. More than one disconnect switch

may be required to de-energize the equipment for

servicing.

Do not remove access panels while cooler is running, this

may cause the blower (fan) motor to overload and damage

the motor windings.

NOTE:

Do not locate unit near exhaust or vent pipes as odors or

fumes may be drawn into cooler.

Use of anode devices, chemical additives or treatments in this

cooler will void the warranty.

Your warranty does not cover shipping damage. Report all

shipping damage at once to dealer or carrier making the

delivery.

For future reference, record the model and serial numbers,

date and place of purchase of your evaporative cooler here:

Model #

Serial #

Date of Purchase:

Place of Purchase:

1-999-2467 Date: 1/14

Page 2

INTRODUCTION

Your Trophy evaporative air cooler was thoroughly tested and

inspected before leaving the factory. This manual is your guide to

proper installation procedures along with information about

reasonable care and maintenance that will ensure safe, economical

and trouble free cooling. Failure to follow these instructions may

damage your cooler, impair its operation, create the potential for

serious personal injury and/or void the warranty. Read it carefully.

Installation normally involves the connection of the blower opening to

a duct system or to a short duct with a ceiling diffuser. For an

installation in an existing building, modifications may be necessary. If

installation is being done by someone other than a professional HVAC

contractor, it is suggested that the installation be thoroughly discussed

with a professional person familiar with cooler installation.

attempt to perform any part of the installation described in this manual

unless you are fully qualified to do so.

Carefully read the contents of this manual before beginning the

installation process.

Don't

Location

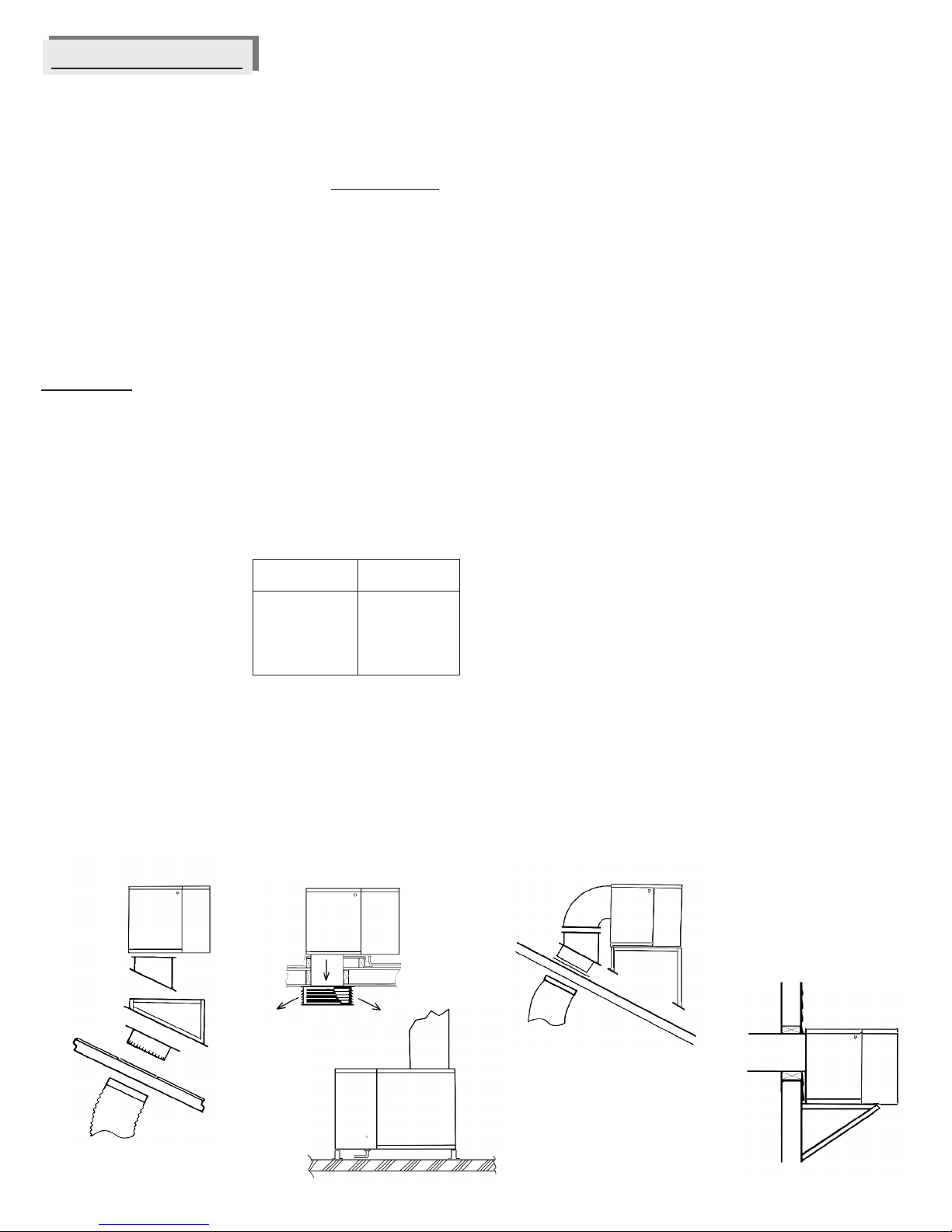

Your cooler may be a down (TD), horizontal (TH) or up (TUP)

discharge model. Down discharge coolers are designed for

installation on either flat or pitched roofs (see Fig. 1). Horizontal

discharge coolers are designed for installation on the side of a building

or, using a 90-degree transition duct, on a flat or pitched roof (see Fig.

2). Up discharge coolers are designed for ground level installation,

mounted on a slab (see Fig 3). Evaporative air-cooling systems

(down, side or up discharge) can be connected to a duct distribution

system with outlet registers for each area to be cooled.

Install coolers in a location where only fresh outside air can enter the

cooling system. Avoid installing units in closed-in areas, such as an

attic or storeroom, which restricts free air movement around and into

the cooler, or near vent pipes, kitchen exhaust, etc.; as obnoxious

odors or fumes may be drawn into unit.

NOTE: When coolers are installed within the jurisdiction of the City of

Los Angeles (C.O.L.A.) Building codes, they can only be installed on

the outside of buildings.

CAUTION: All mechanical, plumbing and electrical

installations must comply with local and national building

and safety codes, and must be performed by qualified

personnel only.

NOTE - References in this manual to local or national codes means

that those items must comply with applicable installation codes as

specified by the building code authority having jurisdiction at the

installation location. It is the installer's duty to comply with all building

code requirements.

Before attempting to install the cooler, confirm that the following

preparations have been made:

Verify that the supporting

surface is strong enough to

bear the weight of the cooler

when in use; remember that

when the system fills with

water, the cooler will be much

heavier than when dry.

Make sure you have adequate resources for lifting the cooler.

Check the electric power supply to see that it matches the

requirements shown on the model and motor nameplates.

Verify that the supporting surface is level in all directions; this is

necessary to ensure proper distribution of water into the pad,

maximizing cooling performance.

Confirm that any planned ductwork and electrical supply installation

needs comply with local and national codes.

Model Number Operating

TD / TH 3800 175

TD / TH 4801 190

TD / TH 4812 215

TD / TH 6801 220

TD / TH 6812 260

TUP 6801 220

Weight (lbs.)

Air Exhausting / Maximum Cooling

Evaporative air coolers will function correctly only if there is a way for

the cooled air to exit the building. Windows, vents, doors or other

exhaust openings at a point most distant from cooled air inlet should

be open to permit free movement of air out of the area being cooled,

and to avoid building up excessive pressure inside the space. Proper

location of exhaust openings is important as they guide flow of air

through areas where cooling is desired.

Since coolers function best when there is plenty of exhaust air, you

can leave doors or windows open so your house can breathe.

the maximum capacity of your cooler, and to help keep insects, dust,

dirt, etc out of the cooled space, the building/space should be

maintained at a slightly positive air pressure (airflow going into the

building should be slightly more than the air that is leaving).

How much should you open your windows? You should open your

windows until the air pressure inside the house is nearly balanced

with the air outside. One method used to determine when the air is

reasonably balanced is to place a tissue paper against the screen

in the window furthest from the cooler and adjust the opening of the

other windows in the house until the tissue paper stays lightly on the

screen. This is usually about 2 square feet of opening per 1000 cfm

of air produced by the cooler. You can adjust different windows in

the house to direct the most airflow to the areas that are occupied

during different times of the day or night (example: living room

windows during the daytime, bedroom windows at night.)

To eliminate a rush of warm air when starting the cooler be sure to

turn on the pump for a few minutes to completely wet out the pads

before turning the blower on.

To get

FIGURE 1

2 Trophy Ducted Evaporative Cooler Use and Care Manual

FIGURE 2

FIGURE 3

Page 3

Duct System

Air can be delivered over a distance to individual rooms or areas by

means of a duct system. The duct system, which is tailored to fit the

building, should be designed, fabricated and installed by a competent

HVAC sheet metal contractor, preferably while building is under

construction.

INSTALLATION

CAUTION: Disconnect all electrical power to the cooler

before attempting to install, open, or service your cooler.

More than one disconnect may be required to de-energize

the equipment for servicing. If the cooler is

thermostatically controlled, the thermostat must not be

used as the power supply disconnect, as it may reset and

start the unit unexpectedly.

Even while routinely inspecting or servicing the inside, the cooler can

be accidentally started. Keep all personnel away from the cooler and

electrical supply when you are working on it. Before servicing or

cleaning unit, switch power off at the service disconnects and lock the

disconnecting means to prevent power from being switched on

accidentally. When the service disconnects cannot be locked,

securely fasten a prominent warning device, such as a tag, to the

service disconnect or panel. Do not turn power to unit on until

installation or service work is complete.

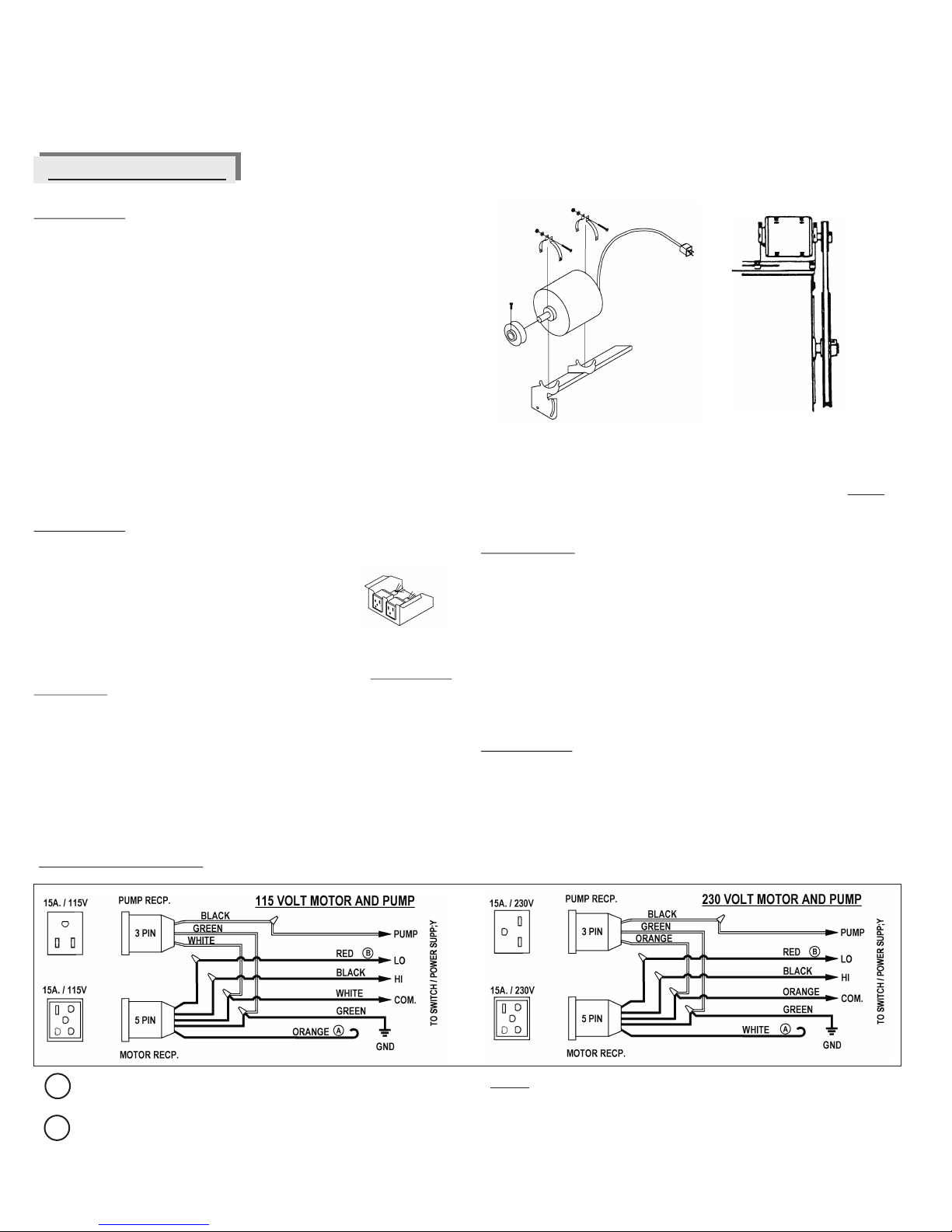

Electrical Installation

CAUTION: All electrical installations must comply with local

and national building & safety codes; all work must be performed

by qualified personnel only.

Locate the junction box installed in the cabinet. Note

That there are two receptacles; one for the pump and

one for the motor. The power supply for the cooler

must be connected to these receptacles to provide

power to the pump and motor. Wire the pump and motor receptacles

per the wiring diagram as shown. Make sure that both the pump and

blower motor are matched to the power supply voltage. DO NOT MIX

VOLTAGES, for example; a 120 Volt pump and a 240 Volt motor.

NOTE: Improper voltage connections will void all warranties.

Electrical Ground

For maximum safety, make sure cooler cabinet, blower motor and

pump are properly grounded to a suitable ground connection as

required by all local and national codes.

Motor Installation

Mount blower motor to the motor cradle using the motor straps as

shown. Position motor so that the vent holes in the motor case are

pointing downward and the motor nameplate label is upwards. Insert

motor cord plug into the receptacle in the junction box.

Install belt over motor and blower pulleys. Align belt vertically by

loosening the set screw holding the motor pulley to the shaft and

moving the pulley in or out on the shaft until aligned. Tighten set

screw.

Adjust Motor Pulley

When the cooler is connected to extended ductwork, the cooler

capacity and motor amperage may decrease due to the increased

duct resistance. The adjustable motor pulley is to be used ONLY to

return the cooler motor to it's maximum allowable amperage and

should not be readjusted except for this purpose.

CAUTION: Do not exceed the maximum motor

amperage (FLA) stamped on the motor specification plate

or motor can be overloaded, damaging motor.

Check amperage with all doors, windows and exhaust

vents open and/or all relief systems operating.

Improper pulley adjustment will overload and severely

damage motor windings (this damage will NOT be covered

under warranty). Only qualified persons with proper

electrical equipment and knowledge should adjust

variable pitch motor pulleys.

CAUTION: Never operate unit with access panels

removed. This will result in an overloaded condition and

may damage the blower motor.

WIRING DIAGRAM

This wire is not used. Isolate bare wire with a wire nut or double it over

A

and securely cover the bare wire with electrical tape.

The red wire is not used on single speed motors. Isolate bare

B

wire with a wire nut or double it over and securely cover the bare

wire with electrical tape.

NOTE:

For 230 Volt installations, it will be necessary to replace the

115 Volt pump receptacle with a 230 Volt pump receptacle

obtained from your dealer. Please see the Replacement Parts

List for the correct part number.

Trophy Ducted Evaporative Cooler Use and Care Manual 3

Page 4

Belt Tension Adjustment

CAUTION: Disconnect all electrical power to the cooler

and insure that belt is not rotating before adjusting belt

tension. Do not adjust belt tension by changing diameter

of motor pulley. Adjust belt tension only by adjusting

motor bracket.

Correct belt tension and alignment is

important, proper setup reduces power

consumption and prolongs life of belt and

motor. Check belt tension by squeezing belt.

Proper tension will allow deflection of ½ to ¾

inch. To increase or decrease belt tension,

loosen bolt in slot of motor support bracket.

Adjust belt to proper tension and retighten bolt.

Do not tighten belt by adjusting motor pulley.

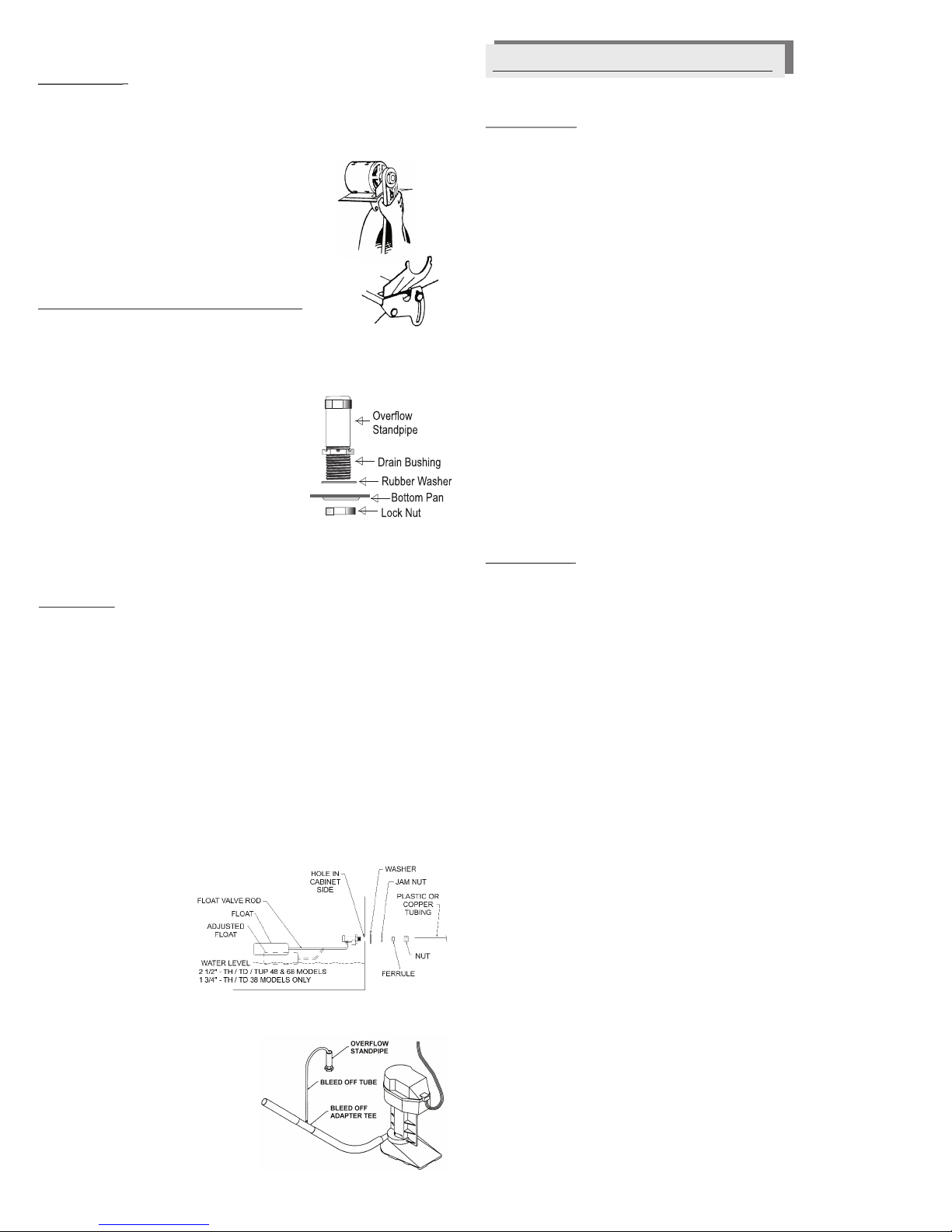

Install Overflow Standpipe /

Drain Line

Install overflow drain bushing in bottom of cooler as follows:

Slide rubber washer over drain bushing.

Push drain bushing through bottom of

cooler, assemble and tighten lock nut.

Screw plastic overflow standpipe into

the drain bushing and tighten snugly

(hand tight) to prevent leakage.

Connect a suitable drain line (copper /

PVC / garden hose) to drain bushing.

Never drain water onto a roof; mineral

build-up or damage to roof may occur.

NOTE: Drain water in accordance with local plumbing codes.

Connect Water Supply

CAUTION: All plumbing installations must comply with

local building and safety codes, and must be performed by

qualified personnel only.

NOTE: Coolers should not be connected to “soft” water systems. Soft

water will accelerate corrosion and decrease the effective life of pads

and cooler cabinet. Connect water line as follows:

A water supply valve should be installed at a convenient location, to

allow the water supply to be turned on and off for servicing or

winterizing. Minimum 1/4“ diameter tubing should be used to

provide water to the cooler, larger tubing is recommended if the

distance from the valve to the cooler is greater than 100 feet, then

reduced to 1/4” at the unit.

Install float valve in the bracket provided.

Connect tubing from water supply to float valve. Place

compression nut and ferrule over end of tubing, insert tube into

float valve then tighten compression nut to secure.

Install Bleed-off

To minimize mineral scale “buildup” use the included bleed-off

assembly. Remove the cap from

the bleed-off tee; insert the black

tubing and route the tubing

through standpipe opening into

the drain line

siphoning of the water, make sure

that the bleed-off tee is a

water level.

4 Trophy Ducted Evaporative Cooler Use and Care Manual

. To prevent

bove the

GENERAL INSPECTION

Initial Start-up or Annual Inspection

CAUTION: Disconnect all electrical power to the cooler

before attempting to install, open, or service your cooler.

More than one disconnect may be required to de-energize

the equipment for servicing. If the cooler is

thermostatically controlled, the thermostat is not to be

used as the power supply disconnect, as it may reset and

start the unit unexpectedly.

Before start-up the cooler for the first time, or at the beginning of each

cooling season, make sure that all required connections,

adjustments, etc. have been made. Verify that:

P Cooler mounting is level; ductwork is sealed.

P Cabinet is securely fastened to mounting.

P Cooler cabinet is properly grounded. Electrical connections are

correctly made, safe and secure.

P Motor, pump, drain, bleed-off, float valve, etc. are correctly

installed and fully functional.

P Water line securely connected, turned on, no leaks noted.

P Float adjusted for proper water level.

P Pump impeller turns free and smooth. If in doubt, remove

impeller cover (see “Cleaning Pump”) and check rotation.

P Blower wheel, shaft, pulley and motor sheave bolts /

setscrews are tight.

P Motor sheave / Blower pulley alignment okay; belt correctly

tensioned, blower wheel turns freely.

Start-up Check List

CAUTION: Never operate cooler with access panels

removed. This will result in an overloaded condition and

may damage the blower motor.

To verify and check out the cooler installation on initial or annual startup, the following procedure should be followed.

P Turn electrical supply to pump on.

P Verify that pump starts and pads are evenly wet.

P Open building exhaust / relief vents (windows, doors, etc.)

P Turn electrical supply to blower motor on.

P Observe that motor starts and runs, check each speed

(where applicable) and confirm air delivery.

P Verify motor amperage does not exceed nameplate.

In case of trouble on any of these steps, refer to the Troubleshooting

Chart on

Cabinet Inspection Checklist

After initial start-up and for a few weeks afterwards, check for and/or

observe the following: Refer to the Troubleshooting Chart on f

necessary.

P Leaks from water lines, cabinet, etc.

P Cooler pads: even wetting, no dry streaks.

P Confirm water level depth setting is correct.

P Verify full, even flow in water distribution system.

P Blower wheel / motor rotates freely, no unusual noises.

P Belt condition / tension / alignment OK.

P Check motor mounting, cabinet hardware, setscrews on pulleys,

page 6.

page 6 i

blower wheel are tight

Page 5

MAINTENANCE SCHEDULE

Regular maintenance and periodic inspection is the key to long and

successful service from your Trophy cooler. The cooler should receive

major servicing at least once a year, more often if conditions require

(dusty environment, constant use, poor water quality, etc.) For

maximum cooling efficiency, long life and appearance, every two

months during operation, the cooler should be inspected and cleaned.

NOTE: Do Not Undercoat the Water Reservoir

The parts of your cooler that are in contact with water are protected by

plastic liners. The plastic surfaces should be very easy to clean, but

care must be taken to avoid damaging them. All foreign materials,

mineral scale, hard water deposits, dirt, etc. should be removed from

plastic liners, water pan and other components by using warm water

and a soft cloth. Use of any asphalt ‘cooler coats’ or other types

undercoating may damage the plastic and will void your warranty.

NOTE: Do not use cooler cleaners, cooler treatments, anodes or other

chemical additives in this evaporative cooler. Use of any additives or

water treatment other than the furnished bleed-off will void your

warranty and may impair the life of the cooler.

Before starting any maintenance operation, thoroughly read all

operating and maintenance instructions and observe all

cautions and warnings.

Cleaning

CAUTION: Never wash your cooler cabinet with a

garden hose; water may harm motor and pump or seep

into ductwork. Motors damaged by water are NOT covered

under warranty.

All foreign materials, mineral scale, hard water deposits, dirt, etc.

should be removed from pad frames, water pan and other

components. Your cooler's long lasting finish can be brought to likenew condition by using warm water and a soft cloth.

Maintenance & Inspection

IMPORTANT: Before operating cooler at the beginning

of each cooling season, turn blower wheel, cooler motor

and pump motor shafts by hand to make sure they turn

freely. Failure to do so may result in burning out motor.

Periodic inspection of your cooler will enhance the chance for long,

trouble-free service life. For maximum efficiency, every two months

during operation, or any time the cooler is opened, the cooler should

be inspected. Some suggested items to look for:

P Check for leaks from water lines, cabinet, etc.

P Any dry spots or streaks on pads when pump is operating?

P Are bolts, nuts and set screws still snug?

P Are the bearings, etc., making any unusual noises?

P Does the blower wheel turn freely?

P Is float level set correctly?

P Is water in the bottom pan clean?

P Belt condition / tension / alignment OK?

Adjust Belt Tension

Each time you inspect your cooler, be sure to check belt tension on

motor and blower assembly. Check belt condition and replace it if

frays or cracks appear. Check alignment of blower pulley with motor

(see page 4 for detailed steps).

pulley

Draining

Drain the cooler (with power off and pads removed) as follows:

Connect a drain hose to the drain fitting on the bottom of the

reservoir, if not already connected to drain line.

Remove overflow standpipe from the drain fitting.

Drain and clean reservoir (avoid draining water onto a roof,

mineral build-up or damage to roof may occur).

Cleaning Water Pump & Hose

CAUTION: Disconnect all electrical power to the cooler

before attempting to install, open, or service your cooler.

More than one disconnect may be required to de-energize

the equipment for servicing. If the cooler is

thermostatically controlled, the thermostat is not to be

used as the power supply disconnect, as it may reset and

start the unit unexpectedly.

CAUTION: Do not allow pump to fall over and become

submerged; water will damage pump motor.

Clean water pump and hose assembly as follows:

Unplug pump cord, remove

mounting bracket screw and

remove pump from cooler. Shake

gently to remove water.

To prevent breakage, carefully

release the snap-out impeller

cover plate and remove cover

plate from the pump body.

Using a mild detergent solution and a soft

cloth, clean deposits from screen, around

impeller and cover plate. Spin impeller to

dislodge any remaining foreign material.

Remove any foreign material in the hose adapter

(between the pump and hose), or between the

hose and the water distributor assembly.

Rinse and reinstall impeller cover plate.

Reinstall pump and reconnect pump cord.

Touch-Up

The hardness, adhesion and smoothness of our Peblar XT®

appliance-type finish on the internal and external surfaces of your

cooler makes it extremely unlikely that scratches or chipping will

occur. Your cooler's long lasting finish can be brought to like-new

condition by using warm water and a soft cloth.

NOTE: Avoid using scouring pads, steel wool or wire brushes, as

these will damage the finish and encourage corrosion.

In the event that finish damage does occur, it should be promptly

repaired by the following procedures:

1. Sand the area around bare metal spots.

2. Prime and paint with a quality paint.

Do not use asphalt type cooler undercoat material in water

reservoir.

Lubrication

Motor Bearings

The motors used in Trophy coolers have ports for lubricating the motor

and are oiled at the factory. If the need for oiling is indicated, see

individual motor nameplate for specific instructions on re-lubricating

the motor. Under normal use, these motors require oiling about every

12 months of operation. Do Not Over-Oil.

Blower Shaft Bearings

Blower shaft bearings need periodic lubrication. They should be

checked 20-30 days after initial start-up of operation. The oil cups on

the bearings should be filled with a good grade of SAE 20W or 30W

non-detergent oil when necessary. Under normal use, oiling is

required every three months of operation. Do Not Over- Oil.

Pump Motor Bearings

The pump motor does not require lubrication.

Trophy Ducted Evaporative Cooler Use and Care Manual 5

Page 6

Changing Cooler Pads

CAUTION: Disconnect all electrical power to the cooler

before attempting to install, open, or service your cooler.

More than one disconnect may be required to de-energize

the equipment for servicing. If the cooler is

thermostatically controlled, the thermostat is not to be

used as the power supply disconnect, as it may reset and

start the unit unexpectedly.

The condition of your cooler pads should be checked at least once a

year; at the beginning of the season is best. However, your pads may

need to be checked more frequently, depending on local air and water

conditions. For instance, in areas where mineral content of the water

is high or the air is dusty, deposits may build up in the cooler pads,

restricting airflow. Clean or replace pads as follows:

1. Disconnect power from unit.

2. Remove pads from wet section cabinet as follows:

a. Remove inlet louver panels from cabinet.

b. Remove top pan from cabinet.

c. Remove water distributor cover and tube assembly.

d. Remove pads by tilting slightly forward and carefully lifting up

and out. If passages are clogged or pad is dirty, hose off inlet

face of pad. Light, gentle brushing of the inlet edges of the

pad with a stiff bristle brush (do not use a wire brush) will not

harm the pad and will remove more stubborn scaling.

e. If necessary, replace with new pads, available from your

dealer. Aspen, expanded paper or other types of evaporative

cooling pads will not work and will void your warranty.

3. Using a mild detergent, wash dirt and scale from the inside of the

wet section cabinet. Wire brushing is not recommended. If finish

is damaged or rusting is noted, repair as noted in the “Touch-Up”

section. Rinse with fresh water.

4. Reinstall pads, making sure they

are positioned correctly (painted

stripe on pad placed to the bottom,

facing outside).

5. Reinstall water distributor cover and

tube assembly.

6. Reinstall top pan and inlet louver

panels.

Winter Shut Down:

- Always drain all of the water out of the cooler and water supply line

when not in use for prolonged periods, and particularly at the end of

the season. Keep the water line disconnected from both the cooler

and the water supply so it does not freeze.

- Disconnect power from cooler during extended periods of non-use.

REPLACEMENT PARTS

When ordering replacement parts, always refer to the serial and

model number of your cooler. Use the part numbers listed in the

accompanying parts list, as illustrated in the diagrams for your model.

TROUBLESHOOTING GUIDE: Should an obvious problem occur with your cooler consult the following table. If you

cannot correct the problem, or if it persists, contact qualified service personnel.

PROBLEM / SYMPTOM

Water draining from unit

Dry pads

Motor does not start or no air delivery

Inadequate air delivery

Motor cycles on & off

Noisy operation

Excessive humidity in house

6 Trophy Ducted Evaporative Cooler Use and Care Manual

POSSIBLE CAUSE

Float valve out of adjustment

Float movement obstructed

Float valve non-functional

Pump intake clogged

Non-functional water pump

Clogged water line

Water distributor clogged

Non-functional switch

Non-functional wiring

Water turned off to cooler

Electrical power disconnected

Belt too loose or too tight

Non-functional motor

Non-functional switch

Broken belt

Insufficient air exhaust

Belt too loose

Pads plugged

Low voltage

Excessive belt tension

Blower shaft tight or locked

Bearings dry

Motor pulley diameter too large

Non-functional motor

Blower rubbing on housing

Motor sheave or blower set screws loose

Inadequate exhaust

CORRECTIVE ACTION

Adjust float to 2 1/2“ water depth

Free float from obstruction

Replace float assembly

Remove obstruction

Replace water pump

Locate and free obstruction

Clear debris from distributor

Replace switch

Repair or replace non-functional wiring

Turn on water supply

Check power receptacle and cord

Adjust belt tension

Replace motor

Replace switch

Replace belt

Open windows to increase air flow

Adjust belt tension or replace is needed

Replace pads

Check voltage

Adjust belt tension

Oil or replace bearings

Oil bearings

Adjust to full load ampere rating on motor

Replace motor

Reposition wheel

Tighten set screws

Open doors and windows to increase ventilation

Page 7

GUÍA DEL PROPIETARO

MANUAL DE USO Y CUIDADO

MODELOS de ENFRIADOR:

TD3800, TD4801, TD4812, TD6801, TD6812

TH3800, TH4801, TH4812, TH6801, TH6812,

TUP6801, TUP6812

Para Asistencia al Cliente

LLAMAR 1-800-325-6952

NO REGRESARLO A LUGAR DE COMPRA!

Felicitaciones: Usted acaba de comprar un producto de superior rendimiento y diseño, que la

dará el mejor servicio cuando sea propiamente instalado, operado y mantenido.

Seguridad

Instalación

Incio

Operación

Mantenimiento

Trazando Fallas

Este manual fue diseñado para proporcionarle a usted y a su instalador la información necesaria

para montar, operar inspeccionar, mantener y encontrar cualquier falla en su enfriador.

La primera sección de Instalación e Inicio, es especialmente para el instalador. La sección

segunda, Mantenimiento, contiene instrucciones de operación y mantenimiento para el

propietario, mientras que la sección de Detección de Problemas incluye información sobre los

problemas mas comunes.

N

O

E

L A Y C SERV

T

S

N RU IO

I

N E

A T

T

R

O

MP

I

Lea estas instrucciones cuidadosamente antes de instalar,

operar o dar servicio a la unidad.

Use solamente las combinaciones para el motor del soplador

y de la bomba(s) marcado en la placa del modelo indicando

que están propios para el uso en este modelo. No sustituya

con otro modelo de motores o bombas.

El trabajo de instalación y alambrado eléctrico se debe llevar

a cabo por personal competente de acuerdo con los códigos y

estándares, incluyendo construcción que prevenga

incendios.

Al cortar o perforar en la pared o cielo, no dañe el alambrado

eléctrico u otros servicios escondidos (lineas de agua, gas o

drenaje, etc.)

El motor del enfriador, la bomba, el gabinete y la caja de

empalme tienen que conectarse a tierra de acuerdo con

todos los códigos locales y nacionales. Un alambre de tierra

eléctrica tiene que ser usado entre el enfriador y la fuente de

poder.

Asegúrese que la unidad sea conectada a una línea propia de

voltaje como lo indica la placa del motor y la bomba. NOTA:

voltaje impropio anulará la garantía del motor y la bomba y

podría causar serias lastimaduras o daños a la propiedad.

No opere el motor de la turbina con dispositivos

transistorizados para controlar la velocidad.

E E

S

E

N

C

C

E S

D

S

U I D

EG

DA

R

ADVERTENCIA - PARA REDUCIR EL RIESGO DE INCENDIO,

DESCARGA ELÉCTRICA O LASTIMADURAS A PERSONAS, OBSERVE LO SIGUIENTE:

S

A

ST

INSTALADOR: Favor de entregar esta guía al propietario.

Siempre desconecte la energía eléctrica antes de trabajar o

darle servicio al enfriador. Posiblemente se requiera apagar

más de un interruptor para desconectar la corriente hacia el

equipo para darle servicio.

No remueva los filtros de la unidad cuando esté funcionando,

esto puede causar que el motor de la turbina se sobre cargue

y dañar el devanado del motor.

NOTA:

No instale el enfriador cerca de extractores o tubos de

ventilación ya que olores o vapores pueden ser inducidos en

la unidad.

El uso de ánodos, aditivos químicos o tratamientos en esta

unidad anulan la garantía.

Su garantía no cubre daños de envío. Reporte cualquier daño

de envío de inmediato al distribuidor o al transportador

realizando la entrega.

Para futura referencia, anote el modelo, número de serie,

fecha y lugar de compra de su enfriador evaporativo:

Modelo #:

Serie #:

Fecha de Compra:

Lugar de Compra:

1-999-2467 Date: 1/14

Page 8

INTRODUCCIÓN

Su enfriador fue detalladamente probado e inspeccionado antes de

salir de la fábrica. Ester manual es una guía de procedimientos para

una instalación propia junto con información de un cuidado razonable

y mantenimiento que le asegurará un enfriamiento seguro,

económico y sin problemas. El no seguir estas instrucciones puede

dañar su enfriador, incapacitar su operación, crear un potencial para

una seria lastimadura personal y/o anular la garantía.

Lea cuidadosamente

La instalación normalmente envuelve la conexión de la descarge del

enfriador a la sistema de ducto o a un ducto de caída con un difusor de

cielo. Para una instalación nueva, será necesario modificar el edifico.

Si la instalación no es hecha por un contratista profesional HVAC, se

sugiere que la instalación sea discutida con una persona profesional

en ventas familiarizada con instalación de enfriadores.

No intente

llevar a cabo ninguna parte de la instalación descrita en este manual

al menos que sea competente para hacerlo.

Lea este manual completamente antes de instalar su enfriador.

PRECAUCION: Todas las instalaciones mecánicas, de

plomería y eléctricas deben cumplir con los códigos

locales, nacionales, edificación y seguridad, y llevadas a

cabo por personal capacitado solamente.

NOTA: Referencias en este manual a: National Electric Code (N.E.C.), códigos

locales o nacionales indica que estos detalles tienen que cumplir con los códigos de

instalación como lo especifica la autoridad del código de edificación que tenga

jurisdicción en el lugar de la instalación. El cumplir con todos los requerimientos es la

responsabilidad del instalador.

Antes de intentar instalar el enfriador, asegúrese que las

siguientes preparaciones se hayan hecho:

Asegúrese que la superficie de

soporte es lo suficiente fuerte

para soportar el peso del

enfriador cuando esté en uso;

recuerde cuando el depósito

está lleno de agua, el enfriador

pesará mucho más que vacío.

Asegúrese de tener recursos

adecuados.

Revise el suministro de electricidad para ver si va de acuerdo con

los requerimientos indicados en las placas del motor.

Verifique que la superficie de soporte esté nivelada en todas

direcciones; Esto es necesario para una propia distribución de

agua en del filtros, maximizando la calidad de enfriamiento.

Confirme que todo trabajo de instalación de conductos y eléctricos

tengan que cumplir con los códigos locales y nacionales.

FIGURA 1

Model Number Operating

TH / TD 3800 175

TD / TH 4801 190

TD / TH 4812 215

TD / TH 6801 220

TD / TH 6812 260

TUP 6801 220

Weight (lbs.)

Ubicación

Su enfriador ya sea modelo de descarga inferior (TD) o de descarga

lateral (TH). Enfriadores de descarga lateral son diseñados para su

instalación en el costado del edifico, en techos con declive o planos

(usando un ducto de transición de 90 grados), o montados a nivel de

tierra en una losa, mientras que enfriadores de descarga inferior son

diseñados para su instalación en techos planos o con declive. (vea

figuras 1 y 2) Sistemas de aire por evaporación (descarga abajo o

lateral) pueden ser conectados a un sistema de ductos de distribución

con salidas de registros para cada area que se va a enfriar.

Instale enfriadores en un sitio donde solamente aire fresco de afuera

entre al sistema de enfriamiento. Evite el instalar las unidades en

áreas cerradas, tal como desvanes o cuarto de almacén, que

restringen el movimiento libre del aire alrededor y la entrada del

enfriador, o cerca de tubos de venteo, extractores de cocina, etc.; ya

que repugnantes olores o vapores pueden ser inducidos por la

unidad.

NOTA: Cuando los enfriadores son instalados dentro de la

jurisdicción de los códigos de edificación de la Ciudad de Los

Ángeles, solamente pueden ser instalados en la parte de afuera del

edificio.

Salidas de aire / Enfriamiento Máximo

Los enfriadores de aire por evaporación funcionan correctamente si

hay manera para que el aire enfriado salga del edificio. Ventanas,

ventilaciones, puertas u otras aberturas de extracción en el punto

más distante de la entrada de aire se deben abrir para permitir el

movimiento libre del aire fuera de las áreas que se estén enfriando, y

para evitar el aumento de presión dentro del espacio. Propias

aberturas en las salidas de extracción es importante porque guían el

flujo del aire a través de las áreas donde enfriamiento es deseado.

Ya que los enfriadores funcionan mejor cuando el escape de aire

es en abundancia, usted puede dejar puertas o ventanas abiertas

para que su casa pueda respirar. Para obtener la capacidad

máxima de su enfriador, y ayudar a mantener insectos, polvo,

tierra, etc fuera del espacio enfridao, el espacio / edifico debe

mantenerse ligeramente a una presión positiva (aire entrando el

edifico sea más que el que sale)

¿Que tanto debe habrir sus ventanas? Debe habrir sus ventanas

hasta que el aire dentro de la casa casi se balance con el aire de

afuera. Un metodo usado para determinar si el aire esta

razonablemente es el de poner un pedazo de papel en contra del

alambre mosquitero de la ventana más lejana al enfriador y ajustar

la abertura de las ventanas hasta que el papel se quede

lijeramente en el alambre mosquitero de la ventana. Esto es

usualmente 2 pies cuadrados de abertura por cada 1000 pcm de

aire producidos por el enfriador. Usted puede ajustar diferentes

ventanas en la casa para dirigir más flujo de aire a las areas que

estén ocupadas durante diferentes tiempos del día o la noche

(ejemplo: ventanas de la sala durante el día, de la recámara

durante la noche)

Para eliminar el torrente de aire caliente al poner a funcionar el

enfriador, asegurese de encender la bomba unos minutos antes

para humedecer los filtros antes de poner a funcionar la turbina.

FIGURA 3

2 Trophy Enfriador Evaporativo- Manual de Uso y Cuidado

FIGURA 2

Page 9

Sistema de Conducto

El aire puede ser llevado a largas distancias para cuartos individuales

o áreas por medio de sistema de conductos. El sistema de conductos

recortados para hormarse al edificio, deben ser diseñados,

fabricados e instalados por un contratista competente en hojalatería

HVAC, preferible mientras que el edificio está bajo construcción.

INSTALACIÓN

PRECAUCION: Desconecte toda la corriente eléctrica

del enfriador antes de intentar instalar, abrir, o darle

servicio a su enfriador. Posiblemente se requiera apagar

más de un interruptor para desconectar la corriente hacia

el equipo para darle servicio. Si el enfriador es controlado

con termostato, no lo use como manera de cortar el

suministro de corriente, ya que puede activar la unidad

inesperadamente.

Aún cuando rutinariamente se inspeccione o de servicio al interior, el

enfriador puede empezar accidentalmente. Mantenga todo el

personal alejado del enfriador y suministro de corriente al trabajar en

él. Antes de darle servicio o limpiar la unidad, corte la corriente en la

caja de servicio y póngale candado para prevenir que la prendan

accidentalmente. Cuando no pueda asegurar los interruptores,

escriba una nota que resalte a la vista en la caja de servicio. No

prender el suministro de corriente hacia la unidad hasta que la

instalación o trabajo de servicio este completo.

Instalación Electrica

PRECAUCION: Todas las instalaciones eléctricas

deben cumplir con los códigos locales, nacionales,

edificación y seguridad, y llevadas a cabo por personal

capacitado.

Ubique la caja de empalme instalada en el

gabinete. Observe que hay dos receptáculos; uno

para la bomba y otro para el motor. El suministro de

corriente debe ser conectado a estos receptáculos

para proveer corriente hacia la bomba y el motor.

Alambrar los receptáculos de la bomba y el motor como lo indica el

diagrama de alambrado. Asegurese que el voltaje de la bomba y el

motor de la turbina coincidan con el voltaje de suministro.

NO MEZCLE VOLTAJES. Pro ejemplo; bomba de 120

voltios y un motor de 240 voltios.

Instalación de Motor

Monte el motor de la turbina en su soporte usando las abrazaderas

como se indica. Coloque el motor de tal manera que las ventalaciónes

queden hacia abajo y la place del motor hacia arriba. Enchufe el

cordón del motor en el receptáculo de la caja de empalme.

Instale la banda sobre las poleas del motor y turbina, alinie la banda

verticalmente aflojando el tornillo opresor de la polea del motor y

moviendola hacia afuera o dentro hasta que quede alineada. Apriete

el tornilo opersor.

Ajuste de polea del motor

Cuando el enfriador esta conectado a conductos extendidos, la

capacidad del enfriador y el amperaje del motor disminuye debido al

aumento en la resistencia del conducto. La polea ajustable del motor

es para ser usada solamente para regresar el enfriador y el motor a su

máxima capacidad permitida y no se debe reajustar excepto para este

propósito.

PRECAUCION: No exceda el máximo amperaje del

motor (FLA) estampado en la placa de especificaciones

del motor o el motor se puede sobrecargar dañándolo.

Revise el amperaje con todas las puertas, ventanas

ventilaciones y/o todos los sistemas de relieve operando.

Ajuste impropio de la polea motriz sobrecarga y daña

severamente los devanados del motor (este daño no es

cubierto bajo la garantía) Solamente personas

capacitadas con el equipo apropiado y conocimiento

deben ajustar poleasdel motor ajustables.

PRECAUCION: Nunca opere la unidad sin los panales

de acceso. Esto resultaría en condición de sobrecarga y

podría dañar el motor de la turbina.

DIAGRAMA de ALAMBRADO

Este alambre no es usado. Aisle el alambre expuesto con

A

conectores de alambre o lo dobla y cubre el alambre expuesto con

cinta eléctrica aislante.

B

Este alambre rojo no es usado en motores de una velocidad. Aisle

el alambre expuesto con conectores de alambre o lo dobla y

cubre el alambre expuesto con cinta eléctrica aislante.

NOTA:

Para 230 Voltios instalaciónes, es necesario remplazar el

receptáculo de 115 voltios de la bomba por uno receptáculo de 230

voltios que puede obtener con su distribuidor. Consultar la lista de

partes de reemplazo para el número de parte.

Trophy Enfriador Evaporativo- Manual de Uso y Cuidado 3

Page 10

Ajuste de banda

PRECAUCION: Desconecte toda la corriente eléctrica

hacia el enfriador y asegúrese que la banda no este dando

vueltas antes de ajustar la tensión. No ajuste la banda

cambiando el diámetro de la polea del motor. Ajuste la

tensión solamente ajustando en los rieles de la base.

Tensión de la banda y alineación correcta es importante,

propia instalación reduce consumo de energía y

extiende la vida de la banda y la del motor.

tensión de la banda apretándola. Una tensión apropiada

permitirá una deflexión de ½ a ¾ de pulgada. Para

aumentar o reducir la tensión de la banda, afloje el

tornillo en la ranura de la montadura del motor. Ajuste la

banda a una tensión apropiada y apriete el tornillo.

Revise la

Instale buje de drenaje y rebosadero

Instale el buje de rebosadero en el fondo del enfriador:

Deslice la arandela de hule en el buje.

Inserte el buje en el agujero del fondo, y

apriete la tuerca.

Atornille el tubo de rebosadero de plástico

al buje y apriételo ligeramente (apretado

con la mano) para prevenir fugas.

Conecte a una línea adecuada de drenaje

(cobre / PVC / manguera de jardín) al buje

de drenaje. Nunca drene el agua en el

techo; minerales se acumulan o daños al

techo pueden ocurrir.

NOTA:

Drene el agua de acuerdo con los códigos locales de plomería.

Tubo de

Rebosader

Buje de Drenaje

Arandela de hule

Fondo

Tuerca

Conecte el Suministro de Agua

PRECAUCION: Todas las instalaciones de plomería

tienen que cumplir con los códigos de edificar y reglas de

seguridad, y llevadas a cabo por personal competente

solamente.

NOTA: Los enfriadores no se deben conectar a sistemas de agua

“blanda”. Agua blanda acelera la corrosión y reduce la vida efectiva de

los filtros y gabinete. Conecte el suministro de agua al enfriador como

sigue:

La válvula de suministro de agua podría instalarse en un sitio

conveniente, para permitir abrir y cerrar para dar servicio o

apagado de invierno. Un tubo con un mínimo de 1/4” se debe usar

para el suministro de agua hacia el enfriador, Un tubo más grande

se debe usar si la distancia es mayor de 100 pies y reducida a 1/4”

en la entrada de la unidad.

Instale la válvula del flotador en la abrazadera proveída.

Conecte un tubo del suministro de agua al flotador. Ponga la tuerca

de compresión y la férula sobre el extremo del tubo, inserte el tubo

en la válvula y apriételo la tuerca de compresión bien.

Instale el sangrado

Para minimizar la “acumulación de

sarro” use la ensambladura de

sangría incluida. Remueva el

tapón del adaptador “T” e inserte

tubo negro y guíelo a través del

tubo de rebosadero. Para prevenir

sifónaje del agua, asegure que la

“T” del sangrado esté arriba del

nivel del agua.

INSPECCIÓN GENERAL

Lista de inspección de pre-comienzo o anual

PRECAUCION: Desconecte toda la corriente eléctrica

del enfriador antes de intentar instalar, abrir, o darle

servicio a su enfriador. Posiblemente se requiera apagar

más de un interruptor para desconectar la corriente hacia

el equipo para darle servicio. Si el enfriador es controlado

con termostato, no lo use como manera de cortar el

suministro de corriente, ya que puede activar la unidad

inesperadamente.

Antes de prender el motor y la bomba por primera vez, o en el

comienzo de cada temporada de enfriamiento, asegúrese de haber

hecho todas las conexiones y ajustes. Y verifique que:

P Montura del enfriador a nivel; conductos sellados.

P Gabinete bien sujetado a la montura.

P Gabinete del enfriador propiamente a tierra. Conexiones eléctricas

hechas correctamente seguros y fuera de peligro.

P Motor, bomba, drenaje, sangrado, válvula del flotador, etc. están

correctamente instaladas y completamente funcionales.

P Línea de agua seguramente conectada, abierta, sin fugas notables.

P Flotador ajustado al propio nivel.

P Impelente de la bomba gira libre y suave. Si hay duda remueva

la cubierta del impelente (véase “limpieza de la bomba”) y revise

la rotación.

P Asegúrese que los tornillos de la turbina, eje, polea impulsada y los

opresores de la polea motríz estén apretados.

P Polea motriz / polea de turbina alineamiento bien; tensión correcta

en la banda, turbina gira libremente.

Chequeo de empiezo

PRECAUCION: Nunca opere la unidad sin los panales

de acceso. Esto resultaría en condición de sobrecarga y

podría dañar el motor de la turbina.

Para verificar y chequeo de la instalación del enfriador en el comienzo

inicial o anual, siga el siguiente procedimiento.

P Prender la corriente eléctrica hacia la bomba

P Verifique si la bomba empezó y los filtros se mojan parejos.

P Habrá las salidas / ventilaciones (ventanas, puertas, etc.)

P Prender la corriente eléctrica hacia el motor de la turbina.

P Observe comienza y funciona, revise cada velocidad (donde se

aplique) y confirme entrega de aire.

P Verifique que el amperaje del motor no exceda al de la placa.

En caso de problemas en alguno de estos pasos, refiérase a la lista de

trazando fallas en página 6.

Lista de inspección del gabinete

Después del comienzo inicial y durante inspecciones periódicas,

revise u observe lo siguiente: Refiérase a la lista trazando fallas en la

página 6 si es que es necesario.

P Fugas de las líneas de agua, filtros, gabinete, etc.

P Filtros del enfriador: se mojen parejos, no áreas secas.

P El ajuste del nivel del agua sea correcto.

P Verifique el flujo de agua completo y parejo en el sistema

de distribución.

P Turbina / motor giran libremente, no ruidos extraños.

P Condición de la banda / tensión / alineamiento.

P Revise la montadura del motor, tornillos del gabinete,

tornillos opresores en las poleas y de la turbina apretados.

4 Trophy Enfriador Evaporativo- Manual de Uso y Cuidado

Page 11

LISTA DE MANTENIMIENTO

Mantenimiento regular e inspecciones periódicas son la clave de un

bueno y prolongado servicio de su Trophy enfriador. El enfriador debe

recibir servicio completo a menos una vez por año y más seguido si

las condiciones lo requieren (ambiente polvo, uso constante, calidad

del agua, etc.) Para máxima eficiencia de enfriamiento, larga vida y

apariencia, cada dos meses durante su operación, el enfriador debe

ser inspeccionado y limpiado.

NOTA: No ponerle brea al depósito de agua

Las partes de su enfriador que están en contacto con el agua están

protegidas con revestidotes de plástico. Las superficies de plástico

son fáciles de limpar, pero debe tener cuidado de no dañarlas, todos

los materiales ajenos, sarro mineral, depósitos de agua dura, tierra,

etc deben ser removidos de los revestidotes, enjuague el depósito y

otros componentes utilizando agua tibia y un trapo suave. El uso de

protectores de asfalto, brea u otro tipo pueden dañar el plástico y

anularán la garantía.

NOTA: No use limpiadores para enfriadores, ánodos, tratamientos u

otro aditivo químico en este enfriador. El uso de aditivos o

tratamientos para el agua u otro que no sea sangrado anulará la

garantía y perjudicará la vida del enfriador.

Antes de comenzar la operación de mantenimiento, lea

detalladamente todas las instrucciones de mantenimiento y

operación y observe todas las precauciones y advertencias.

Limpieza

PRECAUCION: Nunca lave su enfriador con manguera

de jardín; El agua puede dañar el motor y la bomba o entrar

al conducto. Motores dañados por el agua NO los cubre la

garantía.

Materiales extraños, sarro, depósitos de sal, minerales etc. Deben de

removerse de las rejillas de los filtros, fondo, y otros componentes.

Mantenimiento e Inspección

IMPORTANTE: Antes de operar el enfriador al comienzo

de cada temporada de enfriamiento, gire los ejes de la

turbina, el motor, la bomba con la mano para asegurarse

que giren libremente. El no hacerlo podría resultar en un

motor quemado.

Inspección periódica de su enfriador puede realzar la vida libre de

problemas de este. Para máxima eficiencia, cada dos meses durante

su operación, o en cualquier ocasión que habrá el enfriador, lo debe

inspeccionar. Algunas sugerencias:

P ¿Revise por goteras de los filtros, gabinete, etc.

P ¿Encuentra puntos secos en la paja cuando en operación?

P ¿Encuentra los tornillos, tuercas y tornillos opresores apretados?

P ¿Sonidos extraños en las chumaceras o motores?

P ¿La turbina gira libremente?

P ¿Flotador al correcto nivel?

P ¿El agua del depósito limpia?

P ¿Condición de la banda/ tensión/ alineamiento?

Ajuste tensión de la banda

Cada vez que inspeccione su enfriador, se asegura de revisar la

tensión de la banda en el ensamble de motor / turbina. Revise la

condición de la banda si tiene desgaste u otros defectos. Revise la

alineación de la polea impulsada con la polea motríz (véase pagina 4

para pasos con más detalles)

Drenando

Vacié el depósito (con la corriente apagada y los filtros removidos)

como sigue:

Conecte la manguera de drenaje en el fondo del depósito, si

no está ya conectado a la línea de drenaje.

Remueva el buje de rebosadero del buje.

Vacié y limpie el depósito (nunca drene el agua en el techo,

minerales se depositan o daño al techo puede ocurrir)

Limpieza de la bomba y manguera

PRECAUCION: Desconecte toda la corriente eléctrica

del enfriador antes de intentar instalar, abrir, o darle

servicio a su enfriador. Posiblemente se requiera apagar

más de un interruptor para desconectar la corriente hacia

el equipo para darle servicio. Si el enfriador es controlado

con termostato, no lo use como manera de cortar el

suministro de corriente, ya que puede activar la unidad

inesperadamente.

PRECAUCION: No permita que la bomba se caiga y se

sumerja; el agua daña el motor.

Limpie la bomba, la manguera y la ensamble

de distribuidor como sigue:

Desenchufe el cordón clavija de la

bomba, remueva el tornillo de la

abrazadera de la bomba y remueva

bomba del enfriador. Sacúdala

ligeramente para removerla del agua.

Para prevenir que se quiebre, con

cuidado remueva la placa de la base del

impelente y remueva la placa de la base

del cuerpo de la bomba.

Usando una solución de detergente

ligera, limpie los depósitos del cedazo de

la bomba, alrededor del impelente y la

tapadera de la base.

Gire el impel

ente para destapar material ajeno.

Remueva cualquier material (ajeno en el adaptador y la

manguera), o entre la manguera y el distribuidor de agua.

Enjuague y reinstale la cubierta del impelente.

Reinstale la bomba y enchufe el cordón de la bomba.

Retocar

La dureza, adhesíon y suavidad de nuestro acabado tipo

electrodoméstico Peblar XT acaban en las superficies internas y

externas de su enfriador lo hace extremadamente improbable de que

ocurran raspones o se descarcare. El acabado duradero de su

enfriador lo puede hacer se mire como nuevo utilizando agua tibia y

un trapo suave

NOTA: Evite estropajos o brochas de alambre, estos dañarán él

acabado estimulando la corrosión.

En un evento que esto ocurra, se debe reparar siguiendo los

siguientes procedimientos:

1. Lije el área alrededor de las partes de metal descubiertas.

2. Use pintura de fondo y pintura de buena calidad.

No use compuestos de asfalto en el depósito de agua.

.

LUBRICACION

Chumaceras del motor

Motores usados en Brisa enfriadores tienen aceiteras para lubricarse

y son lubricados en la fábrica. Si la necesidad por lubricarse es

indicada, vea la placa individual del motor para instrucciones

específicas para relubricar el motor. Bajo uso normal, estos motores

requieren lubricación alrededor de cada 12 meses de operación.

No sobre-aceite.

Chumaceras del eje de la turbina

Las chumaceras del eje de la turbina requieren lubricación periódica.

Se deben revisar después de 20-30 días de operación. Las aceiteras

en las chumaceras se deben llenar con aceite de buena calidad SAE

20W o 30W no-detergente cuando sea necesario. Bajo uso normal,

lubricación se requiere cada tres meses de operación.

No sobre-aceite.

Chumaceras de la bomba

Las chumaceras de la bomba están permanentemente lubricadas.

la

Trophy Enfriador Evaporativo- Manual de Uso y Cuidado 5

Page 12

Cambiando los filtros (aspen)

PRECAUCION: Desconecte toda la corriente eléctrica del

enfriador antes de intentar instalar, abrir, o darle servicio a su

enfriador. Posiblemente se requiera apagar más de un

interruptor para desconectar la corriente hacia el equipo para

darle servicio. Si el enfriador es controlado con termostato,

no lo use como manera de cortar el suministro de corriente,

ya que puede activar la unidad inesperadamente.

Los filtros de su enfriador se deben revisar una vez por año.....de

preferencia al principio de la temporada. O cuando los filtros requieran

revisarse más frecuentemente, de acuerdo con el aire y las condiciones del

agua local. Por ejemplo, en áreas donde el contenido de minerales del

agua es alto o el aire es sucio, depósitos se acumulan en los filtros,

restringiendo el flujo del aire. Reemplace los filtros como sigue:

1. Remueva el armazón del gabinete.

2. Remueva los filtros del gabinete como sigue:

a. Remueva las rejillas de entrada del gabinete.

b. Remueva la tapa de la sección húmeda.

c. Remover el distribuidor de agua.

d. Remueva los panales ligeramente inclinando hacia el frente y

cuidadosamente levantándolo hacia arriba y afuera. Si los pasajes

están tapados o el panal está sucio, con una manguera de jardín y

presión ligera limpie la entrada del panal. Cepille en forma ligera y

suave con cepillo de cerdas duras (no use cepillo de alambre) el cual

no dañará el panal y removerá el sarro duro.

e. Si es necesario, remplace con panales nuevos, disponibles en su

distribuidor. Aspen, papel extendido u otros tipos de filtros

evaporativo no funcionan y anulan su garantía.

3. Usando detergente ligero, lave tierra y sarro en la parte de adentro en la

sección húmeda. No se recomienda brochas de metal. Si el acabado

está dañado o nota óxido, repare como se indica en la sección "Retocar".

Enjuague con agua limpia.

4. Reinstale los panales, asegurándose que

su posición es correcta (Raya pintada en

la parte de abajo del panal hacia afuera)

5. Reinstale el distribuidor de agua.

6. Reinstale la tapadera de la sección

húmeda.y las rejillas.

Apagado de Invierno:

- Siempre vacie toda el agua del enfriador y de la tubería cuando no esté en

uso por periodos prolongados, y particularmente enel término de la

temporada. Mantenga la tuberia del agua desconectada en ambos lados para

que no se reviente en bajas temperaturas.

- Disconecte el enfriador de la fuente durante largos periodos de no uso.

Reemplazo De Partes

Cuando ordene partes de reemplazo, siempre refiérase al modelo y numero

de serie de su Brisa enfriador. Use él número de parte en la acompañante lista

de partes, como esta ilustrado en los diagramas de su modelo.

TRAZANDO FALLAS : Si un problema obvio ocurre en su enfriador, consulte la siguiente tabla. Si no

puede corregir el problema, contacte a un representante competente de servicio.

PROBLEMA / SÍNTOMA:

Derrame de agua en la unidad

Filtros Secos

No comienza o no hay entrega de aire

Entrega de aire inadecuado

El motor se prende y se apaga

Operación ruidosa

Humedad excesiva dentro de la casa

6 Trophy Enfriador Evaporativo- Manual de Uso y Cuidado

CAUSA PROBABLE:

Válvula de flotador fuera de ajuste

Movimiento del flotador obstruido

Válvula no funciona

Entrada de agua de la bomba tapada

Bomba no funciona

Linea de agua tapada

Canaleta de filtro tapada

Interruptor no funciona

Alambrado no funciona

Agua hacia el enfriador cerrada

Corriente eléctrica desconectada

Banda muy floja o apretada

Motor no funciona

Interruptor no funciona

Banda rota

Insuficiente escape de aire

Banda muy floja

Filtros tapada

Baja voltaje

Banda demasiado apretada

Eje de soplador congelado

Chumaceras secas

Diámetro de la polea motriz muy grande

Motor no funciona

La turbina rosa con la caja del soplador

Tornillos opresores de la turbina o polea

motriz muy flojos

Inadecuado escape de aire

ACCIÓN CORRECTIVA:

Ajuste el flotador 2 1/2“ de profundidad de agua

Libere el flotador de la obstrucción

Remplace el ensamble de flotador

Remueva la obstrucción

Remplace la bomba

Localice y remueva la obstrucción

Limpie la basura de las canaletas

Remplace el interruptor

Repare o remplace alambres no funciona

Abrir el suministro de agua

Revisar el receptáculo de corriente y el cordón

Ajuste la tensión

Remplace el motor

Remplace el interruptor

Remplace banda

Abra ventanas para aumentar el flujo

Ajuste la tensión o remplacela

Remplace filtros

Revise el voltaje

Ajuste la tensión

Lubrique o remplace las chumaceras

Lubrique con aceite las chumaceras

Ajustar al amperaje indicado en la placa del motor

Remplace el motor

Alinear la turbina

Apriete tornillos opresores

Abra ventanas para aumentar la ventilación

Loading...

Loading...