Page 1

8 Channel Bi-Directional

Booster Amplifier

50289-BDA

Operations, Installation and Maintenance

Instruction Manual

Model 50289-BDA

ALL INFORMATION CONTAINED IN THIS DOCUMENT IS PROPRIETARY TO AeroComm, Inc.

AND SHALL NOT RELEASED, DISCLOSED, USED, OR DUPLICATED FOR ANY PURPOSE

OTHER THAN EVALUATION, INSPECTION, OR MAINTENANCE OF EQUIPMENT DELINEATED

HEREIN.

AEROCOMM UNCONDITIONALLY GUARANTEES THE MERCHANDISE PROVIDED AGAINST

DEFECTS OF ANY KIND INCLUDING, WITHOUT LIMITATION, DEFECTS IN OPERATION, DESIGN,

MATERIALS, AND WORKMANSHIP FOR TWO YEARS FROM THE DATE OF DELIVERY.

AEROCOMM IS NOT RESPONSIBLE FOR ANY EQUIPMENT REPAIRED OR ALTERED BY PERSONS

NOT AUTHORIZED BY AEROCOMM OR NOT IN ACCORDANCE WITH INSTRUCTIONS

FURNISHED BY AEROCOMM. AEROCOMM. IS NOT RESPONSIBLE FOR EQUIPMENT RENDERED

DEFECTIVE AS A RESULT OF MISUSE, IMPROPER REPAIR, OR ABNORMAL CONDITIONS OF

OPERATION, NOR DOES AEROCOMM ASSUME ANY LIABILITY FOR ANY CONSEQUENTIAL

DAMAGE CAUSED BY SUCH EQUIPMENT.

SERVICE CONTRACTS OR CUSTOMER ASSISTANCE AGREEMENTS ARE AVAILABLE FOR

AEROCOMM. PRODUCTS THAT REQUIRE MAINTENANCE AND/OR REPAIR. AEROCOMM ALSO

HAS SERVICE AND CONSULTATION CONTRACTS FOR ENTIRE SYSTEM CONFIGURATIONS.

Page 2

800MHz Bi-directional Booster Amplifier 50289-BDA

Page 3

800MHz BDA

Model 50289-BDA

Specifications

Frequency Range: 806-824MHz, 851-869MHz

Pre-selectors: 819-824MHz, 864-869MHz

Talk-Out, Outband: 821-823MHz

Talk-In, Inband: 866-869MHz

Channel Spacing: 25kHz

Channel Bandwidth: 15kHz

Phase Noise: 10kHz - - 90dBc/Hz

RF Frequency Accuracy: Signal exactly

Adjacent Channel Selectivity: 70dB @ +17.5kHz

RF Output Power (to cable): +31dBm per carrier

RF Output Power (to antenna): +25dBm per carrier

Variation of Output Power with Input Level: +0, -1dB

Max Passband Ripple (full band): 2dB

Max Passband Ripple (100Khz segment): 0.1dB

Amplifier Input Port Burnout

(no damage I/O segment):

Amplifier Output Damage (no damages): open/short

Reliability: 50K hours minimum

Intermodulation/Crossmodulation Distortion: -60dBc

Channel to Channel Isolation: -70dBc

-90dBm Input Output +31dBm (High Band)

Duty Cycle: Continuous

RF Spurious Output

(0.5-800MHz, 1-2.5GHz):

RF Spurious Output (800-1000MHz): -85dBc max

Operating Temperature Range:

System Noise Figure: <9dB

Input/Output Impedance: 50 ohms nominal

Input/Output VSWR: 1.5:1, worst case

Input/Output Connectors at top of cabinet: Type N Female

Input Power: 110vac

Passband Group Delay: 220 microseconds

Alternate Power Source, battery Backup: +12vdc @ 56 amps (High Band)

Operation Conditions: Unconditionally stable

Time-out timer 1 sec to 99 minutes and 59 seconds

Annunciating LEDs: Power

Enclosure: NEMA 12 72”Hx24”Wx24”D

Number of Enclosures: 2 (1 High Band/1 Low Band)

Weight: <650 lbs each

@-15dBm

Output +25dBm (Low Band)

-60dBc

-20°C to +60°C

+12vdc @ 38 amps (Low Band)

PLL Lock Detect

Status – Key On

Fault

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

3

Page 4

800MHz BDA

Model 50289-BDA

Specifications Continue:

DC Power Supply:

No. per enclosure: High Band: 3 (1 Dual Chassis/ 1 Single)

Low Band: 2 (1 Dual Chassis)

Input: 105-125 VAC, 50-400Hz, single phase

Output (each supply): 12 VDC+/- 0.5V @20 amps

Operating Temperature:

Battery Charger:

Type: Multi-Stage (Bulk/Absorption/Float)

DC Output: 13.8-14.8Vdc (depending on setting)

AC Input: 95-125 VAC

Charging Rate: Bulk Charge: 40 amps max.

Absorption: 5 amps max.

Float: 0.05 amps

Battery:

Specifications dependant on required UPS cycle

System Load: 95 amp/hr

Software:

Title: 800MHz-Linc (50486-09-01)

Version: 1.0

Operator, User Functions: Time-out Timer (set time interval)

Mode (Keyed or Continuous)

Technician Functions: Set Attenuation

Set Frequency

Set RSSI Attack

Peripheral Requirements:

Operating System (requirements): Window 95, Windows 98, or Windows NT 4.0

Computer or Laptop (requirements): 486DX66Mhz (minimum)

Communication, Serial Port (requirements): 4800 baud,

N8+1 (8 bits, no parity)

-20°C to +70°C

Optionally Provided or User Supplied

Optionally provided or User supplied:

(or higher)

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

4

Page 5

TABLE OF CONTENTS

SECTION I INSTALLATION............................................................................................................... 9

INTRODUCTION .............................................................................................................................. 9

DETAILED INSTALLATION INSTRUCTIONS ............................................................................... 9

MECHANICAL INSTALLATION OF THE CABINETS.................................................................... 9

AC POWER CONNECTION............................................................................................................ 10

SETTING THE THERMOSTATS .................................................................................................... 10

CONNECT EXTERNAL RF CABLING........................................................................................... 11

INSTALLING POWER SUPPLIES & BATTERY CHARGER ......................................................... 11

INSTALLING THE POWER AMPLIFIER....................................................................................... 15

INSTALLING THE IF CHANNEL MODULES................................................................................ 16

INTERNAL RF CABLE INSTALLATION....................................................................................... 18

IF MODULE CABLING ........................................................................................................................18

DUPLEXER CABLING.........................................................................................................................19

DUPLEXER CABLING (CONTINUED)................................................................................................22

POWER AMPLIFIER CABLING...........................................................................................................23

BATTERY CONNECTION.............................................................................................................. 24

POWER UP SEQUENCE................................................................................................................. 25

SECTION II OPERATION PROCEDURES...................................................................................... 27

USER’S SOFTWARE....................................................................................................................... 28

CHANGING THE TIME-OUT DURATION..................................................................................... 29

CHANGING THE MODE SETTING................................................................................................ 29

TECHNICIAN’S SOFTWARE......................................................................................................... 29

SETTING THE ATTACK TIME ...................................................................................................... 29

CHANGING THE INPUT ATTENUATION..................................................................................... 29

SETTING THE FREQUENCY ......................................................................................................... 30

CHANGING THE CHANNEL ID..................................................................................................... 30

CHANGING THE CHANNEL SERIAL NUMBER.......................................................................... 30

SECTION III MAINTENANCE.......................................................................................................... 31

BDA MAINTENANCE: ................................................................................................................... 31

AIR FILTRATION:................................................................................................................ 31

CABLE INSPECTION: .......................................................................................................... 31

ENCLOSURE INSPECTION:................................................................................................. 31

OPERATIONAL TESTS: ....................................................................................................... 31

BATTERY MAINTENANCE (BACKUP BATTERY):..................................................................... 31

ADDITIONAL INFORMATION...................................................................................................... 31

SECTION IV RECOMMENDED SPARES........................................................................................ 32

SECTION V THEORY OF OPERATION......................................................................................... 33

DUPLEXER: .................................................................................................................................... 36

TALK-IN BA: ........................................................................................................................ 36

TALK-OUT BA:..................................................................................................................... 36

LNA/8-WAY SPLITTER:....................................................................................................... 36

CHANNEL MODULE (IF MODULE):............................................................................................. 36

IF CHANNEL MODULE: ...................................................................................................... 37

MICRO CONTROLLER: ....................................................................................................... 37

THE MOTHERBOARD: ........................................................................................................ 37

RF POWER AMPLIFIER/8-WAY COMBINER:.............................................................................. 37

THE HIGH BAND BA: .................................................................................................................... 38

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

5

Page 6

THE LOW BAND BA: ..................................................................................................................... 38

SECTION VI USER’S GUIDE............................................................................................................ 43

OVERVIEW..................................................................................................................................... 43

PROGRAM INSTALLATION .......................................................................................................... 43

PROGRAM STARTUP .................................................................................................................... 43

MAIN SCREEN ............................................................................................................................... 44

COMMUNICATION CONNECTION .............................................................................................. 45

SETTING A TIME-OUT TIME ........................................................................................................ 46

CHANGING THE MODE ................................................................................................................ 47

EXITING THE SOFTWARE............................................................................................................ 47

ADDITIONAL INFORMATION...................................................................................................... 48

SECTION VII TECHNICIAN’S GUIDE............................................................................................ 49

ACTIVATING TECHNICIAN FUNCTIONS ................................................................................... 50

CLOSING THE TECHNICIAN FUNCTIONS.................................................................................. 50

SETTING RSSI ATTACK TIME...................................................................................................... 51

CHANGING THE CHANNEL ID..................................................................................................... 51

CHANGING THE CHANNEL SERIAL NUMBER.......................................................................... 52

SETTING ATTENUATION ............................................................................................................. 52

SETTING A FREQUENCY.............................................................................................................. 52

CLOSING THE TECHNICIAN FUNCTIONS.................................................................................. 54

SECTION VIII TUNE UP PROCEDURE........................................................................................... 55

SECTION IX FCC CERTIFICATION LABEL LOCATION............................................................ 56

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

6

Page 7

Table of Figures

Figure 1. Thermostat & Electrical Power InFigure 1. Thermostat & Electrical Power In

stallationstallation ......................................................1010

Figure 2. External RF Cabling InstallationFigure 2. External RF Cabling Installation

........................................................................ 1111

Figure 3. Equipment Cabinet Configuration Figure 3. Equipment Cabinet Configuration

as Shippedas Shipped ......................................................1212

Figure 4. Battery Charger ModuleFigure 4. Battery Charger Module ................1313

Figure 5. Power ConnectionsFigure 5. Power Connections on the Rear of on the Rear of

the Power Supply and Charger Module the Power Supply and Charger Module ( (

as viewed from the toas viewed from the top)p) .......................... 1515

Figure 6. Power & Signal Connections on thFigure 6. Power & Signal Connections on th

e Rear of the Power Amplifiere Rear of the Power Amplifier .............. 1616

Figure 7. IF Channel Module Jumper LocationFigure 7. IF Channel Module Jumper Location

........................................................................ 1717

Figure 8. Semi-Rigid Cables for ConnecFigure 8. Semi-Rigid Cables for Connectingting

IF Channel Modules & 8-Way Splitter IF Channel Modules & 8-Way Splitter .. 1919

Figure 9. Arrangement of Internal RF CabliFigure 9. Arrangement of Internal RF Cabli

ngng ...................................................................... 2020

Figure 10. Semi-Rigid Cables Connecting IF Figure 10. Semi-Rigid Cables Connecting IF

Channel Modules & Power AmplifierChannel Modules & Power Amplifier ........2121

Figure 11. Semi-Rigid Cable for ConnectingFigure 11. Semi-Rigid Cable for Connecting

the Duplexer to the 8-Way Splitter the Duplexer to the 8-Way Splitter .... 2222

Figure 12. Semi-Rigid Cable Connecting theFigure 12. Semi-Rigid Cable Connecting the

Power Amplifier to the Cabinet-Mounted Power Amplifier to the Cabinet-Mounted

Feed-Thru Connector Feed-Thru Connector .................................. 2323

FiguFigure 13. Battery Cabling Installationre 13. Battery Cabling Installation .. 2424

Figure 14. Main Power Switches for Power SFigure 14. Main Power Switches for Power S

upplies and Battery Status Panelupplies and Battery Status Panel ..........2626

Figure 15. Normal LED Illuminations after PFigure 15. Normal LED Illuminations after P

ower Up ower Up ..........................................................2626

Figure 16. Channel Module LED Indicator IllFigure 16. Channel Module LED Indicator Ill

umination Patternsumination Patterns ......................................2828

Figure 17. Normal Channel ID Numbering SchFigure 17. Normal Channel ID Numbering Sch

emeeme .................................................................... 3030

Figure 18. Overall System Figure 18. Overall System .......................... 3434

Figure 19. SysteFigure 19. System Outlinem Outline ............................ 3535

Figure 20. Power Distribution Unit OutlineFigure 20. Power Distribution Unit Outline

........................................................................ 4040

Figure 21. Power Distribution High BandFigure 21. Power Distribution High Band .. 4141

Figure 22. Power Distribution Low BandFigure 22. Power Distribution Low Band .... 4242

Figure 23. 800MHz-Linc Main screenFigure 23. 800MHz-Linc Main screen ................ 4444

Figure 24. 800 MHz-Linc Main Screen with ConFigure 24. 800 MHz-Linc Main Screen with Con

nection Error windownection Error window ................................ 4545

Figure 25. Set Time Out windowFigure 25. Set Time Out window.................... 4646

Figure 26. Set ModFigure 26. Set Mode windowe window............................ 4747

Figure 27. Exit confirmation windowFigure 27. Exit confirmation window .......... 4848

Figure 28. 800 MHz-Linc about windowFigure 28. 800 MHz-Linc about window .......... 4949

Figure 29. 800MHz-Linc Main ScreenFigure 29. 800MHz-Linc Main Screen .............. 5050

Figure Figure 30. Set RSSI Attack window30. Set RSSI Attack window .............. 5151

Figure 31. Set Attenuation windowFigure 31. Set Attenuation window.............. 5252

Figure 32. Set Frequency windowFigure 32. Set Frequency window .................. 5353

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

7

Page 8

Figure 33. 800 MHz-Linc screenFigure 33. 800 MHz-Linc screen ...................... 5454

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

8

Page 9

SECTION I INSTALLATION

INTRODUCTION

AeroComm strongly recommends that the user install the two rack enclosures for the

system by bolting them down onto level concrete flooring. The user must equip the

concrete floor with appropriate anchors and drill the floor of the cabinet to match.

AeroComm recommends stainless steel wedge anchors with a minimum diameter of 3/8”

and a thread length of 2 ¼”. The hole pattern in the concrete floor and in the floor of the

cabinet should be arranged such that the anchor studs are centered 2” from each wall of

the cabinet in each of the four corners.

WARNING

FAILURE TO SECURE THE CABINET AS RECOMMENDED MAY RESULT IN

CABINET TIP-OVER DURING INSTALLATION OF THE POWER SUPPLIES.

AeroComm recommends installing the two cabinets 3 feet apart. This separation distance

provides easy access to the sides and top of each cabinet; additionally, this separation

provides necessary RF isolation of the two units. Under no circumstances should the two

units be located more than 10 feet from one another; separation distances greater than 10

feet will increase path loss on the RF cables connecting the two units and result in nonoptimal operation.

DETAILED INSTALLATION INSTRUCTIONS

MECHANICAL INSTALLATION OF THE CABINETS

Determine the bolt pattern to be used for anchoring the two cabinets.

Install anchors in concrete floor & match drill cabinet floors.

Position cabinets over the floor anchors and fasten the cabinets to the floor.

WARNING

ENSURE AC POWER SERVICE LINES ARE NOT LIVE PRIOR TO

CONNECTING TO THE EQUIPMENT CABINETS.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

9

Page 10

AC POWER CONNECTION

Install AC power conduit. Each cabinet is configured with clamping-ring hardware

suitable for attachment of ½” electrical conduit.

Each cabinet is fitted with an electrical junction box inside at the top rear of the cabinet.

Remove the cover plate and connect the AC source lines to the appropriate terminals in

the junction box. Refer to figure 1. Re-install the cover plate.

Figure 1. Thermostat & Electrical Power InFigure 1. Thermostat & Electrical Power In

stallationstallation

BATTERY

CABINET CEILING INCOMING

CONNECTION

THERMOSTAT MAIN AC POWER

OUTLETS FOR CABINET

COOLING FAN

POWER SWITCH

AC SERVICE CONDUIT

ELECTRICAL

JUNCTION BOX

SETTING THE THERMOSTATS

Set the thermostat inside each cabinet for 90-95ºF (32-35°C). This will keep the cabinet

at optimal operating temperatures. Refer again to Figure 1. The Thermostat is marked

with three dots between 80ºF and 130ºF(27-54°C). Turn the thermostat dial so the pointer

is just past the first dot above 80ºF (27°C).

NOTE

THE THERMOSTATS MAY BE ADJUSTED AFTER INSTALLATION BY

REMOVING THE GRILL AND FILTER ON THE TOP OF EACH CABINET. THE

USER CAN THEN REACH THROUGH THE ACCESS HOLE TO ADJUST THE

THERMOSTAT SETTINGS.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

10

Page 11

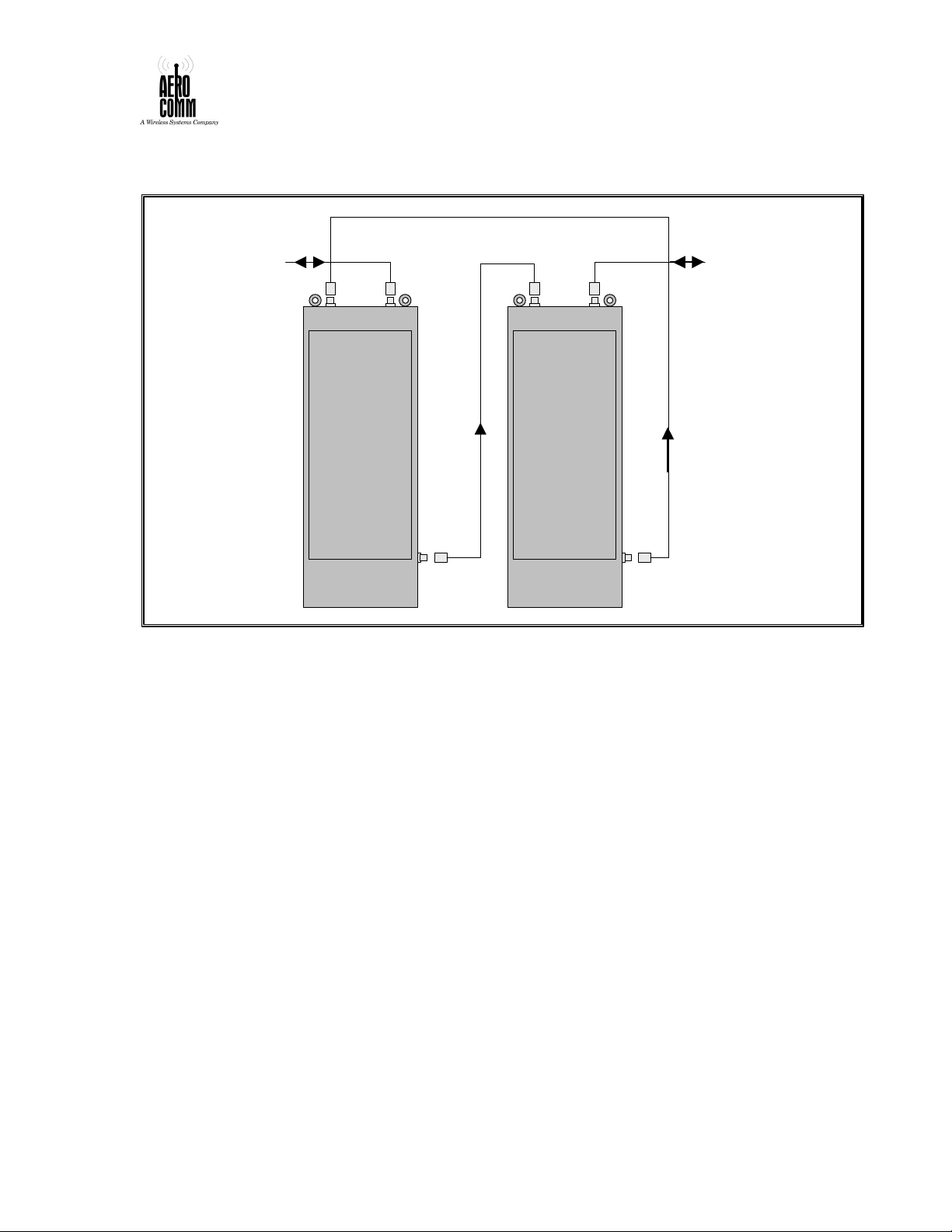

TALK IN

HIGH BAND

TALK OUT

LOW BAND

Figure 2. External RF Cabling InstallationFigure 2. External RF Cabling Installation

TO ROOF ANTENNA TO RADIATING CABLE

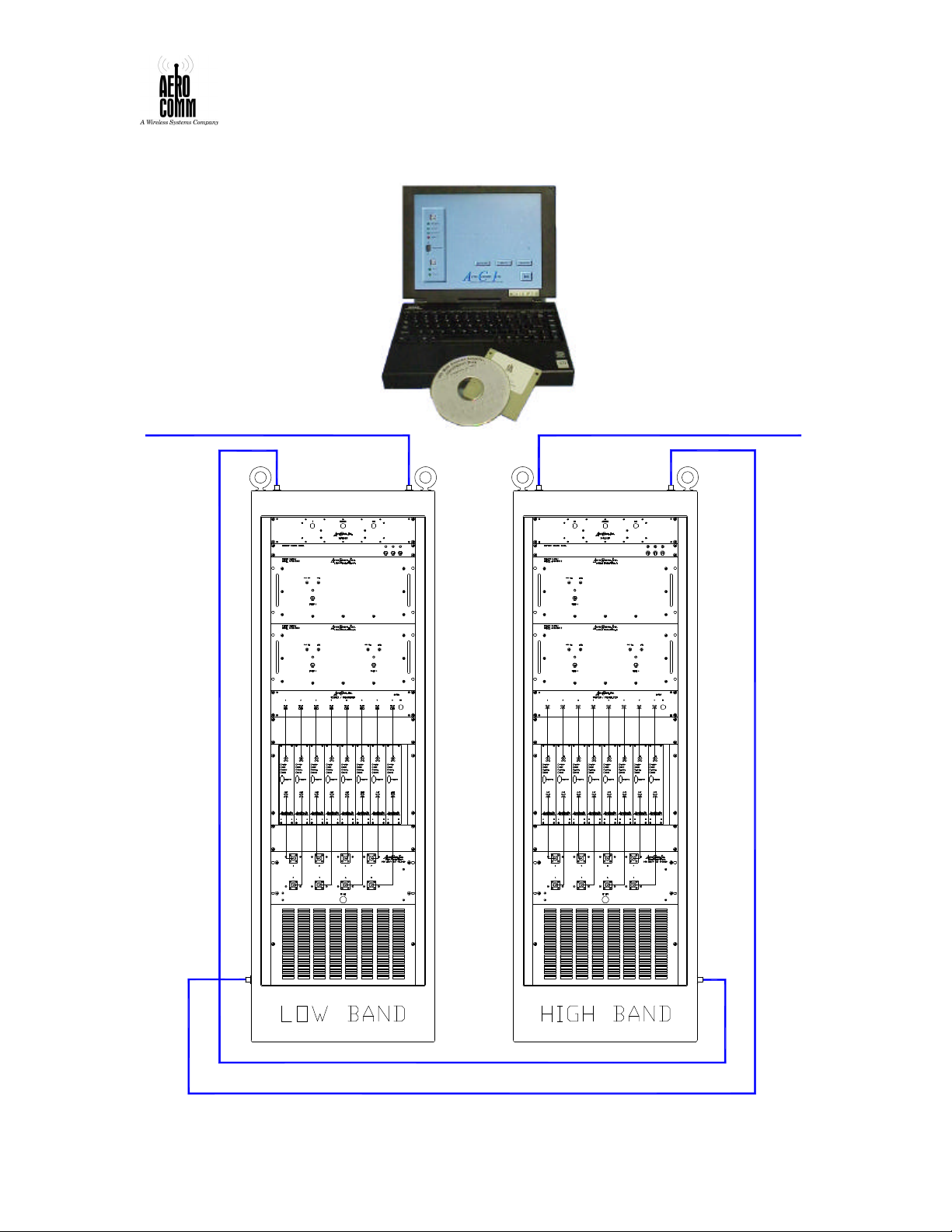

CONNECT EXTERNAL RF CABLING

Connect the two cabinets to one another using low-loss ½” heli-axial cable as shown in

the Figure 2 above.

Connect the cable leading to the roof antenna to the type N connector on the top right

(when viewed from the front) of the “Talk In” / High Band cabinet.

Connect the radiating cable to the type N connector on the top right (when viewed from

the front) of the “Talk Out” / Low Band cabinet.

INSTALLING POWER SUPPLIES & BATTERY CHARGER

The power supplies and battery charger are the first items to be loaded into the equipment

cabinets by the user. The following items were shipped in each cabinet (listed from top to

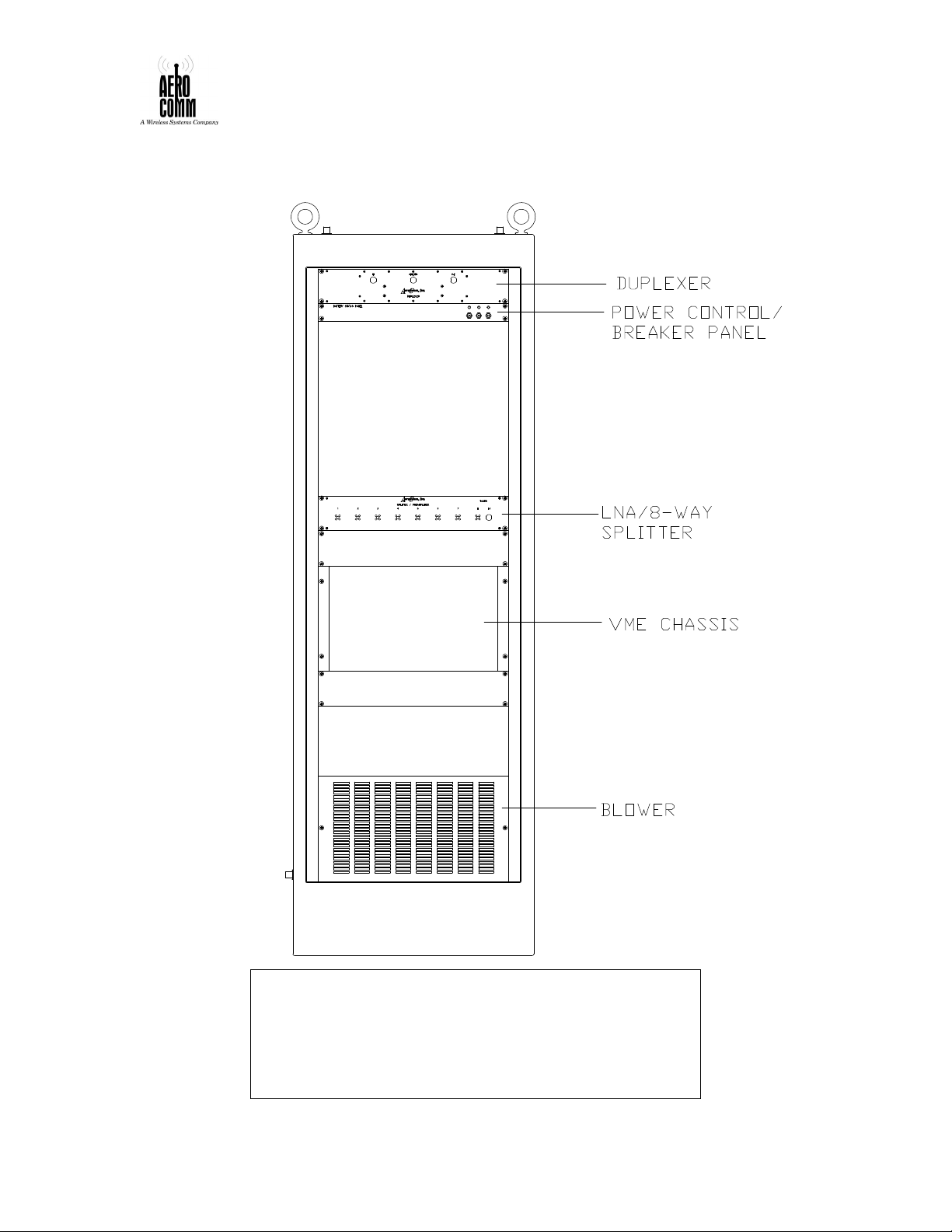

bottom of the cabinet):

I. Duplexer

II. Power Control Breaker Panel

III. LNA / 8-Way Splitter

IV. VME Chassis for Channel Cards

V. Blower

1. Verify equipment listed above is installed in each cabinet. Refer to Figure 3 below.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

11

Page 12

Figure 3. Equipment Cabinet Configuration Figure 3. Equipment Cabinet Configuration

as Shippedas Shipped

50289-BDA

WARNING

THE DUAL POWER SUPPLY MODULES WEIGH APPROXIMATELY 60

POUNDS.

THE SINGLE POWER SUPPLY MODULE WEIGHS ABOUT 40 POUNDS.

THE BATTERY CHARGER MODULE WEIGHS ABOUT 15 POUNDS.

TWO PEOPLE SHOULD LIFT THE MODULES TOGETHER TO

PREVENT INJURY DURING INSTALLATION INTO THE CABINETS.

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

12

Page 13

2. Locate the dual power supply modules (2 ea.), the single power supply module (1 ea.)

and the battery charger module (1 ea.).

The modules are distinguished by the following features:

• The dual power supply modules have two large gold power supplies (made by

Acopian) mounted side-by-side in the chassis.

• The single power supply module has a single gold Acopian power supply mounted on

the left side of the chassis (when viewed from the front).

• The battery charger module has a single yellow TrueCharge 40™ battery charger

(made by StatPower) mounted on the right side of the chassis (when viewed from the

front). The battery charger module is shown in Figure 4.

Figure 4. Battery Charger ModuleFigure 4. Battery Charger Module

CAUTION

MAKE SURE THE POWER SUPPLIES AND CHARGER ARE SWITCHED OFF

PRIOR TO INSTALLATION. THESE UNITS ARE OFF WHEN THE CIRCUIT

BREAKER PUSS-PULL SWITCHES ON THE FRONT PANEL ARE PULLED

OUT (THE WHITE BAND AROUND THE BODY OF THE SWITCH IS VISIBLE).

3. Load one dual power supply module into the High Band equipment cabinet. This

module goes directly above the LNA / 8-Way Splitter Module.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

13

Page 14

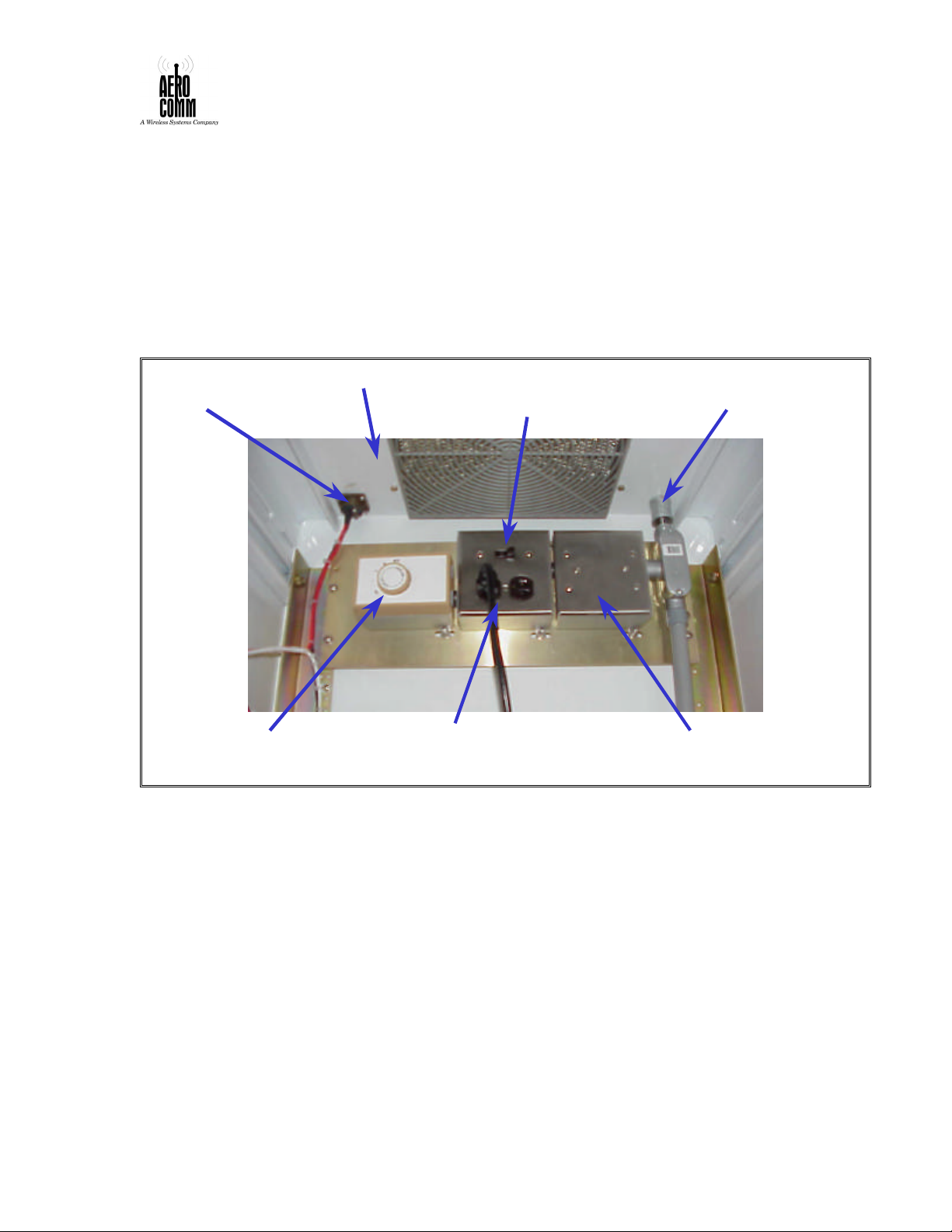

4. Attach the power connections on the rear of the chassis. Refer to Figure 5 below.

Note that there are two connections that must be made on the left side of the module

(as viewed from the front). The longer harness lead in the cabinet should be attached

to the connector further in from the left edge of the cabinet.

5. Load the other dual power supply into the Low Band equipment cabinet, directly

above the LNA / 8-Way Splitter Module.

6. Attach the power connections on the rear of the chassis as in step 4.

7. Load the single power supply into the High Band equipment cabinet, directly above

the dual power supply module.

8. Attach the power connections on the rear of the chassis. Note that the single power

supply has only one connection that must be made on the left side of the module (as

viewed from the front).

9. Load the battery charger supply into the Low Band equipment cabinet, directly above

the dual power supply module.

10. Attach the AC power connection on the right rear of the chassis.

11. Connect unterminated AC power leads to the rear of the charger using the wire nuts

provided. Install the cover over the wire nut junctions per the manufacturer’s

instructions provided in the appendix.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

14

Page 15

Figure 5. Power ConnectionsFigure 5. Power Connections on the Rear of on the Rear of

the Power Supply and Charger Module the Power Supply and Charger Module ( (

as viewed from the top)as viewed from the top)

3-PIN FEMALE CIRCULAR CONNECTORS

AMP206425-1

(DC POWER OUTPUT)

J1 J2 J3

DUAL

POWER SUPPLY

J1 J3

SINGLE

POWER SUPPLY

3-PIN MALE CIRCULAR CONNECTORS

AMP206036-1

(AC POWER INPUT)

J3

BATTERY

CHARGER

NOTE

ALL FREQUENCY DEPENDENT MODULES FOLLOW A FIXED SERIAL-

NUMBER CONVENTION. LOW-BAND MODULES ARE HAVE “1XX”

SERIAL NUMBERS AND HIGH-BAND MODULES ARE HAVE “2XX"

SERIAL NUMBERS.

INSTALLING THE POWER AMPLIFIER

Locate the two power amplifier modules.

Load the “2XX” power amplifier module into the High Band equipment cabinet, between

the IF Channel Module chassis and the blower assembly. Repeat this procedure for the

Low Band equipment cabinet using the “1XX” module.

Attach the power & signal cables in the cabinet to the mating connectors on the rear of

the Power Amplifier chassis as shown in Figure 6 on the next page.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

15

Page 16

Figure 6. Power & Signal Connections on thFigure 6. Power & Signal Connections on th

CONNECTOR (DC POWER)

CONNECTOR (SIGNAL)

e Rear of the Power Amplifiere Rear of the Power Amplifier

(as viewed from the top)(as viewed from the top)

7-PIN MALE CIRCULAR

AMP 206137-1

POWER AMPLIFIER

9-PIN MALE CIRCULAR

AMP 206705-1

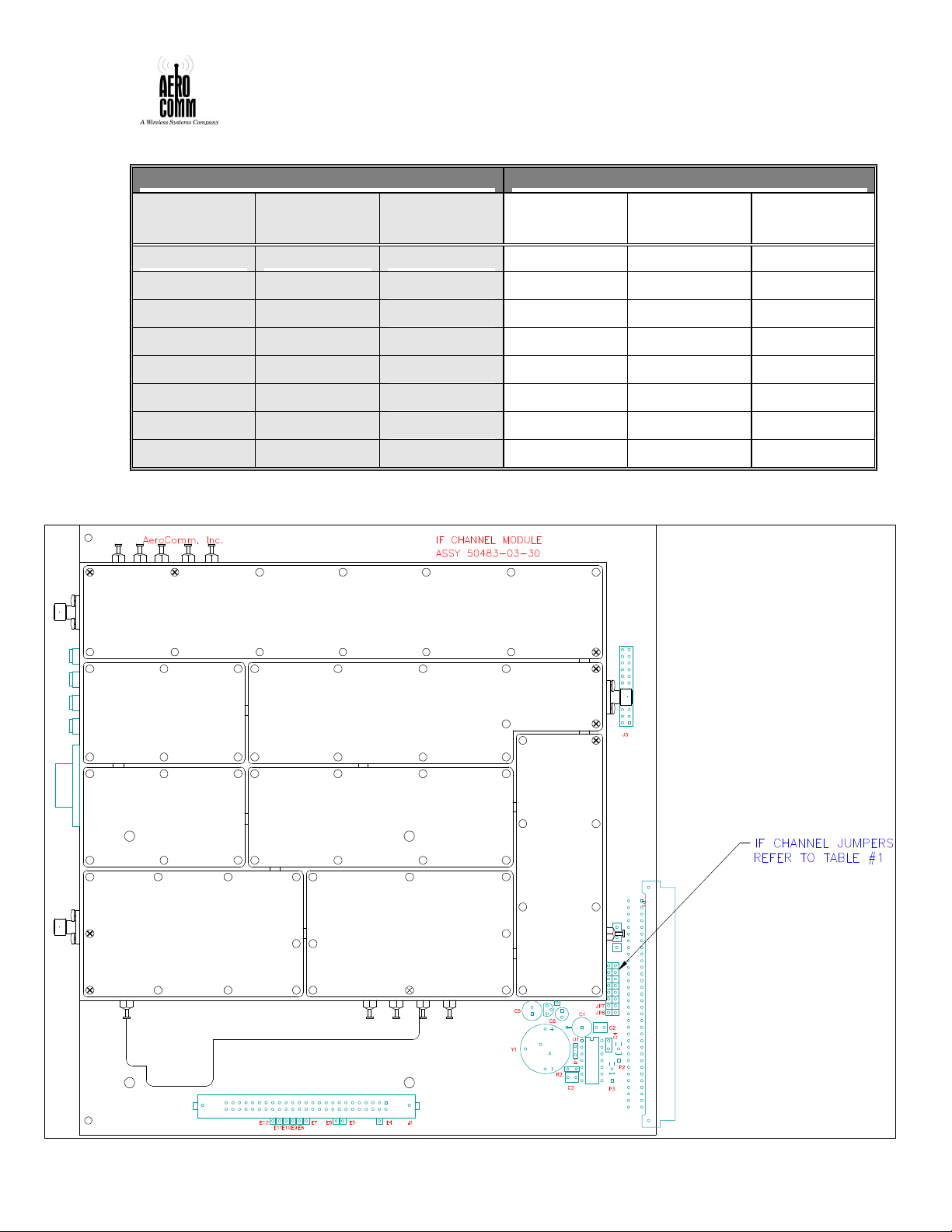

INSTALLING THE IF CHANNEL MODULES

The channel slots have been factory preset to be installed in order, from low to high

frequency, from left to right, in the VME-style IF Channel rack located in lower middle

of each cabinet.

Note that each IF channel module is labeled with the frequency to which it was factorytuned; the frequency is written on the “TESTED” sticker located on the top rear corner of

the RF enclosure in each module.

Also note the bank of jumpers at the rear of each IF channel module; the jumper position

determines the keying of the power amp directly below the IF channel rack and,

consequently, which slot each IF channel module should be placed in. The IF channel

module slots are ordered 1 through 8 from left to right.

The factory preset frequencies and jumper settings for the High- and Low-Band IF

Channel Modules are listed in Table 1. Jumper location is depicted in Figure 7

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

16

Page 17

Table 1. Factory Preset IF Channel ModuTable 1. Factory Preset IF Channel Modu

LOW BAND / TALK-OUT

HIGH BAND / TALK-IN

JP1

821.21250

Far left

JP1

866.21250

Far left

le Frequencies and Jumper Settingsle Frequencies and Jumper Settings

Jumper

Setting

JP2 821.81250 2nd from

JP3 822.37500 3rd from

Frequency

(MHz)

Chassis

Position

Jumper

Setting

Frequency

(MHz)

Chassis

Position

JP2 866.81250 2nd from

JP3 867.37500 3rd from

JP4 822.87500 Left center JP4 867.87500 Left center

JP5 823.01250 Right

JP6 823.55000 3rd from

JP7 823.60000 2nd from

JP5 868.01250 Right

JP6 868.55000 3rd from

JP7 868.60000 2nd from

JP8 823.91250 Far right JP8 868.91250 Far right

Figure 7. IF Channel Module Jumper LocationFigure 7. IF Channel Module Jumper Location

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

17

Page 18

1. Locate the IF Channel Modules for the Low Band equipment cabinet.

2. Verify the frequencies and jumper settings as per Table 1. Re-install jumpers, if

necessary.

3. Slide the IF Channel Modules into the IF channel rack in the order described above.

Secure the self-retaining thumbscrews at the top & bottom of each IF Channel

Module.

4. Locate the IF Channel Modules for the High Band equipment cabinet. Repeat steps 2

& 3.

INTERNAL RF CABLE INSTALLATION

IF MODULE CABLING

CAUTION

THE INTERNAL RF CABLING SUPPLIED WITH THIS SYSTEM IS HAND-

FORMABLE SEMI-RIGID COAXIAL CABLE. THE USER IS CAUTIONED TO

NOT RE-FORM THE CABLES, AS THIS MAY CAUSE THE CABLES TO

BREAK.

NOTE

ALL CABLING HAS BEEN FACTORY FORMED TO FIT THE INSTALLATION.

IF THE USER FINDS THAT A CABLE DOES NOT FIT, IT IS PROBABLY NOT

INSTALLED IN THE CORRECT LOCATION.

Locate the 16 SMA male to male semi-rigid cables formed as shown in Figure 8. These

cables are used to connect the IF Channel Modules to the 8-Way Splitter.

Install the cables connecting the Splitter output ports (labeled “1” through “8”) to the IF

Channel Module input ports (labeled “IN” on each module). A photo of the finished cable

installation is shown in Figure 9.

CAUTION

DO NOT OVER-TIGHTEN SMA CONNECTORS. OVER-TIGHTENING

CAN LEAD TO CONNECTOR FAILURE. RECOMMENDED TORQUE IS 8

TO 10 INCH-POUNDS.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

18

Page 19

Figure 8. Semi-Rigid Cables for ConnectingFigure 8. Semi-Rigid Cables for Connecting

IF Channel Modules & 8-Way Splitter IF Channel Modules & 8-Way Splitter

(dimensions are approximate)

12”

2”

SMA Male SMA Male

Locate the 16 SMA male to type-N male semi-rigid cables formed as shown in Figure 10.

Note that there are two types; these cables are used to connect the IF Channel Modules to

the Power Amplifier Module. Type I cables are used to connect the odd-numbered IF

Channel Modules to their respective ports on the power amp; type II cables are used to

connect even-numbered modules.

Install the cables connecting the IF Channel Module output ports (labeled “OUT” on each

module) to the Power Amplifier input ports (labeled “1” through “8”). Refer again to the

photo of the finished cable installation shown in Figure 9.

DUPLEXER CABLING

At the top of each equipment cabinet, verify that the ANTENNA port on the Duplexer

Module is connected to the type N feed-thru connector at the top of the cabinet on the

right side (when viewed from the front). Confirm that connectors are tightened.

Verify that the IN port on the Duplexer Module is connected to the type N feed-thru

connector at the top of the cabinet on the left side (when viewed from the front). Confirm

that connectors are tightened.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

19

Page 20

Figure 9. Arrangement of Internal RF CabliFigure 9. Arrangement of Internal RF Cabli

ngng

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

20

Page 21

Type I

Type II

14”

20”

SMA Male

Type-N Male

2”

FRONT VIEW

SIDE VIEW

Figure 10. Semi-Rigid Cables Connecting IF Figure 10. Semi-Rigid Cables Connecting IF

Channel Modules & Power AmplifierChannel Modules & Power Amplifier

(dimensions are approximate)

2”

SMA Male Type-N Male

SIDE VIEW

3.5

”

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

21

Page 22

DUPLEXER CABLING (CONTINUED)

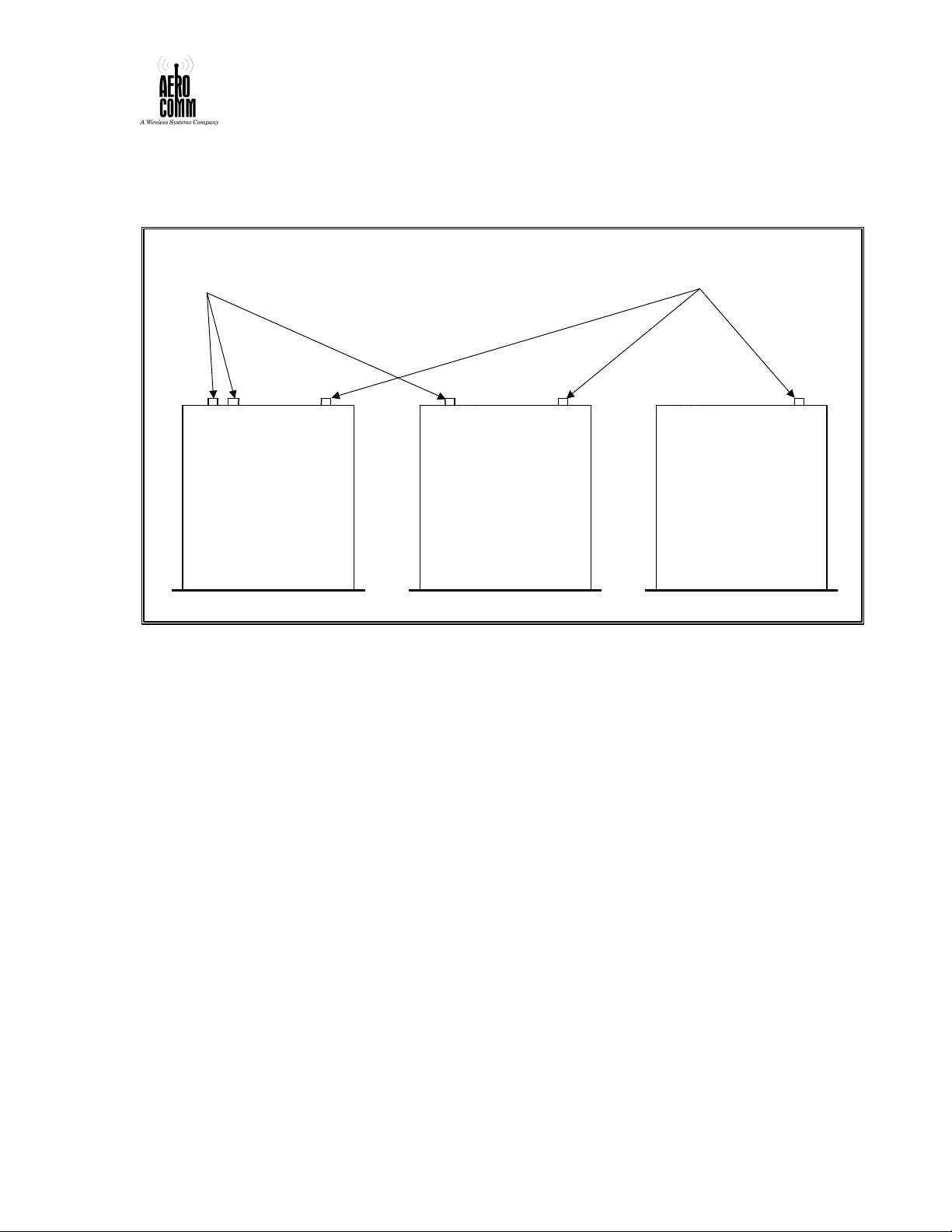

Locate the two long type-N male to male semi-rigid cables formed as shown in Figure 11.

These cables are used to connect the Duplexer Modules to the 8-Way Splitters.

Install one cable in the High Band cabinet, connecting the Duplexer OUT port to the 8Way Splitter IN port. When installed properly, the cable runs down the right side of the

cabinet. Refer again to the photo of the finished cable installation shown in Figure 11.

Install the other cable in the Low Band cabinet in the same manner.

Figure 11. Semi-Rigid Cable for ConnectingFigure 11. Semi-Rigid Cable for Connecting

the Duplexer to the 8-Way Splitter the Duplexer to the 8-Way Splitter

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

22

Page 23

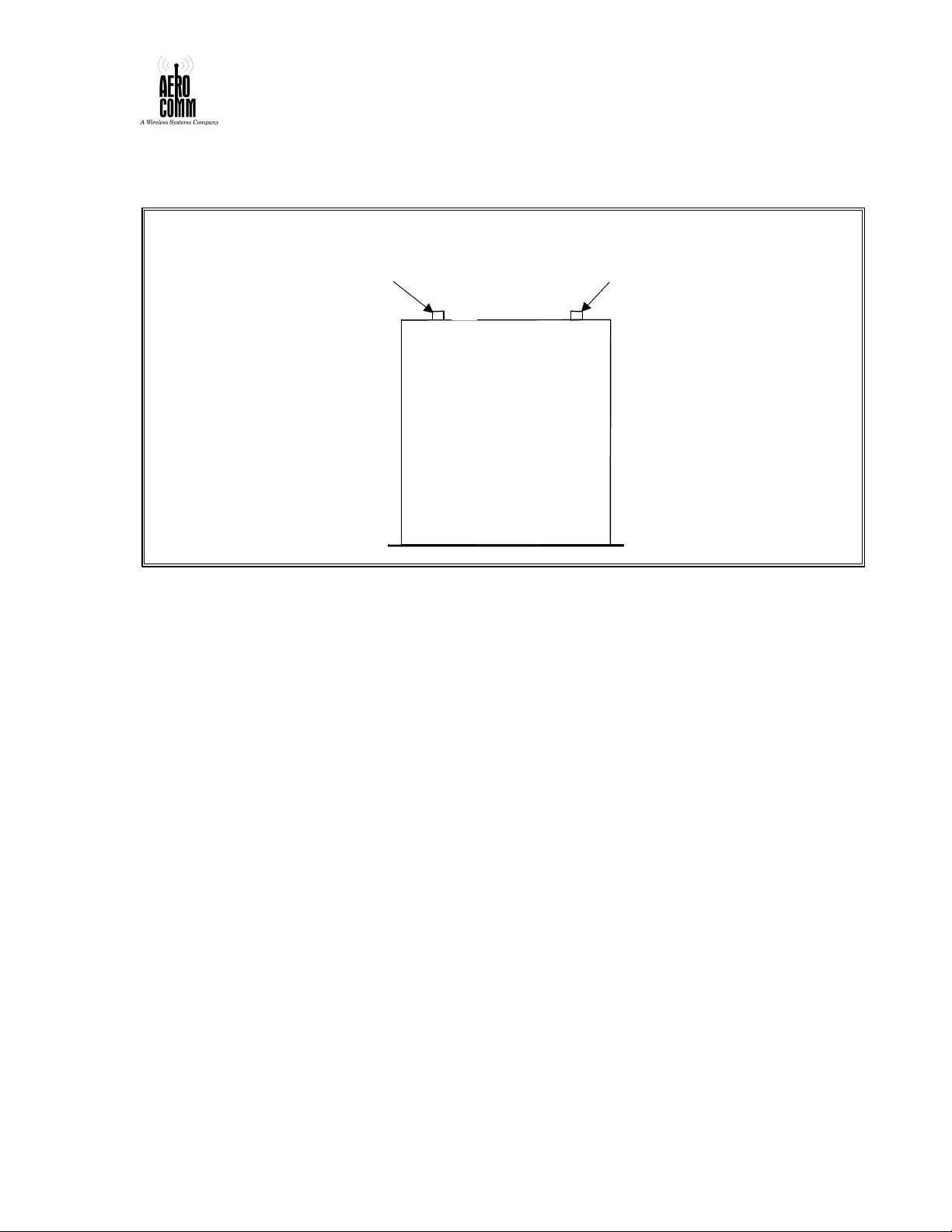

POWER AMPLIFIER CABLING

1. Locate the two 16” long type-N male to male semi-rigid cables formed as shown in

Figure 12. These cables are used to connect the Power Amplifiers to the output feedthru connectors on the lower right side of the cabinets.

2. Install one cable in the High Band cabinet, connecting the Power Amplifier OUT port

to the feed-thru connector on the lower right side of the cabinet.

3. Install the other cable in the Low Band cabinet in the same manner.

Figure 12. Semi-Rigid Cable Connecting theFigure 12. Semi-Rigid Cable Connecting the

Power Amplifier to the Cabinet-Mounted Power Amplifier to the Cabinet-Mounted

Feed-Thru Connector Feed-Thru Connector

(dimensions are approximate)

Type-N Male

FRONT VIEW

Type-N Male

SIDE VIEW

16”

2”

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

23

Page 24

BATTERY CONNECTION

CAUTION

PRIOR TO CONNECTING THE BACKUP BATTERIES, ENSURE THE CIRCUIT

BREAKERS “BANK 1” “BANK 2” AND “BANK 3” ON THE BATTERY

STATUS PANEL ARE IN THE OFF POSITION (PULLED OUT SO THE WHITE

BAND SHOWS).

1. Locate the mating circular 4-pin male battery connectors provided with the units.

2. Solder the battery leads to the connectors per drawing number 50483-01-30.

3. Attach the battery leads to the top of the cabinets as shown in Figure 13 below.

Figure 13. Battery Cabling InstallationFigure 13. Battery Cabling Installation

BATTERY CONNECTIONS

HIGH

BAND

HIGH BAND HAS THE BATTERY INPUT (2 WIRE HARNESS)

LOW BAND HAS THE BATTERY INPUT AND CHARGER OUPUT (4 WIRE HARNESS)

LOW

BAND

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

24

Page 25

POWER UP SEQUENCE

NOTE

THE POWER UP SEQUENCE DESCRIBED HEREIN, WAS DEVELOPED TO

AVOID STARTUP IN BATTERY BACKUP MODE AND TO PREVENT

OVERLOADING A 15 AMP AC SOURCE CIRCUIT . THE KEY ACTIONS ARE

TWO: (1) TURN ON THE POWER SUPPLIES ONE AT A TIME TO AVOID

EXCESSIVE INRUSH CURRENT, AND (2) TURN ON THE POWER SUPPLIES

BEFORE THE BATTERY CHARGER AND BATTERY BACKUP SYSTEM TO

AVOID STARTUP IN BATTERY BACKUP MODE. THE DETAILED

PROCEDURE PROVIDED BELOW IS FOR THE USER’S CONVENIENCE.

1. Ensure the AC service input is live.

2. Switch on the power supplies in the following order: (Refer to Figure 14)

I. Lower Right

II. Lower Left

III. Upper Left

3. Enable the battery backup system by depressing the circuit breakers on the Battery

Status Panel in the following order:

Bank I

Bank II

Bank III

4. Verify all Battery Status Panel indicator LEDs are illuminated steady GREEN.

5. Verify all Power Supply Panel indicator LEDs are illuminated steady GREEN.

6. Verify flashing indicator LEDs on all IF Channel Modules, alternating between

POWER / STATUS and LOCK / FAULT. This is followed by the POWER, STATUS

and FAULT lights illuminating. Finally, all module indicators should show:

POWER (green) – ON steady

LOCK (green) – ON steady

STATUS (green) – ON or OFF

FAULT (red) – OFF

The STATUS indicator LED may be on if an incoming signal is being received.

7. If the indicator LEDS on all modules do not illuminate in the final state after boot-up

sequence as described above, refer to the operations portion of this manual for

troubleshooting instructions. Normal LED indications for the entire unit are shown in

Figure 15.

8. The units are now ready for programming, if necessary, as described in the operations

section of this manual. If no programming is required (i.e., the channel frequencies

programmed by the factory are correct), the door on each cabinet should be closed

and bolted tight.

9. Each channel left the factory set for the carrier frequencies as described in Table 1 in

accordance with the contracted customer specifications. With a timeout of 1 minute

and an attack time of 50 Milliseconds.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

25

Page 26

Figure 14. Main Power Switches for Power SFigure 14. Main Power Switches for Power S

upplies and Battery Status Panelupplies and Battery Status Panel

Figure 15. Normal LED Illuminations after PFigure 15. Normal LED Illuminations after P

ower Up ower Up

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

26

Page 27

SECTION II OPERATION PROCEDURES

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

27

Page 28

The Eight-channel, Bi-Directional 800 MHz-Band, RF Distribution Amplifier system

requires no regular operator intervention to perform its function. The system is

accompanied by two software programs, the User’s software and the Technician’s

software. All adjustments to the system are made using these software packages. The

User’s software allows the operator to change channel frequencies, channel time-out

settings, and channel keying mode. The Technician’s software provides the user with the

ability to perform maintenance actions; this software is described in detail in the

maintenance sectio n.

Given that the channel settings provided by the factory are satisfactory and the system

performs without any trouble, no adjustments need be made. If any troubles are

suspected, the front of the cabinet should be opened and the indicator lights observed.

For normal operations, the indicator lights should be as follows:

Battery Status Panel – 3 green LEDs on steady

Power Supply / Charger Panel – 3 green LEDs on steady

Channel status may be determined by observing the indicator LEDs on the channel

modules. Possible LED illumination patterns are shown in Figure 16 below for both

normal and failure modes.

Figure 16. Channel Module LED Indicator IllFigure 16. Channel Module LED Indicator Ill

umination Patternsumination Patterns

NORMAL INDICATIONS FAILURE INDICATIONS

CHANNEL

KEYED

POWER

LOCK

STATUS

FAULT

NOT

KEYED

POWER

LOCK

STATUS

FAULT

TIMEOUT

FAIL

POWER

LOCK

STATUS

FAULT

SYNTHESIZER

LOCK FAIL

POWER

LOCK

STATUS

FAULT

MICROPROCESSOR

POWER FAIL

POWER

LOCK

STATUS

FAULT

USER’S SOFTWARE

The guide for using the User’s software is provided in Section VI. The user’s software is

designed to run on a Windows-based Pentium PC or laptop. A serial cable must be

connected between the computer’s COM1 port and the PROGRAM port on the front of

the channel being adjusted. The channel must be powered up in order to be programmed.

A brief discussion of the functions is provided here; details of actually affecting the

desired changes are presented in the User’s Guide.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

28

Page 29

CHANGING THE TIME-OUT DURATION

The time-out duration is how long a channel can be held open (keyed on) for a

retransmission. This feature prevents a channel from being disabled by an inadvertent or

intentional “key and hold” action without any voice communication. The time-out

duration can be up from 1 second to 99 minutes 59 seconds in 1 second intervals. The

time-out duration can be disabled by setting it to 00 minutes 00 seconds. When disabled,

the channel will key continuously with the presence of a received signal.

CHANGING THE MODE SETTING

The channel mode may be set to either CONTINUOUS or RSSI (Received Signal

Strength Indication). In the continuous mode, the channel is always keyed and

continuously transmitting. In the RSSI mode, the channel is keyed only when the

incoming signal strength is above the factory set threshold level. Normal operation will

be in RSSI mode; continuous mode is normally used only for testing.

The factory-set RSSI threshold level is –90dBm.

If regular traffic is below this level, call the factory to arrange for adjustment of this

threshold level. If the ambient noise on the channel is above this level, refer to the

Technician’s Guide on how to set the attenuation to overcome this.

TECHNICIAN’S SOFTWARE

The Technician’s guide for using the software is provided in Section VII. A

brief discussion of the functions are provided here; details of actually

affecting the desired changes are presented in the Technician’s Guide.

SETTING THE ATTACK TIME

Changing the attack time adjusts the time interval allowed between a transmission keying

off and a subsequent transmission keying on. This feature is designed to provide the

system operator with the ability to minimize an attacker’s ability to disable a channel by

repeatedly keying a radio. The attack time is adjustable in 50 millisecond intervals from

50 milliseconds to 4.9 seconds.

CHANGING THE INPUT ATTENUATION

The input attenuation control serves two purposes. First, it can be used to reduce the

ambient RF noise level below the channel module’s threshold key level. This must be

adjusted incrementally until the noise floor is below the threshold, while the intended

signal still has enough level to key the booster amplifier on. Second, if the intended

signal is unusually high, the attenuation control can be use to “trim” the signal level down

to minimize the channel’s IM products which may interfere with adjacent channels.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

29

Page 30

SETTING THE FREQUENCY

Each module’s frequency may be set using the User’s software. The User’s software

allow the operator to change the frequency of the module to any other frequency within

the operating band.

CHANGING THE CHANNEL ID

The channel ID is an optional software upgrade to the 800 MHz-Linc software.. The

channel ID identifies each channel module. This is useful if modules are moved around

or a new module is installed in place of a defective one. Normal channel IDs are depicted

in Figure 17.

CHANGING THE CHANNEL SERIAL NUMBER

The serial numberis an optional ugradeto the 800MHz-Linc software. The serial number

of each channel module is stored in non-volatile memory. This is an optional function

and not normally programmed. The channel serial number can be used for customer asset

tracking.

Figure 17. Normal Channel ID Numbering SchFigure 17. Normal Channel ID Numbering Sch

emeeme

CH1CH1 CH2CH2 CH3CH3 CH4CH4 CH5CH5 CH6CH6 CH7CH7 CH8CH8

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

30

Page 31

SECTION III MAINTENANCE

BDA MAINTENANCE:

The 8 Channel Booster Amplifier, BDA, is designed for unattended operations requiring

minimal maintenance. General maintenance consists of the cleaning/replacement of the

intake/exhaust filters, equipment inspection and operational tests. It is recommended the

routine maintenance be accomplished monthly and the schedule revised to meet the

requirements of your unique installation. Equipment tune-up and alignment is required

only if indicated by the operational tests.

AIR FILTRATION:

The intake and exhaust air filters should be periodically checked and cleaned. The

two filter grills (on the enclosure’s top and front door) are easily removable; access to

the interior of the enclosure is not required. When required, use only aluminum filter

replacements.

CABLE INSPECTION:

The exterior cables and connectors should be periodically inspected for evidence of

corrosion.

ENCLOSURE INSPECTION:

The interior of the enclosures should be inspected for evidence of condensation. The

internal cabling should be inspected. In addition, the operation of the cooling fan

should be tested.

OPERATIONAL TESTS:

Operational testing may consists of keying up each channel with a handheld. The

performance of the BDA will indicate if more detailed test are required.

The maintenance schedule should take in consideration the environment of the

installation a performance of the BDA. The inspection and cleaning of the air filters

should be preformed monthly. In general, all recommended maintenance should be

preformed tri-monthly.

BATTERY MAINTENANCE (BACKUP BATTERY):

It is recommended that the inspection of the condition and maintenance of the user

supplied batteries should be performed as prescribed by the battery manufacture.

ADDITIONAL INFORMATION

For additional maintenance information refer to the Technicians Guide in

Section VII.

AEROCOMM Maintenance Program – Call 1-201-227-0066

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

31

Page 32

SECTION IV RECOMMENDED SPARES

Card extender P/N 50483-03-32

Battery Backup P/N 50483-02-33

RF Power Amplifier /8 Way Combiner P/N 50483-02-09-01 (Low Band)

P/N 50483-02-09-02 (High Band)

Channel Card P/N 50483-02-12

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

32

Page 33

SECTION V THEORY OF OPERATION

THEORY OF OPERATION

The eight channel bi-directional amplifier uses 16 channels of synchronized down-up

conversions.

The multi-channel booster is divided into two independent 8-channel systems (8 high

band and 8 low band) for full duplex operations. Inbound signals, talk-in, are received at

the roof antenna, 8 selected frequencies are processed (filtering and amplification), and

rebroadcast on radiating cable. Conversely, outbound signals induced onto the radiating

cable are similarly processed and rebroadcast on the roof antenna. The 8 talk-in channels

are the high band signals (864-869Mhz), and the 8 talk-out channels are low band (819824Mhz).

Each system consists of a duplexer, LNA/8-way splitter, 8 channel modules (down-up

converters with synthesized LOs), 8 class C RF power amplifiers with an 8-way power

combiner. In addition there are internal power supplies for 110vac operation, provisions

for connecting to and charging external batteries for battery back-up operation, and a

thermostat controlled cooling fan.

The RF signal flow of the two systems are identical. RF band pass filters internal to the

system modules determine high band or low band operations. (Refer to Figure 19).

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

33

Page 34

Figure 18. Overall System Figure 18. Overall System

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

34

Page 35

Figure 19. System OutlineFigure 19. System Outline

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

35

Page 36

DUPLEXER:

The duplexer allows for full duplex operation, simultaneous transmit and receive into a

common antenna port. The pass/reject filtering of the duplexer provides band preselection, minimal insertion loss between the antenna port to the two ports, transmit and

receive ports, and provides high isolation between the transmit and receive ports. For

proper operations, the talk-in booster amp, BA, is connected to the roof antenna, and the

talk-out BA to the radiating cable. Duplexer configuration as follows:

TALK-IN BA:

Through a type N connector on the top of the enclosure, the antenna port of the

duplexer is connected to the roof antenna. The receive port is connected to the BA’s

LNA/8 way splitter for processing of the inbound signals. Through a type N

connector on the top of the enclosure, the transmit port is externally cabled to the RF

output port of the talk-out BA to broadcast the outbound signals on the roof antenna.

TALK-OUT BA:

Through a type N connector on the top of the enclosure, the antenna port of the

duplexer is connected to the radiating cable. The receive port is connected to the

BA’s LNA/8 way splitter for processing of the outbound signals. Through a type N

connector on the top of the enclosure, the transmit port is externally cabled to the RF

output port of the talk-in BA to inject the inbound signals onto the radiating cable.

LNA/8-WAY SPLITTER:

The LNA/8-way consists of two modules, a low noise amplifier, to provide band preselection and amplification of the received signal, and an 8-way splitter. In the LNA

module, the operational band is selected by two 5 pole ceramic band pass filters. For

low band operation, filters centered at 821.5, with a bandwidth of 5Mhz are installed;

for high band operation, filters are centered at 866.5Mhz are installed. The 8-way

splits the LNA output to the inputs of the 8 channel modules.

Splitter output port: “1” to the input of channel module “1”

“2” to the input of channel module “2”

etc. Through channel 8.

CHANNEL MODULE (IF MODULE):

The CHANNEL MODULE consists of three components; an IF module (a synchronized

down-up converter to provide a high degree of filtering and hard limiting of a channel

frequency), a micro-controller (to monitor and control the IF module), and a motherboard

(to route signals to the back panel of the channel module chassis).

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

36

Page 37

IF CHANNEL MODULE:

The IF module consists of 5 compartments:

• The RF amplifier provides for additional channel pre-selection of the received RF

signal.

• The down conversion of the signal received to an IF of 90Mhz, two cascade

crystal filters provides a high degree of filtering

• The hard limiting of the IF eliminates the requirements of an AGC loop. An

analog RSSI from the IF is compared to a threshold setting to produce a logic

output, RSSI KEY. This signal is monitored by the micro-controller to produce

the key line and key line time-out functions. Keying the final stages of the IF

module and the final RF power amplifier prevents unwanted spurious outputs

when no sign carrier is detected.

• The up conversion and filtering to the original frequency. With hard limiting at

the IF frequency, a constant output level verse the input level is produced.

• A dual output synthesized LO. Synchronized conversions mean that the frequency

received equals the frequency transmitted. The synthesizer output (Fc+90Mhz)

determines the channel frequency and is programmable in 12.5Khz steps to

produces the 25Khz channel spacing over the pre-selected band. The mother

board in the MACS slot of the card cage provides a 8Mhz common reference

oscillator to all the PLLs in the channel modules.

MICRO CONTROLLER:

The controller performs 4 functions:

• Programs the IF module synthesizer to the desired frequency and monitors lock

detect for a fault detection.

• Monitors the IF’s RSSI KEY and generate the key line function.

• Performs the key line time out and delay functions, of the time-out timer.

• Interface to the operator. Using a computer and AeroComm’s proprietary

software, the operator can program the channel frequency and time-out functions.

The software runs on Windows 95, 98, NT or 2000.

THE MOTHERBOARD:

The IF module and micro controller are configured as plug in modules. The mother

board routes the power and control signal between the modules, to the front panel

LEDs and RS232 connector and the card cage back panel.

RF POWER AMPLIFIER/8-WAY COMBINER:

The final RF power amplifier consists of a pre-driver amplifier stage and a hybrid class C

RF power module. The pre-driver adds additional filtering the channel modules output,

and amplifies to a sufficient level to drive the power amp. To shut-down the power amp,

the pre-drive amplifier is controlled (on/off) by the micro-controller output, key line,

from the associated channel module. To produce the required per carrier output level after

the power combiner, the low band channels utilize a 6 watt RF power module, and the

high band requires a 20 watt module. The outputs of the 8 RF power module both lo w

and high are summed by the 8-way combiner.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

37

Page 38

DC POWER DISTRIBUTION/BATTERY BACKUP:

The DC power requirements of the channel modules and their associated RF power

amplifiers are distributed among multiple power ‘banks’ (VCC1, VCC2, and VCC3).

Dividing the power requirements among multiple power supplies prevents a complete

shut down due to ‘a’ power supply failure. In addition, it allows for an effective switch

over to battery operations. (Refer to Figure 20):

The BA is configured with up to 3 power supplies. The power distribution panel unit,

PDU, consists of 7 relays to switch between the internal power supplies and external

batteries during an interruption of the AC source. For redundancy, for each required VCC

voltage, two relays are wired in parallel. . The external batteries are wired into the BA’s

battery status panel through 2 pins of a 4 pin connector located on the top of the

enclosure (battery input). On the battery status panel, 3 circuit breakers split the battery

service for each VCC voltage required. The power supplies and battery bank switches

(circuit breaker) are paired as follows:

PS1 with battery switch ‘Bank 1’ to supply VCC1.

PS2 with battery switch ‘Bank 2’ to supply VCC3.

PS3 with battery switch ‘Bank 3” to supply VCC2.

To minimize the interruption of the BA operations during switch over to batteries, the 8

channel’s micro-controllers and synthesizers are on a UPS. The UPS voltage source is

supplied by diode ‘OR’ing the DC supplies and the bank switch 3 (external batteries)

across the 7th relay of the PDU.

NOTE: TURN OFF THE BA, FIRST TURN OFF THE 3 BATTERY BREAKERS

(PULLED OUT). This prevents the switch over to battery back during shut down

procedures.

THE HIGH BAND BA:

(20 watt RF power modules) (refer to Figure 21):

In the high band (talk-in) BA, 3 power supplies are required. The channel modules and

their associated RF power modules are distributed between the 3 VCC sources as

follows:

Channels 1, 2, and 3 to VCC1

Channels 4, 5, and 6 to VCC2

Channels 7 and 8 to VCC3

THE LOW BAND BA:

(6 watt RF power modules)(refer to Figure 22):

In the low band (talk-out) BA, 2 power supplies are required. The channel modules and

their associated RF power modules are distributed between the 2 VCC sources as

follows:

Channels 1, 2, 3 and 4 to VCC1

Channels 5, 6, 7 and 8 to VCC3

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

38

Page 39

In the low band BA, due to the requirements of only two power supplies, the ‘3 state’

battery charger is installed. The output of the battery charger is wire directly to a second

pair of pins of the ‘battery input’ connector (located on the top of the enclosure). The

output of the charger is terminated directly at the batteries; there are no internal

connections between the charger to the battery status panel or PDU.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

39

Page 40

Figure 20. Power Distribution Unit OutlineFigure 20. Power Distribution Unit Outline

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

40

Page 41

Figure 21. Power Distribution High BandFigure 21. Power Distribution High Band

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

41

Page 42

Figure 22. Power Distribution Low BandFigure 22. Power Distribution Low Band

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

42

Page 43

SECTION VI USER’S GUIDE

800MHz-Linc

Version 1.0

OVERVIEW

This software, 800MHz-Linc is designed for the control and configuration of

each channel of the 8-channel Directional Amplifier (BDA). It allows the

users to set the duration of time-out, and mode.

PROGRAM INSTALLATION

To install/reinstall the software:

1. Insert the AeroComm Inc. CD-ROM and locate the Setup program on the

CD-ROM.

2. The Setup software will prompt the user to click ok, then click on the

Install icon.

3. Continue to click on the default to settings to complete the installation.

PROGRAM STARTUP

Windows NT requires a user ID and password. The User ID is

Administrator and the password is blank so just press the <Enter> key or

click OK to Login to the system.

The 800 MHz software should run upon completion of the login.

Click on the Start/Programs/AeroComm Inc/800Mhz from the Start button.

This software is typically installed on the c:\program files\800Mhz directory.

All data files are also stored on the c:\program files\800Mhz directory. You

must login to the computer to start 800 MHz.

IN the event the software is stopped, to restart simply repeat the above

procedure: Click on the Start/Programs/AeroComm Inc/800Mhz.

In addition to using the mouse, the keyboard can be used to select buttons on

the screen by using the <CTL> key simultaneously with the underlined letter

on the button.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

43

Page 44

MAIN SCREEN

Figure 23 below is the main working screen used to configure the channel Time Out and

Mode setting.

The main screen of the software is displayed below. It has a picture of the channel on the

left with the lights having the same on or off status as those on the channel. Every change

of the lights on the channel is reproduced in the main screen’s picture.

Figure 23. 800MHz-Linc Main screenFigure 23. 800MHz-Linc Main screen

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

44

Page 45

COMMUNICATION CONNECTION

This software automatically checks the condition of its communication connection with

the intended channel not only when it is started but also continuously every ten seconds.

If the software does not receive a response from the channel, a warning message is

displayed and indicated in Figure 24 below. The user is given three choices: Abort exits

the software; Retry re-checks the connection, and Ignore skips the connection test and

opens the main screen. The user can recheck the connection condition by clicking at the

Refresh button on the main screen. The Refresh button restarts the software without

rebooting.

Figure 24. 800 MHz-Linc Main Screen with ConFigure 24. 800 MHz-Linc Main Screen with Con

nection Error windownection Error window

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

45

Page 46

TIME-OUT DURATION

The time-out duration is how long a channel can be held open (keyed on) for a

retransmission. An inadvertent or intentional “key and hold” action without any voice

communication will not disable the channel because of this feature. The time-out

duration can be up from 1 second to 99 minutes 59 seconds in 1 second intervals. The

time-out duration can be disabled by setting it to 00 minutes 00 seconds. When disabled,

the channel will key continuously with the presence of a received signal.

SETTING A TIME-OUT TIME

To set a time-out time, click the function button Time Out at the bottom of the main

screen, a time-out setting board appears as displayed in Figure 25 below. Select the

desired time-out time up to 99 minutes (MM) and 59 seconds (SS) and then click Set with

the mouse button. Setting 00 minute and 00 second disables the Time-out function. If the

Set button is not clicked, the setting in place upon entry to the window remains in effect.

Click Exit button on the setting board to go back to the main screen.

Figure 25. Set Time Out windowFigure 25. Set Time Out window

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

46

Page 47

MODE SETTING

The channel mode may be set to either CONTINUOUS or RSSI (Received Signal

Strength Indication). In the continuous mode, the channel is always keyed and

continuously transmitting. In the RSSI mode, the channel is keyed only when the

incoming signal strength is above the factory set threshold level. Normal operation will

be in RSSI mode; continuous mode is normally used for testing.

CHANGING THE MODE

To change the Mode, click the function button Mode at the bottom of the main screen. A

mode setting window seen in Figure 26 below, appears with a picture of a switch on it

showing which is the current Mode of the channel is. Click the Keyed or CONT

(continue) button to set the desired mode. Alternatively, you can click the picture of the

switch to toggle the mode. Click Exit button on the setting board to go back to the main

screen.

Figure 26. Set Mode windowFigure 26. Set Mode window

EXITING THE SOFTWARE

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

47

Page 48

To Exit the software, click the Exit button at the bottom right corner of the main screen, a

dialog box is presented, see the example in Figure 27 below, to insure your intention.

Click Yes to exit the software, or No to go back to the main screen.

Figure 27. Exit confirmation windowFigure 27. Exit confirmation window

ADDITIONAL INFORMATION

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

48

Page 49

To know more about this software and AeroComm, Inc,: Point the mouse to

the logo of AeroComm, Inc at the bottom of the main screen. Click when the mouse

pointer changes to (an information icon). An information screen Figure 28 below is

displayed.

Figure 28. Figure 28. 800 MHz-Linc about window800 MHz-Linc about window

SECTION VII TECHNICIAN’S GUIDE

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

49

Page 50

800MHz-Linc

Version 1.0

ACTIVATING TECHNICIAN FUNCTIONS

To activate the technician function buttons (i.e. Attack, Attenuation, and Frequency):

On the main screen, point the mouse to the upper left corner, click when the mouse

pointer changes to a circle. The technician function buttons are then displayed at the top

of the main screen Figure 29 visible below.

Figure 29. 800MHz-Linc Main ScreenFigure 29. 800MHz-Linc Main Screen

CLOSING THE TECHNICIAN FUNCTIONS

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

50

Page 51

To close the technician function buttons: In the technician main screen, click the function

button Finish at the far left of the top, then those function buttons for technician

disappears.

SETTING RSSI ATTACK TIME

To set a RSSI Attack time: click the function button Attack at the top of the main screen.

A RSSI Attack setting window Figure 30 appears with the current setting shown in

Millisecond. By clicking at either the up or down arrow next to the text box, the setting

of attack time is increased or decreased by 50 Millisecond by each click. The range of the

setting is from 50 milliseconds to 4.9 seconds. Click Exit button on the setting board to

go back to the main screen.

Figure 30. Set RSSI Attack windowFigure 30. Set RSSI Attack window

CHANGING THE CHANNEL ID

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

51

Page 52

An optional feature of the software is setting and changing the Channel ID. The channel

ID can be set for each channel module. This is useful if modules are swapped around or a

new module is installed in place of a defective one. Normal channel IDs are depicted in

Figure 17.

CHANGING THE CHANNEL SERIAL NUMBER

Another optional feature of the software is setting and changing the channel serial

number. The channel serial number could be used to assist with asset tracking.

SETTING ATTENUATION

To set Attenuation: click the function button Attenuation at the top of the main screen.

An Attenuation setting window appears with the current setting shown in dB seen below

in Figure 31. Click the down arrow next to the text box, a drop down list of available

attenuation setting are displayed. Click the desired new setting and then with the mouse,

click the Set button to confirm the change to the attenuation setting. Click Exit button on

the setting board to go back to the main screen.

Figure 31. Set Attenuation windowFigure 31. Set Attenuation window

SETTING A FREQUENCY

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

52

Page 53

A click of the function button Frequency, Time Out, or Mode causes a setting window to

appear in the middle of the main screen with the channels current setting shown in a text

box. An example is presented in Figure 32 below.

To set a frequency, click the function button Frequency at the bottom of the main screen,

a frequency setting board appears. Select the desired frequency in either the high band or

low band selection list by clicking on it and then click Set button. The new setting is

verified in the Current Setting text box. You can also set a frequency by typing the

desired frequency in the text box above the Set button and then press the ENTER key on

the keyboard or click on Set button. Click the Exit button on the Set Frequency window

to go back to the main screen.

Figure 32. Set Frequency windowFigure 32. Set Frequency window

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

53

Page 54

CLOSING THE TECHNICIAN FUNCTIONS

To close the technician function buttons: In the technician main screen, click the function

button Finish at the far left of the top, then those function buttons for technician

disappears.

Figure 33. 800 MHz-Linc screenFigure 33. 800 MHz-Linc screen

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

54

Page 55

SECTION VIII TUNE UP PROCEDURE

No tune up procedures are required for this unit. All setting are adjusted at the

manufacturing facility.

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

55

Page 56

SECTION IX FCC CERTIFICATION LABEL LOCATION

MODEL:

FCC ID:

MODEL:

FCC ID:

Germantown, MD 20874

Germantown, MD 20874

50289-BDA

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS MANUAL

56

Loading...

Loading...