ROOF-TOP UNITS R410A - Manual selection, installation and maintenence

RTE

240-400

GB

1102. 6180892_00

AERMEC S.p.A.

37040 Bevilacqua (VR) – Italy

Via Roma, 996

Tel. (+39) 0442 633111

www

.aermec. com

1115

DICHIARAZIONE DI CONFORMITA’

DECLARATION OF CONFORMITY

DÉCLARATION DE CONFORMITÉ

KONFORMITÄTSERKLÄRUNG

Tipo macchina / Type of unit / Type

de machine / Maschinentyp

Condizionatore d'aria tipo Roof-top, Roof-top air conditioning unit

Unité de climatisation Roof-top, Autonome Klimaanlage

Modello / Model / Modèle / Modell

Matricola / Serial No /

Numéro de série / Seriennummer

La macchina è conforme alle disposizioni contenute nelle seguenti direttive: / The unit complies with the

provisions contained in the following directives: / La machine est conforme aux dispositions contenues

dans les directives suivantes: / Das Gerät entspricht den Bestimmungen der folgenden Richtlinien

enthaltenen:

2006/42/CE Direttiva Macchine / Machine Directive / Machine Direct ive / Mas ch inenr ic htlinie

2006/95/CE Direttiva Bassa Tensione / Low voltage Directive / Basse Tension / Niederspannungsrichtlinie

2004/108/CE Direttiva EMC / EMC Directive / EMC Directive / EMV-Richtlinie

97/23/CE Direttiva PED / PED Directive / PED Directive / PED- Ric htlinie

ed è stato sottoposto alla procedura di valutazione A1 con controlli dell’organismo Società Consortile

PASCAL a r.l. (n° 1115) via A. Scarsellini, 13 – 20161 Milano (certificato n° 20 del 10/02/2003)

has been evaluated according to the A1 procedures with controls carried out by PASCAL (n°1115)

company, address A. Scarsellini 13, 20126 Milan (certificate n°20 dated 10/02/2003)

et a été vérifiée selon la procédure A1 par l’organism Società Consortile PASCAL a r.l. (n° 1115) via A.

Scarsellini, 13 – 20161 Milano (certificat n° 20 date 10/02/2003)

wurde überwacht nach Beobachtung Unternehmen PASCAL (n°1115), Adresse A. Scarsellini 13, 20126

Mailand (Zertifikat n°20 von 10/02/2003

Componente / Component / Élément / Komponente Modulo / Module / Module / Modul

Pressostato di alta pressione / Pressure switch / Pressostat / Druckschalter B + D

Valvola di sicurezza / Pressure relief valve / Valve de sécurité / Sicherheitsventil B + D

Compressore / Compressor / Compresseur / Kompressor D1

Ricevitore di liquido / Liquid receiver / Flüssigkeitssammler / Boutilles liquide A

Separatore di liquido / Suction accumulator / Flüssigkeitsabscheider / Boutilles anti-coup A

Filtro deidratatore / Filter / Filter / Filtres A

Rubinetti / Ball valve / kleinventile / Vanes A

Batteria di scambio termico / Coil / Register / Batterie A

La persona autorizzata a costituire il fascicolo tecnico è: / The person authorized to compile the technical

file is: / La personne autorisée à constituer le dossier technique est: / Die Person berechtigt, die

technischen Unterlagen zusammenzustellen:

Giampaolo Cardin via Luppia Alberi,170

Bevilacqua, 25/01/2011 Luigi Zucchi

Index

General norm 4

Units identification and description 5

Version cambination 6

Unit configuration 7

Description of components 10

Regulation system 11

Accessories 12

Technical data 14

Operating limits 20

Sound data 20

Cooling capacity and input power 21

Heating capacity and input power 22

Corrective coefficients for different flow rates 23

Total capacities for different relative humidities 23

Performance tables for water heating coils 24

Technical data generator Gxxx 25

List of pressure equipment - Directive PED 97/23 CE 26

Refrigerant circuits 26

Dimensions 28

Nominal dimensions 32

Refrigerant charge 32

Weights 33

Configurations 34

RTE with three-way mixing box 35

RTE with heat recovery unit 35

RTE with heat generators G72 - G92 - G150 kW 37

PR2 remote panel 38

Installing and using the unit 39

Norms covering the use of R410A gas 40

Hydraulic connections - Condensate drain pain 40

Connection aeraulic 41

Joining RTE sections 42

Improper use 43

Electrical wiring 43

Security 44

Unit maintenance 44

Monthly maintenence program 45

Diagnosis and fault solving 46

English

General norms

Roof-top units - RTE series-

This manual is an integral

part of the documentation

enclosed with the unit.

It must be preserved for

future reference and must

accompany the machine throughout its

life.

The manual defines the purpose for

which the machine has been built and

establishes its correct installation and

the limits of its use.

• This manual provides all the

technical instructions and

instructions for the installation

of this unit and the main accident

prevention regulations.

Read carefully and thoroughly all the

information referred to in this manual.

Pay particular attention to the usage

instructions accompanied by the words

"DANGER" or "WARNING" because, if

not observed, they can cause damage

to the machine and/or property and/or

injury to people.

If any malfunctions are not included

in this manual, contact the local After

Sales Service immediately.

• AERMEC S.p.A. declines all liability

for any damage due to improper

use of the machine or the partial or

superficial reading of the information

contained in this manual.

• Installation and maintenance

must be carried out by trained

and qualified personnel, having

the requirements laid down by

law 46/90 and/or DPR 380/2001

for electric/electronic and air

conditioning installations, with

consequent registration at the

local CHAMBER of COMMERCE.

Otherwise AERMEC S.p.A. decline

all responsibility regarding the safety

of the product.

THE MANUFACTURER DECLINES ALL

LIABILITY FOR DAMAGE TO THINGS

OR INJURY TO PERSONS AND

ANIMALS CAUSED BY THE FAILURE

TO OBSERVE THE INSTRUCTIONS

AND STANDARDS IN THIS MANUAL.

Even though during the design phase of

the RTE unit adequate assessment of the

risks was made, pay ATTENTION to the

pictograms on the machine that helps

the reading the manual by drawing the

reader's attention rapidly to the risk

situations that cannot be avoided or

sufficiently limited by using measures

and technical means of protection.

GENERAL HAZARD SIGNAL

Carefully adhere to all the

indications next to the icon.

Failure to comply with the instructions

may generate hazardous situations

with possible damage to the health

of the operator and user in general.

DANGEROUS ELECTRICAL

VOLTAGE SIGNAL

Carefully adhere to all the

indications next to the icon.

The signal indicates components of the

unit or, in this manual, specifies actions

that could generate electrically-related

risks.

GENERAL PROHIBITION

SIGNAL

Carefully adhere to all the

indications next to the icon that limit

actions in order to guarantee better

operator safety.

IT IS PROHIBITED TO

CLEAN, OIL AND GREASE,

repair or manually adjust

parts in motion.

INFLAMMABLE MATERIAL.

MAIN WARRANTY

CONDITIONS

• The warranty does not include

payment for damage due to the

incorrect installation of the unit by

the installation engineer.

• The warranty does not include

payment for damage due to the

improper use of the unit by the user.

• The manufacturer does not consider

itself liable for accidents to the user

or the installer due to the incorrect

installation or improper use of the

unit.

The warranty is not valid when:

• the services and the repairs have

been carried out by non-authorised

personnel or companies;

• the unit has been repaired or

modified in the past with non OEM

spare parts;

• the unit has not been adequately

maintained;

• if the instructions described in this

manual have not been followed;

• if non-authorised modifications have

been made.

Note:

The Manufacturer reserves the right at

all times to make any modification for

the improvement of its product and is

not obliged to add these modification

to machines of previous manufacture

that have already been delivered or are

being built.

The warranty conditions are any

subject to the general sales conditions

at the moment the contract is finalised.

Manual selection, installation and maintenance

4

Roof-top units - RTE series-

The RTE rooftop units are identified

by means of a product identification

code created by the selection program

AERMECPro. A product identification

code example is the following:

Units identification and description

RTE240F001600000000000

For further information, please refer to

the selection program.

Unit description

The “ ROOFTOP “ units of the RTE series

have been designed taking into account

the precise requirements in the system

necessary for treating large air volumes,

typical of supermarket and hypermarket

buildings and environments for shows, fairs

and industrial uses in general.

These units are usually situated on the roofs

or anyway in the open air, offering these

main advantages:

• because they are installed on the roof

they do not take operational space away

from the room;

• they offer the maximum modularity,

therefore making it possible to differentiate

the treatments in different volumes with

different destination characteristics (food,

clothing department etc.);

• they offer high levels of environmental

comfort by controlling the exchange,

filtering and humidification or

dehumidification of the air in addition to

the temperature;

• the environmental noise level is kept low due

to the careful soundproofing of the machine.

Components

The RTE Rooftop units are all available in

the cooling only version (RTE F) or in heat

pump version (RTE H).

RTE units are equipped with an adhesive label that summarizes the main technical data such as model, heat output

and cooling capacity, rated capacity of

the air in recovery and extraction and

electrical data.

For any future reference and for all

communication with the AERMEC SpA

must indicate the number.

In addition, each piece is accompanied

by targhettta with weight and other

information traceability.

The rating plate and the plate of the

weight of the package are applied outside the main rooftop, on the side panel

near the electrical panel inspected the

same.

The plate of the weight of each package

is applied externally on the panel additional inspections, or packaging.

The rooftop RTE units come complete with :

• condenser unit with 6 pole axial fans and

scroll compressors;

• complete refrigeration circuit complete

with thermostatic valve, filters, sight glass;

• synthetic undulated filter class G4

(EN779);

• direct expansion coil with aluminium

condensate drain pan;

• radial supply fan with forward-curved

blades with belt and variable pulley

transmission;

• microprocessor control complete with

sensors and actuators;

• electrical panel;

Sizes

The units in the RTE series are available in

four sizes (240-260-300-350 -400) each of

which with the possibility of standard, low

noise L (excluding 350 and 400) or high

temperature operation mode A (excluding

350 and 400). By aptly combining the

several available options, it is possible to

configure each model in such a way as to

meet the specific of system requirements.

The RTE Series rooftop units are identified

by a commercial speaker symbol generated directly from the breeding program. An

example of an acronym speaker is as follows:

RTE260FA0A000PD00P00000

For more information, refer to the selection

program.

The table in fig.01 shows how to make up

the commercial code with twenty-four fields,

representative of the available options.

Available versions

N.B. the figures shown refer to the

dimensional specifications on pages 27-29.

STANDARD CONFIGURATION: consists of

the single block rooftop module with G4 flat

filters (efficiency according to EN779), direct

expansion coil (hot coil optional) (fig.1)

SMP : rooftop with 2-way mixing box rear

NOTE:

(1) Damper without actuators and

recirculation damper upon request.

(1)

exhaust

SM2: rooftop with 2-way mixing box side/

bottom exhaust

SM3: rooftop with 3-way mixing box with

temperature free-cooling (fig. 7)

FT7: rooftop with panel pre-filters G3 and

rigid bag filters F7 (EN779) (fig.3)

REC: rooftop with plate type heat recovery

section and exhaust fan. The cross-flow

heat recuperator allows the sensible heat

recovery from the exhaust air with a winter

operation efficiency over 50%. The two air

flows (supply and exhaust) are completely

separated and therefore all types of

contamination are avoided. (fig.13)

G72, G92, G150: rooftop with condensation

heat generator with rated heating capacity

of 72 kW

condensation generator is fed by methane

gas. The air is heated through the passage

over the surface of the combustion chamber

and heat exchanger pipes. The combustion

chamber is fully made of AISI 430 stainless

steel, while the surfaces in contact with

the condensate (exchanger, fume hood)

are made of AISI 304 L stainless steel to

give outstanding resistance to corrosion. It

is provided with an automatic reset safety

thermostat (fig.6).

(fig.2)

(1)

(2)

, 92 kW or 150 kW. The hot air

Air heater model

G72

G92

G150

(fig.4)

RTE

Methane gas

consumption

G20 (15°C 1013 mbar)

2,3 - 8,3 mc/h

3,2 - 10,4 mc/h

4,7 - 16,4 mc/h

R410A

RTE

Manual selection, installation and maintenance

5

Version combinations

SM2-FT7: rooftop with 2-way mixing box,

side/bottom exhaust and bag filters F7

(fig.5)

G72-SMP: rooftop with 72kW heat

generator and 2-way mixing box rear

exhaust (fig.8)

(1)(2)

G72-FT7: rooftop with 72 kW heat

generator and bag filters F7 (fig.9)

G92-SMP: rooftop with 92kW heat

generator and 2-way mixing box rear

exhaust (fig.8)

G92-FT7: rooftop with 92 kW heat

generator and bag filters F7 (fig.9)

G150-SMP: rooftop with 150kW heat

generator and 2-way mixing box rear

exhaust (fig.8)

G150-FT7: rooftop with 150 kW heat

generator and bag filters F7 (fig.9)

SM3-FT7: rooftop with 3-way mixing box

and bag filters F7 (fig.10)

SM2-G72:

and

rooftop with 72kW heat generator

2-way

mixing box (fig.11)

(1)(2)

SM2-G92: rooftop with 92kW heat

generator and 2-way mixing box (fig.11)

SM2-G150: rooftop with 150kW heat

generator and 2-way mixing box (fig.11)

SM2-G72-FT7: rooftop with 72kW heat

generator, 2-way mixing box and bag filters

F7 (fig.12)

(1)(2)

SM2-G92-FT7: rooftop with 92kW heat

generator, 2-way mixing box and bag filters

F7 (fig.12)

(1)

SM2-G150-FT7: rooftop with 150kW heat

generator, 2-way mixing box and bag filters

F7 (fig.12)

(1)

REC-FT7: rooftop with static heat recovery

unit and bag filters F7 (fig.14)

SM3-G72: rooftop with 72kW heat

generator and 3-way mixing box (fig.15)

SM3-G92: rooftop with 92kW heat

generator and 3-way mixing box (fig.15)

SM3-G150: rooftop with 150kW heat

generator and 3-way mixing box (fig.15)

(1)

(2)

(1)

(1)

(2)

Version combinations

SM3-G72-FT7: rooftop with 72kW heat

generator, 3-way mixing box and bag filters

F7 (fig.16)

SM3-G92-FT7: rooftop with 92kW heat

generator, 3-way mixing box and bag filters

F7 (fig.16)

SM3-G150-FT7: rooftop with 150kW

heat generator, 3-way mixing box and bag

filters F7 (fig.16)

REC-G72: rooftop with static heat recovery

unit and 72kW heat generator (fig.17)

REC-G92: rooftop with static heat recovery

unit and 92kW heat generator (fig.17)

REC-G150: rooftop with static heat

recovery unit and 150kW heat generator

(fig.17)

REC-G72-FT7: rooftop with section with

heat recovery unit, 72kW heat generator

and bag filters F7 (fig.18)

REC-G92-FT7: rooftop with crossflow

recovery unit, 92kW heat generator, and

bag filters F7 (fig.18)

REC-G150-FT7: rooftop with crossflow

recovery unit, 150kW heat generator, and

bag filters F7 (fig.18)

(1)()

NOTE:

(1) dampers without actuators

(2) not available for sizes 260 - 300 - 350 - 400

e.g.: (REC+G72+FT7) is an example of version

combination. To see the sizes, refer to the sizes

chapter (page 25).

Roof-top units - RTE series-

(2)

Manual selection, installation and maintenance

6

Unit configuration

Roof-top units - RTE series-

Field 1, 2, 3,4

Field 5, 6, 7

Field 8 Versions

Field 9 Operation

Field 10 Power supply

Field 11 Versions and combinations (THE FIGURES INDICATED REFER TO THE SIZES FROM PAGE 25 TO 28)

RTE

240

260

300

350

400

F cooling only

H heat pump

0 Standard

L Low-noise operation (no 350 and 400)

A High temperature (no 350 and 400)

O ° 3~ 400 V -50 Hz (standard)

W TV2 3~ 230 V -50 Hz

Z TV3 3~ 460 V -60 Hz

0 ° Basic configuration (Fig. 1)

1 SMP 2-way mixing box rear exhaust (Fig.2) (1)

2 FT7 Bag filters F7 (Fig. 3)

A SM2 2-way mixing box side/bottom exhaust (Fig.4) (1)

B SM2-FT7 2-way mixing box, side/bottom exhaust and bag filters (Fig.5) (1)

C G72 Heat generator 72 kW (Fig. 6) (4)

D G92 Heat generator 92 kW (Fig. 6)

3 G150 Heat generator 150 kW (Fig. 6) (5)

E SM3 3-way mixing box with ventilator fan (Fig. 7 on dimensional indications)

F G72-SMP 72 kW heat generator and 2-way mixing box rear exhaust (fig.8) (4)

G G92-SMP 92 kW heat generator and 2-way mixing box rear exhaust (Fig.8)

4 G150-SMP 150 kW heat generator and 2-way mixing box rear exhaust (Fig.8) (5)

H G72-FT7 72 kW heat generator and bag filters F7 (Fig.9) (4)

I G92-FT7 92 kW heat generator and bag filters F7 (Fig.9)

5 G150-FT7 150 kW heat generator and bag filters F7 (Fig.9) (5)

J SM3-FT7 3-way mixing box with bag filters F7 (Fig.10)

K SM2-G72 72kW heat generator and two-ways mixing box(Fig.11) (1)(4)

L SM2-G92 2-way mixing box with 92kW heat generator (Fig.11) (1)

6 SM2-G150 2-way mixing box with 150kW heat generator (Fig.11) (1) (5)

M SM2-G72-FT7: 2-way mixing box with 72kW

N SM2-G92-FT7: 2-way mixing box with 92kW

7 SM2-G150-FT7: 2-way mixing box with 150kW

P REC

Q REC-FT7

R SM3-G72 3-way mixing box with

S SM3-G92 3-way

8 SM3-G150 3-way

T SM3-G72-FT7 3-way mixing box with

U SM3-G92-FT7 3-way

9 SM3-G150-FT7 3-way

V REC-G72

Y REC-G92

Z REC-G150

X REC-G72-FT7

W REC-G92-FT7

O REC-G150-FT7

Section with crossflow plate heat recuperator (Fig. 13)

Section with crossflow plate heat recuperator and bag filters F7 (fig.14)

mixing box with 92kW heat generator (Fig.15)

mixing box with 150W heat generator (Fig.15) (5)

mixing box with 92kW heat generator and bag filters F7 (Fig.16)

mixing box with 150kW heat generator and bag filters F7 (Fig.16) (5)

Section with crossflow plate heat recuperator and 72kW heat generator (Fig.17) (4)

Section with crossflow plate heat recuperator and 92kW heat generator (Fig.17)

Section with crossflow plate heat recuperator and 150kW heat generator (Fig.17) (5)

Section with crossflow plate heat recuperator, 72kW heat generator, and bag filters F7(fig.18)(4)

Section with crossflow plate heat recuperator

Section with crossflow plate heat recuperator

heat generator and bag filters F7(Fig.12)

heat generator and bag filters F7 (Fig.12)

heat generator and bag filters F7 (Fig.12)

72kW heat generator (Fig.15)

72kW heat generator and bag filters F7 (Fig.16)

, 92kW heat generator, and bag filters F7(fig.18)

, 150kW heat generator, and bag filters F7(fig.18) (5)

(4)

(1)(4)

(1)

(1) (5)

(4)

(1) = Dampers without actuators

(2) = The right or left direction refers to the direction of air flow inside the air handling sections

(3) = The coil to water connection side is always on the left

(4) = 72 kW Generator only available on RTE 240

(5) = No RTE 240 model

Manual selection, installation and maintenance

7

Roof-top units - RTE series-

Field 12

Field 13 Heating coil accessory

Field 14 Outside coil treatment accessory

Field 15 Air intake accessory

Field 16 Air supply accessory

Filter pressure switch /coil protection grille accessory

0 ° No accessory of the PF/GP type

2 BP Heat recovery unit with by-pass (option only valid if field 10 =

3 PF Filter pressure switch

4 GP Condenser protection grille

5 PF+GP

6 BP+PF (option only valid if field 10 =

7 BP+GP (option only valid if field 10 = P, Q, V, Y, Z, X, W, O)

8 BP+PF+GP (option only valid if field 10 = P, Q, V, Y, Z, X, W, O)

0 ° No battery

W BTR Two-row hot-water heating coil with three-way modulating valve (3)

E BRE 12 Two stages electric heating coil (12 kW)

F BRE 18 Two stages electric heating coil (18 kW)

G BRE 24 Two stages electric heating coil (24 kW)

H BRE 36 Two stages electric heating coil (36 kW)

0 ° Coils with copper pipes and aluminium fins

A BSP Coil with copper pipes and pre-painted aluminium fins

B BSR Coil with copper pipes and copper fins

C BSS Coil with copper pipes and tin-plated copper fins

0 ° Std. rear return air intake. If there is a return fan, the head is up to 150 Pa

(value always 0 when field

M T1 Right side return air intake, rear fresh air intake

(option only valid if field 10 = A, B, K, L, M, N, 6, 7) (2)

N T2 Left side return air intake, rear fresh air intake

(option only valid if field 10 = A, B, K, L, M, N, 6, 7) (2)

P T3 Rear return and fresh air intake

(option only valid if field 10 = A, B, K, L, M, N, 6, 7) (2)

Q T4 Bottom return air intake, rear fresh air intake

(option only valid if field 10 = A, B, K, L, M, N, 6, 7) (2)

T T5 Right side return air intake, left side fresh air intake

(option only valid if field 10 = A, B, K, L, M, N, 6, 7) (2)

U T6 Left side return air intake, left side fresh air intake

(option only valid if field 10 = A, B, K, L, M, N,) (2)

R AI Bottom air intake, return fan available pressure up to 150 Pa

(option valid only if field 10 =E, J, R, S, T, U, 8, 9)

S AS Top air intake, return fan available pressure up to 150 Pa

(option valid only if field

W PA4 Rear air intake, return fan available pressure up to 300 Pa

(option valid only if

Z Al+PA4 Bottom air intake, return fan available pressure up to 300 Pa

(option valid only if field

V As+PA4 Top air intake, return fan available pressure up to 300 Pa

(option valid only if field

0 ° Bottom air supply, supply fan available pressure up to 200 Pa (standard)

D MA Top air supply, supply fan available pressure up to 200 Pa

E MS Left side air supply, supply fan available pressure up to 200 Pa (2)

F MD Right side air supply, supply fan available pressure up to 200 Pa (2)

G PM4 Bottom air supply, supply fan available pressure up to 400 Pa

H MA+PM4 Top air supply, supply fan available pressure up to 400 Pa

I MS+PM4 Left side air supply, supply fan available pressure up to 400 Pa (2)

L MD+PM4 Right side air supply, supply fan available pressure up to 400 Pa (2)

P, Q, V, Y, Z, X, W, O)

P, Q, V, Y, Z, X, W, O)

10 = 0, 1, 2, C, D, F, G, H, I, P, Q, V, Y, X, W)

10 =E, J, R, S, T, U, 8, 9)

field 10 = E, J, P, Q, R, S, T, U, V, Y, X, W, O)

10 =E, J, R, S, T, U, 8, 9)

10 =E, J, R, S, T, U, 8, 9)

(1) = Dampers without actuators

(2) = The right or left direction refers to the direction of air flow inside the air handling sections

(3) = The coil to water connection side is always on the left

(4) = 72 kW heat generator only available on RTE 240

(5) = No RTE 240 model

Manual selection, installation and maintenance

8

Field 17 Refrigeration circuit accessories

0 ° No refrigeration circuit accessory

1 DCPR Low temperature device (external temperature down to - 20 °C) (standard on the low noise operation

2 TP Pressure transducers (standard in the heat pump version)

3 RUB Discharge and Liquid shut-off valves (for cooling only version)

4 DCPR+TP

5 DCPR+RUB

6 TP+RUB

7 DCPR+TP+RUB

Field 18 Enthalpy control accessories

0 ° No enthalpy control accessory

A PUC Humidification control provision

B FCH Enthalpic Freecooling

C DP Dehumidification and re-heating management

D PUC+FCH

E PUC+DP

F FCH+DP

G PUC+FCH+DP

Field 19 Electronic accessories

0 ° No electronic accessory

P PR2 Remote panel

S SSV RS485 interface card for supervision

Q SQA VOC air quality sensor

R PR2+SSV

T PR2+SQA

U SSV+SQA (option only valid if field 10 = E, J, O, P, Q, R, S, T, U, V, Y, Z, W, 8, 9)

V PR2+SSV+SQA (option only valid if field 10 = E, J, O, P, Q, R, S, T, U, V, Y, Z, W, 8, 9)

Field 20 Damper actuator accessory

0 ° Modulating damper actuator series for versions with SM3 and REC

1 SCSR Return air damper for SMP mixing box (if field 10 = 1, 4, F, G)

2 SCS2 Return air damper for SM2 mixing box (if field 10 = A, B, K, L, 6, M, N, 7)

3 SCM3 Modulating spring return actuator for versions with 3-way mixing box and heat recovery unit (that

4 SRP Return air damper for SMP mixing box and modulating damper actuator (if field 10 = 1, 4, F, G)

5 SR2 Return air damper for SM2 mixing box and modulating damper actuator (if field 10 = A, B, K, L, 6,

6 SCMP Return air damper for SMP mixing box and modulating spring return actuator (if field 10 = 1, 4, F,

7 SCM2 Return air damper for SM2 mixing box, modulating damper actuator on fresh air and modulating

Field 21 Shock absorbing accessory

0 ° No shock absorbers

3 VT3 Rubber shock absorbers for units in basic version

5 VT5 Rubber shock absorbers for units from the 5m to the 7.1m

7 VT7 Rubber shock absorbers for units of over the 7.1m

Field 22 Inspection side

0 SX Left-hand supply inspection side (default)

1 DX Right-hand supply inspection side (if field 15 = 0, D, F, G, H, L)

Field 23 Condensate drain side

0 SX Left-hand condensate drain side (standard)

D DX Right-hand condensate drain side

Field 24 Special requirements

0 All according to catalogue

S Unit with at least one special requirement

Roof-top units - RTE series-

units)

(option only valid if field 10 = E, J, O, P, Q, R, S, T, U, V, Y, Z, W, 8, 9)

(option only valid if field 10 = E, J, O, P, Q, R, S, T, U, V, Y, Z, W, 8, 9)

(if field 10 = E, J, R, S, T, U, V, Y, X, W); no actuators in all the other case

contain the code SM3 or REC in the version)

M, N, 7)

G)

spring damper actuator on return air (if field 10 = A, B, K, L, 6, M, N, 7)

(if field 15 = 0, D, F, G, H, L)

(1) = Dampers without actuators

(2) = The right or left direction refers to the direction of air flow inside the air handling sections

(3) = The water coil connection side is always on the left

(4) = 72 kW Generator only available on RTE 240

(5) = No RTE 240 model

Manual selection, installation and maintenance

9

Roof-top units - RTE series-

Refrigeration

Description of components

circuit

Compressors

Scroll-type hermetic compressors with

crankcase heater provided as a standard in the

heat pump version (and in the only coolung

version, if provided with DCPR accessory)

Provided the unit is under voltage the heating

element is automatically switches on when the

unit stops.

Internal heat exchanger

Made with copper pipes and aluminium

fi ns locked into place through mechanical

expansion of the pipes. The coil is of the high

effi ciency type; grooved pipes and corrugated

fi ns.

External heat exchanger

Made with copper pipes and aluminium

fi ns locked into place through mechanical

expansion of the pipes. The coil is of the high

effi ciency type; grooved or smooth pipes

according to the size.

Liquid receiver

(only for heat pump version)

Safety valve

Set to 30 bar, it protects the circuit against

excessive pressures.

Check valve (only for heat pump version)

The valve allows the refrigerant to fl ow in one

direction only.

Frame and fans

Thermostatic valve

The valve with external equaliser on the

evaporator outlet, modulates the gas fl ow to

the evaporator according to the heat load in

such a way as to assure a suffi cient degree of

overheating at the intake gas.

Drier-fi lter

Made of ceramics and hygroscopic material it

traps impurities and any traces of humidity in

the cooling circuit.

Sight glass

To check the refrigerating gas charge and verify

presence of humidity in the cooling circuit.

Solenoid valve

Switches on after the compressor has stopped,

interrupting the migration of the liquid

refrigeration gas to the evaporator.

Liquid and discharge shut-off valves (accessory

only available for the cooling only versions).

They stop the refrigerant fl ow in case of

extraordinary maintenance.

4-way valve (only for heat pump version)

To control the refrigerant fl ow for the summer/

winter mode changeover and to operate the

defrosting cycles.

Solenoid by-pass valve

(only for heat pump version)

The valve by-passes the thermostatic valve

during the defrosting cycles.

Condensing section

It is provided with statically and dynamically

balanced axial fans. The fans are provided of

protection grilles while the electric motors

are protected by means of magnetothermal

switches.

Air handling section

It is provided with a double intake radial

fan with forward curved blades for better

performance and quietness. The fan is driven

by a three phases electric motor with belts and

adjustable pulleys.

Structure

The air handling section is made of 50

mm thick sandwich panels with type of

construction for the air treatment side is:

external peraluman sandwich-type panelling

and galvanised steel 50 mm thick inside with

injected polyurethane insulation (thickness 42

kg/m3). Accessible panels are provided with

proper knobs, while the others are set through

screws.

Control and safety

components

Door lock switch

For safety the electrical panel can only be

accessed by cutting off the power using the

opening lever on the panel itself. This lever

can be locked in place using one or more

padlocks, during maintenance in order to

prevent the machine being powered up

accidentally.

Control keyboard and display on the machine

This allows the complete control of the unit.

For a detailed description refer to the user

manual.

Electrical panel

Contains the power section and the

management of the controls and safety

devices. This conforms with standard CEI

60204-1, and electromagnetic compatibility

directives EMC 89/336/EEC and 92/31/EEC.

Antifreeze sensor (only with BTR)

When the water temperature is below +5°C,

the dedicated software, in the control card,

completely opens the three-way valve,

thereby circulating hot water through the

digital output signal.

Refrigerator circuit pressure switches

These are placed one on the high-pressure

side and one on the low pressure side of the

refrigeration circuit. They stop compressor

from operating in the case of abnormal

operating pressures.

Flow switch

This has the task of ensuring that air circulates

in the air handling section. If there is no air, it

switches off the unit.

High and low pressure transducers

(standard on the heat pump version)

Placed on the high- and low-pressure sides of

the refrigerator circuit making it possible to

show the value of the pressure on the display.

Optional on the cooling only versions.

Manual selection, installation and maintenance

10

The architecture of the microprocessor

control (fig. 02) provides for:

• a BASE CARD with microprocessor

dedicated to the execution of the

control program, provided with

display, keyboard and LED to allow

for the programming of the set-points

and the basic user operations (on/off,

display of checked values, optional

print-out ).

Roof-top units - RTE series-

Regulation system

• the program is written on the

EPROM while the set-points set are

memorised permanently on EPROM,

so that they can be kept even when

there is no power (without the need

for a support battery).

It is possible to connect the basic

card with the pLAN local network

(pCO Local Area Network) consisting

of different basic cards and terminals.

Each board can exchange data

(any parameter, whether digital or

analogue, depending on the program)

at high transmission speeds. Up to

sixteen units can be connected

(between cards and terminals) for a

maximum of 5 rooftops in such a way

as to share the information quickly.

The connection through the serial

supervision/remote assistance line in

accordance with the RS485 standard,

is made through optional serial cards

and MODBUS communication

protocol.

RT- 5.1

RT+5.1

GND5.2

-XTXR

+XTXR

DNG

6J

NALT

DNG

8J

82 2.3

84 2.3

89 4.4

86 2.5

82 2.6

87 2.6

88 3.4

82 3.4

1ON

2ON

3ON

4ON

5ON

5

1

C

9

J

4C

01J

C

5

C

N

11J

7J

5J

CLOCK CARD

built-in terminal

SERIAL CARD

1J

2

J

3

J

4J

Thanks to its versatile software, the

user terminal permits:

• to modify the basic set points at any

moment which may be protected

with a password

• the display of the detected alarms

and their acoustic detection by means

of a beeper

• the indication of the active functions

by means of leds.

• the display of all the measured

parameters.

Manual selection, installation and maintenance

0G

1B

2B

3B

CNYS

G

5.3 1

5.3 0

5.3 1

5.4 10

4B

DNG

5.4 12

5.4 13

5.5 14

5.5 9

5.5 11

1Y

FERV5

+

2

CDV42+

Y

5.6 15

3.7 6

5.2 8

1

3

D

Y

D

N

I

G

5.2 0

4.7 46

4

3DI

2DI

4.7 44

2.7 35

4.6 43

D

I5DI

D

I

2.8 36

3.5 45

4.8 30

1CDI

6

fig.02

11

DCPR - Pressure switch control device

Extends the operating range of the rooftop,

both in the summer cycle (minimum outside

air temperature to 10 ° C), and in the winter

with heat pump (maximum temperature

of outside air to 25 ° C). It also makes the

operation very quiet at part load. An

electronic control varies the speed of the fans

depending on the condensing condensing

pressure, which has a special transducer,

ensuring proper supply to the thermostatic

valve.

TP - Pressure transducers (standard on heat

pumps)

These show the high and low pressures on

a display, manage the compressor and valve

activities during defrosting and inhibit their

operation when the pressure exceeds the set

limits.

Discharge and liquid shut-off valves (only for

cooling only version).

Hermetic taps with manual closing on the

compressor supply on the circuit liquid side.

GP - Protection grills

They protect the external coils from

accidental blows and hail.

T1 - Air intake on the right side (only on the

SM2)

See page. 30.

T2 - Air intake on the left side (only on the

SM2)

See page. 30.

T3 - Rear air intake (only on the SM2)

See page. 30.

T4 - Bottom air intake (only on the SM2)

See page. 30.

AI - Bottom intake (only on the SM3)

See page. 31.

PA4 - Rear air intake

Return fan available pressure up to 300 Pa for

nominal flow rate.

MA - Upper air supply

Top air supply, supply fan available pressure

up to 200 Pa at the nominal air flowrate.

MS - Left air supply

Left air supply, supply fan available pressure

up to 200 Pa at the nominal air flowrate.

MD - Right air supply

Right air supply, supply fan available pressure

up to 200 Pa at the nominal air flowrate.

PM4 - Supply fan available pressure up to

400 Pa

Supply fan available pressure up to 400 Pa for

rated flow rate.

Accessories

BTR- Two-row heating coil

Two-row hot water coil with three way

modulating valve. These can only be

managed in the post-heating phase with the

DP accessory.

BRE- Electrical heating coil

Two-stage heating electric heating battery

provided with double safety thermostat, one

automatic resetting and the other manual

resetting. The capacities proposed are 36,

48, 60 and 72 kW (or in the order phase

indicated the capacity required). These can

only be managed in the post-heating phase

with the DP accessory.

PUC- Provision for humidification control.

ON/OFF Contact (normally open) for

humidification enabling. The unit in this

case has humidity sensor situated on the

ambient air recovery. A humidity valve is

also supplied to be positioned down line

from the humidification section.

DP - Kit for the management of the

humidification and post heating

The control will force the operation of the

compressors to dehumidify the air up to

the humidity set point set. If there is a water

or electric coil, it will also be possible to

manage the post heating.

The PUC accessory can be combined

(humidification contact).

SCS - Damper actuators for two-way

versions

Modulating actuators fitted directly on the

exhaust air damper and external damper for

the management of the air change.

SCSM damper actuators with spring return

for 2-damper-valve versions

Actuators with spring return fitted directly

on the recovery air dampers and outside

air for the management of the air change,

in case of blackout completely close the

outside air damper and open the fresh air

damper completely.

SCM3 damper actuators with spring return

for 3-damper-valve versions

Actuators with spring return mounted

directly on the dampers for the management

of the freecooling to replace the standard

ones ; in case of blackout they close the

outside air dampers completely and open

the fresh air dampers completely.

FCH - Enthalpic Free-cooling

Only with three damper mixing box.

It manages the outside air flow and recovery

referring to their enthalpic values

.

Roof-top units - RTE series-

PR2 - Remote panel

This enables rooftop control operations to be

carried out at a distance.

SSV - RS485 Serial interface for supervision

Serial card necessary for the supervision

system interface.

SQA - Air quality sensor

This analyses the quality of the air on the

basis of a mixed gas SnO2 VOC sensor by

assessing the contamination by polluting

gases. The presence of the sensor combined

with the rooftop control permits:

- the setting of a sensitivity threshold

depending on the maximum contamination

of the air predicted.

- the ventilation of the rooms only when

necessary so as to ensure energy saving.

TV2 - Power voltage 3~230V - 50HZ.

TV3 - Power voltage 3~ 460V - 60HZ.

VTR (3 - 5 - 7)- Shock absorbers

Rubber antivibration dampers. Select the VTR

model from the accessories table (see page 13).

PF - Filter dirtying pressure switch

BSP - Special batteries

Condensing coil with copper pipes and

prepainted aluminium fins.

BSR - Special coils

Condensing coil with copper pipes and

copper fins.

BSS - Special coils

Condensing coil with copper pipes and tin

plated copper fins.

Manual selection, installation and maintenance

12

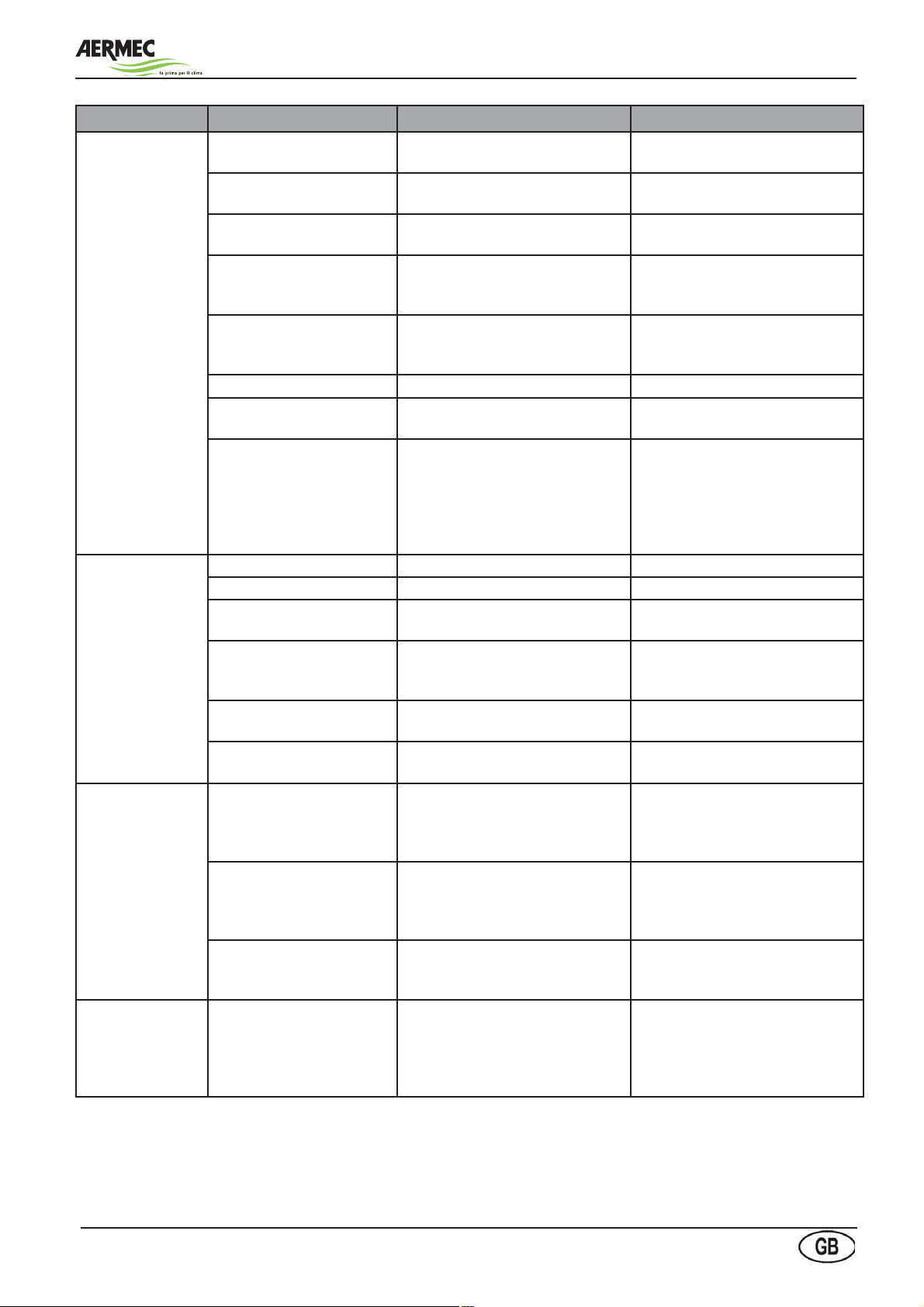

Available accessories table

Roof-top units - RTE series-

Size

Version

Operation

DCPR

TP

RUB

GP

T1 (1)

T2 (1)

T3

T4

AI

PA4

MA

MS (1)

MD (1)

PM4

BTR

BRE

PUC

DP

SCS

SCSM

SCM3

FCH

PR2

SSV

SQA

TV2

TV3

VTR3 (for basic version units)

VTR5 (for units from 5 to 7.1 m)

VTR7 (for units over 7.1 m)

PF

BSP

BSR

BSS

cooling only (F) hot pump (H)

std L (no 350 and 400) A (no 350 and 400) std L (no 350 and 400) A (no 350 and 400)

o•oo•o

ooo•••

ooo- - -

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

oooooo

240 - 260 - 300 - 350 - 400

BSR oooooo

BSS

oooooo

1) = The right or left direction refers to the direction of air flow inside the air handling sections

• = standard

o = optional

- = not available

Hot water coil data (BTR accessory)

RTE Size 240 260 300 350 400

Heating capacity (kW) 400 179 200 213 219

Rows (number) 22222

Hot water coil performance referred to : inlet air 20°C; water 80/70 °C;

N.B.: for data about the water flowrate, water side pressure drops and performances with conditions different from the standard

please see page. 24

Electrical coil data (BRE accessory)

RTE Size 240 260 300 350 400

Heating capacity (kW) 12 18 24 36 12 18 24 36 12 18 24 36 12 18 24 36 12 18 24 36

Number of stages 22222

Manual selection, installation and maintenance

13

Roof-top units - RTE series-

Cooling only F (standard)

RTE

Cooling capacity F kW 77.1 88.6 103.0 129.4 142.5

Sensible cooling capacity F kW 50.1 61.2 67.0 77.7 92.6

Total input power F kW 20.7 25.3 31.8 39.7 44.5

Version 240 260 300 350 400

Energy indices

E.E.R. *

F 4.49 4.30 4.01 3.91 3.85

Condensing unit section

Compressors

Type

Number / circuit

Capacity step control

Compressor input power

L.R.A. (Locked Rotor Amps)

F scroll

F n° 2/2 2/2 2/2 2/2 2/2

F % 0-50-100 0-50-100 0-50-100 0-50-100 0-50-100

F kW 16.04 18.87 23.56 30.13 33.95

F A 350 135 175 215 215

Axial Fans

Number / Input power

Air flow rate

F n°/kW 4x0.53 4x0.53 4x0.53 4x0.56 4x0.56

Fm

3

/h 32000 29000 28000 40000 36000

Air handling section

Evaporator

Number of rows

Fn°44444

Fan

Type

Nominal air flow rate

Minimum air flow rate

Maximum air flow rate

Number

Total installed power

Available pressure with std motor

Air filters

Thickness

Efficiency

Operating limits

Max. external air temperature

Base version sizes

Height

Width

Lenght

Weight

F Radial, forward curved blades

Fm

Fm

Fm

Fn°11111

F kW 2.58 4.37 6.13 7.34 8.35

F Pa 200 200 200 200 200

Fmm5050505050

F EN779 G4 G4 G4 G4 G4

F°C4343434343

F

F

F

F

3

/h 40000 17000 20000 22000 23000

3

/h 10400 14800 17400 19100 19550

3

/h 14100 20000 23500 23500 23500

mm

mm

mm

kg

1.830 1.830 1.830 1.830 1.830

2.166 2.166 2.166 2.166 2.166

3.290 3.290 3.290 3.290 3.290

1.300 1.390 1.480 1.565 1.645

Performances referring to:

Room air 27 °C / 50% r.h.

External air 35 °C

* Energy indices referring to cooling circuit

Manual selection, installation and maintenance

14

Roof-top units - RTE series-

Heat pump H (standard)

RTE

Cooling capacity H kW 76.3 87.7 104.9 128.2 141.1

Sensible cooling capacity H kW 49.6 60.6 66.3 76.9 91.7

Heating capacity H kW 73.4 86.3 103.0 127.6 142.2

Total input power in cooling mode H kW 20.4 25.0 30.8 38.5 43.1

Total input power in heating mode H kW 18.9 21.8 26.1 34.4 38.6

Version 240 260 300 350 400

Energy indices

E.E.R.*

C.O.P.*

H 3.7 3.5 3.4 3.3 3.2

H 3.9 3.9 3.9 3.7 3.6

Condensing unit section

Compressors

Type

Number / circuit

Capacity step control

Input power in cooling mode

Input power in heating mode

L.R.A. (Locked Rotor Amps)

Axial Fans

Number / Input power

Air flow rate

H scroll

H n° 2/2 2/2 2/2 2/2 2/2

H % 0-50-100 0-50-100 0-50-100 0-50-100 0-50-100

H kW 15.7 18.5 23.1 29.5 33.2

H kW 14.2 15.3 18.4 25.4 28.7

H A 350 135 175 215 215

H n°/kW 4x0.53 4x0.53 4x0.53 4x0.56 4X0.56

Hm

3

/h 36000 33000 32000 40000 34200

Air handling section

Evaporator

Number of rows

Fan

Type

Nominal air flow rate

Minimum air flow rate

Maximum air flow rate

Number

Total installed power

Available pressure with std motor

Air filters

Thickness

Efficiency

Operating limits

Max. external air temperature

Min. winter external air temperature

Base version sizes

Height

Width

Lenght

Weight

Performances referring to:

Cooling mode: Ambient air 27 °C/50% r.h. External air 35 °C

Heat pump mode: Ambient air 20 °C/50% r.h. External air 7 °C/70% r.h.

* Energy indices referring to cooling circuit

Hn°44444

H Radial, forward curved blades

Hm

Hm

Hm

Hn°11111

H kW 2.5 4.3 5.6 6.7 7.6

H Pa 200 200 200 200 200

Hmm5050505050

H EN779 G4 G4 G4 G4 G4

H°C4343434343

H °C -10 -10 -10 -10 -10

H

H

H

H

3

/h 14000 17000 20000 22000 23000

3

/h 10400 14800 17400 19100 19550

3

/h 14100 20000 23500 23500 23500

mm

mm

mm

kg

1.830 1.830 1.830 1.830 1.830

2.166 2.166 2.166 2.166 2.166

3.290 3.290 3.290 3.290 3.290

1.300 1.390 1.480 1.565 1725

Manual selection, installation and maintenance

15

Roof-top units - RTE series-

Cooling only F-A (high temperature)

RTE

Cooling capacity F A kW 78.0 89.9 105.6

Sensible cooling capacity F A kW 50.7 62.1 68.7

Total input power F A kW 20.3 24.8 30.7

Version 240 260 300

Energy indices

E.E.R.*

F A 4.68 4.30 4.01

Condensing unit section

Compressors

Type

Number / circuit

Capacity step control

Compressor input power

L.R.A. (Locked Rotor Amps)

F A scroll

F A n° 2/2 2/2 2/2

F A % 0-50-100 0-50-100 0-50-100

F A kW 15.5 18.2 22.4

F A A 350 135 175

Fans

Number / Input power

Air flow rate

F A n°/kW 4x0.53 4x0.53 4x0.53

F A m3/h 14500 14000 16500

Air handling section

Evaporator

Number of rows

F A n° 4 4 4

Fan

Type

Nominal air flow rate

Minimum air flow rate

Maximum air flow rate

Number

Total installed power

Available pressure with std motor

Air filters

Thickness

Efficiency

Operating limits

Max. external air temperature

Base version sizes

Height

Width

Lenght

Weight

F A Radial, forward curved blades

F A m3/h 14000 17000 20000

F A m3/h 10400 14800 17400

F A m3/h 14100 20000 23500

F A n° 1 1 1

F A kW 2.58 4.37 6.13

F A Pa 200 200 200

F A mm 50 50 50

F A EN779 G4 G4 G4

F A °C 46 46 46

F A

F A

F A

F A

mm

mm

mm

kg

1.830 1.830 1.830

2.166 2.166 2.166

3.290 3.290 3.290

1.300 1.390 1.480

Performances referring to:

Room air 27 °C / 50% r.h.

External air 35 °C

* Energy indices referring to cooling circuit

Manual selection, installation and maintenance

16

Roof-top units - RTE series-

Heat pump H-A (high temperature)

RTE

Cooling capacity H A kW

Sensible cooling capacity H A kW

Heating capacity H A kW

Total input power in cooling mode H A kW

Total input power in heating mode H A kW

Version 240 260 300

Energy indices

E.E.R.*

C.O.P.*

H A 4.59 4.51 4.31

H A 4.81 5.06 4.98

Condensing unit section

Compressors

Type

Number / circuit

Capacity step control

Input power in cooling mode

Input power in heating mode

L.R.A. (Locked Rotor Amps)

Axial Fans

Number / Input power

Air flow rate

H A scroll

H A n° 2/2 2/2 2/2

H A % 0-50-100 0-50-100 0-50-100

H A kW 15.3 17.9 22.0

H A kW 14.5 15.7 18.5

H A A 350 135 175

H A n°/kW 4x0.53 4x0.53 4x0.56

H A m3/h 14500 14000 16500

77.2 89.0 104.6

50.0 61.1 68.0

77.1 87.4 101.5

20.0 24.4 30.4

19.2 22.1 26.9

Air handling section

Evaporator

Number of rows

Fan

Type

Nominal air flow rate

Minimum air flow rate

Maximum air flow rate

Number

Total installed power

Available pressure with std motor

Air filters

Thickness

Efficiency

Operating limits

Max. external air temperature

Min. winter external air temperature

Base version sizes

Height

Width

Lenght

Weight

H A n° 4 4 4

H A Radial, forward curved blades

H A m3/h 14000 17000 20000

H A m3/h 10400 14800 17400

H A m3/h 14100 20000 23500

H A n° 1 1 1

H A kW 2.58 4.37 6.13

H A Pa 200 200 200

H A mm 50 50 50

H A EN779 G4 G4 G4

H A °C 46 46 46

.

H A °C -10 -10 -10

H A

H A

H A

H A

mm

mm

mm

kg

1.830 1.830 1.830

2.166 2.166 2.166

3.290 3.290 3.290

1.300 1.390 1.480

Performances referring to:

Cooling mode: Ambient air 27 °C/50% r.h. External air 35 °C

Heat pump mode: Ambient air 20 °C/50% r.h. External air 7 °C/70% r.h.

* Energy indices referring to cooling circuit

Manual selection, installation and maintenance

17

Roof-top units - RTE series-

Cooling only F-L (low-noise)

RTE

Cooling capacity F L kW 68.7 84.5 102.6

Sensible cooling capacity F L kW 44.7 58.3 66.7

Total input power F L kW 24.8 27.3 32.1

Version 240 260 300

Energy indices

E.E.R.*

F L 3.2 4.3 4.0

Condensing unit section

Compressors

Type

Number / circuit

Capacity step control

Compressor input power

L.R.A. (Locked Rotor Amps)

F L scroll

F L n° 2/2 2/2 2/2

F L % 0-50-100 0-50-100 0-50-100

F L kW 20.1 20.8 23.8

F L A 350 135 175

Fans

Number / Input power

Air flow rate

F L n°/kW 4x0.53 4x0.53 4x0.53

F L m3/h 9500 9000 11000

Air handling section

Evaporator

Number of rows

F L n° 4 4 4

Fan

Type

Nominal air flow rate

Minimum air flow rate

Maximum air flow rate

Number

Total installed power

Available pressure with std motor

Air filters

Thickness

Efficiency

Operating limits

Max. external air temperature

Base version sizes

Height

Width

Lenght

Weight

F L Radial, forward curved blades

F L m3/h 14000 17000 20000

F L m3/h 10400 14800 17400

Hm

F L n° 1 1 1

F L kW 2.6 4.4 6.1

F L Pa 200 200 200

F L mm 50 50 50

F L EN779 G4 G4 G4

F L °C 39 39 39

F L

F L

F L

F L

3

/h 14100 20000 23500

mm

mm

mm

kg

1.830 1.830 1.830

2.166 2.166 2.166

3.290 3.290 3.290

1.300 1.390 1.480

Performances referring to:

Ambient air 27 °C / 50% r.h.

External air 35 °C

* Energy indices referring to cooling circuit

Manual selection, installation and maintenance

18

Roof-top units - RTE series-

Heat pump H-L (low-noise)

RTE

Cooling capacity H L kW 68.0 83.6 101.6

Sensible cooling capacity H L kW 44.2 55.6 65.9

Heating capacity H L kW 74.5 83.6 98.5

Total input power in cooling mode H L kW 24.4 26.8 31.6

Total input power in heating mode H L kW 19.0 21.8 26.5

Version 240 260 300

Energy indices

E.E.R.*

C.O.P.*

H L 3.13 3.72 3.94

H L 4.74 4.94 4.89

Condensing unit section

Compressors

Type

Number / circuit

Capacity step control

Input power in cooling mode

Input power in heating mode

L.R.A. (Locked Rotor Amps)

Axial Fans

Number / Input power

Air flow rate

H L scroll

H L n° 2/2 2/2 2/2

H L % 0-50-100 0-50-100 0-50-100

H L kW 19.7 20.4 23.4

H L kW 14.3 15.3 18.3

H L A 350 135 175

H L n°/kW 4x0.53 4x0.53 4x0.53

H L m3/h 9500 9000 11000

Air handling section

Evaporator

Number of rows

Fan

Type

Nominal air flow rate

Minimum air flow rate

Maximum air flow rate

Number

Total installed power

Available pressure with std motor

Air filters

Thickness

Efficiency

Operating limits

Max. external air temperature

Min. winter external air temperature

Base version sizes

Height

Width

Lenght

Weight

Performances referring to:

Cooling mode: Ambient air 27 °C/50% r.h. External air 35 °C

Heat pump mode: Ambient air 20 °C/50% r.h. External air 7 °C/70% r.h.

* Energy indices referring to cooling circuit

H L n° 4 4 4

H L Radial, forward curved blades

H L m3/h 14000 17000 20000

H L m3/h 10400 14800 17400

H L m3/h 14100 20000 23500

H L n° 1 1 1

H L kW 2.6 4.4 6.1

H L Pa 200 200 200

H L mm 50 50 50

H L EN779 G4 G4 G4

H L °C 39 39 39

H L °C -10 -10 -10

H L

H L

H L

H L

mm

mm

mm

kg

1.830 1.830 1.830

2.166 2.166 2.166

3.290 3.290 3.290

1.300 1.390 1.480

Manual selection, installation and maintenance

19

Operating limits

46

39

Alta temperatura (A)

Standard

Silenziata (L)

Roof-top units - RTE series-

The units, in their standard configuration,

are not suitable for installation in a salty

Summer mode

Winter mode:

(heat pump)

environment.

N.B: If you wish to operate the

machine beyond the limits indicated in

High temperature (A)

the diagram, please contact AERMEC

engineering/commercial department.

Quiet (L)

If the unit is situated in particularly

windy environments it is necessary to

install a wind break protection to avoid

unstable operation of the DCPR device.

(dry bulbe temperature)

Model 240 260 300 350 240 260 300 240 260 300

Version Standard Vers. High temp Vers.. (A)

Max. external temperature in cooling mode °C 43 46 46 46 39 39 39

Min. external temperature in cooling mode °C 20

Max. input temp. to evaporating coil in cooling mode °C 30

Min. input temp. to evaporating coil on cooling mode °C 18

Min. external temperature in heat pump mode °C -10

Max. external temperature in heat pump mode °C 20

Max. input temp. to evaporator coil in heat pump mode °C 24

Min. input temp. to evaporator coil in heat pump mode °C 10

Quiet operation vers.(L)

fig.03

Sound data

Lw: sound power level

Lp: sound pressure level

* 1 mt. away from the unit, ducted fan,

direction factor Q = 4.

240 80 75 85 78 78 76 72 65 54

260 81 76 86 79 78 76 72 65 54

300 82 78 88 81 79 77 73 66 56

350std 85 79 92 85 82 79 75 68 58

240 77 72 79 75 74 72 71 64 53

260 78 73 80 76 75 72 71 64 53

300 79 74 82 77 76 73 72 65 54

Manual selection, installation and maintenance

Standard version and High Temperature version(A)

Total sound levels Octave band [Hz]

Lw tot

[dBA]

Lp tot *

[dBA]

125 250 500 1000 2000 4000 8000

Sound power levels Lw [dB]]

Low Noise version (L)

Total sound levels Octave band [Hz]

Lw tot

[dBA]

Lp tot *

[dBA]

125 250 500 1000 2000 4000 8000

Sound power levels Lw [dB]

20

Roof-top units - RTE series-

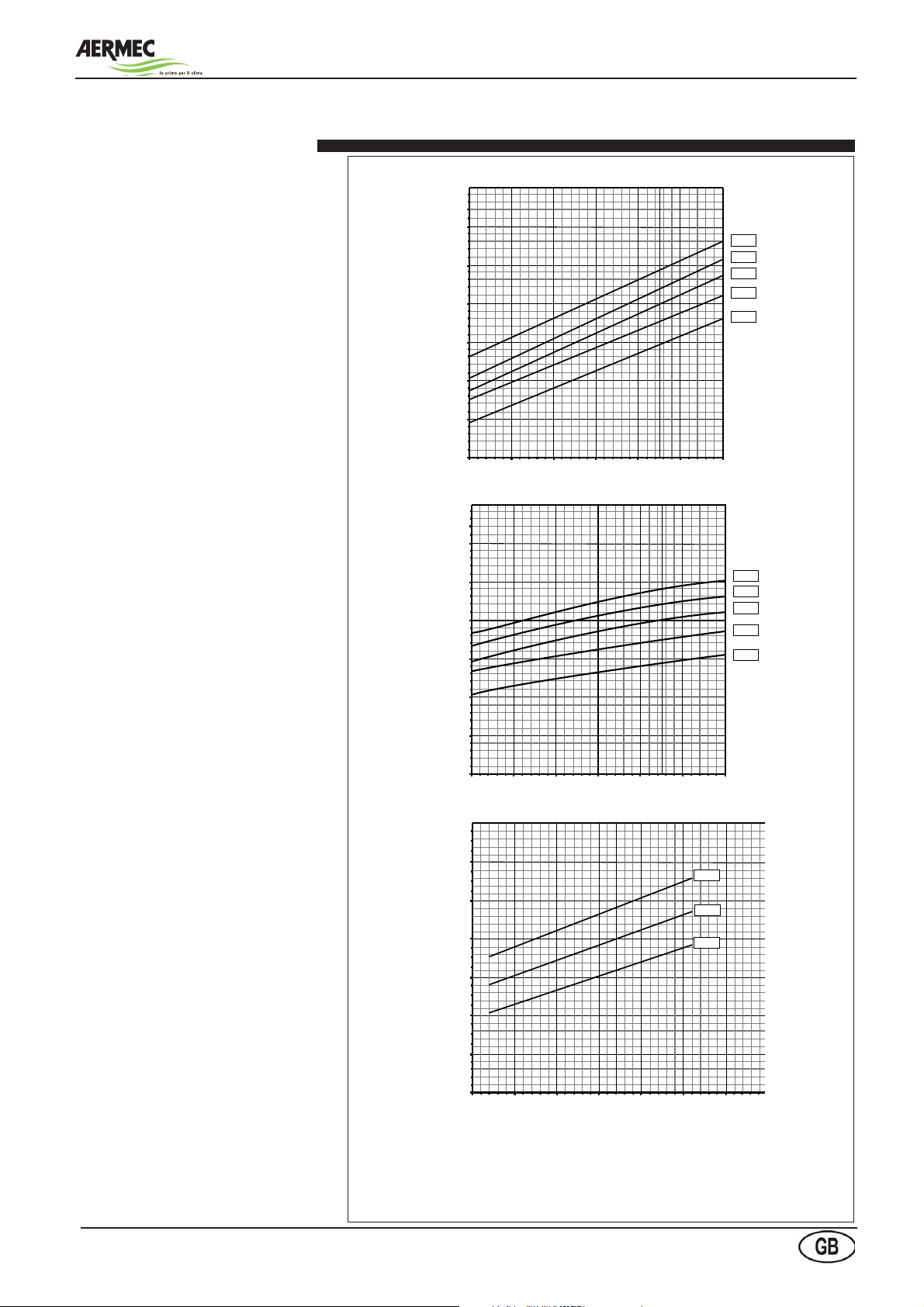

Cooling capacity and input power

The following diagrams make it possible

to obtain the corrective coefficient to be

used for the rooftop units in the cooling

function. Alongside each curve, the

temperature of the outside air it refers

to is reported.

The total cooling capacity, the sensible

cooling capacity and the electrical

input power in conditions other than

the nominal ones are obtained by

multiplying the nominal values in the

technical data table for the respective

correction coefficients (Cft, Cfs e Cpa).

Example: if RTE 240F on the technical

data sheet capacities with nominal air

flow at 27°C and 50% R.H.: tot. refrig.

cap. of 66.0 kW and sens. refrig. cap.

45.2 kW with outside air 35°C;

Then at 24°C and 50% H.R. will supply

respectively : 66.0x0.92=60.7 kW and

45.2x0.97=43.8 kW.

Cft

Total cooling capacity coefficient

Cfs

#

#

#

#

#

#

#

#

#

#

Te [°C]

Te [°C]

Cpa

Input power coefficient Sensible cooling capacity coefficient

#

#

#

Te [°C]

Tav.01

Key

Cft Coefficient Total cooling capacity

Cfs Sensible cooling capacity coefficient

Cpa Input power coefficient

Manual selection, installation and maintenance

Temperature of the air to be treated b.s. 50% R.H. [°C]

Te External air temperature °C

b.s. Dry bulb

R.H. Relative Humidity

21

The following diagrams give the

corrective coefficients to be used for the

rooftop units operating in heat pump

mode. Each curve refers to a specific

room temperature (16-20-24°C). The

x-axis shows the dry temperature of

the external air with variable relative

humidity, according to the data shown

in the table below.

The performances are given net of the

defrosting cycles.

The corrective coefficients (Cpt, Cpa)

allow to calculate the heating capacity

and the electrical input power at

conditions other than the nominal ones.

Roof-top units - RTE series-

Heating capacity and input power

Cpt

Heating capacity coefficient

#

#

#

T [°C]

Cpa

Input power coefficient

KEY

Cpt Heating capacity coefficient

Cpa Input power coefficient

d.b. Dry bulb

T [°C] Dry bulb temperature of the handled air.

External air d.b. [°C]

#

#

#

T [°C]

The x-axes show a temperature which refers to the following humidity conditions:

Temp. in x-axis °C -8 -6 -4 -2 0 246810121416

Dry bulb temp °C-8-6-4-20246810121416

Rel. Humid. %90908580757570707065656565

Manual selection, installation and maintenance

22

Roof-top units - RTE series-

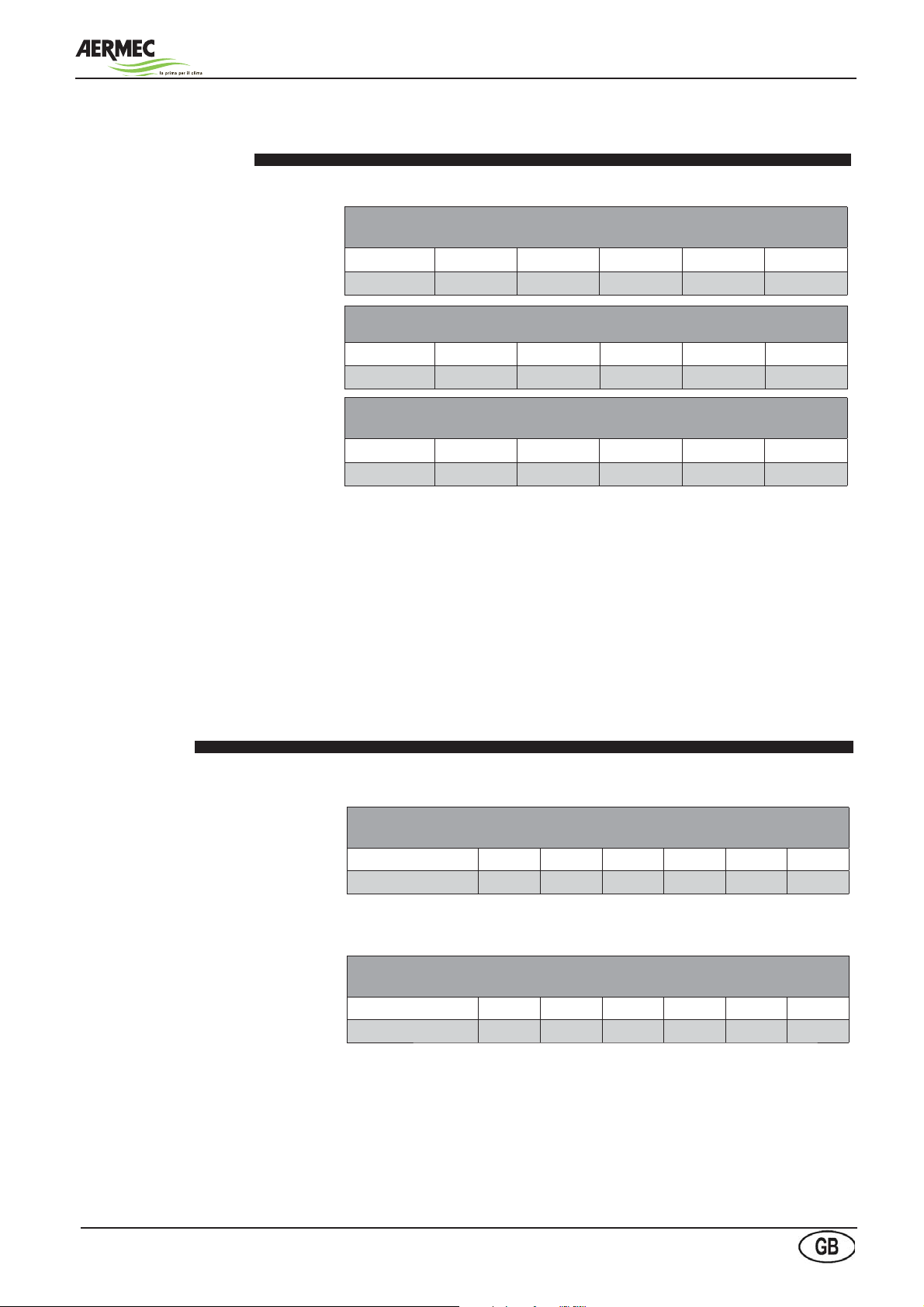

Corrective coefficients for different flow rates

The data given by the diagrams at pg.

21-22 refer to nominal air flowrates

(Wn).

For different flowrates (W) please apply

the corrective coefficients shown in the

tables on the right.

Correction coefficients for flow rates other than the rated flow rates by total

cooling capacity

W/Wn 0,8 0,9 1 1,1 1,2

Cft 0,974 0,987 1 1,014 1,027

Correction coefficients for flow rates other than the rated flow rates and for sensitive

cooling capacity

W/Wn 0,8 0,9 1 1,1 1,2

Cfs 0,905 0.953 1 1.048 1.095

Correction coefficients for flow rates other than the rated flow rates for heating

capacity

W/Wn 0,8 0,9 1 1,1 1,2

Cpt 0,974 0,987 1 1,014 1,027

KEY

Cft Coefficient Total cooling capacity

Cfs Sensible cooling capacity coefficient

Cpt Heating capacity coefficient

The input power does not vary greatly with the variation in the flow rate of the air

to be treated

Total capacities for different relative humidities

The table gives the corrective

coefficients to calculate the TOTAL

COOLING CAPACITY for different

relative humidities, dry bulb

temperature unchanged.

The table gives the corrective

coefficients to calculate the SENSIBLE

COOLING CAPACITY for different

relative humidities, dry bulb

temperature unchanged

Correction coefficients for total refrigeration capacities as the relative humidity

changes

R.H. % 30 40 50 60 70

Coefficient 0.89 0.94 1 1.06 1.12

Correction coefficients for sensible refrigeration capacities as the relative

humidity changes

R.H. % 30 40 50 60 70

Coefficient 1.23 1.11 1 0.89 0.79

Example: if RTE 240F on the technical data sheet supplies at 27°C and 50% R.H.:

tot. refrig. cap. of 66.0 kW and sens. cooling cap. 45.2 kW with outside air 35°C;

Then at 27°C and 70% R. H. supplies respectively: 66.0x1.12=73.9 kW

and 45.2x0.79=35.7 kW.

Manual selection, installation and maintenance

23

0,9

1,0

1,1

1,2

1,3

1,4

0% 5% 10% 15% 20% 25% 30% 35% 40%

FcGDpC

FcGQC

Performance tables for water heating coils

The RTE units may be supplied with a

two-row hot water coil (accessory)

provided with modulating three-way

valve (actuator included).

The first diagram shows the corrective

coefficients to be applied to the nominal

performances of the hot water coil given

on pg. 13.

Example :

Calculate the performances of the hot

water coil installed on a RTE 240 at the

following design conditions:

· Heating water inlet temperature: 70 °C;

· Room temperature: 22 °C;

· Water thermal drop

The coil heating capacity, with air at 20°C

and water 80/70°C, is 140 kW according

with the technical data sheet at pg. 13.

The temperature difference between

the water inlet and the air is DAW=7022=48°C.

The diagram gives the corrective

coefficient Cfpt=0.63. Hence the coil

heating capacity at the given condition is

140x0.63=88.2 kW.

T20=20 °C.

CfPT

key• key

CfPT Heating

capacity corrective

coefficient

DAW Temperature

difference between

water inlet - air inlet

[°C]

∆ t Water thermal

drop [°C]

[kPa]

351

Roof-top units - RTE series-

AW

$4#

$4#

$4#

K

Water coil pressure

drops

Fig.04 shows the heating coil water

pressure drops.

The pressure drops due to the three-way

valves are included.

Corrective coefficients

for pressure drop and

flowrate with glycoled

water

FcGDpC = Pressure drop corrective

coefficient

FcGQC = Flowrate corrective

coefficient

The water flowrate and pressure drop

corrective coefficients have to be

applied directly to the data for normal

water.

Water pressure drop

Water flow rate [l/h]

Percentage of ethylene glycole

Percentuale di glicole etilenico

fig.04

Manual selection, installation and maintenance

24

Roof-top units - RTE series-

Technical data generator Gxxx

Gxxx Model G72 G92 G150

RTE

Matching with sizes RTE

Combination thermal modu-

les

Temperature rise (at nominal air flow and maximum

heat output)

Thermal Module 072 092 150

Nominal air flow kW 22 78 30 98 44 155

Efficiency % 105 93,8 105 95,3 105,2 93,5

Nominal thermal power kW 23,1 73,2 31,5 93,4 46,3 145

Condensate produced l/h 2,2 2,6 3,9

NOx mg/kWh 35 37 43

Gas connection diameter UNI ISO 7/1 - 1” M UNI ISO 7/1 - 1” M UNI ISO 7/1 - 1” M

diameter tube suction / discharge mm 100 / 100 100 / 100 350 / 350

Available pressure exhaust fumes Pa 120 120 100

Minimum working temperature °C -15 -15 -15

Power supply V / Hz 230 / 50 230 / 50 230 / 50

Category II 2H 3B/P

G20 natural gas supply pressure mbar 20 (min. 17; max. 25)

G20 natural gas consumption (15 ° C - 1013mbar)

Carbon dioxide gas supply pressure G30CO2 G20

Supply Pressure G30 mbar 37

Consumption G30 (15 ° C - 1013mbar)

Carbon dioxide CO2 G30 % 9,5 +/- 0,3

Supply Pressure G31 mbar 37

Consumption G31 (15 ° C - 1013mbar)

Carbon dioxide CO2 G31 % 9,5 +/- 0,3

RTE240 RTE240 RTE260 RTE300 RTE350 RTE400 RTE260 RTE300 RTE350 RTE400

model

n° x

model

1x72 1x92 1x92 1x92 1x92 1x92 1x150 1x150 1x150 1x150

°C

20 25,5 17,9 15,2 13,8 13,2 27,7 23,5 21,4 20,5

min. max. min. max. min. max.

m3/h 2,33 - 8,25 3,18 - 10,38 4,50 - 15,80

% 8,7 +/- 0,2

m3/h 1,42 - 5,02 1,93 - 6,31 2,83 - 9,97

m3/h 1,40 - 4,95 1,88 - 6,14 2,76 - 9,71

Manual selection, installation and maintenance

25

Roof-top units - RTE series-

List of pressure equipment - Directive PED 97/23 CE

The table alongside shows the list of pressure equipment

and form mounted on the roof-top RTL, according to

Directive 97/23 CE PED module A1.

Refrigerant circuits

RTE 240 F - 400 F refrigerating circuit

EB

AP

PA

COMPONENT MODULE

Compressor D1

Coil A

Three way valve esclusa (art. 3.3)

Liquid receiver D1

High pressure switch B+D

Safety valve high pressure side B+D

Safety valve low pressure side B+D

IB

SR

MV

SV

PC

P

B

AP

TV

L

I

SR

NOTE: This scheme refers to only one of the two circuits. Scketched elements are optional.

CP compressor FI filter drier

VS high pressure safety valve 30 bar VO solenoid valve (optional)

AP high pressure switch (27 bar) IL liquid and humidity indicator

PA pressure transducer VT thermostatic expansion valve

RS ball valve (optional) VM centrifugal fan

EV axial fan BI internal coil

BE external coil BP low pressure switch (it stops the compressor at 2 bar and starts it at 2,3 bar)

IF

OV

Manual selection, installation and maintenance

26

RTE 240 H - 400 H refrigerating circuit

EV

EB

Roof-top units - RTE series-

CIV

P

A

B

I

MV

PA

SV

PC

AP

UV

UV

PBSV

TV

I

L

P

Z

V

O

LR

FI

V

U

NOTE: This scheme refers to only one of the two circuits.

CP compressor VO solenoid valve

VS high pressure safety valve 30 bar PZ temperature probe pit

AP high pressure switch (27 bar) IL liquid and humidity indicator

PA pressure transducer VT thermostatic expansion valve

VIC refrigerant reversing valve VSBP by pass solenoid valve

EV axial fan VM centrifugal fan

BE external coil BI internal coil

FI filter drier RL liquid receiver

VU one way valve

U

V

Manual selection, installation and maintenance

27

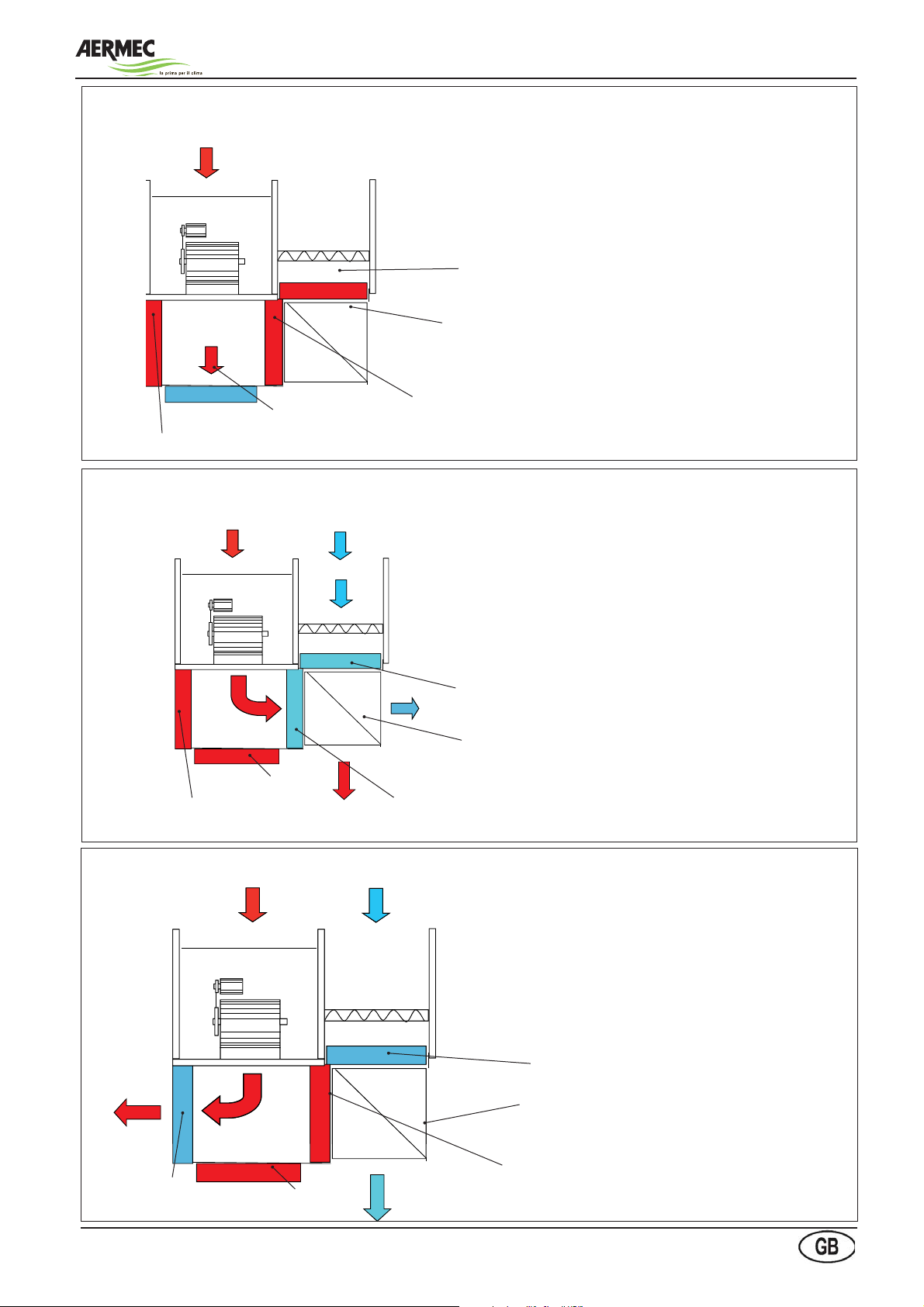

Base versions

Base versions

Single section rooftop

• front exhaust

• downwards supply

• filters G4

(optional heating coil)

(fig.1)

Standard air flow

SMP

Single section rooftop

• two-ways mixing box, rear exhaust

intake (actuator as optional)

• filters G4

(optional heating coil)

FT7

Single section rooftop

• prefilter G3

• bag filters F7

(heating coil as optional)

SM2

Single section rooftop

• two-ways mi x i n g bo x , s i d e or

bottom exhaust intake (actuators as

optional)

• filters G4

(optional heating coil)

SM2-FT7

Single section rooftop

• two-ways mixing box with side,

bo ttom or front exhaust i ntake

(actuators as optional)

• prefilter G3

• bag filters F7

(heating coil as optional)

(fig.2)

(fig.3)

(fig.4)

(fig.5)

Single section rooftop

• front exhaust

• downwards supply

• filters G4

(optional heating coil)

Roof-top units - RTE series-

Dimensions

SMP

Single section rooftop

• two-ways mixing box, rear exhaust

intake (actuator as optional)

• filters G4

(optional heating coil)

FT7

Single section rooftop

• prefilter G3

• bag filters F7

(heating coil as optional)

Standard air flow

3930

3930

3290

(fig.1)

(fig.2)

(fig.3)

SM2

Single section rooftop

• two-ways mixing box, side or

bottom exhaust intake (actuators as

optional)

• filters G4

(optional heating coil)

SM2-FT7

Single section rooftop

• two-ways mixing box with side,

bottom or front exhaust intake

(actuators as optional)

• prefilter G3

• bag filters F7

(heating coil as optional)

Manual selection, installation and maintenance

28

4500

4500

(fig.4)

(fig.5)

G72 - G92 - G150

G72 - G92 - G150

Single section rooftop

• prefilter G3

• hot air condensation type generator with

72 or 92 kW heating capacity according

to the selected rooftop version. The

generator is installed in a module with

sandwich panels with mineral wool

insulation (density 100 kg/m

3

)

SM3

Rooftop

• three-way mixing box with:

exhaust fan with variable pitch

pulley

- standard rain hoods

- modulating actuators for all the

da m pers (modulat ing s pring

return actu ators for external

damper as optional).

Exhaust

air intake

Optional exhaust air

intake

G72 - SMP / G92 - SMP / G150 - SMP

G72 - F7 / G92 - FT7 / G150 - FT7

SM3 - FT7

(fig.6)

(fig.7)

(fig.8)

(fig.9)

(fig.10)

Single section rooftop

• prefilter G3

• hot air condensation type generator with

72 or 92 kW heating capacity according

to the selected rooftop version. The

generator is installed in a module with

sandwich panels with mineral wool

insulation (density 100 kg/m

SM3

Rooftop

• three-way mixing box with:

-

exhaust fan with variable pitch

pulley

- standard rain hoods

- modulating actuators for all the

dampers (modulating spring

return actuators for external

damper as optional).

3

)

Exhaust

air intake

4985

5310

Optional exhaust air

intake

Roof-top units - RTE series-

(fig.6)

(fig.7)

G72 - SMP / G92 - SMP / G150 - SMP

G72 - F7 / G92 - FT7 / G150 - FT7

5625

5625

(fig.8)

(fig.9)

SM3 - FT7

Manual selection, installation and maintenance

29

5950

(fig.10)

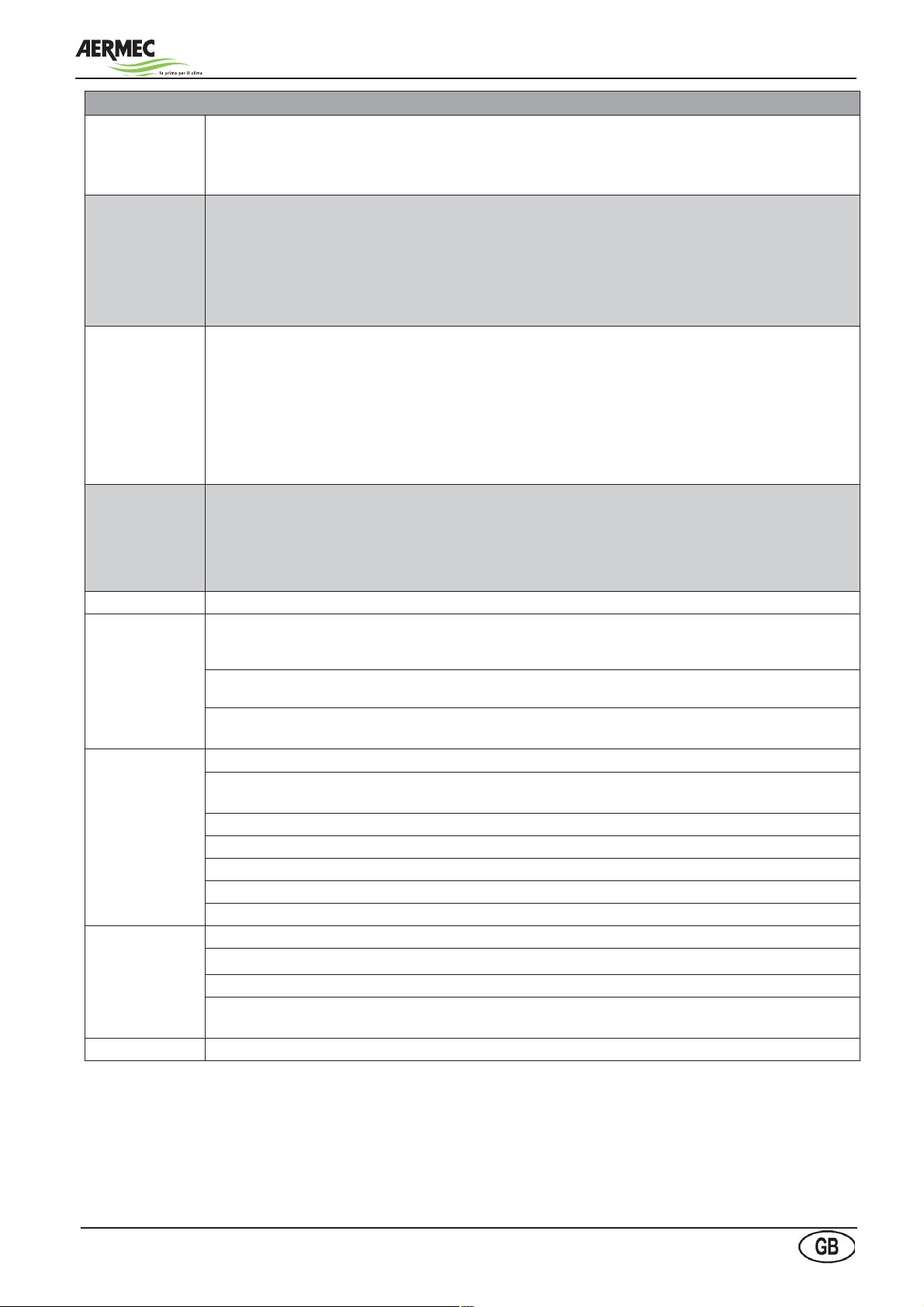

SM2 - G72 / SM2 - G92 / SM2 - G150

SM2 - G72 / SM2 - G92 / SM2 - G150

SM2 - G72 - FT7

SM2 - G92 - FT7

REC

REC - FT7

(fig.11)

(fig.12)

(fig.13)

(fig.14)

SM2 - G72 - FT7

SM2 - G92 - FT7

SM2 - G150 - FT7

SM2 - G72 - FT7

SM2 - G72 - FT7

SM2 - G92 - FT7

SM2 - G92 - FT7

SM2 - G150 - FT7

6280

Roof-top units - RTE series-

(fig.11)

REC

Rooftop:

• Heat recovery unit provided with :

- exhaust fan with variable pitch

pulley

- panel filters G4 for exhaust air

- panel filters G4 for fresh air

- modulating actuators for all the

dampers (modulating spring

return actuators for external

dampers as optinal).

- double filter differential pressure

switch as optional

REC - FT7

6280

7080

(fig.12)

(fig.13)

Manual selection, installation and maintenance

30

7080

(fig.14)

(fig.15)

(fig.16)

(fig.17)

(fig.18)

SM3 - G72

SM3 - G72

SM3 - G92

SM3 - G150

SM3 - G72 - FT7

SM3 - G92 - FT7

SM3 - G150 - FT7

REC - G72

REC - G92

REC - G150

REC - G72 - FT7

REC - G92 - FT7

REC - G150 - FT7

SM3 - G92

SM3 - G150

SM3 - G72 - FT7

SM3 - G92 - FT7

SM3 - G150 - FT7

7005

Roof-top units - RTE series-

(fig.15)

REC - G72

REC - G92

REC - G150

REC - G72 - FT7

REC - G92 - FT7

REC - G150 - FT7

8125

7645

(fig.16)

(fig.17)

Manual selection, installation and maintenance

31

8765

(fig.18)

Nominal dimensions

RTE 240-260-300-350 - 400 standard base version

Roof-top units - RTE series-

2172

2162

3291

3282

2246

1830

1730

Refrigerant charge

R410A REFRIGERANT CHARGE -ONLY COOLING VERSION

Model 240 F 260 F 300 F 350 F 400 F

Std version [kg]

High temperature version [kg]

Low noise version [kg]

R410A REFRIGERANT CHARGE - HEAT PUMP VERSION

Model 240 H 260 H 300 H 350 H 400 H

Std version [kg]

High temperature version [kg]

Low noise version [kg]

Manual selection, installation and maintenance

Contact the technical department AERMEC S.p.A.

Contact the technical department AERMEC S.p.A.

32

Roof-top units - RTE series-

Weights

WEIGHTS - ONLY COOLING VERSION

Model 240 F 260 F 300 F 350 F 400 F

Std version [kg] 3500 1420 1460 1610 1695

SMP [kg] 1460 1590 1630 1770 1855

FT7 [kg] 1532 1660 1700 1840 1925

SM2 [kg] 1600 1640 1770 1910 1995

SM2 - FT7 [kg] 1630 1670 1800 1940 2025