TECHNICAL MANUAL

MANUAL TÉCNICO

Air/water chillers and heat pumps and condensing units with scroll

compressors

Enfriadoras y bombas de calor aire agua y motocondensadores con

compresores scroll

nra

ESPAÑOL pag.42 ENGLISH pag.2

INRATV. 0705 4034403_02

replace il 4034403_01 del 0607

INSTRUCTIONS FOR THE SELECTION

Compliance declaration ........................................................................................................................................................................................................... 1

1 General standards ............................................................................................................................................................................................pag. 2

2 Description and choice of unit .....................................................................................................................................................................pag. 3

2.1 Models available .........................................................................................................................................................................pag. 3

2.2 Versions available .......................................................................................................... ............................................................pag. 3

2.2.1 Standard equipment .................................................................................................................................................................pag. 3

2.3 Configurator ................................................................................................................................................................................. pag. 4

3 Description of components ...........................................................................................................................................................................pag. 5

3.1 Refrigerating circuit ..................................................................................................................................................................pag. 5

3.2 Frame and fans ...........................................................................................................................................................................pag. 5

3.3 Hydraulic components .............................................................................................................................................................pag. 5

3.4 Safety and control components ..........................................................................................................................................pag. 6

3.5 Electrical components .............................................................................................................................................................pag. 6

4 Accessories and table of possible combinations ................................................................................................................................pag. 7

5 Technical data

5.2 Standard versions ..................................................................................................................................................................... pag. 9

5.3 High ef ficiency versions ...........................................................................................................................................................pag. 10

5.4 Silenced ver sions .......................................................................................................................................................................pag. 11

5.5 Heat pump versions .................................................................................................................................................................. pag. 12

5.6 Silenced heat pump versions ................................................................................................................................................pag. 13

6 Selection criteria

6.1 Operating limits ........................................................................................................................................................................... pag. 14

6.2 Project data ..................................................................................................................................................................................pag. 14

7 Correction coefficients

7.1 Cooling input capacities, standard versions - high efficiency (cold mode)

high efficiency ..............................................................................................................................................................................pag. 15

7. 2 Cooling capacity, silenced versions ....................................................................................................................................pag. 16

7. 3 Heating and input capacities, heat pump versions .....................................................................................................pag. 17

7. 4 Correction factors for ∆T other than nominal .............................................................................................................pag. 17

7. 5 Fouling factors ............................................................................................................................................................................ pag. 17

8 Ethylene glycol solution ...................................................................................................................................................................................pag. 18

9 Pressure drops .................................................................................................................................................................................................. pag. 20

10 Accumulation .......................................................................................................................................................................................................pag. 21

11 Effective pressures for the system ........................................................................................................................................................... pag. 22

12 Desuperheaters .................................................................................................................................................................................................pag. 23

13 Total heat recovery ...........................................................................................................................................................................................pag. 25

14 Sound data ........................................................................................................................................................................................................... pag. 26

15 Capacity contro ..................................................................................................................................................................................................pag. 27

16 Calibration of check and safety parameters .........................................................................................................................................pag. 28

17 Dimensions ...........................................................................................................................................................................................................pag. 29

18 Weights and centres of mass .....................................................................................................................................................................pag. 30

18.1 Distribution weights percentage on rests for models WITHOUT WATER ........................................................pag. 31

18.2 Distribution weights percentage on rests for models WITH WATER ...............................................................pag. 36

Dear Customer,

Thank you for choosing AERMEC. It is the fruit of many years of experience and special design studies and has been

made of the highest grade materials and with cutting edge technology.

In addition, all our products bear the EC mark indicating that they meet the requirements of the European Machine

Directive regarding safety. The standard of quality is permanently being monitored and AERMEC products are

therefore a synonym for Safety, Quality and Reliability.

The data may undergo modifications considered necessary for the improvement of the product, at any time and without

the obligation for any notice thereof.

Thank you again.

AERMEC S.p.A

AERMEC S.p.A.

I-37040 Bevilacqua (VR) Italia – Via Roma, 44

Tel. (+39) 0442 633111

Telefax 0442 93730 – (+39) 0442 93566

www.aermec.com - info@aermec.com

NRA

NRA H

MODEL:

SERIAL NUMBER

COMPLIANCE DECLARATION We, the undersigned, declare on our own exclusive responsibility that the object in question, so

defined:

Product identification AIR / WATER chiller, HEAT PUMP NRA RANGE

is in compliance with:

1. Directive 97/23/EC and has been subjected (with reference to Attachment II of the said

directive) to the following compliance evaluation procedure:

module H

with checks made via inspections by the appointed body CEC via Pisacane 46 Legnano (MI)

- Itally, identity number 1131;

2. Designed, produced and marketed in observance of the following technical specifications:

Harmonised standards:

- EN 378: Refrigerating system and heat pumps - Safety and environmental

requirements;

- EN 12735: Copper and copper alloys - Seamless, round copper tubes for air

conditioning and refrigeration;

- UNI 1285-68: Calculation of the strength of metal pipes subject to internal pressure;

3. Designed, produced and marketed in observance of the following EC directives:

98/37/EC: Machine Directive

2006/95/CE LVD

Bevilacqua 26/03/2007

Marketing Director

Signature

1

1 GENERAL STANDARDS

• This manual, and the electrical

layouts supplied with the unit, must

be kept in a dry place for any future

consultation, and for the lifespan of

the machine.

This manual has been drawn up

with the aim of supporting the

correct installation of the unit and

providing all the indications for the

correct use and maintenance of

the device. Before proceeding with

the installation, please read all the

information in the manual carefully,

as well as the procedures necessary

for the correct installation and use of

the unit.

• Be careful to adhere t o the instructions

in this manual and observe the safety

regulations currently in place.

• The device must be installed in

compliance with the local legislation

currently in force in the country of

destination.

• Non-authorised tampering with

the equipment, whether electrical

or mechanical, will make THE

WARRANTY VOID and exclude any

liability on the part of the company.

• Check the electrical characteristics

shown on the registration plate

(fig.1) before making the electrical

connections. Read the instructions in

the specific section about electrical

connections.

• If the unit needs to be repaired, in all

cases contact a specialised AERMEC

After Sales Service centre and only

use OEM spare parts.

• The manufacturer furthermore

declines any liability for injury to

persons or damage to things

resulting from the failure to comply

with the information in this manual.

• Permitted uses: this series of chillers

is suitable for producing cold water

to use in hydronic systems designed

for air conditioning. The units are not

suitable for producing hot water for

bathrooms.

Any use other than that permitted,

or outside the operating limits

mentioned in this manual, is forbidden

unless previously agreed with the

company.

The warranty does not include

payment for damage due to wrong

installation of the unit by the

installer.

• The warranty does not include

payment for damage due to the

improper use of the unit by the user.

• The manufacturer is not to be

considered liable for accidents to

the user or the installer due to the

incorrect installation or improper

use of the unit.

•The device must be installed in such a

way that maintenance and/or repair

operations can be carried out. The

warranty of the device does not in any

case cover costs incurred as a result

of motorised ladders, scaffolding or

any other lifting systems necessary

to carry out the operations under

warranty.

The warranty is not valid when:

• the services and repairs have

been carried out by non-authorised

personnel or companies;

• the unit has been repaired or

modified in the past with non-OEM

spare parts;

• the unit has not been adequately

maintained;

• the instructions described in this

manual have not been followed;

• non-authorised modifications have

been made.

N.B:

The Manufacturer reserves the right

at all times to make any modification

for the improvement of its product,

and is not obliged to add these

modification to machines of previous

manufacture that have already been

delivered or are being built.

The warranty conditions are anyway

subject to the general sales conditions

at the moment the contract is

finalised.

1.1 Technical plate

Technical

plate

Fig. 1

2

2 DESCRIZIONE E SCELTA DELL'UNITÀ

The devices of the NRA range are

units used to produce cold water for

technological systems; the heat pump

models also allow you to produce hot

water for heating. They consist of two

R407C refrigerating circuits and a

single hydraulic circuit (which may or

may not be fitted with an accumulation

unit).

The presence of more than one scroll

type compressor allows the NRA chillers

various capacity controls of the cooling

capacity.

The use of more than one scroll type

compressor allows a high level of

efficiency, even with partial loads. In

these cases in fact, a variable number

of scroll compressors are working,

each at 100% (i.e. maximum efficiency)

of the output power. By means of

a microprocessor, the electronic

regulation controls and manages

all the components and working

parameters of the unit; an internal

memory registers the working

conditions in the moment when an

alarm condition arises, in order to

visualise it on the display. The units

have a protection rating of IP 24.

2.1 MODELS AVAILABLE

- “STANDARD COOLING ONLY (°)”

maximum outside temperature

allowed 42°C. Acoustic protection

cover for the compressor, for quiet

operation.

- “HEAT PUMP (H)” in cooling mode

the operating limits arrive to a

maximum outside air temperature

of 46°C. NRAH do not envisage the

following configurations:

- YH (with processed water lower

than 4°C)

- HC (condensing heat pump)

- HA (heat pump in high

temperature because the heat

pump is, by its very nature, a

machine for high temperatures)

2.2 VERSIONS AVAILABLE

- "STANDARD/BASE"

Maximum outside temperature

allowed 42°C, acoustic cover for the

compressor, for quieter operation.

- "HIGH TEMPERATURE" (available

only for cold working versions)

via the expansion of the pack finned

heat exchanger, it allows you to

widen the operating limits, arriving at

a maximum outside air temperature

of 46°C.

- “SILENCED (L)” r e pr e s ents the

models designed for particularly

quiet operation. All the sizes

are fitted with a device for

regulating the fan speed. When

the temperature is lower than

35°C, the low noise version

further reduces the number of fan

rotations, thereby obtaining an

even quieter operation than that in

nominal conditions.

- “SILENCED HEAT PUMPS (HL)”

represents the models designed for

particularly quiet operation.

All the sizes are fitted with a device

for regulating the fan speed.

- “HEAT RECOVERY”

A unit with air condensation, complete

with section for partial heat recovery.

The heat exchanger is specially scaled

to guarantee heat recovery for the

production of hot water for use in

bathrooms or other purposes.

1. Desuperheater (D)

The desuperheater is also available for

heat pump versions, limitedly in the cooling function. It must be intercepted in

the heating function.

2. Total heat recovery (T)

In heat pumps total recovery is only

available for the “OO versions without

hydronic kit”

- “CONDENSING UNITS C”

-

“SILENCED CONDENSING UNITS

LC”

- “VERSION Y” is the version that allows

you to produce chilled water below

the standard value of +4°C, to a

minimum of -6°C.

For lower values, contact the

company headquarters.

ONLY THE VERSION YA IS

AVAILABLE.

WARNING

For the devices designed to work with a

low air temperature, and also the heat

pumps, before starting up the unit (or

at the end of each period of prolonged

disuse) it is extremely important for

the oil of the compressor carter to

be heated beforehand, via the power

supply to the special heaters, for at

least 8 hours.

The carter heater is automatically

powered when the unit stops, provided

that the unit is kept under tension.

2.2.1 Standard equipment

ALL THE VERSIONS COME WITH:

Evaporator anti-freeze heater

1.

Compressor carter heater

2.

Remote control panel

3.

Water filter (supplied with the ver-

4.

sions without accumulation)

Flow switch only in the versions with

5.

accumulation

HEAT PUMPS

TP1 Trasduttore di bassa pressione

TP2 Trasduttore di alta pressione

DCPX Dispositivo di regolazione della ve-

locità dei ventilatori di serie per la

sola versione HL

CHILLERS WITH ACCUMULATION

1. Evaporator anti-freeze heater

2. High or low pressure pumping unit

3. OPTION:

4. For the heat pump versions, an

CHILLERS WITH DESUPERHEATER

DCPX Standard

There is also the possibility

to have a reserve pump.

The stand-by pump that in NRA 800

- 900 - 1000 models is controlled by

the electronic card which enables

the alternate operation of the two

pumps to optimize the working time.

A switch on the NRA 1250 - 1400

- 1500 - 1650 - 1800 electric panel

enables the pumps to be manually

switched over.

accumulation (pre-set for the

insertion of integrative heaters) is

available upon request.

3

2.3 SELECTION

1,2,3 4,5,6,7 8 9 10 11 12 13 14 15,16

NRA 1650 ° ° D L ° ° ° 00

fields 15 - 16

HYDRONIC KIT

00

01 Accumulation and low pressure pump

02 Accumulation, low pressure pump and

03 Accumulation and high pressure pump

04

05 Accumulation with holes for integrative

06

07 Accumulation with holes for integrative

08

P1 Only low pressure pump

P2

P3

P4

Without accumulation

reserve pump

Accumulation, high pressure pump and reserve

pump

resistance, and low pressure pump

Accumulation with holes for integrative resistance,

low pressure pump and reserve pump

resistance, high pressure pump

Accumulation with holes for integrative resistance,

high pressure pump and reserve pump

Low pressure pump and reserve pump

Only high pressure pump

High pressure pump and reserve pump

fields 14

fields 13

fields 12

fields 11

fields 10

Power supply

° 3~400V-50Hz with thermomagnetic switches

4 3~230V-50Hz with thermomagnetic switches

9 3~500V-50Hz with thermomagnetic switches

Evaporator

° According to PED standards

C Condensing (without evap.)

Coils

° - Aluminium

R - Copper

S - Tinned copper

V - Varnished aluminium copper

Version

° Standard

A High temperature

L Standard in Silenced operation

Heat recoverers

° Without recoverers

D Desuperheater

T Total recovery

fields 9

Model

° Cooling only

H Heat pump

fields 8

Refrigerant

° Standard

Y Version for low temperature of processed water, down to -6°C

fields 4 - 5 - 6 - 7

0800 - 0900 - 1000 - 1250 - 1400 - 1500 - 1650 - 1800

4

Esempio NRA 1650 00

3 DESCRIPTION OF COMPONENTS

KEY

1 Compressor

2 Exchanger water side

3 Exchanger air side

4 Frame

5 Control keypad

6 Fans

7 Electric panel

3.1 REFRIGERATING CIRCUIT

Compressors

Hermetic scroll type compressors

equipped, as standard, with anti-freeze

heater.

The heater is automatically powered when

the unit stops, provided that the unit is

kept under tension. The compressor area

is acoustically insulated. The use of more

than one scroll type compressor allows a

high level of efficiency with partial loads. In

these cases in fact, a variable number of

scroll compressors are working, each at

its own 100% (i.e. maximum efficiency) of

the output power.

Air side heat exchanger

It is made of copper pipes and aluminium

fins locked into place through mechanical

expansion of the pipes. Of the high efficiency

type; furrowed tube and corrugated fins for

heat pump, smooth tube and turbo fins for

cooling only.

Water side heat exchanger

Of the plate type (AISI 316), externally

insulated with closed cell material to

reduce thermal dispersion. Fitted, as

standard, with anti-freeze heater.

Liquid separator

(heat pump only)

Suction from compressor, to protect from

any liquid refrigerant return, flooded starts,

working in the presence of liquid.

Filter drier

Of the mechanical type, made of ceramic

and hygroscopic material, able to hold back

any impurities and traces of humidity in the

refrigerating circuit.

Sight glass

For checking the refrigerating gas load and

any humidity in the refrigerating circuit.

Thermostatic valve

The mechanical valve, with outside equaliser on the evaporator outlet, modulates the

gas flow to the evaporator on the basis of

the thermal load, in such a way as to ensure the proper degree of overheating of the

intake gas.

Liquid and force gas taps

(cooling-only versions)

They allow the refrigerant to be cut off

during extraordinary maintenance.

Solenoid valve

The valve closes when the compressor

turns off, preventing the flow of refrigerant

gas towards the evaporator.

Reverse cycle valve

(heat pump only)

Inverts the flow of the refrigerant when

there is a change of summer / winter

operation and during the defrosting cycles.

One-way valve

This allows the refrigerant to flow in just

one direction.

Desuperheater (only upon request)

Of the plate type (AISI 316), externally

insulated with closed cell material to reduce

thermal dispersion.

The desuperheater is also available for heat

pump versions, limitedly in the cooling function. It must be intercepted in the heating

function.

Total recovery (only upon request)

Of the plate type (AISI 316), externally

insulated with closed cell material to reduce

thermal dispersion.

NOTE

In heat pumps total recovery is only available

for the “OO versions without hydronic kit”

Liquid accumulation

only for heat pumps, or with total heat

recovery.

It is used in the heat pump or total recovery

versions. Used to keep the refrigerating

gas in a liquid state if the machine, in that

particular working point, has an excess

of it.

3.2 FRAME AND FANS

Fan unit

Screw type, statically and dynamically

balanced. The electric fans are protected

electrically with thermomagnetic switches

and mechanically with metal anti-intrusion

grilles, in accordance with the standard CEI

EN 60335-2-40.

Load-bearing structure

Made of hot-galvanised steel sheet of a

suitable thickness, varnished with polyester

powders able to resist atmospheric agents

over time.

3.3 HYDRAULIC COMPONENTS

Circulation pump

Depending on the characteristics of the

pump chosen, it offers an ef fective pressure

to overcome the pressure drops in the

system. There is also the possibility to have

a reserve pump.

The stand-by pump that in NRA 800

- 900 - 1000 models is controlled by

5

the electronic card which enables the

alternate operation of the two pumps

to optimize the working time. A switch

on the NRA 1250 - 1400 - 1500 - 1650

- 1800 electric panel enables the pumps

to be manually switched over.

Flow switch only in versions with accumulation feature and or pumps

This checks that the water is circulating. If

this is not the case, it shuts down the unit..

NOTE

In the versions without accumulation a flow

switch must be introduced or the WARRANTY becomes void.

Water filter Supplied with standard versions

(Mounted in versions with accumu-

lation and/or Pope

Allows you to block and eliminate any

impurities in the hydraulic circuits. Inside, it

has a filtering mesh with holes not greater

than one millimetre. It is essential in order

to avoid serious damage to the plate heat

exchanger.

Accumulation tank

It is made of stainless steel, with a capacity

of 700 litres. In order to reduce the thermal

dispersion and eliminate the phenomenon of

the formation of condensation, it is insulated

with polyurethane material of a suitable

thickness. It is fitted, as standard, with an

anti-freeze heater (down to -20°C outside

temperature, tank water temperature

5°C), commanded by the anti-freeze probe

situated in the tank.

Drain valve

(only in the versions with hydronic unit or

pump(s))

Of the manual type, it discharges any air

pockets. It is intercepted by a stopcock so

that it can be substituted if necessary.

Filling unit

(only in the versions with accumulation or

pump(s))

This has a pressure gauge showing the

pressure in the system.

Two expansion tanks (of 25 litres)

(only in the versions with accumulation or

pump(s))

of the membrane type, with nitrogen precharge.

Hydraulic circuit safety valve

(only in the versions with hydronic unit or

pump(s))

CALIBRATED AT 6 bar and with a discharge

that can be channelled, it intervenes by

discharging the overpressure in the event

of anomalous pressures.

)

3.4 SAFETY AND CONTROL

COMPONENTS

Low pressure switch

not present in the heat pump versions, as

these functions are carried out directly by

the board.

Of fixed calibration, located on the low

pressure side of the refrigerating circuit, it

stops the operation of the compressor in

the event of anomalous work pressures.

High pressure switch

Of variable calibration, located on the high

pressure side of the refrigerating circuit, it

stops the operation of the compressor in

the event of anomalous work pressures.

Anti-freeze heater

(installed as standard)

Its operation is commanded by the antifreeze probe located in the plate evaporator.

It is activated when the water temperature

is +3°C, and deactivated when the water

temperature is +5°C. The dedicated

software in the regulation card manages

the heater.

Refrigerating circuit safety valve

Calibrated at 30 Bar, it cuts in by letting off

the overpressure in the case of anomalous

pressures.

Low pressure transducers TP1,

standard in the heat pumps.

accessory in the cooling only versions

High pressure transducer TP2

standard on all the versions

3.5 ELECTRICAL COMPONENTS

Electrical panel

Contains the power section and the

management of the controls and safety

devices. This conforms with standard

CEI 60204-1, and Electromagnetic

Compatibility Directives EMC 89/336/

EEC and 92/31/EEC.

Door lock sectioner

IT IS POSSIBLE TO ACCESS THE ELECTRIC

PANEL BY disconnecting the voltage, then

using the opening lever of the panel itself.

This lever can be blocked with one or more

padlocks during maintenance, in order to

prevent the machine being powered up

accidentally.

Control keypad

Provides full control functions.

For a detailed description of the keypad

refer to the user manual.

Remote control panel

This allows the chiller command operations

to be given from a distance.

- thermomagnetic compressor

protection.

- thermomagnetic fan protection;

- thermomagnetic auxiliary protection.

- thermostat for discharge gas

temperature control

3.6 ELECTRONIC REGULATION

Microprocessor card

Consisting of a management/control card and a

visualisation card. Functions carried out:

• regulation of evaporator water inlet

temperature (also outlet can be

selected), with thermostat action up

to 12 levels and proportional/integral

control of fan speed.

• delayed compressor start-up.

• operation as chiller, with possibility to

integrate refrigerating capacity by

means of “free-cooling”.

• compressor sequence rotation.

• management of low temperature

device (accessory).

• compressor operation hour count.

• start/stop.

• reset.

• permanent alarms memory.

• automatic start-up after drop in

voltage.

• multi-lingual message service.

• operation with local or remote

control.

• visualisation of machine status:

ON/OFF compressors;

alarms summary.

• alarms management:

high pressure; flow switch;

low pressure; anti-freeze;

compressor overload;

fan overload; pump overload.

• visualisation of the following

parameters:

water inlet temperature;

evaporator water inlet temperature;

water outlet temperature; delta T;

high pressure; low pressure;

waiting time for restart.

• alarms visualisation.

• settings:

a) without password:

cooling set;

total differential;

b) with password:

anti-freeze set;

low pressure exclusion time;

display language;

access code.

For further information, refer to the user

manual.

6

4 ACCESSORIES

AER485 Scheda per sistemi

MODBUS

Questo accessorio consente il collegamento dell’unità con sistemi di supervisione BMS con standard elettrico RS

485 e protocollo di tipo MODBUS.

AVX anti-vibration support

Spring-operated, anti-vibration

supports.

DCPX

1

device for low temperatures

It consists of an electronic regulation

card that varies the number of

fan rotations on the basis of the

condensation pressure

GP protection grille

Each kit has two grilles.

PGS daily/weekly timer.

Card to be inserted in the electronic

card of the unit. Allows you to

programme two time bands per day,

and to have different programmings

for each day of the week.

TP1 2 low pressure transducer

It makes it possible to show the value of

the compressor's intake pressure (one

per circuit) on the microprocessor card

display. Placed on the low pressure

side of the refrigerating circuit, it shuts

down compressor operation in the case

of abnormal operating pressure.

3

DRE

Dispositivo riduyion ecor-

rente di spunto

Electronic peak current reducer. It

must be factory-mounted.

3

RIF

Current rephaser.

Parallel connection

with the motor makes the reduction of

input current possible. This can only

be installed when the machine is being

made and must therefore be specified

when the order is placed.

ROMEO

Remote Overwatching Modem Enablig

Operation (Remote Overwatching

Modem Enabling Operation) is a device that enables a remote control of a

chiller from an ordinary mobile phone

with WAP browser. Furthermore it

allows to send alarm or pre-alarm SMS

up to 3 GSM mobile phones which may

not be equipped with WAP browser

KEY

1

Standard in models: NRA L/ NRA D

2 Standard in models: NRA H - HL

3 It must be factory-mounted

MOD. ROMEO TP1 DRE AER485 PGS GP DCPX RIF AVX

VERSION STANDARD (°) S.a C.a

0800 • • (x2) 25 (x4) • • 260 29 64 151 152 151

0900 • • (x2) 25 (x2) - 30 (x2) • • 260 29 74 151 152 151

1000 • • (x2) 30 (x4) • • 260 29 84 151 152 151

12 50 • • (x2) 38 (x4) • • 350 30 84 153 154 153

140 0 • • (x2) 38 (x2) - 31 (x3) • • 350 30 85 153 154 153

15 00 • • (x2) 30 (x6) • • 350 30 86 153 154 153

165 0 • • (x2) 38 (x3) - 31 (x3) • • 500 30 86 601 602

18 00 • • (x2) 38 (x6) • • 500 30 86 604 602

NRA A

0800 • • (x2) 25 (x4) • • 260 29 64 151 152 151

0900 • • (x2) 25 (x2) - 30 (x2) • • 260 29 74 151 152 151

1000 • • (x2) 30 (x4) • • 260 29 84 151 152 151

12 50 • • (x2) 38 (x4) • • 350 30 84 153 154 153

140 0 • • (x2) 38 (x2) - 31 (x3) • • 350 30 85 153 154 153

15 00 • • (x2) 30 (x6) • • 350 30 86 153 154 153

165 0 • • (x2) 38 (x3) - 31 (x3) • • 500 30 86 604 602

18 00 • • (x2) 38 (x6) • • 500 30 86 604 602

NRA L

0800 • • (x2) 25 (x4) • • 260

0900 • • (x2) 25 (x2) - 30 (x2) • • 260

1000 • • (x2) 30 (x4) • • 260

12 50 • • (x2) 38 (x4) • • 350

140 0 • • (x2) 38 (x2) - 31 (x3) • • 350

15 00 • • (x2) 30 (x6) • • 350

165 0 • • (x2) 38 (x3) - 31 (x3) • • 500

18 00 • • (x2) 38 (x6) • • 500

std.

std.

std.

std.

std.

std.

std.

std.

6 4 151 15 2 151

74 151 15 2 151

8 4 151 15 2 151

8 4 153 15 4 15 3

8 5 153 15 4 15 3

8 6 153 15 4 15 3

86 604 602

86 604 602

P1/P2/P3/P4

P1-P3=601/P2-P4=603

P1-P3=604/P2-P4=605

P1-P3=605/P2-P4=606

P1-P3=605/P2-P4=606

P1-P3=605/P2-P4=606

P1-P3=605/P2-P4=606

NRA HEAT PUMP VERSION H

0800 •

0900 •

1000 •

12 50 •

140 0 •

15 00 •

165 0 •

18 00 •

std.

std.

std.

std.

std.

std.

std.

std.

25 (x4) • • 260 29 64 151 152 151

25 (x2) - 30 (x2) • • 260 29 74 151 152 151

30 (x4) • • 260 29 84 151 152 151

38 (x4) • • 350 30 84 153 154 153

38 (x2) - 31 (x3) • • 350 30 85 153 154 153

30 (x6) • • 350 30 86 153 154 153

38 (x3) - 31 (x3) • • 500 30 86 604 602

38 (x6) • • 500 30 86 604 602

P1-P3=605/P2-P4=606

P1-P3=605/P2-P4=606

7

MOD. ROMEO TP1 DRE AER485 PGS GP DCPX RIF AVX

NRA HL S.a C.a. P1/P2/P3/P4

0800 •

0900 •

1000 •

12 50 •

140 0 •

15 00 •

165 0 •

18 00 •

NRA C

0800 • • (x2) 25 (x4) • • 260 29 64 151 152 151

0900 • • (x2) 25 (x2) - 30 (x2) • • 260 29 74 151 152 151

1000 • • (x2) 30 (x4) • • 260 29 84 151 152 151

12 50 • • (x2) 38 (x4) • • 350 30 84 153 154 153

140 0 • • (x2) 38 (x2) - 31 (x3) • • 350 30 85 153 154 153

15 00 • • (x2) 30 (x6) • • 350 30 86 153 154 153

165 0 • • (x2) 38 (x3) - 31 (x3) • • 500 30 86

18 00 • • (x2) 38 (x6) • • 500 30 86

NRA LC

0800 • • (x2) 25 (x4) • • 260

0900 • • (x2) 25 (x2) - 30 (x2) • • 260

1000 • • (x2) 30 (x4) • • 260

12 50 • • (x2) 38 (x4) • • 350

140 0 • • (x2) 38 (x2) - 31 (x3) • • 350

15 00 • • (x2) 30 (x6) • • 350

165 0 • • (x2) 38 (x3) - 31 (x3) • • 500

18 00 • • (x2) 38 (x6) • • 500

KEY

DRE - RIF

It must be factory-mounted

S.a = Without storage tank

C.a With storage tank

std.

std.

std.

std.

std.

std.

std.

std.

25 (x4) • • 260

25 (x2) - 30 (x2) • • 260

30 (x4) • • 260

38 (x4) • • 350

38 (x2) - 31 (x3) • • 350

30 (x6) • • 350

38 (x3) - 31 (x3) • • 500

38 (x6) • • 500

NOTE

The numbers in parenthesis indicate the

necessary quantity

std.

std.

std.

std.

std.

std.

std.

std.

std.

std.

std.

std.

std.

std.

std.

std.

6 4 151 15 2 151

74 151 15 2 151

8 4 151 15 2 151

8 4 153 15 4 15 3

8 5 153 15 4 15 3

8 6 153 15 4 15 3

86 604 602

86 604 602

6 4 151 15 2 151

74 151 15 2 151

8 4 151 15 2 151

8 4 153 15 4 15 3

8 5 153 15 4 15 3

8 6 153 15 4 15 3

86

86

P1-P3=605/P2-P4=606

P1-P3=605/P2-P4=606

5.1 NOMINAL REFERENCE

CONDITIONS

The technical data is calculated as follows

Cooling mode

- Temperature water inlet 12 °C

- Temperature of processed water 7 °C

- Ambient air temperature 35 °C

- ∆t 5°C

Heating mode

- Temperature of processed water 50 °C

- Ambient air temperature b.s. 7 °C

b.u. 6 °C

- ∆t 5°C

Sound Power

Aermec determines the value of sound

power on the basis of measurements performed in compliance with regulation 9614,

in respect with that requested by Eurovent

certification.

(1) Sound Pressure

Sound pressure in free field on a reflective

surface (factor of directionality Q=2), at 10

metres from the external surface of the

unit, using the parallel expansion method

(box-method, ISO 3744)

5 TECHNICAL DATA

NOTE

- The noise data refer to configuration without

pump.

- For heat pumps the data refers to functioning

in cooling mode

E.S.E.E.R.

There is a growing awareness in Europe

as well that attention needs to be paid

to the electricity consumed by air conditioning machines. For many years now in

the United States talk has not just been

about efficiency in the plan conditions, but

an assessment index is used that takes

account of the marginal operation of the

unit under plan conditions and the greater

use with partial loads with external air that

is less than that planned and in conditions

of compressor capacity control. In Europe

the proposed EECCAC (Energy Efficiency

ESEER = (3xEER100%+33xEER75%+41xEER50%+23xEER25%) / 100

Acqua uscita evaporatore 7 °C

∆T a pieno carico 5 °C

Carico 100% 75% 50% 25%

Temperatura aria esterna 35°C 30°C 25°C 20°C

and Certification of Central Air Conditioner)

has been adopted, the ESEER (European

Seasonal Energy Efficiency Ratio), that has

the purpose of being able to compare the

chillers with each other.

After estimating the total energy required

by the system during summer management (kW/h), the seasonal electrical energy consumption can be deduced with this

formula:

Input energy = Required energy

Efficiency index

The actual energy calculation can be obtained, more accurately, by considering:

1. The load profile with external temperature

2. The climatic profile

3. The total number of hours

With this data, every consultant or designer will be able to his or her evaluations.

8

5.2 TECHNICAL DATA, STANDARD VERSIONS (°)

NRA° 800 900 1000 1250 1400 1500 1650 1800

Cooling capacity: kW 211,0 236,0 261,0 320,0 363,0 390,0 434 480

Total input power kW 84,5 93,0 102,0 129,0 141,0 153,0 172 189

Evaporator water flow rate l/h 36290 40590 44890 55040 62440 67080 74650 82560

Evaporator pressure drop kPa 34,429,333,934,530,635,1 38,040,3

ENERGY INDICES

EER W/W 2,50 2,54 2,56 2,48 2,57 2,55 2,52 2,54

ESEER W/W 3.36 3.25 3.41 3.33 3.67 3.70 3.64 3.66

ELECTRICAL DATA

Fuel feed V3

Total input power A 145 160 174 222 242 261 296 323

Maximum current A 200 219 237 285 322 355 395 423

Peak current A 343 383 423 487 470 519 569 584

COMPRESSORS

Typ e scroll scroll scroll scroll scroll scroll scroll scroll

Number n° 44445666

Number per circuit

COMPRESSOR HEATER

Compressor carter heater n° x W 4 x 13 0 4 x 13 0 4 x 130 4 x 13 0 5 x 130 6 x 130 6 x 13 0 6 x 130

n°+n°+n°+n°

2+2 2+2 2+2 2+2 2+3 3+3 3+3 3+3

400 V 50Hz

~

FANS

Typ e Axial Axial Axial Axial Axial Axial Axial Axial

Number n° 44466688

Input current ventilation unit A 1616162424243232

Input power ventilation unit kW 7,2 7,2 7,2 10,8 10,8 10,8 15,2 15,2

Air flow rate m3/h 86000 83000 80000 126000 120500 115000 170000 168000

EVAPORATORS

Typ e Plate Plate Plate Plate Plate Plate Plate Plate

Number n° 11111111

HYDRAULIC CIRCUIT

Water accumulation lt 700 700 700 700 700 700 700 700

Accumulation anti-freeze heater n°xW 2x300 2x300 2x300 2x300 2x300 2x300 2x300 2x300

PLUMBING CONNECTIONS STANDARD VERSIONS (hydraulic parallel not supplied)

Hydraulic connections Victaulic 3” 3” 3” 4” 4” 4” 4” 4”

LOW PRESSURE PUMPING UNIT

Input power kW 3,8 3,8 3,8 4,8 4,8 6,5 6,5 6,5

Input current A 6,226,226,228,14 8,14 11 11 11

Useful pressure pumping kPa 979582785868119101

HIGH PRESSURE PUMPING UNIT

Input power kW 6,5 6,5 6,5 8,6 8,6 8,6 12,5 12,3

Input current A 11111114,614,614,621,221,2

Useful pressure pumping kPa 215 212 195 215 190 157 257 24 0

SOUND DATA

Sounud Power dB(A) 88.5 88.5 88.5 91.5 91.0 90.5 92.0 94.0

Sound pressure (1) dB(A) 56.5 56.5 56.5 59.5 59.0 58.5 60.0 62.0

DIMENSIONS for all versions

Height mm 245 0 245 0 2450 245 0 24 50 24 50 245 0 245 0

Width mm 2200 2200 2200 2200 2200 2200 2200 2200

Length mm 3400 3400 3400 4250 4250 4250 5750 5750

EMPTY WEIGHT versions without accumulation and pumps

kg 2350 2430 2465 3060 3150 3250 3640 3740

9

5.2 TECHNICAL DATA, HIGH EFFICIENCY VERSIONS A

NRA A 800 900 1000 1250 1400 1500 1650 1800

Cooling capacity:

Total input power kW 80,0 88,0 96,0 124,0 134,0 144,0 166 184

Evaporator water flow rate l/h 37320 41800 46100 56760 64330 68800 77400 85140

Evaporator pressure drop kPa 36,4 31,0 35,8 36,7 32,3 37,0 40,8 42,8

ENERGY INDICES

EER W/W 2,71 2,76 2,79 2,66 2,79 2,78 2,71 2,69

ESSER W/W 3.64 3.71 3.75 3.58 4.02 4.00 3.91 3.88

ELECTRICAL DATA

Fuel feed V3

Total input power A 140 154 168 213 233 253 287 315

Maximum current A 200 219 237 285 322 355 395 423

Peak current A 340 373 406 475 458 511 555 569

COMPRESSORS

Typ e scroll scroll scroll scroll scroll scroll scroll scroll

Number n° 44445666

Number per circuit

COMPRESSOR HEATER

Compressor carter heater n° x W 4 x 130 4 x 13 0 4 x 13 0 4 x13 0 5 x 13 0 6 x 13 0 6 x 13 0 6 x13 0

kW 217,0 243,0 268,0 330,0 374,0 400,0 450 495

400 V 50Hz

~

n°+n°+n°+n°

2+2 2+2 2+2 2+2 2+3 3+3 3+3 3+3

FANS

Typ e Axail Axail Axail Axail Axail Axail Axail Axail

Number n° 44466688

Input current ventilation unit A 1616162424243232

Input power ventilation unit kW 7,2 7,2 7,2 10,8 10,8 10,8 15,2 15,2

Air flow rate m3/h 80000 78000 76000 115000 111500 111000 162000 160000

EVAPORATORS

Typ e Plate Plate Plate Plate Plate Plate Plate Plate

Number n° 11111111

HYDRAULIC CIRCUIT

Water accumulation lt 700 700 700 700 700 700 700 700

Accumulation anti-freeze heater n°xW 2x300 2x300 2x300 2x300 2x300 2x300 2x300 2x300

PLUMBING CONNECTIONS STANDARD VERSIONS (hydraulic parallel not supplied)

Hydraulic connections Victaulic 3” 3” 3” 4” 4” 4” 4” 4”

LOW PRESSURE PUMPING UNIT

Input power kW 3,83,83,84,84,86,56,56,5

Input current A 6,22 6,22 6,22 8,14 8,14 11 11 11

Useful pressure pumping kPa 95907570455011495

HIGH PRESSURE PUMPING UNIT

Input power kW 6,5 6,5 6,5 8,6 8,6 8,6 12,3 12,3

Input current A 11111114,614,614,621,221,2

Useful pressure pumping kPa 210 207 185 203 180 142 252 234

SOUND DATA

Sounud Power dB(A) 88.0 88.0 88.0 91.0 90.5 90.0 91.5 93.5

Sound pressure (1) dB(A) 56.0 56.0 56.0 59.0 58.5 58.0 59.5 61.5

DIMENSIONS for all versions

Height mm 24 50 2450 24 50 245 0 24 50 2450 24 50 245 0

Width mm 2200 2200 2200 2200 2200 2200 2200 2200

Length mm 3400 3400 3400 4250 4250 4250 5750 5750

EMPTY WEIGHT versions without accumulation and pumps

kg 2430 2520 2560 3170 3270 3370 3840

10

3950

5.3 TECHNICAL DATA, SILENCED VERSIONS

NRA L 800 900 1000 1250 1400 1500 1650 1800

Cooling capacity:

Total input power kW 89,0 98,5 107,5 136,5 148,0 160,0 180 199

Evaporator water flow rate l/h 32680 36640 40420 50220 56590 60720 69490 76710

Evaporator pressure drop kPa 27,8 23,827,6 28,924,828,532,734,7

ENERGY INDICES

EER W/W 2,13 2,16 2,19 2,14 2,22 2,21 2,24 2,24

ESSER W/W 2.72 2.76 2.79 2.88 3.05 3.02 3.07 3.07

ELECTRICAL DATA

Fuel feed V3

Total input power A 151 166 180 229 250 270 301 330

Maximum current A 188 207 225 269 304 340 373 400

Peak current A 342 382 422 486 469 522 568 582

COMPRESSORS

Typ e scroll scroll scroll scroll scroll scroll scroll scroll

Number n° 44445666

Number per circuit

COMPRESSOR HEATER

Compressor carter heater n ° x W 4 x13 0 4 x 13 0 4 x13 0 4 x 13 0 5 x 130 6 x 13 0 6 x 130 6 x13 0

kW 190,0 213,0 235,0 292,0 329,0 353,0 404 446

400 V 50Hz

~

n°+n°+n°+n°

2+2 2+2 2+2 2+2 2+3 3+3 3+3 3+3

FANS

Typ e Axail Axail Axail Axail Axail Axail Axail Axail

Number n° 44466688

Input current ventilation unit A

Input power ventilation unit kW 2,9 3,0 3,1 4,0 4,5 5,0 6 6,2

Air flow rate m3/h 44000 50000 56000 68000 76000 84000 100000 112000

EVAPORATORS

Typ e Plate Plate Plate Plate Plate Plate Plate Plate

Number n° 11111111

HYDRAULIC CIRCUIT

Water accumulation lt 700 700 700 700 700 700 700 700

Accumulation anti-freeze heater n°xW 2x300 2x300 2x300 2x300 2x300 2x300 2x300 2x300

PLUMBING CONNECTIONS STANDARD VERSIONS (hydraulic parallel not supplied)

Hydraulic connections Victaulic 3” 3” 3” 4” 4” 4” 4” 4”

LOW PRESSURE PUMPING UNIT

Input power 3,8 3,8 3,8 4,8 4,8 6,5 6,5 6,5

Input current 6,22 6,22 6,22 8,14 8,14 11 11 11

Useful pressure pumping 12 0 116 10 2 110 9 0 12 2 13 0 113

HIGH PRESSURE PUMPING UNIT

Input power 6,5 6,5 6,5 8,6 8,6 8,6 12,5 12,3

Input current 11 11 11 14,6 14,6 14,6 21,2 21,2

Useful pressure pumping 232 235 216 245 230 200 267 251

DATI SONORI

Sounud Power dB(A) 83.0 83.0 83.0 86.0 85.5 85.0 86.5 88.5

Sound pressure (1) dB(A) 51.0 51.0 51.0 54.0 53.5 53.0 54.5 56.5

DIMENSIONI per tutti gli allestimenti

Height mm 24 50 24 50 2450 24 50 24 50 2450 24 50 24 50

Width mm 2200 2200 2200 2200 2200 2200 2200 2200

Length mm 3400 3400 3400 4250 4250 4250 5750 5750

PESO a vuoto senza accumulo e pompe

kg 2530 2570 2580 3310 3350 3390 3850 3950

11

5.4 TECHNICAL DATA, HEAT PUMP VERSIONS H

COLD MODE

Cooling capacity

Total input power kW 81,0 89,0 97,0 123,0 134,0 146,0 166 182

Evaporator water flow rate l/h 33710 37840 41620 53660 59340 62780 72240 80840

Evaporator pressure drop kPa 29,6 25,3 29,4 33,1 26,4 30,4 35,8 38,6

ENERGY INDICES

EER W/W 2,42 2,47 2,49 2,54 2,57 2,50 2,53 2,58

COP W/W 2,57 2,61 2,64 2,58 2,64 2,64 2,57 2,59

ESEER 3.25 3.32 3.35 3.41 3.67 3.60 3.65 3.72

HOT MODE

Cooling capacity kW 230,0 257,0 284,0 356,0 396,0 426,0 480 534

Total input power kW 89,5 98,5 107,5 138,0 150,0 161,5 187 206

Evaporator water flow rate l/h 39560 44200 48850 61230 68110 73270 82560 91850

Evaporator pressure drop kPa 43,7 40,6 43,4 42,6 42,1 44,7 66,7 71,3

DATI ELETTRICI

Fuel feed V3

Total input current only COOLING A 142 157 171 212 235 257 288 314

Corrente assorbita totale HEATING A 151 166 180 233 252 270 317 345

Maximum current A 200 219 237 285 322 355 395 423

Peak current A 340 380 420 491 484 515 586 611

COMPRESSORS

kW 196,0 220,0 242,0 312,0 345,0 365,0 420 470

Typ e

Number

Number per circuit

COMPRESSOR HEATER

Compressor carter heater n°xW 4x130 4x130 4x130 4x130 5x130 6x130 6x130 6x130

n° 44445666

n°+n°+n°+n° 2+2 2+2 2+2 2+2 2+3 3+3 3+3 3+3

800 900 1000 1250 1400 1500 1650 1800

400 V 50Hz

~

scroll scroll scroll scroll scroll scroll scroll scroll

FANS

Typ e

Number

Input current ventilation unit

Input power ventilation unit

Air flow rate

EVAPORATORS

n° 44466688

A 1616162424243232

kW 7,2 7,2 7,2 11,4 10,8 10,8 15,2 15,2

m3/h 86000 83000 80000 129000 120500 115000 162000 160000

Typ e

Number

HYDRAULIC CIRCUIT

Water accumulation lt 700 700 700 700 700 700 700 700

Accumulation anti-freeze heater n°xW 2x300 2x300 2x300 2x300 2x300 2x300 2x300 2x300

PLUMBING CONNECTIONS STANDARD VERSIONS (hydraulic parallel not supplied)

Hydraulic connections Victaulic 3” 3” 3” 4” 4” 4” 4” 4”

n° 11111111

Axial Axial Axial Axial Axial Axial Axial Axial

Plate Plate Plate Plate Plate Plate Plate Plate

LOW PRESSURE PUMPING UNIT

Input power

Input current

Useful pressure pumping

HIGH PRESSURE PUMPING UNIT

Input power

Input current

Useful pressure pumping

SOUND DATA

Sound Power dB(A) 88.5 88.5 88.5 91.5 91.0 90.5 92.0 94.0

Sound pressure (1) dB(A) 56.5 56.5 56.5 59.5 59.0 58.5 60.0 62.0

kW 3,8 3,8 3,8 4,8 4,8 6,5 6,5 6,5

A 6,22 6,22 6,22 8,14 8,14 11 11 11

kPa 115 110 97 101 80 105 124 105

kW 6,5 6,5 6,5 8,6 8,6 8,6 12,5 12,3

A 11111114,614,614,621,221,2

kPa 230 230 213 237 220 185 261 244

DIMENSIONS for all versions

Height

Width

Length

EMPTY WEIGHT versions without accumulation and pumps

mm 24 50 24 50 24 50 245 0 24 50 24 50 24 50 245 0

mm 2200 2200 2200 2200 2200 2200 2200 2200

mm 3400 3400 3400 4250 4250 4250 5750 5750

kg 2480 2580 2610 3360 3400 3440 3880

12

3960

5.5 TECHNICAL DATA, HEAT PUMP VERSIONS HL

NOTE

Silenced functioning is only in cooling

COLD MODE

Cooling capacity kW 175,0 196,0 217,0 286,0 312,0 326,0 387 430

Total input power kW 88,5 98,0 107,0 130,0 145,0 160,5 177 194

Evaporator water flow rate l/h 30100 33710 37320 49190 53660 56070 66050 73960

Evaporator pressure drop kPa 23,620,223,527,9 21,1 24,329,832,5

ENERGY INDICES

EER W/W 1,98 2,00 2,03 2,20 2,15 2,03 2,17 2,22

COP W/W 2.57 2.61 2.64 2.58 2.64 2.64 2.57 2.59

ESEER 2.53 2.56 2.59 2.96 2.95 2.78 2.97 3.04

HOT MODE

Cooling capacity kW 230,0 257,0 284,0 356,0 396,0 426,0 480 534

Total input power kW 89,5 98,5 107,5 0,0 0,0 161,5 0,0 0,0

Evaporator water flow rate l/h 39560 44200 48850 61230 68110 73270 82560 91850

Evaporator pressure drop kPa 43,7 40,6 43,4 42,6 42,1 44,7 66,7 71,3

DATI ELETTRICI

Fuel feed V3

Total input current only COOLING A 147 163 180 212 241 270 298 323

Corrente assorbita totale HEATING A 151 166 180 233 252 270 301 329

Maximum current A 200 219 237 285 322 355 395 423

Peak current A 355 395 435 510 503 538 610 635

COMPRESSORS

Typ e

Number

Number per circuit

COMPRESSOR HEATER

Compressor carter heater n°xW 4x130 4x130 4x130 4x130 5x130 6x130 6x130 6x130

n° 44445666

n°+n°+n°+n° 2+2 2+2 2+2 2+2 2+3 3+3 3+3 3+3

800 900 1000 1250 1400 1500 1650 1800

400 V 50Hz

~

scroll scroll scroll scroll scroll scroll scroll scroll

FANS

Typ e

Number

Input current ventilation unit

Input power ventilation unit

Air flow rate

EVAPORATORS

n° 44466688

A

kW 2,2 2,3 2,4 3,3 4,15 5 4,6 4,8

m3/h 44000 50000 56000 68000 76000 84000 100000 112000

Typ e

Number

HYDRAULIC CIRCUIT

Water accumulation lt 700 700 700 700 700 700 700 700

Accumulation anti-freeze heater n°xW 2x300 2x300 2x300 2x300 2x300 2x300 2x300 2x300

PLUMBING CONNECTIONS STANDARD VERSIONS (hydraulic parallel not supplied)

Hydraulic connections Victaulic 3” 3” 3” 4” 4” 4” 4” 4”

n° 11111111

Axila Axila Axila Axila Axila Axila Axila Axila

piastre piastre piastre piastre piastre piastre piastre piastre

LOW PRESSURE PUMPING UNIT

Input power

Input current

Useful pressure pumping

HIGH PRESSURE PUMPING UNIT

Input power

Input current

Useful pressure pumping

SOUND DATA

Sound Power dB(A) 83.0 83.0 83.0 86.0 85.5 85.0 86.5 88.5

Sound pressure (1) dB(A) 51.0 51.0 51.0 54.0 53.5 53.0 54.5 56.5

kW 3,8 3,8 3,8 4,8 4,8 6,5 6,5 6,5

A 6,22 6,22 6,22 8,14 8,14 11 11 11

kPa 128 128 118 130 116 155 135 118

kW 6,5 6,5 6,5 8,6 8,6 8,6 12,5 12,3

A 11 11 11 14,6 14,6 14,6 21,2 21,2

kPa 240 245 235 265 260 230 273 256

DIMENSIONS for all versions

Height

Width

Length

EMPTY WEIGHT versions without accumulation and pumps

mm 245 0 245 0 245 0 24 50 24 50 24 50 24 50 24 50

mm 2200 2200 2200 2200 2200 2200 2200 2200

mm 3400 3400 3400 4250 4250 4250 5750 5750

kg 2480 2580 2610 3360 3400 3440 3880

3960

13

6 SELECTION CRITERIA

50

The devices in their standard

configurations are not suitable for

installation in salty environments. The

maximum and minimum limits for

the water flow rate to the exchanger

are indicated by the curves of the

pressure drop diagrams. For the

operating limits, refer to t he diagrams

6.1 OPERATING LIMITS

"Cold mode"

46 46

40

36

35

30

25

20

15

10

5

Outside air temp. d.b. °C

0

-5

-10

1

2

-6

-4 1514131211109876543210-2

Processed water temperature °C

42

below, valid for ∆t = 5°C.

WARNING:

-

operation with a processed water

temperature of less than 4°C is only

allowed for the versions specifically

designed for this (version YA).

- if you want to operate the machine

outside the limits indicated in

VERSION

•standard (°) 35 - 42°C

•high temperature 40 - 46°C

•silenced L 40 - 46°C

•heat pump H 40 - 46°C

42

3

versioni Y

40

35

4

the diagram, please contact the

AERMEC technical/commercial

office.

- if the machine is positioned in

particularly windy areas, it is

necessary to install windbreak

barriers to avoid the inconstant

operation of the DCPX device.

KEY

Operation with glycol water

1

only for versions YA

2 Operation with glycol water

and DCPX

Standard operation

3

4 Operation with DCPX

"Hot mode"

55

50

45

40

35

30

25

Processed water temperature °C

20

-15 -10 -5 0 5 10 15 20 25

50

Outside air temp. d.b. °C

6.2 PROJECT DATA

(1) = only for heat pump versions

VERSION

•H in heat pump

High pressure

side

Maximum pressure allowed bar 30 / 28

Maximum temperature allowed °C 120 52

Minimum temperature allowed °C -10 -16 / -10

(1)

Low pressure

side

22

(1)

14

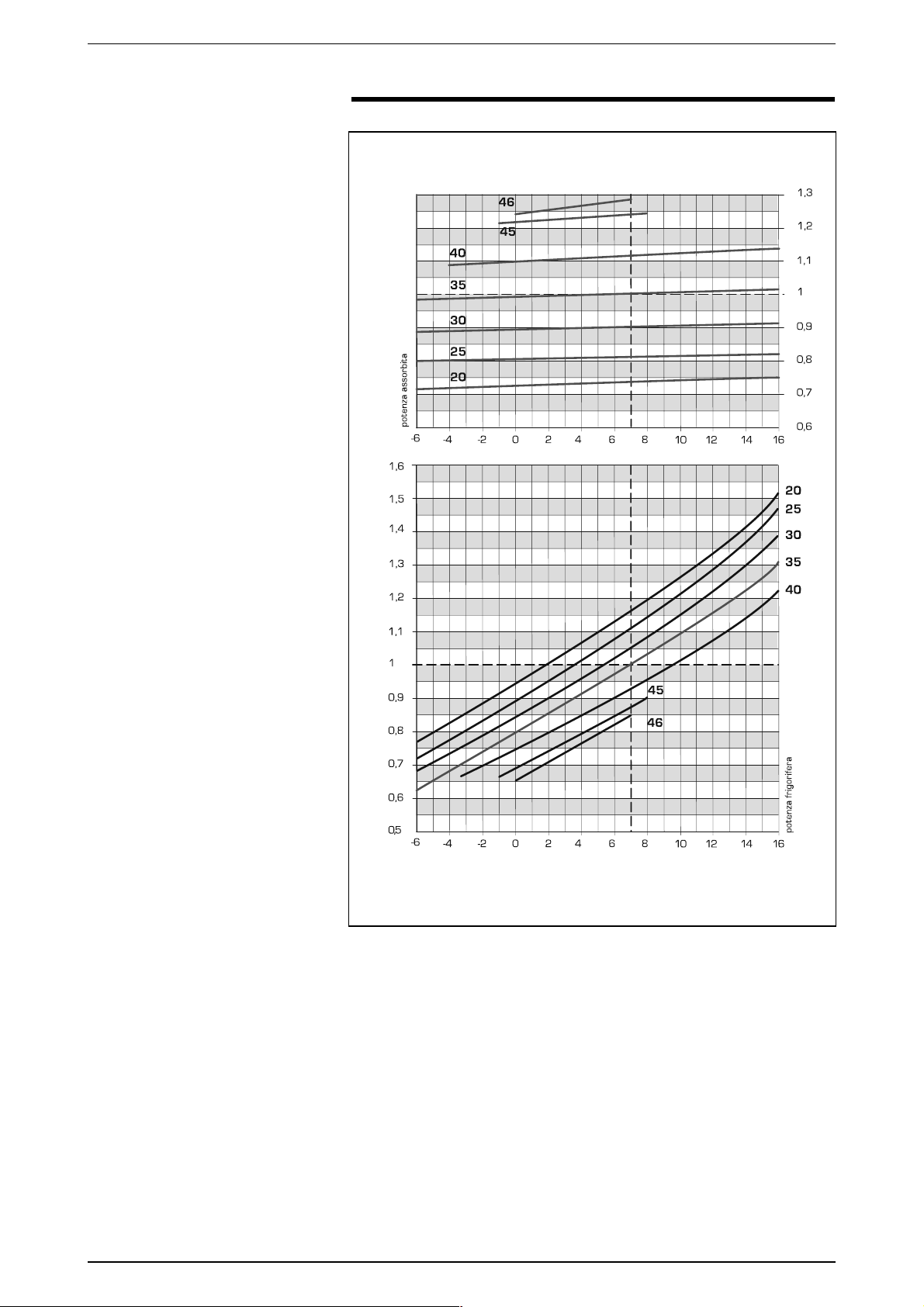

7.1 COOLING AND INPUT

CAPACITIES

- “STANDARD VERSIONS”

- “HEAT PUMP VERSIONS IN COLD

MODE”

- “HIGH TEMPERATURE VERSIONS”

The refrigerating capacity yielded

and the input electrical capacity in

conditions other than rated conditions

are obtained by multiplying the rated

values (Pf, Pa) by the respective

correction coefficients (Cft, Cpa).

The following diagrams allow you to

obtain the correction coefficients to

be used for the various versions of the

devices, in cold mode; next to each curve

you can see the outside air temperature

to which it refers.

7 CORRECTION COEFFICIENTS

(Ca)

¨:Y©

(Cf)

¨:^©

KEY:

Cf = Cooling capacity correction

coefficient

Ca = Input power correction

coefficient

N.B.

FOR VERSIONS Y with temperatures

lower than 4°C, contact the company

headquarters

FOR ∆T OTHER THAN 5°C

For the evaporator, the Tav.7.4 is

used to obtain the correction factors

of the cooling and input capacities.

To take into account the dirtying of

the exchangers, the relative dirtying

factors are used

Outside air temperature

Temperature of the water produced (∆t = 5°C)

15

7.2 COOLING AND INPUT

Y

^

CAPACITIES

- “SILENCED VERSIONS”

The cooling capacity yielded and the

electrical input power in conditions

other than rated conditions are

obtained by multiplying the rated values

(Pf, Pa) by the respective correction

coefficients (Cf, Ca).

The following diagrams allow you to

obtain the correction coefficients to

be used for the various versions of the

devices, in cold mode; next to each curve

you can see the outside air temperature

to which it refers.

(Ca)

¨:

KEY:

Cf = Cooling capacity correction

coefficient

Ca = Input power correction

coefficient

N.B.

- FOR THE VERSIONS Y

with temperatures below 4°C

contact company headquarters

(Cf)

¨:

Processed water temperature (∆t = 5°C)

16

7.3 HEATING AND INPUT

CAPACITIES

- “HEAT PUMP VERSIONS”

The heating capacity yielded and the

electrical input power in conditions

other than rated conditions are

obtained by multiplying the rated values

(Pf, Pa) by the respective correction

coefficients (Cft, Cpa).

The following diagram makes it possible

to obtain the correction coefficients;

next to each curve, you can see the

temperature of the hot processed

water to which it refers, assuming

a difference of water temperature

between the inlet and outlet of the

condenser equal to 5°C.

The yields are intended as net of the

defrosting cycles.

(Ct)

~

~

~

~~

~

(Ca)

~~

~

hgl]frYÛYkkgjZalY

¤~

¤

¤¤¤

~ ~ ~ ~

Processed water temperature

KEY:

Ct = Heating capacity correction

coefficient

Ca = Input power correction

coefficient

7.4 FOR ∆T OTHER

THAN NOMINAL

For ∆t other than 5°C, the Tav.1 is

used on the evaporator to obtain the

correction factors of the cooling and

input capacities. To take into account

the dirtying of the exchangers, the

relative dirtying factors are used

7.5 FOULING FACTORS

The performance shown by the table

refers to conditions with clean tubes,

with a fouling factor = 1. For other

fouling factor values, multiply the data

of the performance tables by the

coefficients given.

¤~

¤

¤¤¤

~ ~ ~ ~

Outside air temperature b.s. with 87% humidity

7.4.1 Correction factors for ∆t other than nominal, Chiller

35810

Cooling capacity correction factors 0,99 1 1,02 1,03

Cooling capacity correction factors 0,99 1 1,01 1,02

7.5.1 Fouling factors

[K*m2]/[W]

Cooling capacity correction factors

Cooling capacity correction factors

0,00005 0,0001 0,0002

1 0.98 0.94

1 0,98 0,95

hgl]frYÛl]jea[Y

17

8 ETHYLENE GLYCOL SOLUTION

The cooling capacity and input power

correction factors make allowance for

the presence of glycol and the different

evaporation temperature.

The correction factors of the water

flow rate and the pressure drops are

applied directly to the data obtained

for operation without glycols. The

correction factor of the water flow

rate is calculated so as to maintain

the same ∆t that would be used in the

absence of glycols.

- The correction factor of the pressure

drop already takes into account the

different capacity deriving from the

application of the water flow rate

correction factor.

- The correction factors of the water

flow rate and the pressure drops are

applied directly to the data obtained

for operation without glycols.

- The correction factors of the cooling

and input capacities take into

account the presence of glycols.

- The correction factors of the water

flow rate and the pressure drops are

applied directly to the data obtained

for operation without glycols.

- The correction factor of the water

flow rate is calculated so as to

maintain the same Dt that would be

used in the absence of glycols.

- The correction factor of the pressure

drop already takes into account the

different capacity deriving from the

application of the water flow rate

correction factor.

NOTE

To make it easier to read the graph, an

example is given on the next page.

By using the diagram opposite it

possible to establish the percentage of

glycol necessary; this percentage can

be calculated taking into account one

of the following factors:

On the basis of the fluid considered

(water or air), it will be necessary to

enter the graph from the right or

left side, from the intersection of the

outside air temperature or processed

water temperature straight lines and

the relative curves, a point is obtained

through which the vertical line that will

identify both the percentage of glycol

and the relative correction coefficients

will have to pass.

8.1 HOW TO READ

THE GLYCOL CURVES

The curves shown in the figure

summarise a notable quantity of data,

each of which is represented by a

specific curve. In order to use these

curves correctly, it is necessary to

make some initial considerations:

- If you want to calculate the

percentage of glycol on the basis

of the outside air temperature, you

must enter from the left-hand axis

and, once you have intersected

the curve, trace a vertical line

which, in turn, will intercept all the

other curves; the points obtained

from the upper curves represent

~

~

~

~

~

~

~

~

~

~~

~

=Yllgj]Û[gjj]llang

¤

¤~

¤~

¤

¤

¤

¤

K]eh]jYlmjYÛYjaYÛ]kl]jfYÛµ:

¤

~ ~

=[>;h=Û¨Y©

=[>;h=Û¨Z©

=[>;h=Û¨[©

=[>;h=Û¨\©

=[>;h=Û¨]©

=[>H=

=[>HÛ¨G\:©

=[>G^Û¨G\:©

=[>GY

=[>G^

K]eh]jYlmjYÛ

¤

KEY:

FcGPf Correction factor of the

cooling capacity

FcGPa Correction factor of the

input power

FcGDpF (a) C o rr ection factor of

the pressure drops

(evaporator) (average

temp. = -3.5°C)

FcGDpF (b) Correction factor of the

pressure drops (average

temp. = 0.5°C)

FcGDpF (c) Correction factor of the

pressure drops (average

temp. = 5.5°C)

FcGDpF (d) Correction factor of the

pressure drops (average

temp. = 9.5°C)

FcGDpF (e) Correction factor of the

pressure drops (average

temp. = 47.5°C)

FcGQF Correction factor of the

outputs (evaporator)

Y[imYÛhjg\gllYÛµ:

(average temp. = 9.5°C)

FcGQC Correction factor of the

outputs (condenser)

(average temp. = 47.5°C)

NOTE

Although the graph reaches

outside air temperatures of 40°C, it is necessary to maintain

the machine's operating limits as

reference.

18

the coefficients for the correction

of the cooling capacity and input

power, for the flow rates and the

pressure drops (remember that

these coefficients must anyway be

multiplied by the nominal value of

the sizes examined); the lower axis

advises the percentage of glycol

necessary on the basis of the outside

air temperature considered.

- If you want to calculate the

percentage of glycol on the

basis of the temperature of the

processed water, you must enter

from the right-hand axis and, once

you have intersected the curve,

trace a vertical line which, in turn,

will intercept all the other curves;

the points obtained from the upper

curves represent the coefficients

for the cooling capacity and input

power, for the flow rates and the

pressure drops (remember that

these coefficients must anyway be

multiplied by the nominal value of

the sizes examined); the lower axis

advises the percentage of glycol

necessary to produce water at the

required temperature.

Remember that the initial sizes

“OUTSIDE AIR TEMPERATURE”

and “PROCESSED WATER

TEMPERATURE”, are not directly

linked to each other, so it is not

possible to enter the curve of

one of these sizes, and obtain the

corresponding point on the other

curve.

~

=[>;h=Û¨Y©

=[>;h=Û¨Z©

=[>;h=Û¨[©

~

~

=[>;h=Û¨\©

~

~

=[>;h=Û¨]©

~

~~

~~

~

~

~

~~~

~

=[>H=

=[>HÛ¨G\:©

=[>G^Û¨G\:©

=[>GY

~

~

~

~~

~

¤

=[>G^

¤

¤

¤~

¤~

¤

¤

¤

¤

¤

~~

Processed water temperature

Outside air temperature

19

9 PRESSURE DROPS

9.1 PRESSURE DROPS,

EVAPORATOR

The following diagrams show the

values of the pressure drops in kPa,

on the basis of the capacity in l/h.

The operation field is defined by the

minimum and maximum values of the

curves, which indicate the limit of use

of the water side heat exchangers

(evaporators).

The pressure drops of the diagrams

are relative to the average water

temperature 10°C. The following table

shows the correction to apply to the

pressure drop when the average

water temperature varies.

9.2 PRESSURE DROPS,

CONDENSER

kPa

Water flow rate m3/h

Average water temperature °C

Multiplicative coefficient 1,02 1 0,985 0,97 0,95 0,93 0,91

5101520304050

kPa

The pressure drops of the diagram

are relative to an average water

temperature of 50°C. The following

table shows the correction to apply to

the pressure drop when the average

water temperature varies.

Water flow rate m3/h

Average water temperature °C

Multiplicative coefficient 1. 2 2 1.10 1. 0 8 1. 0 6 1.0 4 1. 02 1

5101520304050

20

9.3 PRESSURE DROPS,

WATER FILTER

kPa

The versions with accumulation offer

different set-ups that vary on the basis

of the effective pressure that you

want to obtain, the characteristics of

the pumping unit, and the presence

or absence of holes for integrative

resistance.

The following tables show the main

characteristics of the components of

the hydraulic circuit, while the graphs

on these pages show the relative

pressures.

The accumulation tanks with holes

for heaters are equipped with plastic,

temporary closing plugs.

WARNING

Before start-up, the installer must

assemble the heaters. If these

heaters are not immediately

necessary, the plastic plugs must be

replaced with suitable metal plugs.

10.1 MAXIMUM WATER CONTENT

in the system

The table below indicates the

maximum water content, in litres,

of the hydraulic system, compatible

with the capacity of the expansion

tank supplied as standard. The values

shown in the table refer to three

conditions of maximum and minimum

~

~

~~

Water flow rate m3/h

10 ACCUMULATION

water temperature. If the effective

water content of the hydraulic

system (including the accumulation

Altezza idraulica

Taratura del vaso di espansione bar 3.2 2.8 2.3 1.8 1.5

Valore di riferimento contenuto acqua l

Valore di riferimento contenuto acqua l

Valore di riferimento contenuto acqua l

Acqua glicolata Temp. acqua °C Coefficiente

max. min.

10 % 4 0 - 2 0 , 50 7 ( 1 )

10 % 6 0 - 2 0 , 68 6 ( 2 )

10 % 8 5 - 2 0 , 80 9 ( 3 )

20% 40 -6 0,434 (1)

20% 60 -6 0,604 (2)

20% 85 -6 0,729 (3)

35% 40 -6 0,393 (1)

35% 60 -6 0,555 (2)

35% 85 -6 0,677 (3)

Working reference conditions:

(1) Cooling: max water temp. = 40°C, min water temp. = 4°C.

(2) Heating (heat pump): max water temp. = 60°C, min water temp. = 4°C.

(3) Heating (boiler): max water temp. = 85°C, min water temp. = 4°C.

tank) is greater than that shown in

the operational conditions table,

another, additional expansion tank

H m 30 25 20 15

(1)

2.174 2.646 3.118 3590 3852

(2)

978 1190 1404 1616 1732

(3)

510 622 732 844 904

Condizione di

di correzione

riferimento

≥ 12.25

21

must be installed, measured (using the

common criteria) with reference to the

additional volume of water.

From the following tables, it is possible

to obtain the values of maximum

system content, also for other

operational conditions with glycol

water.

The values are obtained by multiplying

the reference value by the correction

coefficient.

10.1.1 Calibration of expansion tank

The standard value of pre-charge

pressure of the two expansion tanks is

1.5 bar, while their volume is 24 litres,

maximum value 6 bar.

The calibration of the tanks must be

regulated on the basis of the maximum

difference of level (H) of the user (see

figure), according to the formula:

p (calibration) [bar] = H [m] / 10.2

+ 0.3.

For example, if the level difference H is

20m, the calibration value of the tank

will be 2.3 bar.

If the calibration value obtained from

the calculation is lower than 1.5 bar

(i.e. for H < 12.25), maintain the

standard calibration.

H = 0 m

Ptar = H / 10.2 + 0.3

Ptar = 1.5 barPtar = 1.5 bar

(1)

H max

H = 12.25 m

H min

= 55 m

(2)

H

KEY

(1) Check that the highest user does

not exceed a level difference of 55

metres.

(2) Check that the lowest user can

sustain the global pressure acting

at that point.

The pressures shown here are net

of the pressure drops of the heat

exchangers, filter, etc.

They should therefore be considered

useful for the system

WARNING

As in the configurator, the pumps can

be high or low pressure, so we will

give two distinct diagrams to avoid

confusion in the selection.

11.1 LOW PRESSURE

PUMPS

11 EFFECTIVE PRESSURE FOR THE SYSTEM

kPa

~

~

~~

~

~

~

~

~

~

hgeh]ÛZYkkYÛhj]nYd]frY

22

Water flow rate m3/h

11. 2 HIGH PRESSURE

PUMPS

kPa

~

~

The heating capacity that can be obtained from the desuperheater is calculated by multiplying the rated value (Pd),

indicated in the table below the diagrams, by a suitable coefficient (Cd).

The diagrams allow the correction

coefficients to be used for the various

versions of chiller to be calculated; the

external air temperature referred to is

indicated in correspondence with each

curve. The pressure drops you see in

the table do not include the filter drop,

whose curve is indicated in table TAV

9.3.

The nominal value refers to:

air temperature 35°C

produced water temperature 50°C.

NOTE

in the models with heat pump the desuperheater must be intercepted when

the heat pump is operating, otherwise

the guarantee will not be valid.

~ ~ ~~ ~ ~ ~ ~

~

~

~

~

~

~

Water flow rate m3/h

12 DESUPERHEATERS

12.1 VERSIONI STANDARD

VERSIONI ALTA EFFICIENZA

~

~

~

12.1.2 LOW NOISE VERSION

~

~

hgeh]ÛYdlYhj]nYd]frY

n]jkagfaÛklYf\Yj\ n]jkagfaÛkad]fqaYl]

Ambient temperatur d.b. Ambient temperatur d.b.

For chilled water production at temperatures other than 7°C or for evaporation temperatures other than 5°C,

use the correction factors in the table

provided, as well as the ones obtained

from the graphs.

~

Temperatura dell'acqua prodotta al desurriscaldatore ∆t 5° C

12.2.3 Values different from the nominal value

Average water temperature °C

Multiplicative coefficient 0.94 1 1.07 1.13 1.2 1.27

Evaporation Temperature °C

Multiplicative coefficient 0.88 0.94 1 1.06 1.13 1.2

579111315

1357911

23

12.3 PRESSURE DROPS

All NRA models with desuperheater

are equipped with two (desuperheaters in parallel).

NOTE

The parallel water connections is to be

made by the installer

Desuperheaters specifications and

pressure drop curves are given below.

kPa

~

~

~

~

~

~

~

For temperatures of produced water

other than 50 °C, multiply the result by

the correction factor that can be determined from the table at the bottom of

the page. 12.2.4.

The heating capacity available to the

total heat recovery is in rated conditions:

Air temperature 35 °C

Water produced 50 °C

∆t 5 °C

h]j\al]Û\aÛ[Yja[gÛ\]kmjjak[Yd\Ylgj]

~~

Water flow rate m3/h

12.2.4

Values different from the nominal value

Average water temperature °C

Multiplicative coefficient 1. 0 4 1. 0 2 1

Taglie 0800 0900 1000 1250 1400 1500 1650 1800

Heating

capacity

available

Water flow

rate

Water pressure drops

kW

55 61 66 82 91 101 110 119

m3/h

9.46 10.43 11.36 14.02 15.72 17.34 18.92 20.46

kPa

16 19 . 5 14 . 5 16 . 5 16 19 2 2 2 2

30 40 50

24

When operating with the total heat

recovery function, machine performance depends on the temperature of the

hot water produced, not on that of

external air; to calculate the absorbed

electrical and heat recovery power

values, multiply the values (Pa, Pr) specified at the bottom of the page by the

relevant correction factors (Ca, Cr)

derived from the diagrams below. The

temperature of the relative hot water

is given for each curve (a difference

of 5°C between total heat recovery

unit input and output is presumed).

Calculate the cooling power (Pf) by

measuring the difference between

heat recovery power (Pr) and power

absorbed (Pa).

NOTA