AERMEC HRS 060, HRS 090, HRS 090W, HRS 160, HRS 160W Installation, Use And Maintenance Manual

...

HEAT RECOVERY UNIT

Installation, Use and Maintenance Manual

HRS-HRS W

4530600_00 dated 0904

A the Manufacturer is constantly committed in the continuous improvement of its entire production, the aesthetic and dimensional features, the technical data, equipment and accessories may be subject to variation.

!

This instruction book is an integral part of the appliance and as a consequence must be kept carefully and must ALWAYS

accompany the appliance even if transferred to other owners or users or transferred to another plant. If damaged or lost,

request another copy from the Manufacturer.

!

Repair and maintenance interventions must be carried out by authorised staff or staff qualified according to that envisioned

by this book. Do not modify or tamper with the appliance as dangerous situations can be created and the appliance manufacturer will not be liable for any damage caused.

!

After having removed the packaging ensure the integrity and completeness of the content. If this is not the case, contact the

Company that sold the appliance.

!

The appliances must be installed by enabled companies in compliance with the Law 5 March n° 46 which, at the end of the

job issues a declaration of conformity regarding installation to the owner, i.e. in compliance with the Standards in force and

the indications supplied in this book.

!

Any contractual or extracontractual liability of the Manufacturer is excluded for injury/damage to persons, animals or objects

owing to installation, regulation and maintenance errors or improper use.

We remind you that the use of products that employ electrical energy and water requires that a number of essential safety

rules be followed, including:

This appliance must not be used be children and unaided disabled persons.

It is prohibited to touch the appliance when you are barefoot and with parts of the body that are wet or damp.

It is prohibited to perform any maintenance or cleaning operation before having disconnected the appliance from the

mains electricity network, by positioning the plant master switch at "off"

It is prohibited to modify the safety or adjustment devices without the manufacturer’s authorisation and precise instructions

It is prohibited to pull, detach or twist the electrical cables coming from the unit even if it is disconnected from the electrical mains

It is prohibited to climb onto the unit, sit on it and/or rest any type of object on it.

It is prohibited to spray or jet water directly onto the unit.

It is prohibited to open the doors for accessing the internal parts of the appliance without first having switched off the master switch of the "system".

It is prohibited to disperse, abandon or leave the packing materials within the reach of children, as they are a potential

source of danger

page 2

Heat Recovery Units Installation, Use and Maintenance Manual

Important Note

The heat recovery unit is a machine designed and built exclusively to change air in the civil environments,

incompatible with toxic and inflammable gases. Therefore it cannot be used in those environments where the

air is mixed and/or altered by other gaseous composites and/or solid particles.

The use of the same for different purposes from those envisioned, not conform to that described in this

manual, will make any direct and/or indirect liability of the Manufacturer automatically become null and void.

SYMBOLS

!

WARNING

!

DANGER

i

DANGER RISK F ELECTRIC SHOCK

f

ATTENTION ONLY AUTHORISED STAFF

PROHIBITION

page 3

Heat Recovery Units Installation, Use and Maintenance Manual

INDEX

SECTION 1 - GENERAL FEATURES

1.1 Manual presentation page 5

1.2 Construction features page 5

1.3 Orientations possible for HRS range horizontal models page 6

1.4 HRS range unit technical data page 7

1.5 HRS - HRSW range unit technical data page 8

1.6 Accessories available page 8

SECTION 2 - TRANSPORT

2.1 Packaging page 11

2.2 Handling and transport

2.3 Control and receipt

2.4 Storage

SECTION 3 - INSTALLATION AND START-UP

page 11

3.1 Safety Standards

3.2 Preliminary operations page 12

3.3 Choosing the place of installation page 12

3.4 Positioning the machine page 12

3.5 Connection to the ducts page 13

3.6 Hydraulic connections

3.7 Any installation of the section with water coil HRS_CS page 14

3.8 Hydraulic connection of the section with water coil HRS_CS page 15

SECTION 4 - ELECTRIC CONNECTIONS page 15

4.1 Electronic speed adjuster HRS_SC page 16

4.2 Wiring diagrams page 17

SECTION 5 - CONTROLS BEFORE START-UP page 22

SECTION 6 - ROUTINE MAINTENANCE

6.1 Warnings page 22

6.2 Monthly checks

6.3 Yearly checks page 24

SECTION 7 - DISPOSAL page 24

DECLARATION OF CONFORMITY page 25

page 4

Heat Recovery Units Installation, Use and Maintenance Manual

INTRODUCTION

The heat recovery units for horizontal installation are characterised by small dimensions and easy assembly.

The heat recovery units allow to join maximum environmental comfort with sure energy saving.

Forced ventilation must be created in current air conditioning and treatment plants, which leads to the expulsion of treated air,

determining large energy consumption and increase in costs.

The HRS heat recovery unit range intend to solve these problems using a static heat recovery unit that saves more than 50%

of the energy that would otherwise be lost.

SECTION 1 - GENERAL FEATURES

1.1 Manual presentation

This manual states the information and that deemed necessary for transport, installation, use and maintenance of the HRS

range heat recovery units.

The user will find that which is normally useful to know for correct safe installation of the heat recovery units described.

Failure to comply with that described in this manual and inadequate installation of the heat recovery unit causes the annulment

of the warranty that the Manufacturer gives its heat recovery units. Moreover, the Manufacturer is not liable for any direct and/or

indirect damage due to incorrect installation or damage caused by units installed by unskilled and unauthorised staff. On purchase, check that the machine is integral and complete.

Any claims must be made in writing within 8 days from receipt of the goods.

1.2 Construction features

• Panels realised in Aluzink sheet steel, removable for inspection and maintenance.

• Acoustic and heat insulation of the panels using polyethylene/polyester with average thickness of 20 mm.

• Fresh air intake and double intake centrifugal type expulsion fans (for the HRS 30 model with simple intake) with directly coupled electric motor.

• Fan body mounted onto anti-vibration mounts so as not to transmit any vibrations.

• Air filters with G3 efficiency, easily extractable laterally, to allow periodical cleaning.

for the HRS range

• Terminal boards on machine to ease the electric connections and fan control.

• Condensate drip tray in ABS with low condensate drain connection.

page 5

Heat Recovery Units Installation, Use and Maintenance Manual

1.3 HRS possible orientations and clearance

• STANDARD ORIENTATION TYPE 03

Depending on the configuration of the network and the space available, it is possible to choose the other 3 orientations

AT THE TIME OF PLACING THE ORDER, (TYPE 01 - 02 - 04).

Heat Recovery Units Installation, Use and Maintenance Manual

page 6

Gli orientamenti raffigurati sono relativi alla macchina vista dall’alto

La batteria di post-riscaldamento (ad acqua) disponibile solo sulla versione HRS-W /

The configurations are referred to the top view

The post-heating water coils is available only for model HRS-W

ORIENTAMENTO TIPO 01 / CONFIGURATION TYPE 01

ORIENTAMENTO TIPO 02 / 02

ORIENTAMENTO TIPO 03 /

(Tipo standard / )$')-&)

ORIENTAMENTO TIPO 04 /

Aria espulsa / Exhaust air

Aria di rinnovo / Fresh air

Aria espulsa / Exhaust air

Aria di rinnovo / Fresh air

Aria espulsa / Exhaust air

Aria di rinnovo / Fresh air

Aria espulsa / Exhaust air

Aria di rinnovo / Fresh air

Orientamento 1 e 2 / Configuration 1 and 2 Orientamento 1 e 2 / Configuration 3 and 4

HRS mod. 030 - 060

HRS mod. 090-160-190-230-300-390

La batteria di post-riscaldamento ad acqua disponibile solo sulla versione MRS_W /

T

he post-heating water coils is available only for model HRS-W

Heat Recovery Units Installation, Use and Maintenance Manual

page 7

MODEL

HRS 030 HRS 060

HRS 090

HRS 090W

HRS 160

HRS160W

HRS 190

HRS190W

HRS 230

HRS 230W

HRS 300

HRS 300W

HRS 390

HRS 390W

Size

A mm 990 990 1140 1300 1380 1650 1650 1750

B mm 290 290 410 500 500 600 600 600

C mm 750 750 860 860 960 1230 1230 1230

D mm / / 260 290 310 410 410 410

D1 mm / / 95 77 87 91 91 116

E mm / / 210 310 330 410 410 410

F mm / / 220 225 225 288 321 321

F1 mm / / 115 109 129 152 135 160

G mm / / 200 255 255 255 280 280

G1 Ø gaz / / 3/4 3/4 3/4 3/4 3/4 3/4

Y mm / / 50 75 75 162 125 125

Ø mm 160 200 / / / / / /

Øi mm 460 355 / / / / / /

Weight kg 41 45 80 125 138 160 174 190

1.4 HRS range unit technical data

1.6 Accessories available

1.5 HRS - HRS W range unit technical data

(1)

Values referring to the nominal air flow rate including recovery unit and filters

(2) Noise pressure level: values referring to 1.5 metres from machine intake in free field. The operational noise level differs from the values indicated according to the functioning conditions, the reflex

noise and peripheral noise

(3) Input power at the electric mains.

(4) Can be adjusted electronically with WM regulator

MODELLO / MODEL HRS 030 060 090 160 190 230 300 390

Portata aria nominale / Nominal air flow m³/h 300 620 920 1580 1850 2250 2950 3920

Pressione statica utile / External static pressure

(1)

Pa 45 55 65 70 77 80 100 100

Assorbimento max. totale macchina / Total max absorbed current

A 0,75 1,8 2,2 4,4 4,8 5,2 8,3 5

Pressione sonora / Sound pressure level

(2)

db (A) 43 51 50 53 52 51 54 56

VENTILATORI / FANS 030 060 090 160 190 230 300 390

Potenza disponibile all'asse / Power input W 92 x 2

(3)

90 x 2 147 x 2 350 x 2 350 x 2 350 x 2 550 x 2 750 x 2

Poli / Poles n° 4

Numero velocità / Speed number n° 1

(4)

3

(5)

1

(6)

Grado di protezione / Enclosure protection IP 44 55 44 55

Classe di isolamento / Insulation class F

Alimentazione elettrica / Electrical supply V/ph/Hz 230/1/50 400/3/50

Heat Recovery Units Installation, Use and Maintenance Manual

page 8

It is possible to intake or expel the air frontally and

laterally by simply changing the position of the

panels, as illustrated at the side.

This can simplify the realisation of the air ducts

greatly, bringing an effective saving to installation

times.

Accessories compatibility

HRS 090 HRS 160 HRS 190 HRS 230 HRS 300 HRS 390

HRS 030 HRS 060 HRS 090W HRS 160W HRS 190W HRS 230W HRS 300W HRS 390W

HRS090CS ✔

HRS160CS ✔

HRS190CS ✔

HRS230CS ✔

HRS300CS ✔

HRS390CS ✔

HRS090ED ✔

HRS160ED ✔

HRS190ED ✔

HRS230ED ✔✔ ✔

HRS090S ✔

HRS160S ✔✔

HRS230S ✔✔ ✔

HRS030SC ✔

HRS060SC ✔

HRS01AT * ✔✔✔✔✔ ✔

PX ✔✔✔✔✔

PX2 ✔✔✔✔✔

* Accessory installed in the factory, compatible only with HRS W version, to be requested when placing the order.

• HRS_CS: Section of water cooling/heating (with

stainless steel condensate drip tray).

• HRS_ED: Regulation shutter.

• HRS_S: N° 4 circular connection kits for direct

connection of the unit to the circular conduits.

- HRS090S (ø 315 mm)

- HRS160S (ø 355 mm)

- HRS230S (ø 400 mm)

• HRS_SC: Electronic speed regulator.Anti-freeze

thermostat, allows to control that the temperature does not fall below a pre-established value. .

Accessory installed in the factory, to be

requested when placing the order for the

HRS W version.

• PX: Control panel with switch-over.

Wall installation. (from size 090 to 300)

• PX2: Control panel with switch-over. Wall instal-

lation (from size 090 to 300)

Heat Recovery Units Installation, Use and Maintenance Manual

page 9

1.7 Accessories technical data

HRS_W UNIT WITH WATER POST-HEATING SECTION

The use of the coil is requested when post-heating is necessary and must be fixed directly inside the heat recovery unit.

Values referring to the following conditions: Water 70/60 °C; Air inp. T = 8°C; Nominal air flow rate.

HRS_ED ADJUSTMENT DAMPER

The adjustment damper is made up from a galvanised sheet steel frame with adjustable louvered fins.

Model B (mm) A (mm)

HRS090ED 260 210

HRS160ED 290 310

HRS190ED 330 310

HRS230-ED 410 410

BATTERIA POST-RISCALDAMENTO

WATER HEATING COIL - BCR

090 160 190 230 300 390

Resa termica / Heating capacity kW 8.2 12.2 14.4 20.3 24.2 29.9

Geometria / Geometry 25x22 25x22 25x22 25x22 25x22 25x22

Tubi per rango / Pipes per row n° 14 18 18 22 22 22

Ranghi / Rows n° 2 2 2 2 2 2

Passo alette / Fins spacing mm 2.5 2.5 2.5 2.5 2.5 2.5

Temp. uscita aria / Outlet air temperature °C 33.4 30.8 30.2 33.2 31.3 29.7

Perdita di carico lato aria / Air pressure drop Pa 25 32 35 24 36 38

Perdita di carico lato acqua / Water pressure drop kPa 8 14 15 17 22 30

Diametro collettori / Connection diameter Ø gas 3/4 3/4 3/4 3/4 3/4 3/4

Peso / Weight kg 2.5 2.5 2.5 5 5 6.5

HRS_CS SECTION WITH WATER COIL

The HRS_CS module contains a water coil and must be positioned outside the machine in front of the introduction vent.

The condensate drip tray in stainless steel with low condensate drain connection.

Model 090 160 190 230 390

A (mm) 500 600 700 700 700

B (mm) 410 500 500 600 600

C (mm) 450 450 480 660 710

D (mm) 260 290 310 410 410

E (mm) 210 310 330 410 410

Ø1 (gas) 3/4" 3/4" 3/4" 3/4" 1"

Ø2 (mm) 22 22 22 22 22

Heat Recovery Units Installation, Use and Maintenance Manual

page 10

HRS with HRS_CS

Geometry

Pipes for row n°

Rows n°

Louver pitch mm

Heating

Heating capacity

(1)

kW

Air outlet temperature °C

Water flow rate m3/h

Water side pressure drops kPa

Air side pressure drops Pa

Cooling

Cooling capacity

(2)

kW

Sensitive cooling capacity kW

Air outlet temperature °C

Water flow rate m3/h

Water side pressure drop kPa

Air side pressure drop Pa

25x22 25x22 25x22 25x22 25x22 25x22

16 22 25 26 26 26

333333

2,1 2,1 2,1 2,1 2,1 2,1

HRS090 HRS160 HRS190 HRS230 HRS300 HRS390

12 19,65 23,7 30,5 37 46,2

45 43,4 45 46,5 43,7 41,5

1,02 1,65 2,08 2,64 3,1 3,73

4 11 20 18 22 21

28 41 39 27 40 53

HRS090 HRS160 HRS190 HRS230 HRS300 HRS390

5 8,8 11,1 14,7 17,4 20,93

3,3 5,8 7,2 9,4 11,4 13,9

19,2 18,9 18,2 17,3 18,3 19,13

0,92 1,65 2,16 2,87 3,2 3,83

4 15 27 26 30 30

38 50 53 45 48 60

HRS – CS TECHNICAL DATA

(1) Values referring to: In/out water 70/60 °C; Air inp. T = 8°C and nominal air flow rate.

(2) Values referring to: Input air temp. 30 °C, RH 50%. In/out water temp. 7/12 - °C. Nominal air flow rate

2.1 Packaging

• The heat recovery unit and their accessories are inserted into cardboard boxes (or polyethylene bubble pack), which

must remain integral until assembly.

2.2 Handling and transport

• Depending on the weight, to handle use suitable means envisioned by the 89/391/EEC Directive and successive

amendments.

• The weight of each individual machine is stated on the following manual.

• Great care must be taken with loading operations. All machines must be loaded and stored on the lorry, positioning

relevant spacers in order to protect all projecting parts such as hydraulic connections, handles and hinges.

2.3 Control and receipt

On receipt of the unit please control al parts in order to check that they have not been damaged during transport.

Any damage must be communicated to the carrier, affixing the reserve clause on the way bill, specifying the type of

damage.

2.4 Storage

In the case of prolonged storage, keep the machines protected from dust and away from sources of vibrations and

heat.

The Manufacturer declines all liability for damage owing to bad draining or no protection from atmospheric

agents.

3.1 Safety Standards

The Manufacturer declines all responsibility for the failure to comply with the Safety and Accident-prevention

Standards described below.

It also declines all liability for damage caused by improper use of the heat recovery unit and/or modifications performed without authorisation.

• Specialised staff must perform installation.

• Wear suitable and accident-prevention clothing during installation, for example: goggles, gloves etc. as indicated in

the 686/89/EEC Standard and successive amendments.

• During installation operate in complete safety, clean environment and free from obstructions.

• Respect the laws in force, in the country in which the machine is installed, relative to use and disposal of packaging

and the products used for cleaning and maintenance of the machine, as well as complying with that recommended

by the producer of these products.

• Before starting the unit, check the perfect integrity of the various components of the entire plant.

• Do not touch moving parts or intervene between these.

• Do not perform maintenance and cleaning until the electric line has been connected.

• The maintenance and replacement of damaged or worn parts must only be performed by specialised staff and following the indications given in this manual.

• The spare parts must correspond to the requirements defined by the Manufacturer.

• If the heat recovery unit must be dismantled, follow the envisioned anti-pollution standards.

N.B. When using the heat recovery unit, the installer and user must consider and solve all risks connected to the

plant. For example, risks deriving from the entry of foreign bodies or risks due to the conveying of dangerous inflammable or toxic gases at a high temperature.

Manuel d'Installation et de Maintenance des Récupérateurs de Chaleur

!

SECTION 2 - TRANSPORT

!

SECTION 3 - INSTALLATION AND START-UP

page 11

3.4 Positioning the machine

Some assembly sequences are illustrated below:

1. Drill the ceiling and fix four M8 threaded tie-rods, as indicated in the figure.

2. Position the unit on the four tie-rods

3. Block the unit by fastening the fixing bolt

Model

HRS

030 060 090 160 190 230 300 390

A (mm) 930 930 1075 1240 1320 1590 1590 1690

B (mm) 690 690 800 800 900 1170 1170 1270

3.2 Preliminary operations

.

• Check the perfect integrity of the various components of the unit.

• Check that the packaging contains the accessories for installation and the documentation.

• Transport the packaged section as near as possible to the place of installation.

• Do not place tools or weights on the packaged unit.

3.3 Choice of place of installation

• Position the heat recovery unit on a solid structure that does not cause vibrations and that can support the weight of

the machine.

• Do not position the unit in places where inflammable gases, acid and aggressive and corrosive substances are present, which can damage the various components irreparably.

• Envision a minimum free space as indicated in the following figures, in order to make installation and routine and

extraordinary maintenance possible.

HRS range models

HRS model 030 060 090 160 190 230 300 390

A (mm) 300 300 350 400 400 450 450 450

page 12

Heat Recovery Units Installation, Use and Maintenance Manual

HRS range models:

with the purpose of favouring the regular flow of condensate, it is advised to mount the machine inclined by 3 mm

towards the condensate drain.

3.6 Hydraulic connections

• The installation and connection operations of the hydraulic pipes are operations that can compromise the good functioning of the plant or worse, cause irreversible damage to the machine. These operations must only be performed

by specialised staff.

3.5 Connection to the ducts

• The ducts must be dimensioned depending on the plant and the aeraulic features of the unit fans. An incorrect calculation

of the ducting causes a loss of power or the intervention of any devices present on the plant.

• It is recommended to use insulated ducts to prevent the formation of condensate and attenuate the noise level.

• To prevent transmission of any machine vibrations into the environment it is recommended top lace an anti-vibration joint

between the fan vents and the ducts. The electrical continuity must however be guaranteed between the duct and the machine via the earth cable.

IMPORTANT: IT IS PROHIBITED TO START THE HRS UNIT IF THE FAN VENTS ARE NOT DUCTED OR PROTECTED WITH ACCIDENT-PREVENTION

MESH ACCORDING TO UNI 9219 STANDARD AND SUCCESSIVE AMENDMENTS

%$$()'"$%$$)"%$'$

• The HRS range units are all equipped with condensate drip tray.

• The stainless steel condensate drip tray has a drain with D. 21 mm.

• The drain system must have a suitable siphon for preventing the undesired entry of air

into the depressurised systems or the undesired exit of air in pressurised systems. This

siphon is also useful to prevent the infiltration of odours or insects.

• The dimensioning and the version of the siphons in the case of the depressurised tray

(or pressurised) must guarantee that H>P, where P expressed in mm.w.c. is equal to the

useful static pressure of the machine installed (figure at the side).

• The siphon must finally have a cap for cleaning the lower part or must however allow

quick disassembly for periodical cleaning.

• The route f the condensate drain pipe must always slope towards the outside. It must

also be as short as possible and with the least number of bends.

page 13

Heat Recovery Units Installation, Use and Maintenance Manual

• Always make sure that the condensate flow pipe does not stress the unit drain connection, envisioning appropriate bracketing if necessary.

• The position of the drain is made clear in the following table

HRS range models

• To access the drain, remove the base counter panel as highligh-

ted in the figure at the side.

Model

HRS

030 060 090 160 190 230 300 390

A (mm) 355 315 640 810 840 965 965 965

B (mm) 225 195 250 250 151 290 290 290

Hole (mm) 28 28 28 28 28 28 28 28

$-"$()##)"%$%)!()"%$+")!+)'%"#

A plastic bag is also supplied with the section with water coil. It contains:

- n. 4 anti-vibration mounts

- n. 4 attachment brackets

- n. 8 M8 x 20 screws

- n. 4 notched washers diam. 8 mm.

%(")"%$"$

• The section with water coil must be positioned in front of the machine flow vent.

The collector marked by the "WATER OUTLET" label must be at the side of the machine (1)

• Remove the side panel of the section with water coil, loosening the screw fasteners (2)

• Partially tighten the 4 M8 screws into the inserts present at the tops of the machine event (3)

• Hitch the section with water coil to the machine, passing the head of the projecting screws through the holes and

push the section down, in a way that the head of the screws is blocked in the upper part of the hole. Access the 4

screw fasteners from the side of the section and tighten them (4)

• Fix the side of the section again (5)

"#"$ ",)*'

• Fix the supplied brackets to the section using the 4 M8 screws to be

tightened in the relevant inserts (6)

• Fix four threaded M8 tie-rods to the ceiling in correspondence with

the brackets. Block the unit by tightening the fixing bolts (7)

1

2 3

4

5 6

7

Attention: the installation of the section with water coil leads to additional pressure drops

in the introduction circuit. These drops are stated in the table on page 9 (“Coil air side pressure drop”)

page 14

Heat Recovery Units Installation, Use and Maintenance Manual

Heat Recovery Units Installation, Use and Maintenance Manual

page 15

-'*#"%$$)"%$%)!()"%$+")!+)'%"#

• The installation and connection operations of the pipes are operations that can compromise the good functioning of the plant or worse, cause irreversible damage to the machine. These operations must only be performed by specialised

staff.

• The section with water coil is supplied with "male" connections with gas threading.

• Tightening must be performed carefully to prevent damage to the copper collectors in the coil.

• The route of the pipes must be studied in a way not to create obstacles if the unit coil is extracted.

• Water inlet/outlet must be such to allow countercurrent heat exchange: follow the indications of the WATER INLET and WATER

OUTLET plates

• Envision a high vent valve and a low discharge valve.

• Clamp the pipes adequately to the outside of the section to prevent the weight being unloaded onto the coil.

• When connection has been made, push the external gasket well against the panel to prevent seepage of air.

• Insulation must be flush to the panel in order to prevent the danger of condensation.

• Envision anti-freeze device.

• Envision on-off valves to isolate the coil from the rest of the circuit in the case of extraordinary maintenance.

• In the case of installation in zones with particularly cold climates, empty the plant for long standstill periods.

3.8.1 Condensate drain connection of the section with water coil HRS_CS

• The stainless steel condensate drip tray has a drain with external

diameter of 22 mm.

• The drain system must have a suitable siphon in order to prevent

the undesired entry of air into the depressurised system. This

siphon is also useful to prevent the infiltration of odours or

insects.

• The dimensioning and version of the siphon must guarantee that

H ³ P, where P expressed in mm.w.c and equal to the useful static pressure of the machine installed.

• The siphon must finally have a cap for cleaning the lower part or

must however allow quick disassembly for cleaning.

• The route of the condensate drain pipe must always slope

towards the outside.

• Make sure that the condensate flow pipe does not stress the unit

drain connection.

SECTION 4 - ELECTRIC CONNECTIONS

• The electric connections to the control board must be made by specialised staff according to the diagrams supplied.

• Make sure that the voltage and the frequency stated on the plate correspond with those of the electric connection

line.

• The use of adapters, multiple sockets and/or extensions is not allowed to power the heat recovery unit.

• It is the installer's responsibility to assemble the unit as near as possible to the power supply isolator and

the necessary to protect the electric parts.

• Connect the unit to an efficient earth socket, using the relevant screw inserted in the unit itself.

Before starting any operation, make sure that the main power supply line has been isolated

Make the connection using cables with suitable section for the power used and in compliance with the local

regulations. Their dimension must be such to realise a voltage drop in the start-up phase, lower by 3% of the

nominal value

4.1 Electronic speed adjuster HRS_SC (mod. 30 - 60)

The speed adjuster is suitable for wall installation and allows the adjustment of the fan with one-speed single-phase

motor. Two adjuster models are envisioned according to the fan motor input current: HRS 030SC and HRS060SC.

The following are present on the front of the contropanel:

• on/off switch

• knob for continuous speed adjustment.

Installation et montage

1. Loosen the 4 screw fasteners and slide out the cap;

2. Fix the small base to the wall using the relevant

holes, at about 1.5 metres from the floor;

3. Make the electric connections;

4. Re-position the cap and tighten the screws.

holes

for wall fixing

cap screw

fasteners

cap screw

fasteners

page 16

Heat Recovery Units Installation, Use and Maintenance Manual

Heat Recovery Units Installation, Use and Maintenance Manual

page 17

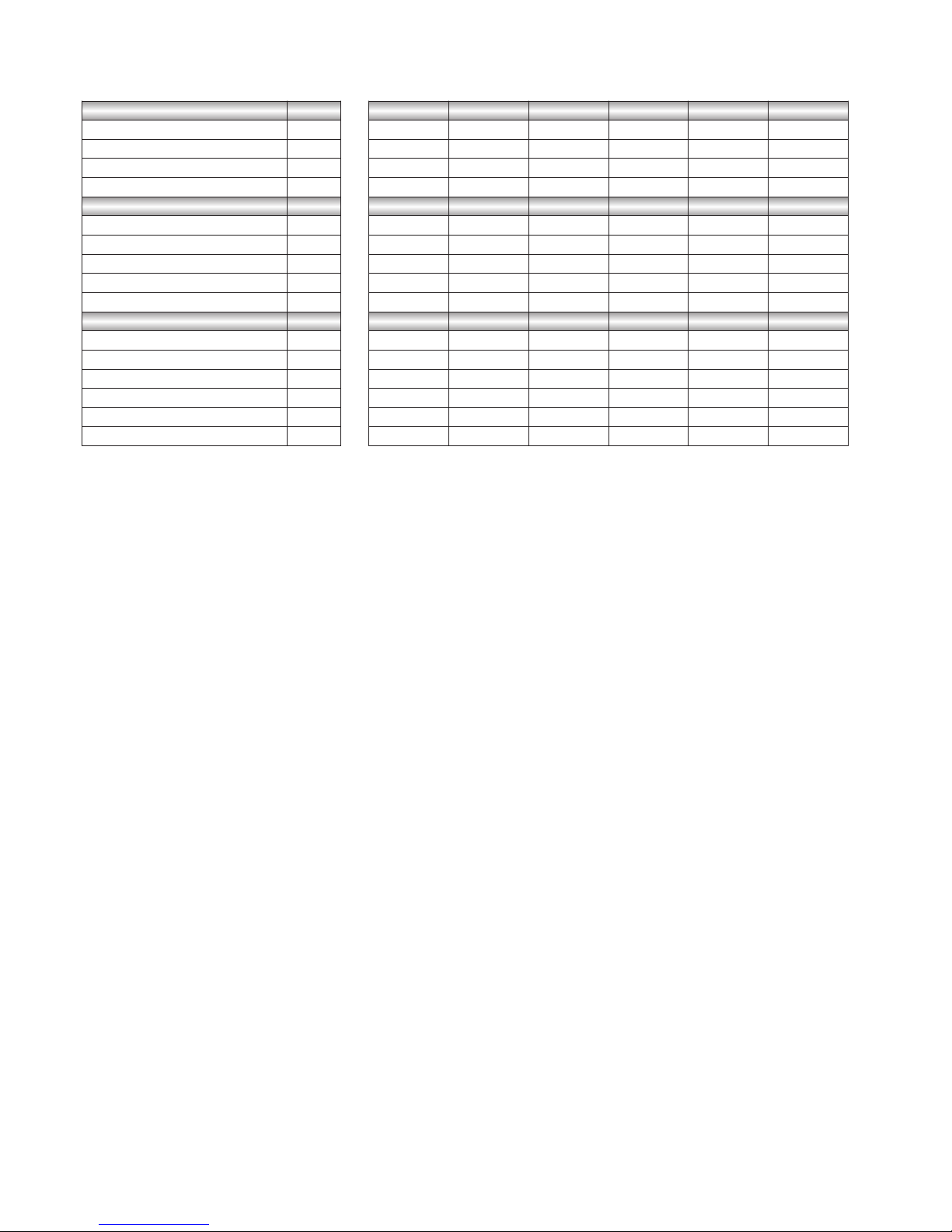

4.2 Wiring diagrams

HRS 030 – 060 WITH ELECTRONIC ADJUSTER HRS_SC WIRING DIAGRAM

HRS 030 – 060 DIRECT WIRING DIAGRAM

A tratteggio sono evidenziati i collegamenti da effettuarsi a cura dell’installatore. / Dashed lines show the connections to be carried out by the installer.

Tutte le linee devono essere protette all’origine a cura dell’installatore. / All lines must be protected at the origin by the installer.

A tratteggio sono evidenziati i collegamenti da effettuarsi a cura dell’installatore. / Dashed lines show the connections to be carried out by the installer.

Tutte le linee devono essere protette all’origine a cura dell’installatore. / All lines must be protected at the origin by the installer.

FACTORY CONNECTIONS

FACTORY CONNECTIONS

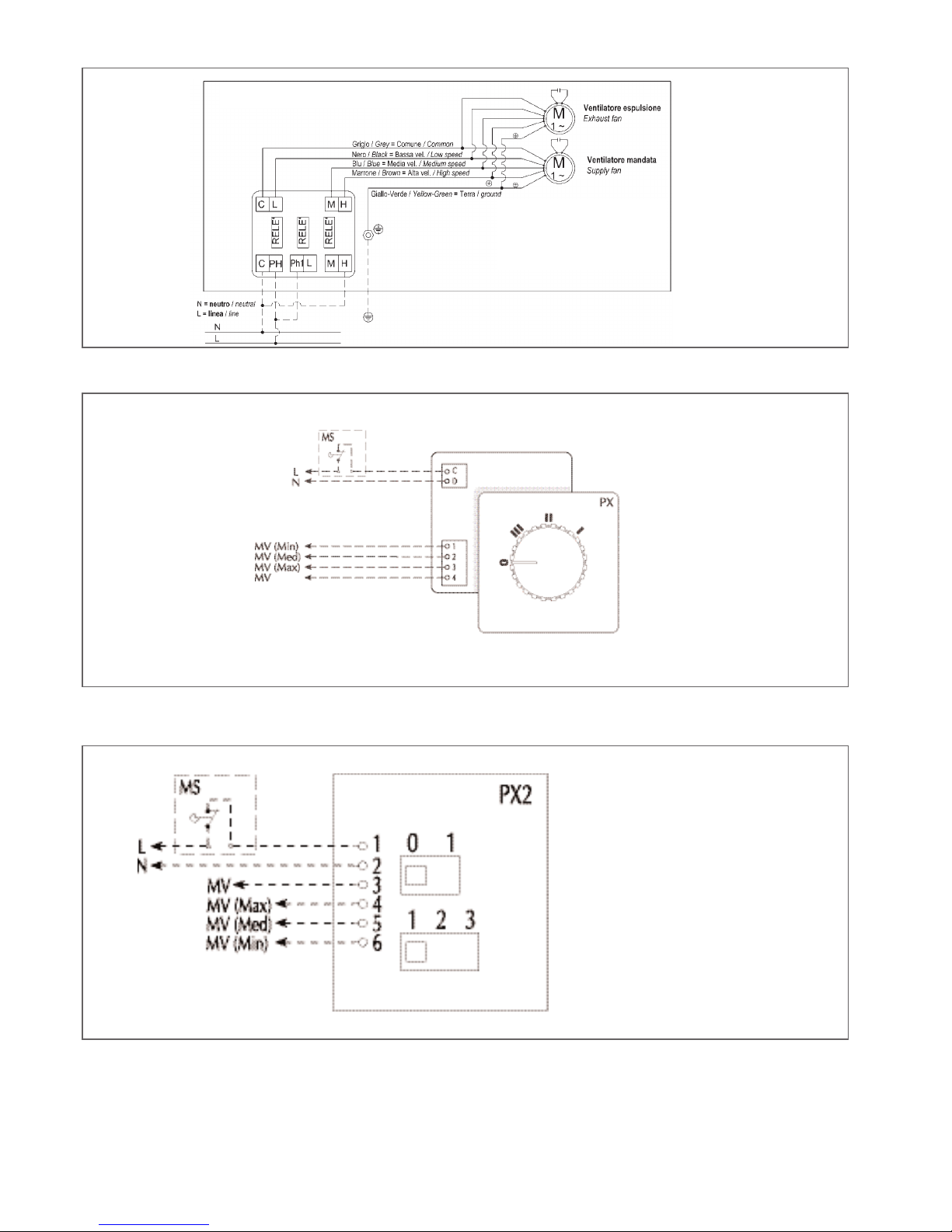

HRS 090 - 160 - 190 WITH SPEED SELECTOR SWITCH PX WIRING DIAGRAM

HRS090 - 160 - 190 DIRECT WIRING DIAGRAM

HRS 090 - 160 - 190 WITH SPEED SELECTOR SWITCH PX2 WIRING DIAGRAM

Nello schema è indicato il funzionamento alla massima

velocità.Per il funzionamento

alla media velocità collegare il

neutro con il morsetto M, per

la bassa con il morsetto L.

The diagram shows operation

at the high speed. For the

medium speed connect the

neutral with clamp named M,

for the low speed with clamp

named L.

FACTORY CONNECTIONS

A tratteggio sono evidenziati i collegamenti da effettuarsi a cura dell’installatore.

Tutte le linee devono essere protette all’origine a cura dell’installatore.

Dashed lines show the connections to be carried out by the installer.

All lines must be protected at the origin by the installer.

C = comune ventilatori / common fan

Ph = fase / phase

Ph1 = comune relé / common relays

L = bassa velocità / low speed

M= media velocità /medium speed

H= alta velocità / high speed

The connections that the installer must make are

dotted.

All lines must be protected at the origin by the

installer.

Dashed lines show the connections to be carried

out by the installer.

All lines must be protected at the origin by the

installer.

page 18

Heat Recovery Units Installation, Use and Maintenance Manual

A tratteggio sono evidenziati i collegamenti da

effettuarsi a cura dell’installatore.

Tutte le linee devono essere protette all’origine a

cura dell’installatore.

Dashed lines show the connections to be carried

out by the installer.

All lines must be protected at the origin by the

installer.

HRS 230-300 DIRECT WIRING DIAGRAM

HRS 230-300 WITH SPEED SELECTOR SWITCH HRS_SC WIRING DIAGRAM

FACTORY CONNECTIONS

Nello schema è indicato il funzionamento alla massima velocità.

Per il funzionamento alla media

velocità collegare il neutro con il

morsetto M, per la bassa con il

morsetto L.

The diagram shows operation at

the high speed. For the medium

speed connect the neutral with

clamp named M, for the low speed

with clamp named L.

A tratteggio sono evidenziati i collegamenti da effettuarsi a cura dell’installatore.

Tutte le linee devono essere protette all’origine a cura dell’installatore.

Dashed lines show the connections to be carried out by the installer.

All lines must be protected at the origin by the installer.

C = comune ventilatori / common fan

Ph = fase / phase

Ph1 = comune relé / common relays

L = bassa velocità / low speed

M= media velocità /medium speed

H= alta velocità / high speed

A tratteggio sono evidenziati i collegamenti da effettuarsi a cura dell’installatore.

Tutte le linee devono essere protette all’origine a cura dell’installatore.

Dashed lines show the connections to be carried out by the installer.

All lines must be protected at the origin by the installer.

C = comune ventilatori / common fan

Ph = fase / phase

Ph1 = comune relé / common relays

L = bassa velocità / low speed

M= media velocità /medium speed

H= alta velocità / high speed

page 19

Heat Recovery Units Installation, Use and Maintenance Manual

HRS 230 - 300 WITH SPEED SELECTOR SWITCH PX WIRING DIAGRAM

A tratteggio sono evidenziati i collegamenti da effettuarsi a cura dell’installatore.

Tutte le linee devono essere protette all’origine a cura

dell’installatore.

Dashed lines show the connections to be carried

out by the installer.

All lines must be protected at the origin by the

installer.

HRS390 THREE-PHASE DIRECT WIRING DIAGRAM

page 20

Heat Recovery Units Installation, Use and Maintenance Manual

HRS 230-300 WITH SPEED SELECTOR SWITCH PX2 WIRING DIAGRAM

A tratteggio sono evidenziati i collegamenti da effettuarsi a cura dell’installatore.

Tutte le linee devono essere protette all’origine a cura

dell’installatore.

Dashed lines show the connections to be carried

out by the installer.

All lines must be protected at the origin by the

installer.

A tratteggio sono evidenziati i collegamenti da effettuarsi a cura dell’installatore.Tutte le linee devono essere protette all’origine a cura dell’installatore.

Dashed lines show the connections to be carried out by the installer. All lines must be protected at the origin by the installer.

FACTORY CONNECTIONS

page 21

Heat Recovery Units Installation, Use and Maintenance Manual

HRS390 THREE-PHASE DIRECT WIRING DIAGRAM

A tratteggio sono evidenziati i collegamenti da effettuarsi a cura dell’installatore.Tutte le linee devono

essere protette all’origine a

cura dell’installatore.

Dashed lines show the connections to be carried out

by the installer. All lines

must be protected at the

origin by the installer.

FACTORY CONNECTIONS

HRS390 THREE-PHASE DIRECT WITH STAR DELTA SWITCH-OVER STC WIRING DIAGRAM

A tratteggio sono evidenziati i collegamenti da effettuarsi a cura dell’installatore.Tutte le linee devono

essere protette all’origine a

cura dell’installatore.

Dashed lines show the connections to be carried out

by the installer. All lines

must be protected at the

origin by the installer.

FACTORY CONNECTIONS

SECTION 5 - CONTROLS BEFORE START-UP

Check the following before starting the unit:

• Anchorage of the unit to the ceiling or the wall.

• Connection of the aeraulic ducts.

• Connection and continuity of the earth cable.

• Tightness of all electric clamps.

SECTION 6 - ROUTINE MAINTENANCE

6.1 Warnings

• The customer must carry out maintenance on the heat recovery unit.

• Only authorised, previously trained and qualified staff can perform the maintenance operations.

• If the unit must be disassembled, protect the hands using work gloves.

6.2 Monthly checks

6.2.1 Check the HRS range filtering section

BEFORE UNDERTAKING ANY MAINTENANCE OPERATION, MAKE SURE THAT THE MACHINE IS NOT AND

CANNOT BE CASUALLY OR ACCIDENTALLY BE POWERED ELECTRICALLY. IT IS THEREFORE NECESSARY

TO REMOVE THE ELECTRIC POWER SUPPLY EVERY TIME MAINTENANCE IS PERFORMED.

page 22

Heat Recovery Units Installation, Use and Maintenance Manual

6.2.2 HRS range other checks

• Check the heat recovery unit

Check that the plate heat exchanger is free from all impurities that could lower its efficiency greatly.

• Check the condensate drain

Remove the lateral panel and if necessary remove the deposits and impurities that have formed in the condensate

drip tray. Also check siphon efficiency.

• Check the water coils

Check that the exchange coils (special version and accessory) are clean and in perfect working order in order to guarantee the normal performance.

Once cleaned, repeat the operations in the reverse order.

Always remember to re-mount the filter before re-starting the unit.

page 23

Heat Recovery Units Installation, Use and Maintenance Manual

SECTION 7 - IDENTIFYING BREAKDOWNS

SECTION 7 - DISPOSAL

At the end of their life span the heat recovery units in the HRS - HRS W range must be disposed of in compliance

with the Standards in force. In particular, the European Community Directive 2002/96/CE regarding electric and electronic appliance waste, prescribe the disposal out of the normal flow of solid urban waste. The appliances that are no

longer used must be collected separately in order to optimise the rate of recovery and recycling of the materials of

which they are made and to prevent potential damage to the health and environment.

The materials making up the heat recovery units are:

• Aluzink sheet steel

• Galvanised sheet steel

• Aluminium

• Copper

• Polyurethane

• Polyethylene

• Plastic

• Stainless steel

If the breakdown cannot be easily solved, disconnect the appliance from the electric power supply and contact the

after-sales assistance or the nearest authorised dealer, stating the identification data of the unit stated on the relative plate.

SYMPTOMS POSSIBLE CAUSES

The fans do not work

The power supply is not inserted.

The thermostat switches are not in the exact functioning position.

There are foreign bodies that block the rotors.

Loosened electric connections.

Motor out of absorption

Static pressure at that requested and therefore excessive flow rate: it is possible to

intervene by increasing the load using dampers and adjusters.

Rotation speed too fast.

Excessive air flow rate

System pressure drops over-estimated.

Low air flow rate

System pressure drops under-estimated.

Obstructions in the ducts.

Rotation speed too slow: check that the connection is correct on the motor terminal

board and also that the voltage corresponds to that on the plate.

The rotor turns in reverse.

Noise

Excessive flow rate.

Wear or cracks in the bearings.

Unbalanced fan.

Presence of foreign material in the auger.

Strong vibrations

Rotor unbalanced due to wear or deposits of dust.

The rotor rubs against the auger due to deformations.

Obstructions in the ducts.

The heat exchanger does

not turn

The power supply is not inserted.

The plug that feeds the induction motor is not connected.

There are foreign bodies that block the rotor.

The electric connections have loosened.

page 24

Heat Recovery Units Installation, Use and Maintenance Manual

6.3 Yearly checks

• Check all electric appliances and particularly the tightness of the electric connections.

• Check the tightness of all bolts, nuts, flanges and water connections that vibrations may have loosened.

Heat Recovery Units Installation, Use and Maintenance Manual

page 25

HRS - HRSW

SERIAL NUMBER

CE DECLARATION OF CONFORMITY

The company named

AERMEC S.p.a.

With Legal Offices in Via Roma, 996

37040 Bevilacqua (VR)

ITALIY

DECLARES

under its own responsibility that

the HRS HRSW heat recovery units

are in compliance with that prescribed by the following Directives:

- Directive for electromagnetic compatibility EMC 2004/108/CE and successive amendments

- 98/37/CE Machinery Directive and successive amendments according to attachment II paragraph B

The unit, subject of this declaration, cannot be put into service before the machine or plant in which it is incorporated has been

declared in compliance with the provisions of the 98/37/CE Machinery Directive and its successive amendments.

This declaration looses all validity in the case of improper use or any modifications, we have not authorised, made to the unit.

Bevilacqua, 01.04.09

Directeur commercial

Luigi Zucchi

Heat Recovery Units Installation, Use and Maintenance Manual

page 29

Heat Recovery Units Installation, Use and Maintenance Manual

page 30

Heat Recovery Units Installation, Use and Maintenance Manual

page 31

Loading...

Loading...