MANUALE D’USO E INSTALLAZIONE

USE AND INSTALLATION MANUAL

MANUEL D'UTILISATION

ET D'INSTALLATION

BEDIENUNGS- UND

INSTALLATIONSANLEITUNG

MANUAL DE USO E INSTALACIÓN

CORNICE DI MANDATA E D’ASPIRAZIONE INVERTER

DELIVERY AND INTAKE FRAME INVERTER

GRILLE DE SOUFFLAGE ET D'ASPIRATION INVERTER

AUSBLAS- UND ANSAUGGITTER INVERTER

PLAFON DE ENVÍO Y DE ASPIRACIÓN INVERTER

GLLI10N

GLLI20N

AGLLI10/20NFJ 07/11_4528572_00

OSSERVAZIONI

Conservare i manuali in luogo asciutto, per evitare il deterioramento, per almeno 10 anni per eventuali riferimenti futuri.

Leggere attentamente e completamente tutte le informazioni contenute in questo manuale. Prestare particolarmente attenzione alle norme d’uso accompagnate dalle scritte

“PERICOLO” o “ATTENZIONE” in quanto, se non osservate,

possono causare danno alla macchina e/o a persone e cose.

Per anomalie non contemplate da questo manuale, interpellare

tempestivamente il Servizio Assistenza di zona.

L'apparecchio deve essere installato in maniera tale da

rendere possibili operazioni di manutenzione e/o riparazione.

REMARKS

Store the manuals in a dry location to avoid deterioration, as

they must be kept for at least 10 years for any future reference.

All the information in this manual must be carefully read and

understood. Pay particular attention to the operating standards with “DANGER” or “WARNING” signals as failure to

comply with them can cause damage to the machine and/or

persons or objects.

If any malfunctions are not included in this manual, contact the

local After-sales Service immediately.

La garanzia dell'apparecchio non copre in ogni caso i costi

dovuti ad autoscale, ponteggi o altri sistemi di elevazione che

si rendesero necessari per effettuare gli interventi in garanzia.

AERMEC S.p.A. declina ogni responsabilità per qualsiasi danno

dovuto ad un uso improprio della macchina, ad una lettura

parziale o superficiale delle informazioni contenute in questo

manuale.

Alcune immagini potrebbero illustrare particolari forniti come

accessori a pagamento.

Il numero di pagine di questo manuale è:

The apparatus must be installed in such a way that maintenance and/or repair operations are possible.

The apparatus's warranty does not in any case cover costs due

to automatic ladders, scaffolding or other lifting systems necessary for carrying out repairs under guarantee.

AERMEC S.p.A. declines all responsibility for any damage

whatsoever caused by improper use of the machine, and a partial or superficial acquaintance with the information contained

in this manual.

The number of pages in this manual is :

REMARQUES

Conserver les manuels dans un endroit sec, afin d’éviter leur

détérioration, pendant au moins 10 ans, pour toutes éventuelles

consultations futures.

Lire attentivement et entièrement toutes les informations contenues dans ce manuel. Prêter une attention particulière aux

normes d’utilisation signalées par les inscriptions “DANGER”

ou “ATTENTION”, car leur non observance pourrait causer un

dommage à l’appareil et/ou aux personnes et objets.

Pour toute anomalie non mentionnée dans ce manuel, contacter aussitôt le service après-vente de votre secteur.

HINWEISE

Bewahren Sie die Gebrauchsanleitungen mindestens 10 Jahre für eventuelles zukünftiges Nachschlagen an einem trockenen Ort auf.

Alle in diesem Handbuch enthaltenen Informationen aufmerksam und vollständig lesen. Insbesondere auf die

Benutzungsanweisungen mit den Hinweisen "VORSICHT" oder

"ACHTUNG" achten, da deren Nichtbeachtung Schäden am

Gerät bzw. Sach- und Personenschäden zur Folge haben kann.

Bei Betriebsstörungen, die in dieser Gebrauchsanweisung nicht

aufgeführt sind, wenden Sie sich umgehend an die zuständige

Kundendienststelle.

Lors de l'installation de l'appareil, il faut prévoir l'espace

nécessaire pour les opérations d'entretien et/ou de réparation.

La garantie de l'appareil ne couvre pas les coûts dérivant de

l'utilisation de voitures avec échelle mécanique, d'échafaudages ou d'autres systèmes de levée employés pour effectuer des

interventions en garantie.

AERMEC S.p.A. décline toute responsabilité pour tout dommage dû à une utilisation impropre de l’appareil et à une lecture

partielle ou superficielle des informations contenues dans ce

manuel.

Ce manuel se compose de pages:

Das Gerät so aufstellen, dass Instandhaltungs- und/oder

Reparaturarbeiten durchgeführt werden können.

Die Garantie des Gerätes deckt in keinem Fall Kosten für

Feuerwehrleitern, Gerüste oder andere Hebesysteme ab, die

sich für die Garantiearbeiten als erforderlich erweisen sollten.

Die AERMEC S.p.A. übernimmt keine Haftung für Schäden aus

dem unsachgemäßen Gebrauch des Gerätes und der teilweisen

oder oberflächlichen Lektüre der in diesem Handbuch enthaltenen Informationen.

Die Seitenanzahl diese Handbuches ist: Nr. Seiten

OBSERVACIONES

Guarde los manuales en un lugar seco para evitar su deterioro,

al menos durante 10 años, por si fuera posible consultarlos en

el futuro.

Leer atenta y completamente todas las informaciones contenidas en este manual. Preste particular atención a las normas de uso acompañadas de las indicaciones “PELIGRO” o

“ATENCIÓN” puesto que, si no se cumplen, pueden causar el

deterioro de la máquina y/o daños personales y materiales.

En caso de anomalías no contempladas en este manual, contacte inmediatamente con el Servicio de Asistencia de su zona.

El aparato debe ser instalado de manera que haga posibles las

operaciones de mantenimiento y/o reparación.

En cualquier caso, la garantía del aparato no cubre los costes

derivados del uso de escaleras automáticas, andamios u otros

sistemas de elevación necesarios para efectuar las intervenciones en garantía.

AERMEC S.p.A. declina cualquier responsabilidad por cualquier daño debido a un uso impropio de la máquina, o bien a

una lectura parcial o superficial de las informaciones contenidas en este manual.

Número de páginas de este manual:

CONTENTS

WARNING: The suction and delivery

English

grille GLLIN is an accessory that must

be connected to the electronic cards

applied to fan coils. Consult the manuals of the fan coils and cards (if they

have been provided as an accessory),

and apply all safety precautions indicated for the electronic cards.

WARNING: the fan coil is connected

to the power supply and water circuit.

Operations performed by unqualified

personnel can lead to personal injury

to the operator or damage to the unit

and surrounding objects.

WARNING Components sensitive

to static electricity may be destroyed

by voltages notably lower than those

at the human perception threshold.

These voltages form when you touch a

component or electric contact of a

unit, without first discharging accumulated static electricity from your body.

The damage caused to the unit by an

overvoltage is not immediately evident

- it only appears after a certain period

of operation.

STATIC ELECTRICITY

ACCUMULATION

Any person not connected in a conduc-

tive manner with the electronic potential of his surrounding environment can

accumulate electrostatic charges.

STANDARD PROTECTION

AGAINST ELECTROSTATIC CHARGES

Earthing quality

When working with units sensitive to

electrostatic electricity, ensure that

people, workplaces and unit casings

are correctly earthed. This will prevent

the formation of electrostatic charges.

Avoid direct contact

Only touch the element exposed to elec-

trostatic risk when absolutely essential

(e.g. for maintenance).

Touch the element without coming into

contact with either the contact pins or

the wire guides. If you follow this rule,

the energy of the electrostatic charges

cannot reach or damage the sensitive

parts.

Before taking measurements on the unit,

it is necessary to discharge all elec-

trostatic charges from your body: to

do this, just touch an earthed metal

object. Only use earthed measuring

instruments.

MALFUNCTIONING

In the case of malfunctioning remove

the power to the unit then re-power it

and start the apparatus up again. If the

problem occurs again, call your areas

After-Sales Service promptly.

DO NOT PULL THE WIRES

It is highly dangerous to pull, crush or

tread on the electric cables, or to fix

them with nails or drawing pins.

A damaged power cable can cause short

circuits and injure people.

WARNING: Avoid any use of the device

by children or incompetent persons

without appropriate supervision; also

note that the unit should not be used

by children as a toy.

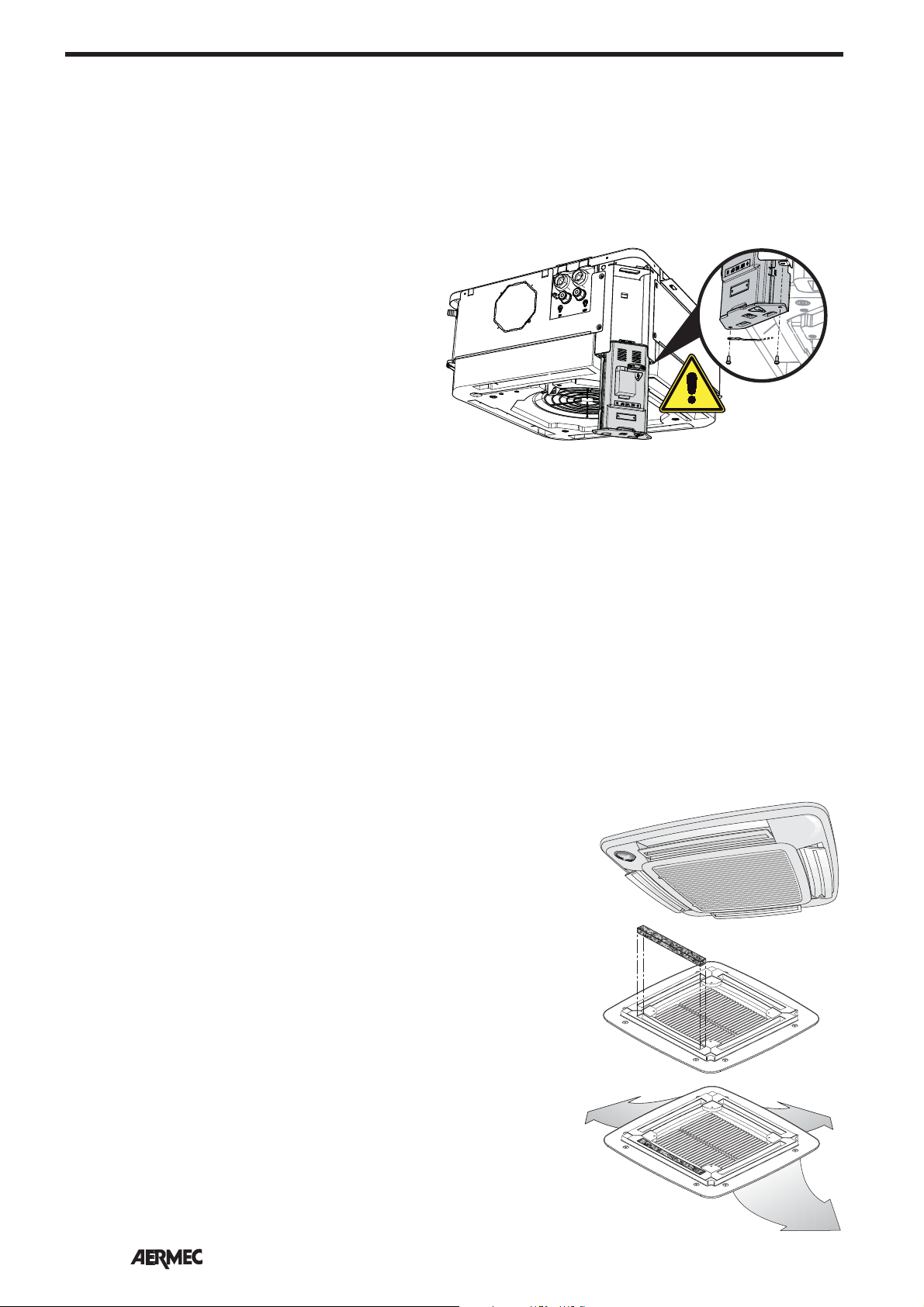

DESCRIPTION

GLLI10N (600x600)

GLLI20N (840x600)

Intake and delivery grille unit with

"VMF System" advanced electronic

thermostat.

The grille is part of the GLLI-N range

grille unit (obligatory accessory).

The form and opening of the suction

louvres were developed in order to

have the best possible distribution

of the air, both when functioning in

winter as well as in summer.

Suction occurs through the central grille,

and delivery through the manually

adjustable, perimetric slots. In plastic,

colour RAL 9010, it contains the air

filter that can be easily removed for

cleaning.

GLLI_N needs to be interfaced with an

external control panel VMF-E4 (NOT

SUPPLIED) if installed in a single

"stand alone" FCLI unit or as a master

unit of a fan coil slave network (max

5).If the GLLI_N is combined with

a VMF-E4 control panel ("Master"

configuration), the fan coil can be

connected to a VMF-E5 central

supervisor system.

The FCLI units are available in two basic

sizes, called:

"Module 600" for units integrable in

standard 600x600mm suspended ceiling panelling

"Module 840" for the more powerful ver-

sions (to be housed in a compartment

measuring 840x840mm).

SUCTION AND DELIVERY GRILLE

UNIT

(GLLIN range accessories)

The FCLI cassette-type fan coil is only

complete when used with a grille of the

GLLIN range - an obligatory accessory

for the operation of the fan coil with

the VMF system. The grille accessories

of the GLLIN range not only offer suction with a filter and air delivery fins,

but also include a special electric box.

The form and opening of the delivery

fins were developed in order to have

the best possible distribution of the air,

both when functioning in winter as

well as in summer.

Intake occurs through the central grille,

and delivery through the adjustable,

outer slots. In plastic, colour RAL 9010,

it contains the air filter that can be easily removed for cleaning.

FILTERING SECTION

The air filter is inserted in the suction

grille.

Mechanical air filter with ABS frame.

Filter in filtering class G1, self-

extinguishing class V0 (UL94).

Easily removable and made from regen-

erable materials. May be cleaned by

washing.

24

AGLLI10/20NFJ 07/11_4528572_00

CONFIGURATION WITH THE VMF SYSTEM

VMF-E4 VMF SERIES THERMOSTAT CONTROL PANEL, WALL MOUNTING

Wired control panel, user interface for thermostats incorporated in

GLLI10N and GLLI20N grille units, and for all other VMF range

thermostats.

The panel must be used with VMF range thermostats and operates

a single or networked fan coil (see characteristics of the

combined thermostat)

Wall mounting with connection cable.

Digital display, "Touch" keyboard, only 11mm thick and

VMF-E4

VMF-E4

FCLI + GLLI10N

FCLI + GLLI20N

mounted on the wall in Type 503 recessed electrical boxes

and compatible with the Type 502 boxes, M20 (see installation

manual).

The following can be selected from the control panel:

- Switching the device on and off

- The ventilation speed, in automatic or manual mode

- The room temperature

- The operating mode

The digital display also shows:

- Thermostat On / Off

- The room temperature / set temperature

- The ventilation speed with 3 positions displayed by graduated

bar

- The operating mode

(Automatic / Heating / Cooling)

- The night-time comfort function (Sleep)

- Supervisor controlled operating mode (VMF-E5)

See the accessories manual for complete information on its

features.

English

Example of a TTL local network consisting only of FCLIs

LUNGHEZZA MAX.30 (m)

VMF-E4

FCLI

FCLI

FCLI

Example of a TTL local network consisting of mixed

fan coils

MAX 30m

VMF-E4

FCLI + GLLI10N

FCX + VMF-E1

FCXI + VMF-E18

FCLI + GLLI20N

FCL + GLL10N

FCL + GLL20N

FCLI + GLLI10N

FCLI + GLLI20N

Example of a network with VMF-E5 supervisor consisting only of FCLIs

VMF-E5

MASTER x

FCLI + GLLI10N

FCLI + GLLI20N

FCLI + GLLI10N

FCLI + GLLI20N

VMF-E4

FCLI + GLLI10N

FCLI + GLLI20N

FCLI + GLLI10N

FCLI + GLLI20N

VMF-E4

MASTER 1MASTER 2MASTER 3

FCLI + GLLI10N

FCLI + GLLI20N

FCLI + GLLI10N

FCLI + GLLI20N

VMF-E4

Example of a network with VMF-E5 supervisor consisting only of

mixed fan coils

VMF-E5

MASTER x

MASTER 3

FCX + VMF-E1

FCXI + VMF-E18

VMF-E4

VMF-E4D

MASTER 2

FCLI + GLLI10N

FCLI + GLLI20N

FCL + GLL10N

FCL + GLL20N

VMF-E4

VMF-E4D

MASTER 1

FCLI + GLLI10N

FCLI + GLLI20N

FCL + GLL10N

FCL + GLL20N

VMF-E4

VMF-E4D

FCX + VMF-E1

FCXI + VMF-E18

FCLI + GLLI10N

FCLI + GLLI20N

FCL + GLL10N

FCL + GLL20N

AGLLI10/20NFJ 07/11_4528572_00

FCLI + GLLI10N

FCLI + GLLI20N

FCL + GLL10N

FCL + GLL20N

25

ACCESSORIES VMF SYSTEM SUPERVISION

VMF-E5B / E5N SYSTEM'S MAIN SUPERVISION INTERFACE

English

VMF-E4

VMF-E4D

MASTER 1

FCLI+GLLI_N

RS485

VMF-E5B

VMF-E5N

RS485

VMF-E4 / VMF-E4D

TTL

RS485 MAX 1000m

MASTER 2

FCLI+GLLI_N

WARNING: the VMF-E5 panel allows the management

of the individual masters; the slave units connected

to each master cannot be individually managed from

the VMF-E5 panel, but they acquire the settings of the

master to which they are connected.

RS485

VMF-E4 / VMF-E4D

TTL

MASTER 64

FCLI+GLLI_N

TTL

TTL MAX 30m

• Maximum number of MASTER fan coils = 64

• Maximum number of SLAVE fan coils that can be connected to each MASTER = 5

CONNECTION TO THE RS485 NETWORK

22AWG-3

GLLI_N

22AWG-3

22AWG-3

VMF-E5

VMF-E5

22AWG-3

12Vdc

24Vac

26

AGLLI10/20NFJ 07/11_4528572_00

GLLI_N/VMF-E4 CONNECTION

Connect the VMF-E4 to the GLLI_N thermostat; this connection must be made

using a 4-pole shielded cable (maximum

Characteristics of the cable to be used

for the connection:

• EIB Bus cable,

4 poles + shield;

• Mutual max capacity 100nF/km

(800Hz);

• Resistance max 130 ohm/km;

Key:

A = 4-pole shielded cable (not supplied) for connection between VMF-E4 and GLLI_N;

B = Shield folded on the cable for earth connection;

C = Clamp made of plastic conductive material

(supplied) to be fi xed on the metallic structure

of the fan coil;

D = Poles to be connected to the interface control board (supplied) with the GLLI_N card

length 30 meters); connect the terminals

on the back of the VMF-E4 to the supplied

control board, and complete the connec-

1

2

3

4

TX/RX

GND-TTL

tion by inserting the connector plug in the

dedicated terminal on the GLLI_N card (as

shown).

MODE

5V

English

TX/RX

MODE

GND-TTL

5V

3

4

5

12

6

12

3

4

5

6

AGLLI10/20NFJ 07/11_4528572_00

27

ELECTRONIC BOARD CONNECTION

English

M26 CONTROL BOARD

EXTERNAL CONTACT CONNECTION

(ECONOMY CONTROL)

(WINDOW CONTROL)

TTL-WITH VMF E4

1

2

3

4

5

6

TTL-SERIAL

TX/RX

GND/TTL

MODE

5V

TX/RX

GND

CONNECTION

CE EXTERNAL CONTACT

CE

1

GND

2

CF

3

A

4

B

5

GND

6

ECONOMY

CONTROL

WINDOW

CONTROL

MODBUS

RS485

MODBUS

RS485

TTL NETWORK CONNECTION WITH VMF-E4

28

AGLLI10/20NFJ 07/11_4528572_00

SERIAL TTL NETWORK CONNECTION

IR CONNECTION (THERMOSTAT RECEIVER) 4-PIPE PROBE CONNECTOR CONNECTION

English

The display card will physically connect to the GLLI_N

control box through a 4-pole cable as shown above

CONNECTOR CONNECTION TO THE CONTROL BOARD

M2 L: power supply input of the Voltage

card: 230 Vac, current 10 A

M1 N: power supply input of the

Voltage card: 230 Vac, current 10 A

M3 GND: ground reference

M4 AUX/RE: electric resistor control

output

Voltage:230 Vac, current 10 A

M5 Neutral reference for the AUX/RE

and MA output Voltage: 230 Vac,

current 7 A

M6 MA: fin motor control output

Voltage: 230 Vac, current 5 A

M7 Y2: water valve control output

Voltage: 230 Vac, current 5 A

M8 Y1: water valve control output

Voltage: 230 Vac, current 5 A

M10 Neutral reference for output V1, V2

V3 Voltage: 230 Vac, current 10 A

M11 V3: maximum speed output

Voltage: 230 Vac, current 5 A

M12 V2: average speed output Voltage:

230 Vac, current 5 A

M13 V1: minimum speed output

Voltage: 230 Vac, current 5 A

M14 Support input, not connected

M26 Service control board

M22 Control board for connection to

the receiver

CN2 SW: water probe NTC 10Kohm

CN1 SA: air probe NTC 10Kohm

CN3 SC: auxiliary water probe NTC

10Kohm

M17 Out 0-10V: Inverter reference

Voltage: 10 Vdc, current 10 mA

M18 GND of the inverter reference

Voltage: 10 Vdc, current 10 mA

M19 Out 0-10V Voltage: 10 Vdc, cur-

rent 10 mA

M20 GND Voltage: 10 Vdc, current

10 mA

M21 Fault inverter reading input

Voltage: 10 Vdc, current 10 mA

M25 Connector for expansions

M27,M28 CC: Condensate discharge

motor fault input Voltage: 5 Vdc,

current 0.5 mA

Pauses 2.: Resistor protection fuse

Delayed 10A fuse

M9 Neutral reference for output Y1, Y2

Voltage: 230 Vac, current 10 A

M15, M16 SR: electric resistor tempera-

ture probe NTC 4Kohm 200°C

AGLLI10/20NFJ 07/11_4528572_00

29

DISPLAY CARD OPERATION

The thermostat can be coupled to a

display card which must meet the

English

following requirements:

• LED Interface to view the operating

status of the fan coil (operating mode,

Yellow/Green LED

alarms, probe read-code)

• Starting point of the special commands

such as: correction of the probe reading,

display of the data read by the probes,

display of the alarm log, start of the

Autotest procedure

The new display card must have a layout

as shown in the following figures:

AUX key

Blue/Red LED

COMMANDS START PROCEDURE, FROM AUX KEY

OFF

AUTOTEST

LED

DISPLAY

ALARMS LOG

AUX

V3

V2

CORRECTION

S.A.

AUTOTEST

AUTO

V1

PROBE

READING

KEY

Pressing MODE/SELECT key

(see VMF-E4)

Pressing AUX key

Pressing OFF or MODE/SELECT

key (see VMF-E4)

To exit the test/correction functions an ON/OFF command (via VMF-E4 panel) or a change mode command (AUTO, V1, V2,

V3, AUX) must be given to the cassette.

30

AGLLI10/20NFJ 07/11_4528572_00

AUTOTEST

The activation of the ventilation and the

valve of the branch corresponding to

the operating season, even in unsuitable

water or environment temperature

conditions, can be "forced" in the selftest mode so as to verify the correct

functioning of the connections and the

windings of the electric motor.

English

Pressing

Autotest

of the

AUX key

PROBE READING

Values of the temperature probes

acquired by the electronic card can be

viewed through the yellow and red LED.

In this mode the card enters in the Probe

V1

ON

Pressing

MODE

SELECT

Display mode. Initially the card displays

the value of the Ambient probe SA.

Press the AUX key normally to view

other probes. The number of flashes by

Pressing

of the

AUX key

V2

ON

Autotest Off

Green LED Probe displayed

2 SW probe

3 Aux SW probe

4 SA probe

5 Resistor probe SR

Pressing

of the

AUX key

the green LED indicates which probe is

displayed (see table).

V3

ON

Pressing

MODE

SELECT

ALARMS LOG

The receiver cyclically indicates the last

5 alarms occurred on the machine in the

"alarms log" view mode:

ALARM VISUALISATION

• yellow LED: cyclically flashes 5 times,

and then remains off for 5 seconds

No alarm

Air probe faulty

Anti-freeze

Insufficient water

E4 interface not connected

Inverter fault

Resistor fault

condensate discharge

Motor fuse

• red LED: lights at the same time as the

yellow LED thereby providing a specific

code

Key

Yellow LED

Red LED

Non-encoded signals

AGLLI10/20NFJ 07/11_4528572_00

31

AMBIENT PROBE READING CORRECTION

For installations of cassette fan coils that

use the ambient probe positioned in the

English

LED box, the correction of the probe

reading may be deemed necessary to

improve the thermostat adjustment.

As for the other operations the correc-

SEASON TYPE OF PROBE CORRECTION

Parameters cold and hot can be different from one another and can take

integer values between 0 and 6 [°C].

To set the hot value for example, the

fan coil should be set to “winter” mode,

and in standby: after pressing the AUX

tion of the probe can only be performed

if the fan coil is in standby, the only

difference is the selection of the correction that is linked to the season of the

thermostat.

key (see coding) the receiver goes into

the "probe reading correction" mode displaying the amount of correction:

LED status

Ambient probe temperature - cold

Ambient probe temperature + hot

Correction coldhot

[C°]

0

Key

LED off

Red LED

Blue LED

Green LED

1

2

3

4

5

6

32

AGLLI10/20NFJ 07/11_4528572_00

VENTILATION CONTROL

Thermostat-controlled ventilation: The

choice of the regulation according to

thermostatically controlled ventilation

(dip3 OFF) foresees the switching off

of the ventilation when the setpoint is

reached. (See the dip switch settings

table).

Position Operations

OFF

AUTO On reaching the setpoint, the ventilation proceedes with the minimum continuous speed.

V1

V2

V3

Aux

The thermostat is off. It may however start again in Heating mode if the room temperature falls

below 7°C and the water temperature is suitable (anti-freeze function).

In this position, the minimum ventilation speed V1 is always active regardless of thermostat

requirements.

In this position, the average ventilation speed V2 is always active regardless of thermostat

requirements.

In this position, the maximum ventilation speed V3 is always active regardless of thermostat

requirements.

In this position, the minimum Aux ventilation speed is always

active.

Continuous ventilation: The continuous

ventilation is selected by means of dip3

that must be set to On. In practice the

continuous ventilation provides ventilation even with thermostat fulfilled at the

speed chosen. This function is disabled if

the machine has no shut-off valve (dip1

OFF). In these particular cases, the ven-

tilation will always be managed with

thermostatically controlled logic.

The following table shows the ventilation

speed activated depending on the position of the selector:

English

MINIMUM CONTINUOUS SPEED PARAMETERS

The "minimum continuous speed" is

linked to the position of dip switch 8

(see paragraph on dip-switch settings) in

the table below.

Position Continuous min. speed Cassette type

ON

OFF

8% of the max inverter speed 600 x 600

12% of the max inverter speed 800 x 800

VALVE OPERATION

If a shut-off valve is present (dip1 ON),

the position of the probe can be managed both upstream and downstream of

the valve itself (in the standard position

on the heat exchanger). The main difference between the two is in managing the

ventilation in different ways. If the water

probe is upstream of the valve (dip2

ON) or is not present, a heat exchanger

pre-heating function occurs and enables

the fan 2'40" after the first opening of

the valve.

The valve in question (for the heat

exchanger pre-heating function) is Y1 if

this is a 2-pipe system (dip5 Off), whereas if it is a 4-pipe system it is Y2 (dip5

On).

The inhibition time of the fan is then

automatically calculated and depends

on how long the valve remains closed; in

this way it could vary from a minimum

of 0' 00" to a maximum of 2' 40". This

ventilation enabling delay in relation

to the opening of the valve is reset if

the electric resistor is enabled, this is to

ensure greater user safety.

Refer to the specific table for the specific

parameters of the dip switches.

AGLLI10/20NFJ 07/11_4528572_00

33

HOT/COLD MODE CHANGE OVER

WATER SIDE SEASON CHANGEOVER

English

If the thermostat is configured for use

without a valve (dip1 OFF) or with a

probe upstream of the valve (dip2 ON),

then the water temperature detected is

that available on the terminal, therefore the season is forced to Hot or Cold

according to this temperature.

The thresholds of the season changeover

are shown in the table below.

In this configuration, the indications of

the left LED correspond to the active

mode.

The ventilation is enabled only if the

water temperature is suitable for the

cooling mode or the heating mode. This

allows on one side to avoid unwanted

cold ventilation in the winter season,

and on the other side to check the turning on and off of all terminals, according to the actual condition of the water

available (centralized control of the

On-Off and Hot-Cold commands).

COLD SEASON CHANGEOVER

THRESHOLD

12 °C / 22°C 35 °C / 39 °C

22°C / 25°C 31 °C / 35°C Reduced band (dip 4 on)

VENTILATION ENABLING

The normal band (hot enabled at 39° C,

cold enabled at 17° C) or the reduced

band (hot enabled at 35° C, cold enabled at 22° C) is selected based on the

(dip4).

SEASON CHANGEOVER BASED ON THE AIR

The season changeover of some systems

is based on air temperature, these are:

- 2-pipe systems with the Water Probe

downstream of the valve.

- All 2-pipe systems without water

probe.

- All 4-pipe systems.

The season changeover occurs as follows:

- Cold mode: if the ambient temperature

detected is below the setpoint of an

interval equal to the dead band (2° C

or 5° C) it switches to the hot mode.

- Hot mode: if the ambient temperature

detected is above the setpoint of an

interval equal to the dead band (2° C

or 5° C) it switches to the cold mode.

HOT SEASON CHANGEOVER

THRESHOLD

DIP SWITCH

MEANING

Normal band (dip 4 off)

The dead band is decided through

dip7 or rather if it has a dead band of

5° C (dip7 OFF) while if the dead band

is 2° C (dip7 ON).

ANTI-FREEZE PROTECTION

The anti-freeze protection allows you to

check that the room temperature never

falls to freezing values (even when the

selector is in the OFF position). If the

temperature drops below 7° C, the thermostat still operates in HEATING mode

with SETPOINT at 12° C and ventilation

in AUTO, if the temperature of the water

permits so. In case of Water Probe not

present or continuous ventilation, the fan

34

AGLLI10/20NFJ 07/11_4528572_00

is always enabled. If the valve is present

and the water probe is upstream or the

water probe is absent, the pre-heating of

the heat exchanger is still executed.

The thermostat exits the Anti-freeze

mode when the room temperature

exceeds 9°C.

EXTERNAL CONTACT LOGIC

The thermostat also includes an external

contact that allows to set it to OFF if it

is closed (except if the thermostat is in

anti-freeze mode or as a slave in the TTL

network). This contact could be useful to

manage inputs such as window contacts,

faulty circulation pump, etc.

SLEEP FUNCTION

English

CE input status Machine status

Closed OFF

Open ON

The Sleep function in the thermostat is

available if the thermostat is interfaced

with a presence sensor (with normally

open logic) connected to its SP input. In

practice the function consists in changing the regulation setpoint of the fan coil

if the air-conditioned environment is not

The air side season changeover is inhibited when the SP input is kept closed; this function prevents incorrect status changes

due to the change of the setpoint

occupied; i.e. decreasing if operating

hot, increasing if operating cold. This

function aims at saving energy. In this

specific case, if the thermostat card was

connected to a presence sensor, the logic

of the SP input occurs as follows:

SP input

Open

Closed °C °C °C °C

Dip 7 Off Dip 7 On Dip 7 Off Dip 7 On

Heating Cooling

COMFORT FUNCTION

The set point of centralized systems in

which there are network connected

fan coils, is decided by a central unit.

The user may have the opportunity to

increase or decrease the setpoint according to the table below.

Dead band [°C] Deviation of the setpoint [°C]

2 +/- 3

5 +/- 6

AGLLI10/20NFJ 07/11_4528572_00

35

DIP-SWITCH SETTING

Turn off the power to the unit. This

operation should be carried out in the

English

installation phase, by suitably trained

and qualified personnel only.

The dip-switches are on the electronic

board.

They can be used to obtain the following functions:

Position Functions

Dip 1 (Default OFF) Check water valve / * Thermostat in centralised network (See table):

OFF No shut-off valve

ON Shutoff valve present / * Thermostat in centralised network:

Dip 2 (Default OFF) Position water temperature probe / * Thermostat in centralised network (See table):

OFF Water temperature probe downstream from shutoff valve / *Thermostat in centralised network

ON Water temperature probe upstream from shutoff valve

Dip 3 (Default OFF) Ventilation control:

OFF Thermostat-controlled ventilation

ON Continuous ventilation

Dip 4 (Default OFF) Ventilation enabling:

OFF Enabling normal band

ON Enabling reduced band

Dip 5 (Default OFF) Machine with two or four pipes

OFF

ON 4-pipe fan coils

Dip 6 (Default OFF) the presence of the accessory

OFF Resistance to integration is not present

ON Presence of resistance to integration

Dip 7 (Default OFF) Dead band

OFF Dead band 5° C

ON Dead band 2° C

Dip 8 (Default OFF) Minimum speed:

OFF Inverter minimum speed 55 %, continuous minimum speed 34% (FCLI 8X/12x)

ON Inverter minimum speed 40 %, continuous minimum speed 25% (FCLI 3X/4x/6x)

2-pipe fan coils

**Warning: if the thermostats are

inserted in systems with Centralised

Control or Supervisor (e.g. VMF-E5),

it is necessary to set: Dip1=ON and

Dip2=OFF. The setting takes priority

over the presence of the valve and the

position of the probe.

SOME EXAMPLES:

ON

1 2 3 4 5 6 7 8

SW

VMF_E18 (default)

ON

1 2 3 4 5 6 7 8

* Centralised control enabled

SW

36

ON

OFF

ON

1 2 3 4 5 6 7 8

* With shutoff valve

ON

OFF

AGLLI10/20NFJ 07/11_4528572_00

ON

1 2 3 4 5 6 7 8

SW

SW

FCXI 20 / 30 / 40

ON

OFF

ON

OFF

ON

1 2 3 4 5 6 7 8

* Water probe upstream from the valve

ON

1 2 3 4 5 6 7 8

SW

ON

OFF

ON

OFF

SW

FCXI 50 / 80

ADDITIONAL CONTROLS

EMERGENCY FUNCTIONING

The two following failure cases are fore-

seen when the thermostat operates in

the described manner.

NO WATER PROBE

- Ventilation is always active

- The season change is made on the

basis of the difference between the setting made and the actual ambient temperature. If the ambient temperature

exceeds by a value equal to the dead

band, the Heating setpoint switches to

the Cooling mode. If the ambient temperature drops by a value equal to the

VENTILATION CYCLES OF 2-PIPE SYSTEM WITHOUT AMBIENT PROBE

dead band below the Cooling setpoint,

it switches to the Heating mode.

- The turning on/off of the resistance

does not depend in this case on the

temperature of the water but on the

sheer demand for the thermostat operation

AMBIENT PROBE ABSENT (2 PIPES)

In this case the thermostat operates as

follows:

- OFF - Aux Mode

The valve is closed

SetPoint

Min value Nil '20"

20 C° 2'20" 2'60"

Max value '20" Nil

ON cycle

duration

OFF cycle

duration

The fan is off

English

- AUTO, V1, V2, V3 mode:

The valve is always open.

Operating season always hot.

- The ventilation runs On-Off cycles.

The duration of the ON cycle is proportional to the setpoint set in the

VMF-E4 panel. The total duration of

the ON-OFF cycle corresponds to

5’20’’. The following table gives duration examples of various ON and OFF

cycles based on the position of the

temperature selector:

AMBIENT PROBE ABSENT (4 PIPES)

In this case the thermostat operates as

follows:

OFF - Aux Mode

The valves are closed

The fan is off

- AUTO, V1, V2, V3 mode:

The operating season is decided

according to the position of the temperature selector and it is activated by

the respective valve as shown in the

Figure

The ventilation in this case is always

performed according to the ON-OFF

cycles, however, increasing the ON

phase from the central position. In

this way the maximum ventilation can

be required with the selector at the

Keys used to

modify the

setpoint value

Minimum value Maximum value

SETPOINT

Cold water valve opening, ventilation

period proportional to the deviation

of the median position

minimum position for cooling operation season and likewise there is maximum ventilation with the selector in

the maximum position. For the heating

operation season. The total duration of

the ON-OFF cycle is again 5’20’’. The

Hot water valve opening, ventilation

period proportional to the deviation

of the median position

following table gives duration examples of various ON and OFF cycles

based on the position of the temperature selector:

VENTILATION CYCLE OF THE 4-PIPE SYSTEM WITHOUT AMBIENT PROBE

Position

Min value '20" Nil

20 C° Nil '20"

Max value '20" Nil

ON cycle

duration

OFF cycle

duration

AGLLI10/20NFJ 07/11_4528572_00

37

CASSETTE LOCAL NETWORK

The VMF-FCL thermostat has been designed to communicate with all thermo-

English

stats of the VMF family through a dedicated serial based on standard TTL logic and

low throughput. This serial communication is essential for the exchange of information within small fan coil networks.

This is in fact a network comprising no

more than 6 thermostats with a maximum length of about 30 meters. It was

designed, in fact, for small areas where

the fan coils (more than one) need to be

controlled from a single control point.

More specifi cally, this network always

contains a Master (to which a user interface VMF-E4 is connected) that controls

the operation of the Slaves connected to

it, according to the settings made on its

user interface.

FCLI

SLAVE

LUNGHEZZA MAX.30 (m)

FCLI

SLAVE

FCLI

MASTER

VMF-E4

OPERATING PRINCIPLE

The fan coil master, or rather the one

with the VMF-E4 user interface connected, cyclically transmits the following information subsequently setting

them on the slave units.

- Regulation Setpoint

- Operating mode (OFF, AUTO, V1, V2,

V3, AUX) (on the On/Off machines)

- Operating season

Therefore the slave fan coils can not

operate (except in particular cases)

according to settings different from

those dictated by the master.

AMBIENT PROBE: the ambient control

probe is not needed on slave fan coils because these can use the control probe of

the master. However, if you want to avoid

having micro-climates, it can be installed

on the slaves that will then adjust with

the respective probe. In particular cases

where the ambient probe on the master

is faulty, the slave without probe will operate in emergency mode (similar to the

master), while the slaves with ambient

probe will continue to operate normally.

EXTERNAL CONTACT INPUT: this digital

input is inhibited on all slave fan coils

while it is enabled on the master only. If

the master input is closed, all the slave

fan coils of the zone are switched off.

PRESENCE SENSOR INPUT: the presence

sensor digital input is only active on the

master fan coil

ANTI-FREEZE FUNCTION: the antifreeze mode is the only case in which

a slave that is in this status can operate

according to settings are not provided by

the master.

WATER PROBE: the water temperature

probe can be installed or not on the various fan coils of the TTL network. The fan

coils with probe will use this for foreseen

minimum and maximum values control,

while the ventilation will always be enabled on the fan coils without water probe.

38

AGLLI10/20NFJ 07/11_4528572_00

TTL NETWORK MANAGEMENT

No Master-Slave communication: the

slave fan coil cyclically await the zone

settings from the master fan coil. If for

some reason a slave fails to communicate with the master, it switches OFF

(i.e. shutdown of all loads) after 10"

from the last command successfully

received.

No Master-User Interface communica-

tion: if at some point the master no

longer communicates with the user

interface, it switches OFF after 10" from

the last command received from it. The

master will also send the OFF command to all the slaves. The user interface also gives the visual alarm AL 1

TTL NETWORK CONSTRAINTS

The constraint concerns the management

of the adjustment dead band; this should

be set on the master fan coil being that it

is ignored on the slaves because both the

setpoint and the operating season of these

depend on the master.

TTL NETWORK EMERGENCY

FUNCTION

Master without Ambient Probe

The operating principle of the master

thermostat in the event that it functions

without ambient probe (or fault of its

local probe) follows what described in

the next paragraph.

Slave without Ambient Probe

The Slave thermostat cards enter into

emergency mode not only if the local

probe is faulty but also if the master

one is faulty too. According to what

previously mentioned, if the slave

probe is faulty and the master probe is

working properly, the slaves continue

to operate using that one of the master.

If the slaves begin to work in emergency mode, they will be operated at

the speed selected in the user interface

and the valve Y1 is opened (this applies

for both 2-pipe and 4-pipe system).

Furthermore, the slaves in emergency

mode do not follow the logic of the

ON-OFF cycles based on the position

of the temperature selector but are

always in the ON phase, therefore with

ventilation always running.

English

TTL NETWORK ANTI-FREEZE

PROTECTION

Master: As described in the ANTI-

FREEZE PROTECTION paragraph, the

thermostat foresees as standard the

control of the ambient temperature to

prevent this fall to freezing values. If

the master has to operate in this condition, it will impose all slaves to operate in AUTO mode with setpoint at

12° C, even though these are operating

according to normal conditions.

Slave: Whereas if it is one of the slaves

operating according to the anti-freeze

protection (despite the master is operating in normal mode), it will operate in AUTO mode with setpoint at

12° C. This is the only case in which

the slave operates according to settings different to those dictated by the

master.

AGLLI10/20NFJ 07/11_4528572_00

39

INSTALLATION

ELECTRICAL WIRINGS

The unit must be connected directly

English

to an electrical outlet or to an

independent circuit.

The FCLI cassette-type fan coils must

be powered with a current of 230V

~50Hz with an earth connection;

the line voltage must however

remain within the tolerance of ±10%

compared with the nominal value.

To protect the unit against short

circuits, fit an omnipolar thermal

trip max. 2A 250V (IG) to the power

line with a minimum contact opening

distance of 3 mm.

The electrical power cable must be of

the H07 V-K or N07 V-K type with

450/750V insulation if inside a tube

or raceway. Use cables with double

H5vv-F type insulation for visible

cable installation.

For all the connections, follow the

wiring diagrams supplied with

the device and shown in this

documentation.

The electric box is supplied with

obligatory accessories (GLLI GLLI_N).

WARNING: check that the power sup-

ply is disconnected before carrying out

any procedures on the unit.

WARNING: before carrying out any

work, put the proper individual protection devices on.

WARNING: the device must be installed

in compliance with the national plant

engineering rules.

WARNING: the electrical connections,

the installation of the fan coils and

relevant accessories should be performed by a technician who has the

necessary technical and professional

expertise to install, modify, extend

and maintain systems, and who is able

to check the systems for the purposes

of safety and correct operation (in

this manual they will be indicated

with the general term "persons with

specific technical skills").

In the specific case of electrical wirings,

the following must be checked:

- measurement of the electrical system

insulation strength

- continuity test of the protection wires

WARNING: install a device, main

switch, or electric plug so you can

fully disconnect the device from the

power supply.

The essential indications to install the

device correctly are given here.

The completion of all the operations in

accordance with the specific requirements is however left to the experience

of the installation engineer.

See also the installation manual of the

FCLI unit and the user's manual provided with the grille unit.

Generally the best position of the fins is

that which allows the launch of the air

adhering to the ceiling for the coined

effect, during cold functioning.

The opening positions are indicated

on the side section of the deflectors

(GLLI10N) for correct machine heating

(20° opening) and cooling (10° opening) operation.

For units with GLLI20N grilles the deflec-

tor should be fully opened in the heating operation and it should be rotated

halfway in the cooling operation.

Depending on the user's needs, the fins

can be adjusted to the intermediate

positions, or completely closed. Thanks

to the special shapes of the fins, the

machine can also function with the

deflectors completely closed.

Do not install at a height above three

metres.

The FCLI unit is prepared for connec-

tions with channelling for the fresh air

and for the delivery of treated air to an

adjacent room.

• INSTALLING NEAR A WALL

If the unit is to be installed near a wall,

the corresponding delivery outlet can

be closed using the gasket supplied.

40

AGLLI10/20NFJ 07/11_4528572_00

FAILURE OF THE THERMOSTAT FUSES AND REPLACEMENT

The installation and the electrical connections of the units and their

accessories must only be carried out

by people possessing the technical/

professional requisites for system

installation, transformation, extension

and maintenance, and who are able

to check these aspects for the purposes of safety and correct operation.

They will be generically referred to in

this manual as "Personnel with specific

technical skills". Check that the power

supply is disconnected before carrying

out any procedures on the unit.

If the fuses are burnt and for possible

replacement:

• Remove the delivery frame

• Extract the thermostat card

• Open the thermostat box

• Replace the faulty fuses

The fuses are 5 x 20 T series

(delayed) from 2 A to 10 A

• WARNING: for correct replacement,

the 2 A fuse must be inserted in location F3, while the 10 A fuse must be

inserted in F2, as shown in the image

below.

English

F3

ELECTRICAL CONNECTIONS WITH GLLI10N AND GLLI20N ACCESSORIES

Before installing the electric box, the

configuration of the electronic board

dip-switches needs to be checked in

order to adjust the board to the system.

Connect the VMF-E4 control panel,

supervision network cable, TTL

network cable, and probe and valve

cables based on system requirements.

For the connections, refer to the

wiring diagrams of the fan coil and

connected accessories.

GLLI10N

GLLI20N

L

N

230VAC

L

N

F2

VMF-SW1

CN3

230VAC

- L - N

> 650mm

AGLLI10/20NFJ 07/11_4528572_00

41

SCHEMI ELETTRICI • WIRING DIAGRAMS • SCHEMAS ELECTRIQUES • SCHALTPLÄNE • ESQUEMAS ELÉCTRICOS

LEGENDA • READING KEY • LEGENDE • LEGENDE • LEYENDA

Español

AL • Supply

= Alimentatore

Power supply

Alimentation electrique

Spannung

Alimentador

AMP=Contatto allarme pompa scarico

condensa

Contact alarm condensate pump

discharge

Contact d'alarme de décharge de

pompe condensat

Kontakt Alarm Kondensatpumpe

Entlastung

Contacto de alarma de bomba de

descarga de condensados

CE = Contatto esterno

CN = Connettore

Connector

Connecteur

Schütz

Conector

F = Fusibile • Fuse • Fusible

Sicherung • Fusible

IG = Interruttore generale

Main switch

Interupteur général

Hauptschalter

Interruptor general

M = Morsettiera

Terminal board

Boitier

Klemmleiste

Placa de bornes

Bomba de desagüe de condensado

MV = Motore ventilatore • Fan motor

Moteur ventilateur •

Ventilatormotor

Motor del ventilador

PE = Collegamento a terra

GND Earth connection

Mise à terre

Erdanschluss

Toma de tierra

SA = Sonda temperatura aria

Air temperature probe

Sonde temp. de l'air

Temperaturfühler

Sonda temperatura del aire

SW1 = Dip Switch

SW (CN2) = (SW4)

Sonda temperatura acqua

Water temperature probe

Sonde temp. eau

Wasserfühler

Sonda temperatura del agua

SW (CN3) = (VMF-SW1)

Sonda temperatura acqua (impianti 4 tubi)

Water temperature probe (4-pipe version)

Sonde temp. eau (systèmes à 4 tuyaux)

Wasserfühler (4-Leiter-Systemen)

Sonda temperatura del agua

(instalaciones de 4 tubos)

VHL =Valvola

Valve

Vanne

Ventil

Válvula

= Componenti non forniti

Components not supplied

Composants non fournis

Nicht lieferbare Teile

Componentes no suministrados

= Componenti forniti optional

Optional components

Composants en option

Optionsteile

Componentes opcionales

=Collegamenti da eseguire in loco

On-site wiring

Raccordements à effectuer in situ

Vor Ort auszuführende Anschlüsse

Cableado in situ

MP = Pompa scarico condensa

Condensate drain pump

Pompe de vidange du condensat

Kondensatablass Pumpe

AR = Arancio • Orange • Orange • Orange • Naranja

BI = Bianco • White • Blanc • Weiss • Blanco

BL = Blu • Blue • Bleu • Blau • Azul

GR = Grigio • Grey • Gris • Gray • Gris

MA = Marrone • Brown • Marron • Braun • Marrón

NE = Nero • Black • Noir • Schwarz • Negro

RO = Rosso • Red • Rouge • Rot • Rojo

ROS = Rosa • Pink • Rose • Rosa • Rosa

VE = Verde • Green • Vert • Grün • Verde

VI = Viola • Violet • Violet • Violet • Violeta

Gli schemi elettrici sono soggetti ad un continuo aggiornamento, è obbligatorio quindi fare riferimento a quelli a bordo macchina.

All wiring diagrams are constantly updated. Please refer to the ones supplied with the unit.

Nos schémas électriques étant constamment mis à jour, il faut absolument se référer à ceux fournis à bord de nos appareils.

Die Schaltpläne werden ständig aktualisiert, deswegen muss man sich stets auf das mit dem Gerät gelieferte Schaltschema beziehen.

El cableado de las máquinas es sometido a actualizaciones constantes. Por favor, para cada unidad hagan referencia a los esquemas suministrados con la misma.

96

AGLLI10/20NFJ 07/11_4528572_00

SCHEMI ELETTRICI • WIRING DIAGRAMS • SCHEMAS ELECTRIQUES • SCHALTPLÄNE • ESQUEMAS ELÉCTRICOS

FCLI

GLLI10N / GLLI20N

WMF-SW1

CN1

CN3

SW4

LED

SA

TX/RX

GND-TTL

MODE

5V

TX/RX

GND

TTL

M22

CN2

M26

CE

1

1

GND

2

2

CF

3

3

A

4

4

B

5

5

GND

6

6

M15

RS485

M14

M16

SW1

L17

M17

M18

M19

M20

M25

M21

JP1

RL1 RL2 RL3

M28

M27

+

C1

CLOSED FOR FCLI

RL4 RL5 RL6

Y2Y1

N

N1V3V2V1

MA

230V 50Hz

IG

NL

L

TR1

M3

RL7

F2 F3

BL

MA

PE

N

Español

F 10A F 4A

AUX/RE

LNN

1234

1234

GND

Signal Supply

INVERTER

Hall

-CBA+

E4

BI

BI

NE

NE

GR

181317

181317

GR

ROS

ROS

6

6

12

12

BL

BL

5

5

14

14

NE

11

11

VHL1

VHL20

VHL2

VHL22

NE

4

4

3

3

BL

10

10

VI

BL

5

5

2

2

MA

BL

MA

15

15

AR

1

1

6

6

NE

BI

BI

2

1

2

1

1

2

1

2

16

16

MA

BL

8

9

7

7

9

8

3

3

4

3

4

3

4

4

MP

VHL

BI

BL

2

55

44

VI

66

1

M

RO

AMP

11

33

2

RONE

GIBLVE

M

Out motor

MV

RST ONLAL V+ IN

Gli schemi elettrici sono soggetti ad un continuo aggiornamento, è obbligatorio quindi fare riferimento a quelli a bordo macchina.

All wiring diagrams are constantly updated. Please refer to the ones supplied with the unit.

Nos schémas électriques étant constamment mis à jour, il faut absolument se référer à ceux fournis à bord de nos appareils.

Die Schaltpläne werden ständig aktualisiert, deswegen muss man sich stets auf das mit dem Gerät gelieferte Schaltschema beziehen.

El cableado de las máquinas es sometido a actualizaciones constantes. Por favor, para cada unidad hagan referencia a los esquemas suministrados con la misma.

3

Dis. 5490480_03

AGLLI10/20NFJ 07/11_4528572_00

97

SCHEMI ELETTRICI • WIRING DIAGRAMS • SCHEMAS ELECTRIQUES • SCHALTPLÄNE • ESQUEMAS ELÉCTRICOS

FCLI

GLLI10N / GLLI20N

WMF-SW1

CN1

CN3

SW4

LED

SA

TX/RX

GND-TTL

MODE

5V

TX/RX

GND

TTL

M22

CN2

M26

CE

1

1

GND

2

2

CF

3

3

A

4

4

B

5

5

GND

6

6

M15

RS485

M14

M16

SW1

L17

M17

M18

M19

M20

M25

M21

JP1

RL1 RL2 RL3

M28

M27

+

C1

CLOSED FOR FCLI

RL4 RL5 RL6

N

230V 50Hz

IG

NL

L

TR1

M3

RL7

F2 F3

BL

MA

F 10A F 4A

MAY2Y1N1V3V2V1

AUX/RE

LNN

PE

N

1234

1234

GND

Signal Supply

INVERTER

Hall

-CBA+

E4

BI

BI

NE

NE

GR

181317

181317

GR

ROS

ROS

6

6

12

12

BL

BL

5

5

14

14

NE

BI

VI

11

11

NE

4

4

BL

5

10

10

BL

3

3

MA

AR

BL

15

15

5

16

6

6

16

7

7

8

9

9

8

VHL1

VHL20

VHL2

VHL22

NE

MA

1

2

1

2

BI

2

44

2

BL

VI

55

GIBLVE

BL

3

3

MP

1

66

3

3

M

RO

MA

4

4

4

4

33

RONE

BI

2

1

2

1

1

2

1

2

AMP

11

M

3

Dis. 5490481_03

Out motor

RST ONLAL V+ IN

MV

FCLI_VL

Gli schemi elettrici sono soggetti ad un continuo aggiornamento, è obbligatorio quindi fare riferimento a quelli a bordo macchina.

All wiring diagrams are constantly updated. Please refer to the ones supplied with the unit.

Nos schémas électriques étant constamment mis à jour, il faut absolument se référer à ceux fournis à bord de nos appareils.

Die Schaltpläne werden ständig aktualisiert, deswegen muss man sich stets auf das mit dem Gerät gelieferte Schaltschema beziehen.

El cableado de las máquinas es sometido a actualizaciones constantes. Por favor, para cada unidad hagan referencia a los esquemas suministrados con la misma.

AERMEC S.p.A.

I-37040 Bevilacqua (VR) - Italia

Via Roma, 996 - Tel. (+39) 0442 633111

Telefax (+39) 0442 93730 - (+39) 0442 93566

www .aermec. com

I dati tecnici riportati nella presente documentazione non sono impegnativi.

AERMEC S.p.A. si riserva la facoltà di apportare in qualsiasi momento tutte le modifiche ritenute necessarie per il miglioramento del prodotto.

Les données mentionnées dans ce manuel ne constituent aucun engagement de notre part. Aermec S.p.A. se réserve le droit de modifier à tous moments les

données considérées nécessaires à l’amelioration du produit.

Technical data shown in this booklet are not binding.

Aermec S.p.A. shall have the right to introduce at any time whatever modifications deemed necessary to the improvement of the product.

Im Sinne des technischen Fortsschrittes behält sich Aermec S.p.A. vor, in der Produktion Änderungen und Verbesserungen ohne Ankündigung durchzuführen.

ILos datos técnicos indicados en la presente documentación no son vinculantes.

Aermec S.p.A. se reserva el derecho de realizar en cualquier momento las modificaciones que estime necesarias para mejorar el producto.

Loading...

Loading...