USE AND INSTALLATION MANUAL

MANUEL D’UTILISATION ET D’INSTALLATION

FAN COIL WITH INVERTER

VENTILO-CONVECTEUR AVEC INVERTER

FCXI US

FCXI 20 / 220 US

FCXI 30 / 220 US

FCXI 40 / 220 US

FCXI 50 / 220 US

FCXI 80 / 220 US

FCXI 24 / 220 US

FCXI 34 / 220 US

FCXI 44 / 220 US

FCXI 54 / 220 US

FCXI 84 / 220 US

IFCXIUSLJ 1203 - 5383620_00

TABLE OF CONTENTS • TABLE DES MATIÈRES

>25Kg

English

Transport • Safety symbols 3

Description of the unit

Important information and maintenance 5

Operating limits 6

Main components • Description of components 7

Installation information • Alarm codes 8

Unit installation • Water connections • Condensate discharge connections 9

Electrical connections • Coil rotation 10

Dimensions 18

Wiring diagrams 23

Trouble shooting 24

Inverter card factory settings 25

Français

Transport • Symboles de sécurité 3

Description • Emballage • Emploi

Informations importantes et entretien 12

Limites de fonctionnement 13

Composants principaux • Description des composants 14

Informations pour l'installation • Encodage des alarmes 15

Installation de l'unité • Raccords hydrauliques • Raccords d'évacuation des condensats 16

Raccordements électriques • Rotation de la batterie 17

Dimensions 18

Schemas electriques 23

Solution des problemes 24

Réglages en usine de la platine inverter 25

• Packaging • Use 4

11

CARRIAGE • TRANSPORT

Do NOT wet

CRAINT l’humidité

Stacking: control the packing to know the

number of machines that can

Empilement: vérifier sur l’emballage pour connaître

le nombre d’appareils pouvant être empilés

Do NOT leave loose packages during transport

ATTACHER les emballages pendant le transport

Fragile, handle with care

Fragile, manipuler avec soin

be stacked

SAFETY SYMBOL • SIMBOLES DE SECURITE

Danger: Danger: Danger!!!

Power supply Movings parts

Danger: Danger: Danger!!!

Tension Organes en mouvement

Do NOT step

NE PAS marcher sur cet emballage

DO NOT handle the machine alone if

its weight is over 55lb / 25Kg

NE PAS transporter tout seul l’appareil

si son poids dépasse 55lb / 25Kg

Arrow: high

Flèche: haut

IFCXIUSLJ 1203 - 5383620_00

3

Congratulations on your purchase of this Aermec FCXI fan coil.

Made with materials of superior quality in strict compliance with safety regulations, "FCXI" is

easy to use and will have a long life.

Thanks to Aermec's FCXI range of inverter fan coils, brushless technology can now make

inroads in the field of chilled water air conditioning, bringing notable energy savings along

with the precise control of both air temperature and humidity in the air-conditioned rooms.

REMARKS

Store the manuals in a dry location to avoid deterioration, as

they must be kept for at least 10 years for any future reference.

All the information in this manual must be carefully read and

understood. Pay particular attention to the operating standards with “DANGER” or “WARNING” signals as failure to

comply with them can cause damage to the machine and/or

persons or objects.

English

If any malfunctions are not included in this manual, contact

the local After-sales Service immediately.

The apparatus must be installed in such a way that maintenance and/or repair operations are possible.

The apparatus's warranty does not in any case cover costs due

to automatic ladders, scaffolding or other lifting systems necessary for carrying out repairs under guarantee.

AERMEC S.p.A. declines all responsibility for any damage

whatsoever caused by improper use of the machine, and a partial or superficial acquaintance with the information contained

in this manual.

The number of pages in this manual is : 28.

DESCRIPTION OF THE UNIT

MACHINE PURPOSE

The fan coil is a room air treatment terminal unit for both winter and summer operation.

AVAILABLE SIZES

The FCXI_US fan coils are available in:

5 sizes 220V 60Hz

with 3-row coil

FCXI 20 / 220 US

FCXI 30 / 220 US

FCXI 40 / 220 US

FCXI 50 / 220 US

FCXI 80 / 220 US

FCXI_US: without control panel and with Inverter motor, 3-rows or 4-rows heat exchanger, universal cabinet for vertical fl oor-

standing installation or wall-mounting, varnished with anti-corrosion polyester powder, colour RAL 9002. The air delivery and

suction grilles are made using plastic material in colour RAL 7044. Requires external control panel.

5 sizes 220V 60Hz

with 4-row coil

FCXI 24 / 220 US

FCXI 34 / 220 US

FCXI 44 / 220 US

FCXI 54 / 220 US

FCXI 84 / 220 US

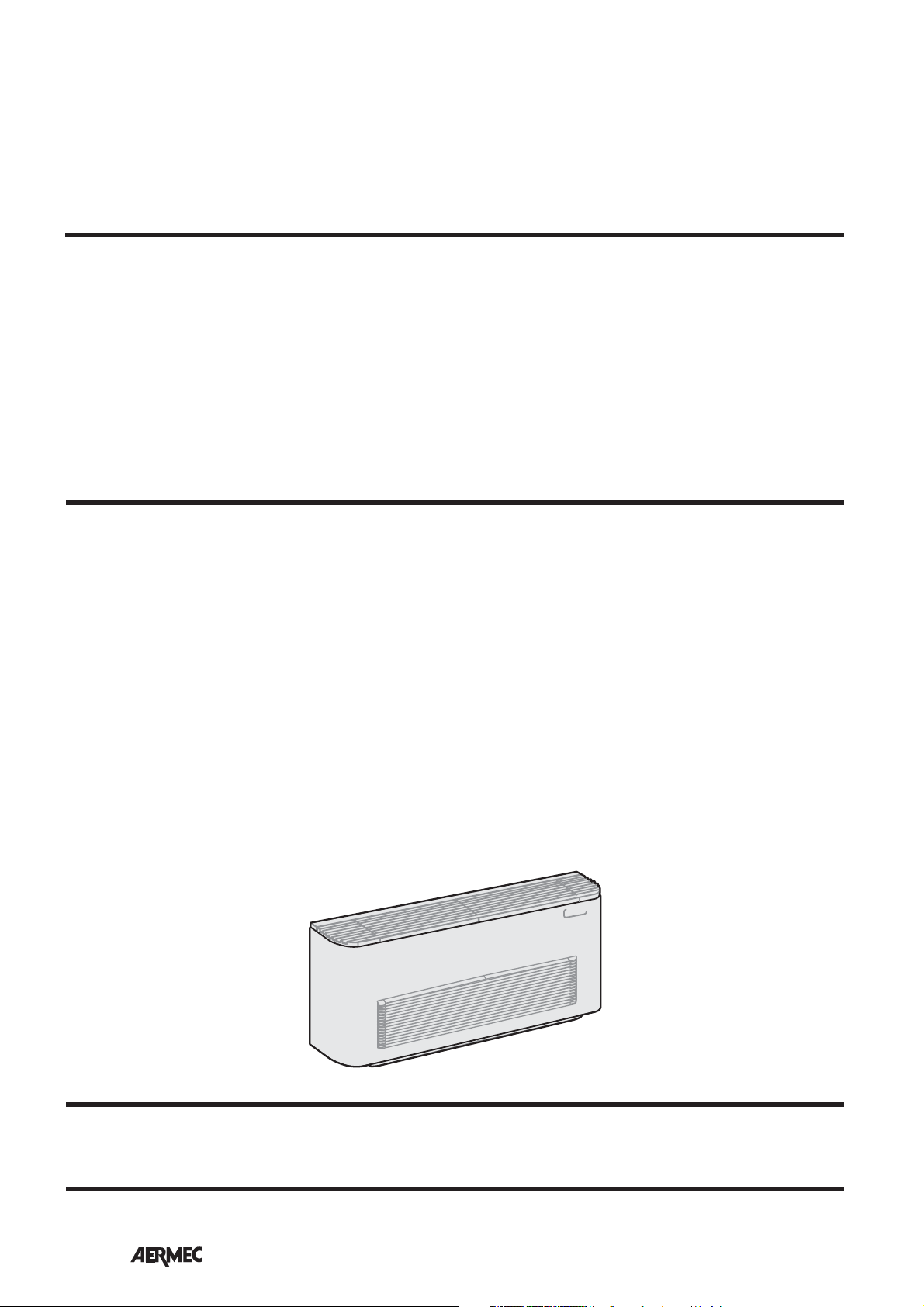

PACKAGING

The fan coils are shipped in standard package which consists of expanded polystyrene foam and cardboard shells.

USE

Consult control panel manual for use instructions.

4

IFCXIUSLJ 1203 - 5383620_00

IMPORTANT INFORMATION AND MAINTENANCE

WARNING: the fan coil is connected

to power supply and water circuit.

Operations performed by persons

without the required technical skills can

lead to personal injury to the operator

or damage to the unit and surrounding

objects.

POWER THE FAN COIL ONLY WITH

220V, SINGLE-PHASE VOLTAGE

Any other type of power supply could

permanently damage the fan coil.

DO NOT USE THE FAN COIL

IMPROPERLY

Do not use the fan coil for animal

husbandry applications (e.g. incubation).

AIR THE ROOM

Periodically air the room in which the

fan coil has been installed. This is

particularly important if the room is

occupied by many people, or if gas

appliances or sources of odours are

present.

ADJUST TEMPERATURE ADEQUATELY

The room temperature should be adjusted

in order to provide maximum comfort to

the people in the room, especially if they

are elderly, children or sick people; avoid

differences over 44.6°F /7°C between the

outdoor temperature and the temperature

inside the room in summer.

In summer, a temperature that is too low

causes higher electrical consumption.

CORRECTLY ADJUST THE AIR JET

Air coming out from the fan coil must not

reach people directly; in fact, even if the

air is warmer than the room temperature,

it could cause a cold sensation and result

in discomfort.

DO NOT USE EXCESSIVELY HOT WATER

To clean the fan coil use soft cloths

or sponges dipped in water with a

maximum temperature of 104°F / 40°C.

Do not use chemical products or solvents

for any part of the fan coil. Do not spray

water on the outer or inner surfaces

of the fan coil (this might cause short

circuits).

CLEAN THE FILTER PERIODICALLY

Cleaning the filter frequently guarantees

enhanced operating efficiency.

Check whether the filter is very dirty: in

this case, clean it more often.

Clean frequently; remove the accumulated

dust with a vacuum cleaner.

Once the filter is clean, refit it on the fan

coil following the removal instructions

but in reverse order.

SUPPLEMENTARY CLEANING

The fact that the blades of examinable

shrouds can be removed (operation

done only by adequately skilled

technicians) ensures a thorough cleaning

of the internal components, which is

particularly important when installing

the unit in crowded areas or venues

requiring high hygiene standards.

DURING OPERATION

Always leave the filter fitted on the fan

coil during operation (otherwise dust in

the air could soil the coil surface area).

WHAT IS NORMAL

In cooling mode, water vapour may be

present in the air delivery of the fan coil.

In the heating operation, a slight hiss might

be heard close to the fan coil. Sometimes

the fan coil might give off unpleasant

smells due to the accumulation of

substances present in the air of the room

(clean the filter more often, especially

if the room is not ventilated regularly).

While the unit is functioning, there could

be noises and creaks inside the device

due to the various thermal expansions

of the elements (plastic and metal), but

this does not indicate any malfunction

and does not damage the unit unless

the maximum input water temperature

is exceeded.

MALFUNCTIONING

In case of malfunction, cut off power

to the unit, then energise it again and

restart the device.

WARNING! Do not attempt to repair the

unit alone, this is extremely dangerous!.

If the problem occurs again, call the local

Aftersales Service immediately.

This section is reserved for the After

Sales service only. There are 2 LEDs on

the Inverter card (Alarm / Power) that

indicate the unit's operating status. The

table for the decoding of messages is

found in Chapter Installation.

DO NOT TUG THE ELECTRIC CABLE

It is very dangerous to pull, tread on or

crush the electric power cable, or fix it

with nails or drawing pins.

A damaged power cable can cause short

circuits and injure people.

DO NOT OBSTRUCT THE AIR OUTLETS

BY PLACING OBJECTS INTO THEM

Do not put anything in the air outlet slots.

This could injure people and damage the

fan.

WARNING

Avoid that the device is used by children

or incompetent persons without

appropriate supervision; also note that

the unit should not be used by children

as a game.

English

°C= (°F-32)/1.8

°F=(°Cx1.8)+32

1mm = 0.03937 inch

1inch = 25.4 mm

IFCXIUSLJ 1203 - 5383620_00

5

OPERATING LIMITS

FCXI

Maximum water inlet temperature 176°F / 80°C

Maximum recommended water inlet temperature 149°F / 65°C

Maximum operating pressure 115psi / 8bar /

Room temperature limits (Ta) 32°F < Ta < 113°F / 0°C < Ta < 45°C

Relative humidity limits in the room (R.H.) U.R. < 85%

Power supply 220V ( ±10% ) ~ 60Hz

Performance values refer to the following conditions:

- at the maximum motor speed;

Water temperature

In order to prevent air stratification in

English

the room, and therefore to achieve

improved mixing, it is advisable not

Minimum average water temperature

If the fan coil is working in continuous

cooling mode in an environment

where the relative humidity is high,

condensate might form on the air

delivery and on the outside of the

device. This condensate might be

deposited on any objects underneath

and on the floor.

to supply the fan coil with water at a

temperature over 149°F / 65°C.

The use of water at high temperatures could

cause squeaking due to the different

To avoid condensate on the external

structure of the device while the fan is

functioning, the average temperature

of the water must not be lower than

the limits shown in the table below,

that depend on the thermo-hygrometric

conditions of the air in the room.

The limits mentioned above refer to

operation while the fan is set to its

20 /220US 30 /220US 40 /220US 50 /220US 80 /220US

24 /220US 34 /220US 44 /220US 54 /220US 80 /220US

- the total input power is determined by adding the input power

for the unit and the input power for the accessories connected

and declared in the corresponding manuals.

thermal expansions of the elements

(plastic and metal), this does not however

cause damage to the unit if the maximum

operating temperature is not exceeded.

minimum speed level.

In the event of prolonged fan inactivity

and with cold water passing through

the coil, condensate may form on the

external case of the unit. As a result,

we recommend including the 3-way

valve accessory.

MINIMUM AVERAGE WATER TEMPERATURE

[°F/°C]

59 / 15 37.4/3 37.4/3 37.4/3 37.4/3 37.4/3 37.4/3

Wet bulb ambient

air temperature

Water flow limits for 3-row coil

FCXI 20 /220US 30 /220US 40 /220US 50 /220US 80 /220US

Minimum water flow

Maximum water flow

Water flow limits for 1-row coil

FCXI 20 /220US 30 /220US 40 /220US 50 /220US 80 /220US

Minimum water flow

Maximum water flow

62.6 / 17 37.4/3 37.4/3 37.4/3 37.4/3 37.4/3 37.4/3

66.2 / 19 37.4/3 37.4/3 37.4/3 37.4/3 37.4/3 37.4/3

69.8/21 48.2/6 41/5 39.2/4 37.4/3 37.4/3 37.4/3

73.4/23 - 46.4/8 44.6/7 48.2/6 41/5 41/5

l/h 100 100 150 150 300

gpm 0.44 0.44 0.66 0.66 1.32

l/h 750 750 1100 1100 2200

gpm 3.3 3.3 4.84 4.84 9.68

l/h 50 50 50 50 100

gpm 0.22 0.22 0.22 0.22 0.44

l/h 400 400 400 400 900

gpm 1.76 1.76 1.76 1.76 3.96

Dry bulb ambient air temperature

70/21 73/23 77/25 80/27 84/29 88/31

Water flow limits for 4-row coil

FCXI 24 /220US 34 /220US 44 /220US 54 /220US 84 /220US

Minimum water flow

Maximum water flow

6

IFCXIUSLJ 1203 - 5383620_00

l/h 150 150 150 150 300

gpm 0.66 0.66 0.66 0.66 1.32

l/h 1100 1100 1100 1100 2200

gpm 4.84 4.84 4.84 4.84 9.68

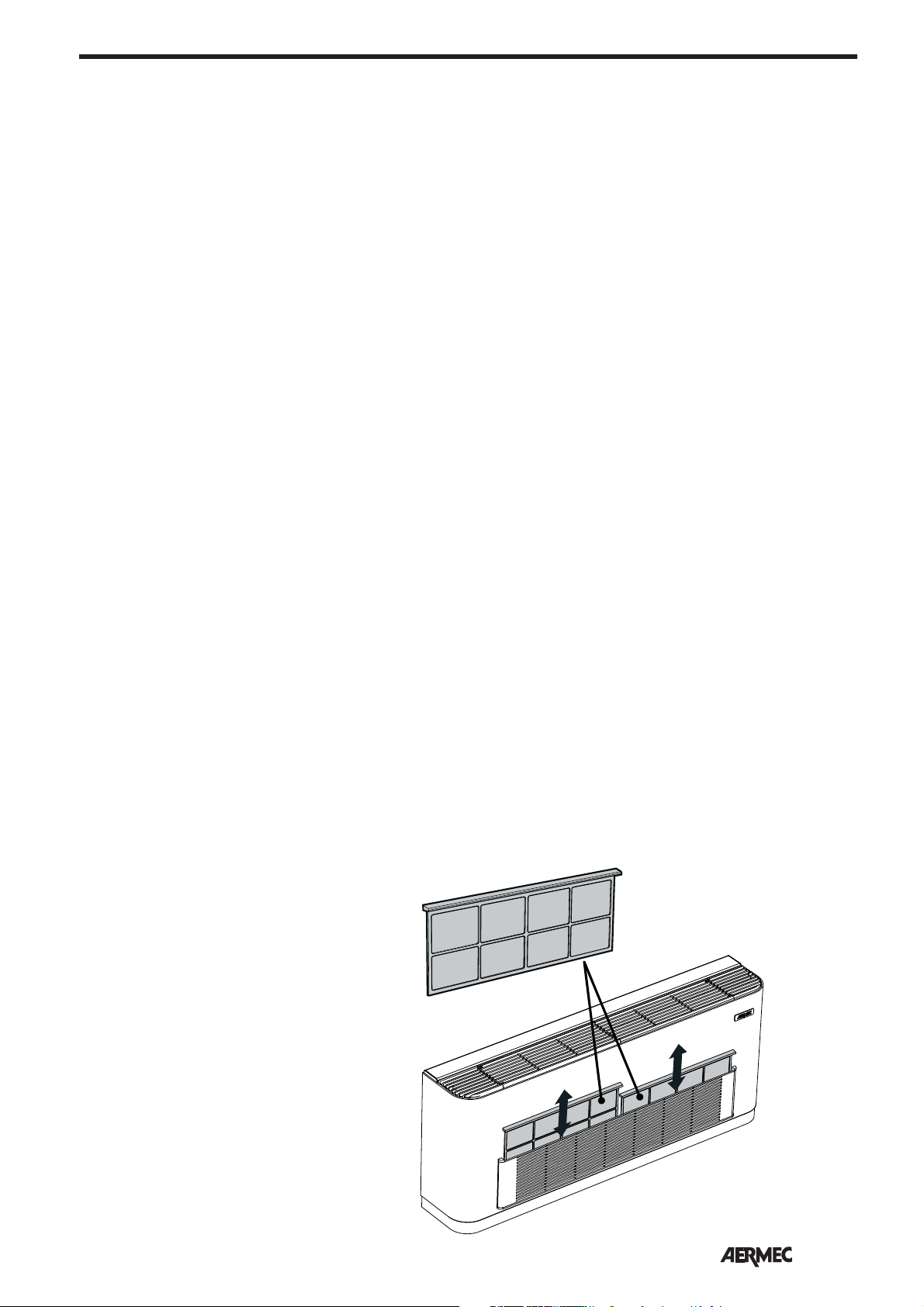

MAIN COMPONENTS

1 Air delivery with fins (RAL7044)

2 Load-bearing structure

3 Heat exchange coil

4 Air vents on the coil

5 Plumbing connections

6 Bracket for mounting

7 Condensate discharge

8 Tray

9 Fan

10 Control Inverter device

11 Electric motor

12 Lower closure (RAL7044)

13 Intake grille (RAL7044)

14 Air filter (suction)

15 Electric box (electrical wiring)

16 Cabinet (RAL9002)

17 Covering cabinet (RAL9002)

FCXI 40/220 US

5

4

6

3

4

7

6

17

1

2

16

3

15

English

14

13

12

DESCRIPTION

SYSTEM TYPES

The fan coils are designed for systems

with 2 and 4 pipes, in the versions:

- 3-Rows: without valve;

- 3-Rows: with valve;

- 3-Rows: with 1-Row hot water coil (BV)

and 2 valves;

- 4-Rows: without valve;

- 4-Rows: with valve.

HEAT EXCHANGE COIL

Coil with copper pipe and aluminium

fins blocked by means of the mechanical expansion of the pipes. The collectors are fitted with female connections

and air vents in the upper part of the

coil.

FILTERING SECTION

Filter in filtering class G2, self-extin-

guishing B1 (DIN 4102). Easily removable and made from regenerable materials.

May be cleaned by washing.

ELECTRIC FAN UNIT

This consists of double suction centrif-

ugal fans with lengthways blades to

obtain a high air flow with a low number of revs. The fans are directly coupled with the shaft of the "brushless"

8 9

electric motor.

The "brushless" electric motor is cush-

ioned with elastic supports.

The "brushless" electric motor is the

result of combining the most sophisticated technologies from the fields of

mechanics and electronics.

The "brushless" electric motor has no

sliding contacts between the rotor and

the stator. With the special inverter

device, it is possible to control the

speed and torque of the rotor continuously, just by means of the stator currents.

Compared with the traditional alternate

current motors, the "brushless" electric

motor offers huge advantages:

- Reduced wear and tear

- The possibility to regulate the rotation

speed in a precise, continuous manner

(0-100%)

- Higher energy yields

- Longer life and greater reliability

LOAD-BEARING STRUCTURE

Made of galvanised sheet iron of a suit-

able thickness. There are holes on the

back for fixing the device to the wall.

The fan unit is closed at the front with a

10 11

IFCXIUSLJ 1203 - 5383620_00

metal panel. Every device is equipped

with condensate collection trays (for

both vertical and horizontal installation).

CONDENSATE DRAIN

Every device is equipped with conden-

sate collection trays, with a connection

for draining the condensate produced

by the unit in cooling mode.

WATER CONNECTIONS

The connections, located on the left

hand side, are female. The coil may

also be rotated.

CABINET

Casing in RAL9002

The casing is made of galvanised steel,

varnished with

guarantee high resistance to rust and

corrosion.

CONTROL PANEL

Use a control panel with thermostat and

ventilation speed control, with 0-10V

outputs.

polyester powders to

7

INSTALLATION INFORMATION

WARNING: check that the power

supply is disconnected before carrying

out any procedures on the unit.

WARNING:before carrying out any

work, put the proper individual

protection equipment on.

WARNING: the device must be installed

in compliance with the national plant

engineering rules.

WARNING: electrical wirings,

installation of the fan coils and

relevant accessories should be

performed by a technician who has the

necessary technical and professional

expertise to install, modify, extend and

maintain systems, and who is able to

check the systems for the purposes of

English

safety and correct operation.

WARNING: install a device, main

switch, or electric plug so you can

fully disconnect the device from the

power supply.

WARNING: Consult all documentation

before starting the installation.

The essential indications to install the

device correctly are given here.

The completion of all the operations

in accordance with the specific

requirements is however left to the

experience of the installation engineer.

The water, condensate discharge

and electrical circuit ducts must be

provided for.

The fan coil must be installed in such a

position that the air can be distributed

throughout the room and so that there

are no obstacles (curtains or objects) to

the passage of the air from the suction

louvers.

The fan coil should be installed in such

a way as to facilitate routine (filter

cleaning) and special maintenance

operations, as well as access to the

air drain valve on the side of the unit

frame (connections side).

Do not install units in rooms where

there are inflammable gases or acid

or alkaline substances that could

irretrievably damage the aluminiumcopper heat exchanger or the internal

plastic parts.

Do not install the unit in workshops or

kitchens where the oil vapours mixed

with the treated air can be deposited

on the exchange coils, reducing their

performance, or on the parts inside the

unit, damaging the plastic parts.

If a three-way valve is installed, the

minimum water temperature sensor

can be installed in two locations:

- in its housing in the coil,

MANDATORY if the thermostat is

connected to a system with centralised

control or monitoring device;

- on the delivery pipe up stream of the

valve.

Check the thermostat manual before

choosing the location of the minimum

water temperature sensor, according

to the preferred control logic. The

thermostat may need the settings of the

dip-switches changed.

WARNING:After completing the

installation check the operation of the

condensate discharge system, the seal

of the hydraulic fittings, insulation

of ducts and pipes. Then perform a

functional test.

In the event of malfunction consult the

Alarm Codes Table to interpret the

alarms indicated by the 2 LEDs (Alarm

/ Power) that indicate the status of the

unit.

The inverter card is located inside the

unit and requires dismantling.

DANGER! Only qualified service

personnel can access it.

ALARM CODES

This section is reserved for the After

Sales service only.

The card is located inside the unit and

requires dismantling.

DANGER! Only qualified service

personnel can access it.

ALARM TYPE INDICATIONS IRREGULARITY Notes

High temperature

Overvoltage

Undervoltage

Overcurrent

Overload

Safety control Temperature limitation

STOP Alarm LED permanently on Motor off

8

IFCXIUSLJ 1203 - 5383620_00

ALARM LED flashes

3sec ON 0.5sec OFF

The LED if permanently ON

after 1.5min

ALARM LED flashes

0.5sec ON 0.5sec OFF

There are 2 LEDs on the Inverter card

(Alarm / Power) that indicate the unit's

operating status.

The table below shows how to decode

the messages.

Motor off

Speed reduction

Auto-Restart Alarm.

If the conditions persist after

1.5min, the alarm becomes

permanent, the Alarm LED stays

on, the system turns off.

Power limitation

For alarms reset:

Set 0V ON INPUT

(turn the power off and then on again)

INSTALLATION

INSTALLING THE UNIT

To install the unit, proceed as follows:

- Remove the covering cabinet

- Use wall plugs (not supplied) for wallmounted installations

- Apply any accessories.

Make the water connections as

described in the relative chapter.

Make the condensate discharge con-

nection as described in the relative

chapter. The fan coils that work in heat

mode only do not require condensate

discharge.

Make the electrical wiring as shown in

the relative chapter and in the wiring

diagrams.

Install and connect any accessories.

Complete the installation by reassem-

bling the casing and air filter.

Start up the fan coil and check all the

components and functions are operating correctly.

English

WATER CONNECTIONS

- Make the water connections.

- In the event of disassembly and rein-

stallation, use new gaskets.

Refer to the size data for the position,

type and diameter of the water connections.

You are advised to adequately insulate

water lines and/or fit the auxiliary

condensate drain tray (available as an

accessory), to prevent dripping during

the cooling function.

After installing, check the seal on the

connections.

CONDENSATE DRAIN

In the event of horizontal installation,

assemble the condensate discharge

connection supplied

seal the connection between the drip

tray and the fitting with silicone. The

condensate drain network must be

properly scaled and the piping situated in such a way as to keep an adequate slope along the route (min. 1%).

If condensate is discharged into the

sewage system, install a siphon to

prevent the return of unpleasant odours

into the room.

Carry out a functioning and seal test of

the condensate drain system by pouring water into the tray

. Make sure you

B

A

Ø 0.807 inches

Ø 20.5 mm

B

B

A

A

IFCXIUSLJ 1203 - 5383620_00

9

ELECTRICAL WIRINGS

The unit must be connected directly

to an electrical outlet or to an

independent circuit.

WARNING: it is compulsory to

connect the power cables Phase (L)

and Neutral (N) to the respective

terminals, do not to reverse the

connections, and observe the wiring

diagram.

install a device, main switch, or

electric plug so you can fully

disconnect the device from the power

supply.

To protect the unit against short

circuits, fit an omnipolar thermalmagnetic trip 2A 250V (IG) to the

power line with a minimum contact

opening distance of 0.12inch / 3mm .

English

The use of B-type circuit breakers is

recommended.

For installations with three-phase power

supply, the following precautions

should be considered:

1. In the presence of breakers or

thermomagnetic switches 3P + N,

the triggering current must be at least

170% of the total load absorbed by

the fan coils for each phase.

2. The section of the neutral wire

must be of a dimension taking into

consideration the operating current

equal to 170% of the total load

absorbed by the fan coils for each

phase.

CHARACTERISTICS OF THE

CONNECTION CABLES

Use H05V-K or N07V-K type cables

with 300/500V with insulation, piped

or ducted.

All the cables must be piped or ducted

until they are inside the fan coil.

The cables leaving the pipe or raceway

must be so positioned that they are

not pulled or twisted and are anyway

protected from outside agents.

Stranded cables can only be used with

crimping terminals. Check the wire

strands are well inserted.

The wiring diagrams are subject to

continuous updates, so it is essential

to use those on the machine as your

reference.

The control panel may not be fitted on

a metal wall unless this is permanently

connected to an earthed outlet.

When using remote control panels,

the relative wiring diagram must be

respected. Before installing the control

panel, read the instructions carefully

and configure the panel if necessary.

Connect the valve and sensor to the

control board, in the positions

indicated in the wiring diagram.

ROTATING THE COIL

If the hydraulic connections require the

rotation of the coil, remove the front

closure panel and proceed as follows:

- Remove the condensate drip tray;

- Undo the screws and remove the coil

cover;

- Remove the screws securing the coil,

then remove the coil;

- Remove the push-outs on the righthand side;

- Rotate the coil and secure it with the

previously removed screws;

- Reassemble the cover and fix it with

the screws;

- Reassemble the plastic plugs

(supplied) in the holes left free by the

water connections;

- All the trays can be used to collect

condensate on both sides. In case

of vertical installation, to discharge

condensate on the right side, position

the drain connection to the right.

- Slide out the electrical wirings from

the right-hand side, remove the pushout and move the cable grommet from

the right to the left side;

- Transfer the electrical wirings to the

left side through the cable grommet;

- Move the control board, the earthing

u-bolt and any electric devices to the

left-hand side.ro

3-Rows and 1-Row coil

FCXI 20 / 220 US

FCXI 30 / 220 US

FCXI 40 / 220 US

FCXI 50 / 220 US

FCXI 80 / 220 US

1R

180°

3R

A

A

4-Row coil

FCXI 24 / 220 US

FCXI 34 / 220 US

FCXI 44 / 220 US

FCXI 54 / 220 US

FCXI 84 / 220 US

4R

B

A

B

180°

B

10

IFCXIUSLJ 1203 - 5383620_00

DIMENSIONS

D

E

E

D

FCXI _ /220US

B

C

A

FCXI

20 /220US

24 /220US

US measure system • Systéme de mesure US

A [inches] 19.17 19.17 19.17 19.17 23.23

B [inches] 29.53 38.58 47.24 47.24 51.97

C [inches] 8.66 8.66 8.66 8.66 8.66

D [inches] 3.94 3.94 3.94 3.94 3.94

E [inches] 1.97 1.97 1.97 1.97 1.97

Weight • Poids [lbs]

33.07

34.17

30 /220US

34 /220US

44.09

45.19

40 /220US

44 /220US

52.91

54.01

50 /220US

54 /220US

52.91

54.01

80 /220US

84 /220US

74.96

75.06

Metric system • Systéme métrique

A [mm] 487 487 487 487 590

B [mm] 750 980 1200 1200 1320

C [mm] 220 220 220 220 220

D [mm] 100 100 100 100 100

E [mm] 50 50 50 50 50

Weight • Poids [Kg]

15

15.5

20

20.5

24

24.5

24

24.5

34

34.5

MINIMUM TECHNICAL SPACE • ESPACE TECHNIQUES MINIMUS

COIL CONNECTIONS (FEMALE) • RACCORDS BATTERIE (FEMELLE)

FCXI

20 /220US 30 /220US 40 /220US 50 /220US 80 /220US

US measure system • Systéme de mesure US

3 R

[inches]

FCXI

1

/2” F

24 /220US 34 /220US 44 /220US 54 /220US 84 /220US

1

/2” F

3

/4” F

3

/4” F

3

/4” F

Metric system • Systéme métrique

4 R

18

[inches]

IFCXIUSLJ 1203 - 5383620_00

3

/4” F

3

/4” F

3

/4” F

3

/4” F

3

/4” F

C

B

13.78

9.76

0.55 0.55

8.50

1.61 4.21

1.26

9.96

21.97

A

4.33

1.545.55

8.50

3.78 2.36

21.97

C 1.971.97

B

A

35 x 0.79

15.28

8.50

1.61 3.98

1.93

5.67

1.773.35

1.18 1.18

8.50

3.78 2.36

7.76

17.83

17.83

0.98

DIMENSIONS WITHOUT EXTERNAL CASING • DIMENSIONS SANS MEUBLE EXTERIEUR

US measure system • Systéme de mesure US

FCXI 20 - 30 - 40 - 50 /220US

FCXI 24 - 34 - 44 - 54 /220US

3 R / 4 R 3 R + 1 R

FCXI 80 US

FCXI 84 US

3 R / 4 R 3 R + 1 R

FCXI 20 /220US 30 /220US 40 /220US 50 /220US 80 /220US

A [inches] 22.56 31.65 40.31 40.31 45.60

B [inches] 20.55 29.65 38.31 38.31 44.17

C [inches] 17.32 26.42 35.08 35.08 43.39

A [inches] 22.56 31.65 40.31 40.31 45.60

B [inches] 20.55 29.65 38.31 38.31 44.17

FCXI 24 /220US 34 /220US 44 /220US 54 /220US 84 /220US

C [inches] 17.32 26.42 35.08 35.08 43.39

IFCXIUSLJ 1203 - 5383620_00

19

DIMENSIONS WITHOUT EXTERNAL CASING • DIMENSIONS SANS MEUBLE EXTERIEUR

Metric system • Systéme métrique

FCXI 20 - 30 - 40 - 50 /220US

FCXI 24 - 34 - 44 - 54

9 x 20

30 30

25

/220US

A

B

3 R / 4 R 3 R + 1 R

216

41 101

49

216

96 60

4585

197

388

Øe 17,5

FCXI 80

FCXI 84

/220US

/220US

144

453

C5050

453

3 R / 4 R 3 R + 1 R

FCXI 20 /220US 30 /220US 40 /220US 50 /220US 80 /220US

A [mm] 573 804 1024 1024 1158

B [mm] 522 753 973 1122 1122

C [mm] 440 671 891 891 1102

FCXI 24 /220US 34 /220US 44 /220US 54 /220US 84 /220US

A [mm] 573 804 1024 1024 1158

B [mm] 522 753 973 1122 1122

C [mm] 440 671 891 891 1102

20

IFCXIUSLJ 1203 - 5383620_00

DIMENSIONS

3 AND 4 ROW COIL • BATTERIE A 3 ET 4 RANGS

D

E

A

F

B

C

FCXI

US measure system • Systéme de mesure US [inches]

A 15.91 15.91 15.91 15.91 20.71

B 10.24 10.24 10.24 10.24 10.75

C 6.02 6.02 6.02 6.02 6.69

D 1.61 1.61 1.61 1.61 1.61

E 5.59 5.59 5.59 5.59 5.83

F 7.64 7.64 7.64 7.64 7.64

Metric system • Metric system [mm]

A 404 404 404 404 526

B 260 260 260 260 273

C 153 153 153 153 170

D 41 41 41 41 41

E 142 142 142 142 148

F 194 194 194 194 194

20 /220US 30 /220US 40 /220US 50 /220US 80 /220US

24 /220US 34 /220US 44 /220US 54 /220US 84 /220US

FCXI 20 /220US 30 /220US 40 /220US 50 /220US 80 /220US

Coil connections (female) • Raccords batterie (femelle)

FCXI 24 /220US 34 /220US 44 /220US 54 /220US 84 /220US

Coil connections (female) • Raccords batterie (femelle)

1/2”F 1/2”F 3/4”F 3/4”F 3/4”F

3/4”F 3/4”F 3/4”F 3/4”F 3/4”F

IFCXIUSLJ 1203 - 5383620_00

21

DIMENSIONS

BV HEATING COIL (Accessory) • BATTERIE DE CHAUFFAGE (Accessories)

D

E

A

B

F

C

20 /220US 30 /220US 40 /220US 50 /220US 80 /220US

BV1 BV1 BV1 BV1 BV1

US measure system • Systéme de mesure US [inches]

A 16.06 16.06 16.06 16.06 20.43

B 12.72 12.72 12.72 12.72 14.88

C 6.02 6.02 6.02 6.02 6.69

D 3.78 3.78 3.78 3.78 3.78

E 6.10 6.10 6.10 6.10 6.14

F 7.64 7.64 7.64 7.64 7.64

Metric system • Metric system [mm]

A 408 408 408 408 519

B 323 323 323 323 378

C 153 153 153 153 170

D 96 96 96 96 96

E 155 155 155 155 156

F 194 194 194 194 194

FCXI 20 US 30 US 40 US 50 US 80 US

Coil connections (female) • Raccords batterie (femelle)

22

IFCXIUSLJ 1203 - 5383620_00

1/2”F 1/2”F 1/2”F 1/2”F 1/2”F

WIRING DIAGRAMS • SCHEMAS ELECTRIQUES

READING KEY • LEGENDE

F = Fusibile • Fuse • Fusible

IG = Main switch

Interupteur général l

M = Terminal board

Boitier

MV = Fan motor

Moteur ventilateur

PE = Earth connection

Mise à terre

VC = Solenoid valve hot

Vanne magnétique chaud

VF = Solenoid valve cold

Vanne magnétique froid

= On-site wiring

Raccordements à effectuer in situ

POWER SUPPL Y

240V/208V ~ - 60Hz

N V1 V2 V3 V4 VF N

L

= Components not supplied

Composants non fournis

= Optional components

Composants en option

AR = Orange • Orange

BI = White • Blanc

BL = Blue • Bleu

GI = Yellow • Jaune

GR = Grey • Gris

MA = Brown • Marron

NE = Black • Noir

RO = Red • Rouge

VE = Green • Vert

VI = Violet • Violet

M

VC

5384050_00

All wiring diagrams are constantly updated. Please refer to the ones supplied with the unit.

Nos schémas électriques étant constamment mis à jour, il faut absolument se référer à ceux fournis à bord de nos appareils.

IFCXIUSLJ 1203 - 5383620_00

23

PROBLEM

PROBLEME

Feeble air discharge.

Il y a peu d’air en sortie.

It does not heat.

Pas de chaleur.

It does not cool.

Pas de froid.

PROBABLE CAUSE

CAUSE PROBABLE

Wrong speed setting on the control panel.

Mauvaise préselection de la vitesse sur le panneau de com-

mandes.

Blocked filter.

Filtre encrassé.

Obstruction of the air flow (inlet and/or outlet).

Obstruction du flux d’air (entrée/sortie).

Poor hot water supply.

Il n’y a pas d’eau chaude.

Wrong setting on control panel.

Mauvaise présélection sur le panneau de commandes.

Poor chilled water supply.

Il n’y a pas d’eau froide.

REMEDY

SOLUTION

Select the speed on the control panel.

Choisir la vitesse sur la panneau de comman-

des.

Clean the filter.

Nettoyer le filtre.

Remove the obstruction.

Enlever l’objet faisant obstruction.

Control the boiler.

Verifier la chaudière.

See control panel settings.

Présélectionner au panneau de commandes.

Control the chiller.

Vérifier le réfrigerateur.

The fan does not turn.

Le ventilateur ne tourne

pas.

Condensation on the unit

cabinet.

Phénomènes de condensation sur la structure

exterieure de l’appareil.

Wrong setting on control panel.

Mauvaise présélection sur le panneau de commandes.

No current.

l n’y a pas de courant.

The water has not reached operating temperature.

L'eau n'a pas atteint la température de service.

The limit conditions of temperature and humidity indicated in “MINIMUM AVERAGE WATER TEMPERATURE”

have been reached.

On a atteint les conditions limite de température et

d’humidité indiquées dans “TEMPERATURE MINIMALE MOYENNE DE L'EAU”.

See control panel settings.

Présélectionner au panneau de commandes.

Control the power supply.

Contrôler l’alimentation électrique.

Please check up the boiler or the chiller.

Check up the thermostat settings.

Contrôler la chaudière ou le refroidisseur.

Contrôler le réglage du thermostat.

Increase the water temperature beyond the

minimum limits indicated in “MINIMUM

AVERAGE WATER TEMPERATURE”.

Elever la température de l’eau audelà des

limites minimales indiquées dans “TEMPERATURE MINIMALE MOYENNE DE L'EAU”.

For anomalies don’t hesitate, contact the aftersales service immediately.

Pour toute anomalie non répertoriée, consulter le service après-vente.

24

IFCXIUSLJ 1203 - 5383620_00

INVERTER CARD FACTORY SETTINGS

RÉGLAGES EN USINE DE LA PLATINE INVERTER

WARNING: Do not modify the unit's settings.

Any change to the inverter card dip switch settings may

cause damage to the unit. For this reason the diagram of

the factory settings are indicated.

FCXI20/220US

FCXI24/220US

FCXI30/220US

FCXI34/220US

ATTENTION : Ne pas modifi er les réglages de l'unité.

Toute modifi cation des réglages des commutateurs DIP de

la platine inverter peut endommager l'unité. Pour cette

raison, on reporte le schéma avec les réglages en usine.

FCXI40/220US

FCXI44/220US

FCXI50/220US

FCXI54/220US

FCXI80/220US

FCXI84/220US

IFCXIUSLJ 1203 - 5383620_00

25

I dati tecnici riportati nella presente documentazione non sono impegnativi.

AERMEC S.p.A. si riserva la facoltà di apportare in qualsiasi momento tutte le modifiche ritenute necessarie per il miglioramento del prodotto.

Les données mentionnées dans ce manuel ne constituent aucun engagement de notre part. Aermec S.p.A. se réserve le droit de modifier à tous moments les

données considérées nécessaires à l’amelioration du produit.

Technical data shown in this booklet are not binding.

Aermec S.p.A. shall have the right to introduce at any time whatever modifications deemed necessary to the improvement of the product.

Im Sinne des technischen Fortsschrittes behält sich Aermec S.p.A. vor, in der Produktion Änderungen und Verbesserungen ohne Ankündigung durchzuführen.

ILos datos técnicos indicados en la presente documentación no son vinculantes.

Aermec S.p.A. se reserva el derecho de realizar en cualquier momento las modificaciones que estime necesarias para mejorar el producto.

AERMEC S.p.A.

I-37040 Bevilacqua (VR) - Italia

Via Roma, 996 - Tel. (+39) 0442 633111

Telefax (+39) 0442 93730 - (+39) 0442 93566

www.aermec.com

Loading...

Loading...