Page 1

AERCO XPC Gateway Communications

USER MANUAL

GF-122

OMM-0044_0C

AERCO XPC GATEWAY

Communications Manual

For Interfacing

AERCO Equipment

To

Building Automation Systems

Utilizing:

BACnet, N2, or LonWorks Protocol

Printed in U.S.A REVISED 11/10/2011

Page 2

GATEWAY COMMUNICATIONS MANUAL

The information contained in this manual is subject to

Telephone Support

Direct to AERCO Technical Support

(8 to 5 pm EST, Monday through Friday):

1-800-526-0288

AERCO International, Inc.

100 Oritani Dr.

Blauvelt, NY 10913

www.AERCO,com

© AERCO International, Inc., 2009

change without notice from AERCO International, Inc.

AERCO makes no warranty of any kind with respect to this

material, including but not limited to implied warranties of

merchantability and fitness for a particular application.

AERCO is not liable for errors appearing in this manual,

nor for incidental or consequential damages occurring in

connection with the furnishing, performance, or use of this

material.

2

Page 3

GF-122 AERCO XPC GATEWAY

Foreword

The AERCO XPC (Extended Protocol Converter) allows a Building Automation Systems (BAS) or

Energy Management System (EMS) utilizing BACnet, Johnson N2 or LonWorks protocol to

communicate with AERCO boilers and water heaters which utilize Modbus.

The AERCO XPC Gateway can monitor and control up to 300 points. Each XPC is individually

programmed to your specific needs.

The information provided in this document is divided into an Introduction followed by three (3) parts:

• Introduction – An introduction to and general description of the AERCO XPC Gateway.

• Part

• Part

• Part

I - Provides a top-level description of the AERCO XPC Gateway features and capabilities.

It also includes detailed set-up and programming instructions to interface the XPC

Gateway to the AERCO equipment to be monitored or controlled on the network.

II - Provides the set-up and programming instructions to interface the AERCO XPC

Gateway to a Building Automation System (BAS) or Energy Management System (EMS)

which utilizes BACnet, Johnson N2 or LonWorks protocol.

III – Provides the protocol mapping points for the standard configurations which can be

monitored or controlled.

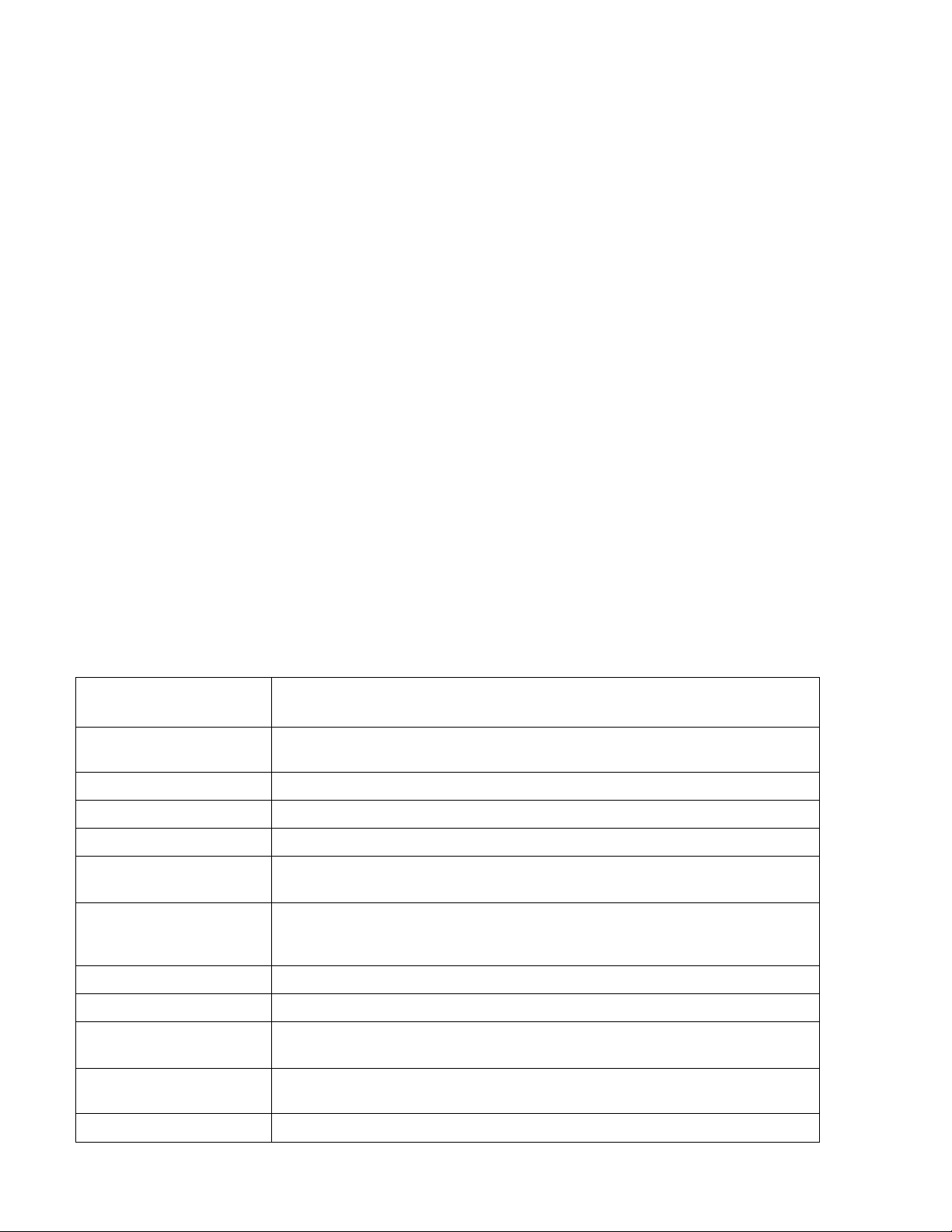

PHRASES, ABBREVIATIONS & ACRONYMS

The phrases, abbreviations and acronyms used in this document are listed in the following table.

Phrases, Abbreviations and Acronyms

Phrase, Abbreviation

or Acronym

ARCnet Attached Resource Computer network. This is a Local Area Network (LAN)

similar to Ethernet.

ASCII American Standard Code for Information Interchange

ASHRAE American Society of Heating, Refrigerati ng and Air Conditioning Engineers

BACnet Building Automation and Control network. Protocol developed by ASHRAE.

BAS Building Automation System, often used interchangeably with EMS (see

below)

Baud Rate Symbol rate, or simply the number of distinct symbol changes (signaling

events) transmitted per second. It is not equal to bits per second, unless

each symbol is 1 bit long.

BCM Boiler Control Module used in a Modulex (MLX) Boil er

Meaning

BMS (BMS II) Boiler Management System (Boiler Management System II)

Bias Resistors A pair of resistors used to force the communi cation line to a definite logic

state so that noise is not picked up as invalid dat a during communication.

C-More Controller

(or Control Box)

DIP Dual In-Line Package

A control system developed by AERCO and currently used in all Benchmark

and KC Series product lines.

3

Page 4

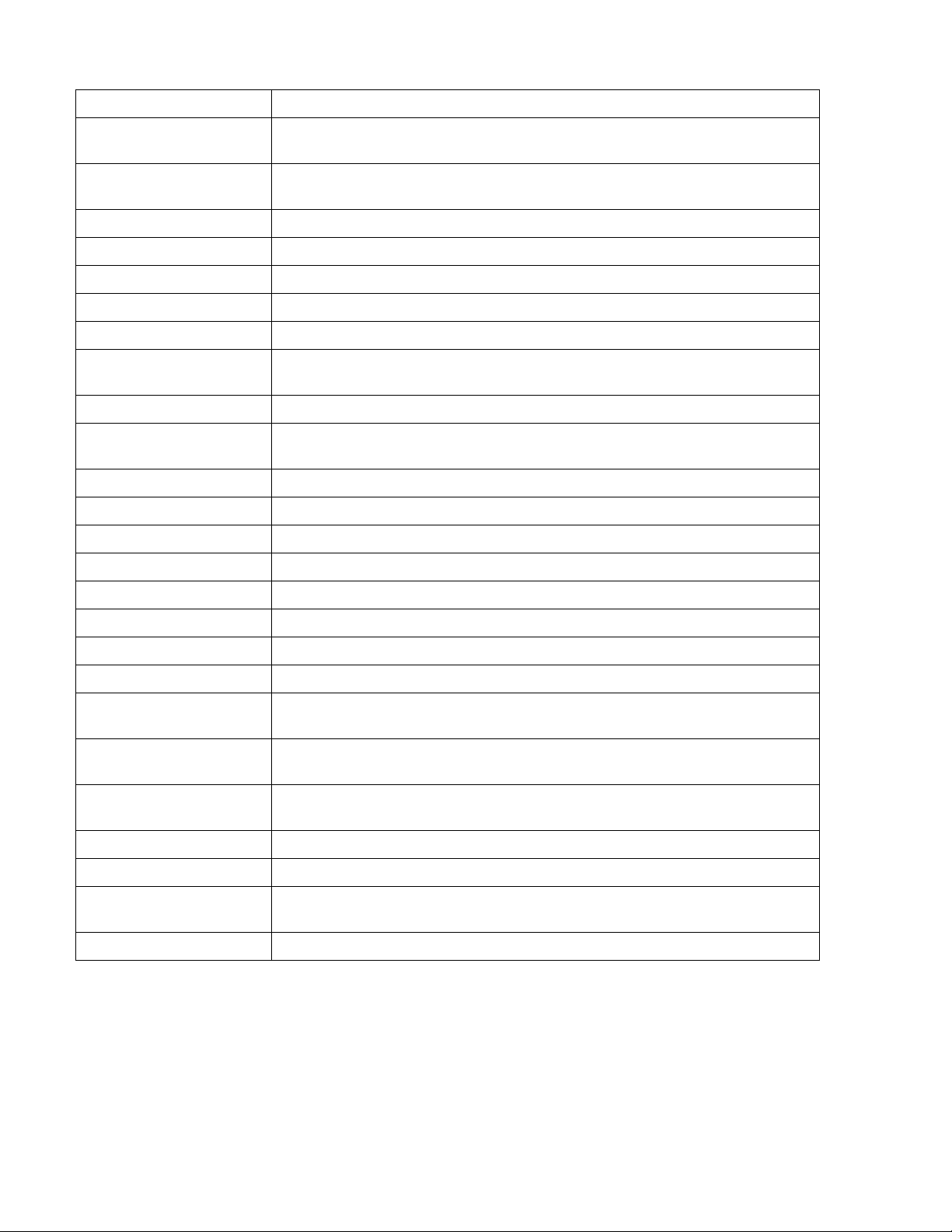

GATEWAY COMMUNICATIONS MANUAL

EIA Electronic Industries Alliance

EIA-232

(or RS232)

EIA-485

(or RS485)

EMS Energy Management System

Ethernet A computer networking technology for Local Area Networks (LANs)

FDX Full-Duplex

HDX Half-Duplex

Hex Hexadecimal Number (0 - 9, A - F)

I/O Box Input/Output (I/O) Box currently used on al l B enchmark and KC Series

IP Internet Protocol

LonWorks A communication protocol developed by t he Echelon Corporation for control

LSB Least Significant Byte

MLX Modulex Boiler

Modbus® A serial, half-duplex data transmission protocol developed by AEG Modicon

MSB Most Significant Byte

A standard for serial, full-duplex (FDX) transmission of data based on the

EIA-232 Standard

A standard for serial, half-duplex (HDX) transmission of data based on the

EIA-485 Standard

products

applications

MS/TP Master-Slave/Token-Passing (usually over RS485 networks)

N2 A communications protocol developed by Johnson Controls

PTP Point-to-Point (usually over RS232 networks)

Response Time The maximum amount of time allowed to receive a response to a request

RS232

(or EIA-232)

RS422

(or EIA-422)

RS485

(or EIA-485)

RTU Remote Terminal Unit

SLTA Serial LonTalk Adapter

Terminating Resistor A resistor placed at each end of a daisy-chain or multi-dr op network in order

XPC Extended P rotocol Converter (manufactured by OEM Ctrl)

A standard for serial, full-duplex (FDX) transmission of data based on the

RS232 Standard

A standard for serial, full-duplex (FDX) transmission of data based on the

RS422 Standard

A standard for serial, half-duplex (HDX) transmission of data based on the

RS485 Standard

to prevent reflections that may cause invalid data in the communication

4

Page 5

GF-122 AERCO XPC GATEWAY

TABLE OF CONTENTS

SECTION 1 INTRODUCTION AND GENERAL DESCRIPTION ................................................ 10

1.1 INTRODUCTION ............................................................................................................................ 10

1.2 REFERENCE DOCUMENTS .......................................................................................................... 10

1.3 AERCO XPC GATEWAY PURPOSE AND USE .......................................................................... 10

1.4 AERCO XPC GATEWAY DESCRIPTION .................................................................................... 11

1.5 GATEWAY PORTS & JUMPERS .................................................................................................. 13

1.5.1 Port 1a ........................................................................................................................................................ 13

1.5.2 Port 2 .......................................................................................................................................................... 13

1.5.3 Local Access Port ...................................................................................................................................... 13

1.5.4 Optional Plug-In Module (Port 1b) ............................................................................................................ 13

1.5.5 Jumper Settings .......................................................................................................................................... 13

1.6 POWER INPUT, PROTOCOL SELECTION & GATEWAY ADDRESSING .............................. 16

1.6.1 Input Power Connection ............................................................................................................................ 16

1.6.2 Protocol and Baud Rate Select ................................................................................................................... 16

1.6.3 Gateway Address Switches ........................................................................................................................ 17

1.7 GATEWAY STATUS INDICATORS ............................................................................................. 17

1.8 BASIC GATEWAY OPERATION .................................................................................................. 19

1.9 XPC GATEWAY REFERENCE DATA .......................................................................................... 20

1.10 QUICK SETUP GUIDE ................................................................................................................. 21

1.10.1 Quick Setup Guide ................................................................................................................................... 22

1.10.2 BACNET MS/TP to AERCO XPC .......................................................................................................... 23

1.10.3 LON to AERCO XPC (with LON-OC) ................................................................................................... 24

1.10.4 LON to AERCO XPC (with SLTA) ........................................................................................................ 25

1.10.5 LON to XPC (with LON-OC) .................................................................................................................. 26

1.10.6 AERCO XPC to Boiler Management System (BMS) .............................................................................. 27

1.10.7 AERCO XPC to Boiler Management System II (BMS II) ...................................................................... 28

1.10.8 AERCO XPC to C-More ......................................................................................................................... 29

1.10.9 AERCO XPC to BCM (on MLX Boiler) ................................................................................................. 30

1.10.10 AERCO XPC to ECS (with Eurotherm Control) ................................................................................... 31

SECTION 2 INTERFACING THE XPC WITH C-MORE CONTROLLED UNITS ................... 34

2.1 INTRODUCTION ............................................................................................................................ 34

2.2 PHYSICAL NETWORK WIRING .................................................................................................. 34

2.3 C-MORE BOILERS OR HEATERS CONTROLLED BY BAS VIA THE GATEWAY ............... 34

2.4 C-MORE CONTROLLER MODBUS COMMUNICATION INTERFACE ................................... 35

2.5 RS485 LOOP TERMINATING RESISTORS AND BIAS .............................................................. 37

2.5.1 C-More Boiler Controller Terminating Resistor and Bias ......................................................................... 37

2.5.2 BAS Terminating Resistor and Bias .......................................................................................................... 41

2.6 C-MORE CONTROLLER WIRING CONNECTIONS TO AERCO XPC GATEWAY ................ 41

2.6.1 C-More Wiring C onnections to XPC Port 2 .............................................................................................. 41

2.6.2 C-More Wiring C onnections to XPC Port 1a ............................................................................................ 42

2.7 CONFIGURING THE C-MORE CONTROLLERS ........................................................................ 43

2.7.1 C-More Controller Monitoring and Configuration Control ....................................................................... 43

2.7.2 Direct Drive Control and Monitoring ........................................................................................................ 44

2.7.3 Remote Setpoint Control ............................................................................................................................ 44

SECTION 3 INTERFACING THE XPC TO BOILER MANAGEM ENT SYSTEMS .................. 47

3.1 INTRODUCTION ............................................................................................................................ 47

3.2 INTERFACING THE XPC GATEWAY TO BMS, MODEL 158 .................................................. 47

3.2.1 BMS Set-Up For Monitoring ..................................................................................................................... 48

3.2.2 C-More Boilers Being Network-Controlled by a BMS ............................................................................. 51

3.2.3 BMS Setup For Remote Setpoint Control From the XPC Gateway .......................................................... 53

3.3 INTERFACING THE XPC GATEWAY TO BMS II, MODEL 5R5-384 ....................................... 55

3.3.1 BMS II Set-Up For Monitoring ................................................................................................................. 56

5

Page 6

GATEWAY COMMUNICATIONS MANUAL

3.3.2 C-More Boilers Being Network-Controlled by a BMS II .......................................................................... 59

3.3.3 Modulex Boile rs Being Network-Controlled by a BMS II ........................................................................ 60

3.3.4 BMS II Setup For Remote Setpoint Control From The XPC Gateway ..................................................... 61

SECTION 4 AERCO XPC GATEWAY TO BCM CONTROLLED MODUL E X BOILERS .. 64

4.1 CONNECTION AND SET-UP OF BOILER COMMUNI CATIONS MODULES (BCMS) .......... 64

4.2 BCM WIRING CONNECTIONS TO AERCO XPC GATEWAY .................................................. 65

4.2.1 BCM Wiring Connections to XPC Port 2 .................................................................................................. 65

4.2.2 BCM Wiring Connections to XPC Port 1a ................................................................................................ 66

4.3 CONFIGURING THE BCM CONTROLLER ................................................................................. 67

SECTION 5 XPC GATEWAY TO ECS CONTROLLED HOT WATER HEATERS .................. 68

5.1 CONNECTION AND SET-UP OF ELECTRONIC CONTROL SYSTEM (ECS) ......................... 68

5.2 ECS WIRING CONNECTIONS TO AERCO XPC GATEWAY ................................................... 70

5.2.1 ECS Wiring Connec t ions to XPC Port 2 .................................................................................................... 70

5.2.2 ECS Wiring Connec t ions to XPC Port 1a .................................................................................................. 71

5.3 CONFIGURING THE ECS CONTROLLER .................................................................................. 72

5.4 CONFIGURING THE ECS CONTROLLER FOR REMOTE SETPOINT OPERATION ............. 72

SECTION 6 WHAT IS PART II OF THIS DOCUMENT ABOUT? .............................................. 74

SECTION 7 PROTOCOL OVERVIEW ............................................................................................ 74

7.1 WHAT IS A PROTOCOL? .............................................................................................................. 74

7.2 WHY ARE THERE SO MANY PROTOCOLS? ............................................................................. 74

7.3 WHY BUILD INTHE MOST WIDELY USED PROTOCOLS? .................................................... 75

7.4 WHAT DOES THE SITE INTEGRATOR NEED? ......................................................................... 75

SECTION 8 BACNET .......................................................................................................................... 76

SECTION 9 BACNET OVER ARC156 .............................................................................................. 76

9.1 CONFIGURING THE AERCO XPC FOR ARC156 ....................................................................... 76

SECTION 10 BACNET MS/TP ............................................................................................................. 78

10.1 CONFIGURING THE AERCO XPC FOR BACNET MS/TP ....................................................... 78

SECTION 11 BACNET PTP ................................................................................................................. 80

11.1 CONFIGURING THE AERCO XPC FOR BACNET PTP ........................................................... 80

SECTION 12 JOHNSON CONTROLS (N2) ....................................................................................... 82

12.1 CONFIGURING THE AERCO XPC FOR N2 F OR PORT 1A .................................................... 82

SECTION 13 LONWORKS ................................................................................................................... 84

13.1 CONFIGURING THE AERCO XPC FOR LONTALK VIA SLTA-10 ........................................ 84

13.2 CONFIGURING THE AERCO XPC FOR LONWORKS OPTION CARD ................................. 86

SECTION 14 TROUBLESHOOTING ................................................................................................. 88

14.1 MOST COMMON COMMUNICATION PROBLEMS ................................................................ 88

14.1.1 No Receive LED Indication ..................................................................................................................... 88

14.1.2 Wiring termination ................................................................................................................................... 88

14.1.3 Jumper selection ...................................................................................................................................... 88

14.1.4 Dipswitch selection .................................................................................................................................. 88

14.1.5 Addressing ............................................................................................................................................... 88

14.2 BACNET OVER ARC156 ............................................................................................................. 88

14.3 BACNET MS/TP ............................................................................................................................ 89

14.4 BACNET PTP ................................................................................................................................. 90

14.5 N2 ................................................................................................................................................... 90

14.6 LONWORKS .................................................................................................................................. 91

14.7 COMMISSIONING THE XPC FOR LONWORKS ...................................................................... 91

14.8 COMMUNICATION LED'S .......................................................................................................... 92

SECTION 15 COMPLIANCE ............................................................................................................... 94

15.1 FCC COMPLIANCE ...................................................................................................................... 94

15.2 BACNET COMPLIANCE ............................................................................................................. 94

SECTION 16 BACNET PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT 94

16.1 ANALOG VALUE (PAR) .............................................................................................................. 96

16.2 BINARY VALUE (PAR), (CLOCK), AND (STAT) ..................................................................... 97

16.2.1 notification_class .................................................................................................................................. 98

6

Page 7

GF-122 AERCO XPC GATEWAY

16.2.2 notify_type ............................................................................................................................................. 98

16.2.3 out_of_service ...................................................................................................................................... 98

16.2.4 present_value ....................................................................................................................................... 98

16.2.5 relinquish_default ................................................................................................................................. 98

16.2.6 time_delay ............................................................................................................................................. 98

16.3 ANALOG VALUE (STAT) ........................................................................................................... 99

16.4 BINARY VALUE (PAR), (CLOCK), AND (STAT) ................................................................... 101

16.5 BINARY VALUE (MODULE ALARM) .................................................................................... 102

16.6 CALENDAR ................................................................................................................................. 103

16.7 DEVICE ........................................................................................................................................ 103

16.8 FILE .............................................................................................................................................. 105

16.9 MULTI_STATE VALUE ............................................................................................................. 105

16.10 MULTI_STATE VALUE (STAT) ............................................................................................. 106

16.11 NOTIFICATION CLASS ........................................................................................................... 107

16.12 PROGRAM ................................................................................................................................. 107

16.13 SCHEDULE ................................................................................................................................ 108

16.14 TREND_LOG (NON-BACNET PROPERTY) .......................................................................... 109

SECTION 17 BACNET DATA LINK LAYER OPTIONS ............................................................... 110

SECTION 18 CONFORMANCE STATEMENT FOR MODBUS IMPL EMENTATION ........... 111

SECTION 19 CONFORMANCE STATEMENT FOR JOHNSON N2 IMPLEMENTATION .... 113

SECTION 20 CONFORMANCE STATEMENT FOR LONWORKS IMPLEMENTATION ..... 116

SECTION 21 INTRODUCTION to Part III ...................................................................................... 120

SECTION 22 APPLOADER SOFTWARE UTILITY ...................................................................... 120

SECTION 23 PROGRAM FILES AND FILENAMES ..................................................................... 120

SECTION 24 CONTROL POINTS AND SPEED OF OPERATION ............................................. 121

SECTION 25 MODBUS TIMERS ...................................................................................................... 121

SECTION 26 MODBUS RESPONSE TIME ..................................................................................... 122

SECTION 27 MODBUS INTERPACKET Delay .............................................................................. 122

SECTION 28 AERCO EQUIPMENT MONITOR & CONTROL POINT DEFINITIONS ......... 123

SECTION 29 PROTOCOL MAPPING TABLES ............................................................................. 129

SECTION 30 C-MORE BOILER CONTROLLER STATUS & FAULT MESSAGES ................ 185

SECTION 31 ERROR CODES ........................................................................................................... 188

7

Page 8

GATEWAY COMMUNICATIONS MANUAL

THIS PAGE INTENTIONALLY BLANK

8

Page 9

GF-122 AERCO XPC GATEWAY

INTRODUCTION

AERCO XPC DESCRIPTION

QUICK SETUP GUIDE

And

9

Page 10

GATEWAY COMMUNICATIONS MANUAL

DOCUMENT

TITLE

AERCO

(www.aerco.com)

GF-108M,

Boiler Management System (BMS or BMS II)

GF-112

C-More Control Panel Operation Manual

GF-114

Modbus Communication Manual

GF-115-C

Operation & Wiring Guides for Modulex E8

Eurotherm

(www.eurotherm.com/controllers/2400_doc.htm)

HA026230

2000 Series Communication Handbook

SECTION 1 INTRODUCTION AND GENERAL DESCRIPTION

1.1 INTRODUCTION

AERCO Boilers and Water Heaters equipped with any of the AERCO Control Systems listed below

can communicate directly with a Building Automation System (BAS) or Energy Management System

(EMS) utilizing Modbus RTU protocol. The AERCO Control Systems include:

• C-More Control System

• Boiler Management System (BMS or BMS II)

• Boiler Communications Module (BCM)

• Electronic Control System (ECS)

Although most BAS and EMS Systems support Modbus communication, many installations may

already be utilizing different types of communication protocol. In addition to Modbus, the most

commonly used protocols are BACnet, LonWorks and N2. In order to bridge the gap between

Modbus and other popular protocols, AERCO has developed the AERCO XPC Communications

Gateway. This Gateway makes connectivity to AERCO equipment as simple as “plug-and-play”.

The remaining sections in Part I provide top level descriptions of the AERCO Gateway and how it can

be implemented to provide connectivity between AERCO equipment and a BAS or EMS system

utilizing Modbus or other popular communication protocols.

Sections 2 through 5 provide detailed information and procedures for implementing network set-ups

to interface the XPC Gateway to AERCO boilers and water heaters.

1.2 REFERENCE DOCUMENTS

References to the following documents are included in the appropriate sections and subsections of

this manual:

AC-105 Electronic Control System

Installation, Operation & Maintenance Manual

GF-124

HA025132 2404/2408 Control Setpoint Programmer Installation

Installation, Operation & Maintenance Manual

Controller & Boiler Communications Module (BCM)

and Operation Handbook

1.3 AERCO XPC GATEWAY PURPOSE AND USE

The primary purpos e of the AERCO XPC Gateway is to allow monitoring or control of AERCO units.

Due to the operational nature of the Gateway, it should not be used to configure the system.

Configuration (or setup information) should not be constantly changed since this information is

generally stored in EEPROM non-volatile memory in the AERCO Controllers (C-More, BMS, and

10

Page 11

GF-122 AERCO XPC GATEWAY

ECS). This type of memory can be read as often as needed, however, it has a limited number of

write cycles.

The Gateway is preprogrammed with standard monitor and control points. These standard points are

those most often requested by AERCO customers (see Part III). If different or additional points are

required for a particular system, custom factory programming is available. There are five (5) standard

pre-programmed configurations to choose from:

• Programmed for 4 C-More controlled boilers and 1 Boiler Management System (BMS/BMS II)

• Programmed for 1 BMS/BMS II and 8 C-More controlled boilers

• Programmed for 1 BMS/BMS II and 12 C-More controlled boilers

• Programming for 1 BMS II and 4 BCM controlled Modulex boilers

• Programmed for 4 ECS controlled water heaters

Multiple XPC Gateways can be used in certain situations.

If necessary, the XPC Gateway can accept up to 300 monitor and control points. Network points and

unit addresses are pre-programmed in the Gateway. In addition, all of the supported protocols –

BACNET, LonWorks, and N2 are preprogrammed for all points. They can be easily selected using

the DIP switches provided on the Gateway.

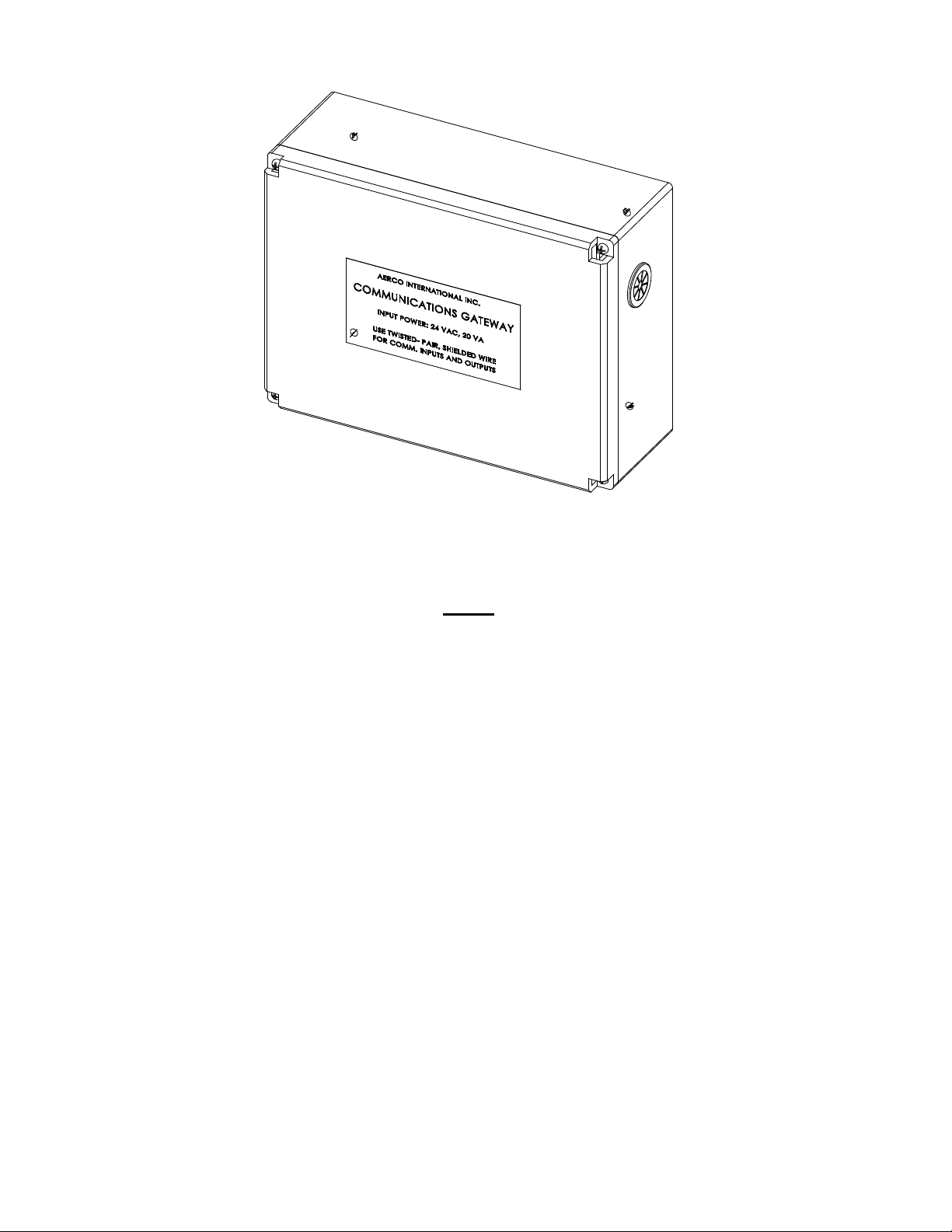

1.4 AERCO XPC GATEWAY DESCRIPTION

The XPC Gateway Controller is shown in Figure 1-1. The Gateway is housed i n a compact enclosure

measuring approximately 6” H x 8” W x 3” D as shown in Figure 1-2. The installed location of the

Gateway will depend on the types of AERCO equipment being used with the Gateway.

Figure 1-1. AERCO XPC Gateway

11

Page 12

GATEWAY COMMUNICATIONS MANUAL

Figure 1-2. AERCO XPC Gateway Installed in Enclosure

NOTE

If desired, the Gateway can always be wall-mounted, regardless of the

types of AERCO equipment being used. However, signaling wire

lengths must not exceed 50 feet for RS232 and 3000 feet for RS485

networks.

• Benchmark Series Boilers: XPC Gateway can be installed behind the front panel door of the

Benchmark below the Input/Output (I/O) Box.

• KC1000 Series Boilers or Heaters: XPC Gateway can be installed on the left side of the unit

above the Input/Output (I/O) Box.

• Boiler Management System (BMS/BMS II): XPC Gateway is normally mounted on a wall in

close proximity to the BMS.

• Indirect-Fired Heaters with ECS Control System: Gateway is normally wall-mounted.

• Modulex Boilers equipped with Boiler Control Modules (BCMs).

The Gateway is powered by 24 VAC, 50/60 Hz, single-phase, 20 VAC. Power and Input/Output

(I/O) signal connections are made via four grommetted cutouts (one on each side and two on

the bottom surface of the Gateway enclosure. I/O signal wiring is routed through the left-side and

bottom-left cutouts of the Gateway enclosure. Connection to the Lon module is accomplished via

the bottom-right cutout. Input power wiring (24 VAC, 50/60 Hz) and earth ground wire is routed

through the right-side cutout of the enclosure to minimize noise on the signal wiring.

12

Page 13

GF-122 AERCO XPC GATEWAY

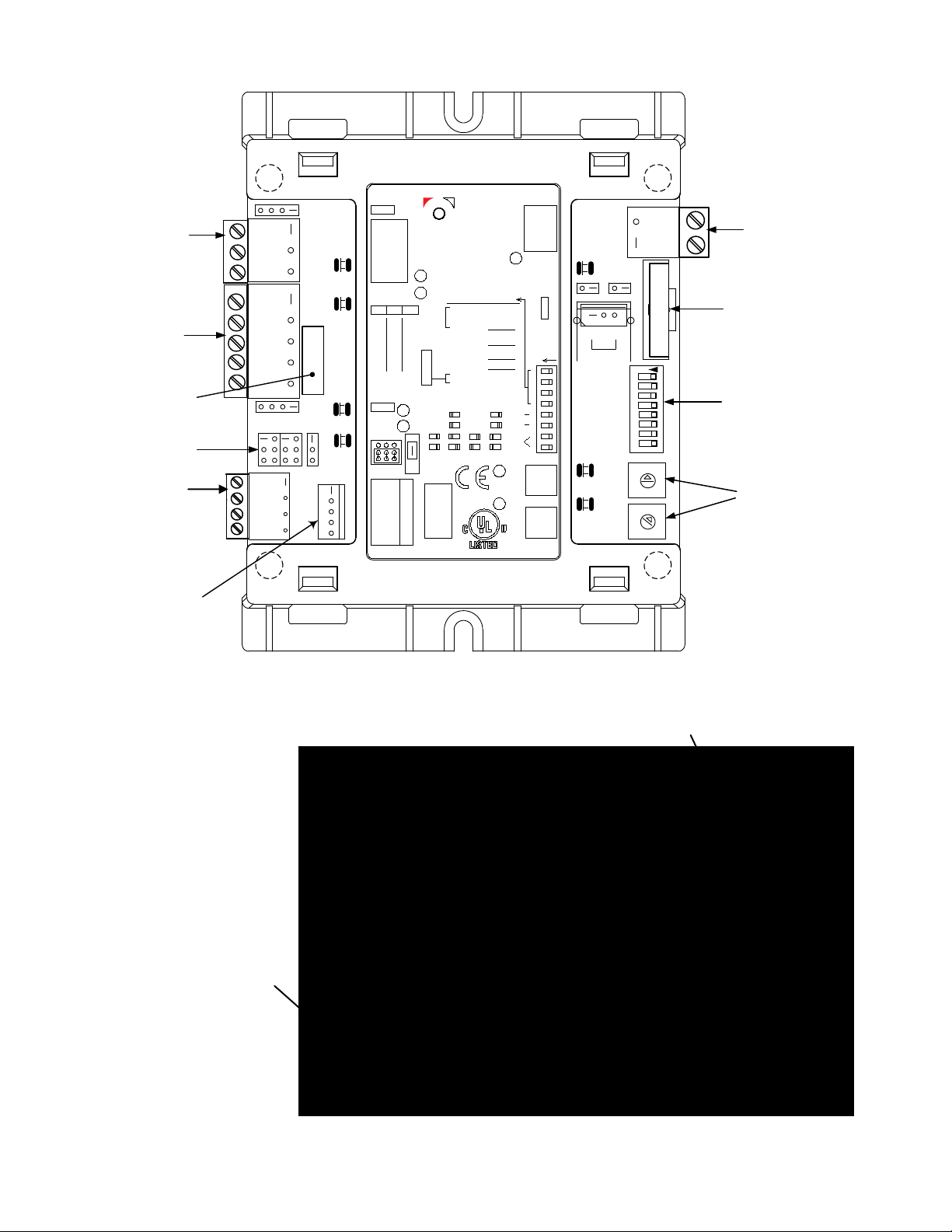

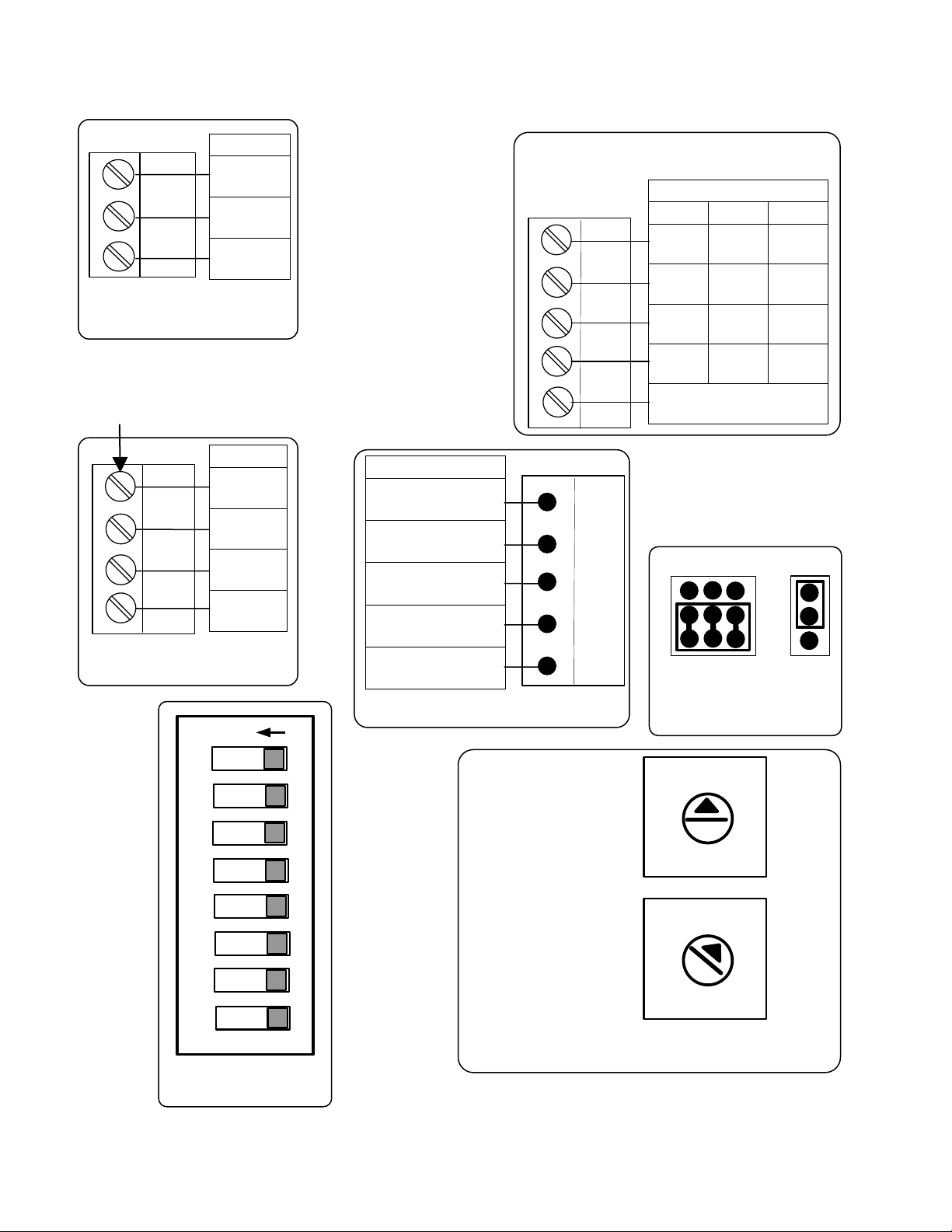

1.5 GATEWAY PORTS & JUMPERS

The Gateway Input/Output (I/O) signal ports are located on the left side of the XPC Gateway, behind

the enclosure cover as illustrated in Figure 1-3. In addition, jumpers are also provided on the left side

of the Gateway to select the physical type of network being utilized on port 2. The following

subsections provide brief descriptions of the ports and jumpers provided.

1.5.1 Port 1a

Port 1a (Figure 1-3, Detail “A”) can only be configured for RS485 communication or special ARC156.

This port is normally used for BAS connections. However, if the BAS is communicating via BACnet

PTP or is connected to a LonWorks SLTA module, Port 1a cannot be used. Refer to the AERCO XPC

Gateway Integration Guide included as Part II of this manual.

1.5.2 Port 2

Port 2 (Figure 1-3, Detail “B”) can be configured for RS485 or RS232 communication. This port

normally connects to AERCO equipment except when the BAS is utilizing BACnet PTP or a

LonWorks SLTA. In this case, Port 1a must be used for the AERCO equipment. The jumpers located

below Port 2 are used to select RS485 or RS232 (EIA-485 or EIA-232) communication and either a 2wire or 4-wire communication interface (see para. 1.5.5).

1.5.3 Local Access Port

The Local Access Port (Figure 1-3, Detail “C2”) is used to program or read Gateway setup

information or to monitor network traffic from the Gateway with a PC using a special interface module.

Special network display monitors can also be connected to this port to display network information.

1.5.4 Optional Plug-In Module (Port 1b)

A 14-pin connector labeled Port 1b is for an optional plug-in module. Currently, there is a LonWorks

transceiver module that allows LonWorks FTT10A communication without the use of a Serial Lon

Talk Adapter (SLTA).

1.5.5 Jumper Settings

Two jumpers are located side-by-side below PORT 2 on the Gateway (Figure 1-3, Detail “D”). These

jumpers provide the following functions:

• EIA-232/EIA-485 Jumper

connector to select either an EIA-485 (RS485) or EIA-232 (RS232) connection to the

BAS. Setting the jumper to the lower position selects EIA-485 (RS485) which is the

default position. Setting the jumper to the upper position selects EIA-232 (RS232).

• 2-Wire/4-Wire Jumper

connector. Setting the jumper to the upper position selects 2-wire communication. Setting

the jumper to the lower position selects 4-wire communication.

- This jumper is connected across 8 of the 12 pins of the header

– This jumper is connected across 2 of the 3 pins of the header

13

Page 14

GATEWAY COMMUNICATIONS MANUAL

+12V

RNET-

RNET+

GND

COM

NET-

RX

TX

FORMAT

POWER

NET+

CMNET

ONE's

ERR

RUN

OPTIONS

TEN's

BATT

24VAC

GND

POWER

485

232

LN-

/S

+12

GND

LN+

2W

RX

TX

4W

BT485

Net +

Net -

Shield

Port 1a

Tx1

Rx1

Port 1b

Port 2

4w

2w

Gnd

+12V

Gnd

Rnet+

Sense

Rnet +

Rnet -

R n e t

Rnet+12V

Local

Access

10's

1's

0

134

5

2

78

9 6

0

134

5

2

78

9 6

4

3

2

1

On

5

6

7

8

Run

Error

Power

Format

Gnd

Hot

EIA-232

EIA-485

Baud

EIA485

19.2k

38.4k 76.8k

BMS

Port 2

ARC156

Port 1

9600

BMS

Switches

(0 = off, 1 = on)

MSTP (m)

MSTP (s)

PTP

8 7 6 5

Protocol

0 0 0 0

0 0 0 1

0 0 1 0

BACnet

BMS

Port 1

TYPE: 002106

Enclosed Energy Management Equipment

Made in USA

®

24V ac

2w 4w

Tx+

n/c

n/c

Net+

Rx+

Rx-

Tx-Net-

232

Tx

DTR

DCD

Rx

Signal Ground

+

-

Batt

CR

2032

BT485

Lon SLTA

1 1 0 1

Lon PlugIn

Ethernet

1 1 1 1

1 1 1 0

N2

Modbus

®

®

0 1 1

0 1 0 0

0

Tx2

Rx2

E143900

88FO

R

Class 2, 24Vac

Conductors Only

Use Copper

50-60Hz, 10VA, 0.42A

®

XPC

PORT 1a

( DETAIL “A”)

PORT 2

( DETAIL “B”)

RNET

(

DETAIL “C1”)

PORT 1b

JUMPERS

( DETAIL “D”)

0

5

1

2

3

4

6

7

8

9

0

5

1

2

3

4

6

7

8

9

8

7

6

5

4

32

1

ON

INPUT

POWER

( 24 VAC)

DIP

SWITCHES

( DETAIL “E”)

ADDRESS

SELECT

SWITCHES

( DETAIL “F”)

BATTERY

(3V)

LOCAL

ACCESS

PORT

(DETAIL “C2”)

NOTE: Ground

(see Sht 2 of 3).

RNET

(DETAIL “C1”)

Ground connection lug for

Earth ground connection lug. Connect

is attached to

Mounting Panel

Figure 1-3. XPC Gateway Ports, Jumpers and Switches (Sheet 1 of 3)

RNET connector. DO NOT

REMOVE. This ground

MUST be connected when

power is applied to the

Gateway Controller.

Figure 1-3. XPC Gateway Chassis Ground Locations (Sheet 2 of 3)

earth ground here.

14

Page 15

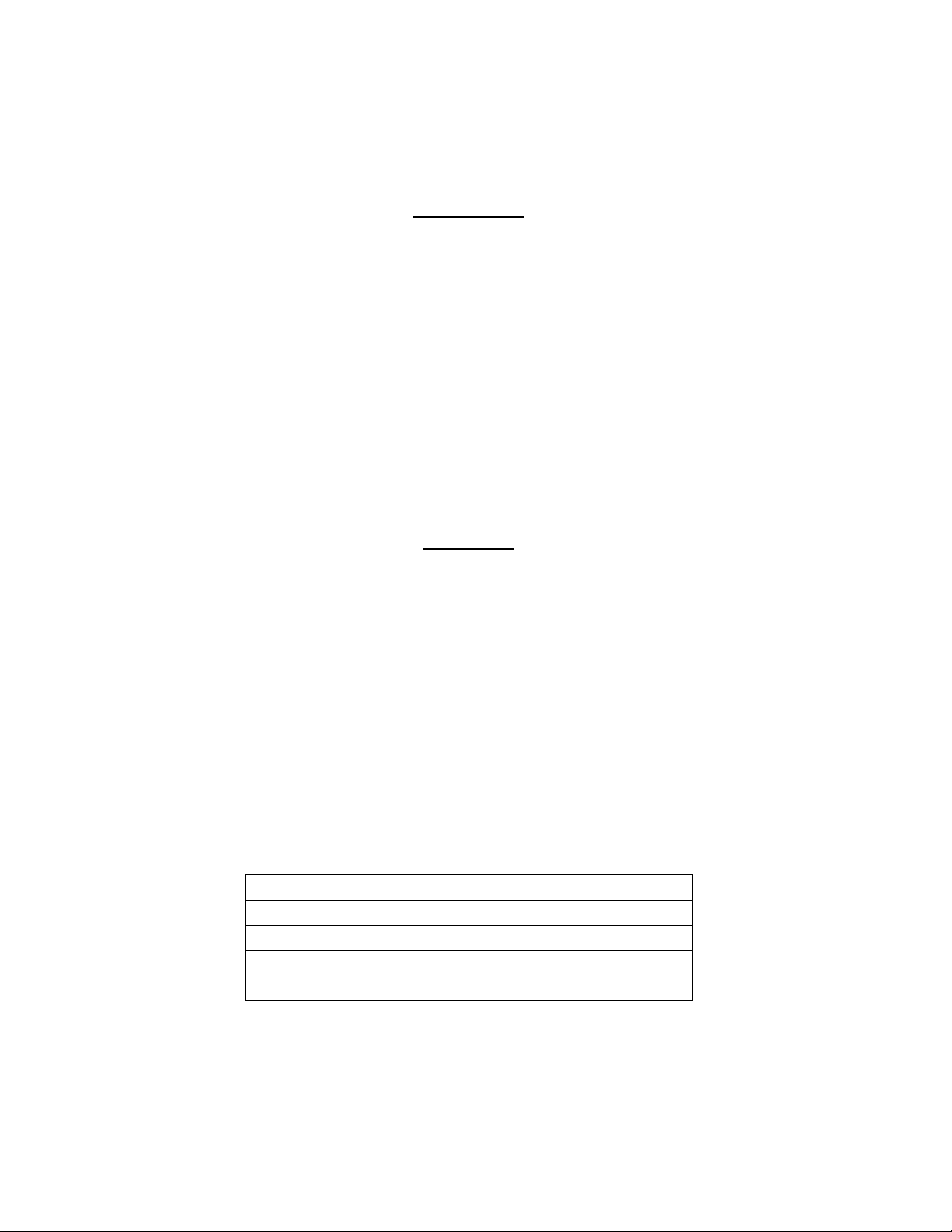

8

7

6

5

4

32

1

ON

0

5

1

2

3

4

6

7

8

9

0

5

1

2

3

4

6

7

8

9

10's

1's

DETAIL F

DETAIL E

EIA-485

EIA-232

2W

4W

DETAIL D

Tx +

Port 2

DETAIL B

2W

4W

232

Net+

Tx

Net -

Tx -

Rx

N/C

Rx +

DTR

N/C

Rx -

DCD

SIGNAL

GROUND

Net +

Net -

Shield

PORT 1a

DETAIL A

RNET

Gnd

Rnet +

Rnet -

+12V

DETAIL C1

Local

Access

Gnd

Rnet +

Rnet -

+12V

Sense

DETAIL C2

Port 2

2W

4W

232

Local Access

RNET

Port 1a

Net +

DETAIL B

This BCD switch

of the address.

This BCD switch

the address.

This BCD switch

the address.

Note for all Pinout

NOTE: This ground must be

Net -

Shield

attached to Mounting Panel

(see Figure 1-3, Sht 2 of 3).

Images:

All connectors on

this page are

shown in the same

orientation as

shown on the

referenced PCB

illustration in

Figure1-3, Sheet 1

of 3.

GF-122 AERCO XPC GATEWAY

Net+ Tx+ Tx

Net- Tx- Rx

N/C Rx+ DTR

N/C Rx- DCD

Signal Ground

Gnd

Rnet +

Rnet -

+12V

Rnet +

Sense

Gnd

Rnet -

+12V

determines the

determines the

10 decimal

10 decimal

position (10, 20,

position (10, 20,

30, 40, etc.) of

30, 40, etc.) of

determines the 1

decimal position

(1, 2, 3, 4, etc.)

10’s

1’s

Figure 1-3. XPC Gateway Ports, Jumpers and Switches (Sheet 3 of 3)

15

Page 16

GATEWAY COMMUNICATIONS MANUAL

BAUD Rate

DIP Switch 1

DIP Switch 2

9600

OFF

OFF

19.2 K

OFF

ON

38.4 K

ON

OFF

76.8 K

ON

ON

1.6 POWER INPUT, PROTOCOL SELECTION & GATEWAY ADDRESSING

The Gateway input power connections, protocol selection, and Gateway addressing are

accomplished utilizing the connector and switches on the right side of the XPC Gateway as shown in

Figure 1-3. The following subsections provide brief descriptions of the ports and jumpers provided.

IMPORTANT

It is imperative that the XPC Gateway be powered by an isolated 24

VAC power supply which is dedicated only for use by the XPC

Gateway. Failure to observe this precaution will result in improper

Gateway operation.

1.6.1 Input Power Connection

The Gateway is powered by 24 VAC (Class 2), 50/60 Hz, 20 VA. The input power connector is

located on the upper right side of the Gateway (Figure 1-3, Sheet 1 of 3).

When connecting the power source, an earth ground MUST be connected to the ground screw on the

mounting panel. See Figure 1-3, Sheet 2 of 3.

In addition, a 3 volt lithium battery (CR2032) is installed below the AC power connector. This battery

is used to retain the current monitoring/control data stored in volatile memory.

WARNING

Do not remove the battery when the power is off. Doing so may erase

some recorded data as well as programming, especially on older

models not utilizing non-volatile memory. The battery maintains the

integrity of the data and coding contained in memory whenever the

supply voltage is not present.

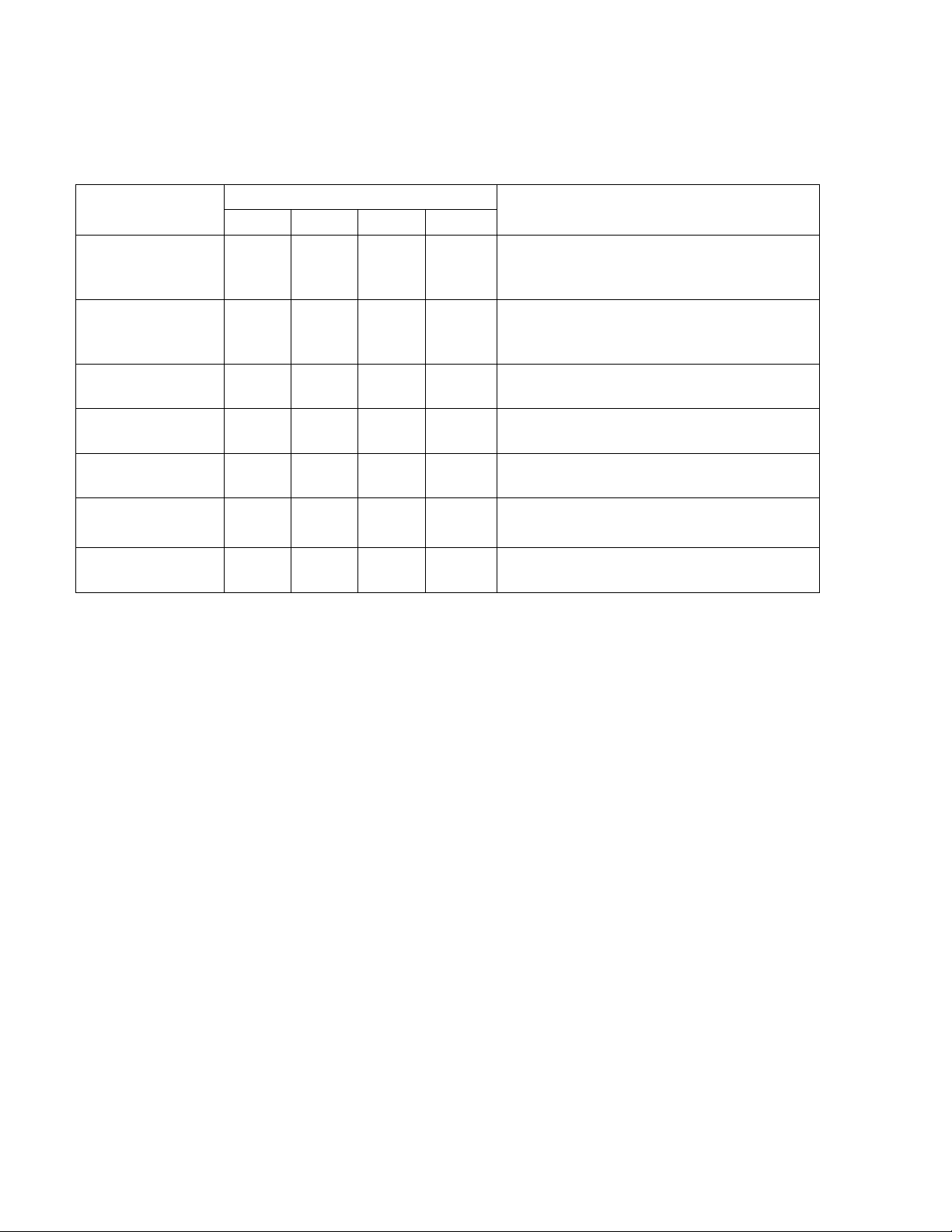

1.6.2 Protocol and Baud Rate Select

Protocol and baud rate selection are accomplished using the 8 DIP switches shown in Figure 1-3,

Detail “E”. The DIP switches can be set to the ON (left) or OFF (right) position. The functions and

settings for each of these switches are listed in the Tables 1 and 2 which follow.

Table 1 Baud Rate Select Switches

• DIP Switch 3 selects whether XPC Port 1 or Port 2 will be connected to the BAS used with the

• DIP Switch 4 will normally be set to ON for RS485 communication. It should only be set to OFF if

Gateway. When DIP Switch 3 is OFF, Port 1 is connected to the BAS. When set to ON, Port 2 is

connected to the BAS. The other port will be used for connection of AERCO equipment.

the BAS Port is 1 and the BAS is communicating BACnet using the ARC156 method.

16

Page 17

GF-122 AERCO XPC GATEWAY

DIP Switch Settings

Protocol

8 7 6

5

Comments

BACnet

RS485 communication to BACnet

BACnet

BACnet

RS232 communication to BACnet

Johnson

RS485 communication to Johnson N2

Modbus

DO NOT USE FOR THIS

LonWorks

Serial LonTalk Adapter required.

LonWorks

Lon Option Card required

Table 2 Building Automation System (BAS) Protocol

MS/TP

Master

MS/TP

Slave

PTP

N2

SLTA

FTT10a

OFF OFF OFF OFF

OFF OFF OFF ON

OFF OFF ON OFF

OFF OFF ON ON

OFF ON OFF OFF

ON ON OFF ON

ON ON ON OFF

1.6.3 Gateway Address Switches

Master

DO NOT USE FOR THIS

APPLICATION

Master

Master

APPLICATION

(currently available from Echelon)

The Gateway contains two rotary address switches labeled 0 - 9 as shown in Figure 1-3, Detail “F”.

The upper switch is labeled “10’s” and the lower switch is labeled “1’s”. When multiple Gateways are

used and controlled by a single BAS/EMS, each Gateway must have its own unique address. Do not

set both the “10’s” and the “1’s” address switches to “0”. Doing so will disable the Gateway on the

network.

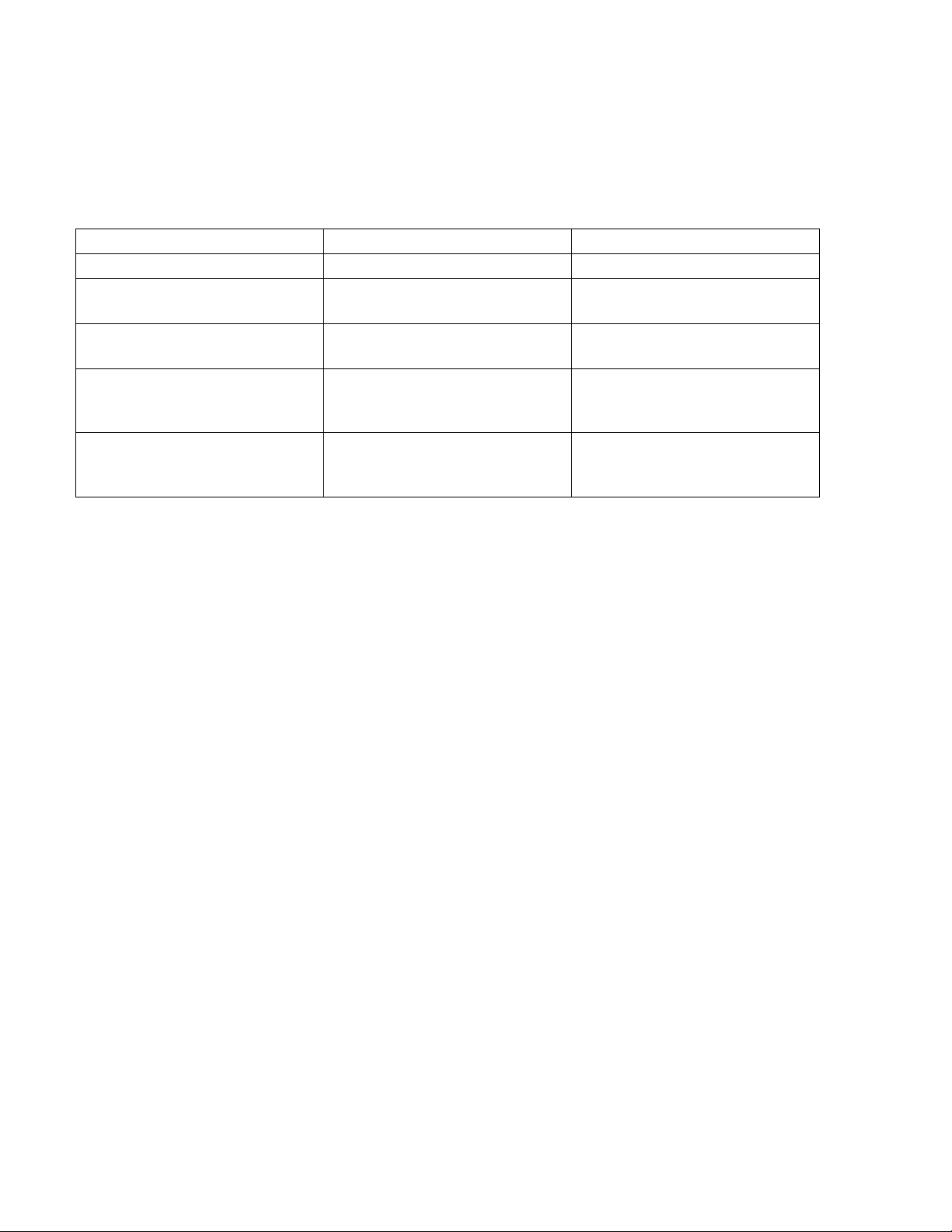

1.7 GATEWAY STATUS INDICATORS

In addition to the ports and switches described in the previous subsections, the XPC Gateway

contains seven (7) LED Status Indicators which can be monitored during Gateway operation. These

LED Status Indicators are illustrated and described in Figure 1-4 and Table 3.

17

Page 18

GATEWAY COMMUNICATIONS MANUAL

+12V

RNET-

RNET+

GND

COM

NET-

RX

TX

FORMAT

POWER

NET+

CMNET

ONE's

ERR

RUN

OPTIONS

TEN's

BATT

24VAC

AGND

POWER

RNET

485

232

LOCAL ACCESS

LN-

/S

+12

GND

LN+

2W

RX

TX

4W

BT485

Net +

Net -

Shield

Port 1a

Tx1

Rx1

Port 1b

Port 2

4w

2w

Gnd

+12V

Gnd

Rnet+

Sense

Rnet +

Rnet -

R n e t

Rnet+12V

Local

Access

10's

1's

0

134

5

2

78

9 6

0

134

5

2

78

9 6

4

3

2

1

On

5

6

7

8

Run

Error

Power

Format

Gnd

Hot

EIA-232

EIA-485

Baud

EIA485

19.2k 38.4k 76.8k

BMS

Port 2

ARC156

Port 1

9600

BMS

Switches

(0 = off, 1 = on)

MSTP (m)

MSTP (s)

PTP

8 7 6 5

Protocol

0 0 0 0

0 0 0 1

0 0 1 0

BACnet

BMS

Port 1

TYPE: 002106

Enclosed Energy Management Equipment

Made in USA

®

24V ac

2w

4w

Tx+

n/c

n/c

Net+

Rx+

Rx-

Tx-Net-

232

Tx

DTR

DCD

Rx

Signal Ground

+

-

Batt

CR

2032

BT485

Lon SLTA

1 1 0 1

Lon PlugIn

Ethernet

1 1 1 1

1 1 1 0

N2

Modbus

®

®

0

1 1

0 1 0 0

0

Tx2

Rx2

E143900

88FO

R

Class 2, 24Vac

Conductors Only

Use Copper

50-60Hz, 10VA, 0.42A

®

XPC

POWER

LED

RUN

LED

ERROR

LED

TX1

LED

RX1

LED

TX2

LED

RX2

LED

RNET

LOCAL

ACCESS

PORT

LED STATUS

TX1

Green LED flashes when data is being transmitted from

RX1

Green LED flashes when data is being received by the

Green LED lights when 24 VAC power is being supplied

RUN

Green LED lights to show Gateway status as described

TX2

Green LED flashes when data is being transmitted to

RX2

Green LED flashes when data is being received from

Figure 1-4. XPC Gateway Status LED Locations

INDICATOR

(LED1)

(LED2)`

POWER

(LED3)

(LED4)

ERROR

(LED5)

(LED6)

(LED7)

Table 3 Gateway LED Status Indicators

the BAS connected to Port 1.

BAS connected to Port 1.

to the Gateway.

in Table 4.

Red LED lights to show Gateway status as described in

Table 4.

the AERCO equipment connected to Port 2.

the AERCO equipment connected to Port 2.

FUNCTION

18

Page 19

If RUN LED Shows:

And ERROR LED Shows:

Status is:

2 flashes per second

Off

Normal

2 flashes per second

2 flashes,

Five minute auto-restart delay

2 flashes per second

3 flashes,

Gateway has just been

2 flashes per second

4 flashes,

Two or more devices on the

2 flashes per second

On

Exec halted after frequent

See also Part II “Communication LED’s”.

Table 4 RUN & ERROR LED Status

GF-122 AERCO XPC GATEWAY

alternating with RUN LED

then Off

then pause

after system error

formatted

network have the same

ARC156 network address

system errors or control

program halted

1.8 BASIC GATEWAY OPERATION

The Gateway scans the points list from top to bottom in a round-robin fashion. It will continually

retrieve the information from the programmed Modbus address and hold it for the BAS to read. The

information is therefore not real-ti me. How current the information is will depend on how quickly the

Gateway can scan all of the required pre-programmed points.

Information is updated based on the update time and priority of the information. If a point is not

updated within the allotted update time because the Gateway was not able to read it in time, the value

of that point will default to its programmed default value (usually zero).

To speed up the update rate of points and prevent dropouts (going to default value), communication

to any unused points can be disabled. This prevents the Gateway from waiting the full Response

Time programmed before moving to the next point, thereby reducing the scan cycle time interval.

19

Page 20

GATEWAY COMMUNICATIONS MANUAL

5-pin port supports EIA-232, EIA-485 2-wire or 4-wire

1.9 XPC GATEWAY REFERENCE DATA

The functional, physical and environmental specifications for the Gateway are listed in Table 5.

Table 5 AERCO XPC Gateway Specifications

Specification Description

Maximum number of points 300

Power 24 VAC ±10%, 50-60 Hz, 20 VA power consumption, Class 2

source only, 100 VA or less

Port 1a 3-pin port supports EIA-485 (RS485) 2-wire communication.

Protocols supported:

• BACnet over ARC156

• BACnet MS/TP

• Modbus (RTU/ASCII)

• Johnson N2

This port can be configured as a device port or a BAS port

NOTE: Port 1a or Port 1b can be used, but not both.

Port 1b 14-pin communication port supports plug-in cards such as

LonWorks or future Ethernet.

Port 2

Rnet Port

Local Access Port For local communication with a laptop computer running

Memory 1 MB non-volatile battery-backed RAM, 1 MB Flash memory,

communications.

Protocols supported:

• EIA-232 BACnet PTP, Modbus (RTU/ASCII), LonWorks

SLTA

• EIA-485 2-wire BACnet MS/TP, Modbus (RTU/ASCII),

Johnson N2

• EIA-485 4-wire BACnet MS/TP, Modbus (RTU/ASCII)

This port can be configured as a device port or BAS port.

4-pin port supports up to four RS Standard sensors and one

RS Plus, RS Pro, or RS Pro-F sensor for averaging or

high/low select control.

WebCTRL or AppLoader.

16-bit memory bus

20

Page 21

GF-122 AERCO XPC GATEWAY

Width

4 in. (102mm)

Height

5 in. (127mm)

Depth

1.75 in. (51mm)

Add for the LonWorks Card:

Width

1.8 in. (45.72mm)

Height

3.25 in. (82.55mm)

Depth

1.5 in. (38.1mm)

Distance apart cannot exceed ribbon cable:

9.75 in. (247.65 mm)

Width

2 in. (51 mm)

Height

4.8 in. (122mm)

LonWorks Option Card

1.325 in. (33.66 mm) apart – top 2 holes

.475 in. (12.07 mm) from edge

.890 in. (22.61 mm) bottom hole – from edge

Width

8.94 in. (227 mm) apart – top 2 & bottom 2 holes

Height

5.00 in. (127 mm) between top 2 & bottom 2 holes

Table 6 XPC Gateway Specifications - Continued

Specification Description

Battery 10-year Lithium CR2032 battery provides a minimum of 10,000

hours of data retention during power outages

Protection Built-in surge and transient protection circuitry - internal solid

state Polyswitches on the incoming power and network

connections.

Status Indicators LED's indicate status of communications, running, errors, and

power.

Environmental operating

range

-40° to 150°F (-40° to 65.6°C), 10–95% relative humidity, noncondensing

Overall dimensions

(without enclosure)

Mounting hole dimensions

(without enclosure)

Mounting hole dimensions

in enclosure

Rommended panel depth 1.75 in. (51mm)

Weight 9 oz.

BACnet support Conforms to the Advanced Application Controller (B-AAC)

Standard Device Profile as defined in ANSI/ASHRAE Standard

135-2004 (BACnet) Annex L

Listed by UL-916 (PAZX), cUL-916 (PAZX7), FCC Part 15-Subpart B-

Class A, CE EN50082-1997

1.10 QUICK SETUP GUIDE

A Quick Setup Guide is provided as additional guidance to configuring and integrating the AERCO

XPC Communications Gateway. The guide now follows.

21

Page 22

GATEWAY COMMUNICATIONS MANUAL

AERCO XPC QUICK SETUP GUIDE

Follow the instructions below to quickly wire and set up the AERCO XPC between your

Building Automation System (BAS) and AERCO equipment - Boiler Management System

(BMS/BMSII), Boiler Controls (C-MORE on Benchmark or KC1000 boilers or Boiler Control

Module (BCM) on Modulex (MLX) boilers), or Electronic Control System (ECS).

Select the 2 pages that apply to your configuration – one from pages 2 to 5 which outlines the

wiring and set up between your BAS and the AERCO XPC, and the other from pages 6 to

10 which outlines the wiring and set up between the AER CO X PC and AERCO equipment.

Note: The AERCO XPC cannot share power with other equipment. It must have its own

dedicated 24VAC supply else communication dropouts could result.

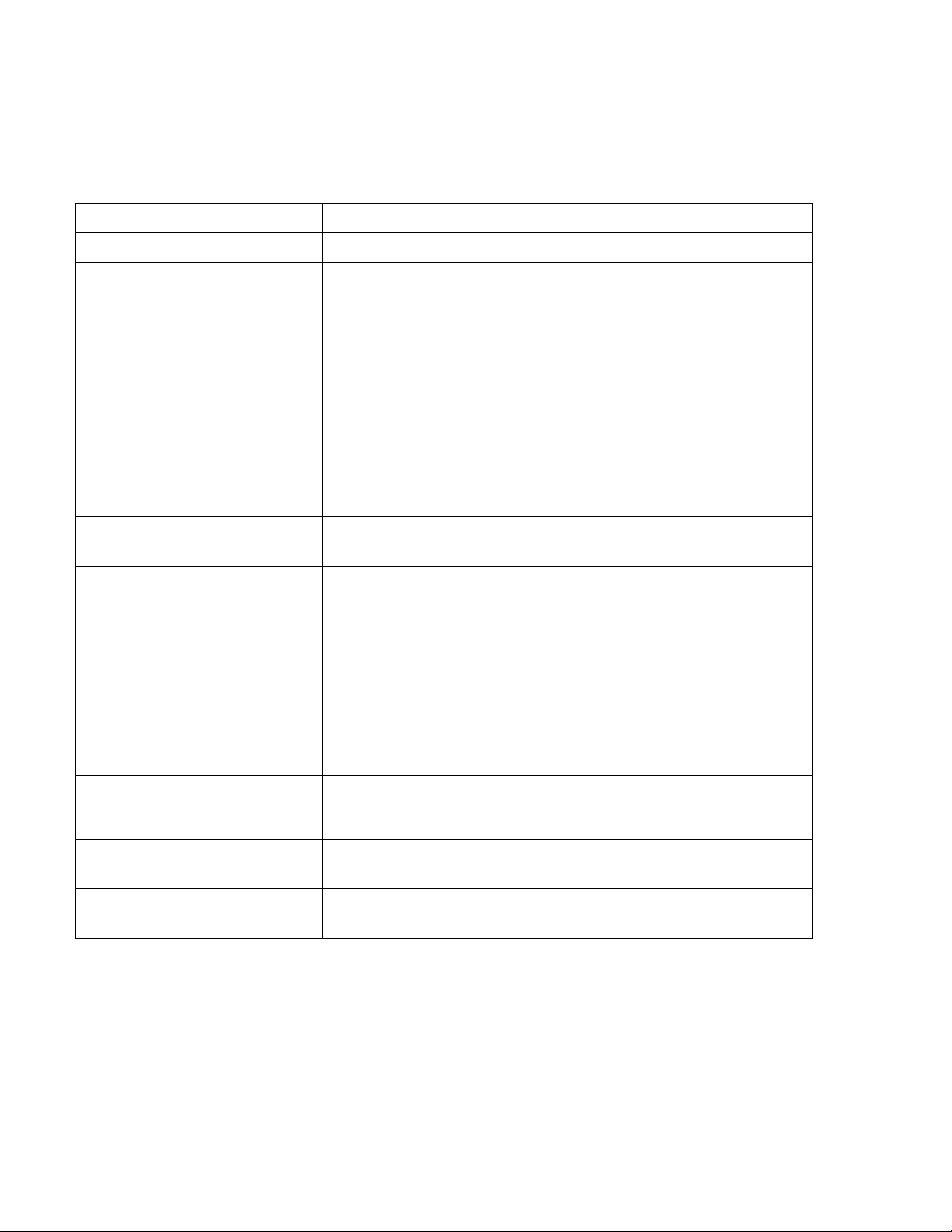

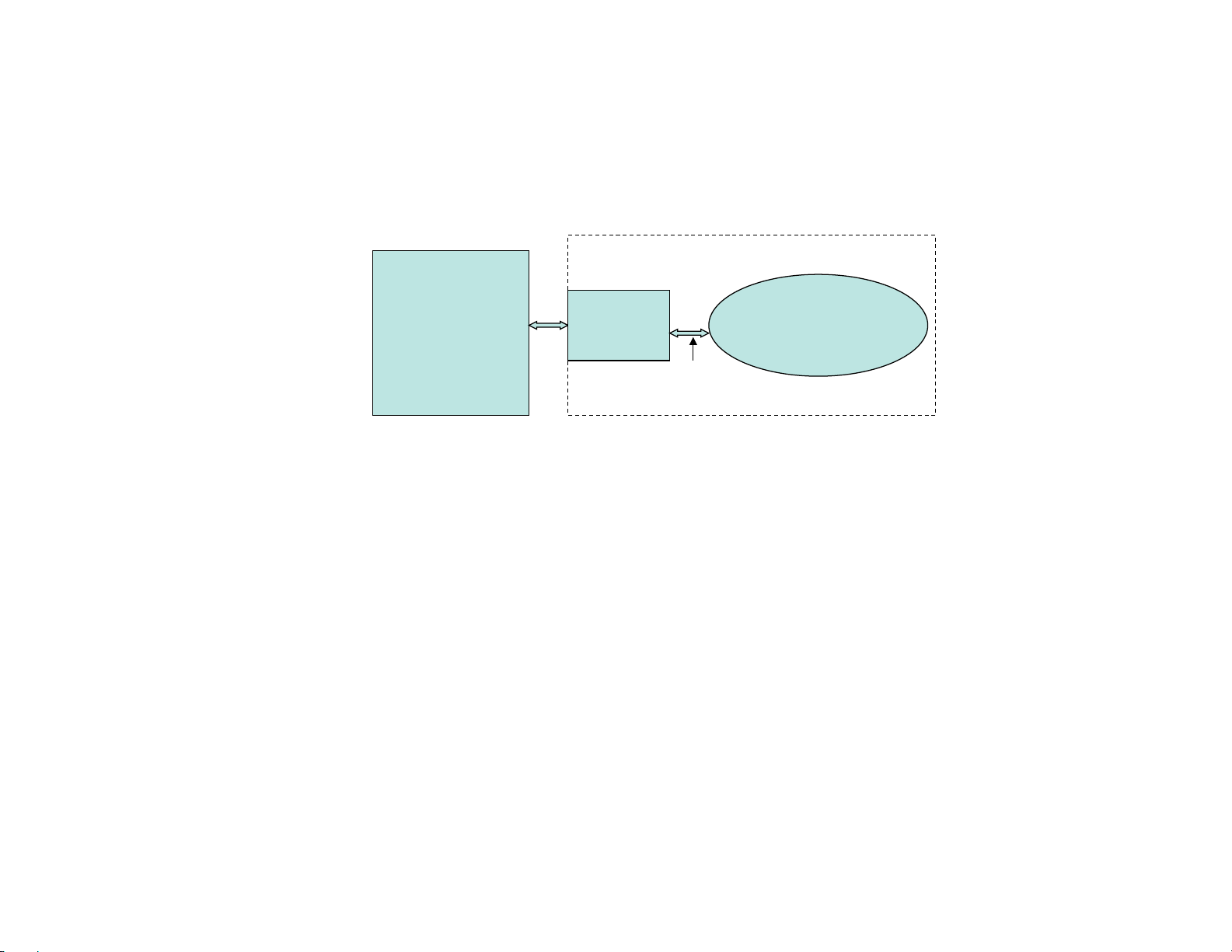

AERCO XPC

AERCO

EQUIPMENT

BUILDING

AUTOMATION

SYSTEM

An extra ground wire must be connected to the earth ground screw in the XPC metal plate.

1.10.1 Quick Setup Guide

22

Page 23

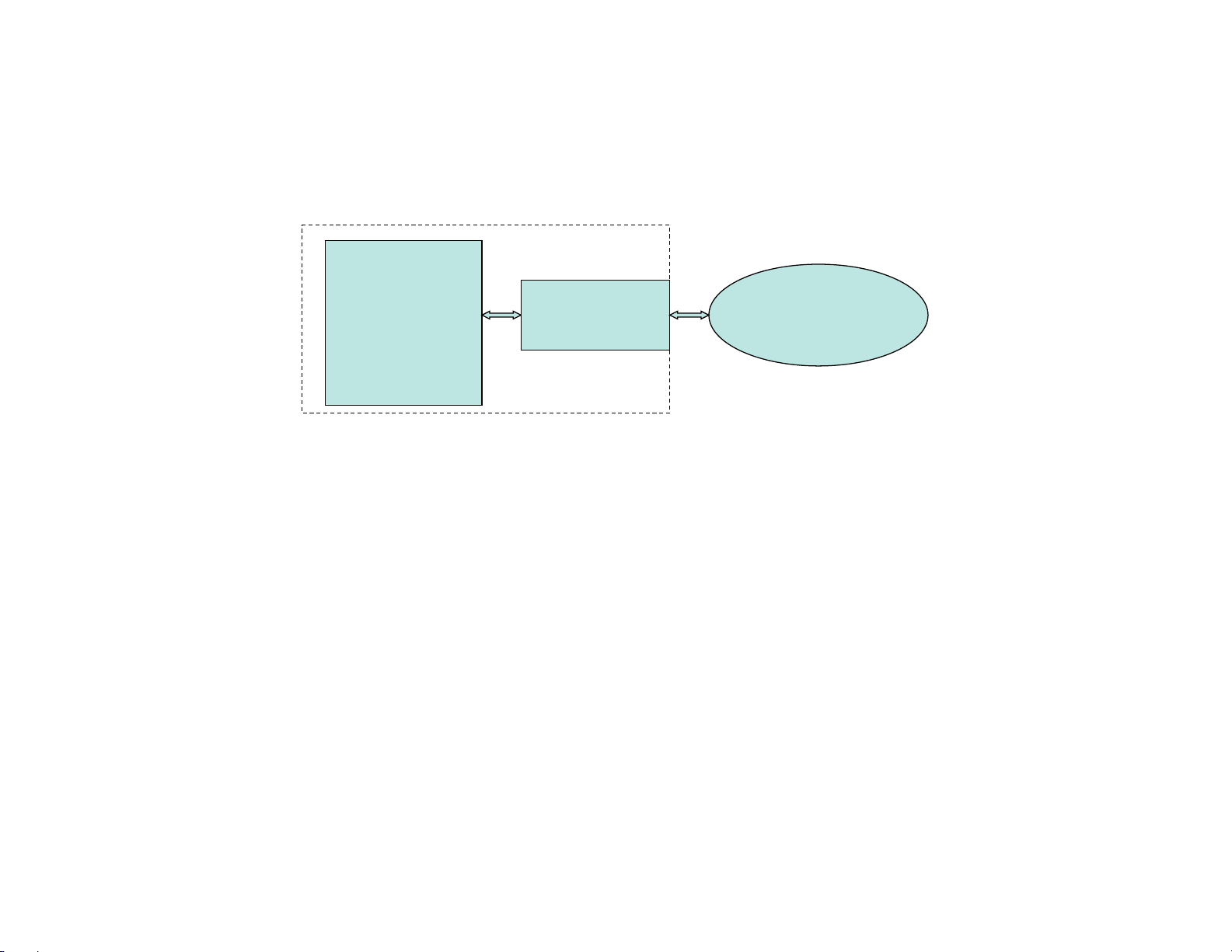

1.10.2 BACNET MS/TP to AERCO XPC

BACNET M S/TP TO AERCO XPC

XPC Port 1a:

• Wir e to Port 1a + to “Net+”, - to “Net-”, and Shi eld connecte d at one end only. If to XPC then to

“Shi eld” connec tor.

8-Position Dipswitch:

• Dipswi tch 1,2 set to BACNET MS/ TP communi cati on baud rate;

• Dipswi tch 3 = Off (B.A. S. on port 1);

• Dipswi tch 4 = O n (EI A485 on port 1) ;

• Dipswitch 5-8 = Off, O ff, Off, Off (for bacnetms/tp(m));

Rotary Address Switches:

• 2 Rotar y Address Swit ches set to BacnetID address for t he XPC)

BE SURE TO CYCLE AERCO XPC POWER AFTER MAKING ANY DIPSWITCH OR JUMPER CHANGES .

AERCO XPC

BACNET

MS/TP

Port 1a Port 2

RS485

RS485

BAS

bacnet

GF-122 AERCO XPC GATEWAY

23

Page 24

GATEWAY COMMUNICATIONS MANUAL

LON TO AERCO XPC (wit h LON-OC)

XPC “Net” Port on LON-OC:

• Wir e to “Net ” Port on LON-OC Polari ty does not matt er in this case. Connect shield at one end onl y.

8-Position Dipswitch:

• Dipswi tch 1, 2 = On, Off ( 38.4 K baud);

• Dipswi tch 3 = Off (B.A. S. on port 1);

• Dipswi tch 4 = On (por t 1b) ;

• Dipswitch 5-8 = Off, On, On, On (for Lon plug-in).

Rotary Address Switches:

• Not appl icable in thi s case.

Note: Lon XIF fil es are downloada ble from “ www.aerco. com ”.

BE SURE TO CYCLE AERCO XPC POWER AFTER MAKING ANY DIPSWITCH OR JUMPER CHANGES .

AERCO XPC

LON

Port 1b Port 2

Ftt -10a

BAS

Lon

LON-OC

Net

Ribbon

cable

Ftt-10a

1.10.3 LON to AERCO XPC (with LON-OC)

24

Page 25

1.10.4 LON to AERCO XPC (with SLTA)

LON TO AERCO XPC (with SLTA)

XPC Port 2:

• Wire SLTA to XPC P ort 2 “TX” to “RX”, “RX” to “TX”, “G nd” to “Signal Ground”, and Shield connected at one end only.

• Place 4-position jumper on EIA-232 (t wo top rows);

• Place 2-position jumper on 2W;

• Jumper “DTR” and “DCD” on SLTA port (port 2).

8-Position Dipswitch:

• Dipswitch 1, 2 = On, Off (38.4 K baud);

• Dipswitch 3 = On (B.A.S. on port 2);

• Dips witc h 4 = Off;

• Dips witc h 5-8 = On, Off, On, On (for Lon SLTA).

Rotary Address Switches:

• Not applicable in this case.

Note: Lon XIF files are on enclosed CD or downloadable from “www.aerco. com”.

BE SURE TO CYCLE AERCO XPC POW ER AFTER MAKI NG ANY DI PSW ITCH O R JUMPER CHANG ES.

AERCO XPC

LON

Port 2 Port 1a

Ftt -10a

BAS

Lon

SLTA

Net

Ftt-10a

RS232

RS232

RS232

GF-122 AERCO XPC GATEWAY

25

Page 26

GATEWAY COMMUNICATIONS MANUAL

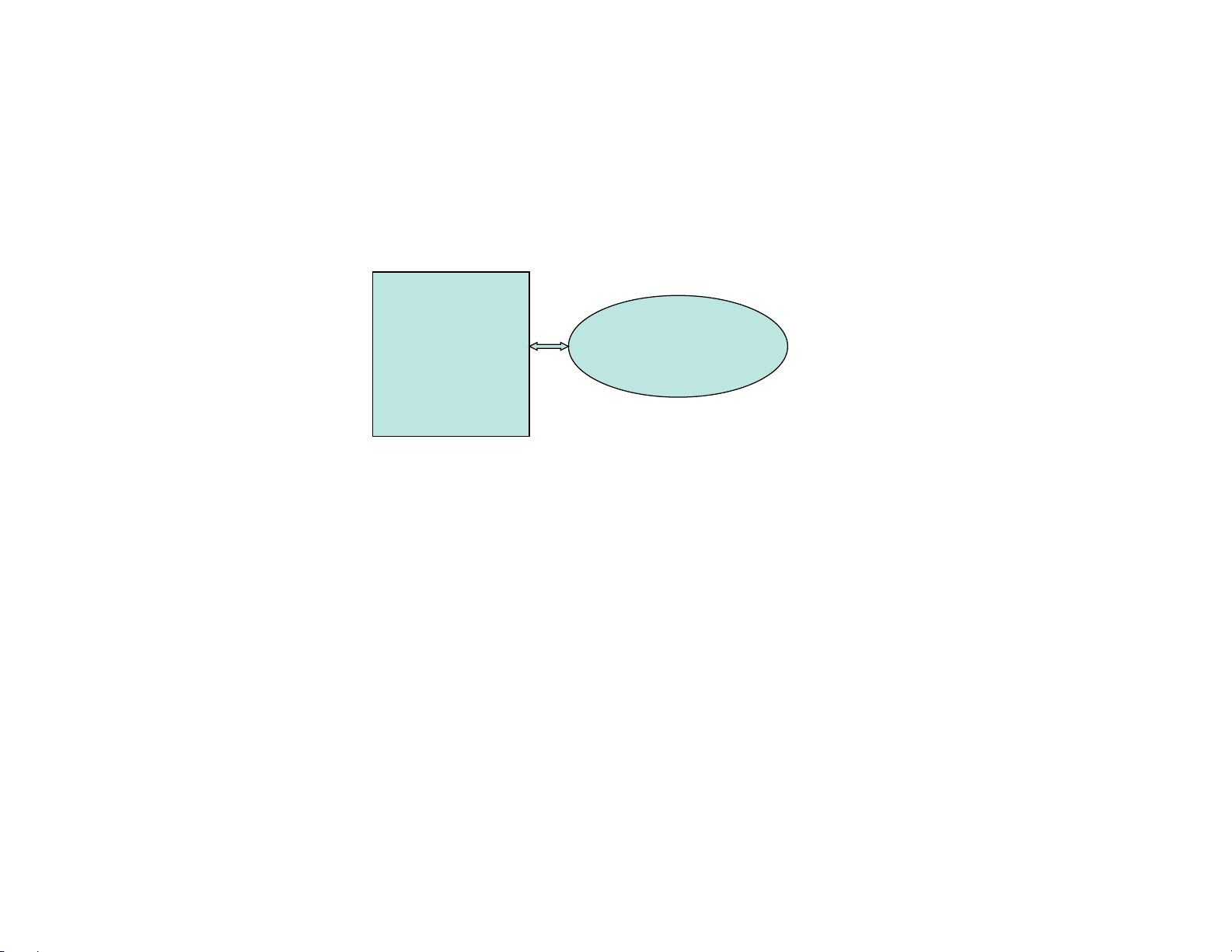

JOHNSON N2 TO AERCO XPC

XPC Port 1a:

• Wir e to Port 1a + to “Net+”, - to “Net-”, and Shi eld connecte d at one end only. If to XPC then to

“Shi eld” connec tor.

8-Position Dipswitch:

• Dipswi tch 1,2 = Off, Off (9600 baud r ate);

• Dipswi tch 3 = Off (B.A. S. on port 1);

• Dipswi tch 4 = O n (EI A485 on port 1) ;

• Dipswitch 5-8 = On, On, Off, Off ( for N2) ;

Rotary Address Switches:

• 2 Rotar y Address Swit ches set to N2 unit address for the XPC)

BE SURE TO CYCLE AERCO XPC POWER AFTER MAKING ANY DIPSWITCH OR JUMPER CHANGES

AERCO XPC

JOHNSON

N2

RS485

BAS

N2

Port 1a Port 2

RS485

1.10.5 LON to XPC (with LON-OC)

26

Page 27

GF-122 AERCO XPC GATEWAY

AERCO XPC TO BO ILER MANAGEMENT SYSTEM

(BMS)

XPC Part Number:

• “25024-1” for 1 BMS and up t o 4 C-MOREs, or “25024-2” for 1 BM S and up to 12 C-MOREs , or

“25024-4” for 1 BMS and up to 4 MLX Boil ers (wi th BCMs), or 25024-5 for 1 BMS and up to 8 C-MOREs

XPC Port 2 to BMS Port JP12:

• Wir e to XPC Por t 2 “TX ” t o “RXD”, “ RX” to “ TXD” , “ Signal Gr ound” t o “G ND”, and Shiel d connecte d at

one end only t o the BMS at the “SHIELD” i nput. Jumper “ DTR” and “DCD” on port 2.

• Place 4-posi tion j umpe r on EIA-232 ( two top rows) ;

• Place 2-posi tion j umpe r on 2W;

XPC Software Setup:

• Modbus Respons e Ti me = 20(x100 msec) (default);

BMSII RS232 Software Setup:

• RS232 Mode = M odbus Slave; RS232 Baudrate= 9600; Modbus Addr ess = 128; Modbus Pass Thru =

Enabled (if r eading informati on from boi lers, else leave Disabled );

BE SURE TO CYCLE AERCO XPC POWER AFTER MAKING ANY DIPSWITCH OR JUMPER CHANGES

AERCO XPC

BMS

Port 1a Po rt 2

RS232 RS485

RS232

modbus

JP 12 JP 11

1.10.6 AERCO XPC to Boiler Management System (BMS)

27

Page 28

GATEWAY COMMUNICATIONS MANUAL

AERCO XPC TO BO ILER MANAGEMENT SYSTEM II

(BMSII)

XPC Part Number:

• “25024-1” for 1 BMSII and up to 4 C-MORE, or “25024-2” for 1 BMSII and up to 12 C-MOREs , or

“25024-4” for 1 BMSI I and up t o 4 MLX Boil ers ( wit h BCMs) , or 25024-5 for 1 BMSII and up to 8 CMOREs

XPC Port 2 to BMSII Port JP5:

• Wi re to XPC Por t 2 “T X” t o “RXD” , “ RX” to “ TXD” , “ Si gnal Gr ound” t o “G ND”, and Shiel d connecte d at

one end only. If to the BMSII at t he “SHI ELD” input . Jumper “ DTR” and “ DCD” on port 2.

• Place 4-posi tion j umpe r on EIA-232 ( two top rows);

• Place 2-posi tion j umpe r on 2W;

XPC Software Setup:

• Modbus Response Time = 20(x100 msec) (default);

BMSII RS232 Menu Setup:

• RS232 Mode = Modbus Slave; RS232 Baudrate= 9600; Modbus Addr ess = 128; Modbus Pass Thru =

Enabled (if r eading informati on from boi lers, else leave Disabled );

BE SURE TO CYCLE AERCO XPC POWER AFTER MAKING ANY DIPSWITCH OR JUMPER CHANGES

AERCO XPC

BMSII

Port 1a Po rt 2

RS232 RS485RS232

modbus

JP5 JP6

1.10.7 AERCO XPC to Boiler Management System II (BMS II)

28

Page 29

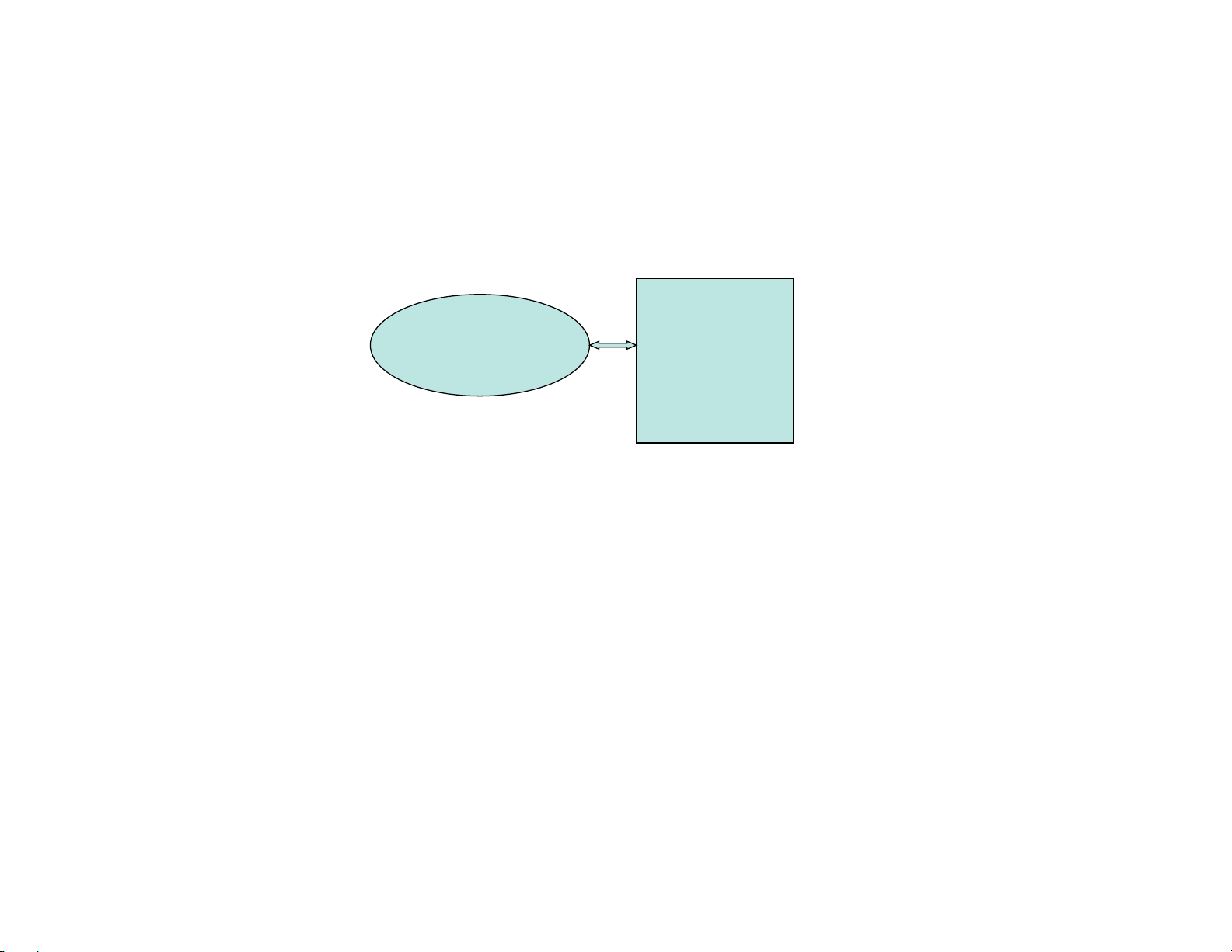

1.10.8 AERCO XPC to C-More

AERCO XPC TO C -MORE

XPC Part Number:

• 25024-1 or 63046-1 for 1 BMS and up to 4 C-MOREs; 25024-2 for 1 BMS and up to 12 C-MOREs; 25024-5 for 1

BMS and up to 8 C-MOREs

XPC Port 2 to C-MORE (I/O Box) RS485:

• Wire to XPC Port 2 “Net+” to “RS485+” , “Net-” to “RS485-”, and Shield connected at one end only - to the C-

MORE (I/O Box) at the “SHLD” input.. Daisy chain to the other units..

• Place 4-position jumper on EIA-485 ( t wo bot t om rows);

• Place 2-position jumper on 2W;

XPC Software Setup:

• Modbus Response Time = 2 (x100 msec); (Must be changed using AppLoader Software and Programmer Cable.)

C-MORE Setup:

• For Monitor Only “Comm Address” = (boiler addr ess s t ar t ing with “1” ) ;

• For M onitor and Remote Setpt Control via Modbus Se t “Comm Address ” as above; Set “Boiler Mode” to

“Remote Setpt” ; Set “Remote Signal” to “Network”.

BE SURE TO CYCLE AERCO XPC POW ER AFTER MAKI NG ANY DI PSW ITCH O R JUMPER CHANG ES

AERCO XPC

C-MORE

Port 1a Po rt 2

RS485 RS485

modbus

GF-122 AERCO XPC GATEWAY

29

Page 30

GATEWAY COMMUNICATIONS MANUAL

AERCO XPC TO BCM (on MLX Boiler )

XPC Part Number:

• 25024-4 or 63046-4 for 1 BMS and up to 4 MLX (with BCM Controls)

XPC Port 2 to BCM Port Y2:

• Wire to XPC Port 2 “Net+” to Y2 pin 1; “Net-” to Y2 pin 2; and Shield connected at one end only - to the XPC at

the “SHIELD” input.. Daisy chain to the other units..

• Place 4-position jumper on EIA-485 ( two bottom rows);

• Place 2-position jumper on 2W;

XPC Software Setup (Must be changed using AppLoader Software and Programmer Cable.):

• Modbus Response Time = 2 (x100 msec); Only if Remote Setpoint control is to be done, set these points from

“False” to “T rue” – “Req Outlet T emp” and “ Net Direct Drive” – for all your boiler addres ses.

BCM Setup:

• Set Addres s Dipswitch on each BCM start ing from 1; Keep termination jumper off on all BCMs;

BE SURE TO CYCLE AERCO XPC POW ER AFTER MAKI NG ANY DI PSW ITCH O R JUMPER CHANG ES

AERCO XPC

BCM

Port 1a Po rt 2

RS485 RS485

modbus

1.10.9 AERCO XPC to BCM (on MLX Boiler)

30

Page 31

1.10.10 AERCO XPC to ECS (with Eurotherm Control)

GF-122 AERCO XPC GATEWAY

31

Page 32

GATEWAY COMMUNICATIONS MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK

32

Page 33

GF-122 AERCO XPC GATEWAY

PART I

AERCO XPC DESCRIPTION

&

SET-UP INSTRUCTIONS FOR INTERFACING

WITH AERCO EQUIPMENT

33

Page 34

GATEWAY COMMUNICATIONS MANUAL

SECTION 2 INTERFACING THE XPC WITH C-MORE CONTROLLED UNITS

2.1 INTRODUCTION

The AERCO XPC Gateway can be connected to any C-More-controlled gas-fired boiler or water heater.

The XPC is configured to work in a “plug-and-play” fashion with AERCO equipment utilizing Modbus

(RS485) communication. The default Modbus communication configuration for all AERCO equipment is

Modbus RTU, 9600 baud, 8 data bits, 1 stop bit, and no parity.

The information in this Section provides basic planning set-up and programming details for implementing

a communication network utilizing the AERCO XPC Gateway with up to 12 C-More controlled boilers or

water heaters. Network control and monitoring is provided by a Master third-party BAS or EMS. Set-up

information for the Master BAS/EMS is provided in the AERCO XPC Gateway Integration Guide, included

as Part II of this manual.

2.2 PHYSICAL NETWORK WIRING

All signal wiring connections between the AERCO XPC Gateway and other AERCO equipment should be

implemented using shielded, twisted-pair wiring from 18 to 24 AWG. Examples of suitable wire types are:

Belden #9841, #8761, #3105A, or equivalent.

The physical locations of the wiring connections necessary to implement a communications network

comprised of the XPC Gateway and AERCO boilers and/or water heaters and a third party BAS or EMS

are provided in the following subsections. Where applicable, connector pinout information is provided for

all AERCO equipment. Refer to the AERCO XPC Gateway Integration Guide (Part II of this manual) for

connection of BAS/EMS equipment used with the XPC Gateway. Also, refer to the BAS/EMS

manufacturer’s equipment manual.

2.3 C-MORE BOILERS OR HEATERS CONTROLLED BY BAS VIA THE GATEWAY

As mentioned in Section 1, C-More Controllers can communicate directly with a BAS utilizing Modbus

RTU protocol via a RS485 network. However, if the BAS does not support Modbus, the XPC Gateway is

required to provide the necessary protocol translation.

All Modbus networks are implemented utilizing a Master-Slave technique where only one device, the

Master, can initiate a communication sequence. AERCO C-More Controllers can only function as Slave

devices on a Modbus network

34

Page 35

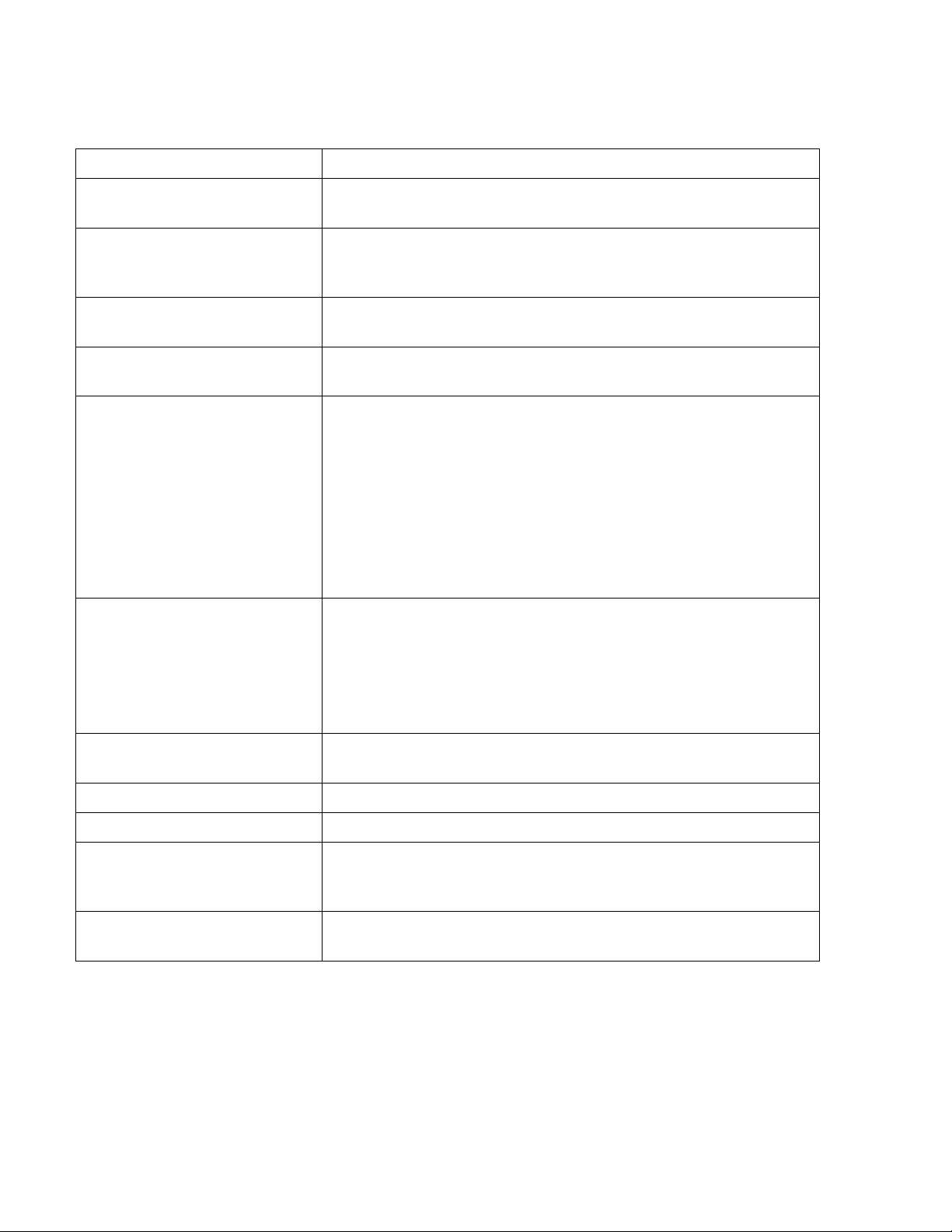

GF-122 AERCO XPC GATEWAY

BAS

MASTER

SLAVE

#1

SLAVE

#2

SLAVE#3SLAVE#4SLAVE

#5

XPC

GATEWAY

Modbus RS485 devices should be wired in a “Daisy-Chain” configuration similar to the example shown

Figure 2-1. DO NOT wire the units in a “Star” configuration where all devices are connected to a central

point (node).

Figure 2-1. Typical Daisy-Chain Modbus/RS485 Network

Subsections 2.4 through 2.7 provide the set-up and programming instructions necessary to implement a

communications network utilizing the AERCO XPC and C-More Controller Slaves controlled by a Master

BAS.

2.4 C-MORE CONTROLLER MODBUS COMMUNICATION INTERFACE

The RS485 Modbus communication (COMM) connections for C-More Controller slaves are made in the

Input/Output (I/O) Box shown in Figure 2-2. Identical I/O Boxes are used for Benchmark Boilers and

KC1000 Boilers or Water Heaters. The connections are made at the RS485 COMM terminals labeled +

(plus), and – (minus). Observe the NOTE in Figure 2-2 and never terminate wire shields to the G

(Ground) terminal.

35

Page 36

GATEWAY COMMUNICATIONS MANUAL

Figure 2-2. I/O Box RS485 COMM Terminal Connections

36

Page 37

GF-122 AERCO XPC GATEWAY

2.5 RS485 LOOP TERMINATING RESISTORS AND BIAS

A terminating resistor (120 ohms) on each end of the RS485 loop is designed to match the electrical

impedance characteristic of the twisted-pair loop and prevent echoes or cross-talk from corrupting data

on the line.

Bias may be necessary on the RS485 loop to minimize noise on the circuit. Loop bias is accomplished

by activating pull-up/pull-down resistors on the last C-More Controller in the chain.

When connected directly to the XPC, a terminating resistor should not be needed unless the circuit is

very long (> 2000 feet) or the number of nodes is high (> 20). If termination is activated in the C-More, a

120 Ohm resistor must be placed across the XPC RS-485 connections. Bias is generally not needed

unless excess noise on the bus seems to warrant it. Activating bias, even when not needed, will not harm

the communications.

2.5.1 C-More Boiler Controller Terminating Resistor and Bias

C-More Boiler Controllers can function only as Slave devices on a Modbus Network. Since the Slaves are

connected in a “Daisy-Chain” configuration, the terminating resistor must be enabled only in the last

More Boiler Controller in the chain. In addition, bias must also be implemented only in the last C-More

Boiler Controller. This is accomplished by setting a DIP switches on the Primary Micro-Controller (PMC)

Board contained in the applicable C-More Boiler Controller. The last unit in the chain must be energized

(even if disabled) to enable bias.

C-

To activate the DIP switches, proceed as follows:

Remove power from the last C-More Boiler Controller in the RS485 loop.

Loosen and remove the four (4) screws securing the front panel assembly to the chassis as shown in

Figure 2-3.

Carefully separate the panel from the chassis. Use care to avoid applying undue stress to the ribbon

cable connected between the back of the panel and the chassis-mounted printed circuit boards.

CAUTION

The C-More Boiler Controller Printed Circuit Boards contain electronic

components that are sensitive to electrostatic discharge (ESD). Prior to

performing the following steps, put on an anti-static wrist strap and connect

the clip lead to earth ground. Failure to observe this precaution may result

in permanent damage to on-board ESD-sensitive components.

1. Attach an anti-static wrist strap to your wrist and connect the clip lead to earth ground.

2. From the back of the Panel Assembly (Figure 2-4), locate the RS485 DIP switches on the PMC

Board.

3. Refer to Figure 2-5 and set the “TERM” switch to the ON (Up) position.

4. Set the BIAS2 and BIAS1 switches to the ON (Up) position.

5. After the DIP switches have been set, reposition the Front Panel Assembly on the chassis and secure

it in place with the four screws.

37

Page 38

GATEWAY COMMUNICATIONS MANUAL

FRONT PANEL

SCREWS (4 PL)

THE C-MORE CONTROLLER MODEL SHOWN WITH A

HORIZONTAL PANEL CONTROL LAYOUT IS USED ON KC1000

BOILERS.

BENCHMARK BOILERS UTILIZE C-MORE CONTROLLERS WITH

A VERTICAL PANEL CONTROL LAYOUT.

NOTE:

Figure 2-3. C-More Control Panel - Front View

38

Page 39

GF-122 AERCO XPC GATEWAY

RIBBON

CABLE

RS485

DIP SW.

CONTROL PANEL REAR VIEW – KC1000

C32

Q1

C41

C29

C20

C31

C35

C47

C44

R29

R30

HB

C53

R74

C4

C3

U1

CBS3

R69

C50

R67

R68

Y1

C52

C57

J2

CR1

C1

C5

U17

R76

C51

R71

R73

R72

C2

JP2

R70

U21

C56

C6

C64

R75

J4

U13

U20

C59

C49

C48

C61

CBS4

U14

R78

R79

DS5DS4

RS232

TX

RX

C60

C62

C46

U19

U15

U18

C58

C55

C54

DS3

R77

Y2

U16

C63

B1

R16

U11

R66

U10

R15

C45

R14

C19

C16

R32

R17

C18

R18

C34

U4

R33

C27

R31

C26

U6

R47

C39

R55

U2

R1

C7

U8

R53

C36

R81

R45

R44

C37

R48

S2

R46

C38

R49

J1

BIAS1

TERM

BIAS2

R50

C40

CBS1

RS485

C11

J3

R51

R9

BH1

U3

R10

C12

C13

DS1

RS485

TX

RX

R52

U7

DS2

R54

R5

C10

R7

R8

R6

S1

R11

R65

C9

R34

R12

R13

C14

C15

R36

C28

C25

R35

C23

R37

R38

C30

U5

C43

C65

R2

R3

R58

C8

R62

R4

R80

OFF = VOLT

CURR/VOLT

ON = CURR

Q2

R57

C66

R64

R56

CBS2

R25

U12

R20

U9

R19

C17

R27

R23

R21

R22

C21

R28

R26

C24

R60

R41

R40

R24

R39

C22

R42

R43

C33

R61

R63

C42

R59

CR2

CONTROL PANEL REAR VIEW – BENCHMARK

C32

Q1

C41

C29

C20

C31

C35

C47

C44

R29

R30

HB

C53

R74

C4

C3

U1

CBS3

R69

C50

R67

R68

Y1

C52

C57

J2

CR1

C1

C5

U17

R76

C51

R71

R73

R72

C2

JP2

R70

U21

C56

C6

C64

R75

J4

U13

U20

C59

C49

C48

C61

CBS4

U14

R78

R79

DS5DS4

RS232

TX

RX

C60

C62

C46

U19

U15

U18

C58

C55

C54

DS3

R77

Y2

U16

C63

B1

R16

U11

R66

U10

R15

C45

R14

C19

C16

R32

R17

C18

R18

C34

U4

R33

C27

R31

C26

U6

R47

C39

R55

U2

R1

C7

U8

R53

C36

R81

R45

R44

C37

R48

S2

R46

C38

R49

J1

BIAS1

TERM

BIAS2

R50

C40

CBS1

RS485

C11

J3

R51

R9

BH1

U3

R10

C12

C13

DS1

RS485

TX

RX

R52

U7

DS2

R54

R5

C10

R7

R8

R6

S1

R11

R65

C9

R34

R12

R13

C14

C15

R36

C28

C25

R35

C23

R37

R38

C30

U5

C43

C65

R2

R3

R58

C8

R62

R4

R80

OFF = VOLT

CURR/VOLT

ON = CURR

Q2

R57

C66

R64

R56

CBS2

R25

U12

R20

U9

R19

C17

R27

R23

R21

R22

C21

R28

R26

C24

R60

R41

R40

R24

R39

C22

R42

R43

C33

R61

R63

C42

R59

CR2

RIBBON

CABLE

RS485

DIP SW.

PMC

BOARD

PMC

BOARD

Figure 2-4. C-More Control Panel - Rear Views

39

Page 40

GATEWAY COMMUNICATIONS MANUAL

C32

Q1

C41

C29

C20

C31

C35

C47

C44

R29

R30

HB

C53

R74

C4

C3

U1

CBS3

R69

C50

R67

R68

Y1

C52

C57

J2

CR1

C1

C5

U17

R76

C51

R71

R73

R72

C2

JP2

R70

U21

C56

C6

C64

R75

J4

U13

U20

C59

C49

C48

C61

CBS4

U14

R78

R79

DS5DS4

RS232

TX

RX

C60

C62

C46

U19

U15

U18

C58

C55

C54

DS3

R77

Y2

U16

C63

B1

R16

U11

R66

U10

R15

C45

R14

C19

C16

R32

R17

C18

R18

C34

U4

R33

C27

R31

C26

U6

R47

C39

R55

U2

R1

C7

U8

R53

C36

R81

R45

R44

C37

R48

S2

R46

C38

R49

J1

BIAS1

TERM

BIAS2

R50

C40

CBS1

RS485

C11

J3

R51

R9

BH1

U3

R10

C12

C13

DS1

RS485

TX

RX

R52

U7

DS2

R54

R5

C10

R7

R8

R6

S1

R11

R65

C9

R34

R12

R13

C14

C15

R36

C28

C25

R35

C23

R37

R38

C30

U5

C43

C65

R2

R3

R58

C8

R62

R4

R80

OFF = VOLT

CURR/VOLT

ON = CURR

Q2

R57

C66

R64

R56

CBS2

R25

U12

R20

U9

R19

C17

R27

R23

R21

R22

C21

R28

R26

C24

R60

R41

R40

R24

R39

C22

R42

R43

C33

R61

R63

C42

R59

CR2

SEE DETAIL “A”

S2

BIAS1

TERM

BIAS2

RS485

DETAIL “A”

SET THE BIAS2, TERM & BIAS1

DIP SWITCHES TO THE ON (UP)

POSITION TO ACTIVATE EACH

FUNCTION IF NECESSARY.

PMC BOARD

RIBBON CABLE

CONNECTOR (J1)

Figure 2-5. C-More Control Panel PMC Board

40

Page 41

GF-122 AERCO XPC GATEWAY

EIA-485

EIA-232

2W

4W

2.5.2 BAS Terminating Resistor and Bias

Refer to the BAS manufacturer’s Technical Manual and follow their recommended guidelines for

termination resistors and bias.

NOTE

DO NOT connect C-More boilers to the XPC Gateway as described in

subsection 2.6 if the boilers are being controlled by a BMS Master on the

Modbus network. Refer to Section 3, subsection 3.3 for wiring and set-up

instructions when controlled by the BMS.

2.6 C-MORE CONTROLLER WIRING CONNECTIONS TO AERCO XPC GATEWAY

XPC Port 2 is normally used to connect to AERCO equipment, except when the controlling BAS is

utilizing a LonWorks SLTA module, or communicating via BACnet PTP. In this case, Port 1a of the XPC

must be used to connect AERCO equipment. Therefore, follow the appropriate wiring instructions in

subsection 2.6.1 (Port 2) or 2.6.2 (Port 1a) as applicable.

2.6.1 C-More Wiring Connections to XPC Port 2

When the controlling BAS is utilizing BACnet MS/TP, Johnson N2 or LonWorks protocol without an

SLTA, use XPC Port 2 as follows:

1. Position the EIA-232/EIA-485 and 2W/4W jumpers to EIA-485 and 2W respectively as shown in

Figure 2-6.

Figure 2-6. Port 2 Jumper Settings

2. At the I/O Box for the first C-More Controller, connect the RS-485 COMM terminals as follows:

(a) Connect the RS485 COMM + (plus) terminal to the Net + (plus) terminal on XPC Port 2.

(b) Connect the RS485 COMM – (minus) terminal to the Net – (minus) terminal on XPC Port 2.

(c) DO NOT connect the wire shield to the Ground (G) terminal at the I/O Box. Connect the wire

shield only to the SIGNAL GROUND terminal at XPC Port 2. Refer to Figure 2-7.

41

Page 42

GATEWAY COMMUNICATIONS MANUAL

+

G

-

2W

4W

232

Net +

Net -

N/C

N/C

Tx +

Tx

Tx -

Rx

DTR

Rx -

DCD

SIGNAL

GROUND

Rx +

Port 2

R

E

D

(

+

)

B

L

U

E

(

-

)

S

H

I

E

L

D

RE

D (

+

)

B

L

U

E

(

-)

S

H

I

E

L

D

RED (+)

BLUE (-)

DAISY-CHAIN

TO OTHER UNITS

(

+

TO +, - TO

-)

TIE TOGETHER WITH

SHIELDS OF OTHER

UNITS

C-MORE I/O BOX

RS485 COMM

XPC GATEWAY

+

G

-

R

E

D

(

+

)

B

L

U

E

(

-

)

S

H

I

E

L

D

RE

D

(

+

)

B

L

U

E

(-

)

S

H

I

E

L

D

DAISY-CHAIN

TO OTHER UNITS

(

+

TO

+, -

TO

-)

TIE TOGETHER WITH

SHIELDS OF OTHER

C-MORE UNITS

Net +

Net -

Shield

PORT 1a

C-MORE I/O BOX

RS485 COMM

XPC GATEWAY

RED (+)

BLUE (-)

Figure 2-7. Port 2 Wiring Connections