Page 1

G

G

GG

G

G

GG

G

G

GG

G

G

GG

G

G

GG

G

G

GG

X

X

XX

X

X

XX

X

X

XX

X

X

XX

X

X

XX

X

X

XX

3

3

33

3

3

33

3

3

33

3

3

33

3

3

33

3

3

33

1

1

11

1

1

11

1

1

11

2

2

22

2

2

22

2

2

22

Function

Generators

G

0

0

00

0

0

00

0

0

00

0

0

00

0

0

00

0

0

00

U

U

U

G

GG

----

G

G

X

X

GG

----

----

----

----

----

s

e

r

’

s

s

s

m

e

r

’

s

m

e

r

’

s

G

G

GG

G

G

GG

G

G

GG

G

G

GG

G

G

GG

a

n

a

n

m

a

n

XX

u

u

u

G

G

GG

G

G

GG

X

X

XX

X

X

XX

X

X

XX

X

X

XX

X

X

XX

a

l

a

l

a

l

X

X

XX

X

X

XX

X

X

XX

3

3

33

3

3

33

3

3

33

3

3

33

3

3

33

3

3

33

3

3

33

3

3

33

3

3

33

1

1

11

1

1

11

1

1

11

2

2

22

2

2

22

2

2

22

0

0

00

0

0

00

0

0

00

0

0

00

0

0

00

0

0

00

0

0

00

0

0

00

0

0

00

5

5

55

5

5

55

5

5

55

P

P

PP

P

P

PP

P

P

PP

E

E

EE

E

E

EE

E

E

EE

Copyright ©

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

99-MAN 100379 - v2 03/17

Page 2

Contents

Contents

C

h

a

p

t

e

r

C

C

General Instructions ............................................................................................................................................. 4

Introduction......................................................................................................................................................... 4

Contents of the box ............................................................................................................................................ 4

Precautions ........................................................................................................................................................ 4

Safety measures ................................................................................................................................................ 4

Guarantee .......................................................................................................................................................... 5

Maintenance, metrological checks ..................................................................................................................... 5

Maintenance....................................................................................................................................................... 5

C

h

C

h

C

h

GX 305 and GX 310 Description........................................................................................................................... 6

Presentation ....................................................................................................................................................... 6

Specifications..................................................................................................................................................6

Front Face .......................................................................................................................................................... 6

Back Face .......................................................................................................................................................... 7

Display................................................................................................................................................................ 7

Keys.................................................................................................................................................................... 9

Pressing keys for less than < 1s.....................................................................................................................9

Pressing keys for more than > 1s.................................................................................................................11

h

a

p

t

e

r

h

a

p

t

e

r

a

p

t

e

r

a

p

t

e

r

a

p

t

e

r

II

I

I

I

C

h

a

p

t

e

r

I

C

h

C

h

GX 320 Description ............................................................................................................................................. 12

Presentation ..................................................................................................................................................... 12

Specifications................................................................................................................................................12

Front Face ........................................................................................................................................................ 12

Back Face ........................................................................................................................................................ 13

Display.............................................................................................................................................................. 13

Keys.................................................................................................................................................................. 16

Pressing keys for less than < 1s...................................................................................................................17

Pressing keys for more than > 1s.................................................................................................................18

Chapter IV

General commands ............................................................................................................................................. 19

Commissioning................................................................................................................................................. 19

in Normal mode ............................................................................................................................................19

in Version mode............................................................................................................................................19

in Calibration mode.......................................................................................................................................19

in Autotest mode...........................................................................................................................................19

Stop .................................................................................................................................................................. 20

Activating MAIN OUT ....................................................................................................................................... 20

Adjusting screen contrast ................................................................................................................................. 21

Selection of the instrument function ................................................................................................................. 21

Display of the software version ........................................................................................................................ 22

Automatic calibration ........................................................................................................................................ 22

Instrument Autotest .......................................................................................................................................... 25

Saving a configuration (GX 320) ...................................................................................................................... 28

Reloading a configuration (GX 320)................................................................................................................. 29

Clearing a configuration (GX 320).................................................................................................................... 30

I

a

p

t

e

r

I

I

a

p

t

e

r

I

I

I

I

I

C

h

a

p

t

e

r

V

C

h

a

C

h

a

Generation of simple CONTinuous periodical signals.................................................................................... 31

Available output signals.................................................................................................................................... 31

Signal selection ................................................................................................................................................ 31

Adjusting signal frequency ............................................................................................................................... 32

Adjusting signal duty cycle ............................................................................................................................... 35

Adjusting signal amplitude................................................................................................................................ 35

Adjusting offset and DC level ........................................................................................................................... 36

Adjusting signal logical levels........................................................................................................................... 36

Find Quality Products Online at: sales@GlobalTestSupply.com

I - 2 Function Generators

www.GlobalTestSupply.com

p

t

e

r

V

p

t

e

r

V

Page 3

Contents

SHIFT Shift Keying function (GX 320 only)....................................................................................................... 37

Connections ..................................................................................................................................................... 37

Selection of FSK mode..................................................................................................................................... 37

Selection of PSK mode .................................................................................................................................... 37

Selection of piloting source .............................................................................................................................. 37

Adjusting jump frequencies (in FSK mode)...................................................................................................... 38

Adjusting jump phases (in PSK mode)............................................................................................................. 38

Other settings ................................................................................................................................................... 38

SWEEP Frequency scan function...................................................................................................................... 39

Connections ..................................................................................................................................................... 39

Selection of the sweep mode ........................................................................................................................... 39

Selection of the scan source ............................................................................................................................ 40

Adjusting START / END frequencies ............................................................................................................... 40

Adjusting scan period using an INTernal source.............................................................................................. 41

Other settings ................................................................................................................................................... 41

MODUL Modulation function (GX 320 only) ..................................................................................................... 42

Connections...................................................................................................................................................... 42

Selection of AM / FM mode .............................................................................................................................. 42

Selection of the modulation source .................................................................................................................. 43

Adjustment of the FM START / END frequencies............................................................................................ 43

Other settings ................................................................................................................................................... 43

C

h

a

p

t

e

r

C

h

C

h

C

h

a

C

h

C

h

C

h

a

C

h

a

C

h

a

V

a

p

t

e

r

V

a

p

t

e

r

V

p

t

e

r

V

a

a

p

p

I

p

t

e

r

V

I

p

t

e

r

V

I

t

e

r

V

I

I

t

e

r

V

I

p

I

t

e

r

V

I

I

I

I

I

I

I

I

I

I

I

C

h

a

p

t

e

r

I

C

h

C

h

FREQ Frequency meter function ....................................................................................................................... 44

Connections..................................................................................................................................................... 44

C

h

C

h

C

h

SYNC Synchronisation function (GX 320 only) ................................................................................................ 45

Connections..................................................................................................................................................... 45

Selection of SLAVE / MASTER mode ............................................................................................................. 46

Adjusting dephasing ........................................................................................................................................ 46

Activating signal generation (MASTER) .......................................................................................................... 47

Other settings .................................................................................................................................................. 48

C

h

a

C

h

C

h

GATE function (GX 320 only) ............................................................................................................................. 50

Connections..................................................................................................................................................... 50

Activation, Deactivation of GATE .................................................................................................................... 50

C

h

a

C

h

a

C

h

a

BURST pulse burst function (GX 320 only) ...................................................................................................... 51

Connections..................................................................................................................................................... 51

Selection of the BURST source....................................................................................................................... 51

Setting the number of pulses........................................................................................................................... 52

Setting the generation time for INTernal source.............................................................................................. 52

Manual triggering in EXTernal source ............................................................................................................. 52

Other settings .................................................................................................................................................. 52

X

a

p

t

e

r

I

X

a

p

t

e

r

I

X

a

p

t

e

r

X

a

p

t

e

r

X

a

p

t

e

r

X

p

t

e

r

X

a

p

t

e

r

X

a

p

t

e

r

X

p

t

e

r

X

I

p

t

e

r

X

I

p

t

e

r

X

I

I

I

I

I

I

I

C

h

a

p

t

e

r

X

I

I

I

C

h

a

p

C

h

a

p

Remote programming (programmable device only) ........................................................................................ 53

C

h

a

p

t

C

h

a

p

t

C

h

a

p

Technical specifications..................................................................................................................................... 56

C

h

a

p

C

h

a

p

C

h

a

p

General, Mechanical specifications............................................................................................................. 60, 61

C

h

a

p

t

C

h

a

p

t

C

h

a

p

Supplies................................................................................................................................................................ 62

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators I - 3

www.GlobalTestSupply.com

t

e

r

X

I

I

I

t

e

r

X

I

I

I

e

r

X

I

V

e

r

X

I

V

t

t

e

r

X

I

V

t

e

r

X

V

t

e

r

X

V

t

e

r

X

V

e

r

X

V

I

e

r

X

V

I

e

r

X

V

I

Page 4

General Instructions

General Instructions

Introduction You have just purchased a GX 305, GX 310 or GX 320 Function Generator

and we appreciate your confidence.

Content of the box

Precautions

Safety measures

• the generator

• the safety notice

• the power supply cable

• the USB A/B cable for the programmable versions

• the ETHERNET cable for the GX 320E

• the CD-ROM containing:

the operating guide in 5 languages

the programming in 2 languages

the USB ‘CP210x USB to UART Bridge Controller’ Drivers

the LabView and LabWindows Drivers

the USBxPress application (USB port identification)

the GX320E-Admin (IP address programming)

To obtain the best service:

- read this notice carefully,

- respect the safety instructions.

Failure to respect the warnings and/or usage instructions may damage the

device and/or installations and may be dangerous for the user.

This instrument complies with the NF EN 61010-1 - Ed. 2 (2001) safety

standard relating to the safety of electric measurement devices.

Definition of

installation

categories

• It is designed for indoor use in an level 2 pollution environment at an altitude

of less than 2000 m, a temperature between 0° C and 40° C and a RH

(relative humidity) of less than 80% up to 40° C.

• The MAIN OUT, SWEEP OUT, TTL OUT outlets are referenced t

o earth and

protected from accidental voltages that are not in excess of 60 V DC or

40 V AC.

• The FREQ EXT entry can only be used for measurements on Category 1

installations and for voltages not exceeding 300 V in relation to the earth.

• Mains power supply: 120 V

CAT II:

Category II corresponds to measurements on circuits that are directly

connected to low voltage installations.

Example: power supply for household appliances and portable tools

CAT III:

Category III corresponds to measurements on the building

installation.

Example: power supply for industrial machinery or devices.

CAT IV:

Category IV corresponds to measurements at the source of the low

voltage installation.

Example: power supply

Find Quality Products Online at: sales@GlobalTestSupply.com

I - 4 Function Generators

www.GlobalTestSupply.com

Page 5

General Instructions

General Instructions (contd.)

Symbols on the

instrument

Guarantee

Warning: potential hazard, refer to the operating guide.

Selective waste sorting for recycling electric and electronic waste. In

compliance with the WEEE 2002/96/EC directive:

the device should not be considered as household waste.

Earth terminal

Alternating signal

This equipment is guaranteed for all manufacturing and parts defects in

compliance with the general terms and conditions which are available on request

During the warranty period (3 years), the instrument may only be repaired by the

manufacturer who reserves the right to make the decision to either repair or

replace all or part of the appliance. In the event of a return of the equipment to

the manufacturer the shipping charge from the customer to the manufacturer is

at the customer’s expense.

Indication of a key double function when pressed for mo

second

USB symbol

re than 1

Maintenance, repairs, metrological checks

Cleaning

The guarantee does not apply in the following conditions:

• inappropriate use of the equipment or use with incompatible equipment

• one or more changes made to the equipment without prior explicit

authorisation from the manufacturer’s technical department

• an intervention is made on the instrument by a person n

manufacturer

• the adapting to a specific application that is not part of the definition of the

instrument or in the operating guide

• damage caused by a mechanical shock, by dropping the instrument or by

flooding.

The device includes no parts that can be replaced by the operator. All operations

must be carried out by competent approved personnel.

For checks and calibrations, contact one of our accredited metrology laboratories

(information and contact details available on request), at our Chauvin Arnoux

subsidiary or the branch in your country.

No interventions are authorised inside the instrument.

- Turn the instrument off (remove the power supply cable).

- Clean using a damp cloth and soap.

ot approved by the

- Never use abrasive products or solvents.

- Dry quickly using a dry cloth or an air blower at max. 80° C.

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators I - 5

www.GlobalTestSupply.com

Page 6

GX 305 and GX 310 Description

GX 305 and GX 310 Description

Presentation

Specifications

Front face

The GX 305 and GX 310 are alternating standard form wave generators, using the

DDS (Direct Digital Synthesis) technology. They may simulate the operation and

specifications of various electronic systems.

They also include a frequency meter input.

The GX 310P is a generator that can be programmed remotely via an USB link.

- Wave form: sinusoidal, square, triangle, logical, TTL, continuous

- Wave frequency: GX 305 0.001 Hz to 5 MHz for the sinus and the square

0.001 Hz to 2 MHz for the triangle

GX 310 0.001 Hz to 10 MHz for the sinus and the square

0.001 Hz to 2 MHz for the triangle

- INT and EXT sweep: GX 305 adjustable from 0.001 Hz to 5 MHz

GX 310 adjustable from 0.001 Hz to 10 MHz

- EXT freq. meter : from 5 Hz to 100 MHz

Back lit LCD display (124 x 43 mm)

Coding wheel

ON /

STANDBY

1.

2.

3.

4.

Terminals

1.

2.

3.

4.

Find Quality Products Online at: sales@GlobalTestSupply.com

II - 6 Function Generators

MAIN OUT

- Main output

VCF IN

- SWEEP input pilot signal in EXTernal source

SWEEP OUT

- Pilot output signal for INTernal SWEEP

TTL OUT

- TTL output

FREQ EXT

Frequency meter input

-

www.GlobalTestSupply.com

Page 7

GX 305 and GX 310 Description

GX 310 Description (contd.)

Back face

GX 305

Working voltage indicator

Network connection

Display

GX 310

GX 310P

USB type B connection

Working voltage indicator

Network connection

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators II - 7

www.GlobalTestSupply.com

Page 8

GX 305 and GX 310 Description (contd.)

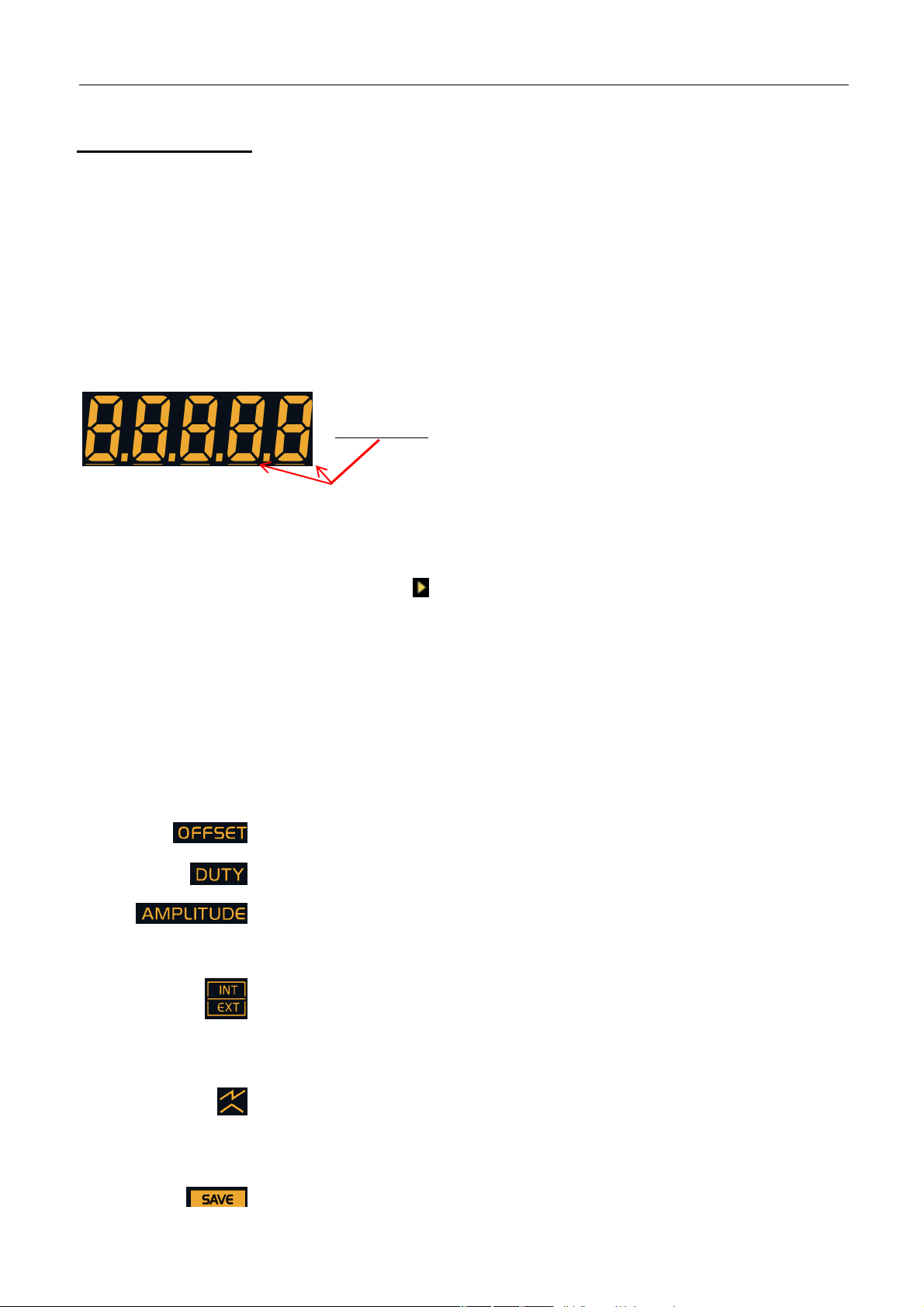

Wave selection:

• Sinusoidal

• square

• logic

• triangle

• continuous

Indication of the displayed frequency:

• Freq, Freq

• Time (sweep interval)

Frequency display (digit height: 20 mm)

Underscores: Indication of the digit to which the wheel

Unit of measure display

• degree

• MHz, kHz, Hz

• seconds

START

or Freq

END

increments apply during adjustment.

GX 305 and GX 310 Description

Function selection: current function indicator

• continuous

• sweep

• frequency

Duty cycle value display

Display of the amplitude value

Display of the offset value or the DC level

OFFSET display

DUTY display

AMPLITUDE display

Logical HIGH / LOW display

INTernal / EXTernal source selection

LINear / LOGarithmic sweep display

Sawtooth or triangle type sweep

Indication that the MODE key is assigned:

• to trigger the adjustment step when calibrating

• to trigger the selected test in Autotest

During calibration the is assigned to saving the parameters.

Find Quality Products Online at: sales@GlobalTestSupply.com

II - 8 Function Generators

www.GlobalTestSupply.com

Page 9

GX 305 and GX 310 Description

GX 305 and GX 310 Description (contd.)

Keys

The keys with the symbol have a specific action when pressed for more

than 1 second.

• The white keys may have a backlight:

Appliance under power but not turned on

Appliance turned on

MAIN OUT

Key lit MAIN OUT exit activated

• The other keys can be:

keys not assigned to the wheel adjustment or

unlit

having no action

the corresponding adjustment is assigned to the

lit

wheel.

the corresponding adjustment can be assigned to

blinking

the wheel.

Each time the WAVEFORM or FUNCTION is changed the keys that can be

assigned to the wheel adjustment blink for 4 seconds; if no keys are used

at this time the frequency adjustment (Freq or Freq

wheel.

) is assigned to the

START

Keys pressed for

less than 1 second

MAIN OUT

Sinusoidal waveform selection

Selects square or logical waveform by successive pressing on the key

Triangular waveform selection or saves adjustments during calibration

Continuous waveform selection

Validation, or not, of the waveform on the MAIN OUT BNC

Adjustment of the duty cycle using the wheel (square, triangle)

Adjustment of the output signal amplitude using the wheel

• Offset adjustment using the wheel

• DC level adjustment if the continuous waveform is selected.

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators II - 9

www.GlobalTestSupply.com

Page 10

GX 305 and GX 310 Description (contd.)

Keys pressed for

less than 1 second

(contd.)

GX 305 and 310 Description

LOGIC LEVEL

FUNCTION

LOGIC waveform selected:

Adjustment of the high or low signal level using the wheel

FUNCTION keys:

Selection of one of the three available functions

SWEEP selection of the INTernal or EXTernal command signal

• SWEEP activated: selection of LIN or LOG sweep

• calibration: triggering of the selected adjustment step

• Autotest: run the selected test

SWEEP function activated in INT: assignment of the desired duration setting

for carrying out the sweep using the wheel.

Then, by pressing several times, selection of the digit on which to increment.

Division or multiplication by 10 of the current frequency value (decade change)

• Assignment of frequency adjustment to the wheel.

Then, by pressing several times, selection of the digit on which to

increment.

• SWEEP function activated: same functions with Freq

requencies.

f

START

and Freq

END

Find Quality Products Online at: sales@GlobalTestSupply.com

II - 10 Function Generators

www.GlobalTestSupply.com

Page 11

GX 305 and GX 310 Description

GX 305 and GX 310 Description (contd.)

Keys pressed for

more than 1 second

Pressing the key for more than 1 second forces the duty cycle to 50%.

Pressing the key for more than 1 second switches from a peak to peak

amplitude display to an RMS (root mean square) display.

Pressing the key for more than 1 second forces the offset value to 0.

LOGIC LEVEL

Pressing the key for more than 1 second assigns the LCD contrast adjustment

to the wheel.

For the SWEEP function, pressing the key for more than 1 second switches

from Freq

These keys assign the selected frequency to the start or end of the current

range.

START

to Freq

and vice versa.

END

Ranges

Press > 1 Second

‘RANGE-’

Press > 1 second

‘RANGE+’

[0.001 Hz ; 0.01 Hz] 0.001 Hz 0.01 Hz

[0.01 Hz ; 0.1 Hz] 0.01 Hz 0.1 Hz

[0.1 Hz ; 1 Hz] 0.1 Hz 1 Hz

[1 Hz ; 10 Hz] 1 Hz 10 Hz

[10 Hz ; 100 Hz] 10 Hz 100 Hz

[100 Hz ; 1 kHz] 100 Hz 1 kHz

[1 kHz ; 10 kHz] 1 kHz 10 kHz

[10 kHz ; 100 kHz] 10 kHz 100 kHz

[100 kHz ; 1 MHz] 100 kHz 1 MHz

GX 305 [1 MHz ; 5 MHz]

GX 310 [1 MHz ; 10 MHz]

1 MHz

GX 305 5 MHz

GX 31010 MHz

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators II - 11

www.GlobalTestSupply.com

Page 12

GX 320 Description

GX 320 Description

Presentation

Specifications

nt face

Fro

The GX 320 is a standard alternating signal generator, using the DDS (Direct Digital

Synthesis) technology. It may simulate the operation and the specifications of various

electronic systems. It also includes a frequency meter input. The GX 320E is remote

programmable via an USB or ETHERNET link.

- Wave form: sinusoidal, square, triangle, logical, TTL, continuous

- Wave frequency: 0.001 Hz to 20 MHz for the sinusoidal and square

0.001 Hz to 2 MHz for the triangle

- INT and EXT sweep: adjustable from 0.001 Hz to 20 MHz

- EXT frequency meter: from 5 Hz to 100 MHz

- AM modulation: internal (1 kHz) and external (< 5 kHz)

- FM modulation: internal (1 kHz) and external (< 15 kHz)

- Frequency Shift Keying FSK: internal (1 kHz) and external (< 1 MHz)

- Phase Shift Keying PSK : internal (1 kHz) and external (< 1 MHz)

- BURST function: internal or external (< 1 MHz)

- GATE function: external (< 2 MHz)

- Function to synchronise several generators

- 15 configurations can be saved and recalled

Back lit LCD display (124 x 43 mm)

Coding wheel

ON / STANDBY

1. 2. 3. 4.

Terminals

1.

2.

3.

4.

Find Quality Products Online at: sales@GlobalTestSupply.com

III - 12 Function Generators

MAIN OUT

- Main output

VCG IN

- External SWEEP, MODUL, SHIFT K, BURST piloting signal input

SYNC CTRL

- Master synchronisation output signal in SYNC function

- Slave synchronisation input signal in SYNC function

SWEEP OUT in SWEEP or SHIFT K INTernal source

- Sweep piloting output signal for FSK and PSK

TTL OUT

- TTL output

SYNC M CLK

- in SYNC function, master clock output

EQ EXT

FR

- Frequency meter input

SYNC S CLK

- in SYNC function, slave synchronisation clock input

GATE IN

- GATE piloting input signal

www.GlobalTestSupply.com

Page 13

GX 320 Description

connection

Network

Connection

working

Network

Conne

ct

ion

working

GX 320 Description (contd.)

Rear panel

GX 320

USB type B connection

Indication of the

voltage

Display

GX 320E

ETHERNET

Indication of the

voltage

USB type B

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators III - 13

www.GlobalTestSupply.com

Page 14

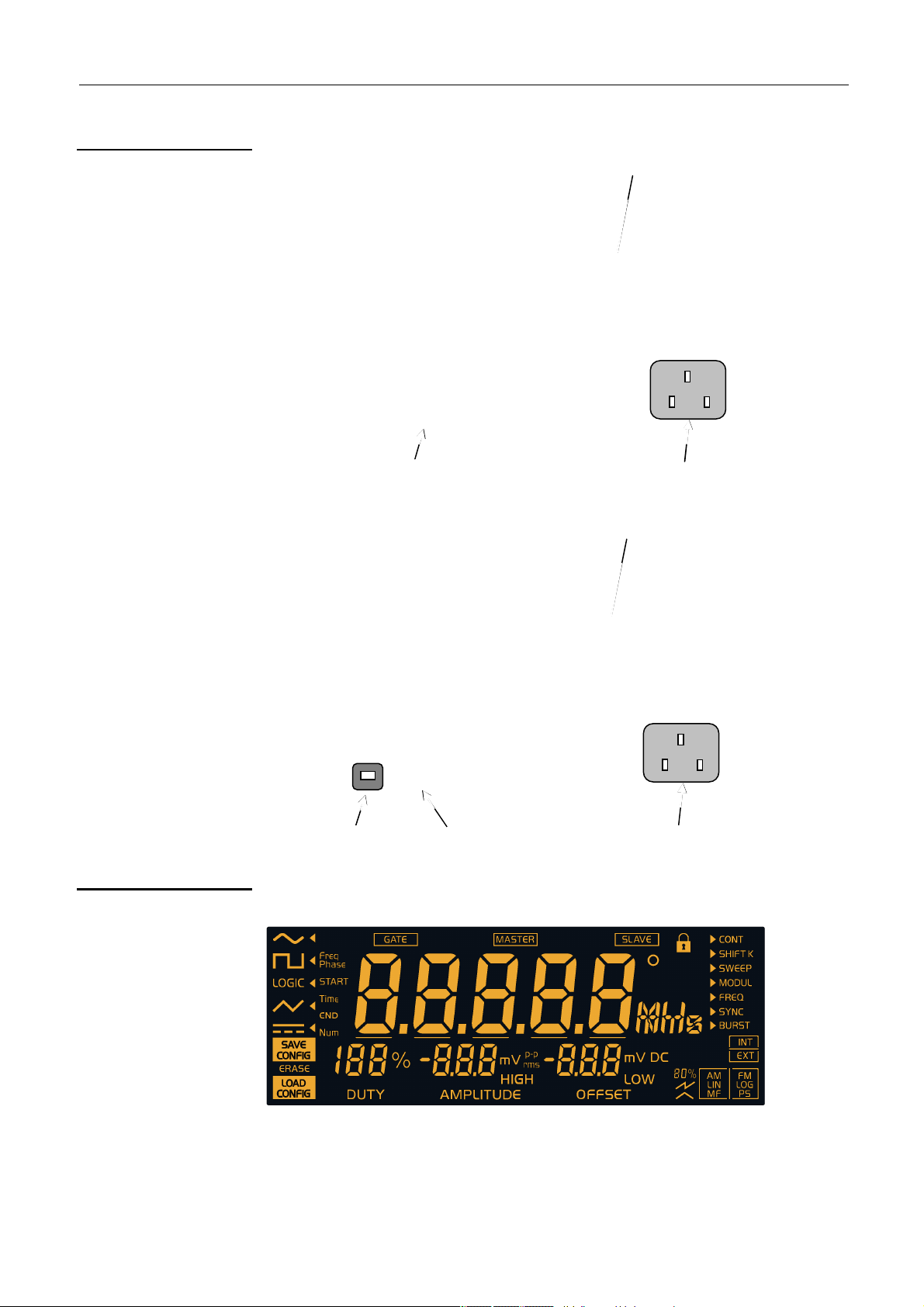

GX 320 Description (contd.)

Signal selection:

• sinusoidal

• square

• logic

• triangle

• continuous

current waveform indicator

Display of the current frequency phase:

• Freq, Freq

• Phase, Phase

• Time (sweep period, pulse period)

• Num : number of pulses

START

Frequency display (digit height 20 mm)

and Freq

, Phase

START

GX 320 Description

END

END

Underscores:

Indicate to which digit the wheel increments apply during

adjustment.

Unit of measure display:

• degree

• MHz, kHz, Hz

• seconds

Function selection:

• continue

• Shift Key

• sweep

• modulation

• frequency meter

• synchronisation

• Burst

Current function indicator

Duty cycle value display

Amplitude value display

Offset value or DC level value display

OFFSET type display

DUTY type display

AMPLITUDE type display

Find Quality Products Online at: sales@GlobalTestSupply.com

III - 14 Function Generators

www.GlobalTestSupply.com

Page 15

GX 320 Description

GX 320 Description (contd.)

HIGH / LOW level logical type display

INTernal / EXTernal source selection

Mode display:

• AM / FM Modulation

• LINear / LOGarithmic sweep

• Master / Slave synchronisation

• Shift key Frequency / Phase

Indication that the MODE key is assigned:

• to triggering the adjustment step when calibrating

• to the manual triggering of a set of pulses in BURST mode

• to triggering the selected test in Autotest mode

Sawtooth or triangle sweep type

Modulation rate display AM 20 % or 80 %

GATE mode activated display

Master synchronisation activated display

Slave synchronisation activated display

For the synchronisation function: indicates that the frequency and phase

adjustment on the slave are restricted by the master.

• During calibration the key is assigned to saving the settings.

• In normal mode selects save configuration mode

Selects configuration recall mode

Selects configuration clearing mode

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators III - 15

www.GlobalTestSupply.com

Page 16

GX 320 Description

GX 320 Description (contd.)

Keys

Keys with the symbol have a specific action when pressed for more than

1 second.

• The white keys may have a back light:

MAIN OUT

MAIN OUT

• The other keys can be:

unlit

lit

blinking

Appliance under power but not turned on (red)

Appliance turned on (green)

Key lit MAIN OUT exit activated

Blinking key MAIN OUT and GATE functions activated

keys not assigned to the wheel adjustment or having no

action

the corresponding adjustment is assigned to the wheel.

the corresponding adjustment can be assigned to the

wheel.

Keys pressed for

less than 1 second

WAVEFORM

Each time the WAVEFORM or FUNCTION is changed the keys that

can be assigned to the wheel adjustment blink for 4 seconds; if no

keys are used at this time the frequency adjustment (Freq or

Freq

WAVEFORM keys:

Selects the waveform to be generated

Saves the current configuration or saves the settings when calibrating

Recalls or clears a saved configuration

) is assigned to the wheel.

START

Find Quality Products Online at: sales@GlobalTestSupply.com

III - 16 Function Generators

www.GlobalTestSupply.com

Page 17

GX 320 Description

GX 320 Description (contd.)

Keys pressed for

less than 1s (contd.)

LOGIC LEVEL

FUNCTION

Validation or not of the wave on the MAIN OUT BNC.

Adjustment of the wave duty cycle (square, triangle) using the wheel.

Adjustment of the output wave amplitude using the wheel.

• Offset adjustment using the wheel.

• Adjustment of the DC level if the continuous waveform is selected.

LOGIC waveform selected: adjustment of the high or low wave level using the

wheel.

FUNCTION keys:

Selection of one of the 7 available functions.

SHIFT K, or SWEEP, or MODUL or BURST functions activated: selection of

the INTernal or EXTernal command signal.

• SHIFT K o

a specific function mode (see Function list and adjustment paragraph).

• BURST function and EXTernal source activated: manual triggering of a

set of pulses.

• calibration: triggers the selected adjustment step.

• Autotest: triggers the selected test.

• SWEEP activated with INTernal source: assignment of the wheel to the

desired timing adjustment to carry out a frequency sweep; then, by

pressing several times, selection of the digit on which to apply the

increment.

• BURST function active: assignment of the wheel to the adjustment of the

number of pulses or the burst generation period (INT source); then, by

pressing several times, selection of the digit on which to apply the

increment.

Division or multiplication by 10 of the current frequency value (decade change).

• Assignment of frequency adjustment to the wheel; then, by pressing

several times, selection of the digit on which to apply the increment.

• SWEEP or MODUL FM or FSK activated: same functions with the

FreqSTART and Freq

r SWEEP or MODUL or SYNC functions activated: selection of

frequencies.

end

• SYNC function activated: adjustment of the de-phasing between the two

generators using the wheel.

• PSK function activated: by pressing several times, adjustment of the

PhaseSTART or Phase

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators III - 17

www.GlobalTestSupply.com

using the wheel.

end

Page 18

GX 320 Description (contd.)

Keys pressed for

more than 1 second

Pressing for more than 1 second sets the GATE function.

Pressing for more than 1 second forces the duty cycle to 50 %.

Pressing the key for more than 1 second switches from a peak to peak

amplitude display to an RMS (root mean square) display.

Pressing the key for more than 1 second forces the offset value to 0.

LOGIC LEV EL

LOGIC LEVE L

LOGIC LEVE LLOGIC LEVE L

Pressing the key for more than 1 second assigns the LCD contrast adjustment

to the wheel.

GX 320 Description

BURST function activated, INTernal source. Pressing the key for more than 1

second is used to switch the number of pulses Num in the pulse generation

period Time, and vice versa.

These keys assign the selected frequency to the start or end of the current

range.

Ranges

[0.001 Hz ; 0.01 Hz] 0.001 Hz 0.01 Hz

[0.01 Hz ; 0.1 Hz] 0.01 Hz 0.1 Hz

[0.1 Hz ; 1 Hz] 0.1 Hz 1 Hz

[1 Hz ; 10 Hz] 1 Hz 10 Hz

[10 Hz ; 100 Hz] 10 Hz 100 Hz

[100 Hz ; 1 kHz] 100 Hz 1 kHz

[1 kHz ; 10 kHz] 1 kHz 10 kHz

[10 kHz ; 100 kHz] 10 kHz 100 kHz

Press > 1 Second

‘RANGE-’

Press > 1 second

‘RANGE+’

[100 kHz ; 1 MHz] 100 kHz 1 MHz

[1 MHz ; 10 MHz] 1 MHz 10 MHz

[10 MHz ; 20 MHz] 10 MHz 20 MHz

For the SWEEP or MODUL FM or FSK functions pressing the key for more

than 1 second is used to switch between Freq

Find Quality Products Online at: sales@GlobalTestSupply.com

III - 18 Function Generators

www.GlobalTestSupply.com

START

and Freq

and vice versa.

END

Page 19

General Commands

General Commands

Commissioning

Check that your instrument is compatible with the mains network voltage

(see the label at the back of the instrument), that the power supply cable

is not damaged and that it is earthed.

The power supply cable plug is used as a cut off point, connect the device

to a mains outlet that is easily accessible and is earthed in order to

ensure safety.

Four start-up modes are possible depending on the key

keys - used:

1. Normal Mode:

The instrument starts up using the last used configuration. By default the

factory configuration is restored.

The key becomes:

2. Version Mode:

– or combination of

FUNCTION

+

MAIN OUT

+

The instrument starts up in Version mode and displays the current software

version number and date.

+

The key becomes: (See Display of the software version).

3. Calibration Mode

The instrument starts up in Calibration mode with the selection of the

calibration to be run: automatic mode CAL_AU, by default.

The key becomes: (See automatic calibration).

4. Autotest Mode:

The instrument starts up in Autotest mode with the selection of the test to

be run: automatic mode tSt_AU by default.

The key becomes: (See Autotest).

:

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators IV - 19

www.GlobalTestSupply.com

Page 20

General Commands

General Commands (contd.)

Stop

Whatever the mode, pressing this key puts the instrument on STANDBY.

When pressed while in Normal mode the context is saved:

- current settings in use for signal generation when the instrument was

stopped,

- settings for other functions that may have been changed.

The key becomes:

Each time Normal mode start-up is used all the settings are reloaded.

In the event of a power failure (or if the power cable is unplugged …), the

instrument restarts using the last backup (backup made the last time the device

was turned off using the ON/STANDBY key).

In the event of an error the default configuration is loaded:

• Signal sinusoidal

• Function CONTinuous

• Frequency 1 kHz

• Amplitude 1 Vpp

• Offset 0 V

• Output MAIN OUT ON not active

• No adjustments assigned to the wheel.

Activating the

N OUT terminal

MAI

MAIN OUT

MAIN OUT

The key becomes: .

At start-up the MAIN OUT terminal is always de-activated.

Pressing the key activates the terminal and the key lights: .

On the GX 320: the key may blink when the GATE function is activated (see

GATE function).

De-activation of the MAIN OUT terminal, the key is no longer lit: .

Find Quality Products Online at: sales@GlobalTestSupply.com

IV - 20 Function Generators

www.GlobalTestSupply.com

Page 21

General Commands

n the 4 seconds following the function validation the wheel is

General Command (contd.)

Setting the screen contrast

LOGIC LEVEL

1s or 1s

Selection of the

instrument function

FUNCTION

The display shows: .

The key becomes:

Adjustment of the contrast value from 0 to 99 using the coding wheel.

Exiting from this mode is made by pressing another key. The frequency display

returns to the screen and the possible associated keys blink.

The key becomes: .

The contrast value is memorised in the device configuration once it is turned off

(see left margin) or when the configuration is saved (GX 320).

Pressing once displays the list of functions available on the device in the top

.

FUNCTION

right hand corner:

The cursor indicates the selected function.

Pressing again moves the cursor towards the top or bottom to select another

function.

If, after 2 seconds, no keys have been pressed or when another key is pressed,

the selected function is validated and is the only one remaining displayed:

When the function has been validated the keys that can be assigned to the

wheel blink until one of them is selected; the key then lights up.

If no keys are used i

automatically assigned to frequency setting

(Freq or Freq

depending on the function).

START

(GX 310) (GX 320).

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators IV - 21

www.GlobalTestSupply.com

Page 22

General Commands

General Commands (contd.)

Software version display

+

The following screen is displayed:

i.e. the 23rd November

for version number: 1.00

for the version date:

2008

Exit Version mode.

The key becomes: .

for GX 305

for GX 310

for GX 320

for Programmable

Automatic calibration

Calibration mode

FUNCTION

+

Entering

The device has an automatic function that can be used to calibrate signal

generation.

This function can be triggered:

- automatically (all settings are run automatically) or

- manually (individual selection and run of settings).

No specific wiring is needed for this function.

For optimal calibration the device must be at operating temperature

(switched on for 30 minutes) before running calibration.

In addition, when in manual mode it is recommended to respect the

running order of the calibration steps.

Entry into this mode is the CAL.AU. automatic mode. The display is as below:

Switching to manual mode is done by turning the wheel and selecting the

calibration step to be run individually.

Find Quality Products Online at: sales@GlobalTestSupply.com

IV - 22 Function Generators

www.GlobalTestSupply.com

Page 23

General Commands

that the adjustment settings may have changed and

General Commands (contd.)

Selecting the calibration step to run:

• CAL.AU : automatic calibration (all settings are triggered automatically)

• CAL.00 : cancels offsets for sine and triangle signals

• CAL.01 : cancels offsets for square and LOGIC signals

• CAL.02 : calculates gains for the DC level offset setting

• CAL.03 : cancels the secondary offset for square and LOGIC signals

• CAL.04 : calculates gains for amplitude setting for sine, triangle, square

and LOGIC

• CAL.05 : calibrates the duty cycle for square and LOGIC

• CAL.06 : sets AM and FM external modulation

• CAL.07 : sets AM modulation for square and LOGIC signals

Running

adjustments

(GX 305/310)

(GX 320)

Pressing the key triggers automatic calibration or the selected calibration step.

The display shows:

for automatic (then the adjustments are

displayed in order) or

in manual mode.

At the end of the run two situations are possible: the adjustment either succeeded

or failed.

If the adjustment succeeded the display shows:

in automatic or

in manual.

The display indicates

that the changes can be saved.

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators IV - 23

www.GlobalTestSupply.com

Page 24

General Commands

General Commands (contd.)

Saving settings

(GX 320)

(GX 305/310)

Calibration mode

Exit from

In the event of an error the automatic calibration stops at the step in error, it

then switches to manual mode.

The display shows:

In the event of repeated errors contact your CHAUVIN-ARNOUX representative

(see p. 5).

Pressing saves the calibration.

The display is cleared once the backup is made. It reappears if the

calibration is changed.

Exit this mode using this key.

The key becomes: .

To save settings a data backup should be made (see abo

exiting the mode, otherwise the settings are lost and the previous

settings are re-loaded at start-up.

ve) before

Find Quality Products Online at: sales@GlobalTestSupply.com

IV - 24 Function Generators

www.GlobalTestSupply.com

Page 25

General Commands

General Commands (contd.)

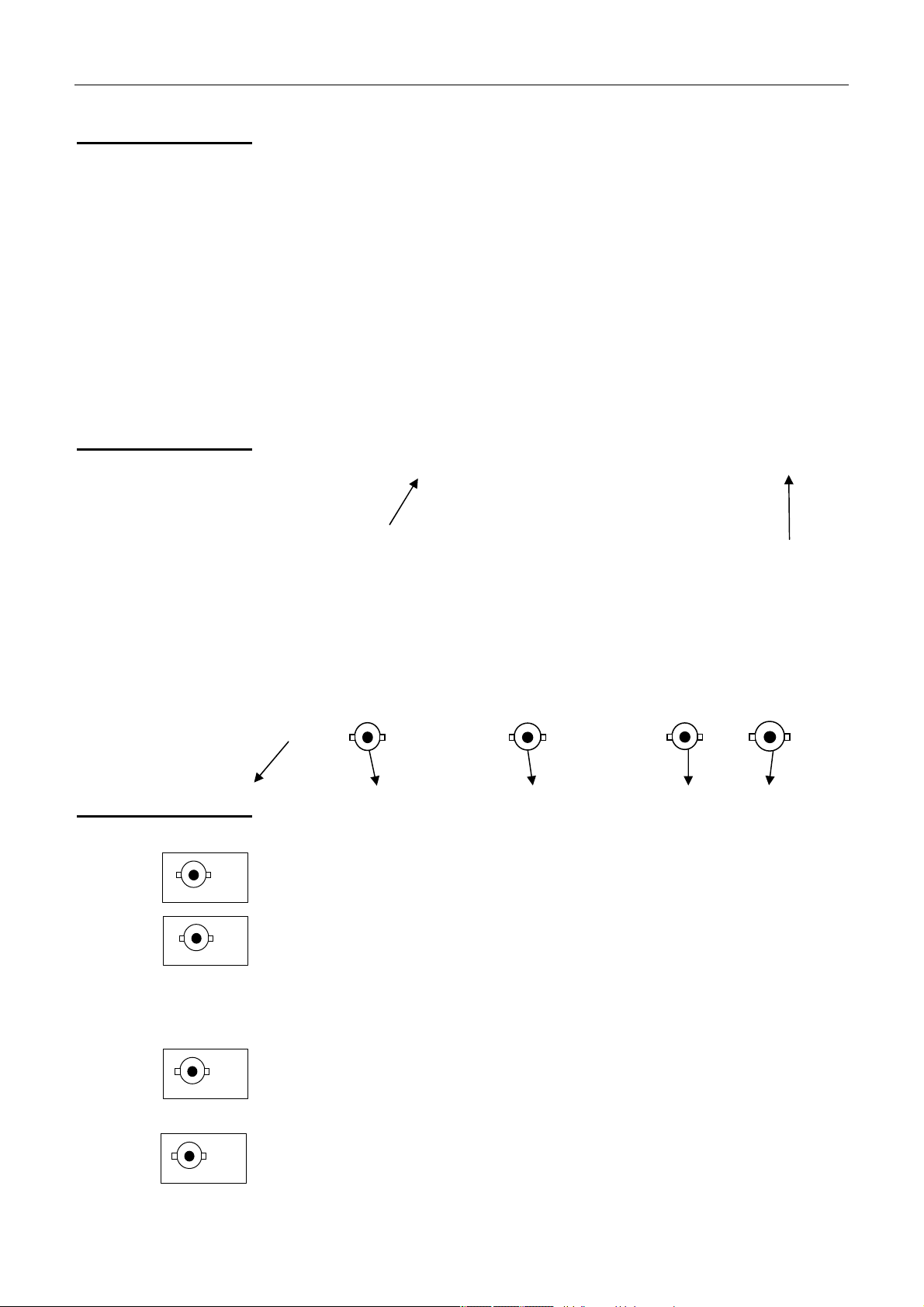

Instrument Autotest

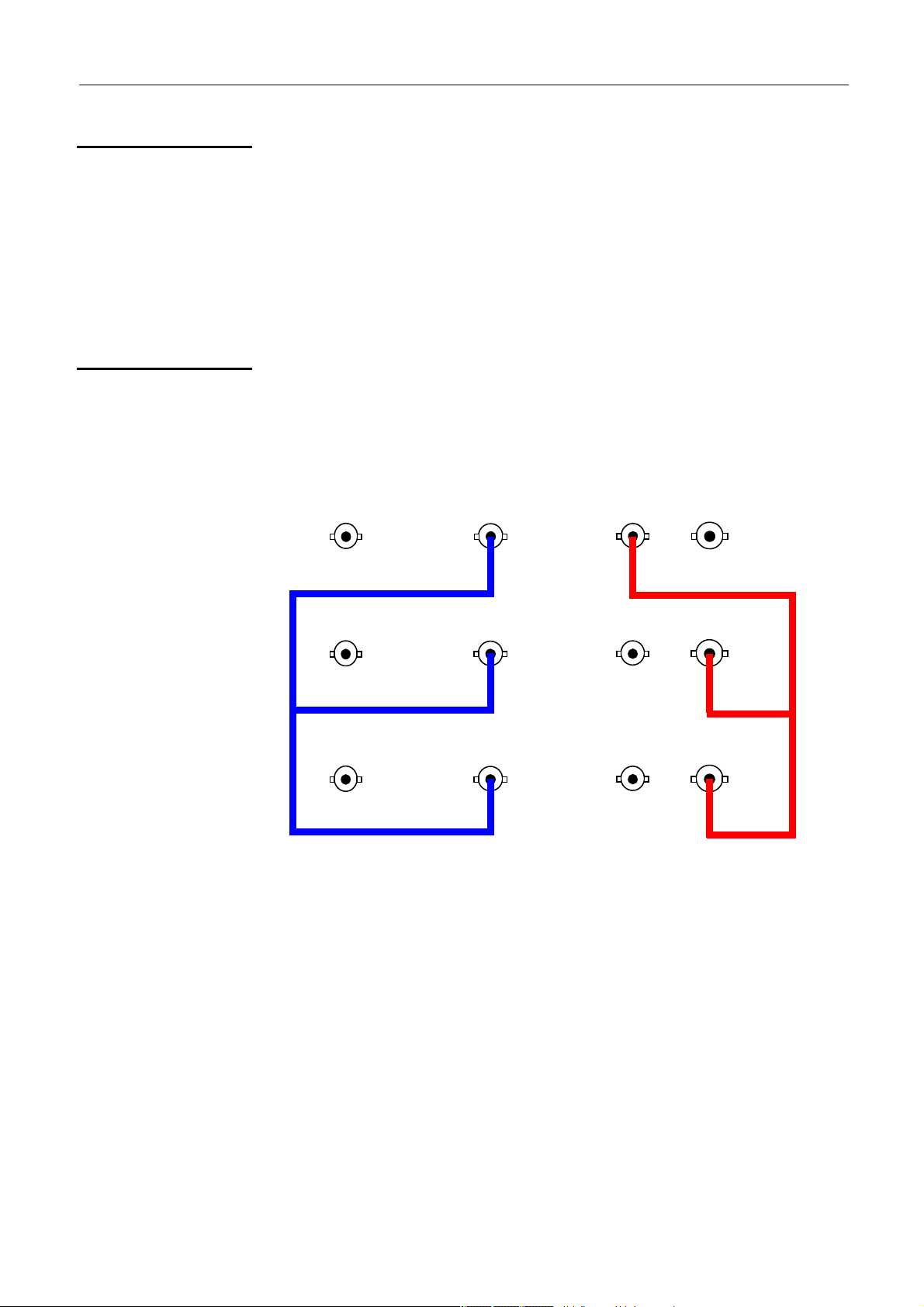

Wiring needed

The device has an automatic electronics test function. This feature can be run

automatically (all tests run automatically) or manually (individual selection and

running of tests).

These tests require specific wiring of the device’s input/output terminals.

Two wirings are needed.

When needed they are indicated by the following messages:

for wiring n° 1:

(GX 305/310)

(GX 320)

(GX 305/310)

(GX 320)

for wiring n° 2:

(GX 305/310)

(GX 320)

Once the wiring has been made pressing the key continues the test.

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators IV - 25

www.GlobalTestSupply.com

Page 26

General Commands

scrolls through all segment, even segment, odd segment

General Commands (contd.)

Entering

AUTOTEST mode

MAIN OUT

+

(GX 305/310)

MAIN OUT

+

(GX 320)

By default this mode is entered using the automatic mo

the following:

Switching to manual mode is done by turning the test step selection wheel and

running individually.

Selection of the test step to run:

• tSt.AU : automatic test (all tests automatically sequenced)

• tSt.00 : LCD test (

displays by pressing the MODE key)

• tSt.01: keyboard and key light test

(you must press all the keys except , each time a key is

pressed an LCD segment is cleared).

N° 1 wiring is needed:

• tSt.02: frequency meter test

• tSt.03: GATE IN test (GX 320)

• tSt.04: CTRL IN test using SYNC function (GX 320)

• tSt.05: FM modulation test (GX 320)

• tSt.06: external AM test (GX 320)

• tSt.07: Reset DDS pilot test

• tSt.08: DDS FS register pilot test (frequency commutation)

• tSt.09: DDS PS register pilot test (phase commutation)

• tSt.10: triangle duty cycle test

N° 2 wiring needed:

• tSt.11 : CTRL OUT test using SYNC function (GX 320)

• tSt.12 : SWEEP OUT test

de tSt.AU. The display is

Find Quality Products Online at: sales@GlobalTestSupply.com

IV - 26 Function Generators

www.GlobalTestSupply.com

Page 27

General Commands

in automatic mode (then scrolls through

General Commands (contd.)

Running the tests

Pressing the key triggers the automatic test or the selected test step.

The display shows:

(GX 310)

(GX 320)

the tests) or

At the end of the run 2 situations are possible: the test was successful or the test

failed.

in manual mode.

If the test succeeded the display shows:

in automatic mode or

in manual mode.

If the test failed the automatic test stops at the failed test step or switches to

manual mode. The display shows:

If the error persists contact your MANUMESURE representative (see p. 5).

Exiting AUTOTEST

Pressing this key exits Autotest mode.

The current test is stopped and the instrument switches to STANDBY, the key

becomes:

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators IV - 27

www.GlobalTestSupply.com

.

Page 28

General Commands (contd.)

Saving a configuration (GX 320)

The GX 320 can save and reload user configurations.

A total of up to 15 files can be saved.

This backup is permanent (the data is saved even if the instrument is powered

down).

Enters the configuration management mode.

is displayed on the screen with the current file number:

General commands

if file 3 is empty;

if file 3 already contains a configuration

the data (other than frequency) is displayed on the screen.

Pressing another key than or exits the mode without saving.

Selects files from SEt.01 to SEt.15. The screen is updated with the data from

the selected file.

Pressing the key again saves the current configuration in the selected file.

The display returns to its pre-backup status and the display is cleared.

When saving the content of the selected file is overwritten by the content

of the current configuration without any warning messages.

Find Quality Products Online at: sales@GlobalTestSupply.com

IV - 28 Function Generators

www.GlobalTestSupply.com

Page 29

General Commands

General Commands (contd.)

Reloading a configuration (GX 320)

The GX 320 can reload 16 saved configurations:

• 15 user configurations,

• plus the default configuration (“factory” configuration see §. Stop).

Entering configuration reload mode.

is displayed on the screen with the current file number:

if file 3 is empty.

if file 3 contains a configuration the data

(except frequency) is displayed on the screen.

Pressing a key other than exits the mode without making any changes.

Selects a file from SEt.00 to SEt.15 (Set.00 is the factory configuration). The

screen is updated using the data from the selected file.

Pressing the key again reloads the configuration from the selected file.

If the file is empty or inconsistent the operation is cancelled:

• the settings used before the reload operation are maintained,

• the initial display is shown.

If the selected file is valid the configuration it contains is loaded and the display

is updated with its data.

is no longer displayed indicating that the configuration reload mode has

been exited.

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators IV - 29

www.GlobalTestSupply.com

Page 30

General Commands (contd.)

Clearing a configuration (GX 320)

Clearing a user configuration file (Set.01 to Set.15) consists in saving a null

configuration in the file.

This configuration is shown by displaying the file number only during file

selection.

Reloading a null configuration has no effect (the existing settings are kept

active).

General commands

It is not necessary to clear a file before saving a con

saving the configuration overwrites the data in the file.

Enters configuration mode.

is displayed with the current file number:

if file 3 is empty

if file 3 already contains a configuration

the data (except frequency) is displayed on the screen.

Pressing a key other than

changes.

or exits the mode without making any

figuration since

Selects file erase mode.

is added to the display:

Pressing the key again unselects the file erase mode.

Selects a file from SEt.01 to SEt.15. The screen is updated with the data from

the selected file.

Pressing the key again saves a null configuration in the selected file and returns

to the current configuration display.

and are cleared from the screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

IV - 30 Function Generators

www.GlobalTestSupply.com

Page 31

Generation of basic periodic signals

Generation of basic “CONTinous” periodic signals

Available output waveforms

Waveform selection

GX 305/310

The instrument generates the following waveforms:

• sine

• square

• TTL logic

• triangular

• continuous.

Sine waveform

Square waveform

Logic output waveform

Triangular waveform

Continuous waveform

GX 320

WAVEFORM

WAVEFORM

Each time a key is pressed the symbol is displayed on the screen and the keys

that can be assigned to the wheel blink.

Pressing once displays the list of available waveforms at the top left of the screen:

The cursor indicates the current waveform.

Pressing again moves the cursor up or down to select a new

waveform.

If the keys are not pressed for 2 seconds or if another key is pressed the

selected waveform is validated and remains displayed:

When the waveform is validated the keys that can be assigned to

the wheel blink until one of them is selected; this key is then lit.

If no key is pressed within 4 s of validation the wheel is

automatically assigned to frequency adjustment (Freq or

Freq

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators V - 31

www.GlobalTestSupply.com

START

).

Page 32

Generation of basic periodic signals

Generation of basic “CONT” periodic signals (contd.)

Adjusting signal frequency

Entering the

5 significant digits

or

Frequency is set in two steps:

• Entry of the five significant digits

• Setting the decimal point and the unit multiplier

The coding wheel and the following key can be used to enter the 5 significant

di

gits.

Assign frequency setting to the wheel. The:

Value adjustment.

By pressing several times, the digit from which wheel increments are added is

selected.

key lights.

By default the digit to which increments are applied is the unit digit

(extreme right). This setting is programmed each time the instrument

is started up.

Positioning the

decimal point and

the unit multiplier

Entry short cuts

1s

1s

These keys position the decimal point and the unit multiplier.

Assigns the minimum value for the current range

(see Pressing keys for more than 1 second in the GX description paragraph).

Assigns the maximum value for the current range

(see Pressing keys for more than 1 second in the GX description paragraph).

Find Quality Products Online at: sales@GlobalTestSupply.com

V - 32 Function Generators

www.GlobalTestSupply.com

Page 33

Generation of basic periodic signals

Generation of basic CONT periodic signals (contd.)

Example 1:

1st possibility

The wheel is not assigned to a setting (FREQ not lit or blinking),

the current frequency value is: .

We want to enter: .

The FREQ key lights: .

The display shows:

The display shows: .

The display shows: .

25

2nd possibility

The display shows: .

The display shows: .

The display shows: .

The FREQ key lights: .

The display shows: .

The display shows: .

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators V - 33

www.GlobalTestSupply.com

Page 34

Generation of basic periodic signals

Generation of basic “CONT” periodic signals (contd.)

The display shows: .

2

The display shows: .

The display shows: .

5

3rd possibility

2500

Example 2:

The display shows: .

The FREQ key lights.

The display shows:

The display shows: .

The display shows: .

The wheel is not assigned to any settings (FREQ key unlit),

the current frequency value is: .

.

We want to enter: .

The FREQ key lights: .

1s

The display shows:

Find Quality Products Online at: sales@GlobalTestSupply.com

V - 34 Function Generators

www.GlobalTestSupply.com

.

Page 35

Generation of basic periodic signals

Generation of basic “CONT” periodic signals (contd.)

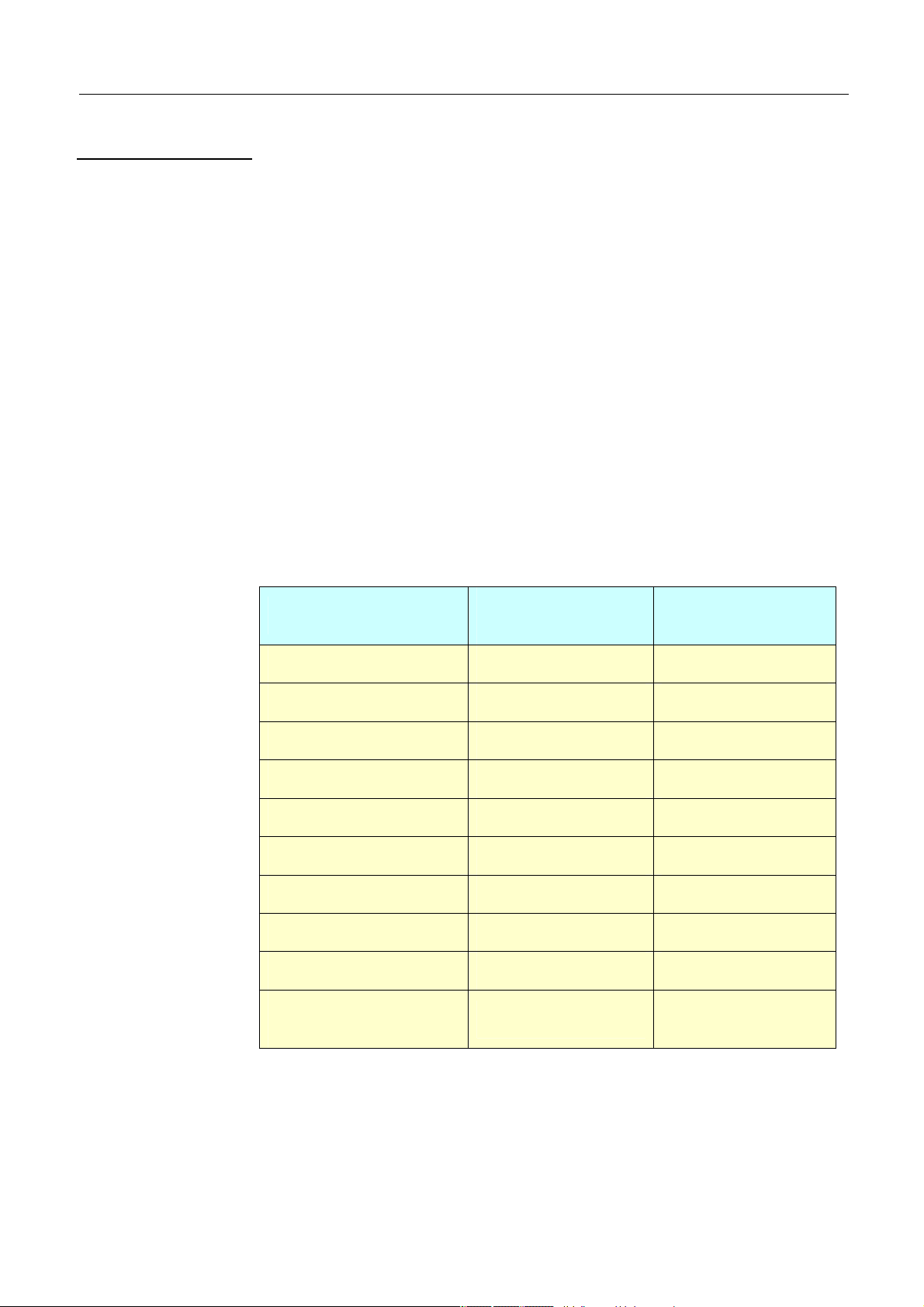

Setting the duty cycle

or

The duty cycle can only be adjusted for square, logic or triangle forms using the

“CONTinuous” function.

The setting can be limited depending on the signal frequency.

Signal Frequency Possible adjustments

Square

Logical

Triangle

Assignment of the duty cycle to the wheel. The key lights: .

Setting the value.

≤ 200 kHz

200 kHz < F ≤ 1 MHz

F > 1 MHz

F < 0.2Hz

0.2Hz ≤ F ≤ 1 kHz

1 kHz < F ≤ 10 kHz

F > 10 kHz

10 to 90 %

20 to 80 %

50 %

50%

10 to 90 %

30 to 70 %

50 %

Setting the signal

litude

amp

or

Vpp/Vrms display

1s

1s

Forces the duty cycle value to 50 %.

The duty cycle is limited by the frequency, turning the wheel may have no

effect.

Amplitude indications are given in open circuit.

Under 50

Assignment of amplitude adjustment to the wheel. The key lights: .

Adjustment of the Vpp or Vrms value depending on the selected display.

Switches from Vpp to Vrms display and vice versa

The variation is from 0 to 20 Vpp in open circuit.

ΩΩΩΩ

, amplitudes are divided by 2.

The sum of continuous voltage + alternating voltage cannot be >>>> ± 10 V.

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators V - 35

www.GlobalTestSupply.com

Page 36

Generation of basic periodic signals

Generation of basic “CONT” periodic signals (contd.)

Setting the offset and DC level

or

1s

Setting signal logical levels

or

Assignment of offset adjustment to the wheel. The key lights.

Value adjustment.

The variation field is from -10 V to +10 V maximum in an open circuit.

Forces the offset value to 0.

The sum of continuous voltage + alternating voltage cannot be >>>> ± 10 V.

This function is only available if the “LOGIC” waveform has been selected.

Assignment of the logic signal low level to the wheel.

The key lights.

The "Adj.LO" message displays instead of the frequency value:

By pressing several times the high or low level is selected, "Adj.HI" is displayed

for high level adjustment:

Adjustment of the selected value.

The field of variation for these levels is from -10 V to +10 V by 100 mV intervals.

high level is always greater than or equal to the low level.

The

Find Quality Products Online at: sales@GlobalTestSupply.com

V - 36 Function Generators

www.GlobalTestSupply.com

Page 37

Fonction SHIFT K

TTL output

Shift Keying function “SHIFT K” (GX 320 only)

The SHIFT KEY function can work with the signal frequency (FSK) or phase

(PSK):

- “FSK” is a frequency commutation piloted either INTernally or EXTernally:

switching from Freq

START

to Freq

and vice versa.

END

INTernal FSK:

Channel1: MAIN OUT

Channel2: VCG IN Sweep out

Connections

- “PSK” is a phase jump with value Phase

START

and Phase

, piloted by a

END

command signal that can be INTernal or EXTernal.

INTernal PSK

Channel1: MAIN OUT

Channel2: VCG IN Sweep out

:

At each change in signal status the programmed phase value (Phase

Phase

is added to the current phase.

END)

• With an INTernal source the command signal has a frequency of 1 kHz. It

can be viewed on the generator SWEEP OUT terminal.

• With an EXTernal source the pilot signal is a TTL signal (0 - 5 V) with a

frequency of < 1 MHz from the generator VCG IN terminal.

Main output signal

TTL input command signal from an

EXTernal F < 1 MHz

Output command signal from an

INTernal source

signal

START

or

FSK mode selection

Pressed successively, “F” mode selection (Frequency).

PSK mode selection

Pressed successively, “P” mode selection (Phase).

Selection of the source

Pressed successively, source selection:

INTernal

or

EXTernal .

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators VI - 37

www.GlobalTestSupply.com

Page 38

SHIFT K Function

Shift Keying “SHIFT K” function (contd.)

Setting frequencies in FSK mode

or

1s or 1s

1s

Setting phases in PSK mode

or

Freq

display and assignment of adjustment to the wheel.

START

The key lights: .

Freq

display and assignment of adjustment to the wheel.

END

The key lights: .

Pressed successively selects the digit from which the increment will be

applied.

Adjustment of the selected value.

Passage from Freq

adjustment to Freq

START

adjustment.

END

Assignment of Phase

adjustment to the wheel.

START

The key lights: .

1s or 1s

Assignment of Phase

The key lights: .

Adjustment of the selected value.

e field of phase variation is of -180° to +180° b y intervals of 1°.

Th

Pressed successively assigns Phase

wheel.

1s

Other settings

Forces the phase being set to 0.

See “CONT” function.

adjustment to the wheel.

END

or Phase

START

adjustment to the

END

Find Quality Products Online at: sales@GlobalTestSupply.com

VI - 38 Function Generators

www.GlobalTestSupply.com

Page 39

SWEEP Function

SWEEP frequency scan function

Connections

Remarks

SWEEP is a frequency scan from Freq

START

to Freq

piloted:

END

•either INTernally by the generator following a linear or logarithmic formula

and a saw tooth or triangle variation.

The user can choose a scan time from 10 ms to 100 s.

•either EXTernally using a voltage of ± 10 V applied to VCF IN (GX 305/310)

or VCG IN (GX 320) with a frequency < 15 kHz.

•Depending on the values of Freq

in ascending or descending order.

be

START

and Freq

the frequency scan will

END

When using EXTernal SWEEP the signal level is read at a frequency of 60 kHz.

This amplitude (coded on 256 values) is then converted into frequency.

When using INTernal SWEEP, the scan is made using a maximum of 256

values.

Main

modulated

output signal

- in EXT: Pilot signal ± 10 V

- in INT: SWEEP OUT

Input:

TTL OUT

Selection of scan mode

Assignment

ence using

sequ

INTernal source

Pressed successively this key selects one of the following scan modes:

Display Description Channel1: MAIN OUT,

Channel2: SWEEP OUT

Linear rule,

triangular variation

Linear rule,

saw tooth variation

Logarithmic rule,

triangular variation

Logarithmic rule,

Saw tooth variation

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators VII - 39

www.GlobalTestSupply.com

Page 40

SWEEP Function

)

SWEEP frequency scan function (contd.)

Assignment

sequence using

EXTernal source

INTernal source

EXTernal source

Display Description Channel 1:

MAIN OUT(F

Channel 2:

Modulation: SINE, 1 kHz, 10Vpp

Linear rule between

the command signal

and the generated

frequency

Logarithmic rule

between the command

signal and the

generated frequency

= 1 kHz, F

start

= 100 kHz

end

A SWEEP OUT signal is available on the VCF IN BNC (GX 305/310)

or VCG IN (GX 320).

It is a proportional signal with a generated frequency, amplitude from 0 to 2V.

The generated output frequency is proportional (according to a linear or

logarithmic rule) to the voltage on VCF IN (GX 305/310) or VCG IN (GX 320).

The command signal is sampled on 8 bits using a frequency of 60 kHz.

For -10 V: the output frequency F ≅ Freq

For 10 V: F ≅ Freq

END

START

Selecting the scan source

Setting the START / END frequencies

or

1s or 1s

Pressing the key successively selects the INTernal source or the

EXTernal source .

Displays Freq

and assigns adjustment to the wheel.

START

The key lights: .

Displays Freq

and assigns adjustment to the wheel.

END

The key lights: .

Pressing successively selects the digit from which the increment will apply.

Adjusts the selected value.

1s

Switches from setting Freq

to setting Freq

START

END

.

Find Quality Products Online at: sales@GlobalTestSupply.com

VII - 40 Function Generators

www.GlobalTestSupply.com

Page 41

SWEEP Function

SWEEP frequency scan function (contd.)

Setting the scan time using INTernal source

Displays the Time and assigns adjustment to the wheel.

or

Other settings

The key lights: .

Pressed successively selects the digit to which the increment will apply.

Adjusts the value using the wheel.

See the CONT function.

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators VII - 41

www.GlobalTestSupply.com

Page 42

MODUL Function

MODUL Modulation function (GX 320 only)

The MODUL function modulates a carrier frequency (FM) or amplitude (AM).

The modulating signal can be:

• either internal (INTernal source, sinusoidal 1 kHz signal)

• or on VCG IN, for an EXTernal source.

The carrier specifications are defined in the same way as the CONT function.

Using an EXTernal source the signal must have an amplitude of ± 10 Vpp

and a frequency of < 15 kHz (FM) and < 5 kHz (AM).

Depending on the voltage the modulation is as follows:

- AM: the output signal amplitude is typically

100 % for -10 V

50 % for 0 V

null for 10 V

- FM: the output signal frequency is typically

Freq

(Freq

Freq

for -10 V

start

+ Freq

start

for +10 V

end

) / 2 for 0 V

end

Remarks • For AM: with LOGIC and square signals modulation is digital:

Connections

Selection of modulation source

the modulating signal is read at a frequency of 150 kHz. This

amplitude (256 values) pilots the output signal amplitude.

For the other types of signal modulation is analogue and the

modulating signal cannot exceed 5 kHz.

• For AM: with the SINE and TRIANGLE signals, TTL OUT is not available

• For FM: modulation is digital: the modulating signal level is read at a

frequency of 65 kHz.

This amplitude (256 values) is then converted into frequency.

Modulated output

signal

Pilot signal

± 10 V; F < 5 kHz

TTL OUT

Pressed successively selects the INTernal source or the EXTernal source

.

Find Quality Products Online at: sales@GlobalTestSupply.com

VIII - 42 Function Generators

www.GlobalTestSupply.com

Page 43

MODUL Function

MODUL Modulation function (GX 320 only, contd.)

Selection of the AM/FM modulation mode

Pressing successively selects the following modulation modes:

INTernal source

EXTernal source

Display Description

20% amplitude

modulation

80% amplitude

modulation

Frequency

modulation

Display Description

Amplitude

modulation

Frequency

modulation

Setting START / END FM frequencies

Displays Freq

or

and assigns adjustment to the wheel.

START

The key lights: .

1s or 1s

Displays Freq

and assigns the adjustment to the wheel.

END

The key lights: .

Pressed successively selects the digit to which the increment will be applied.

Adjusts the selected value.

Switches from setting Freq

1s

to setting Freq

START

END

.

Other settings

See CONT function.

Find Quality Products Online at: sales@GlobalTestSupply.com

Function Generators VIII - 43

www.GlobalTestSupply.com

Page 44

Fonction FREQ

Frequency meter function “FREQ”

Selecting the FREQ function activates measurement of the frequency of the

signal input to the FREQ EXT terminal.

The frequency meter can measure frequencies from 5 Hz to 100 MHz with the

following precision:

< 50 mV sensitivity F ≤ 30 MHz

< 60 mV sensitivity for 30 MHz < F ≤ 80 MHz

< 90 mV sensitivity for 80 MHz < F ≤ 100 MHz

The maximum amplitude (*) of the measured signal is:

300 V sensitivity from 5 Hz to 5 kHz

30 V sensitivity from 5 kHz to 1 MHz

10 V sensitivity above this value

(*) signal with a 50% duty cycle.

Measurement stabilisation time depends on the input frequency:

≤ 1 s from 5 to 20 Hz (≥ 1 measurements per second)

≤ 100 ms from 20 to 400 Hz (2 measurements per second)

≤ 40 ms from 400 Hz to 100 MHz (2 measurements per second)

Connections

Indication of the 300 V protection (50 - 60 Hz) CAT I

FREQ EXT terminal

for the measured

signal

Find Quality Products Online at: sales@GlobalTestSupply.com

VIII - 44 Function Generators

www.GlobalTestSupply.com

Page 45

SYNC Function

r

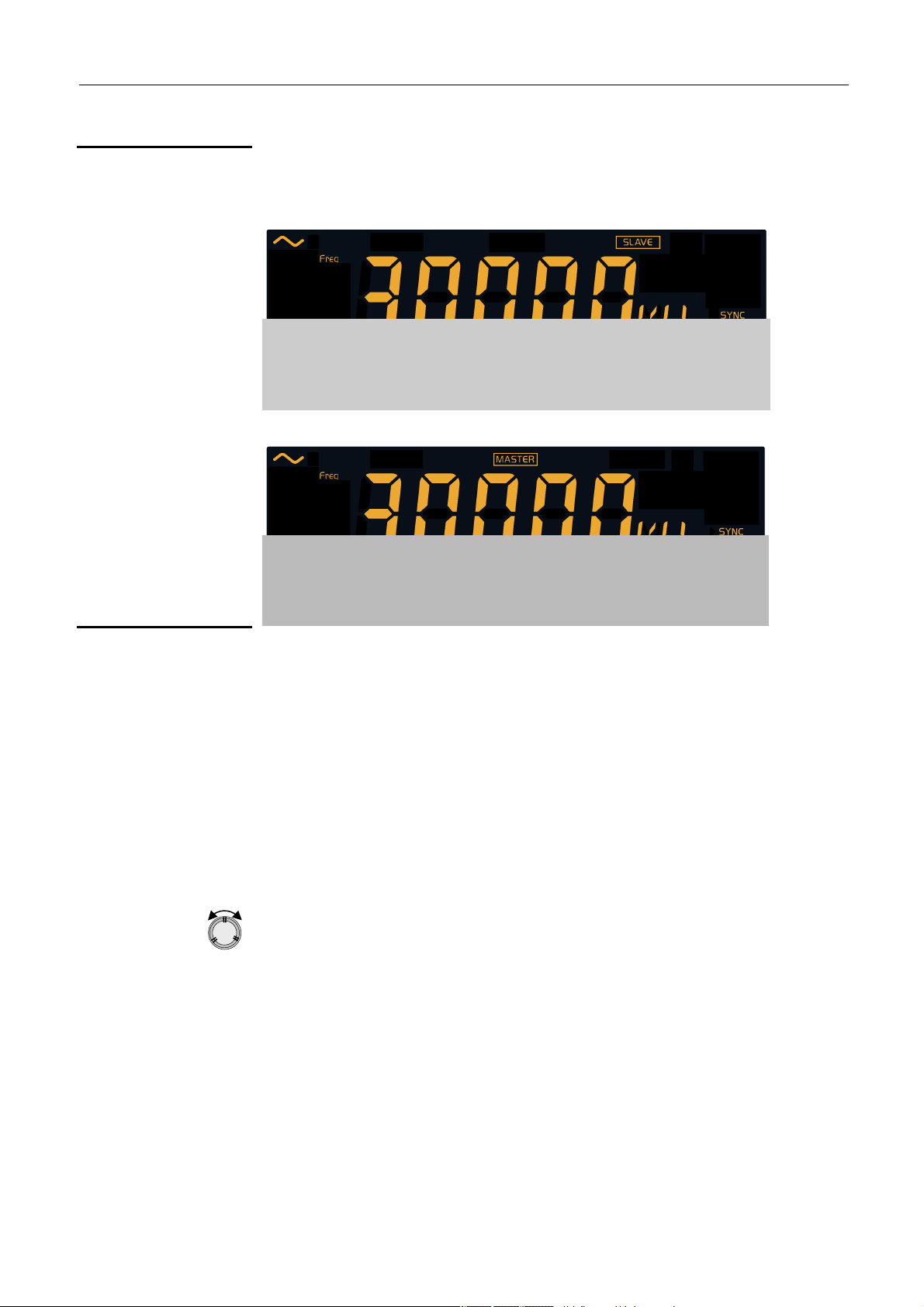

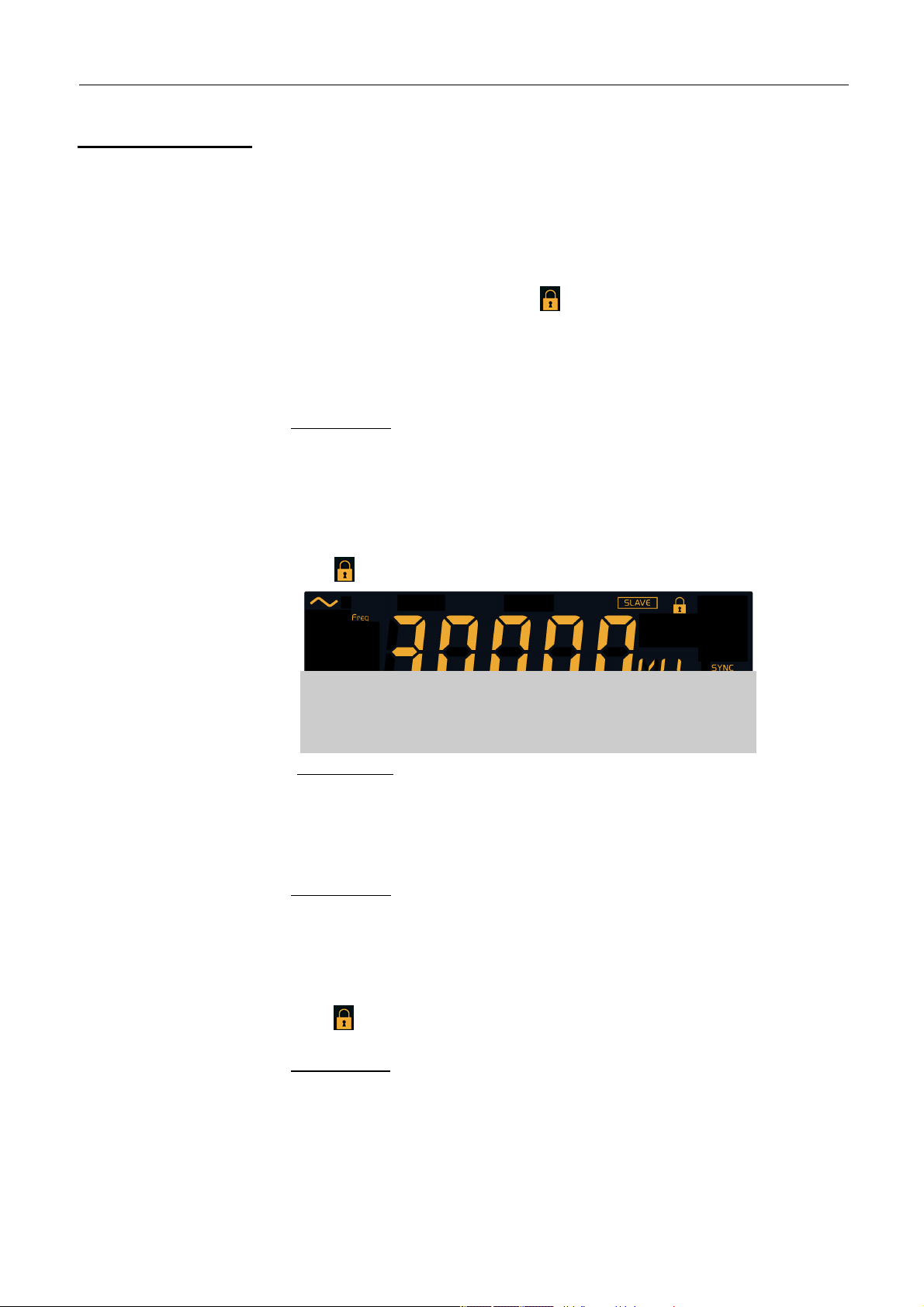

SYNC Synchronisation Function (GX 320 only)