Page 1

8436

3-PHASE POWER QUALITY

ANALYZER

PowerPad

®

ENGLISH

Find Quality Products Online at: sales@GlobalTestSupply.com

User Manual

www.GlobalTestSupply.com

Page 2

2

Statement of Compliance

Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments certifies that

this instrument has been calibrated using standards and

instruments traceable to international standards.

We guarantee that at the time of shipping your instrument has

met its published specifications.

An N.I.S.T. traceable certificate may be requested at the time

of purchase, or obtained by returning the instrument to our

repair and calibration facility, for a nominal charge.

The recommended calibration interval for this instrument is 12

months and begins on the date of receipt by the customer. For

recalibration, please use our calibration services. Refer to our

repair and calibration section at

Serial #:

Catalog #: 2136.43/2136.44

Model #: 8436

Please fill in the appropriate date as indicated:

Date Received:

Date Calibration Due:

®

Chauvin Arnoux

d.b.a AEMC

®

, Inc.

Instruments

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

3

®

Thank you for purchasing a PowerPad

enclosed operating instructions carefully and comply with the precautions for use. These products must be only used by qualified

and trained users.

WARNING, risk of DANGER! The operator must refer to these instructions whenever this danger symbol appears.

CAUTION! Risk of electric shock. The voltage at the parts marked with this symbol may be dangerous.

Equipment is protected by double insulation.

USB socket.

SD Card.

Ground/Earth.

Important instructions to read and to fully understand.

Useful information or hint to read.

The CE marking guarantees conformity with European directives and with regulations covering EMC.

The trash can with a line through it means that in the European Union, the product must undergo selective disposal for

the recycling of electric and electronic material, in compliance with Directive WEEE 2002/96/EC.

III Model 8436. For best results from your instrument and for your safety, read the

Definition of Measurement Categories (CAT)

■ CAT IV corresponds to measurements taken at the source of low-voltage installations.

Example: power feeders, counters and protection devices.

■ CAT III corresponds to measurements on building installations.

Example: distribution panel, circuit-breakers, machines or fixed industrial devices.

■ CAT II corresponds to measurements taken on circuits directly connected to low-voltage installations.

Example: power supply to domestic electrical appliances and portable tools.

PRECAUTIONS FOR USE

This device is compliant with safety standard IEC 61010-2-030, the leads are compliant with IEC 61010-031, and the current sensors

are compliant with IEC 61010-2-032, for voltages up to 600 V in category IV or 1000 V in category III. Failure to observe the safety

instructions may result in electric shock, fire, explosion, and destruction of the instrument and of the installations.

■ The operator and/or the responsible authority must carefully read and clearly understand the various precautions to be taken

in use. Sound knowledge and a keen awareness of electrical hazards are essential when using this instrument.

■ If you use this instrument other than as specified, the protection it provides may be compromised, thereby endangering you.

■ Do not use the instrument on networks of which the voltage or category exceeds those mentioned.

■ Do not use the instrument if it appears to be damaged, incomplete, or poorly closed.

■ Before each use, check the condition of the insulation on the leads, housing, and accessories. Any item of which the insulation

is deteriorated (even partially) must be set aside for repair or scrapping.

■ Use only the leads and accessories supplied. Using leads (or accessories) of a lower voltage or category reduces the voltage

or category of the combined instrument + leads (or accessories) to that of the leads (or accessories).

■ Use personal protection equipment systematically.

■ Keep your hands away from the terminals of the instrument.

■ When handling the leads, test probes, and alligator clips, keep your fingers behind the physical guard.

■ Use only the external power adaptor and battery pack supplied by the manufacturer. They include specific safety features.

■ Some current sensors must not be placed on or removed from bare conductors at hazardous voltages: refer to the sensor

manual and comply with the handling instructions.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

4

CONTENTS

1. INTRODUCTION ........................................................................................................................................................................................................7

1.1. DELIVERY CONDITION ...................................................................................................................................................................................7

1.2. ORDERING INFORMATION ............................................................................................................................................................................7

1.3. ACCESSORIES ...............................................................................................................................................................................................7

1.4. REPLACEMENT PARTS ..................................................................................................................................................................................7

1.5. BATTERY CHARGING .....................................................................................................................................................................................8

1.6. LANGUAGE SELECTION ................................................................................................................................................................................9

2. DESCRIPTION......................................................................................................................................................................................................... 10

3. OPERATION ............................................................................................................................................................................................................ 19

4. CONFIGURATION ................................................................................................................................................................................................... 23

2.1. FUNCTIONS ................................................................................................................................................................................................... 10

2.1.1. MEASUREMENTS ............................................................................................................................................................................. 10

2.1.2. DISPLAY FUNCTIONS ....................................................................................................................................................................... 11

2.1.3. CONFIGURATION ............................................................................................................................................................................. 11

2.2. INSTRUMENT INTERFACE ........................................................................................................................................................................... 12

2.3. ON/OFF BUTTON .......................................................................................................................................................................................... 13

2.4. DISPLAY ........................................................................................................................................................................................................ 13

2.4.1. PRESENTATION................................................................................................................................................................................ 13

2.4.2. FUNCTION BUTTONS ....................................................................................................................................................................... 14

2.5. KEYPAD BUTTONS ........................................................................................................................................................................................ 15

2.5.1. FUNCTION (YELLOW) BUTTONS ..................................................................................................................................................... 15

2.5.2. NAVIGATION BUTTONS .................................................................................................................................................................... 15

2.5.3. MODE BUTTONS ............................................................................................................................................................................... 15

2.5.4. OTHER BUTTONS ............................................................................................................................................................................. 16

2.

6. CONNECTORS .............................................................................................................................................................................................. 16

2.6.1. CONNECTION TERMINALS .............................................................................................................................................................. 16

2.6.2. SIDE CONNECTORS ......................................................................................................................................................................... 17

2.7. POWER SUPPLY ........................................................................................................................................................................................... 17

2.8. ABBREVIATIONS .......................................................................................................................................................................................... 17

3.1. START-UP ..................................................................................................................................................................................................... 19

3.2. CONFIGURATION ......................................................................................................................................................................................... 19

3.3. LEADS INSTALLATION ................................................................................................................................................................................. 20

3.3.1. SINGLE-PHASE NETWORK .............................................................................................................................................................. 21

3.3.2. SPLIT-PHASE NETWORK ................................................................................................................................................................. 21

3.3.3. THREE-PHASE NETWORK ............................................................................................................................................................... 21

3.3.4. CONNECTION ................................................................................................................................................................................... 22

3.4. INSTRUMENT FUNCTIONS .......................................................................................................................................................................... 22

3.4.1. WAVEFORM CAPTURE .................................................................................................................................................................... 22

3.4.2. HARMONICS DISPLAY ...................................................................................................................................................................... 22

3.4.3. WAVEFORM MEASUREMENTS ........................................................................................................................................................ 22

3.4.4. ALARM RECORDING ......................................................................................................................................................................... 22

3.4.5. RECORDING ..................................................................................................................................................................................... 22

3.4.6. ENERGY MEASUREMENTS.............................................................................................................................................................. 22

4.1. CO

NFIGURATION MENU .............................................................................................................................................................................. 23

4.2. DISPLAY LANGUAGE ................................................................................................................................................................................... 23

4.3. DATE/TIME .................................................................................................................................................................................................... 23

4.4. DISPLAY ..................................................................................................................................................................................................... 24

4.4.1. BRIGHTNESS .................................................................................................................................................................................... 24

4.4.2. COLORS ........................................................................................................................................................................................... 24

4.4.3. DISPLAY SHUTDOWN ...................................................................................................................................................................... 24

4.4.4. NIGHT MODE .................................................................................................................................................................................... 25

4.5. CALCULATION METHODS ............................................................................................................................................................................ 25

4.5.1. NON-ACTIVE QUANTITIES CALCULATION ...................................................................................................................................... 25

4.5.2. UNITS OF ENERGY ........................................................................................................................................................................... 26

4.5.3. K FACTOR .......................................................................................................................................................................................... 26

4.

5.4. PHASE HARMONICS......................................................................................................................................................................... 27

4.5.5. LONG-TERM FLICKER (PLT) ............................................................................................................................................................. 27

4.6. CONNECTION ............................................................................................................................................................................................... 28

4.7. SENSORS AND RATIOS ............................................................................................................................................................................... 32

4.7.1. CURRENT SENSORS AND RATIOS .................................................................................................................................................. 32

4.7.2. VOLTAGE RATIOS ............................................................................................................................................................................. 32

4.8. CAPTURE MODE .......................................................................................................................................................................................... 33

4.8.1. TRANSIENT VOLTAGE THRESHOLDS .............................................................................................................................................. 33

4.8.2. TRANSIENT CURRENT THRESHOLDS ............................................................................................................................................ 34

4.8.3. INRUSH CURRENT THRESHOLDS ................................................................................................................................................... 35

4.

9. TREND MODE ............................................................................................................................................................................................... 35

4.10. ALARM MODE ............................................................................................................................................................................................. 37

4.11. ERASE MEMORY ........................................................................................................................................................................................ 38

4.12. ABOUT ..................................................................................................................................................................................................... 39

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

5

5. WAVEFORM CAPTURE ........................................................................................................................................................................................... 40

5.1. TRANSIENT MODE ....................................................................................................................................................................................... 40

5.1.1. CONFIGURING AND STARTING A SEARCH ..................................................................................................................................... 41

5.1.2. DISPLAYING A TRANSIENT .............................................................................................................................................................. 41

5.1.3. DELETING A SEARCH FOR TRANSIENTS ....................................................................................................................................... 42

5.1.4. DELETE A TRANSIENT ..................................................................................................................................................................... 42

5.2. INRUSH CURRENT MODE ............................................................................................................................................................................ 43

5.2.1. CONFIGURING THE CAPTURE ........................................................................................................................................................ 43

5.2.2. CAPTURE PARAMETERS ................................................................................................................................................................. 44

5.2.3. TRUE RMS CURRENT AND VOLTAGE ............................................................................................................................................. 44

5.2.4. INSTANTANEOUS INRUSH CURRENT ............................................................................................................................................. 46

6. HARMONICS ..................................................................................................................................................................................................... 48

6.1. PHASE-TO-NEUTRAL VOLTAGE ................................................................................................................................................................... 48

6.1.1. 3L PHASE-TO-NEUTRAL VOLTAGE HARMONICS DISPLAY SCREEN ............................................................................................. 48

6.1.2. L1 PHASE VOLTAGE HARMONICS DISPLAY SCREEN .................................................................................................................... 49

6.2. CURRENT ..................................................................................................................................................................................................... 49

6.2.1. 3L CURRENT HARMONICS DISPLAY SCREEN ................................................................................................................................ 49

6.2.2. L1 CURRENT HARMONICS DISPLAY SCREEN ................................................................................................................................ 50

6.3. APPARENT POWER ...................................................................................................................................................................................... 50

6.3.1. 3L APPARENT POWER HARMONICS DISPLAY SCREEN ................................................................................................................ 50

3.2. L1 APPARENT POWER HARMONICS DISPLAY SCREEN ................................................................................................................ 51

6.

6.4. PHASE-TO-PHASE VOLTAGE ....................................................................................................................................................................... 51

6.4.1. 3L PHASE-TO-PHASE VOLTAGE HARMONICS DISPLAY SCREEN ................................................................................................. 51

6.4.2. L1 PHASE-TO-PHASE VOLTAGE HARMONICS DISPLAY SCREEN ................................................................................................ 52

6.5. EXPERT MODE ............................................................................................................................................................................................. 52

6.5.1. PHASE-TO-NEUTRAL VOLTAGE EXPERT MODE DISPLAY SCREEN ............................................................................................. 52

6.5.2. CURRENT EXPERT MODE DISPLAY SCREEN................................................................................................................................. 53

7. WAVEFORM ..................................................................................................................................................................................................... 54

7.1. TRUE RMS .................................................................................................................................................................................................... 54

7.1.1. 3U RMS DISPLAY SCREEN ............................................................................................................................................................... 55

7.1.2. 4V RMS DISPLAY SCREEN ............................................................................................................................................................... 55

7.1.3. 4A RMS DISPLAY SCREEN ............................................................................................................................................................... 55

7.1.4. RMS DISPLAY SCREEN FOR THE NEUTRAL ................................................................................................................................... 56

7.2. TOTAL HARMONIC DISTORTION ................................................................................................................................................................. 56

7.2.1. 3U THD DISPLAY SCREEN ............................................................................................................................................................... 56

7.2.2. 4V THD DISPLAY SCREEN ................................................................................................................................................................ 56

7.2.3. 4A THD DISPLAY SCREEN ................................................................................................................................................................ 57

7.3. PEAK FACTOR .............................................................................................................................................................................................. 57

7.3.1. 3U CF DISPLAY SCREEN .................................................................................................................................................................. 57

7.3.2. 4V CF DISPLAY SCREEN.................................................................................................................................................................. 57

7.3.3. 4A CF DISPLAY SCREEN

.................................................................................................................................................................. 58

7.4. MAX - MIN AND MEAN VOLTAGE AND CURRENT ........................................................................................................................................ 58

7.4.1. 3U MAX-MIN DISPLAY SCREEN........................................................................................................................................................ 58

7.4.2. 4V MAX.-MIN. DISPLAY SCREEN ...................................................................................................................................................... 59

7.4.3. 4A MAX.-MIN. DISPLAY SCREEN ...................................................................................................................................................... 59

7.4.4. L1 MAX.-MIN. DISPLAY SCREEN ...................................................................................................................................................... 59

7.4.5. NEUTRAL MAX.-MIN. DISPLAY SCREEN ......................................................................................................................................... 60

7.5. SIMULTANEOUS DISPLAY ........................................................................................................................................................................... 60

7.5.1. 3U SIMULTANEOUS DISPLAY SCREEN ........................................................................................................................................... 60

7.5.2. 4V SIMULTANEOUS DISPLAY SCREEN ........................................................................................................................................... 60

7.5.3. 4A SIMULTANEOUS DISPLAY SCREEN ........................................................................................................................................... 61

7.5.4. L1 SIMULTANEOUS DISPLAY SCREEN............................................................................................................................................ 61

7.5.5. SCREEN FOR SIMULTANEOUS DISPLAY OF NEUTRAL .................................................................................................................. 61

7.6. PHASOR DIAGRAM ....................................................................................................................................................................................... 62

7.6.1. 3V PHASOR ....................................................................................................................................................................................... 62

7.6.2. 3U PHASOR DIAGRAM DISPLAY SCREEN ....................................................................................................................................... 62

7.6.3. 3A PHASOR DIAGRAM DISPLAY SCREEN ....................................................................................................................................... 62

7.6.4. L1 PHASOR DIAGRAM DISPLAY SCREEN ....................................................................................................................................... 63

8. ALARM MODE ..................................................................................................................................................................................................... 64

8.1. ALARM MODE CONFIGURATION ................................................................................................................................................................. 64

8.

2. ALARM CAMPAIGN CONFIGURATION ........................................................................................................................................................... 64

8.3. CAMPAIGNS LIST .......................................................................................................................................................................................... 65

8.4. ALARMS LIST ................................................................................................................................................................................................ 65

8.5. DELETING AN ALARM CAMPAIGN ................................................................................................................................................................ 65

8.6. ERASING ALL ALARM CAMPAIGNS .............................................................................................................................................................. 65

9. TREND MODE ..................................................................................................................................................................................................... 66

9.1. CONFIGURING AND STARTING A RECORDING .......................................................................................................................................... 66

9.2. TREND MODE CONFIGURATION ................................................................................................................................................................. 66

9.3. VIEWING THE RECORDING LIST ................................................................................................................................................................. 67

9.4. DELETING RECORDINGS ............................................................................................................................................................................ 67

9.5. VIEWING RECORDS ..................................................................................................................................................................................... 67

9.5.1. RECORDING PARAMETERS ............................................................................................................................................................ 67

9.5.2. TREND GRAPHS ............................................................................................................................................................................... 68

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

6

10. POWER AND ENERGY MODE .............................................................................................................................................................................. 74

10.1. 3L FILTER .................................................................................................................................................................................................... 74

10.1.1. POWERS DISPLAY SCREEN............................................................................................................................................................. 74

10.1.2. QUANTITIES ASSOCIATED WITH THE POWERS DISPLAY SCREEN ............................................................................................. 74

10.1.3. ENERGIES CONSUMED DISPLAY SCREEN ..................................................................................................................................... 75

10.1.4. ENERGIES GENERATED DISPLAY SCREEN ................................................................................................................................... 75

10.2. FILTERS L1, L2 AND L3 ............................................................................................................................................................................... 75

10.2.1. POWERS AND ASSOCIATED QUANTITIES DISPLAY SCREEN ....................................................................................................... 75

10.2.2. ENERGY METERS DISPLAY SCREEN .............................................................................................................................................. 76

10.3. FILTER Σ ..................................................................................................................................................................................................... 76

10.3.1. TOTAL POWERS AND ASSOCIATED QUANTITIES DISPLAY SCREEN ........................................................................................... 76

10.3.2. TOTAL ENERGY METERS DISPLAY SCREEN .................................................................................................................................. 77

10.4. START ENERGY METERING ...................................................................................................................................................................... 77

10.5. STOP ENERGY METERING ........................................................................................................................................................................ 78

10.6. RESET ENERGY METERING ...................................................................................................................................................................... 78

11. SCREEN SNAPSHOT MODE ................................................................................................................................................................................ 79

11.1. SCREEN SNAPSHOTS ............................................................................................................................................................................... 79

11.2. HANDLING SCREEN SNAPSHOTS ............................................................................................................................................................ 79

11.2.1. VIEWING A SNAPSHOT .................................................................................................................................................................... 79

11.2.2. DELETING A SNAPSHOT .................................................................................................................................................................. 79

12. HELP BUTTON ..................................................................................................................................................................................................... 80

13. DATAV IEW® SOF TW ARE ....................................................................................................................................................................................... 81

13.1. INSTALLING DATAVIEW

®

........................................................................................................................................................................... 81

13.2. POWERPAD III CONTROL PANEL .............................................................................................................................................................. 82

13.3. CONNECTING TO A COMPUTER ............................................................................................................................................................... 82

14. GENERAL SPECIFICATIONS ............................................................................................................................................................................... 83

14.1. ENVIRONMENTAL CONDITIONS ................................................................................................................................................................ 83

14.2. MECHANICAL CONDITIONS ....................................................................................................................................................................... 83

14.3. OVERVOLTAGE CATEGORIES PER IEC 61010-1 ...................................................................................................................................... 83

14.4. ELECTROMAGNETIC COMPATIBILITY ....................................................................................................................................................... 84

14.5. POWER SUPPLY ......................................................................................................................................................................................... 84

14.5.1. EXTERNAL POWER SUPPLY ............................................................................................................................................................ 84

14.5.2. BATTERY POWER SUPPLY .............................................................................................................................................................. 84

14.5.3. CONSUMPTION................................................................................................................................................................................. 84

14.5.4. BATTERY LIFE .................................................................................................................................................................................. 84

14.5.5. DISPLAY UNIT ................................................................................................................................................................................... 84

15. FUNCTIONAL SPECIFICATIONS.......................................................................................................................................................................... 85

15.1. REFERENCE CONDITIONS ........................................................................................................................................................................ 85

15.2. NOMINAL CURRENT ACCORDING TO TYPE OF SENSOR ....................................................................................................................... 85

15.3. ELECTRICAL CHARACTERISTICS ............................................................................................................................................................. 86

15.3.1. VOLTAGE INPUT CHARACTERISTICS ............................................................................................................................................. 86

15.3.2. CURRENT INPUT CHARACTERISTICS ............................................................................................................................................ 86

15.

3.3. BANDWIDTH ...................................................................................................................................................................................... 86

15.3.4. INSTRUMENT SPECIFICATIONS (EXCLUDING CURRENT SENSOR) ............................................................................................ 86

15.3.5. CURRENT SENSOR SPECIFICATIONS (AFTER LINEARIZATION) ................................................................................................. 95

15.4. CLASS B UNDER STANDARD IEC 61000-4-30 ........................................................................................................................................... 96

15.4.1. INSTRUMENT CONFORMITY ........................................................................................................................................................... 96

15.4.2. UNCERTAINTIES AND MEASUREMENT RANGES .......................................................................................................................... 96

15.4.3. REAL-TIME CLOCK UNCERTAINTY ................................................................................................................................................. 96

16. MAINTENANCE ..................................................................................................................................................................................................... 97

16.1. CLEANING THE CASING ............................................................................................................................................................................ 97

16.2. SENSORS.................................................................................................................................................................................................... 97

16.3. BATTERY REPLACEMENT ........................................................................................................................................................................... 97

16.4. MEMORY CARD .......................................................................................................................................................................................... 99

16.5. FIRMWARE UPDATE ................................................................................................................................................................................ 100

REPAIR AND CALIBRATION ................................................................................................................................................................................... 101

TECHNICAL AND SALES ASSISTANCE ................................................................................................................................................................. 101

LIMITED WARRAN TY ............................................................................................................................................................................................... 101

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

7

1. INTRODUCTION

1.1. DELIVERY CONDITION

®

NOTE: After receiving your PowerPad

the battery indicator is accurate.

Ensure the contents shipped are consistent with the packing list. Notify your distributor of any missing items. If the equipment appears

damaged, file a claim immediately with the carrier and notify your distributor at once. Save the damaged packing container to

substantiate your claim. Do not use equipment which is damaged or appears to be damaged.

1.2. ORDERING INFORMATION

PowerPad

Includes extra-large tool bag, accessory pouch, 5 ft (1.5m) USB cable, five 10 ft black voltage leads with alligator clips, 110V US

power cord, NiMH battery, twelve color-coded input ID markers, quick start guide, high-voltage warning/caution card, and a USB drive

containing DataView

PowerPad

Includes all items listed in Cat. #2136.43 above, as well as four water-tight IP67 AmpFlex

®

III Model 8436 (No Sensors - Waterproof IP67).....................................................................................…… Cat. #2136.43

®

software and user manual

®

III Model 8436 (AmpFlex

®

- Waterproof IP67).............................................................................................. Cat. #2136.44

1.3. ACCESSORIES (not IP67)

10 ft USB cable................................................................................................................................................................... Cat. #2136.80

AC/DC Current Probe Model SL261* (10A-100mV/A, 100A-10mV/A, BNC) ..................................................................... Cat. #1201.51

*Adapter - BNC Adapter (mandatory if using an SL261 w/ the 8436)................................................................................. Cat. #2140.40

AC Current Probe Model MR193-BK.................................................................................................................................. Cat. #2140.28

AC Current Probe Model MN93-BK.................................................................................................................................... Cat. #2140.32

AC Current Probe Model SR193-BK ................................................................................................................................. Cat. #2140.33

AC Current Probe Model MN193-BK ................................................................................................................................. Cat. #2140.36

MiniFlex

AC/DC Current Probe Model J93-BK…….......................................................................................................................... Cat. #2140.49

MiniFlex

®

Sensor 10" Model MA193-10-BK ...................................................................................................... Cat. #2140.48

®

Sensor 14” Model MA193-14-BK........................................................................................................................ Cat. #2140.50

III Model 8436, charge and discharge the instrument one or two cycles to ensure

®

196A-24-BK with documentation.

1.4. REPLACEMENT PARTS

Extra Large Classic Tool Bag ............................................................................................................................................ Cat. #2133.73

Battery 9.6V NiMH.............................................................................................................................................................. Cat. #2140.19

Set of 12, Color-coded Input ID Markers ........................................................................................................................... Cat. #2140.45

5 ft USB cable..................................................................................................................................................................... Cat. #2140.46

Accessory Pouch (accessories not included) .................................................................................................................... Cat. #2140.72

Lead – One 10 ft (3M) Black Lead (Waterproof cap) {Rated 1000V CAT IV} &

One Black Alligator Clip {Rated 1000V CAT IV, 15A} ....................................................................................................... Cat. #2140.73

AmpFlex® Sensor 24" Model 196A-24-BK.......................................................................................................................... Cat. #2140.75

Power Cord 110V (IP67)..................................................................................................................................................... Cat. #5000.63

Line power cord 110-1000V DC to 440Hz.......................................................................................................................... Cat. #5000.89

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

8

1.5. BATTERY CHARGING

230 V ± 10 %, 50 Hz

Figure 1-1

Before first use, fully charge the battery.

120 V ± 10 %, 60 Hz

It is also possible to charge the battery using the voltage on the voltage measurement terminals. To do this: with the connector cover

removed, connect the power supply cord to the battery charging connector and the two safety-series banana plugs with rear-mounted

sockets to any two of the phases (L1, L2, L3).

1. Remove the connector cover on the instrument (see Figure 1-1).

2. Connect the AC power cord and screw it in place.

3. Plug the power cord into a power outlet.

The button lights; it will go out only when the plug is disconnected.

When the battery is fully discharged, charging takes approximately 5

hours.

Figure 1-2

To make measurements while charging the battery, connect the measurement leads to the terminals and to the safety- series banana

plugs with rear-mounted sockets.

Figure 1-3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

9

1.6. LANGUAGE SELECTION

Before using the instrument, choose the language in which you want the instrument to display its messages.

1. Press the button to turn the instrument ON.

2. Press the Configuration button. This displays the Configuration menu

(Figure 1-4).

3. At the bottom of the screen are the language options. Press the function

button that corresponds with the desired language. (The selected language

appears in yellow.) If the desired language is not displayed, press the

button to view additional options.

Figure 1-4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

10

2. DESCRIPTION

2.1. FUNCTIONS

The Model 8436 a three-phase network analyzer with color graphic display and built-in rechargeable battery. The instrument:

■ measures RMS values, powers, and perturbations of electric distribution networks

■ delivers a snapshot of the principal characteristics of a three-phase network

■ tracks variations of various parameters over time

■ provides IP67 (watertight) operation

The measurement uncertainty of the Model 8436 is better than 1% (excluding uncertainties due to connected sensors). The instrument

is also versatile, with a choice of sensors providing measurements ranging from a few mA (MN193) to several kA (AmpFlex

The instrument is compact and impact resistant, with a simple and easy-to-use interface. It is designed for technicians and engineers

performing electrical network installation, inspection and maintenance.

2.1.1. MEASUREMENTS

The Model 8436 measures:

■ RMS values of AC voltages up to 1000V between terminals. By using the ratios, the instrument can measure voltages up to

hundreds of gigavolts.

■ RMS values of AC currents up to 10,000A (neutral included). By using the ratios, the instrument can measure currents up to

hundreds of kiloamperes.

■ DC components of voltages and currents (neutral included).

■ Minimum and maximum half-cycle RMS voltage and current values (excluding neutral).

■ Peak voltage and current values (neutral included).

■ Frequency of 50Hz and 60Hz networks.

■ Current and voltage peak factors (neutral included).

■ Harmonic loss factor (FHL), application to transformers in the presence of harmonic currents.

■ K factor (FK), application to transformers in the presence of harmonic currents.

■ Total harmonic distortion with respect to the fundamental (THD in %f) of the current and of the voltages (excluding neutral).

■ Total harmonic distortion with respect to the RMS AC value (THD in %r) for the current and the voltages (neutral included).

■ Active, reactive (capacitive and inductive), non-active, distortion, and apparent power, by phase and cumulative (excluding

neutral).

■ Power factor (PF) and displacement factor (DPF) or cos Φ (excluding neutral).

■ RMS distortion value (d) for the current and the voltages (excluding neutral).

■ Short-term voltage flicker (PST) (excluding neutral).

■ Long-term voltage flicker (PLT) (excluding neutral).

■ Active, reactive (capacitive and inductive), non-active, distortion, and apparent energy (excluding neutral).

■ Current and voltage harmonics (excluding neutral) up to order 50: RMS value, percentage referred to the fundamental, (%f)

(excluding neutral), or the total RMS value (%r), minimum and maximum and sequence harmonics.

■ Apparent harmonic power up to order 50 (excluding neutral): percentages referred to the fundamental apparent power (%f) or

the total apparent power (%r), minimum and maximum of a rank.

■ Inrush currents, starting of motors.

®

).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

11

2.1.2. DISPLAY FUNCTIONS

■ Waveforms (voltages and currents).

■ Frequency bar chart (voltages and currents).

■ Inrush Current function: displays parameters useful for study of the starting of a motor.

• Instantaneous current and voltage at the instant designated by the cursor.

• Maximum instantaneous absolute value of the current and of the voltage (over the entire starting time).

• RMS value of the half-cycle (or lobe) of the current and voltage (excluding neutral) on which the cursor is positioned.

• Maximum half-cycle RMS current (over the entire starting time).

• Instantaneous network frequency at the instant designated by the cursor.

• Maximum, mean, and minimum network frequencies (over the entire starting time).

• Time at which starting of motor commenced.

■ Screen captures (up to 50).

■ Transients function. Detection and recording of transients (up to 210) between user-defined start and stop dates and times.

Recording of four complete cycles (one before the triggering event and three after) in the eight acquisition channels.

■ Trend recording (data logging) function. 2GB memory with date-stamping and user-defined start and stop dates for recording,

with a maximum of 100 recordings. Display, in bar chart or graph form, of the means of many parameters vs. time, with or

without maximum and minimum values.

■ Alarm function. List of recorded alarms (up to 16,362) exceeding thresholds defined in the configuration menu. User-defined

alarm monitoring start and stop times.

2.1.3. CONFIGURATION

■ Date and time.

■ Screen brightness.

■ Graph colors.

■ Management of switching off of the screen.

■ Night mode.

■ Calculation methods (non-active quantities broken down or not, choice of the unit of energy, choice of the coefficients of

calculation of the K factor), choice of reference for the level of harmonics, PLT calculation (sliding or not).

■ Distribution system (single-phase, two-phase, three-phase with or without neutral) and of the connection method (standard,

2-element method or 2½-element method).

■ Recording, alarms, inrush currents, and transients.

■ Data erasure (total or partial).

■ Software and hardware version numbers display.

■ Language setting.

■ Display of current sensors detected not detected, not managed, simulated or impossible to simulate (2-element connection

method). Setting of voltage and current ratio, of the transduction ratios and of the sensitivity.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

12

2.2. INSTRUMENT INTERFACE

1

Cover

9

ON/OFF button

2

LCD display

10

Help button

3

Measurement connection terminals

11

Screen snapshot button

4

USB socket

12

Configuration button

5

Confirm/Enter button

13

Return /previous button

6

Navigation buttons

14

Function (yellow) buttons

7

Battery compartment and memory card slot cover

15

Battery charging connector

8

Mode buttons

Figure 2-1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

13

2.3. ON/OFF BUTTON

1

Mode icon

2

Battery charge level

3

Date/time

4

Frequency calculated over 1 second

5

Function icons

6

Active mode screen

The instrument can operate either on its battery or on external power. Pressing the button powers ON the instrument. If the instrument

is shut off suddenly (line power outage in the absence of the battery) or automatically (battery low), an information message is displayed

the next time it is started.

Pressing again turns the instrument OFF. If the instrument is recording, metering energy, or searching for transients, alarms, and/or

inrush current acquisition, it requests confirmation. Select Yes or No on the corresponding yellow button, then press the button to

validate.

■ No: recording will continue.

■ Yes: data recorded up to that point is finalized and the instrument is turned OFF.

2.4. DISPLAY

2.4.1. PRESENTATION

The backlit 320x240 (1/4 VGA) pixel graphic screen displays all measurements with their graphs, the parameters of the unit, the graphs

selected, the instantaneous values of the signals, and the type of measurement selected. When the instrument is powered ON, it initially

displays the Waveform screen (see §7).

Figure 2-2

Automatic display shutdown is configured via the Display Configuration Mode menu (see §4.4.3).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

14

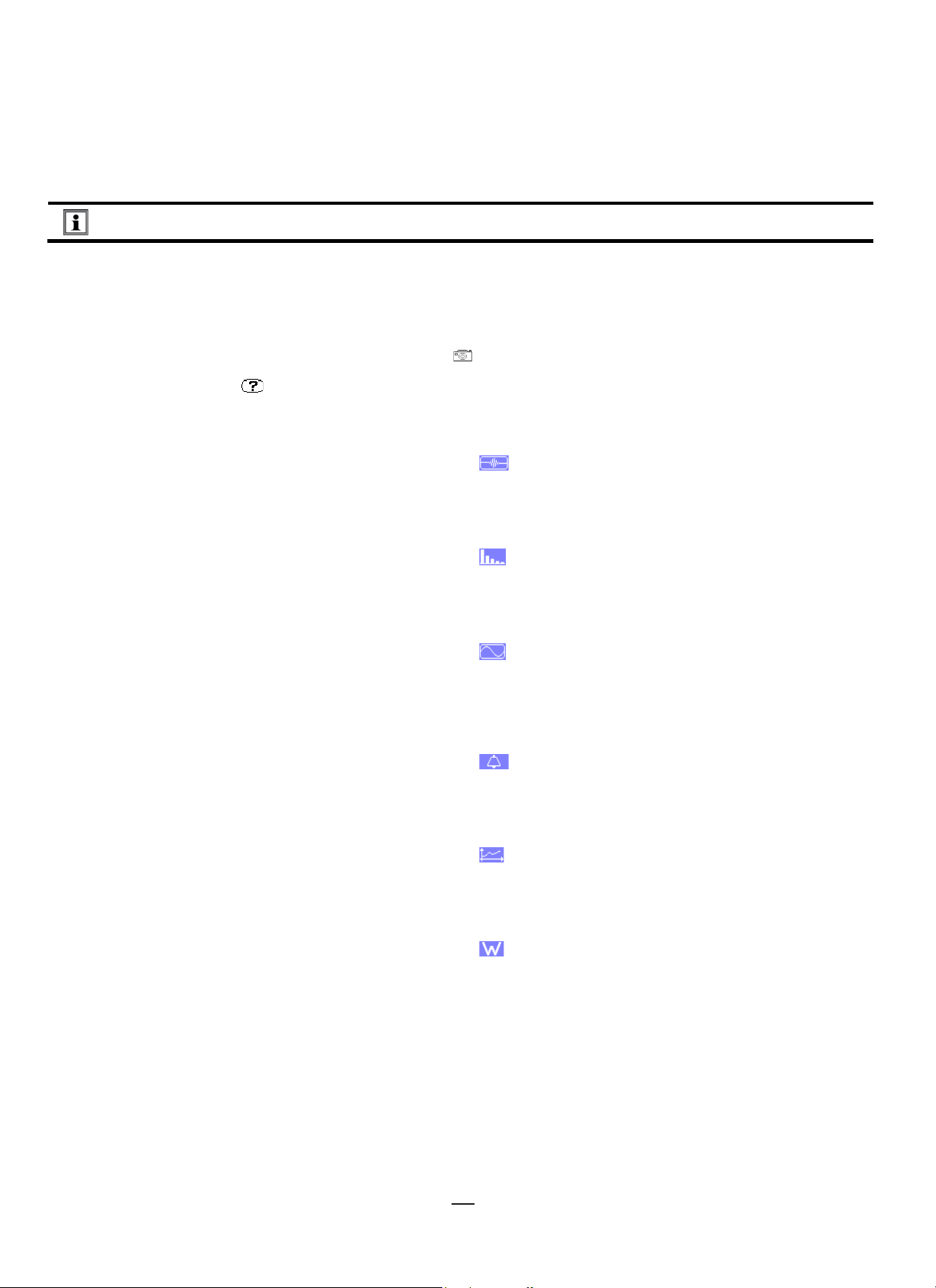

2.4.2. FUNCTION BUTTONS

V

Move the cursor to the first occurrence of the

The display uses the following icons for the yellow function buttons:

Icon Function

Phase-to-neutral voltage mode.

A

S

U

var

Wh

FK

%f-%r

PLT

CF

RMS

PEAK

THD

PF…

W…

Wh…

Phase-to-neutral current mode.

Power mode.

Phase-to-phase voltage mode.

Non-active quantities.

Units of energy.

K factor coefficients.

Reference for the level of harmonics.

Long-term flicker calculation mode.

Peak factors and graphs.

RMS values and graphs.

PEAK values and graphs.

Harmonic distortion and graphs.

PF, cos Φ (DPF), tan Φ, and Φ.

Powers and associated quantities (PF, cos Φ, DPF,

tan Φ and

Energy meters.

Energy calculation activation/de-activation.

Zoom in.

Zoom out.

Display contrast.

Measurement channel colors.

Screen ON/OFF.

Night mode.

Recording configuration mode.

Recording look-up mode.

Start recording.

Rapid configuration and start of recording.

Stop recording.

Stop function in progress.

Delete.

Configuration mode

).

Φ

VA

Icon Function

>t=0<

>t=-T<

Transient list display filter activate/deactivate.

Maximum/minimum display.

Move the cursor to the first occurrence of the

maximum phase-to-neutral voltage.

Move the cursor to the first occurrence of the

minimum phase-to-neutral voltage.

Move the cursor to the first occurrence of the

maximum phase-to-phase voltage.

Move the cursor to the first occurrence of the

minimum phase-to-phase voltage.

Move the cursor to the first occurrence of the

maximum current.

Move the cursor to the first occurrence of the

minimum current.

maximum instantaneous frequency.

Move the cursor to the first occurrence of the

minimum instantaneous frequency.

Move the cursor to the first occurrence of the

maximum of the measurement displayed.

Move the cursor to the first occurrence of the

minimum of the measurement displayed.

Simultaneous display of all voltage and current

measurements (RMS, DC, THD, CF, PST, PLT, FHL,

FK).

Select all items.

Deselect all items.

Transient mode.

Inrush current mode.

Phasor diagram.

Move cursor to transient triggering time.

Move the cursor to one signal period before the

triggering date of the transient.

Energies consumed by the load.

Energies generated by the load.

Page 1 of Help.

Page 2 of Help.

Page 3 of Help.

Page 4 of Help.

Previous configuration.

Next configuration.

Previous page.

Next page.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

15

2.5. KEYPAD BUTTONS

Up arrow.

Down arrow.

Return.

2.5.1. FUNCTION (YELLOW) BUTTONS

These six buttons activate the function or tool represented by the corresponding icon on the screen.

2.5.2. NAVIGATION BUTTONS

A block of four arrow buttons, a select button and a Return button are used for navigating menus.

Button Function

2.5.3. MODE BUTTONS

These buttons display specific modes:

Button Function See

Right arrow.

Left arrow.

Confirm selection.

Waveform acquisition mode, with two sub-modes: transients mode (blackouts, interference, etc.) and

inrush current mode (starting of motor).

Harmonic graphs display mode: representation of voltage, current, and power harmonics, order by

order; determination of harmonic currents produced by nonlinear loads, analysis of problems caused

by harmonics according to their order (overheating of neutrals, conductors, motors, etc.).

Waveform display mode: display of voltage and current waveforms, display of minima and maxima

of summary tables, determination of phase rotation.

Alarm mode: list of recorded alarms exceeding selected thresholds; recording of network blackouts

with half-cycle resolution (Vrms, Arms, Urms), determination of energy consumption overshoots,

monitoring of compliance with a power supply quality contract.

§ 5

§ 6

§ 7

§ 8

Trend mode: recording of selected parameters.

Power/energy mode: display of power and energy measurements.

Three buttons are real-time mode buttons: , and .

In each of these modes, colored circles on a white background (for example ) indicate channel number or type. These indicate

saturation; the circle background is colored when the channel measured is potentially full (for instance ).

When the circle corresponds to a simulated channel (for example in 4-wire three-phase with selection V1V2, 2½-element method, or in

3-wire three-phase with selection A1A2, 2-element method; see connections in §4.6), this channel is potentially full if at least one channel

used in calculating it is potentially full.

Similarly, if the circle corresponds to a phase-to-phase voltage channel, it is potentially full if at least one of the phase- to-neutral

voltage channels used in calculating it is potentially full.

§ 9

§ 10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

16

2.5.4. OTHER BUTTONS

Function

Configuration.

Snapshot of

Help:

Button

See

§ 4

current screen and retrieval of screens already stored. § 11

provides information about the currently displayed functions and symbols. § 12

2.6. CONNECTORS

2.6.1. CONNECTION TERMINALS

These are located on one side of the housing. Each terminal is protected by a plug. The plugs must be removed to connect the leads,

then stowed in the pouch in the cover of the instrument.

To keep the instrument water- and air-tight and the terminals clean, put the plugs back on the unused terminals. The terminals let the

operator:

■ screw special leads in place to ensure total water-tightness

■ or connect standard leads that are slightly less water-tight

Four current input terminals for

current sensors (MN clamp, C

clamp, MiniFlex

clamp, SL261 clamp, etc.)

®

, AmpFlex®, PAC

Five voltage input terminals

Figure 2-3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

17

2.6.2. SIDE CONNECTORS

kilo

Mega

Tera

On the right side of the instrument is the connector used to charge the battery and operate the instrument on AC power, or supply it

from the voltages on the measurement terminals.

Figure 2-4

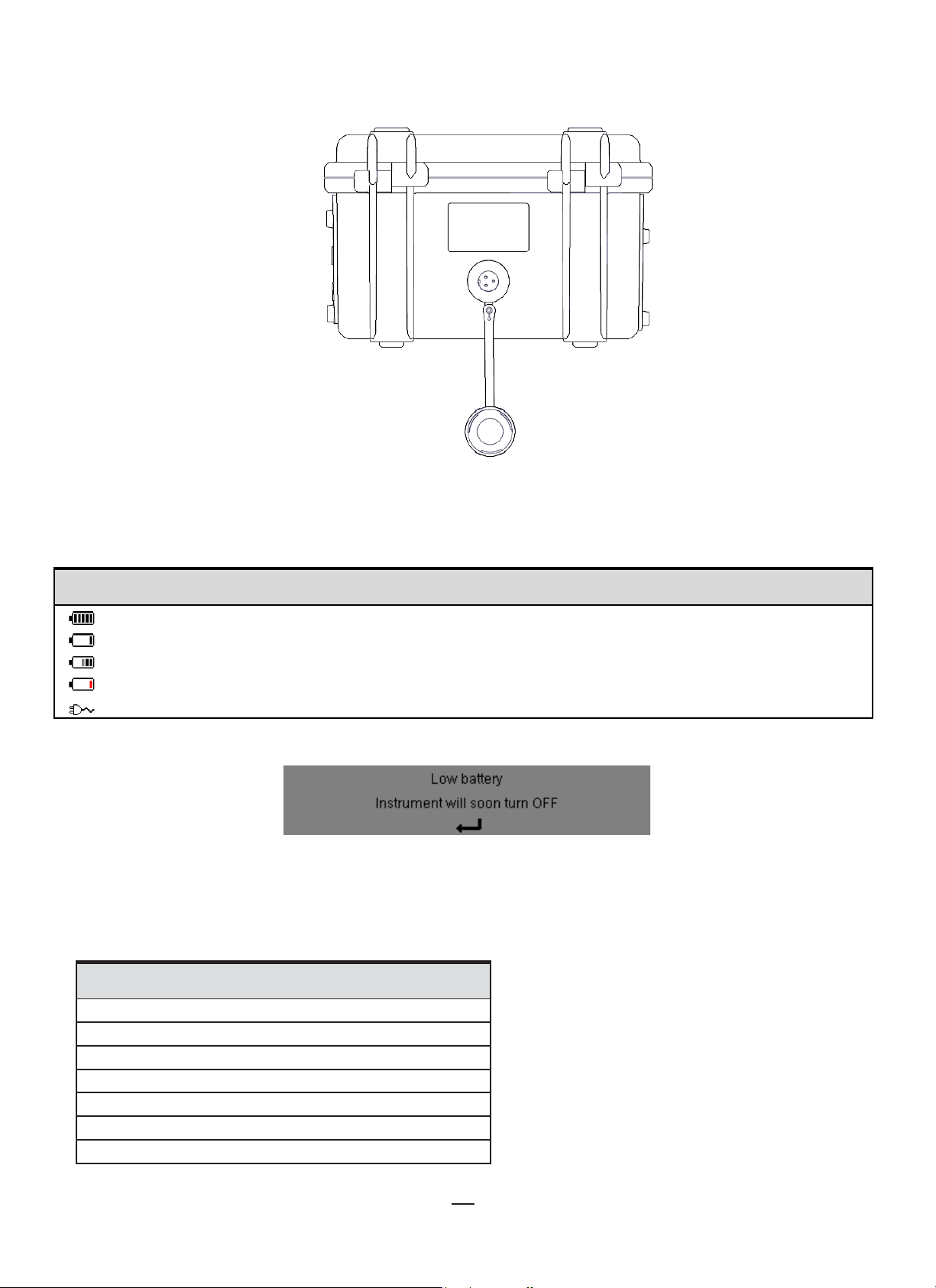

2.7. POWER SUPPLY

The battery icon in the top right corner of the screen shows the battery charge level. The number of bars is proportional to the charge

level.

Icon Description

Battery charged

Low battery

Moving bars: battery charging

Red bar: the condition of the battery is unknown because it has never been fully charged

The instrument is connected to external power without the battery

When instrument shutdown due to low battery is imminent, a warning message is displayed:

Press

to confirm the message. If you do not connect the instrument to external power, it turns OFF one minute after this message is

displayed. To avoid this, start re-charging the battery immediately.

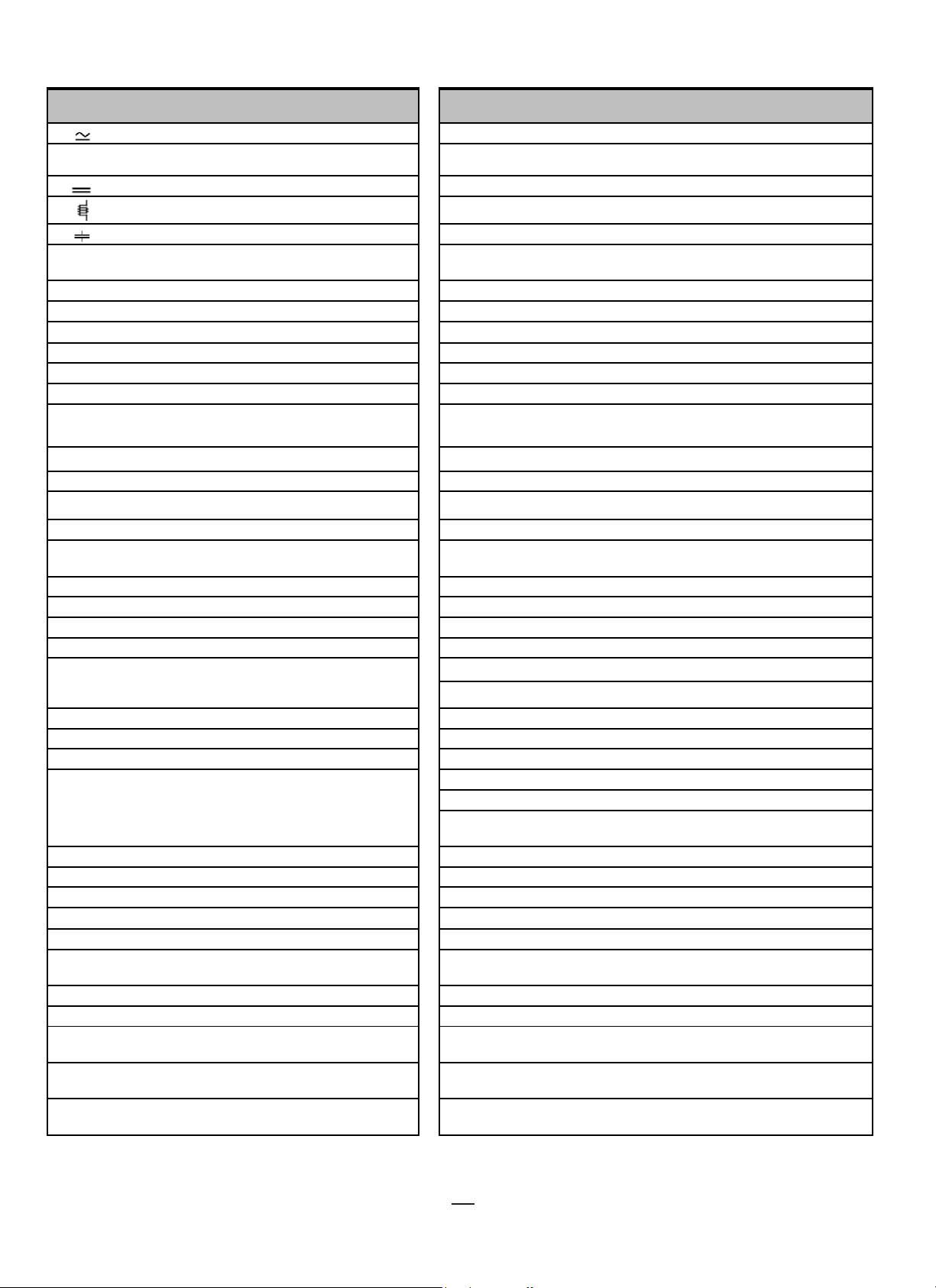

2.8. ABBREVIATIONS

Prefixes of International System (SI) units:

Prefix Symbol Multiplies by

milli

Giga

Peta

Exa

m 10

k 10

M 10

G 10

T 10

P 10

E 10

-3

3

6

9

12

15

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

18

Symbols used by the instrument:

AC and DC components.

N

Non-active power.

~

DC component only.

P

Active power.

Capacitive phase shift.

Pdch

DC energy.

Maximum (+) or minimum (-) peak instantaneous

value of the signal.

-.+

Expert mode.

PF

Power factor.

| |

Absolute value.

Ph

Active energy.

Sum of values.

PLT

Long-term flicker.

%

Percentage.

PST

Short-term flicker.

%f

Fundamental value as reference.

Q1

Reactive power (fundamental).

%r

Total value as reference.

Q1h

Reactive energy (fundamental).

UA

A-h

Current harmonic.

S-h

Apparent harmonic power.

Ad

RMS distortion current.

t Relative date of time cursor.

Tangent of the phase shift of voltage with respect to

current.

Apk+

Maximum peak value of current.

THD

Total harmonic distortion (in %f or in %r).

Apk-

Minimum peak value of current.

U Phase-to-phase voltage.

Arms

True RMS current.

U-h

Phase-to-phase voltage harmonic.

Athdf

Total harmonic distortion of current in %f.

Ucf

Phase-to-phase voltage crest factor.

Aunb

Negative-sequence current unbalance rate.

Upk+

Maximum peak value of phase-to-phase voltage.

AVG

Mean value (arithmetic mean).

Upk-

Minimum peak value of phase-to-phase voltage.

CF

Peak factor (current or voltage).

Urms

True RMS phase-to-phase voltage.

Uthdf

Total phase-to-phase voltage harmonic distortion in %f.

Uthdr

Total phase-to-phase voltage harmonic distortion in %r.

Negative-sequence phase-to-phase voltage

unbalance rate.

D

Distortion power.

V

Phase-to-neutral voltage; also Volt (unit).

DC

DC component (current or voltage).

V-h

Phase-to-neutral voltage harmonic.

Dh

Distortion energy.

Vcf

Voltage crest (peak) factor.

DPF

Displacement factor (cos Φ).

Vd

Phase-to-neutral RMS distortion voltage.

FHL

Harmonic loss factor.

Vdc

Peak factor of the phase-to-ground voltage.

Maximum peak value of the phase-to-neutral

voltage.

Hz

Frequency of network.

Vpk-

Minimum peak value of the phase-to-neutral voltage.

L

Channel (Line).

Vrms

True RMS phase-to-neutral voltage.

Total harmonic distortion of phase-to-neutral voltage

in %f.

Total harmonic distortion of phase-to-neutral voltage

in %r.

Negative-sequence phase-to-ground voltage

Symbol Definition

AC component only.

Inductive phase shift.

°

Degree.

Σ

Φ

or

VA

Φ

A

Acf

Phase shift of voltage with respect to current.

Current; also Ampere (unit).

Crest (peak) factor of current.

Symbol Definition

Nh

Pdc

PEAK or PK

RMS

S

Sh

Non-active energy.

DC power.

True RMS value (current or voltage).

Apparent power.

Apparent energy.

Adc

Athdr

cos Φ

FK

DC current.

Total harmonic distortion of the current with

the total RMS value without DC as reference.

Cosine of the phase shift of voltage with

respect to current (DPF – fundamental

power factor or displacement factor).

K factor.

tan Φ

Ud

Udc

Uunb

Vpk+

Phase-to-phase RMS distortion voltage.

Phase-to-phase DC voltage.

MAX

MIN

ms

Maximum value.

Minimum value.

Millisecond.

Vthdf

Vthdr

Vunb

unbalance rate.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

19

3. OPERATION

3.1. START-UP

To turn the instrument ON, press the button.

After the software check, the home page is displayed, followed by the information screen that indicates the software version of the

instrument and its serial number. The Waveform screen is then displayed:

Figure 3-1

3.2. CONFIGURATION

To configure the instrument:

1. Press . The Configuration screen appears (see Figure 4-1).

2. Press or to select the parameter to be modified.

3. Press to enter the selected sub-menu.

4. Use the arrow buttons ( or and or ) and the button to validate. For more details, see §§4.3 to 4.10.

The following settings must be checked (and if necessary modified) for each measurement:

■ Calculation methods (see §4.5).

■ Distribution system (single-phase to five-wire three-phase) and connection method (2 wattmeters, 2 ½ elements, standard)

(§4.6).

■ Current ratios according to the type of current sensor connected (§4.7).

■ Voltage ratios (§4.7).

■ Triggering levels (transients mode and inrush current capture) (§4.8).

■ Values to be recorded (trend mode) (§4.9).

■ Alarm thresholds (§4.10).

To return to the Configuration screen from a sub-menu, press the button.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

20

3.3. LEADS INSTALLATION

To identify the leads and input terminals, you can mark them in accordance with the usual phase/neutral color code using the colored rings

and inserts supplied with the instrument.

1. Detach the insert and place it in the hole provided for it near the terminal (large insert for a current terminal; small insert for a

voltage terminal).

Figure 3-2

2. Clip rings of the same color to the ends of the lead you will connect to the terminal. Twelve sets of rings and inserts of different

colors are provided to enable you to coordinate the instrument with any applicable phase/neutral color codes.

3. Connect the measurement leads to the instrument terminals. Be sure to define the transformation ratios of the current sensors

and of the voltage inputs (see §4.7).

To make a measurement, at a minimum you must select:

■ calculation method (§4.5)

■ connection (§4.6)

■ sensor ratios (§4.7)

The measurement leads must be connected to the electrical network to be measured as shown by the following diagrams.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

21

3.3.1. SINGLE-PHASE NETWORK

Figure 3-3 (2-wire single-phase connection)

Figure 3-4 (3-wire single-phase connection)

Figure 3-5 (2-wire split-phase connection)

Figure 3-6 (3-wire split-phase connection)

Figure 3-7 (4-wire split-phase connection)

Figure 3-8 (3-wire three-phase connection)

Figure 3-9 (4-wire three-phase

connection)

Figure 3-10 (5-wire three-phase connection)

3.3.2. SPLIT-PHASE NETWORK

3.3.3. THREE-PHASE NETWORK

When connecting to a three-phase network, you do not need to connect all terminals in voltage or current.

For 3-wire three-phase, indicate the current sensors that will be connected: all 3 sensors (3A) or only 2 (A1 and A2, or A2 and A3, or A3

and A1).

For 4- and 5-wire three-phase, indicate the voltages that will be connected: all 3 voltages (3V) or only 2 (V1 and V2, or V2 and V3, or

V3 and V1).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

22

3.3.4. CONNECTION

1. Turn the instrument ON.

2. Configure the instrument for the measurement to be made and the network type (see §4).

3. Connect the leads and current sensors to the instrument.

4. Connect the ground and/or neutral lead to the network ground and/or neutral (when it is distributed) and connect the

corresponding current sensor.

5. Connect the L1 phase lead to the network L1 phase and connect the corresponding current sensor.

6. If applicable, repeat the procedure for phases L2 and L3, and for N.

NOTE: Complying with this procedure minimizes connection errors and saves time.

Disconnection procedure:

1. Proceed in reverse order of connection, always finishing by disconnecting the neutral (when distributed).

2. Disconnect the leads and turn the instrument OFF.

3.4. INSTRUMENT FUNCTIONS

Any screen display can be saved as a “snapshot” by pressing the button for 3 seconds (see §11).

You can press the Help button at any time. The Help screen will provide information about the symbols and mode currently

displayed.

3.4.1. WAVEFORM CAPTURE

With the instrument powered up and connected to the network, press .

You can display the Transients mode (see §5.1) or the Inrush current mode (§5.2).

3.4.2. HARMONICS DISPLAY

With the instrument powered up and connected to the network, press .

You can display the phase-to-neutral voltage (see §6.1), current (§6.2), apparent power (§6.3) or phase-to- phase voltage (see §6.4).

3.4.3. WAVEFORM MEASUREMENTS

With the instrument powered up and connected to the network, press .

You can display the measurements of the true RMS value (see §7.1), total harmonic distortion (§7.2), peak factor (§7.3),

maximum/minimum voltage and current (§7.4), multiple values simultaneously (§7.5), or phasor diagram (§7.6).

3.4.4. ALARM RECORDING

With the instrument powered up and connected to the network, press .

You can configure the alarm mode (§8.1), configure an alarm campaign (§8.2), look it up (§8.4), or erase it (§8.6).

3.4.5. RECORDING

With the instrument powered up and connected to the network, press .

You can configure and start recordings (§9.1 and §9.2). You can view (§9.5) and erase (§9.4) them.

3.4.6. ENERGY MEASUREMENTS

With the instrument powered up and connected to the network, press .

You can measure the energies consumed (§10.1.3) or generated (§10.

1.4, §10.2.2, or §10.3.2).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

23

4. CONFIGURATION

The Configuration button displays the Configuration menu for configuring the instrument. This must be done before each new